Design and fabrication of ceramic/fiber interlayer hybrid composites and test of projectile impact resistance

-

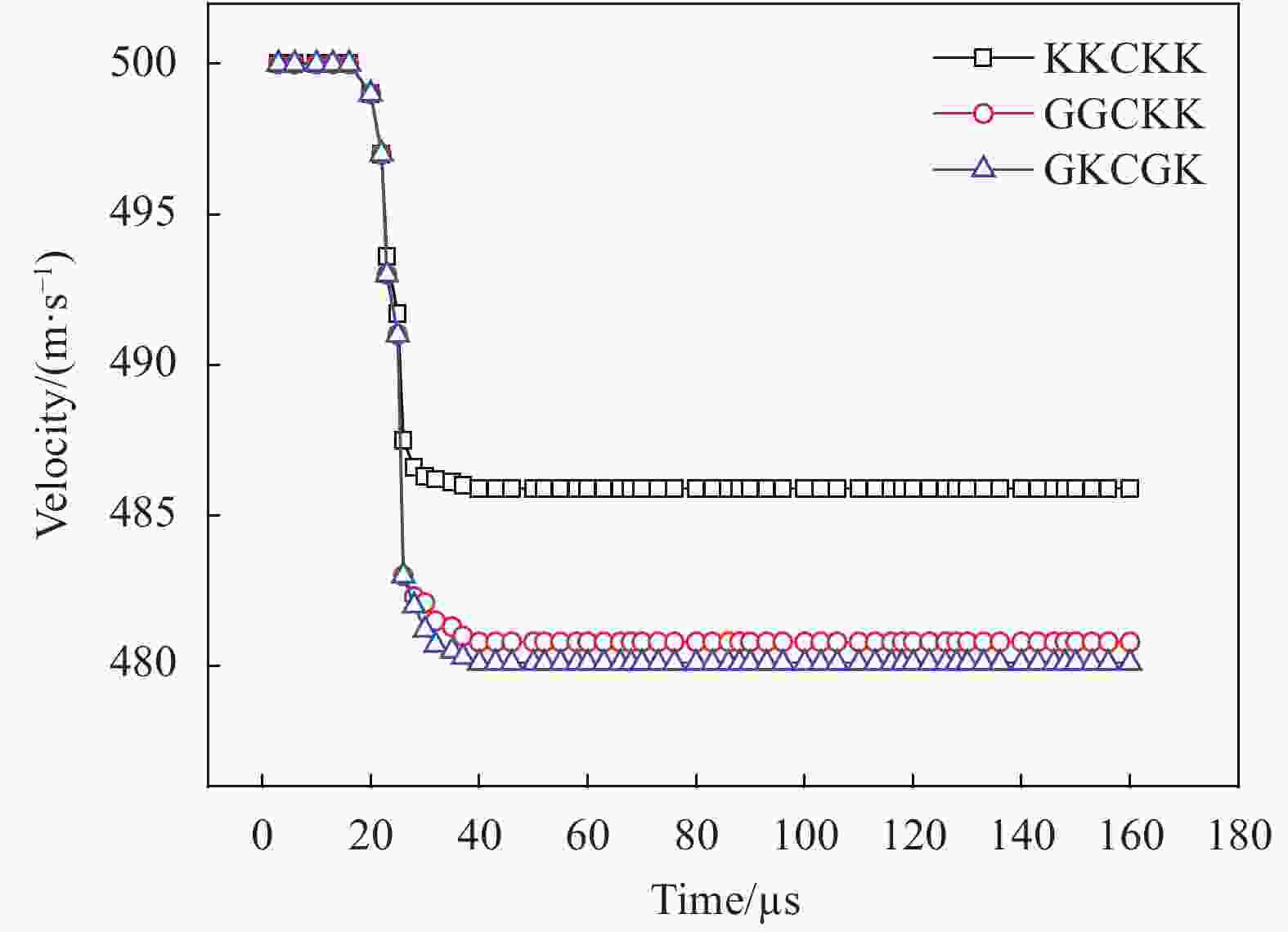

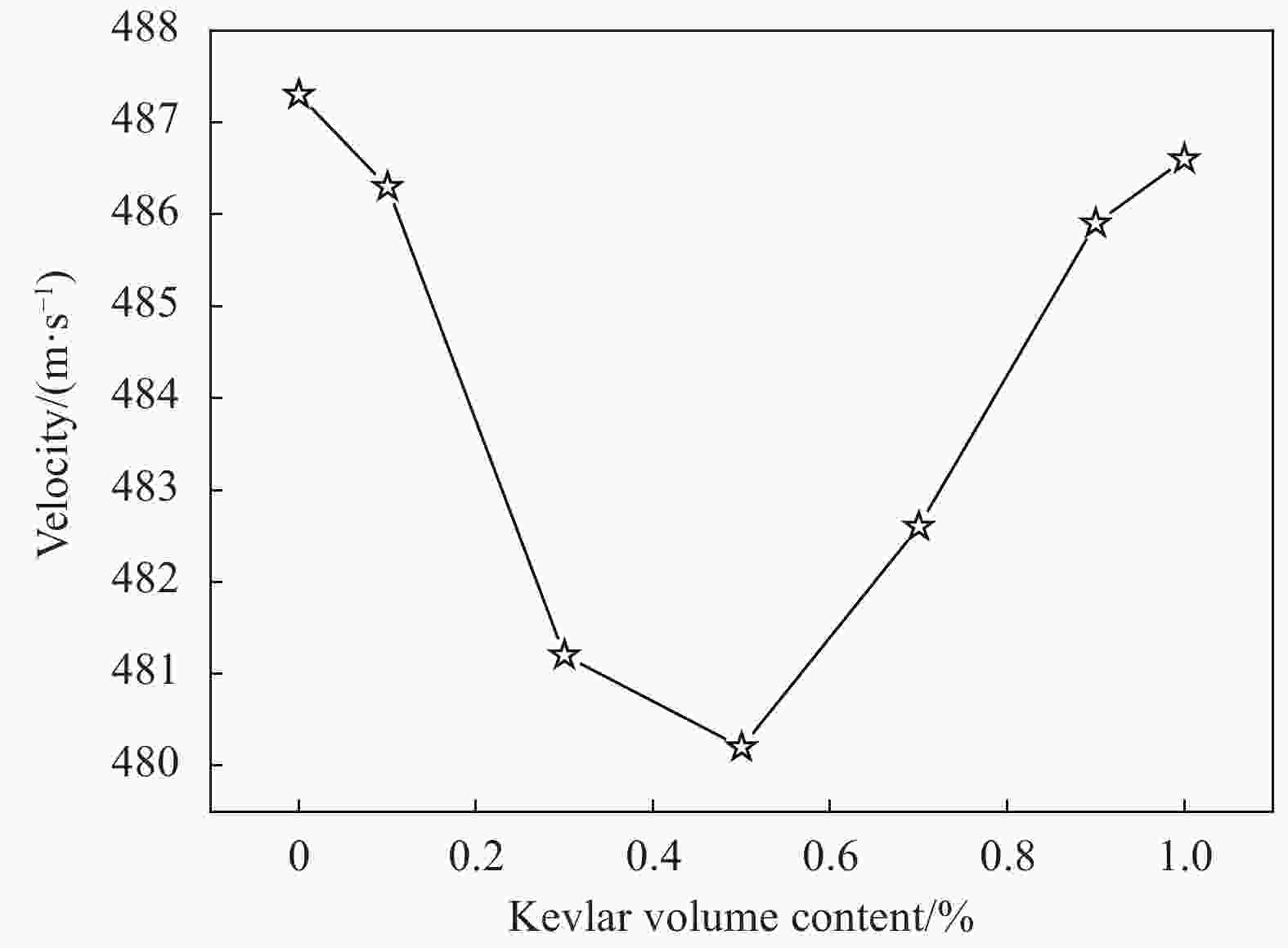

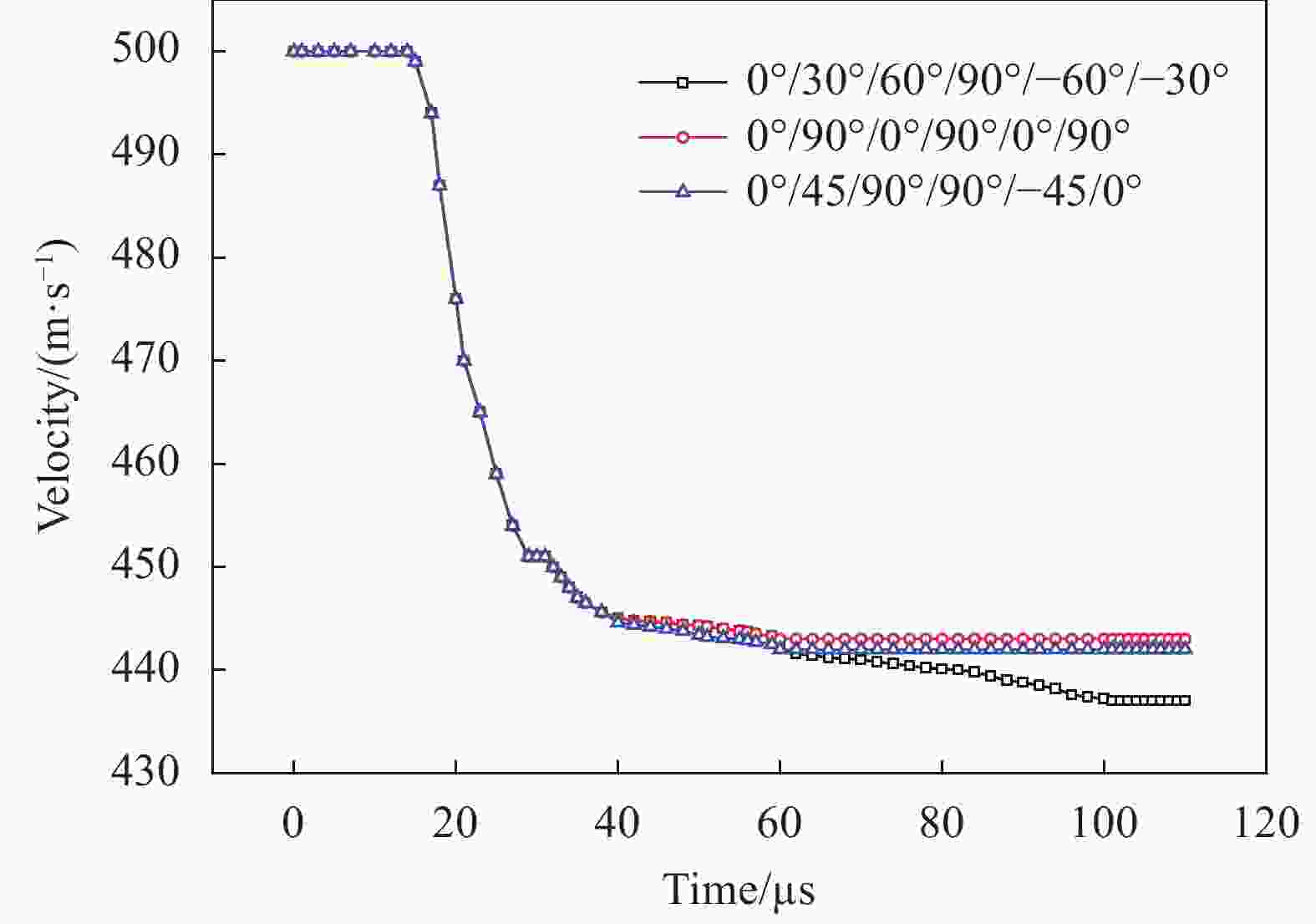

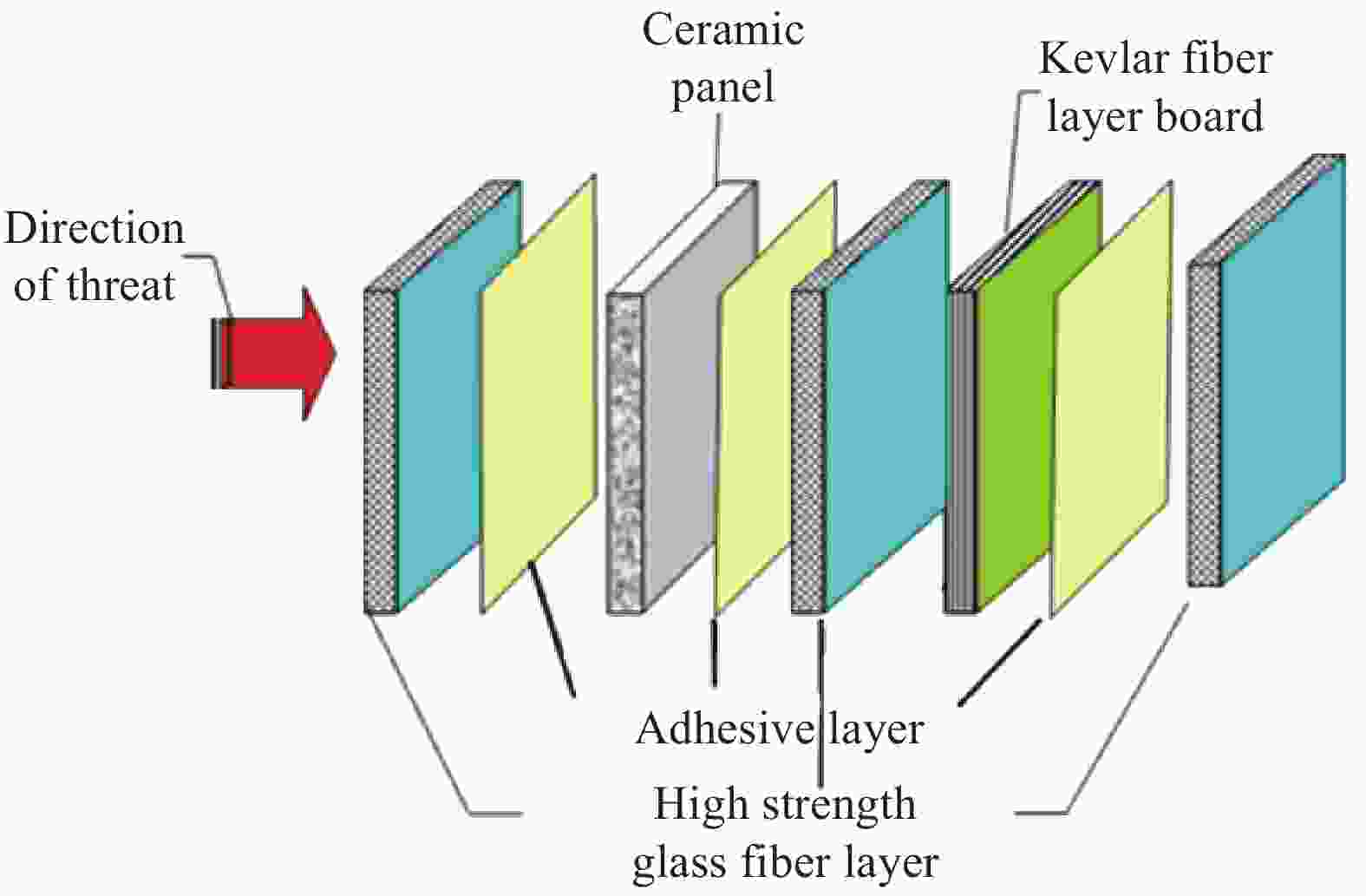

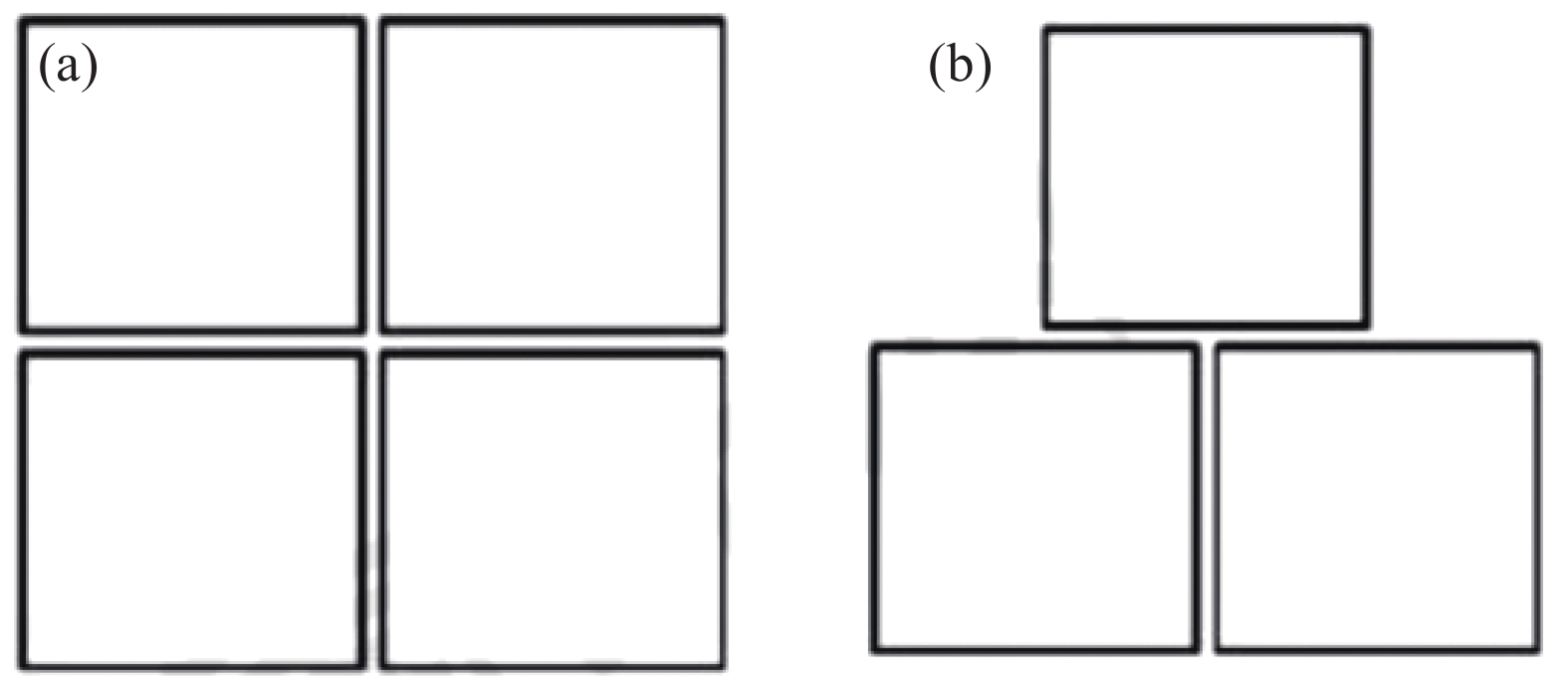

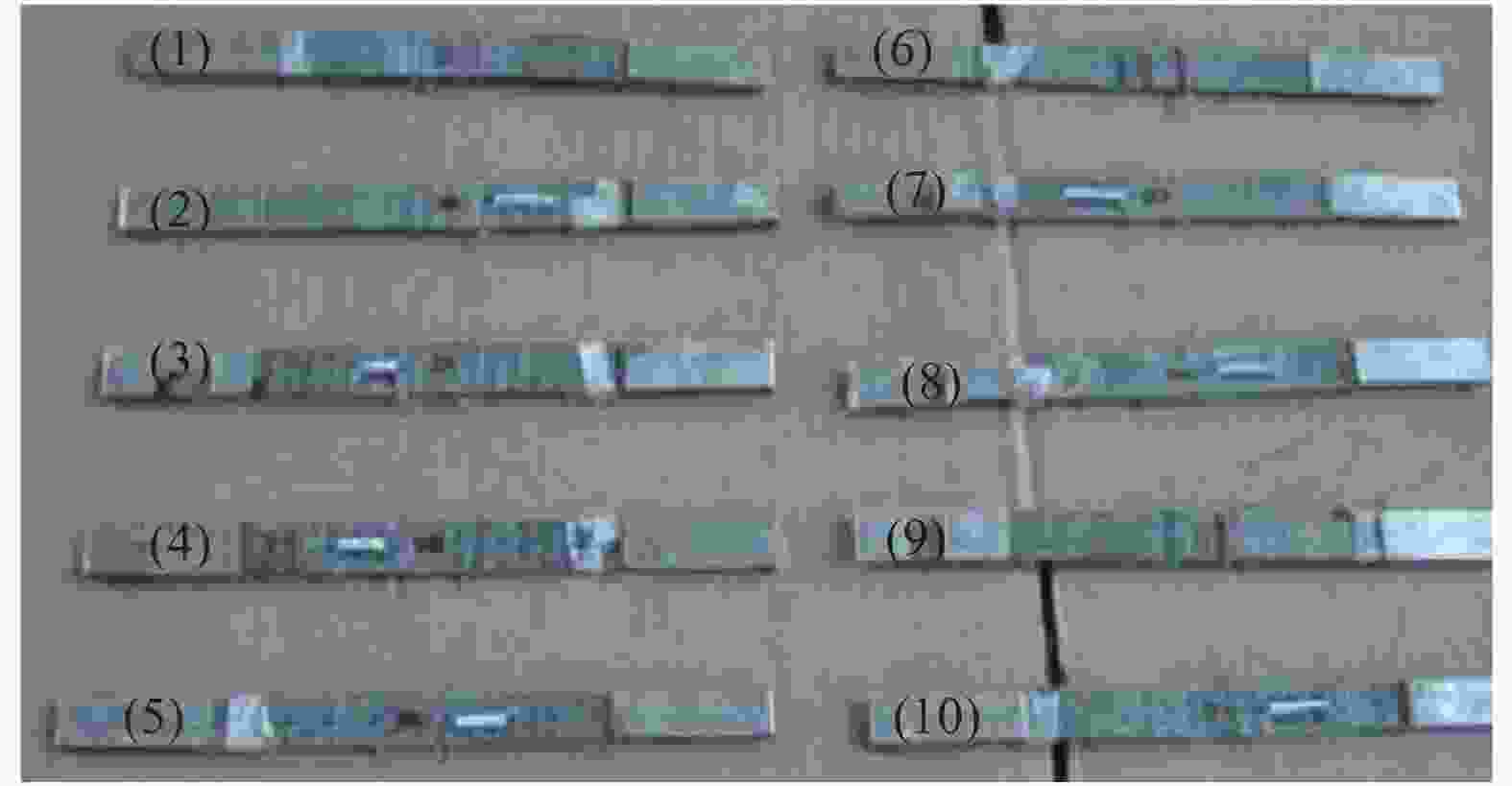

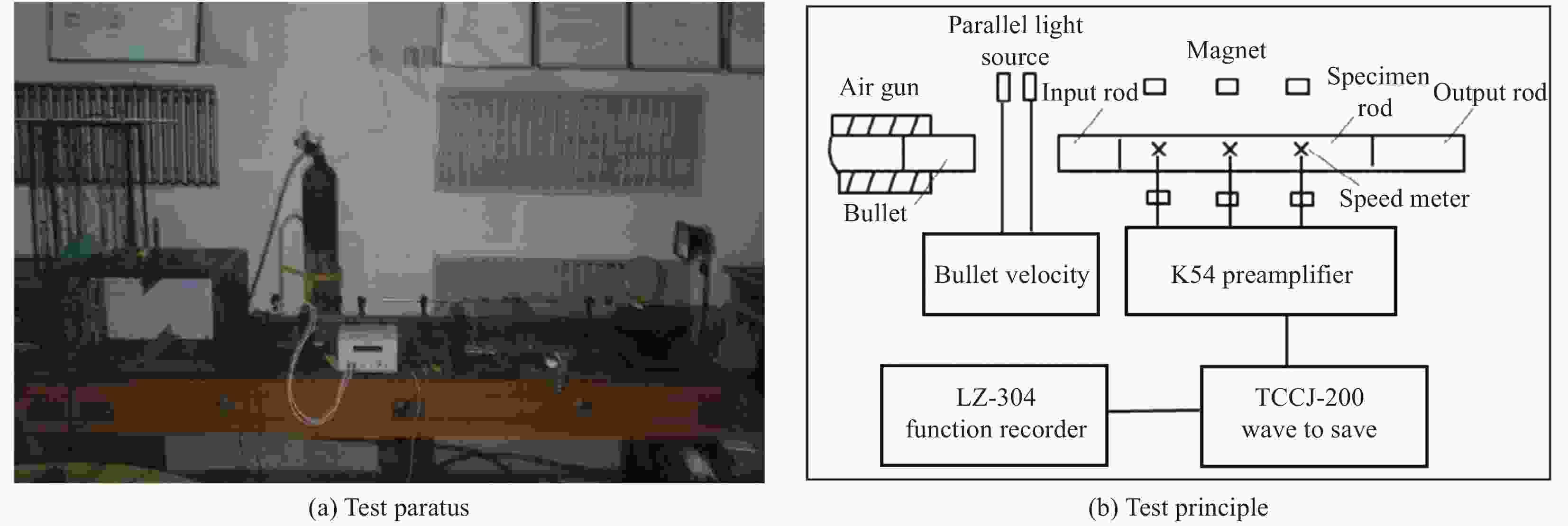

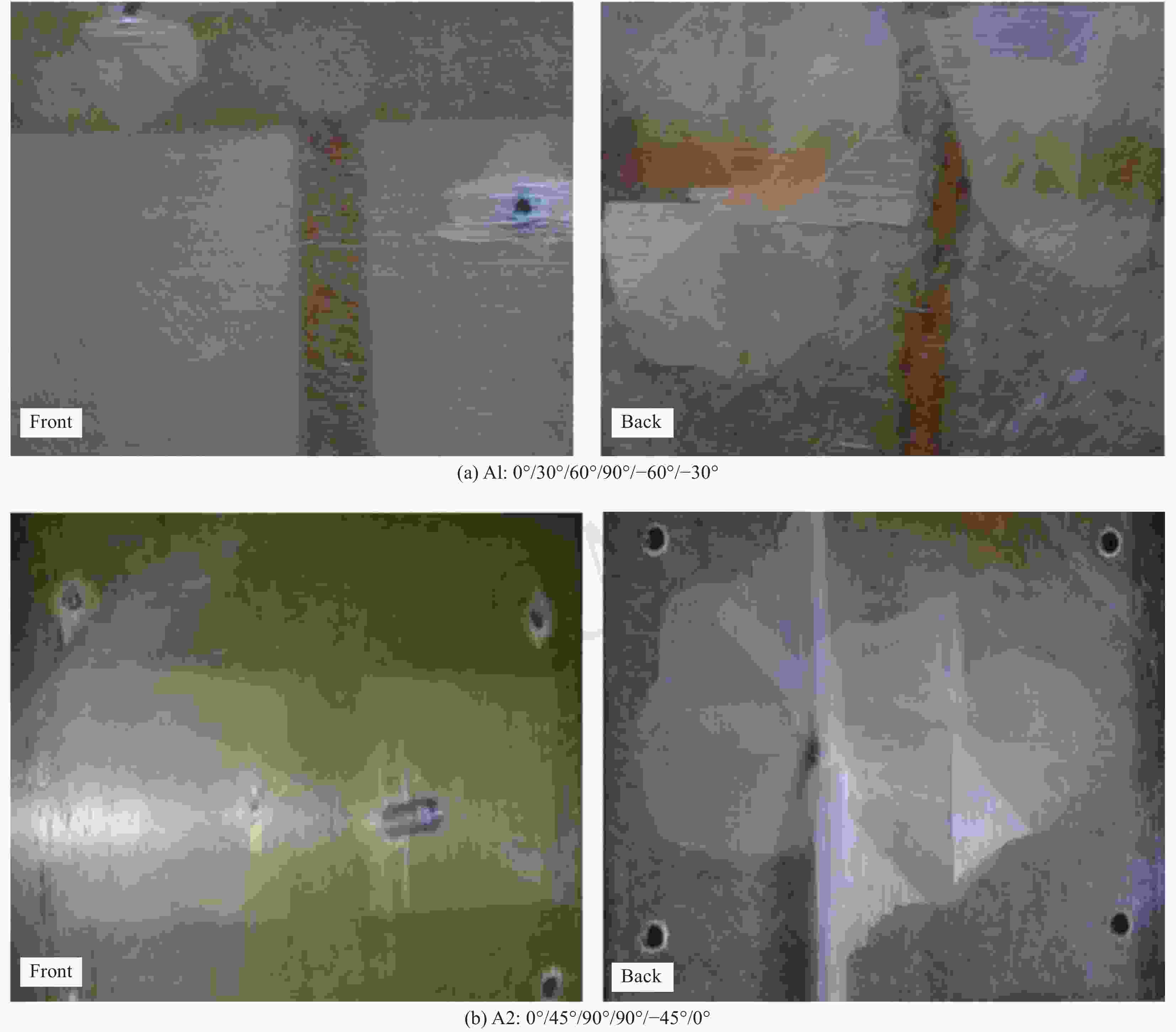

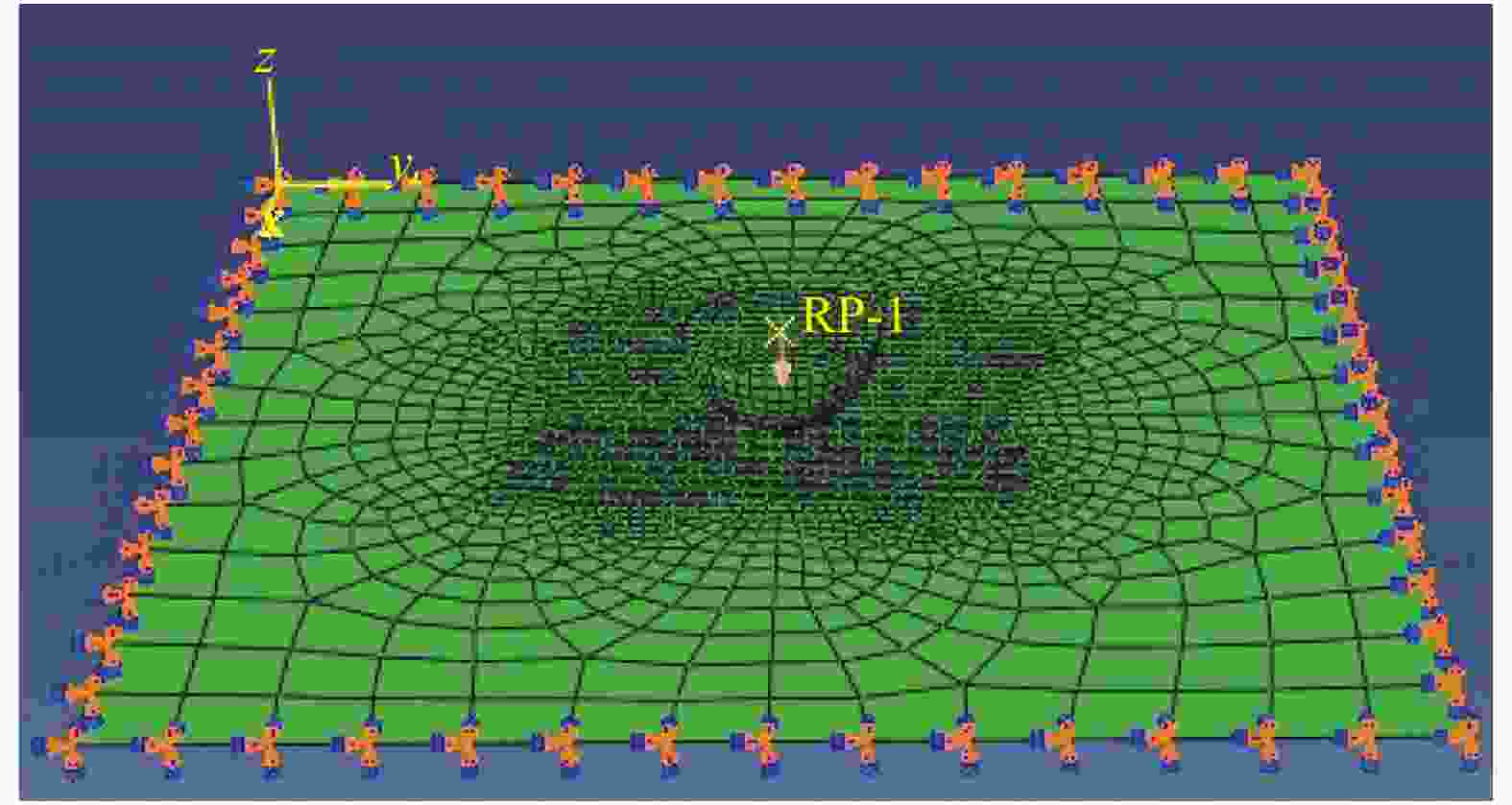

摘要: 掩体作为战场中指挥、防御、观察、射击的综合性军事工事,其观察口为薄弱点,防护能力的大小关系着其内部人员是否安全。本文以防护轻武器为设计目标,设计、制作一种纤维/陶瓷层间混杂复合材料,并对其防弹能力进行测试。首先,基于显式有限元软件ABAQUS/Explicit,建立弹体冲击纤维/陶瓷层间混杂复合材料防护甲板的数值模型,研究混杂纤维与同种纤维、混杂纤维的不同比例及纤维的铺设角度对复合材料防护甲板抗冲击性能的影响。结果表明:两种纤维混杂且混杂比例为0.3~0.7、纤维铺设角度为:0°/30°/60°/90°/−60°/−30°/0°时防护效果最好。其次,根据模拟结果,利用缠绕成型和手糊工艺相结合的方式将高强玻璃纤维S-2/TDE-85环氧树脂复合材料层合板、SiC陶瓷及凯芙拉49纤维/TDE-85环氧树脂复合材料层合板依次堆叠,制作纤维/陶瓷层间混杂复合材料防护甲板试件。最后,利用改进的霍普金森压杆装置进行防护甲板的弹体冲击试验。结果表明:设计的防护甲板能够抵挡住平均速度为500 m/s子弹的贯穿,与理论计算的结果相符合。Abstract: As a comprehensive military fortifications for command, defense, observation, shooting in the battlefield, the porthole of the shelter often becomes the weak point and the protection performance determines the internal personnel security. This paper focused on designing and fabricating the fiber/ceramic interlayer hybrid composite material for protective small arms, and the bulletproof ability of the composites was tested. Firstly, a numerical model of the protective deck produced with fiber/ceramic interlayer hybrid composite was established based on ABAQUS/Explicit. The effects of the different ratio of the hybrid fiber and the homogenous fiber, and the laying angle of fiber on the impact resistance of the composite protective deck were studied. The results indicate that the composites show the best protection when the Kevlar-glass fiber mixed ratio is 0.3-0.7 and the fiber laying angle is 0°/30°/60°/90°/−60°/−30°/0°. Secondly, according to the simulation results, the high strength glass fiber S-2/TDE-85 epoxy composite laminates, SiC ceramics and Kevlar 49 fiber/TDE-85 epoxy composite laminates were stacked successively by combination of winding and hand lay-up techniques to fabricate the fiber/ceramic interlayer hybrid composite material protective deck specimens. Finally, the improved Hopkinson pressure bar device was applied to carry out the projectile impact tests on the protective deck. The results demonstrate that the designed protective deck can withstand the penetration of bullets with an average velocity of 500 m/s, which agrees with the theoretical calculation results.

-

Key words:

- interlaminar hybrid composites /

- Kevlar fiber /

- glass fiber /

- impact /

- numerical simulation

-

表 1 黏聚力参数

Table 1. Cohesive force parameter

Mode Ⅰ Mode Ⅱ Mode Ⅲ Normalised elastic modulus/(GPa·mm−1) 1 373.3 493.3 493.3 Inter-laminar strength/MPa 62.3 92.3 92.3 Inter-laminar fracture toughness/(kJ·m−2) 0.28 0.79 0.79 表 2 SiC陶瓷的JH-2力学参数[18]

Table 2. Jh-2 mechanical parameters of SiC ceramics

ρ/(kg·m−3) G A B C M N β ${\dot \varepsilon _{\rm{0}}}$/s−1 3215 193 0.96 0.35 0.009 1 0.65 1.0 1.0 $\sigma _{{\rm{max}}}^{\rm{f}}$ ${\sigma _{{\rm{HEL}}}}$/GPa PHEL/GPa D1 D2 K1 K2 K3 0.132 11.7 5.13 0.48 0.48 220 361 0 Notes: ρ—Density; G—Shear modulus; β—Ratio of elastic energy loss; ${\dot \varepsilon _{\rm{0}}}$—Reference strain rate; K1—Bulk modulus; K2 and K3—Equation of state constant; A, B, C, D, M, N—Material constant. 表 3 不同纤维/TDE-85环氧树脂层合板弹性参数

Table 3. Elastic parameters of different fiber/TDE-85 epoxy laminates

Material Young’s modulus E/GPa Shear modulus G/GPa Poisson’s ratio ν Density/

(kg·m−3)E1 E2 E3 G12 G13 G23 ν12 ν13 ν23 Kevlar 49 fiber/TDE-85

epoxy resin80 5 6 2.65 3.02 1.65 0.34 0.34 0.34 2.0 High strength glass fiber

S-2/TDE-85 epoxy resin28.7 13.7 4.0 12.8 8.30 5.6 0.23 0.23 0.23 1.1 Note: E1, E2, E3、ν12, ν13, ν23, G12, G13, G23—Young’s modulus,Poisson’s ratio and shear modulus of the composite in transverse, axial and normal directions, respectively. 表 4 不同纤维/TDE-85环氧树脂层合板强度参数

Table 4. Strength parameters of different fiber/TDE-85 epoxy laminates

Material XT/GPa XC/GPa YT/GPa YC/GPa ST/GPa SC/GPa Kevlar 49 fiber/TDE-85 epoxy resin 2.42 0.36 0.034 0.50 0.078 0.041 High strength glass fiber S-2/TDE-85 epoxy resin 1.20 1.15 0.065 0.13 0.059 0.031 Notes: XT—Axial tensile strength; XC—Axial compression strength; YT—Transverse tensile strength; YC—Transverse compression strength; ST—Transverse shear strength; SC—Axial shear strength. 表 5 三种陶瓷/纤维层间混杂复合材料防护甲板吸收的能量和比吸能

Table 5. Energy absorption and specific energy absorption of three ceramic/fiber interlayer hybrid composite protective decks

GGCKK KKCKK GKCGK Final velocity/(m·s−1) 480.8 485.9 480.1 Absorbed energy W/J 462.8 335.6 468.2 Specific energy absorption EA/(J·kg−1·m−2) 79.03 79.23 80.07 Notes: GGCKK—Composed of two six layers of high strength glass fiber/epoxy composite laminates, ceramic laminates, two six layers of Kevlar fiber/epoxy composite laminates; KKCKK—Composed of two six-layer Kevlar/epoxy composite laminates, ceramic layers, and two six-layer Kevlar/epoxy composite laminates stacked in sequence; GKCGK—Composed of six layers of high strength glass fiber/epoxy resin composite laminates, six layers of Kevlar fiber/epoxy resin composite laminates, ceramic layers, six layers of high strength glass fiber/epoxy resin composite laminates, and six layers of Kevlar fiber/epoxy composite laminates. 表 6 不同凯芙拉纤维/环氧树脂复合材料比例时陶瓷/纤维层间混杂复合材料防护甲板的吸能比较

Table 6. Comparison of energy absorption of ceramic/fiber interlayer hybrid composite protective decks with different ratios of Kevlar fiber/epoxy composite

Mixed proportion 0 0.1 0.3 0.5 0.7 0.9 1 Absorbed energy W/J 334.6 366.2 433.2 460.4 434.8 373.5 335.2 Specific energy absorption EA/(J·kg-1·m-2) 42.9 45.2 76.1 81.3 88.5 83.3 79.3 表 7 弹体冲击陶瓷/纤维层间混杂复合材料防护甲板试验结果

Table 7. Test results of projectile impacting ceramic/fiber interlaminar hybrid composite protective deck

Number Mass/g Initial

velocity/

(m·s−1)Residual

velocity/

(m·s−1)Unit surface

density absorbs

energy/(J·(kg·m2)−1)Damage A1(1) 7.8 465 0 108.3 Hold, projectile body is ejected, slight bulge on deck back A1(2) 19.8 361 0 119.6 Hold, projectile body is ejected, large bulge on deck back A2(1) 7.8 478 0 113.5 Defend, projectile body is ejected, large bulge on deck back, larger fiber fracture and is pulled out A2(2) 19.8 387 0 126.2 The projectile is stuck inside the deck, the deck is not penetrated, the fiber is pulled out -

[1] 李顺林. 复合材料大全[M]. 北京: 化学工业出版社, 2000.LI Shunlin. Composite materials[M]. Beijing: Chemical Industry Press, 2000(in Chinese). [2] 刘伟伟, 张维, 崔淑玲. 高性能纤维的结构及其在防弹领域的应用[J]. 广西纺织科技, 2009, 38(3):25-27.LIU W W, ZHANG W, CUI S L. The structure of high performance fiber and its application in bulletproof field[J]. Guangxi Textile Technology,2009,38(3):25-27(in Chinese). [3] 张振英, 戴芳. 复合材料在坦克装甲车辆上的应用[J]. 塑料, 2000, 29(3):37-42.ZHANG Z Y, DAI F. Application of composite materials in tank armored vehicles[J]. Plastics,2000,29(3):37-42(in Chinese). [4] FUKATSU K. Thermal degradation behaviour of aromatic polyamide fiber blended with cotton fiber[J]. Polymer Degradation and Stability,2002,75(3):479-484. doi: 10.1016/S0141-3910(01)00251-8 [5] 岳升彩. 新型纺织材料在军事上的应用—软质防弹衣[J]. 山东纺织经济, 2007(6):78-80. doi: 10.3969/j.issn.1673-0968.2007.06.030YUE S C. The application of new textile material in military-soft bulletproof vest[J]. Shandong Textile Economy,2007(6):78-80(in Chinese). doi: 10.3969/j.issn.1673-0968.2007.06.030 [6] 石小富, 陈源. 轻质复合防弹材料在车辆上的应用[J]. 新技术新工艺, 2017(2):4-6.SHI X F, CHEN Y. Application of lightweight composite bulletproof materials in vehicles[J]. New Technology and New Process,2017(2):4-6(in Chinese). [7] 缪备军. 轻型车辆车身防弹防爆设计研究[J]. 指挥信息系统与技术, 2010(5):66-68. doi: 10.3969/j.issn.1674-909X.2010.05.016MIAO B J. Study on bulletproof and explosion-proof design of light vehicle body[J]. Command Information System and Technology,2010(5):66-68(in Chinese). doi: 10.3969/j.issn.1674-909X.2010.05.016 [8] 毛占稳, 李炜, 刘宇强. 复合材料在电动车辆电池包中的应用及分析[J]. 电源技术, 2016, 40(5):977-978. doi: 10.3969/j.issn.1002-087X.2016.05.011MAO Z W, LI W, LIU Y Q. Application and analysis of composite materials in battery pack of electric vehicle[J]. Power Supply Technology,2016,40(5):977-978(in Chinese). doi: 10.3969/j.issn.1002-087X.2016.05.011 [9] KAMMERER C. Plane behaviour at high strain rates of a quasi-unidit E-glass/polyester composite: Application to balistic impacts[J]. European Journal of Mechanics-A/Solids,1998,17(3):461-477. doi: 10.1016/S0997-7538(98)80055-7 [10] 李伟, 朱锡, 梅志远, 等. 能量平衡法在防弹性能估算中的应用研究[J]. 振动与冲击, 2009(11):191-194.LI W, ZHU X, MEI Z Y, et al. Application research of energy balance method in bulletproof performance estimation[J]. Journal of Vibration and Shock,2009(11):191-194(in Chinese). [11] LEN L M. Infiltrate and perforation of thick FRP laminates[J]. Composites and Technology,2001:1163-1172. [12] CZARNECKI G J. Estimation of the V50 using semi-empirical proceedures composite science and technology[J]. Composites Part B: Engineering,1998,29(4):321-329. [13] NANDLALL D , WILLIAMS K , VAZIRI R. Numerical simulation of the ballistic response of GRP plates[J]. Composites Science and Technology,1998,58(9):1463-1469. [14] BILLON H H, ROBINSON D J. Models for the ballistic lmpact of fabric armour[J]. International Journal of Impact Engineering,2001,25(4):411-414. doi: 10.1016/S0734-743X(00)00049-X [15] 王云聪, 何煌, 曾首义. Kevlar纤维层合板抗弹性能的数值模拟[J]. 四川兵工学报, 2011, 32(3):17-20.WANG Y C, HE H, ZENG S Y. Numerical simulation of bullet-proof performance of Kevlar fiber laminates[J]. Journal of Sichuan Weapon and Engineering,2011,32(3):17-20(in Chinese). [16] SHI Y, SWAIT T, SOUTIS C. Modelling damage evolution in composite laminates subjected to low velocity impact[J]. Composite Structures,2012,94(9):2902-2913. doi: 10.1016/j.compstruct.2012.03.039 [17] JOHNSON G R, HOLMQUIST T J. An improved computational constitutive model for brittle materials[C]//American Institute of Physics, 1994: 981-984. [18] SHARMA A, MISHRAR, JAIN S, et al. Deformation behavior of single and multi-layered materials under impact loading[J]. Thin-Walled Structures,2018,126:193-204. doi: 10.1016/j.tws.2017.08.021 [19] 赵渠森, 郭恩明. 先进复合材料手册[M]. 北京, 机械工业出版社, 2003.ZHAO Q S, GUO E M. Advanced composites handbook[M]. Beijing, China Machine Press, 2003(in Chinese). [20] ASTM. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039—74[S]. West Conshohocken: ASTM, 1974. [21] IMPACT B, ARMOR C, MODEL A. A new analytical model to simulate impact onto ceramic/composite armors[J]. International Journal of Impact Engineering,1998,21(6):461-471. doi: 10.1016/S0734-743X(98)00006-2 -

下载:

下载: