A method of CFRP drilling assisted by ultrasonic, cryogenic temperature and ice support

-

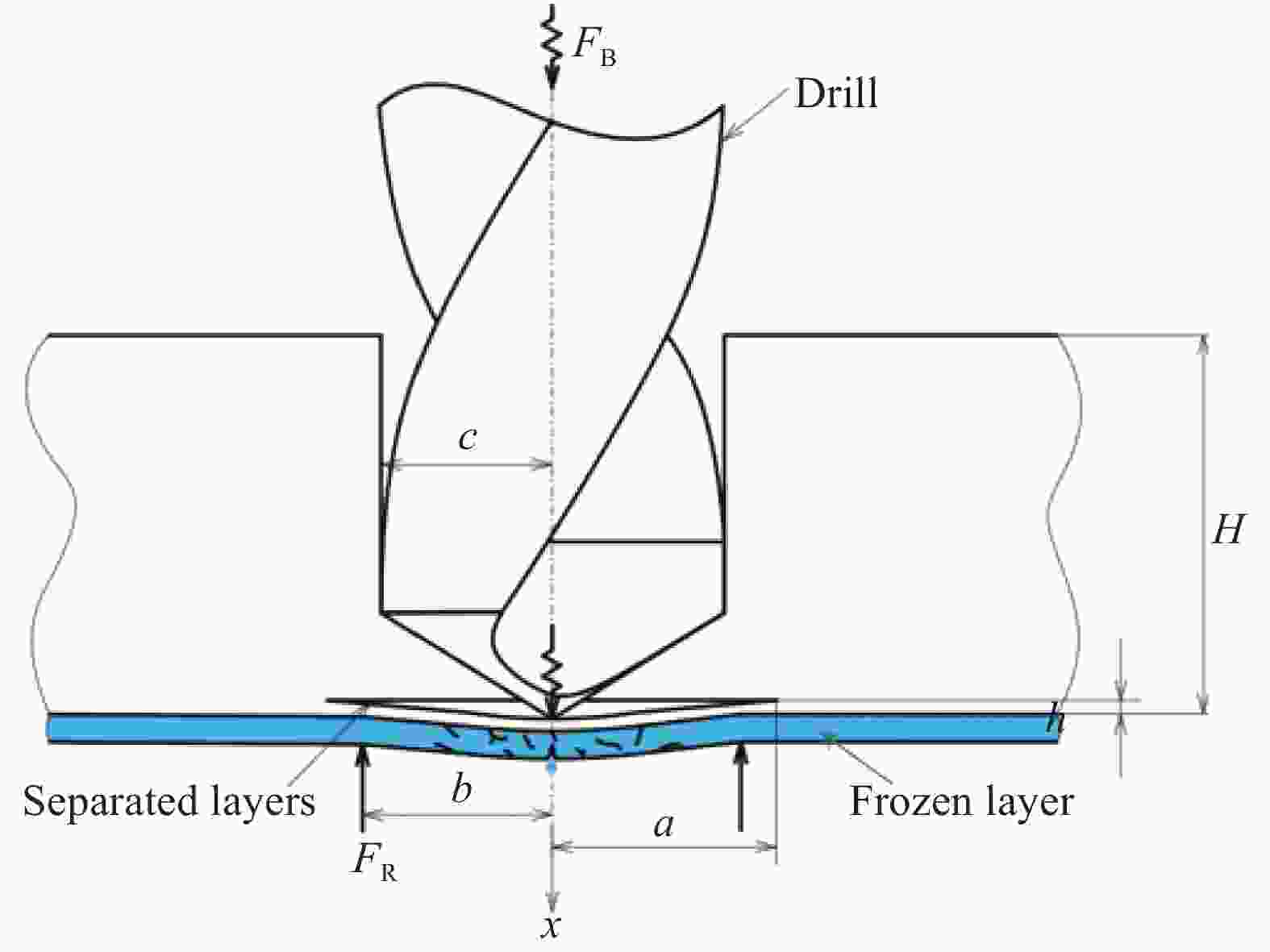

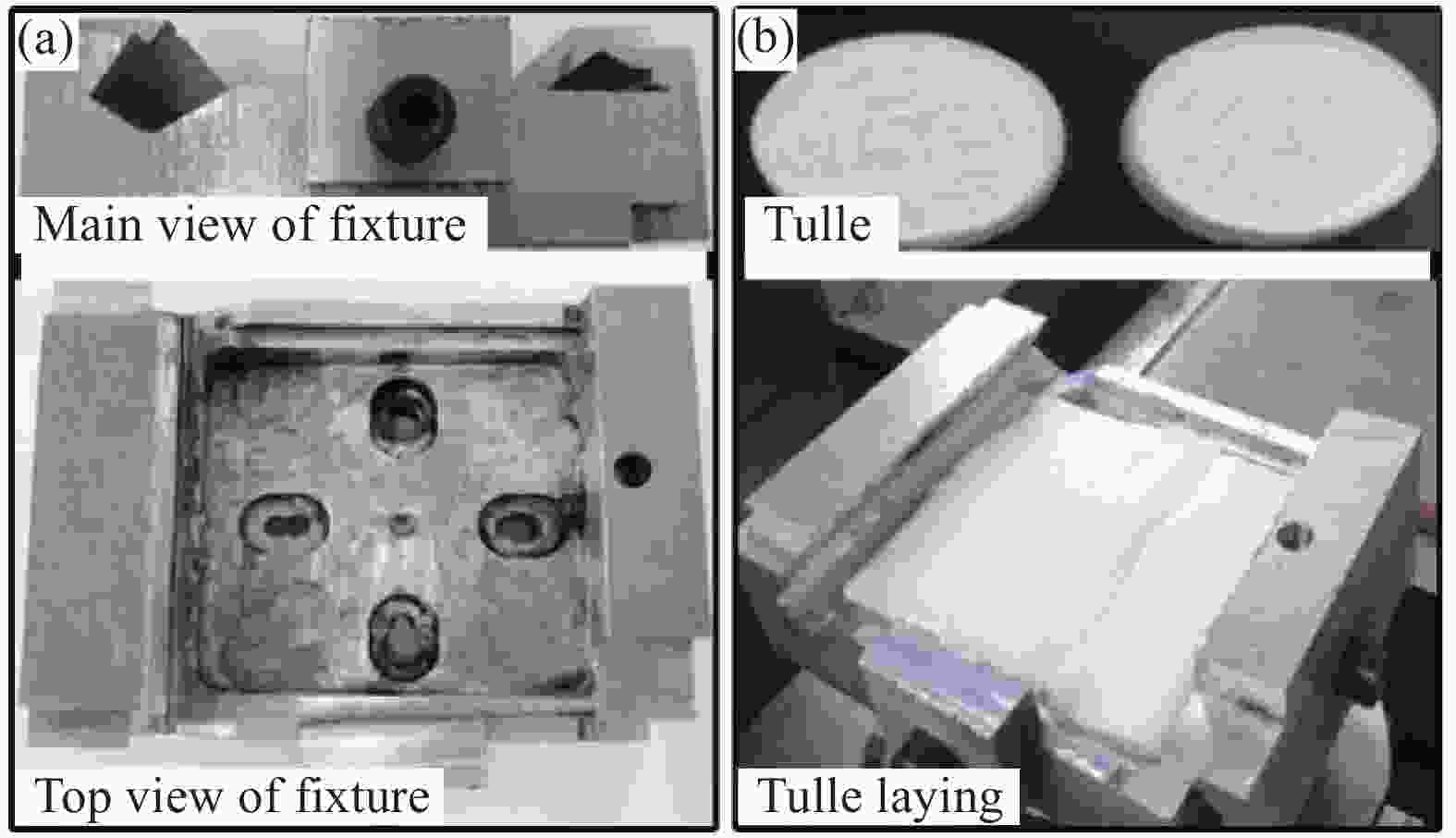

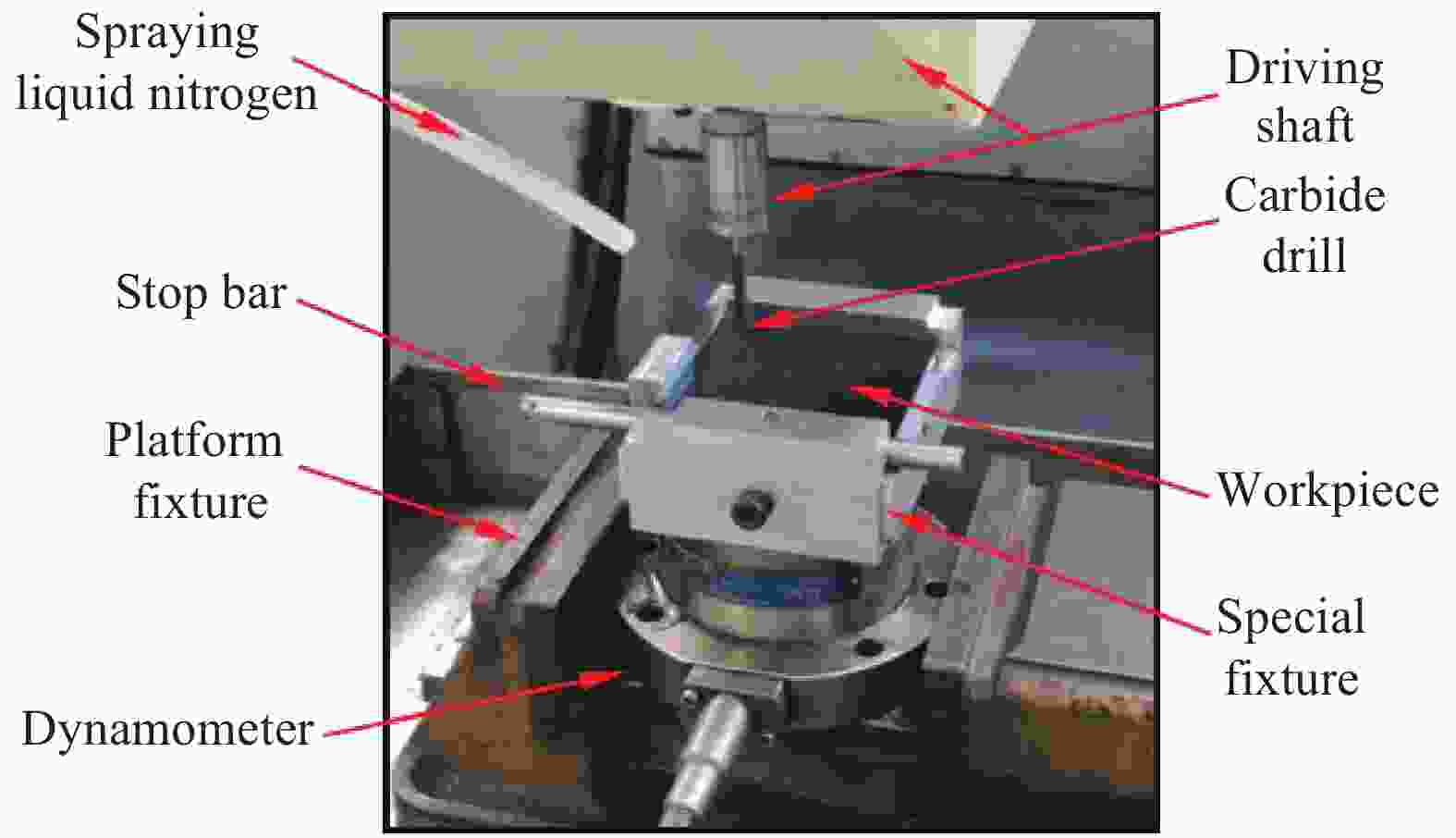

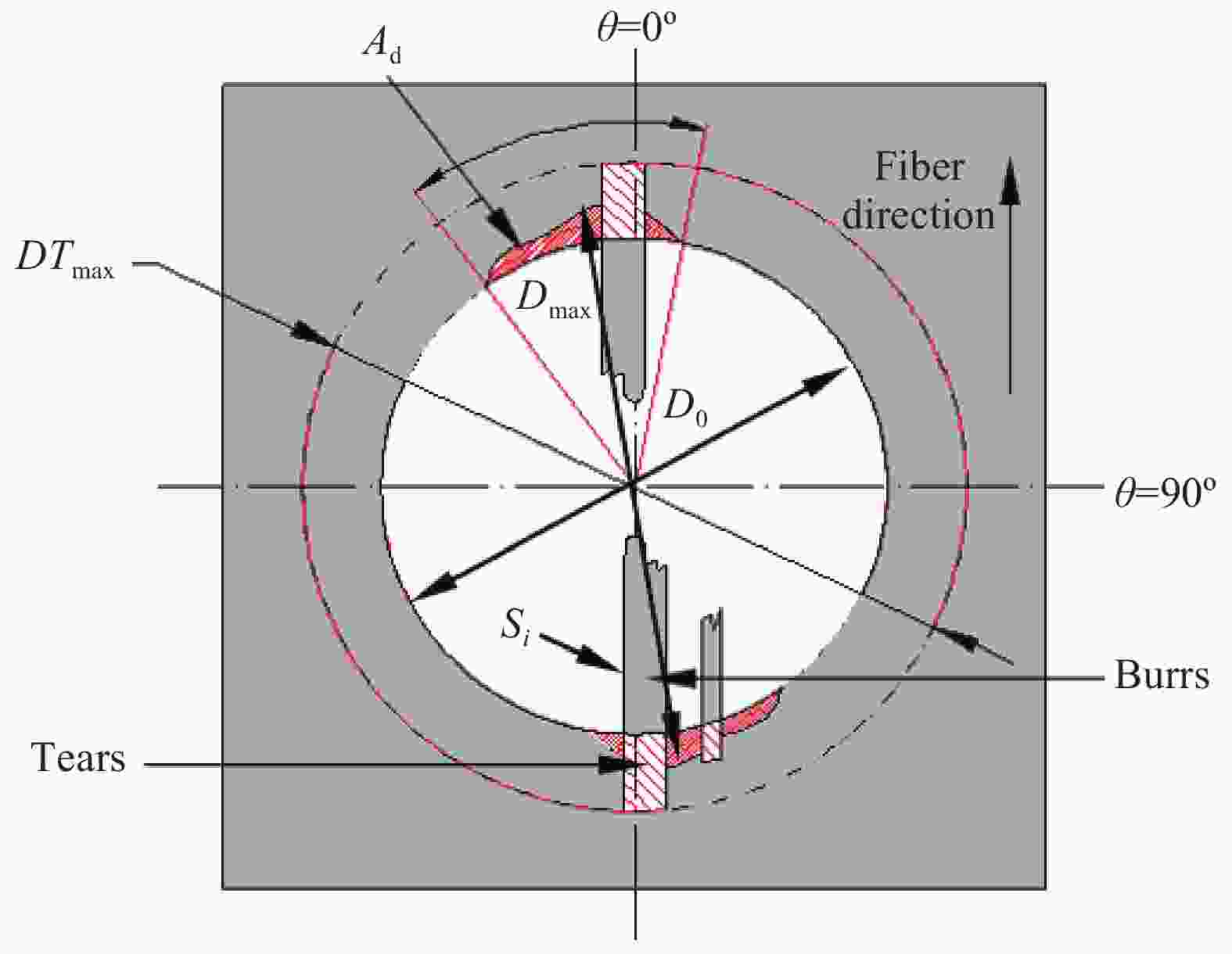

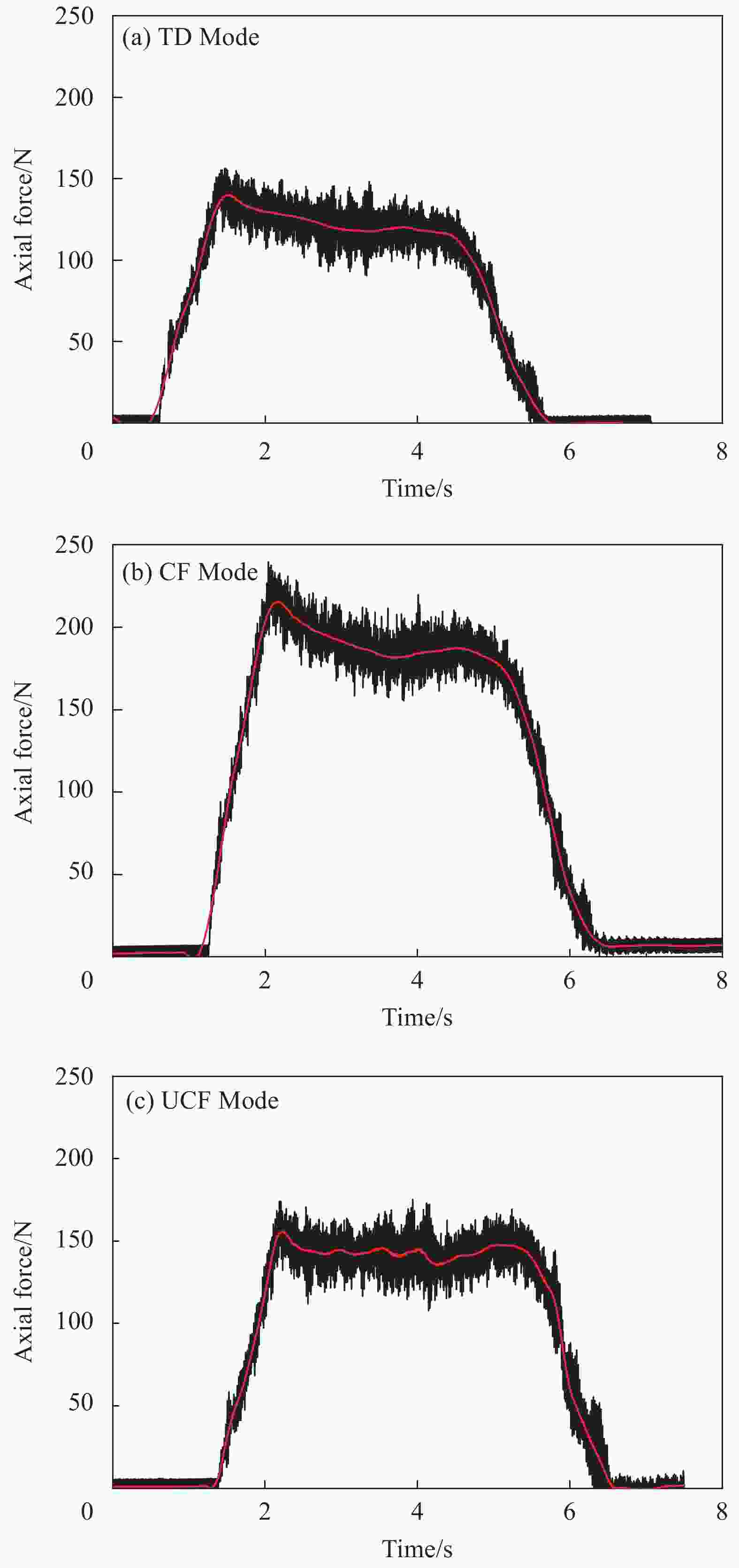

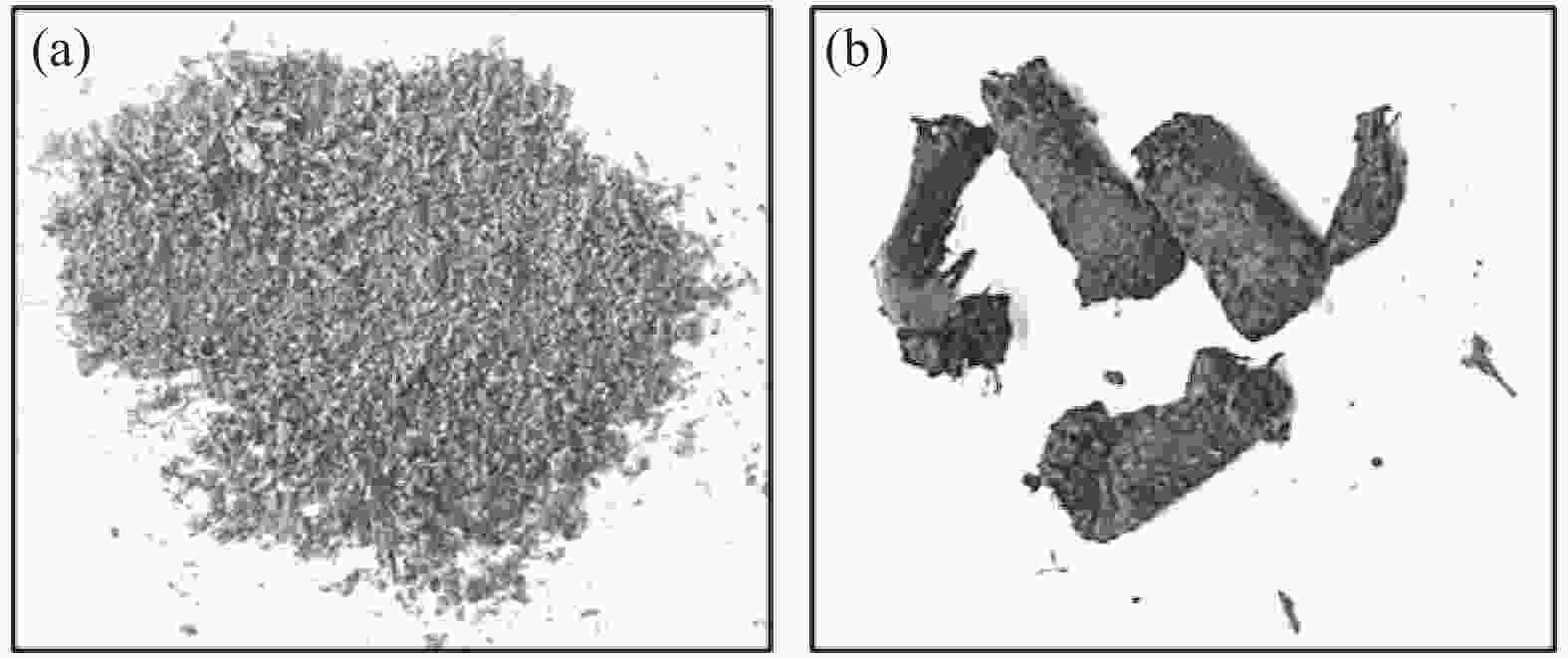

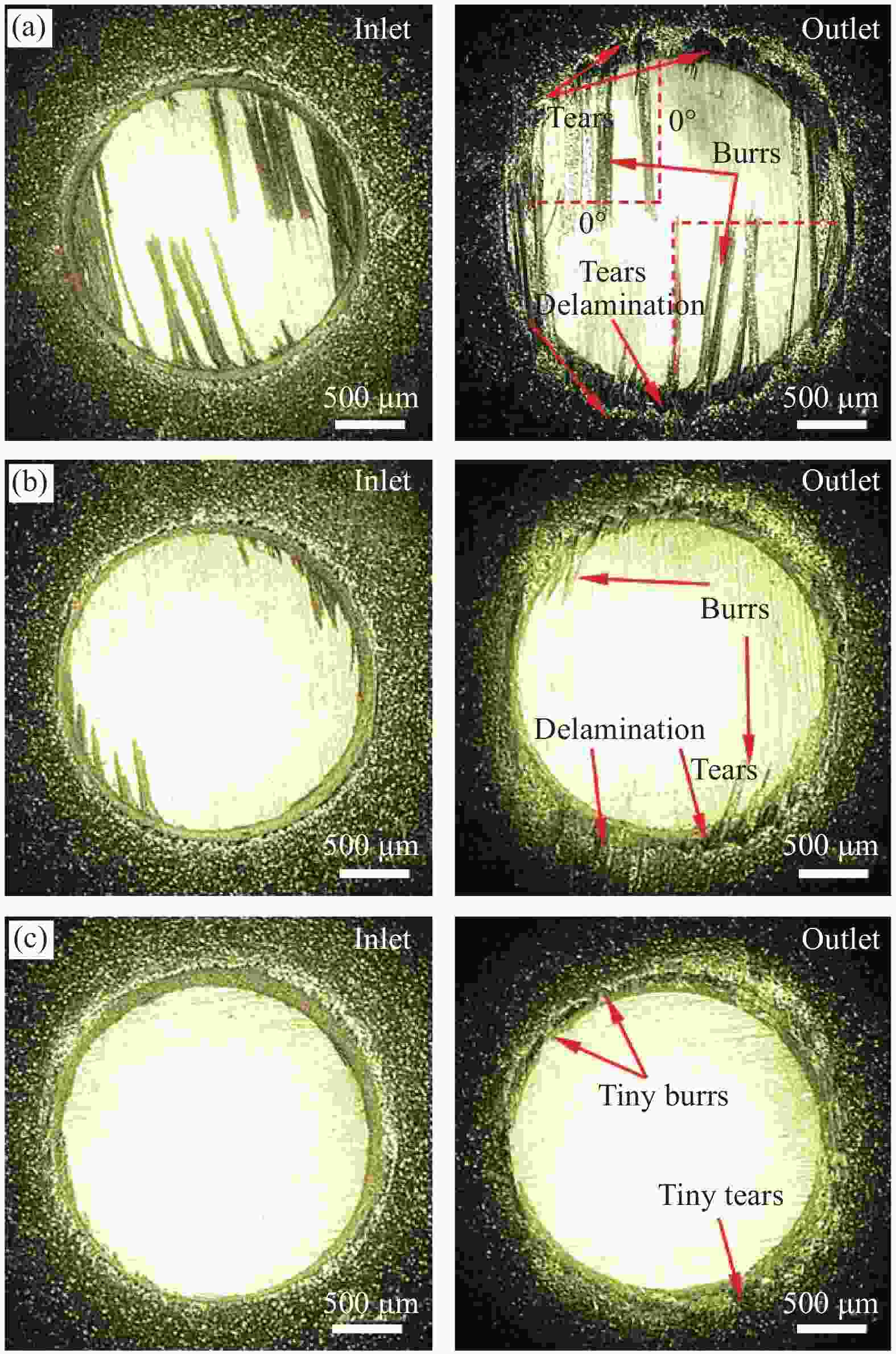

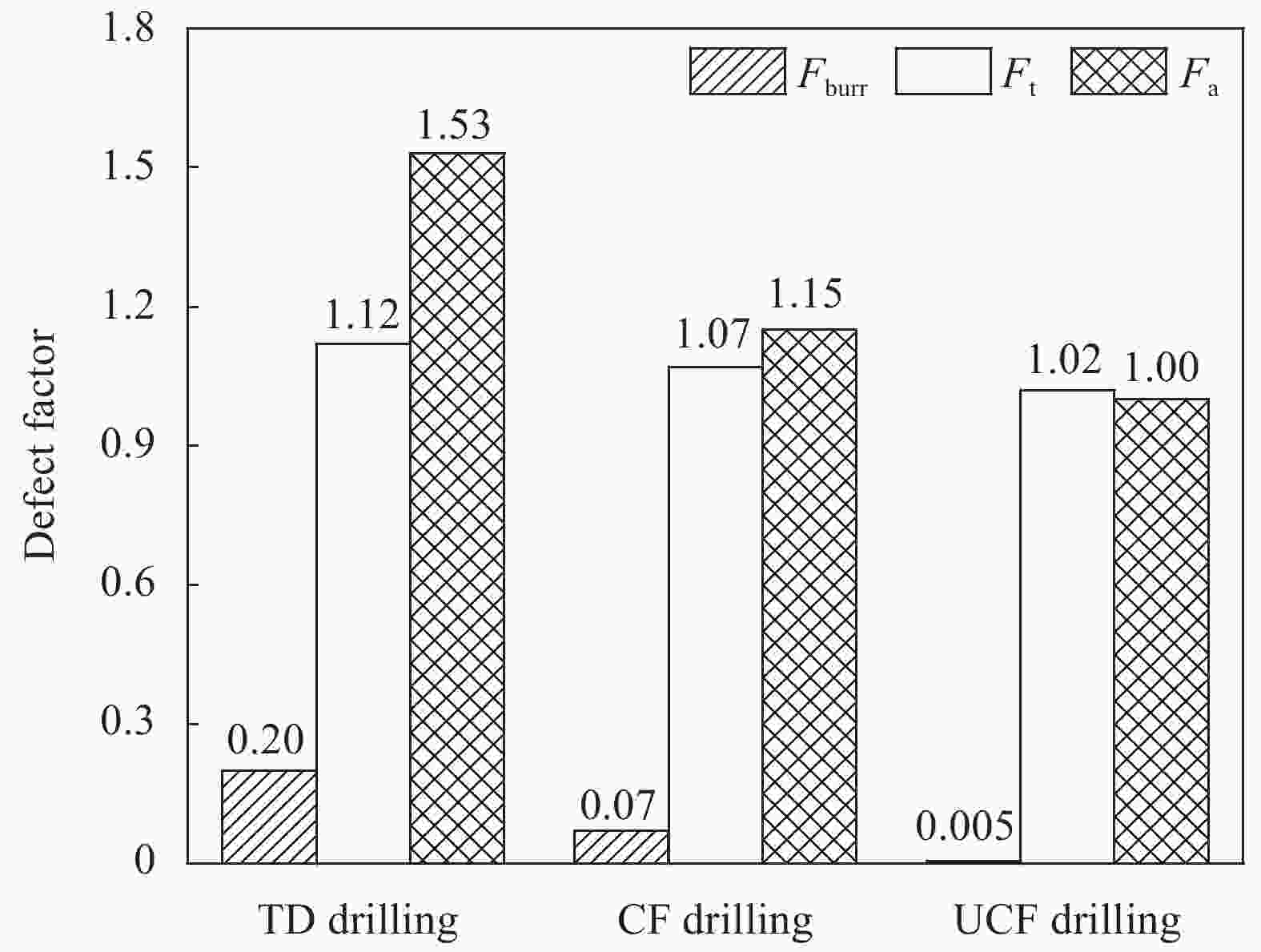

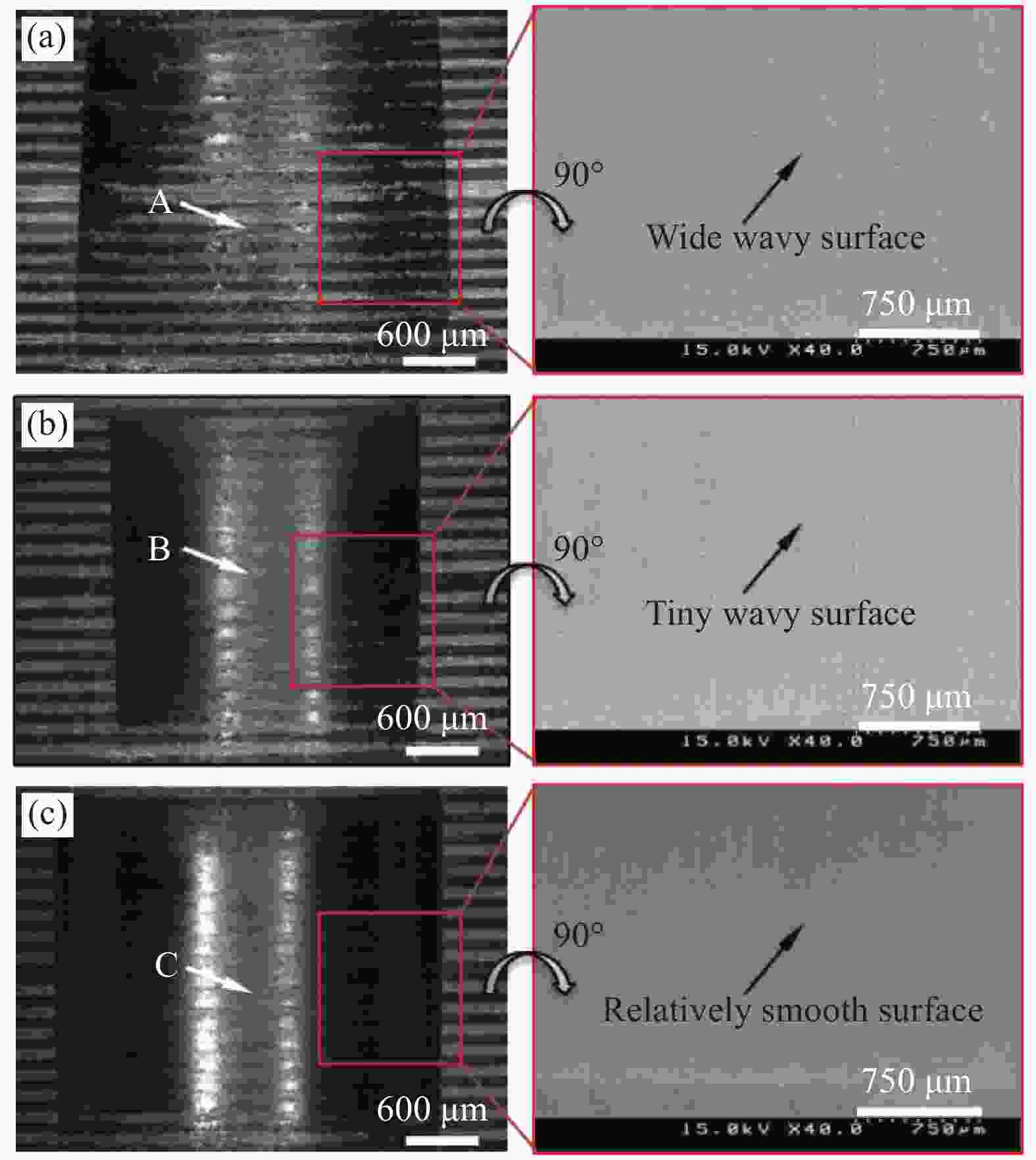

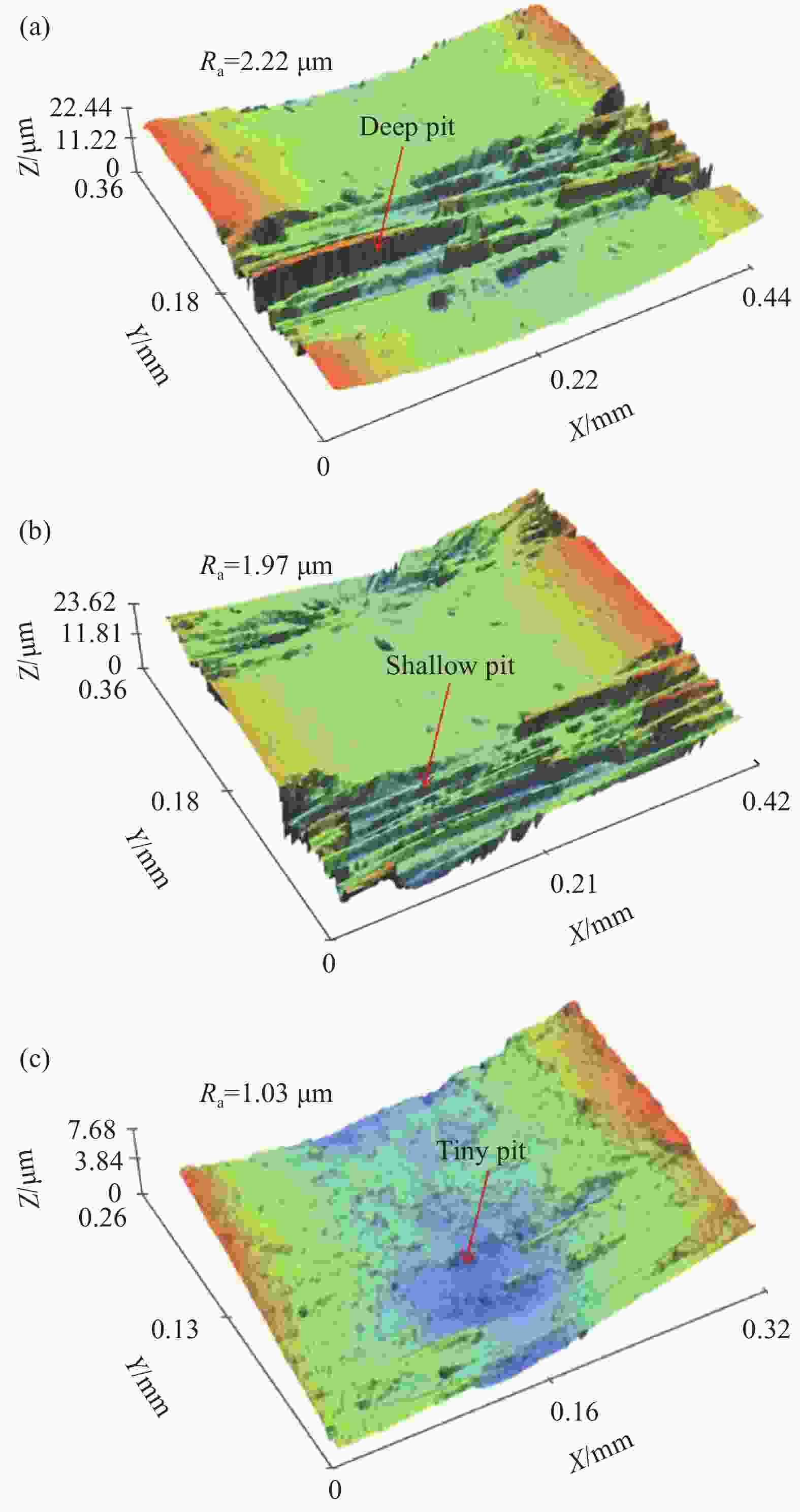

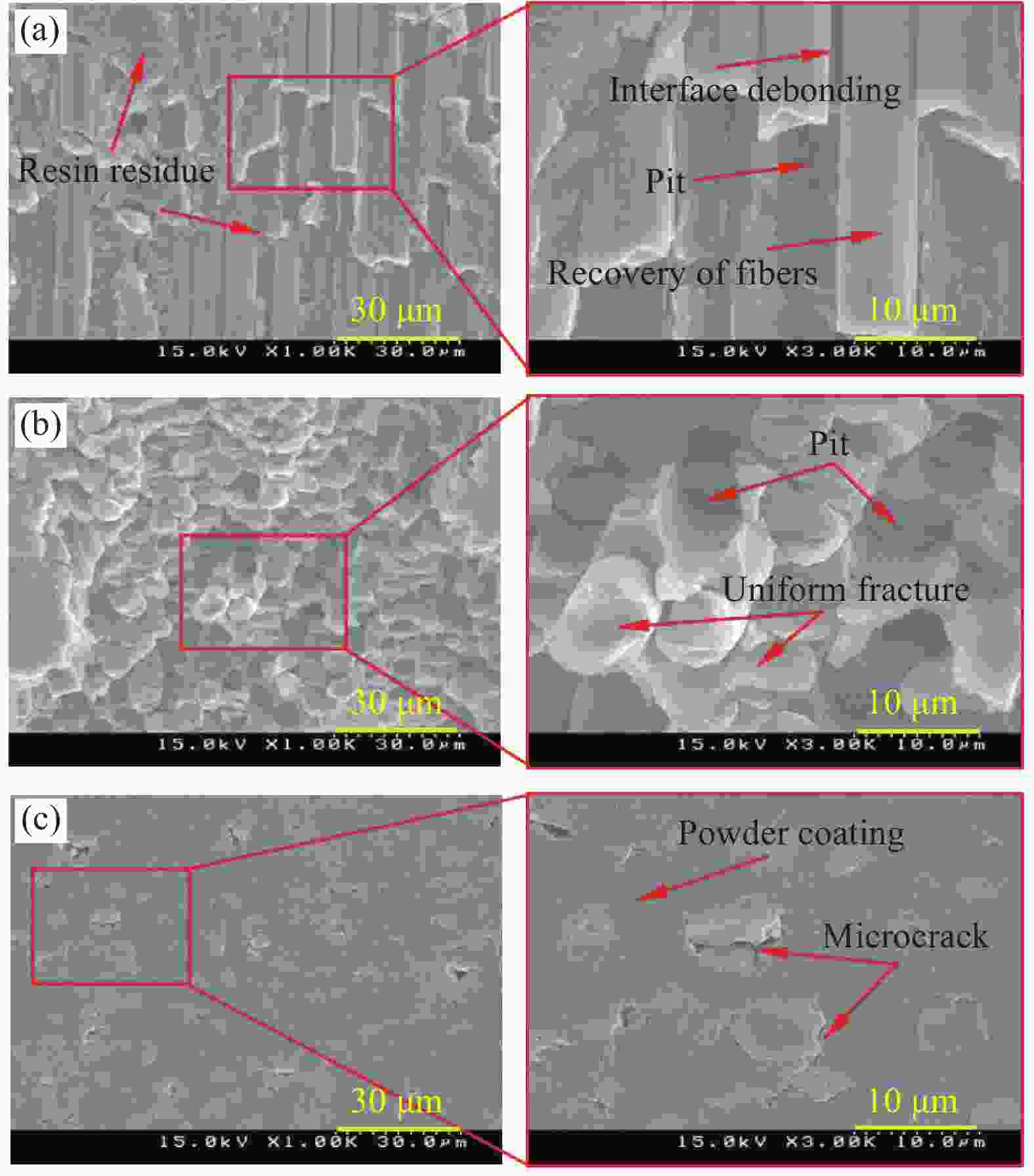

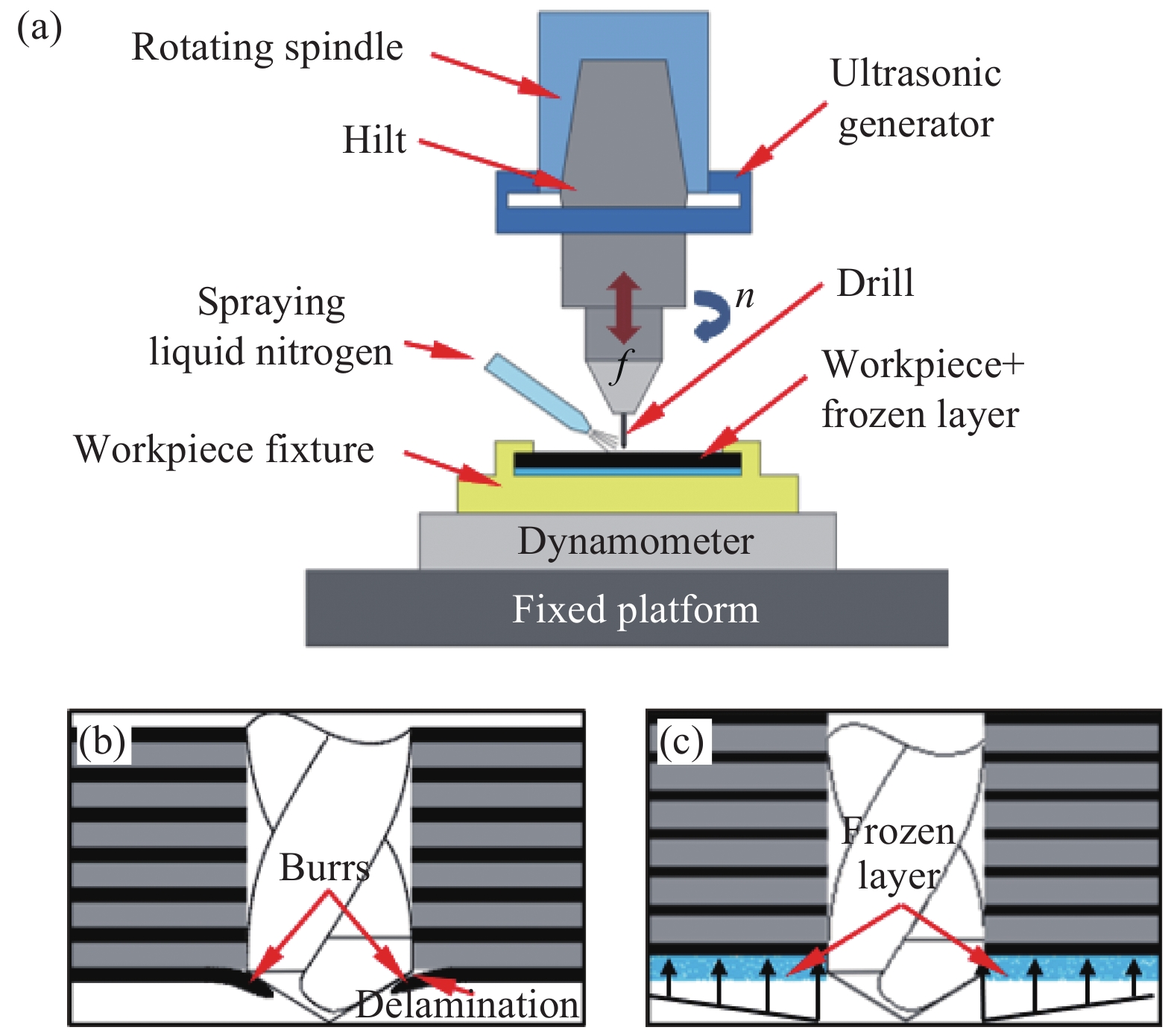

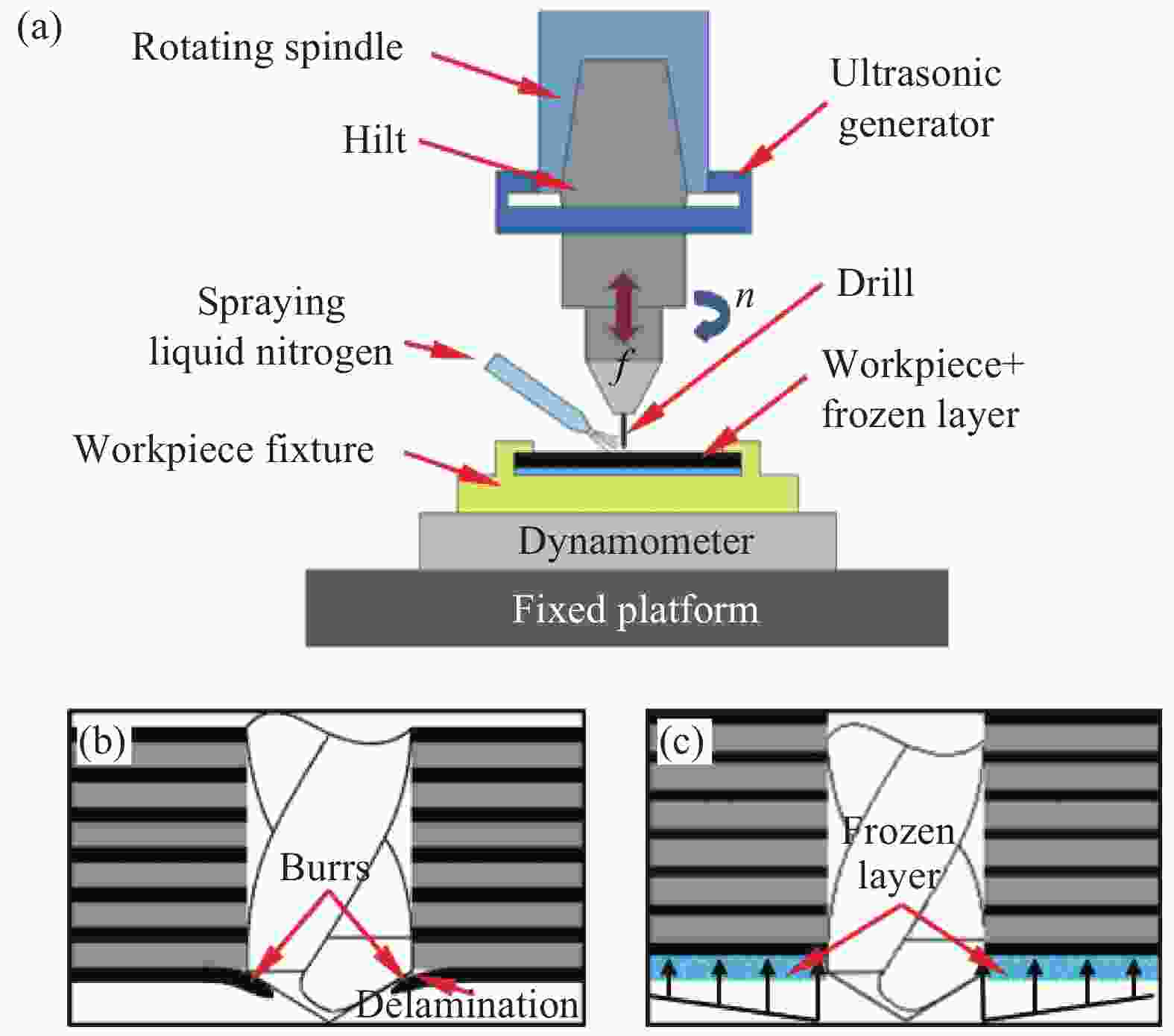

摘要: 提出一种超声振动+超低温液氮+由超低温环境形成的冰冻支撑层(Ultrasonic vibration+Cryogenic liquid nitrogen+Frozen support layer,UCF)来辅助碳纤维增强树脂基复合材料(Carbon fiber reinforced polymer, CFRP)钻削制孔,有效降低钻削缺陷的加工方法。该方法的基本原理为:利用超声作用下的钻头高频振动实现轴向钻削力的弱化,利用超低温液氮以及形成的冰冻支撑层来实现钻削出口侧材料的约束和支撑,并有效降低加工过程的钻削热影响。基于UCF的基本原理,开展了相应的UCF辅助加工实验,通过微观检测表征和缺陷因子计算等手段,与传统钻削模式(Traditional drilling, TD)、低温液氮+冰冻支撑模式(Cryogenic liquid nitrogen +Freezing support,CF)下的CFRP制孔质量进行了对比分析。结果表明,采用UCF模式和CF模式均会引起轴向力增加,但UCF模式下的最大轴向力增幅相对较小;与TD模式相比,采用UCF辅助加工方法最大可使CFRP钻削出口的毛刺因子降低75%,撕裂因子降低8.9%,分层因子降低34.6%,孔壁表面粗糙度Ra降低53.6%。Abstract: A method of ultrasonic vibration + cryogenic liquid nitrogen + frozen support layer (UCF) is proposed to assist carbon fiber reinforced polymer (CFRP) drilling and effectively reduce machining defects. The basic principle of this method is as follows: the high frequency vibration of the drill bit under ultrasonic action is used to weaken the axial drilling force; the cryogenic temperature liquid nitrogen and the formation of frozen support layer are used to realize the constraint and support of the material at the drilling exit side, and effectively reduce the whole process of drilling heat effect. Based on the basic principle of UCF, corresponding experiment of UCF assisted drilling were carried out, and the hole quality of CFRP under traditional drilling mode (TD) and cryogenic liquid nitrogen + freezing support mode (CF) was compared and analyzed by means of microscopic inspection and characterization and defect factor calculation. The results show that both UCF and CF can increase the axial force, but the maximum axial force increased little. Compared with TD mode, UCF can reduce burr factor by 75%, tear factor by 8.9%, delamination factor by 34.6% and surface roughness Ra by 53.6%.

-

Key words:

- CFRP /

- machining defects /

- back plate support /

- cryogenic drilling /

- axial force

-

表 1 CFRP的性能参数

Table 1. Performance parameters of CFRP

Parameter Value Tensile strength/MPa 950 Compressive strength/MPa 570 Young’s modulus/GPa 61.5 Shear modulus/GPa 3.7 Poisson’ ratio 0.3 Density/(kg·m−3) 155 Hardness (HRB) 70-75 表 2 CFRP钻削模式设定

Table 2. Setting of CFRP drilling mode

Mode Auxiliary factor Cryogenic liquid nitrogen Support by freezing Ultrasonic vibration TD × × × CF √ √ × UCF √ √ √ Notes: TD—Traditional drilling; CF—Cryogenic liquid nitrogen +

Freezing support; UCF—Ultrasonic vibration + Cryogenic liquid nitrogen + Frozen support layer. -

[1] 石经纬, 赵娟, 刘传军, 等. 复合材料翼面壁板剪切稳定性[J]. 复合材料学报, 2020, 37(7):1590-1600.SHI Jingwei, ZHAO Juan, LIU Chuanjun, et al. Stability of composite stiffened panels in plane shear[J]. Acta Materiae Compositae Sinica,2020,37(7):1590-1600(in Chinese). [2] 孟庆勋, 姜寿山, 刘书暖, 等. CFRP层合板制孔周期内轴向力分布规律研究[J]. 机械工程学报, 2018, 54(11):110-120. doi: 10.3901/JME.2018.011.110MENG Qingxun, JIANG Shoushan, LIU Shunuan, et al. Study of thrust force distribution in a drilling cycle during drilling of CFRP laminates[J]. Journal of Mechanical Engineering,2018,54(11):110-120(in Chinese). doi: 10.3901/JME.2018.011.110 [3] 李树健, 湛利华, 白海明, 等. 基于树脂流动的变截面复合材料结构固化过程热-流-固多场强耦合数值仿真[J]. 复合材料学报, 2018, 35(8):119-126.LI Shujian, ZHAN Lihua, BAI Haiming, et al. Numerical simulation of heat-flow-solid multi-field strong coupling in curing process of variable cross-section composite structures based on the resin flow[J]. Acta Materiae Compositae Sinica,2018,35(8):119-126(in Chinese). [4] QIU X Y, LI P N, LI C P, et al. Study on chisel edge drilling behavior and step drill structure on delamination in drilling CFRP[J]. Composite Structures,2018,203:404-413. doi: 10.1016/j.compstruct.2018.07.007 [5] 贾振元, 毕广健, 王福吉, 等. 碳纤维增强树脂基复合材料切削机理研究[J]. 机械工程学报, 2018, 54(23):213-222.JIA Zhenyuan, BI Guangjian, WANG Fuji, et al. The research of machining mechanism of carbon fiber reinforced plastic[J]. Journal of Mechanical Engineering,2018,54(23):213-222(in Chinese). [6] XU W X, ZHANG L C. Heat effect on the material removal in the machining of fibre-reinforced polymer composites[J]. International Journal of Machine Tools and Manufacture,2019,140:1-11. doi: 10.1016/j.ijmachtools.2019.01.005 [7] DONG G J, LANG C Y, LI C, et al. Formation mechanism and modelling of exit edge-chipping during ultrasonic vibration grinding of deep-small holes of microcrystalline-mica ceramics[J]. Ceramics International, 2020, 46(8): 12458-12469. [8] GAUGEL S, SRIPATHY P, HAEGER A, et al. A comparative study on tool wear and laminate damage in drilling of carbon-fiber reinforced polymers (CFRP)[J]. Composite Structures,2016,155:173-183. doi: 10.1016/j.compstruct.2016.08.004 [9] YU Z, LI C P, QIU X Y, et al. Study on damage in carbon fiber reinforced plastic drilling using step cutting mecha-nism drill[J]. Journal of Alloys and Compounds,2020,826:154058. doi: 10.1016/j.jallcom.2020.154058 [10] JIA Z Y, FU R, NIU B, et al. Novel drill structure for damage reduction in drilling CFRP composites[J]. International Journal of Machine Tools and Manufacture,2016,110:55-65. doi: 10.1016/j.ijmachtools.2016.08.006 [11] XU J Y, LI C, MI S P, et al. Study of drilling-induced defects for CFRP composites using new criteria[J]. Composite Structures,2018,201:1076-1087. doi: 10.1016/j.compstruct.2018.06.051 [12] SU F, ZHENG L, SUN F J, et al. Novel drill bit based on the step control scheme for reducing the CFRP delamination[J]. Journal of Materials Processing Technology,2018,262:157-167. doi: 10.1016/j.jmatprotec.2018.06.037 [13] WANG X C, SHEN X T, ZENG C, et al. Combined influences of tool shape and as-deposited diamond film on cutting performance of drills for CFRP machining[J]. Surface and Coatings Technology,2018,347:390-397. doi: 10.1016/j.surfcoat.2018.05.024 [14] DOLUK E, RUDAWSKA A, JÓZEF K, et al. Milling of an Al/CFRP sandwich construction with non-coated and TiAlN-coated tools[J]. Materials,2020,13(17):3763. doi: 10.3390/ma13173763 [15] SHUNMUGESH K, PANNEERSELVAM K P. Investigation and optimization of machining parameters in drilling of carbon fiber reinforced polymer (CFRP) composites[J]. Pigment and Resin Technology,2017,46(1):21-30. doi: 10.1108/PRT-03-2016-0029 [16] SU Y L. Effect of the cutting speed on the cutting mecha-nism in machining CFRP[J]. Composite Structures,2019,220:662-676. doi: 10.1016/j.compstruct.2019.04.052 [17] SORRENTINO L, ESPOSITO L, BELLINI C. A new method-ology to evaluate the influence of curing overheating on the mechanical properties of thick FRP laminates[J]. Composites Part B: Engineering,2017,109:187-196. doi: 10.1016/j.compositesb.2016.10.064 [18] NING F, CONG W, PEI Z, et al. Rotary ultrasonic machining of CFRP: A comparison with grinding[J]. Ultrasonics,2016,66:125-132. doi: 10.1016/j.ultras.2015.11.002 [19] DONG G J, ZHANG L M. Investigation on grinding force and machining quality during rotary ultrasonic grinding deep-small hole of fluorophlogopite ceramics[J]. International Journal of Advanced Manufacturing Technology, 2019, 104(5/8): 2815-2825. [20] GENG D X, LU Z H, YAO G, et al. Cutting temperature and resulting influence on machining performance in rotary ultrasonic elliptical machining of thick CFRP[J]. International Journal of Machine Tools and Manufacture,2017,123:160-170. doi: 10.1016/j.ijmachtools.2017.08.008 [21] FEITO N, DÍAZ-ÁLVAREZ J, LÓPEZ-PUENTE J, et al. Experimental and numerical analysis of step drill bit performance when drilling woven CFRPs[J]. Composite Structures,2018,184:1147-1155. doi: 10.1016/j.compstruct.2017.10.061 [22] LIU L P, QI C L, WU F, et al. The effect of support on multi-hole drilling for glass fiber-reinforced plastic composite materials[J]. International Journal of Advanced Manufacturing Technology,2017,93:953-965. doi: 10.1007/s00170-017-0534-4 [23] KOKLU U, MORKAVUK S. Cryogenic drilling of carbon fiber reinforced composite (CFRP)[J]. Surface Review and Letters,2019,26(1):1950060. [24] 刘书暖, 夏文强, 王宁, 等. CFRP/钛合金叠层构件低温钻削的轴向力与成孔质量研究[J]. 航空制造技术, 2019, 62(13):82-86.LIU Shunuan, XIA Wenqiang, WANG Ning, et al. Research on thrust force and hole luality of drilling CFRP/Ti stacks in low temperature[J]. Aeronautical Manufacturing Technology,2019,62(13):82-86(in Chinese). [25] THIRUMALAI K S, KO T J, LI C, et al. Rotary ultrasonic machining of woven CFRP composite in a cryogenic envi-ronment[J]. Journal of Alloys and Compounds,2017,698:984-993. doi: 10.1016/j.jallcom.2016.12.275 [26] KARIMI N Z, HEIDARY H, KIANFAR P, et al. The effect of support plate on drilling-induced delamination[J]. Acta Polytechnica CTU Proceedings,2016,3:19-24. doi: 10.14311/APP.2016.3.0019 [27] 郑建新, 刘传绍, 赵波. 振动钻削中轴向平均切削力的理论研究[J]. 工具技术, 2009, (6):48-50.ZHENG Jianxin, LIU Chuanshao, ZHAO Bo. Theoretical study on average axial cutting force in vibration drilling[J]. Tool Technology,2009, (6):48-50(in Chinese). [28] DAVIM J, RUBIO J, ABRAO A. A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates[J]. Composites Science and Technology,2007,67:1939-1945. doi: 10.1016/j.compscitech.2006.10.009 [29] FUJUN X, FAN W, ZHANG Y, et al. Modification of tensile, wear and interfacial properties of kevlar fibers under cryogenic treatment[J]. Composites Part B: Engineering,2017,116:398-405. doi: 10.1016/j.compositesb.2016.10.082 [30] ISHIDA T, NOMA K, KAKINUMA Y, et al. Helical milling of carbon fiber reinforced plastics using ultrasonic vibration and liquid nitrogen[J]. Procedia Cirp,2014,24:13-18. doi: 10.1016/j.procir.2014.07.139 -

下载:

下载: