Enhancing interlaminar fracture toughness of carbon fiber composite with interleaved polyvinylidene fluoride electrospun fiber veils cooperating FeOOH nanoparticles

-

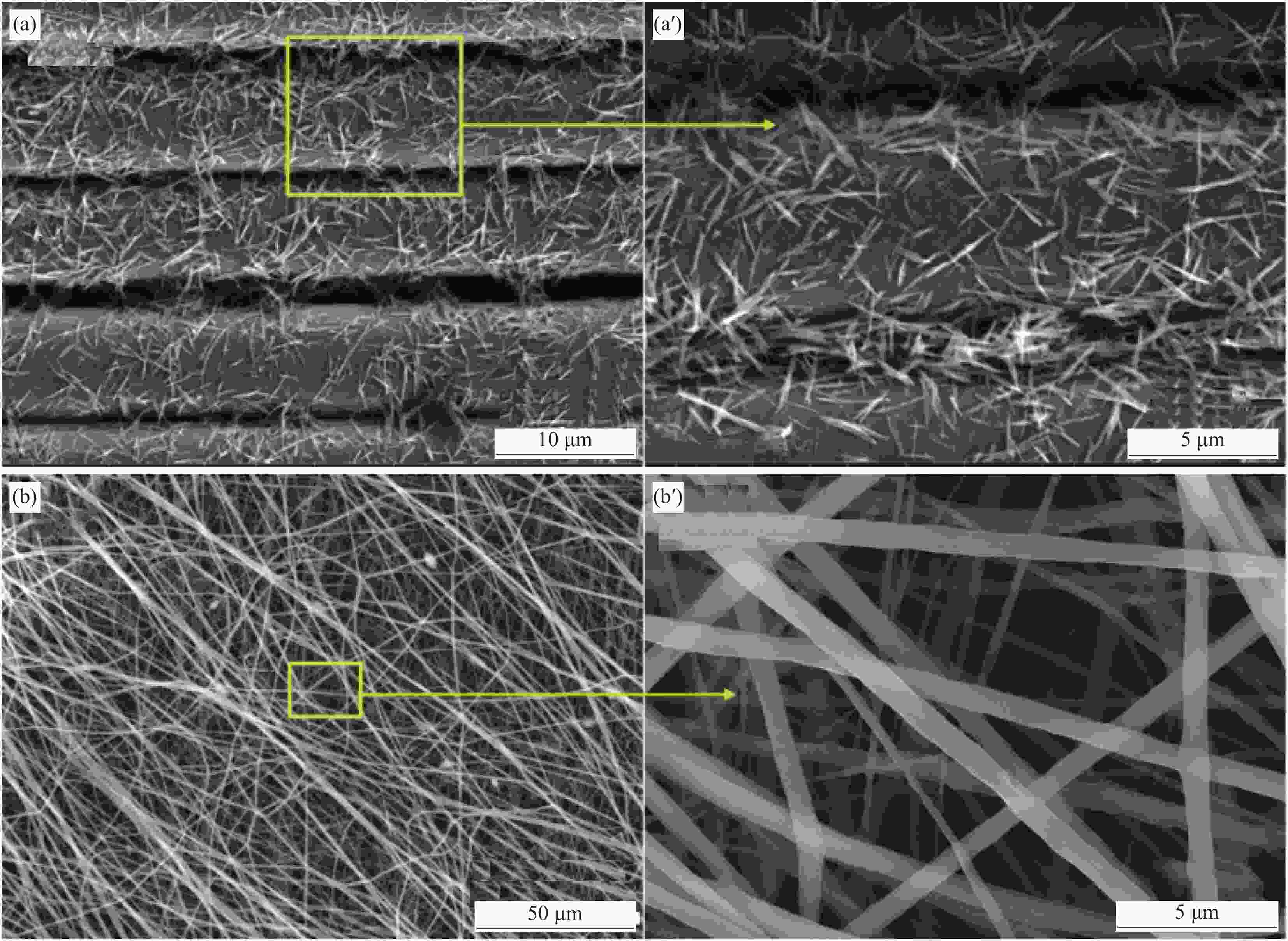

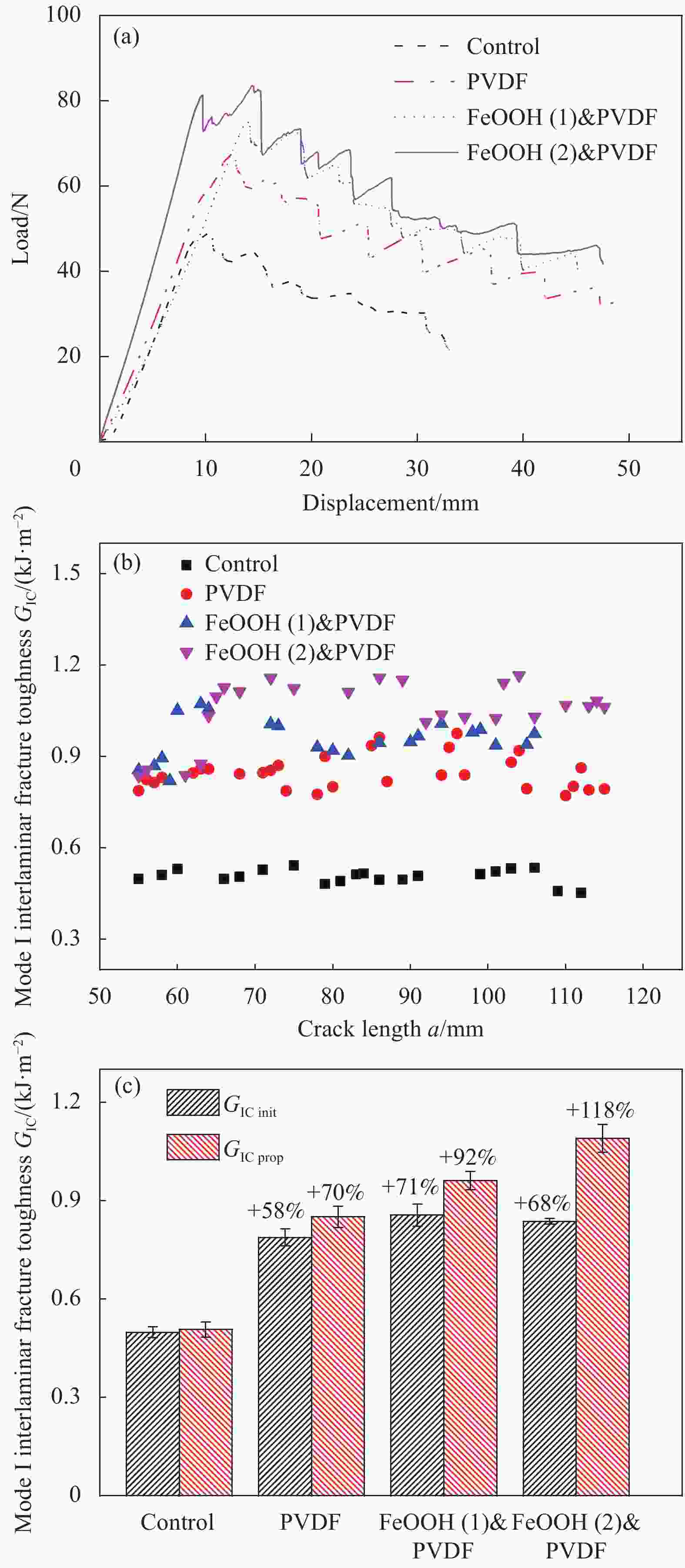

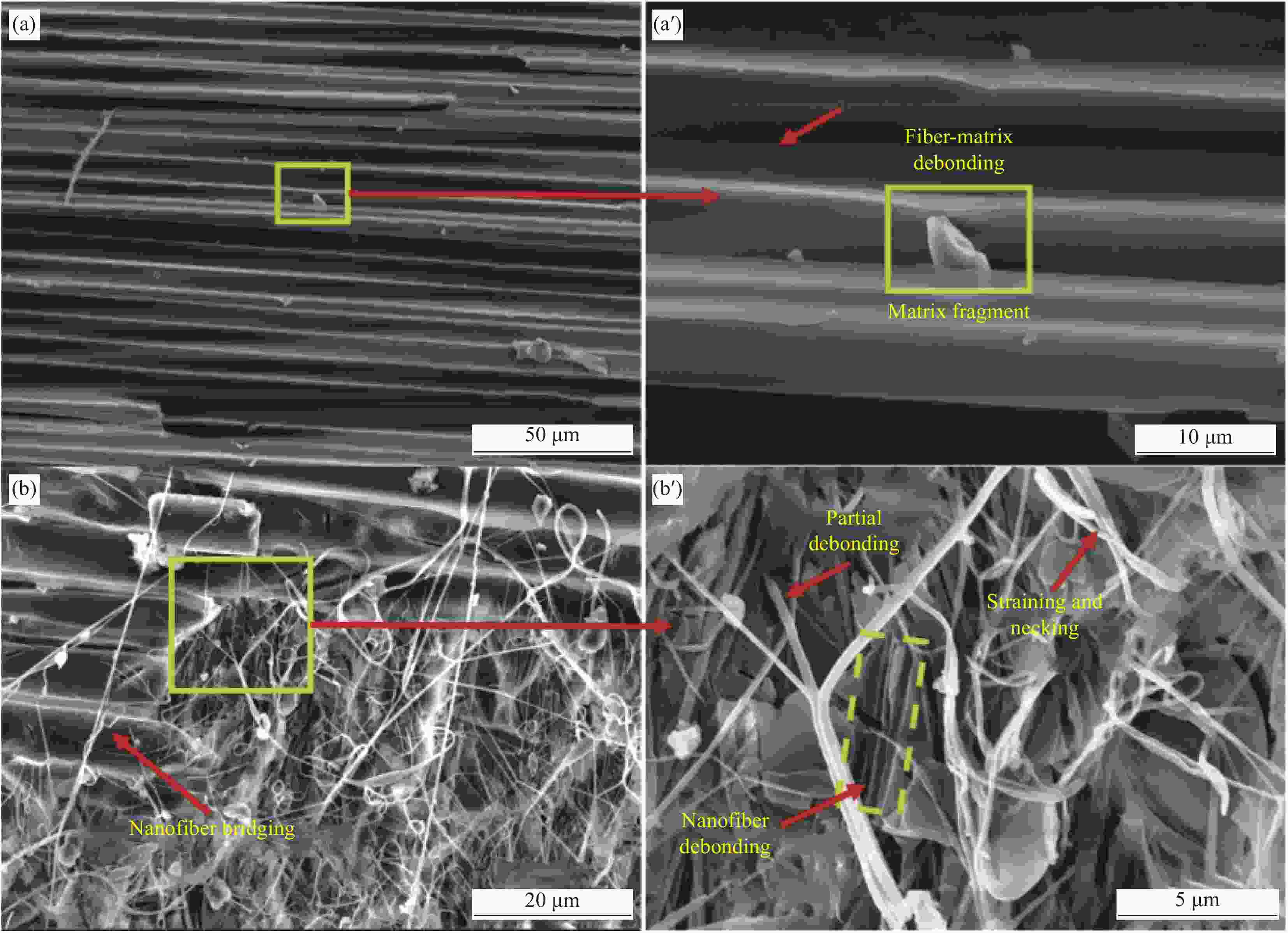

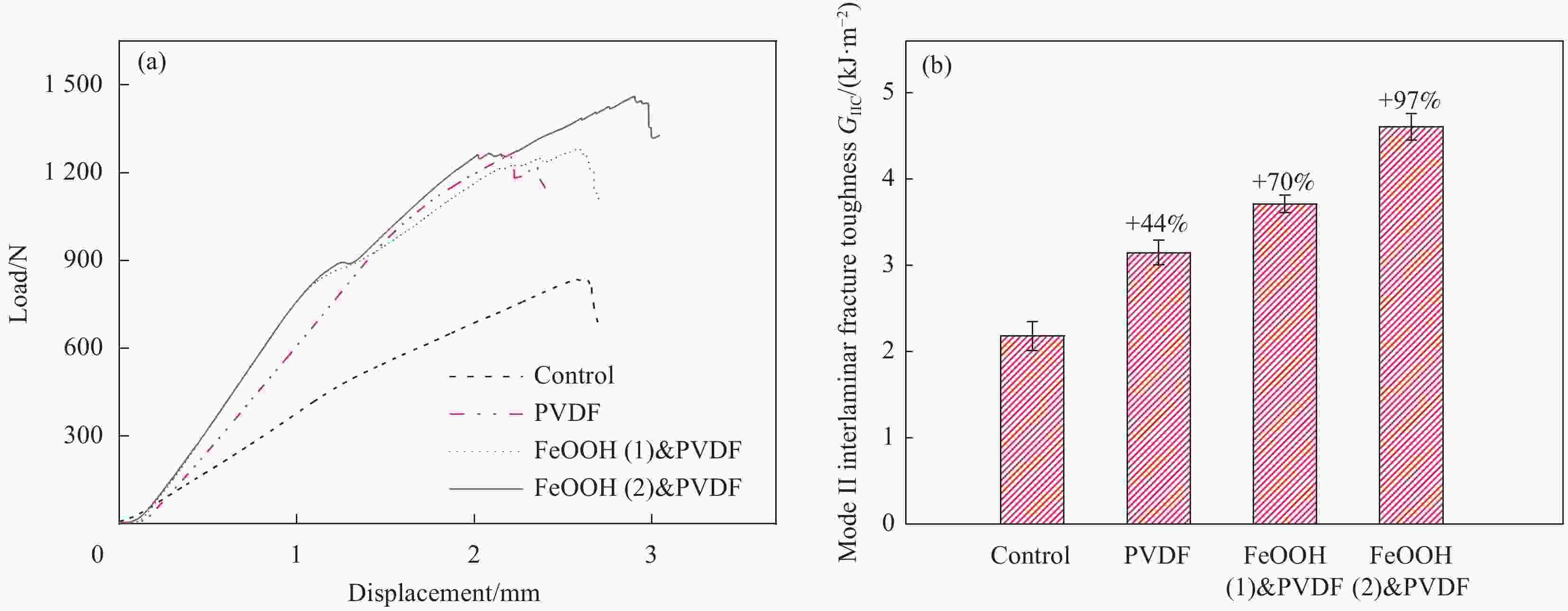

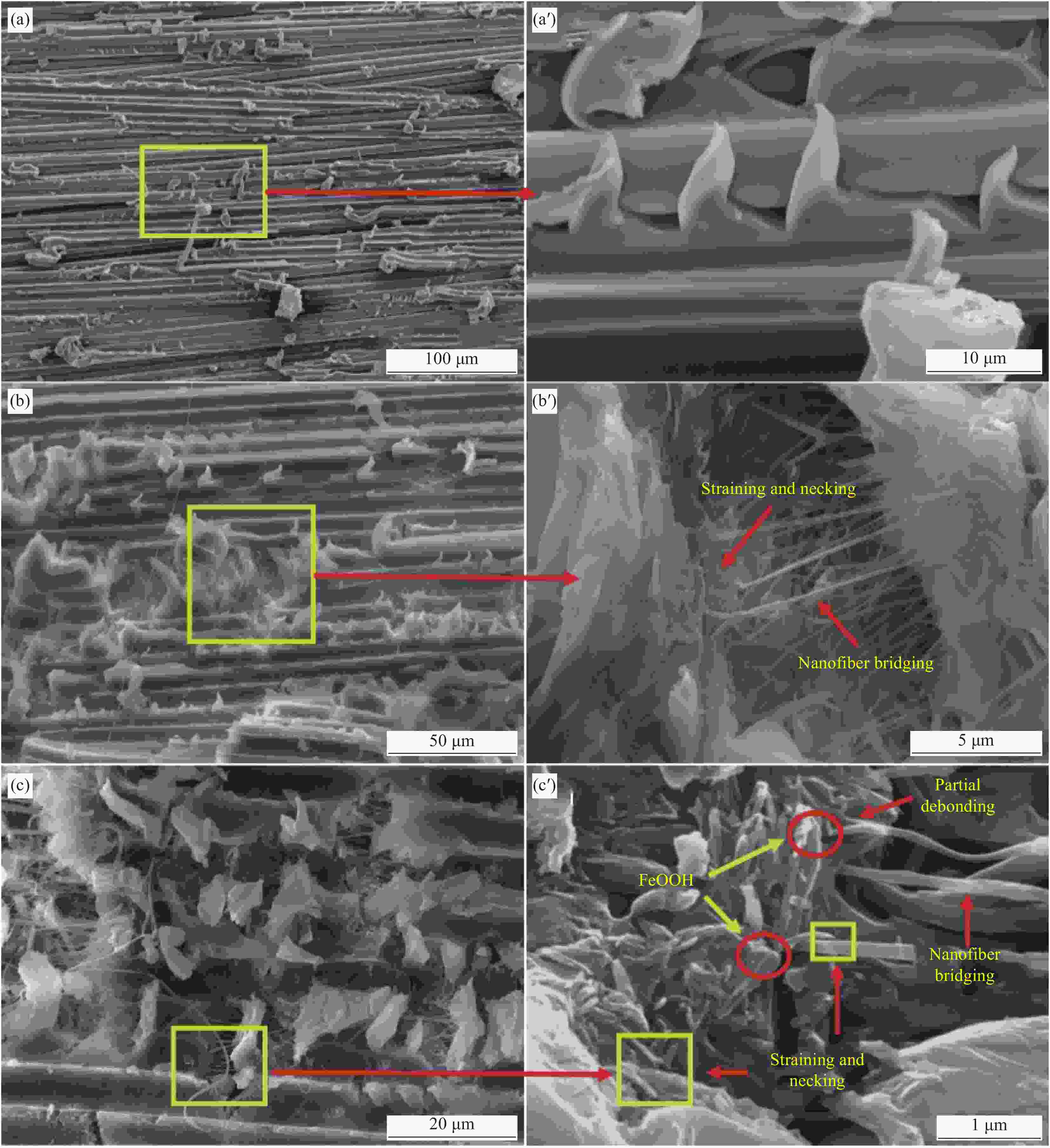

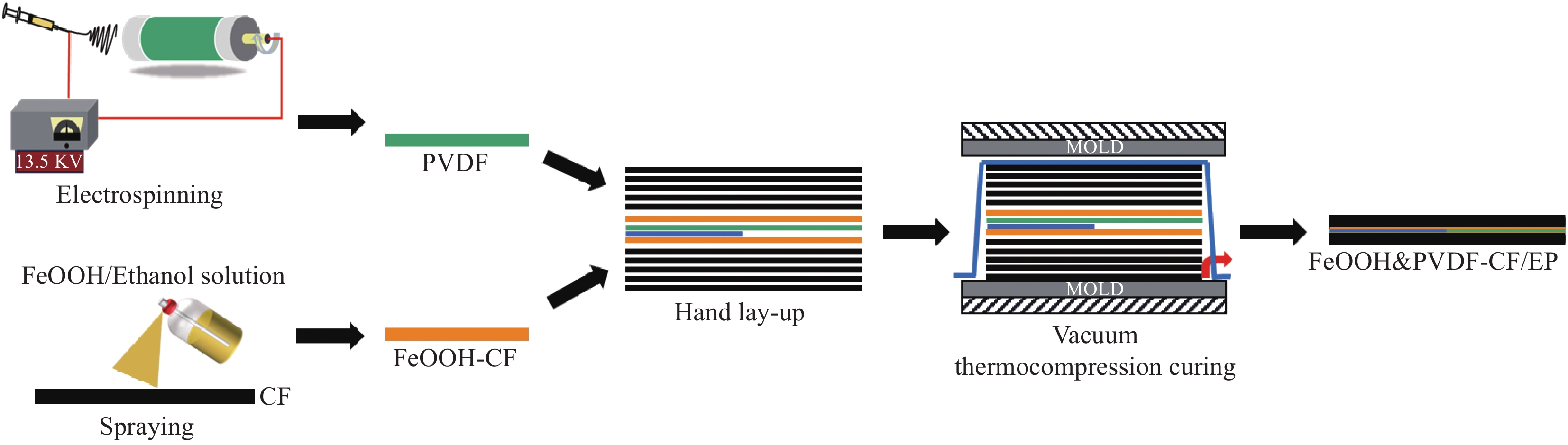

摘要: 为有效增强碳纤维/环氧树脂复合材料层压板(CF/EP)的层间断裂韧性,提出了一种纳米粒子协同纳米纤维膜插层改性方法。首先利用喷涂法将针状羟基氧化铁(FeOOH)纳米粒子均匀负载于碳纤维布表面,然后将制得的静电纺丝聚偏氟乙烯纳米纤维膜(PVDF)插入碳纤维布的层间,采用手工铺设-真空热压法制备了改性复合材料层压板PVDF&FeOOH-CF/EP,研究了不同面密度的FeOOH协同PVDF增强CF/EP层间断裂韧性的作用效果及增强机制。结果表明,FeOOH在碳纤维布上分布均匀,在面密度为2 g/m2时,PVDF&FeOOH-CF/EP层压板获得了最佳的增韧效果,相对于CF/EP,其I型层间断裂韧性GIC提高了118%,II型层间断裂韧性GIIC提高了97%,而PVDF-CF/EP的GIC和GIIC只分别提高了70%和44%。SEM分析显示,FeOOH的加入不仅提高了基体的断裂韧性,同时也增强了PVDF纤维与基体的界面作用,进而强化了PVDF的增韧行为。Abstract: For effectively enhancing the interlaminar fracture toughness of carbon fiber epoxy resin composite laminates (CF/EP), a modification method of nanofiber veils intercalation cooperating nanoparticles was proposed. First, the needle-like FeOOH nanoparticles were uniformly loaded on the surface of the carbon fiber cloth by spraying method, and then the prepared electrospun polyvinylidene fluoride (PVDF) nanofiber veils was interleaved between the layers of the FeOOH loaded carbon fiber cloth, and the modified composite laminate PVDF&FeOOH-CF/EP was prepared by manual laying-vacuum hot pressing method, and the effective effect and mechanism of FeOOH with different areal densities in enhancing the interlaminar fracture toughness of CF/EP with the PVDF were studied. The results show that FeOOH is evenly distributed on the carbon fiber cloth. When the areal density is 2 g/m2, the PVDF&FeOOH-CF/EP laminate has the best toughening effect. Compared with that of CF/EP, the mode-I interlaminar fracture toughness GIC is increased by 118% and mode-II interlaminar fracture toughness GIIC is increased by 97%, while the GIC and GIIC of PVDF-CF/EP only are increased by 70% and 44%, respectively. SEM analysis shows that the addition of FeOOH not only improves the fracture toughness of the matrix, but also enhances the interface between the PVDF fiber and the matrix epoxy resin, thereby enhancing the toughening behavior of PVDF fiber.

-

Key words:

- carbon fiber /

- laminate /

- fracture toughness /

- nano-structures /

- electrospun

-

图 3 不同层压板的I型断裂试验分析:(a) 典型载荷-位移曲线;(b) R曲线;(c) 层间断裂韧性

Figure 3. Mode I fracture test analysis of different laminates: (a) Typical load-displacement curves; (b) R curves; (c) Mode I interlaminar fracture toughness

GIC init—Initial fracture toughness of crack; GIC prop—Propagation fracture toughness of crack

表 1 不同纳米粒子协同电纺纤维插层材料增强CF/EP复合材料层间断裂韧性比较

Table 1. Comparison of the enhancement of interlaminar fracture toughness of CF/EP composites with different nanoparticles and electrospun fiber interleaves

Interleave Nanoparticle content Use of nanoparticle GIC/(kJ·m−2)

modifiedIncrease in GIC/% GIIC/(kJ·m−2)

modifiedIncreasein GIIC/% Ref. FeOOH&PVDF 2 g/m2 Sprayed on CF 1.09 118 4.29 97 This work TiO2/PA6 25wt% Dispersed in electrospun fiber 0.44 14 2.64 4 [18] SiO2/nSF 20wt% 0.54 37 1.76 30 [19] CNC/PSF 0.5wt% 1.12 29 2.44 49 [20] Al2O3-PAN 1wt% 1.22 47 — — [21] CNT/PAN 3wt% 1.10 77 — — [22] CNT /PA66 14wt% Coated on electrospun fiber 0.82 122 3.01 81 [9] CNT/PCL 15 g/m2 0.67 68 2.30 44 [23] CNT/PSF 10wt% 0.75 53 1.87 34 [24] Notes: PA6—Polyamide 6; nSF—Silk fibroin nanofiber; CNC—Cellulose nanocrystal; PSF—Polysulfone; PAN—polyacrylonitrile; CNT—

Carbon nanotubes; PCL—Polycaprolactone; PA66—Polyamide 66; GIIC—Mode II critical energy release rate. -

[1] 范雨娇, 顾轶卓, 邓火英, 等. 碳纳米管加入方式对碳纤维/环氧树脂复合材料层间性能的影响[J]. 复合材料学报, 2015, 32(2):332-340.FAN Y J, GU Y Z, DENG H Y, et al. Effect of adding method of carbon nanotube on inerlaminar property of carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2015,32(2):332-340(in Chinese). [2] 刘新, 陈铎, 何辉永, 等. 热塑性颗粒-无机粒子协同增韧碳纤维增强环氧树脂复合材料[J]. 复合材料学报, 2020, 37(8):1904-1910.LIU X, CHEN D, HE H Y, et al. Synergistic toughening of thermoplastic particles-inorganic particles to carbon fiber reinforced epoxy resin composites[J]. Acta Materiae Compositae Sinica,2020,37(8):1904-1910(in Chinese). [3] NAGI C S, OGIN S L, MOHAGHEGHIAN I, et al. Spray deposition of graphene nano-platelets for modifying interleaves in carbon fibre reinforced polymer laminates[J]. Materials and Design,2020,193:108831. doi: 10.1016/j.matdes.2020.108831 [4] SASIDHARAN S, ANAND A. Epoxy-based hybrid structural composites with nanofillers: A review[J]. Industrial & Engineering Chemistry Research,2020,59(28):12617-12631. [5] WANG J, MA C G, CHEN G, et al. Interlaminar fracture toughness and conductivity of carbon fiber/epoxy resin composite laminate modified by carbon black-loaded polypropylene non-woven fabric interleaves[J]. Compo-site Structures,2020,234:111649-111658. doi: 10.1016/j.compstruct.2019.111649 [6] MONTESERIN C, BLANCO M, MURILLO N, et al. Effect of different types of electrospun polyamide 6 nanofibres on the mechanical properties of carbon fibre/epoxy compo-sites[J]. Polymers (Basel),2018,10(11):1190-1206. doi: 10.3390/polym10111190 [7] SAGHAFI H, BRUGO T, MINAK G, et al. The effect of PVDF nanofibers on mode-I fracture toughness of composite materials[J]. Composites Part B: Engineering,2015,72:213-216. doi: 10.1016/j.compositesb.2014.12.015 [8] ALJARRAH M T, ABDELAL N R. Improvement of the mode I interlaminar fracture toughness of carbon fiber composite reinforced with electrospun nylon nanofiber[J]. Compo-sites Part B: Engineering,2019,165:379-385. doi: 10.1016/j.compositesb.2019.01.065 [9] SONG Y, ZHENG N, DONG X, et al. Flexible carboxylated CNT/PA66 nanofibrous mat interleaved carbon fiber/epoxy laminates with improved interlaminar fracture toughness and flexural properties[J]. Industrial& Engineering Chemistry Research,2020,59(3):1151-1158. [10] BECKERMANN G W, PICKERING K L. Mode I and Mode II interlaminar fracture toughness of composite laminates interleaved with electrospun nanofibre veils[J]. Composites Part A: Applied Science and Manufacturing,2015,72:11-21. doi: 10.1016/j.compositesa.2015.01.028 [11] ZHANG J, YANG T, LIN T, et al. Phase morphology of nano-fibre interlayers: Critical factor for toughening carbon/epoxy composites[J]. Composites Science and Technology,2012,72(2):256-262. doi: 10.1016/j.compscitech.2011.11.010 [12] 陈官, 马传国, 王静, 等. 氧化石墨烯包覆羟基氧化铁协同增强环氧树脂的断裂韧性[J]. 工程塑料应用, 2020, 48(6):8-13. doi: 10.3969/j.issn.1001-3539.2020.06.002CHEN G, MA C G, WANG J, et al. Synergistic strengthening of the fracture toughness of epoxy resin with graphene oxide coated with hydroxyl iron oxide[J]. Engineering Plastics Application,2020,48(6):8-13(in Chinese). doi: 10.3969/j.issn.1001-3539.2020.06.002 [13] 李玉婷, 马传国, 欧气局, 等. 棒状纳米铁氧化物增强碳纤维/环氧树脂复合材料的层间性能[J]. 桂林电子科技大学学报, 2017, 37(6):508-512. doi: 10.3969/j.issn.1673-808X.2017.06.016LI Y T, MA C G, OU Q J, et al. Enhanced interlaminar properties of epoxy composites with iron oxide nanorods[J]. Journal of Guilin University of Eletronic Technology,2017,37(6):508-512(in Chinese). doi: 10.3969/j.issn.1673-808X.2017.06.016 [14] DA C C, LAUNOIS P, VEBER M. Original magnetic alignment of a nematic phase containing single-walled nano-tubes[J]. Journal of Nanoscience and Nanotechnology,2004,4(1/2):86-90. [15] FISCHER JE, ZHOU W, VAVRO J, et al. Magnetically aligned single wall carbon nanotube films: Preferred orientation and anisotropic transport properties[J]. Journal of Applied Physics,2003,93(4):2157-2163. doi: 10.1063/1.1536733 [16] MA C G, LIU H Y, DU X S, et al. Fracture resistance, thermal and electrical properties of epoxy composites containing aligned carbon nanotubes by low magnetic field[J]. Composites Science and Technology,2015,114:126-135. doi: 10.1016/j.compscitech.2015.04.007 [17] CHENG C, CHEN Z, HUANG Z, et al. Simultaneously improving mode I and mode II fracture toughness of the carbon fiber/epoxy composite laminates via interleaved with uniformly aligned PES fiber webs[J]. Composites Part A: Applied Science and Manufacturing,2020,129:105696-105707. doi: 10.1016/j.compositesa.2019.105696 [18] MONTESERIN C, BLANCO M, MURILLO N, et al. Novel antibacterial and toughened carbon-fibre/epoxy composites by the incorporation of TiO2 nanoparticles modified electrospun nanofibre veils[J]. Polymers,2019,11(9):1524-1537. doi: 10.3390/polym11091524 [19] BACH Q V, VU C M, VU H T, et al. Enhancing mode I and II interlaminar fracture toughness of carbon fiber-filled epoxy-based composites using both rice husk silica and silk fibroin electrospun nanofibers[J]. High Performance Polymers,2019,31(9-10):1195-1203. doi: 10.1177/0954008319840404 [20] CAI S M, LI Y, LIU H Y, et al. Effect of electrospun polysulfone/cellulose nanocrystals interleaves on the interlaminar fracture toughness of carbon fiber/epoxy composites[J]. Composites Science and Technology,2019,181:107673-107681. doi: 10.1016/j.compscitech.2019.05.030 [21] RAZAVI S M J, NEISIANY R E, KHORASANI S N, et al. Effect of neat and reinforced polyacrylonitrile nanofibers incorporation on interlaminar fracture toughness of carbon/epoxy composite[J]. Theoretical and Applied Mechanics Letters,2018,8(2):126-131. doi: 10.1016/j.taml.2018.02.008 [22] ESKIZEYBEK V, YAR A, AVCI A, et al. CNT-PAN hybrid nano-fibrous mat interleaved carbon/epoxy laminates with improved Mode I interlaminar fracture toughness[J]. Composites Science and Technology,2018,157:30-39. doi: 10.1016/j.compscitech.2018.01.021 [23] SONG X, GAO J F, ZHENG N, et al. Interlaminar toughening in carbon fiber/epoxy composites interleaved with CNT-decorated polycaprolactone nanofibers[J]. Composites Communications,2021,24:100622-100629. doi: 10.1016/j.coco.2020.100622 [24] ZHENG N, HUANG Y D, LIU HY, et al. Improvement of interlaminar fracture toughness in carbon fiber/epoxy composites with carbon nanotubes/polysulfone interleaves[J]. Composites Science and Technology,2017,140:8-15. doi: 10.1016/j.compscitech.2016.12.017 [25] PRASAD V, SEKAR K, VARGHESE S, et al. Enhancing Mode I and Mode II interlaminar fracture toughness of flax fibre reinforced epoxy composites with nano TiO2[J]. Compo-sites Part A: Applied Science and Manufacturing,2019,124:105505-105516. doi: 10.1016/j.compositesa.2019.105505 [26] DAMODARAN V, CASTELLANOS AG, MILOSTAN M, et al. Improving the mode-II interlaminarfracture toughness of polymeric matrix composites through additive manufacturing[J]. Materials and Design,2018,157:60-73. doi: 10.1016/j.matdes.2018.07.006 [27] RAVINDRAN A R, LADANI R B, WANG C H, et al. Synergistic mode II delamination toughening of composites using multi-scale carbon-based reinforc-ements[J]. Composites Part A: Applied Science and Manufacturing,2019,117:103-115. doi: 10.1016/j.compositesa.2018.11.011 [28] DAELEMANS L, HEIJDEN S, DE B I, et al. Using aligned nanofibres for identifying the toughening micromechanisms in nanofibre interleaved laminates[J]. Composites Science and Technology,2016,124:17-26. doi: 10.1016/j.compscitech.2015.11.021 [29] MOHAMMADI R, AHMADI N M, SAGHAFI H, et al. A quantitative assessment of the damage mechanisms of CFRP laminates interleaved by PA66 electrospun nano-fibers using acoustic emission[J]. Composite Structures,2021,258:113395-113407. doi: 10.1016/j.compstruct.2020.113395 [30] MOHAMMADI R, NAJAFABADI M A, SAGHAFI H, et al. Mode-II fatigue response of AS4/8552 carbon/epoxy composite laminates interleaved by electrospun nanofibers[J]. Thin-Walled Structures,2020,154:106811-106823. doi: 10.1016/j.tws.2020.106811 [31] RODRÍGUEZ-GONZÁLEZ J A, RUBIO-GONZÁLEZ C. Influence of sprayed multi-walled carbon nanotubes on mode I and mode II interlaminar fracture toughness of carbon fiber/epoxy composites[J]. Advanced Composite Materials,2018,28:1-18. -

下载:

下载: