Experimental study on mechanical properties of polypropylene fiber grouting material and its rebar sleeve connection

-

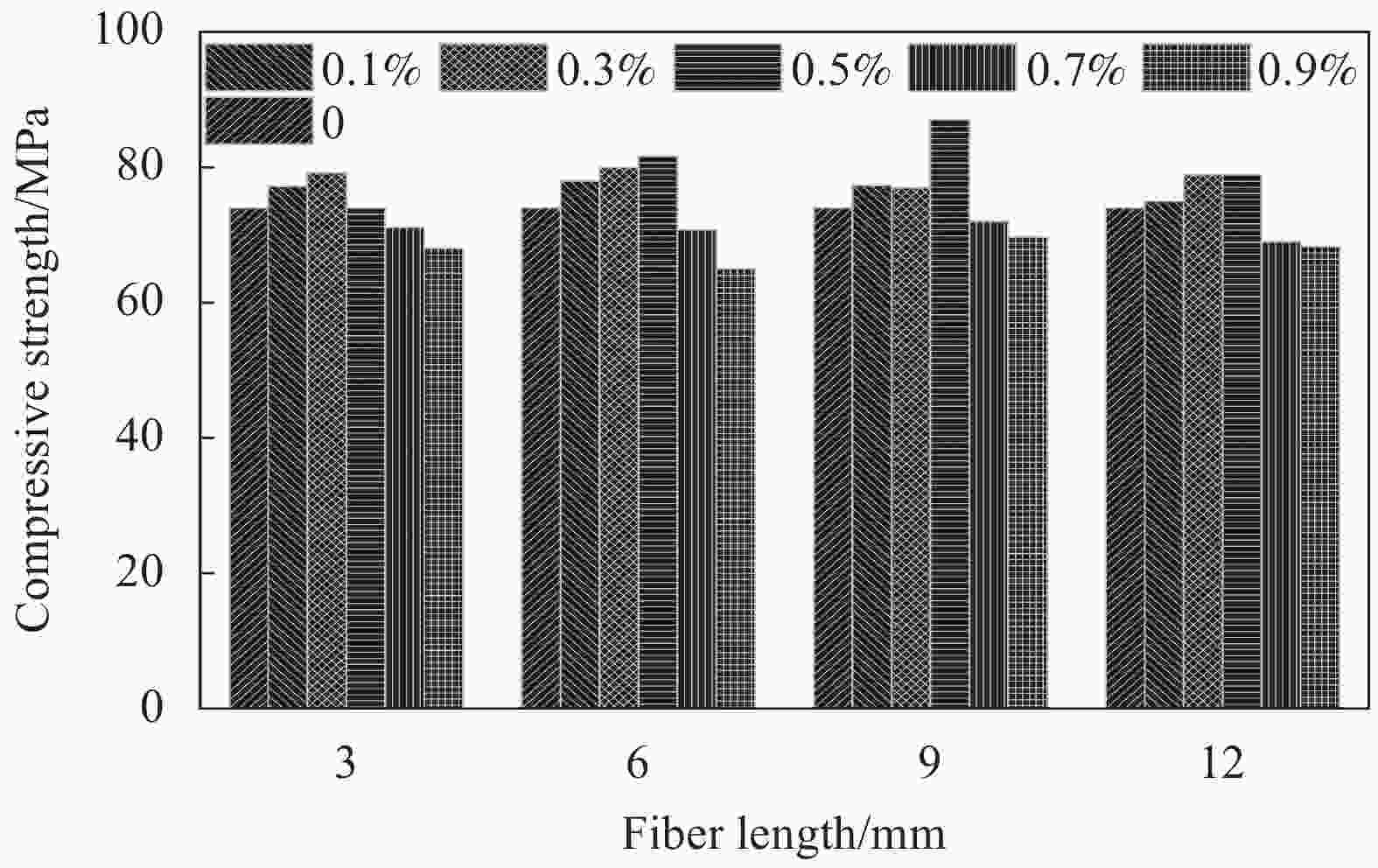

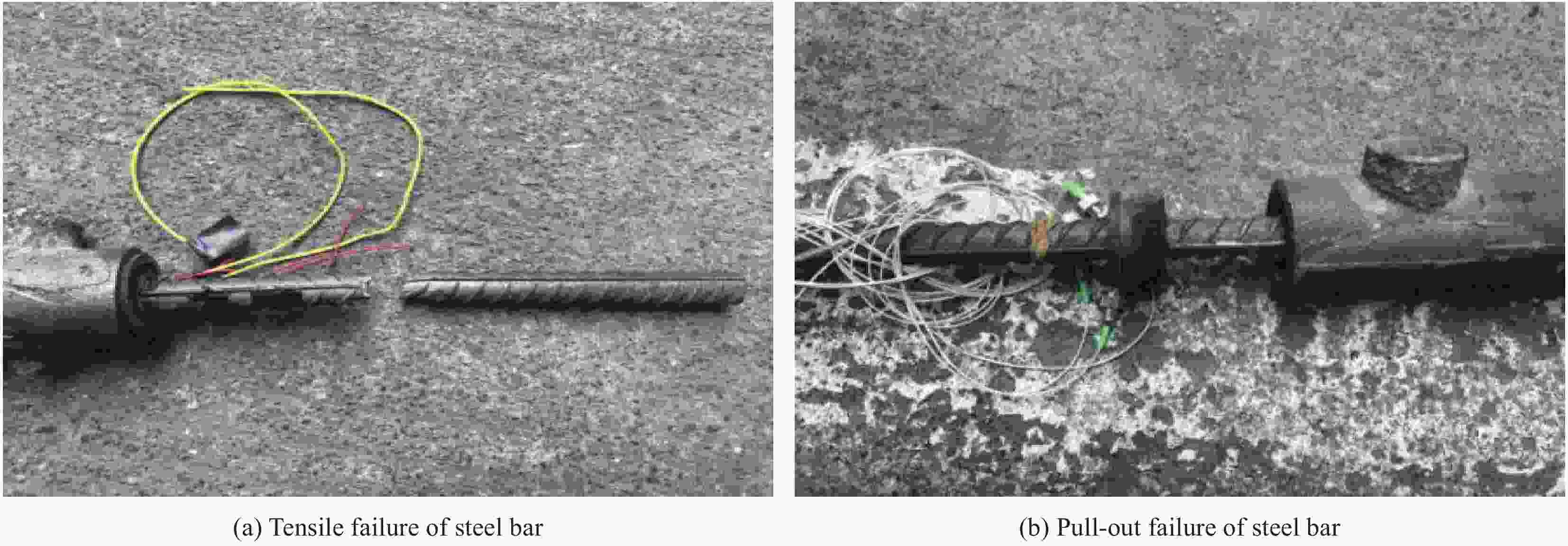

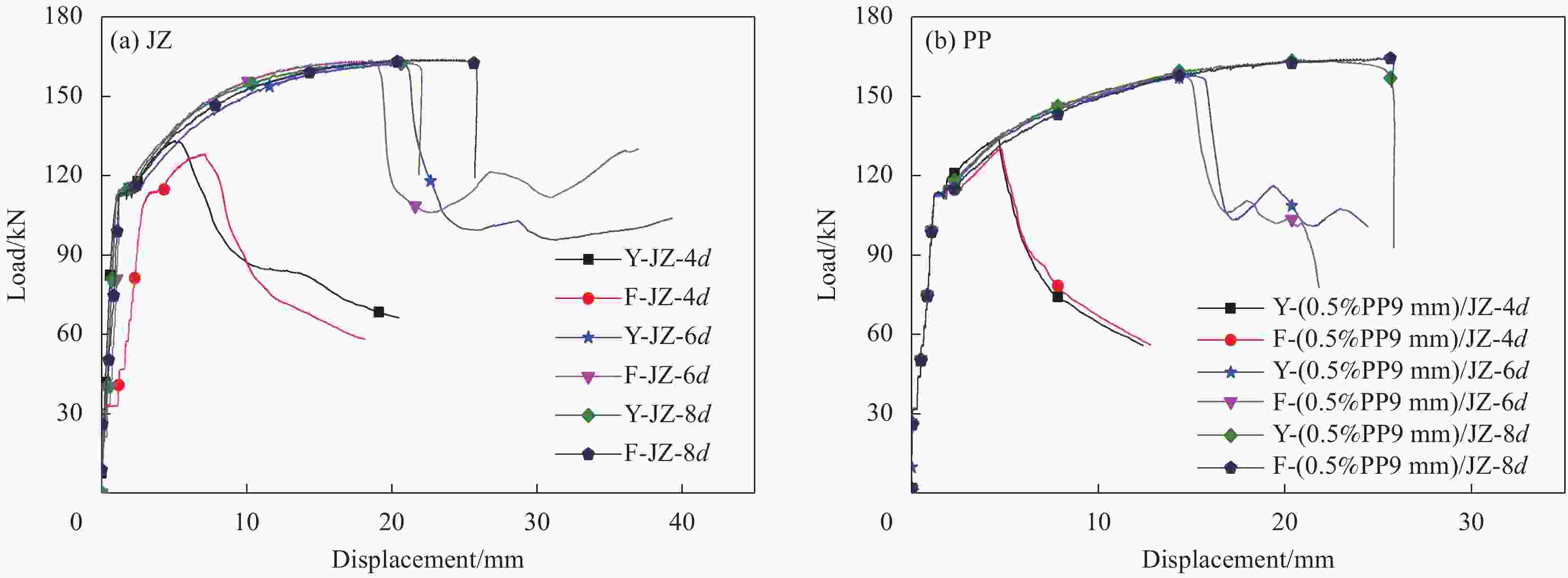

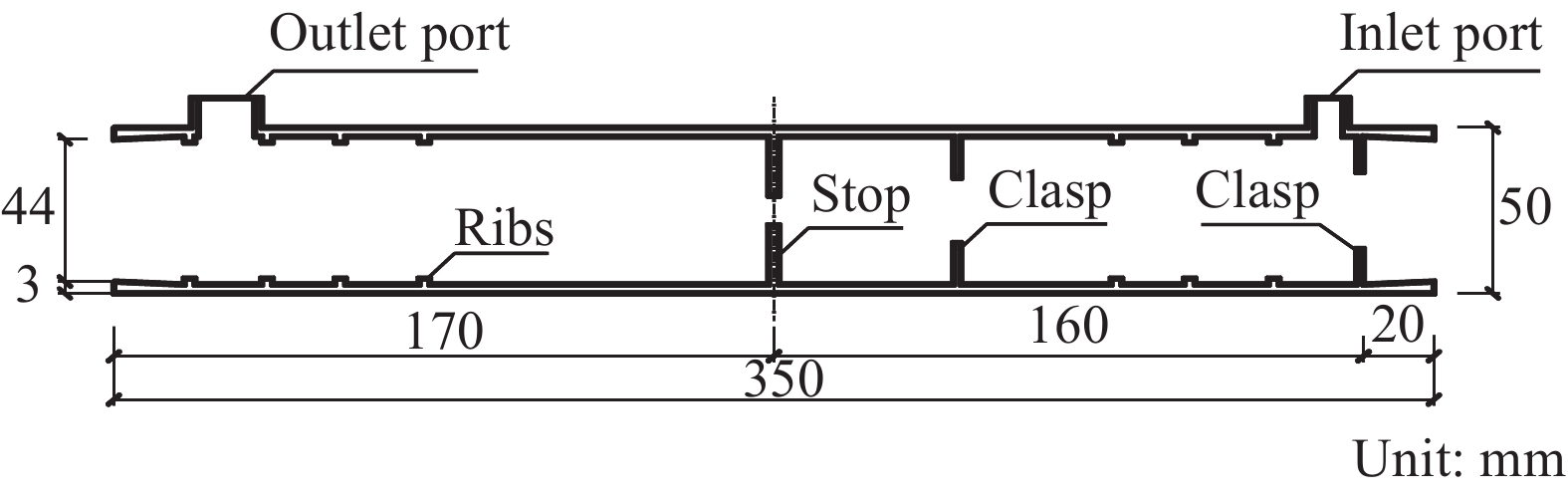

摘要: 为改善装配式结构节点的力学连接性能,对聚丙烯(PP)纤维灌浆料进行材性性能及其钢筋套筒连接接头的力学性能研究。选用不同掺量、长度PP纤维的灌浆料进行力学性能试验,确定PP纤维最佳掺量(占普通(JZ)灌浆料的体积比)和长度分别为0.5%和9 mm。以JZ灌浆料为对照组,设置了4d、6d、8d(d为钢筋直径)3种锚固长度的套筒接头试件并进行单向拉伸试验,采用光纤光栅传感器(FBG)和应变片两种测试方法研究PP纤维灌浆料下的粘结应力分布。结果表明:PP纤维增强灌浆料钢筋套筒的最小锚固长度在6d以上;PP纤维能够有效改善接头韧性,增强了套筒的粘结锚固效果,提高了筋粘结应力分布均匀程度,使其呈“马鞍形”或“斜梯型”分布;FBG传感器与应变片所得结果基本一致,FBG传感器所采集的应变数据精度高于应变片。

-

关键词:

- 聚丙烯(PP)纤维灌浆料 /

- 钢筋套筒连接接头 /

- 力学性能 /

- 单向拉伸试验 /

- 光纤光栅传感器(FBG) /

- 粘结应力

Abstract: To improve the mechanical connection performance of fabricated structural joint, the material properties of polypropylene (PP) fiber grouting material and the mechanical properties of its rebar sleeve joint were studied. The mechanical properties of grouting material with different PP fiber contents and length were tested. The optimum content (Volume ratio to ordinary (JZ) grouting material) and length of PP fiber is 0.5% and 9 mm, respectively. Taking JZ grouting material as control group, the anchorage length of 4d, 6d and 8d (d is the diameter of bar) was set and the uniaxial tensile test was carried out. The bond stress distribution of PP fiber grouting material was also studied by using Bragg Grating sensors (FBG) and strain gauge. The results show that: The minimum anchorage length of rebar sleeve of PP fiber reinforced grouting material is more than 6d; PP fiber can effectively improve the joint toughness, enhance the bond anchorage effect of the sleeve, and improve the uniform distribution of the bond stress of the reinforcement, which shows “saddle” or “inclined ladder” distribution; the results of FBG sensor and strain gauge are basically consistent, and the accuracy of strain data collected by FBG sensor is higher than that of strain gauge. -

图 9 不同分级载荷下应变片测试灌浆料套筒接头试件的钢筋应力分布:(a) Y-JZ-8d; (b) Y-JZ-6d; (c) Y-JZ-4d; (d) Y-(0.5%PP9mm)/JZ-8d; (e) Y-(0.5%PP9mm)/JZ-6d; (f) Y-(0.5%PP9mm)/JZ-4d

Figure 9. Stress distribution of reinforcing steel bar in grout sleeve joint specimen measured by strain gauge under different step loads:(a) Y-JZ-8d; (b) Y-JZ-6d; (c) Y-JZ-4d; (d) Y-(0.5%PP9mm)/JZ-8d; (e) Y-(0.5%PP9mm)/JZ-6d; (f) Y-(0.5%PP9mm)/JZ-4d

图 10 不同分级载荷下FBG测试灌浆料套筒接头试件的钢筋应力分布:(a) F-JZ-8d; (b) F-JZ-6d; (c) F-JZ-4d; (d) F-(0.5%PP9mm)/JZ-8d; (e) F-(0.5%PP9mm)/JZ-6d; (f) F-(0.5%PP9mm)/JZ-4d

Figure 10. Stress distribution of reinforcing steel bar in grout sleeve joint specimen measured by FBG under different step loads: (a) F-JZ-8d; (b) F-JZ-6d; (c) F-JZ-4d; (d) F-(0.5%PP9mm)/JZ-8d; (e) F-(0.5%PP9mm)/JZ-6d; (f) F-(0.5%PP9mm)/JZ-4d

图 11 不同分级载荷下应变片测试灌浆料套筒接头试件的钢筋粘结应力分布:(a) Y-JZ-8d; (b) Y-JZ-6d; (c) Y-JZ-4d; (d) Y-(0.5%PP9mm)/JZ-8d; (e) Y-(0.5%PP9mm)/JZ-6d; (f) Y-(0.5%PP9mm)/JZ-4d

Figure 11. Bond stress distribution of reinforcing steel bar in grout sleeve joint specimen measured by strain gauge under different step loads:(a) Y-JZ-8d; (b) Y-JZ-6d; (c) Y-JZ-4d; (d) Y-(0.5%PP9mm)/JZ-8d; (e) Y-(0.5%PP9mm)/JZ-6d; (f) Y-(0.5%PP9mm)/JZ-4d

图 12 不同分级载荷下FBG测试灌浆料套筒接头试件的钢筋粘结应力分布:(a) F-JZ-8d; (b) F-JZ-6d; (c) F-JZ-4d; (d) F-(0.5%PP9mm)/JZ-8d; (e) F-(0.5%PP9mm)/JZ-6d; (f) F-(0.5%PP9mm)/JZ-4d

Figure 12. Bond stress distribution of reinforcing steel bar in grout sleeve joint specimen measured by FBG under different step loads:(a) F-JZ-8d; (b) F-JZ-6d; (c) F-JZ-4d; (d) F-(0.5%PP9mm)/JZ-8d; (e) F-(0.5%PP9mm)/JZ-6d; (f) F-(0.5%PP9mm)/JZ-4d

表 1 聚丙烯(PP)纤维参数

Table 1. Parameters of polypropylene (PP) fiber

Density/(g·cm−3) Diameter/μm Compressive strength/MPa Young’s modulus/MPa Elongation at break/% 0.91 27 556 4186 18 表 2 普通(JZ)灌浆料的力学性能试验结果

Table 2. Main mechanical test results of ordinary (JZ) grouting materials

Specimen Fluidity/mm Compressive strength/MPa Flexural strength/MPa Initial 30 min JZ 390 382 74 13.8 表 3 灌浆料套筒接头试件单向拉伸力学性能及破坏模式

Table 3. Uniaxial tensile mechanical properties and failure mode of grouting material rebar sleeve connection specimens

Specimen $ {P}_{\rm{y}} $/kN $ {P}_{\rm{u}}/ $kN $ {\tau }_{\rm{max}} $/MPa $ {S}_{\rm{q}} $/mm Failure mode Y-JZ-8d 114.1 163.1 >20.04 20.09 Bar fracture Y-JZ-6d 113.8 157.4 25.79 14.13 Bar pull-out Y-JZ-4d 113.1 132.5 32.56 2.77 Bar pull-out Y-(0.5%PP9mm)/JZ-8d 113.8 163.3 >20.06 23.71 Bar fracture Y-(0.5%PP9mm)/JZ-6d 113.8 161.9 26.52 17.40 Bar pull-out Y-(0.5%PP9mm)/JZ-4d 113.9 134.5 33.05 2.67 Bar pull-out F-JZ-8d 114.0 163.2 >20.03 23.57 Bar fracture F-JZ-6d 113.2 162.6 25.69 15.46 Bar pull-out F-JZ-4d 114.0 127.8 31.40 2.71 Bar pull-out F-(0.5%PP9mm)/JZ-8d 113.6 163.7 >20.07 23.70 Bar fracture F-(0.5%PP9mm)/JZ-6d 113.6 166.8 26.64 18.24 Bar pull-out F-(0.5%PP9mm)/JZ-4d 114.9 128.3 33.05 2.08 Bar pull-out Notes: Y and F—Strain gauge and FBG; JZ and PP—JZ and PP grouting material;8d—Anchorage length is 8d. $ {P}_{\rm{y}} $ and $ {P}_{\rm{u}} $—Yield load and ultimate force. $ {\tau }_{\rm{max}} $—Ultimate bond strength, in the case of bar pull-out, it is the bond strength corresponding to the maximum tensile load; in the case of bar fracture, it must be greater than this value. $ {S}_{\rm{q}} $—Ultimate bond strength whose length from the starting point of strengthening to the point of ultimate tensile strength. -

[1] MARTINEZ S, JARDON A, NAVARRO J M, et al. Building industrialization: Robotized assembly of modular products[J]. Assembly Automation,2008,28(2):134-142. [2] YEE A A. Prestressing concrete for buildings[J]. Pci Journal,1976,21(5):112-157. doi: 10.15554/pcij.09011976.112-157 [3] 韩超, 郑毅敏, 赵勇. 钢筋套筒灌浆连接技术研究与应用进展[J]. 施工技术, 2013, 42(21):113-116. doi: 10.7672/sgjs2013210113HAN Chao, ZHENG Yimin, ZHAO Yong. Research and application development of grout sleeve splicing for reinforcement[J]. Construction Technology,2013,42(21):113-116(in Chinese). doi: 10.7672/sgjs2013210113 [4] ALLAN M L, KUKACKA L E. Strength and durability of polypropylene fibre reinforced grouts[J]. Cement and Concrete Research,1995,25(3):511-521. doi: 10.1016/0008-8846(95)00040-J [5] 冯虎, 陈风波, 李经业. 聚丙烯纤维灌浆材料的技术与应用分析[J]. 山东交通科技, 2014(3):33-35.FENG Hu, CHEN Fengbo, LI Jingye. Technology and application analysis of grouting material admixed with polypropylene fiber[J]. Shandong Jiaotong Keji,2014(3):33-35(in Chinese). [6] 梁影. 聚丙烯纤维水泥浆板底灌浆材料性能研究[D]. 重庆: 重庆交通大学, 2014.LIANG Ying. Research on the performance of polypropylene fiber cement material for pavement grouting[D]. Chongqing: Chongqing Jiaotong University. 2014(in Chinese). [7] 郑永峰. GDPS灌浆套筒钢筋连接技术研究[D]. 南京: 东南大学, 2016.ZHENG Yongfeng. Research on rebar splicing system By GDPS grout-filled coupling sleeve[D]. Nanjing: Southeast University, 2016(in Chinese). [8] 余琼, 孙佳秋, 袁炜航. 带肋钢筋与套筒约束灌浆料黏结性能试验[J]. 哈尔滨工业大学学报, 2018, 50(12):98-106. doi: 10.11918/j.issn.0367-6234.201711108YU Qiong, SUN Jiaqiu, YUAN Weihang. Experimental Study on bond behavior between ribbed steel bars and sleeve constrained grouting material[J]. Journal of Harbin Institute of Technology,2018,50(12):98-106(in Chinese). doi: 10.11918/j.issn.0367-6234.201711108 [9] LING J H, RAHMAN A B A, IBRAHIM I S, et al. Tensile capacity of grouted splice sleeves[J]. Engineering Structures,2016,111:285-296. doi: 10.1016/j.engstruct.2015.12.023 [10] HOSSEINI S J A, RAHMAN A B A. Analysis of spiral reinforcement in grouted pipe splice connectors[J]. Gradevinar,2013,65(6):537-546. [11] ALIAS A, ZUBIR M A, SHAHID K A, et al. Structural performance of grouted sleeve connectors with and without transverse reinforcement for precast concrete structure[J]. Procedia Engineering,2013,53:116-123. doi: 10.1016/j.proeng.2013.02.017 [12] KOUSHFAR K, RAHMAN A, AHMAD Y, et al. Bond behavior of the reinforcement bar in glass fiber-reinforced polymer connector[J]. Gradevinar,2014,66(4):301-310. [13] SEO S Y, NAM B R, KIM S K. Tensile strength of the grout-filled head-splice-sleeve[J]. Construction and Building Materials,2016,124:155-166. doi: 10.1016/j.conbuildmat.2016.07.028 [14] XU Tengfei, LI Quanwen, ZHAO Renda, et al. On the early-age bond-slip behavior of an eccentric bar embedded in a grouted sleeve[J]. Engineering Structures,2019,190:160-170. doi: 10.1016/j.engstruct.2019.04.020 [15] 中国建筑标准设计研究院. 钢筋连接用套筒灌浆料: JG/T 408—2019[S]. 北京: 中国标准出版社, 2019.China Architecture Design & Research Group. Cementitious grout for sleeve of rebar splicing: JG/T 408—2019[S]. Beijing: Standards Press of China, 2019(in Chinese). [16] 中国建筑科学研究院. 钢筋套筒灌浆连接应用技术规程: JGJ 355—2015[S]. 北京: 中国建筑工业出版社, 2015.China Academy of Building Research. Technical specification for grout sleeve of rebars: JGJ 355—2015[S]. Beijing: China Architecture & Building Press, 2015(in Chinese). [17] 中华人民共和国住房和城乡建设部. 水泥基灌浆材料应用技术规范: GB/T 50448—2015[S]. 北京: 中国建筑工业出版社, 2015.Ministry of Housing and Urban Rural Development of the People’s Republic of China. Technical code for application of cementitious grout: GB/T 50448—2015[S]. Beijing: China Architecture &Building Press, 2015(in Chinese). [18] 中国国家标准化管理委员会. 水泥胶砂强度检验方法: GB/T 17671—1999[S]. 北京: 中国标准出版社, 1999.Standardization Administration. Method of testing cements-Determination of strength: GB/T 17671—1999[S]. Beijing: China Standard Press, 1999(in Chinese). [19] 中国建筑科学研究院. 钢筋机械连接技术规程: JGJ 107—2016[S]. 北京: 中国建筑工业出版社, 2016.China Academy of Building Research. Technical specification for mechanical splicing of steel reinforcing bars: JGJ 107—2016[S]. Beijing: China Architecture & Building Press, 2016(in Chinese). [20] LUBLINER J, OLIVER J, OLLER S, et al. A plastic-damage model for concrete[J]. International Journal of Solids & Structures,1989,25(3):299-326. [21] WU J Y, LI J, RUI F. An energy release rate-based plastic-damage model for concrete[J]. International Journal of Solids & Structures,2006,43(3-4):583-612. [22] 郭乃胜, 赵颖华, 孙略伦. 纤维掺量对聚酯纤维沥青混凝土韧性的影响[J]. 交通运输工程学报, 2006(4):32-35. doi: 10.3321/j.issn:1671-1637.2006.04.008GUO Naisheng, ZHAO Yinghua, SUN Luelun. Effect of fiber contents on toughness of polyester fiber asphalt concrete[J]. Journal of Traffic and Transportation Engineering,2006(4):32-35(in Chinese). doi: 10.3321/j.issn:1671-1637.2006.04.008 [23] 许成顺, 刘洪涛, 杜修力. 高应力反复拉压作用下钢筋套筒灌浆连接性能试验研究[J]. 建筑结构学报, 2018, 39(12):178-184, 193.XU Chengshun, LIU Hongtao, DU Xiuli. Experimental study on connection performance of grouted sleeve splicing for rebars under high stress repeated tension-compression loading[J]. Journal of Building Structures,2018,39(12):178-184, 193(in Chinese). [24] 武立伟. 矿用钢管混凝土套筒灌浆连接性能试验研究[D]. 唐山: 华北理工大学, 2018.WU Liwei. Experimental study on sleeve connection performance of mine concrete filled steel tube[D]. Tangshan: North China University of Science and Technology, 2018(in Chinese). -

下载:

下载: