Preparation and performance of EVOLi-OMMT separator material for lithium ion battery

-

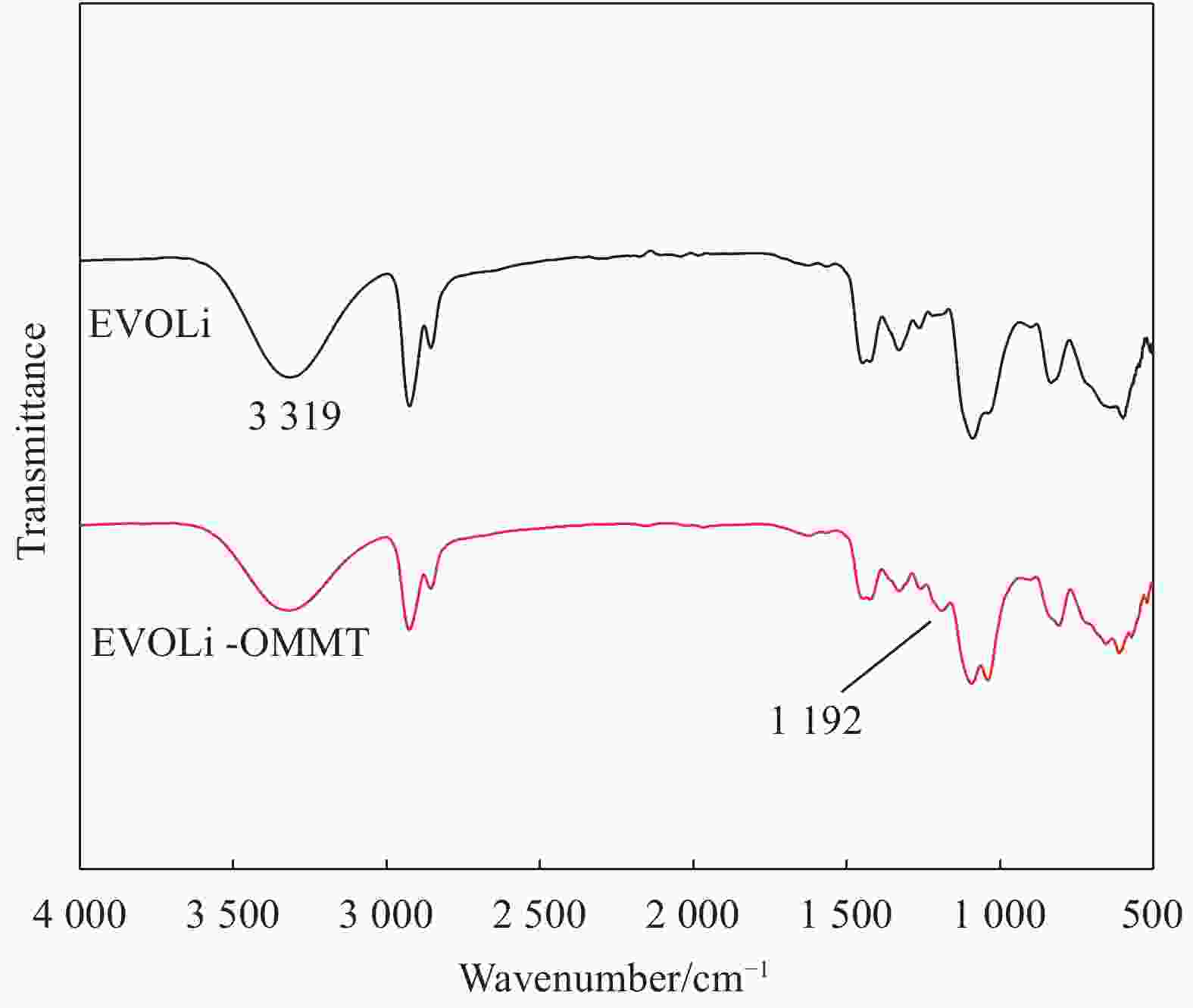

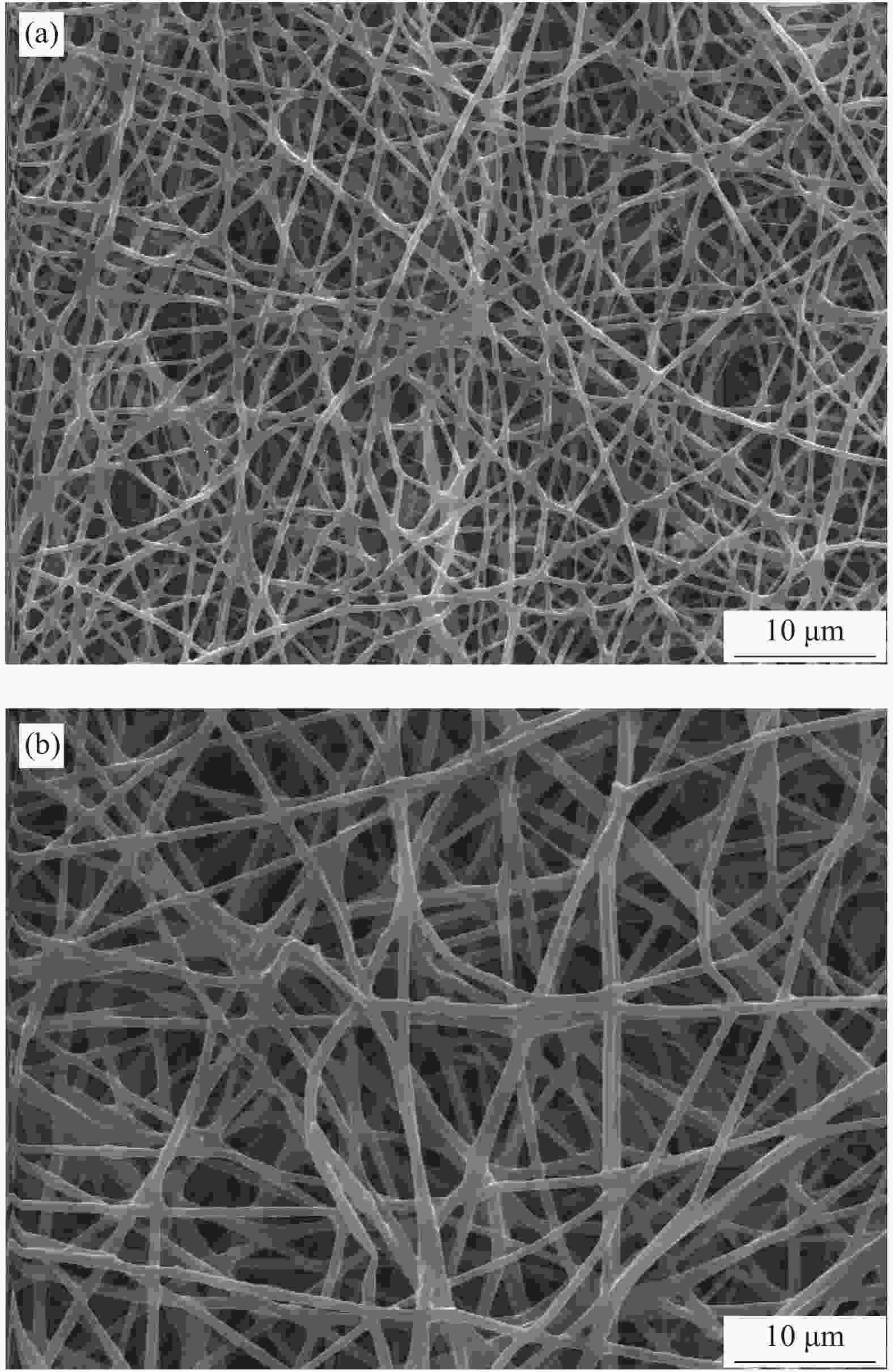

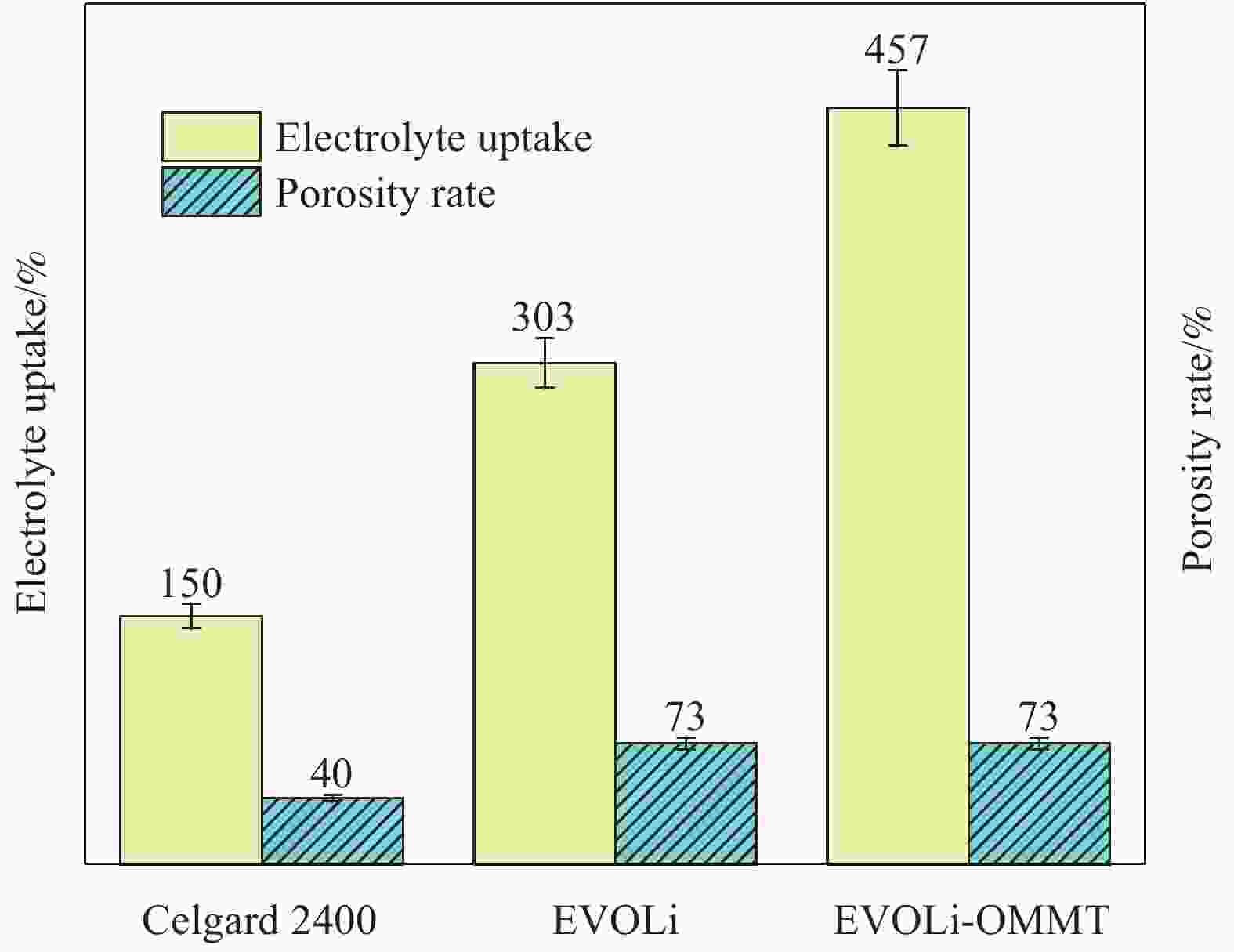

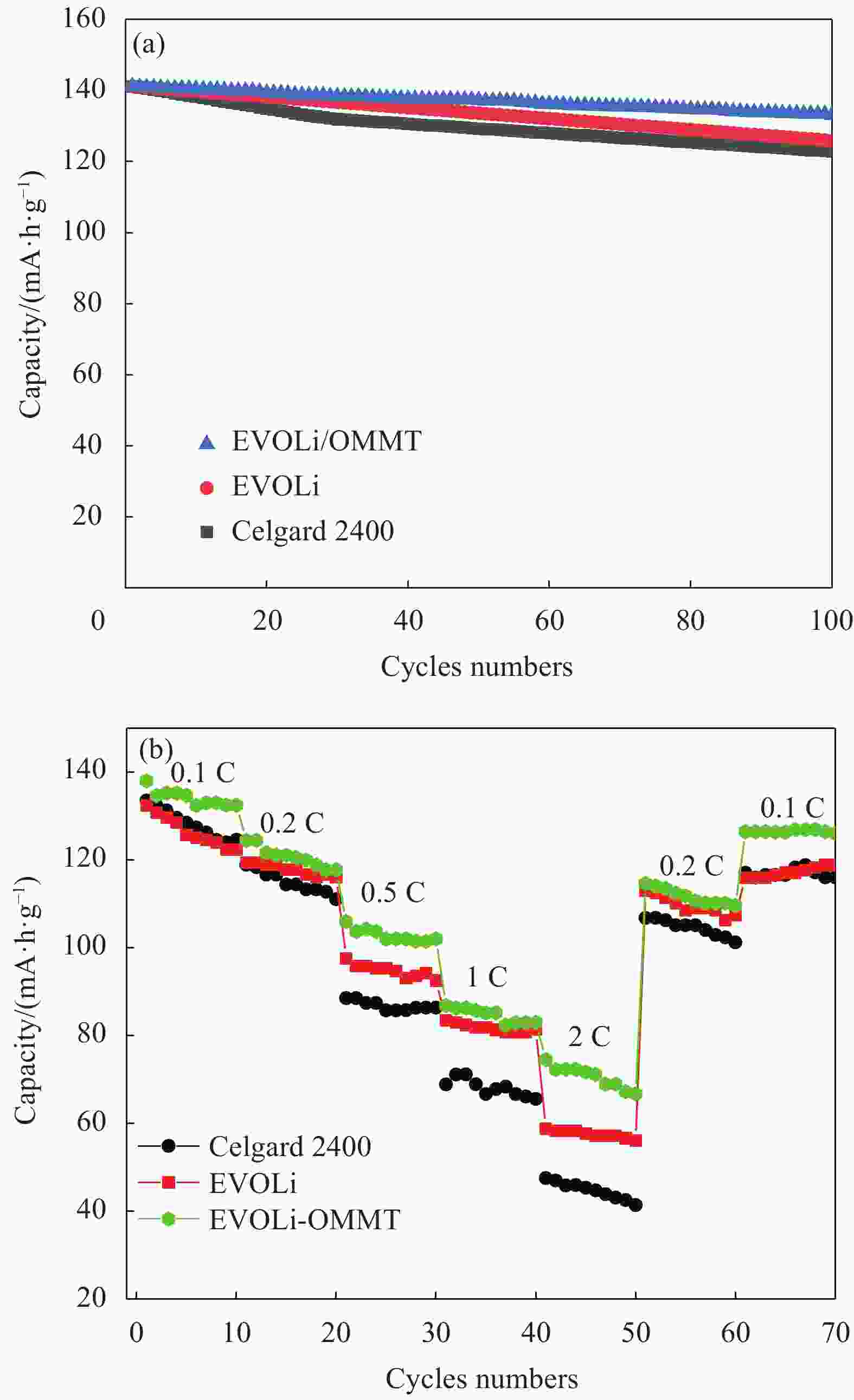

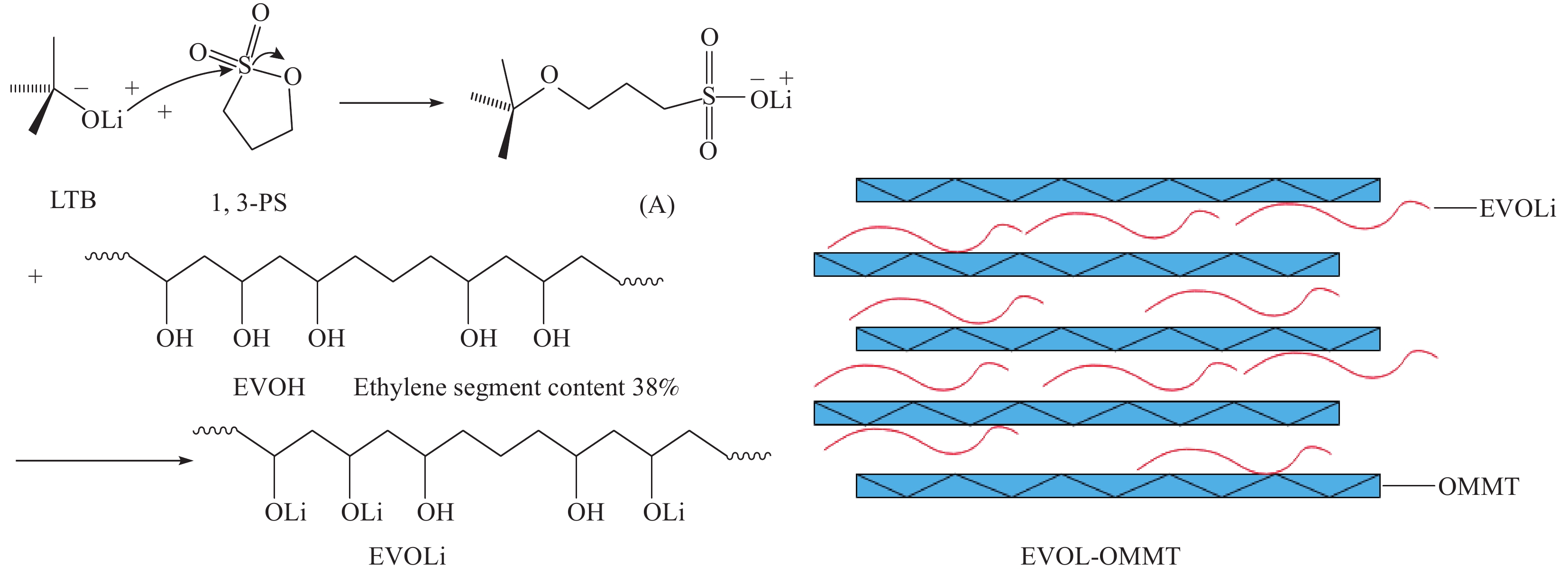

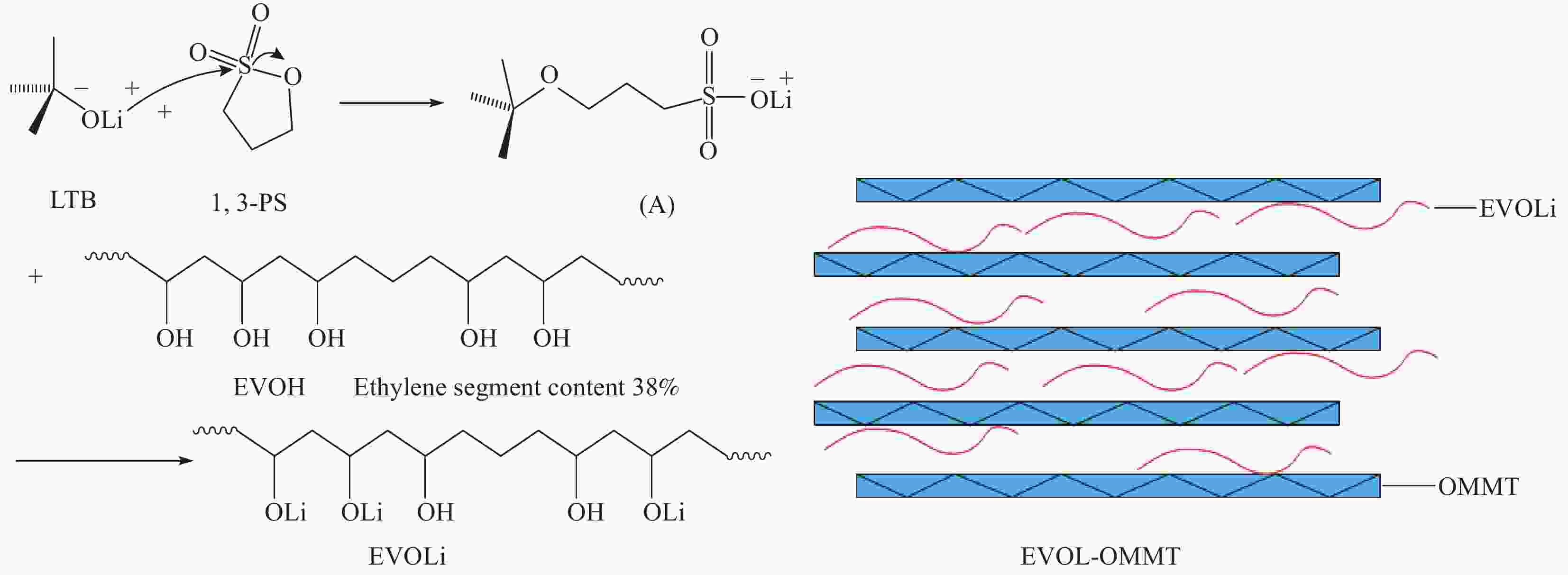

摘要: 以聚(乙烯-乙烯醇)(EVOH),锂基蒙脱土(Li-OMMT)为主要原料,先合成了一种离子型树脂,后与锂基蒙脱土复合以制备一种全新的有机-无机杂化材料EVOLi-OMMT。采用高压静电纺丝法,将其制成锂离子电池用无纺布隔膜。先用红外表征了杂化材料的键接结构,又用SEM表征了隔膜的微观结构,后将合成的两种复合隔膜与Celgard 隔膜进行了吸液率、孔隙率、热性能和电性能的对比。结果表明,EVOLi与OMMT之间生成了新的化学键,形成了插层交联结构,隔膜力学强度比EVOLi提升了68.12%,隔膜孔径均一,改性后的隔膜孔隙率和吸液率分别达457%和73%,初始温度较高,可达270℃,可耐175℃不发生皱缩;电化学测试结果表明改性过后的隔膜离子界面迁移阻抗小,可低至96.59 Ω;100次0.1 C循环以后容量保持率可达93.4%,并在循环测试中表现出优异的倍率性能。

-

关键词:

- 锂离子电池 /

- 隔膜 /

- 杂化材料 /

- 静电纺丝 /

- 聚(乙烯-乙烯醇)(EVOH) /

- 锂基蒙脱土(Li-OMMT)

Abstract: Using Poly (ethylene-vinyl alcohol) (EVOH) and Lithium montmorillonite (Li-OMMT), an ionic resin is synthesized first, and then compounded with the lithium montmorillonite to prepare a new organic-inorganic hybrid material EVOLi-OMMT. Electrospinning is used to make it into a non-woven fabric separator for lithium-ion batteries. The bonding structure of the hybrid material was first characterized by infrared, and the microstructure of the diaphragm was characterized by SEM. Then the two composite diaphragms synthesized were compared with the Celgard diaphragm for liquid absorption, porosity, thermal performance and electrical performance. The results show that a new chemical bond is formed between EVOLi and OMMT to form an intercalation cross-linked structure. The mechanical strength of the diaphragm is 68.12% higher than that of EVOLi. The pore diameter of the diaphragm is uniform. The modified diaphragm has a porosity and liquid absorption rate of 457% and 73% respectively, the initial temperature is higher, up to 270℃, and can withstand 175℃ without shrinkage; the electrochemical test results show that the modified membrane has a small ion interface migration resistance, which can be as low as 96.59 Ω; 100 times 0.1 C After the cycle, the capacity retention rate can reach 93.4%, and it shows excellent rate performance in the cycle test. -

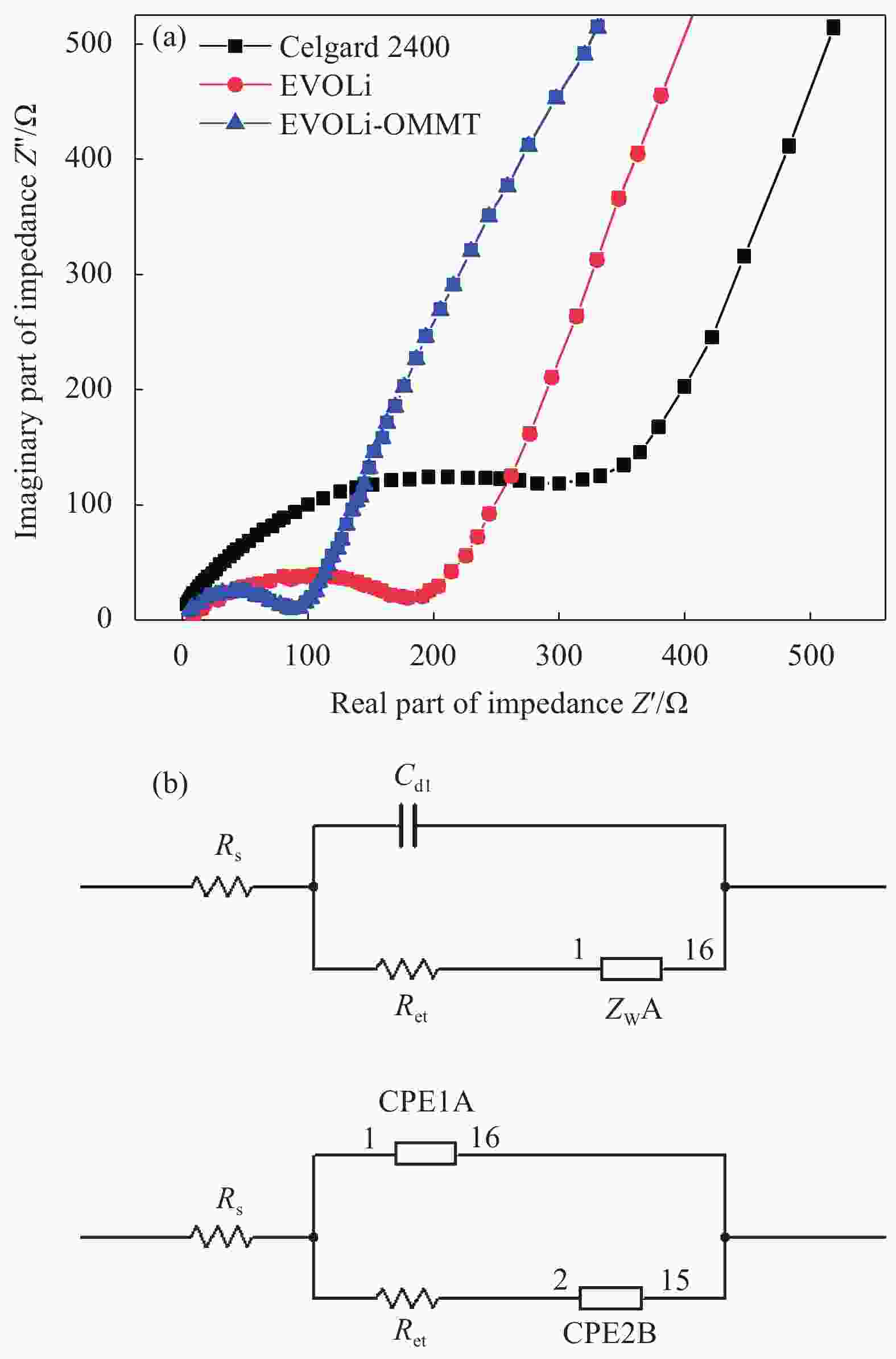

图 6 Celgard 2400、EVOLi、EVOLi-OMMT隔膜的界面阻抗谱 (a) 和等效电路图 (b)

Figure 6. equivalent circuit diagrams of Celgard 2400, EVOLi, EVOLi-OMMT (a) and AC impedance spectroscopy (b)

Rs—Electrolyte and electrode resistance; Cdl—Hole electrode interface electric double layer capacitance; Ret—Electron transfer resistance; CPE—Constant phase angle element; Zw—Warburg impedance during diffusion

表 1 隔膜的力学性能数据

Table 1. Mechanics performance data of separator

Separator name Elongation at break/% Tensile strength/MPa Celgard 2400 30.00 134.15 EVOLi 42.13 2.76 EVOLi-OMMT 38.15 4.64 Notes: Celgard 2400—Commercial single-layer polypropylene (PP) separator; EVOLi—Lithium ionized ethylene vinyl alcohol copolymer; EVOLi-OMMT—Lithium ionized ethylene vinyl alcohol copolymer grafted with montmorillonite. -

[1] GARCIA Plaza, JEG M Carrasco, NEZ Alonso-Marti, et al. A new representation model of standard and available active materials for electrochemical batteries[J]. Journal of Renewable and Sustainable Energy,2018,10(4):44-101. [2] HWANG J Y, MYUNG S T, SUN Y K. Recent progress in rechargeable potassium batteries[J]. Advanced Functional Materials,2018,28(43):1802938. doi: 10.1002/adfm.201802938 [3] 董缇, 彭鹏, 王亦伟, 等. 锂离子电池大电流放电过程模拟研究[J]. 化工学报, 2020, 71(8):3710-3721.DONG Ti, PENG Peng, WANG Yiwei et al. Simulation study on high current discharge process of lithium ion battery[J]. Journal of Chemical Industry,2020,71(8):3710-3721(in Chinese). [4] 谢松, 巩译泽, 李明浩. 锂离子电池在民用航空领域中应用的进展[J]. 电池, 2020, 50(4):388-392.XIE Song, GONG Yiyi, Li Minghao. Progress in the application of lithium-ion batteries in the field of civil aviation[J]. Battery,2020,50(4):388-392(in Chinese). [5] LI Z J, ZHONG D, ZHANG J, et al. Silicon nanoparticles/carbon composites for lithium-ion battery[J]. Progress in Chemistry,2019,31(1):201-209. [6] WANG X, ZHANG Y, MA L, et al. Recent development on binders for silicon-based anodes in lithium-ion batteries[J]. Acta Chimica Sinica,2019,77(1):24-40. doi: 10.6023/A18070272 [7] HARPER G, SOMMERVILLE R, KENDRICK E, et al. Recycling lithium-ion batteries from electric vehicles[J]. Nature,2019,575(7781):75-86. doi: 10.1038/s41586-019-1682-5 [8] HONG W, ZHANG Y, YANG L, et al. Carbon quantum dot micelles tailored hollow carbon anode for fast potassium and sodium storage[J]. Nano Energy,2019,65:104038. [9] GOODENOUGH J B, KIM Y. Challenges for rechargeable Li batteries[J]. Chemistry of Materials,2010,22(3):587-603. doi: 10.1021/cm901452z [10] YUAN L X, WANG Z H, GOODENOUGH J B, et al. Development and challenges of LiFePO4 cathode material for lithium-ion batteries[J]. Energy & Environmental Science, 2011, 4(2): 269-284. [11] SAHOO S, JOANNI E, SINGH R K, et al. Recent progress in the synthesis of graphene and derived materials for next generation electrodes of high performance lithium ion batteries[J]. Progress in Energy and Combustion Science,2019,75:100786. [12] POMERANTSEVA E, BONACCORSO F, FENG X, et al. Energy storage: The future enabled by nanomaterials[J]. Science, 2019, 366(6468): 969. [13] SUN G, KONG L, LIU B, et al. Ultrahigh-strength, nonflammable and high-wettability separators based on novel polyimidecore@polybenzimidazole-sheath nanofibers for advanced and safe lithium-ion batteries[J]. Journal of Membrane Science,2019,582:132-139. doi: 10.1016/j.memsci.2019.04.005 [14] ZENG G, ZHAO J, Feng C, et al. Flame-retardant bilayer separator with multifaceted van der waals interaction for lithium-ion batteries[J]. ACS Applied Materials & Interfaces,2019,11(29):26402-26411. [15] LI L, CHEN Z, ZHANG Q, et al. A hydrolysis-hydrothermal route for the synthesis of ultrathin LiAlO2-inlaid LiNi0.5Co0.2Mn0.3O2 as a high-performance cathode material for lithium ion batteries[J]. Journal of Materials Chemistry A,2015,3(2):894-904. doi: 10.1039/C4TA05902F [16] CHENG Q, LI A, LI N, et al. Stabilizing solid electrolyte-anode interface in Li-metal batteries by boron nitride-based nanocomposite coating[J]. Joule,2019,3(6):1510-1522. doi: 10.1016/j.joule.2019.03.022 [17] 杨富杰, 王亮, 阮文红, 等. 石墨烯基聚合物复合电解质的设计、性能及其应用研究进展[J]. 复合材料学报, 2021, 38(3):680-697.YANG Fujie, WANG Liang, RUAN Wenhong, et al. Research progress on design, performance and application of graphene based polymer composite electrolytes[J]. Acta Materiae Compositae Sinica,2021,38(3):680-697(in Chinese). [18] 赵丹妮, 田芳禺, 于雅琳, 等. 锂离子电解液/环氧乙烯基酯树脂固态电解质的制备与性能[J]. 复合材料学报, 2018, 35(2):253-259.ZHAO Danni, TIAN Fangyu, YU Yalin, et al. Preparation and performance of lithium ionic liquid/epoxy vinyl ester resin solid electrolyte[J]. Acta Materiae Compositae Sinica,2018,35(2):253-259(in Chinese). [19] JIANG L, ZHANG X, CHEN Y, et al. Modified polypropylene/cotton fiber composite nonwoven as lithium-ion battery separator[J]. Materials Chemistry and Physics,2018,219:368-375. doi: 10.1016/j.matchemphys.2018.08.035 [20] 王郗, 宋召飞, 李旦, 等. 高安全性锂离子电池隔膜发展现状[J]. 通化师范学院学报, 2020, 41(8):51-56.WANG Xi, SONG Zhaofei, LI Dan, et al. The development status of high-safety lithium ion battery separator[J]. Journal of Tonghua Teachers College,2020,41(8):51-56(in Chinese). [21] SHEKARIAN E, NASR M R J, MOHAMMADI T, et al. Preparation of 4A zeolite coated polypropylene membrane for lithium-ion batteries separator[J]. Journal of Applied Polymer Science,2019,136(32):47841. [22] JIANG W, LIU Z, KONG Q, et al. A high temperature operating nanofibrous polyimide separator in Li-ion battery[J]. Solid State Ionics,2013,232:44-48. doi: 10.1016/j.ssi.2012.11.010 [23] LUO X, LU X, CHEN X, et al. A robust flame retardant fluorinated polyimide nanofiber separator for high-temperature lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2020,8(29):14788-14798. doi: 10.1039/D0TA00439A [24] CHO S J, CHOI H, YOUK J H. Evaluation of PBI nanofiber membranes as a high-temperature resistance separator for lithium-ion batteries[J]. Fibers and Polymers,2020,21(5):993-998. doi: 10.1007/s12221-020-9955-z [25] HAO X, ZHU J, JIANG X, et al. Ultrastrong Polyoxyzole nanofiber membranes for dendrite-proof and heat-resistant battery separators[J]. Nano Letters,2016,16(5):2981-2987. doi: 10.1021/acs.nanolett.5b05133 [26] 陈连周, 蹇锡高. 新型多芳环取代杂萘联苯型聚芳醚酮的合成[J]. 化学通报, 1998(12):3-5.CHEN Lianzhou, JIAN Xigao. Synthesis of a new type of polyaromatic ring substituted poly(phthalazinone biphenyl) polyaryl ether ketone[J]. Chemistry Bulletin,1998(12):3-5(in Chinese). [27] LIU J C, QIN J X, MO Y D, et al. Polyphenylene sulfide separator for high safety lithium-ion batteries[J]. Journal of the Electrochemical Society,2019,166(8):A1644-A1652. doi: 10.1149/2.1041908jes [28] CHO J H, CHO S Y, JIN, H J, et al. Cellulose nanocrystal-enhanced poly(vinyl alcohol-co-ethylene) barrier film[J]. Textile Science and Engineering,2017,54(6):421-428. [29] 巩桂芬, 徐阿文, 邹明贵, 等. EVOH-SO3Li/P(VDF-HFP)/HAP锂离子电池隔膜的制备及电化学性能[J]. 材料工程, 2020, 48(5):75-82.GONG Guifen, XU Awen, ZOU Minggui, et. al. Preparation and electrochemical performance of EVOH-SO3Li/P(VDF-HFP)/HAP lithium ion battery separator[J]. Materials Engineering,2020,48(5):75-82(in Chinese). [30] DANEV R, BUIJSSE B, KHOSHOUEI M, et al. Volta potential phase plate for in-focus phase contrast transmission electron microscopy[J]. Proceedings of the National Academy of Sciences of the United States of America,2014,111(44):15635-15640. doi: 10.1073/pnas.1418377111 [31] 王锦成, 杨科, 郑晓昱. 蒙脱土的有机化改性及其结构与性能研究[J]. 化工矿物与加工, 2010, 39(7):11-13. doi: 10.3969/j.issn.1008-7524.2010.07.004WANG Jincheng, YANG Ke, ZHENG Xiaoyu. Study on organic modification of montmorillonite and its structure and properties[J]. Industrial Minerals and Processing,2010,39(7):11-13(in Chinese). doi: 10.3969/j.issn.1008-7524.2010.07.004 [32] LI J, YU J, WANG Y, et al. Intercalated montmorillonite reinforced polyimide separator prepared by solution blow spinning for lithium-ion batteries[J]. Industrial & Engineering Chemistry Research,2020,59(28):12879-12888. -

下载:

下载: