Preparation of carbon nanotubes/polyaniline buckypaper composite electrode by directional pressure filtration and its electrochemical properties

-

摘要: 采用定向加压过滤技术获得直径约为120 mm、厚度约为10 μm的碳纳米管/聚苯胺(CNT/PANI)自支撑纸基柔性电极。在电极中CNT均匀弥散分布,PANI均匀地嵌入CNT网络中。PANI为纳米至亚微米级球形颗粒,其负载量最高为2.7 mg·cm−2。PANI负载量为2.2 mg·cm−2的电极的孔隙率为70.33%,密度为0.4 g·cm−3,孔面积为67.31 m2·g−1。该电极可紧绕直径为4 mm的玻璃棒数圈而无损伤。该电极在4 mA·cm−2的电流密度条件下,单电极比电容为1.88 F·cm−2;在充放电1200次循环过程中,比电容先下降后增大,至900次循环时比电容达到2.41 F·cm−2,1200次循环时容量保持率为125.78%;经180°弯折500次后,容量保持率为78.43%。该电极所组装的对称三明治结构超级电容器在5 mA·cm−2的电流密度条件下比电容为0.48 F·cm−2,经1000次充放电循环容量保持率为94.3%,能量密度和功率密度分别为213.75 mW·h·cm−3和2163.22 mW·cm−3。Abstract: Carbon nanotubes/polyaniline (CNT/PANI) buckypaper self-supporting flexible electrodes with a diameter of about 120 mm and a thickness of about 10 μm were obtained by directional pressure filtration technology. CNTs distributed uniformly and dispersed in the electrode, and PANI was uniformly embedded in the CNT network. PANI was spherical particles of nanometer to submicron size, with a maximum loading capacity of 2.7 mg·cm−2. The electrode with PANI loading of 2.2 mg·cm−2 has a porosity of 70.33%, a density of 0.4 g·cm−3 and a total pore area of 67.31 m2·g−1. The electrode can be wound several times around the glass rod with diameter of 4 mm without damage. At the current density of 4 mA·cm−2, the specific capacitance of the electrode is 1.88 F·cm−2. In the process of 1200 charging-discharging cycles, the specific capacitance decreases first and then increases, and reaches 2.41 F·cm−2 at the 900th cycle, and the capacity retention rate is 125.78% at the 1 200th cycle. After 500 times of bending at 180° angle, the retention rate of capacity is 78.43%. The symmetrical sandwich structure supercapacitor assembled by this electrode has a capacitance of 0.48 F·cm−2 at a current density of 5 mA·cm−2. Its capacity retention rate after 1000 charge-discharge cycles is 94.3%. Its energy density and power density are 213.75 mW·h·cm−3 and 2163.22 mW·cm−3, respectively.

-

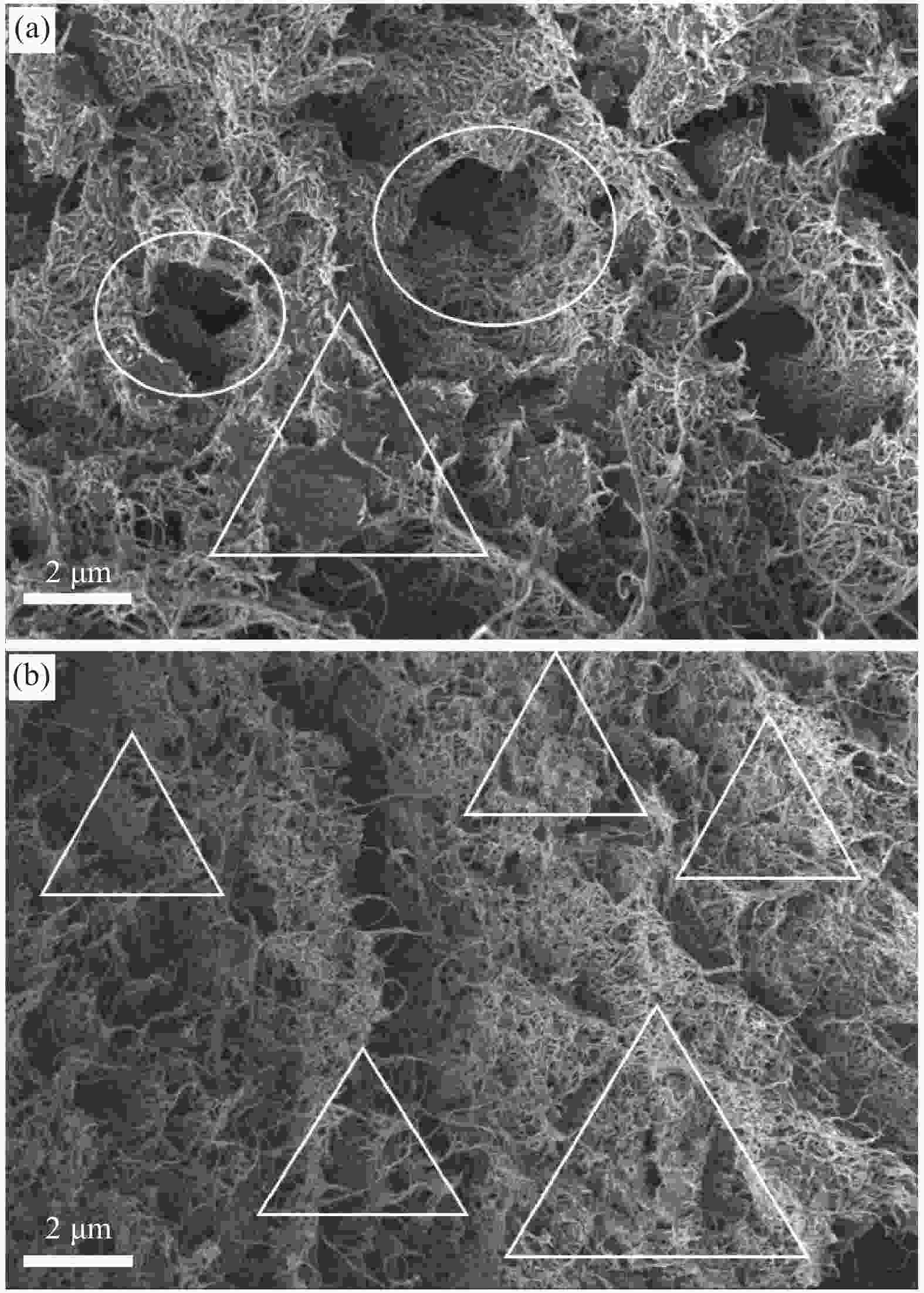

图 1 CNT/PANI纸的宏观和微观形貌:(a)伸展的CNT/PANI纸及其厚度;(b)卷曲的CNT/PANI纸及其直径;((c)、(d))断面微观形貌

Figure 1. Macroscopic and microscopic morphologies of CNT/PANI buckypaper: (a) Stretched CNT/PANI buckypaper and its thickness; (b) Curled CNT/PANI buckypaper and its diameter; ((c), (d)) Cross-section microscopic morphologies

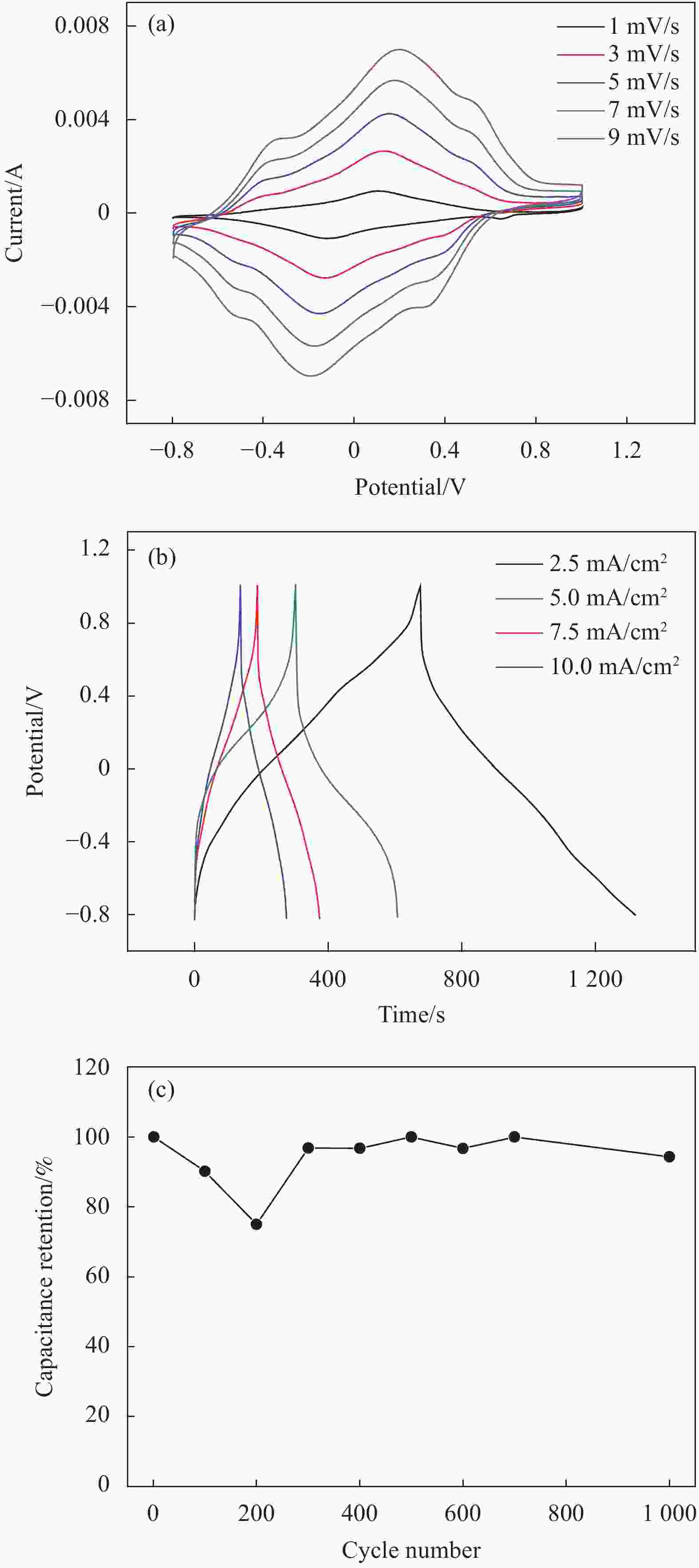

图 5 CNT/PANI38wt%纸的电化学稳定性和阻抗测试:(a) 电化学测试前后阻抗变化;(b)扫速1~9 mV·s−1 CV曲线;(c)不同电流密度GCD曲线;(d)不同电流密度容量变化

Figure 5. Electrochemical stability and Impedance test of CNT/PANI38wt% buckypaper: (a) Impedance change before and after electrochemical test; (b) CV curves at 1-9 mV·s−1 scanning speed; (c) GCD curves at different current density; (d) Capacity change at different current density

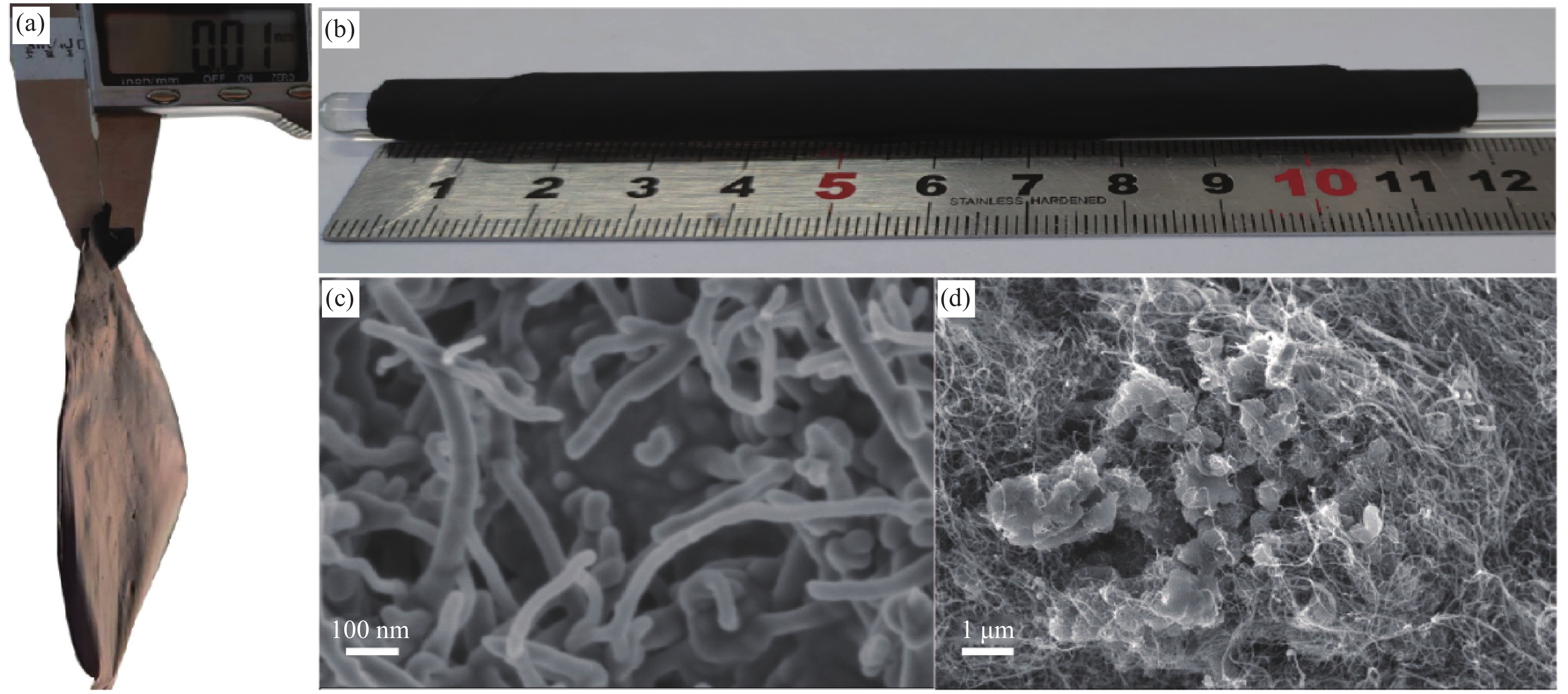

图 12 CNT/PANI纸基超级电容器的电化学测试:(a)扫速1-9 mV·s−1 循环伏安曲线;(b)不同电流密度恒电流充放电曲线;(c) 5 mA·cm−2循环1000次容量保持率

Figure 12. Electrochemical test of CNT/PANI buckypaper-based supercapacitor: (a) Sweep speed 1-9 mV·s−1 Cyclic voltammetry curves; (b) Different current density Constant current charge-discharge curves; (c) 5 mA·cm−2 cycle 1000 times capacity retention

表 1 碳纳米管/聚苯胺(CNT/PANI)纸基复合电极材料的组成

Table 1. Composition of carbon nanotubes/polyaniline (CNT/PANI) buckypaper composite electrode

Sample Mass fraction of CNT/wt% Mass fraction of PANI/wt% Specific areal mass loadings of PANI /(mg·cm−2) CNT/PANI0wt% 100 0 0 CNT/PANI21wt% 79 21 1.2 CNT/PANI29wt% 71 29 1.8 CNT/PANI38wt% 62 38 2.2 CNT/PANI43wt% 57 43 2.7 Note: Specific areal mass loadings of PANI—Mass fraction of PANI × Mass of buckypaper /Area of buckypaper. 表 2 近年来文章中碳/赝电容电极材料电化学性能总结

Table 2. Summary of electrochemical performance of carbon/pseudocapacitance electrode materials in recent years

Compound Specific

capacitanceCycle

stabilityEnergy

densityPower

densityElectrode

thickness/μmLiterature CNT buckypaper 3.0 F·cm−3 90% (10000 cycle) 1.5 mW·h·cm−3 4.2 W/cm3 [19] CNT/graphene/PANI 10.3 mF·cm−2 15 [32] PANI/CNT/PVC 298 mF·cm−2 86.5% (5 000 cycle) [44] PANI hydrogel 237.7 mF·cm−2 90% (1 000 cycle) 27.2 mW·h·cm−2 210 mW·cm−2 40 [30] PANI hydrogel 17.4 F·cm−3 82% (5 000 cycle) 6.16 mW·h·cm−3 [45] CNT/graphene/PANI 261 mF·cm−2 36.3 μW·h·cm−2 0.17 μW·cm−2 [13] CNT/MnO2 135 mF·cm−2 86% (10 000 cycle) 0.018 mWh·cm−2 0.72 mW·cm−2 50 [12] PANI/Co(OH)2 8.14 F·cm−2 201.5 μW·h·cm−2 3000 μW·cm−2 [46] VN/CNT 7.9 F·cm−3 82% (1 000 cycle) 0.54 mW·h·cm−3 0.4 W·cm−3 48 [11] CNT/PANI buckypaper 2.16 F·cm−2 125.78% (1 200 cycle) 213.75 mW·h·cm−3

2.14 mW·h·cm−22163.22 mW·cm−3

21.6 mW·cm−210 This work Notes: PVC—Polyvinyl chloride; VN—Vanadium nitride. -

[1] ZHANG J, CHEN Z, XU X, et al. A simple and efficient approach to fabricate graphene/CNT hybrid transparent conductive films[J]. RSC Advances,2017,7(83):52555-52560. doi: 10.1039/C7RA09809J [2] NAM D H, LIM S J, KIM M J, et al. One-step synthesis of a Si/CNT–polypyrrole composite film by electrochemical deposition[J]. RSC Advances,2014,4(20):10212-10215. doi: 10.1039/c3ra47135g [3] JIAO S, LI T, ZHANG Y, et al. A three-dimensional vertically aligned carbon nanotube/polyaniline composite as a supercapacitor electrode[J]. RSC Advances,2016,6(112):110592-110599. doi: 10.1039/C6RA17674G [4] NILCHIAN A, LI C Z. Mechanical and electrochemical characterization of CNT/PDMS composited soft and stretchable electrodes fabricated by an efficient solution-based fabrication method[J]. Journal of Electroanalytical Chemistry,2016,781:166-173. doi: 10.1016/j.jelechem.2016.08.013 [5] EL-BASATY A B, MOUSTAFA E, FOUDA A N, et al. 3D hierarchical graphene/CNT with interfacial polymerized polyaniline nano-fibers[J]. Spectrochim Acta A Mol Biomol Spectrosc,2020,226:117629. doi: 10.1016/j.saa.2019.117629 [6] WANG H, LIU D, DU P et al. Facile deposition of polyaniline on the multi-walled carbon nanotubes/polyvinyl chloride composite films as flexible and robust electrodes for high performance supercapacitors[J]. Electrochimica Acta,2018,289:104-111. doi: 10.1016/j.electacta.2018.09.031 [7] ASIM S, JAVED M S, HUSSAIN S, et al. RuO2 nanorods decorated CNTs grown carbon cloth as a free standing electrode for supercapacitor and lithium ion batteries[J]. Electrochimica Acta,2019,326:135009-135018. doi: 10.1016/j.electacta.2019.135009 [8] YAO B, ZHANG J, KOU T, et al. Paper-based electrodes for flexible energy storage devices[J]. Advanced Science,2017,4(7):1700107-1700139. doi: 10.1002/advs.201700107 [9] ABDOLLAHI A, ABNAVI A, GHASEMI S, et al. Flexible free-standing vertically aligned carbon nanotube on activated reduced graphene oxide paper as a high performance lithium ion battery anode and supercapacitor[J]. Electrochimica Acta,2019,32:134598-134611. [10] LI X, TANG Y, SONG J, et al. Self-supporting activated carbon/carbon nanotube/reduced graphene oxide flexible electrode for high performance supercapacitor[J]. Carbon,2018,129:236-244. doi: 10.1016/j.carbon.2017.11.099 [11] XIAO X, PENG X, JIN H, et al. Freestanding mesoporous VN/CNT hybrid electrodes for flexible all-solid-state supercapacitors[J]. Advanced Materials,2013,25(36):5091-5097. doi: 10.1002/adma.201301465 [12] PATIL B, AHN S, PARK C, et al. Simple and novel strategy to fabricate ultra-thin, lightweight, stackable solid-state supercapacitors based on MnO2-incorporated CNT-web paper[J]. Energy,2018,142:608-611. doi: 10.1016/j.energy.2017.10.041 [13] OLENA OKHAYA, AlEXANDER T, MARIA J. et al. Energy storage of supercapacitor electrodes on carbon cloth enhanced by graphene oxide aerogel reducing conditions[J]. Journal of Energy Storage,2020,32:101839-101850. doi: 10.1016/j.est.2020.101839 [14] SUN D, MIAO X, HE Y, et al. 3D Interconnected porous graphitic carbon@MoS2 anchored on carbonized cotton cloth as an anode for enhanced lithium storage performance[J]. Electrochimica Acta,2019,320:134616-134625. doi: 10.1016/j.electacta.2019.134616 [15] PATIL B, AHN S, YU S, et al. Electrochemical performance of a coaxial fiber-shaped asymmetric supercapacitor based on nanostructured MnO2/CNT-web paper and Fe2O3/carbon fiber electrodes[J]. Carbon,2018,134:366-375. doi: 10.1016/j.carbon.2018.03.080 [16] PANG Z, SUN X, WU X, et al. Fabrication and application of carbon nanotubes/cellulose composite paper[J]. Vacuum,2015,122:135-142. doi: 10.1016/j.vacuum.2015.09.020 [17] AYDINLI A, YUKSEL R, UNALAN H E. Vertically aligned carbon nanotube-Polyaniline nanocomposite supercapacitor electrodes[J]. International Journal of Hydrogen Energy,2018,43(40):18617-18625. doi: 10.1016/j.ijhydene.2018.05.126 [18] LIANG X, ZHAO L, WANG Q, et al. A dynamic stretchable and self-healable supercapacitor with a CNT/graphene/PANI composite film[J]. Nanoscale,2018,10(47):22329-22334. doi: 10.1039/C8NR07991A [19] XIAO X, LI T, PENG Z, et al. Freestanding functionalized carbon nanotube-based electrode for solid-state asymmetric supercapacitors[J]. Nano Energy,2014,6:1-9. doi: 10.1016/j.nanoen.2014.02.014 [20] SUN P, DENG Z, YANG P, et al. Freestanding CNT-WO3 hybrid electrodes for flexible asymmetric supercapacitors[J]. Journal of Materials Chemistry A,2015,3(22):12076-12080. doi: 10.1039/C5TA02316E [21] JUAN DU, CHENYANG LI. Three-dimensional binder-free polyaniline-aligned CNT on flexible etched Al foil substrate[J]. Journal of Energy Storage,2021,33:102165-10275. doi: 10.1016/j.est.2020.102165 [22] TAO J M, CHEN X F, HONG P, et al. Microstructure and electrical conductivity of laminated Cu/CNT/Cu composites prepared by electrodeposition[J]. Journal of Alloys and Compounds,2017,717:232-239. doi: 10.1016/j.jallcom.2017.05.074 [23] 蔡艳芝, 王源, 成来飞, 等. CNT纸/SiC对称梯度层状复合材料的高温电磁屏蔽性能和介电性能[J]. 复合材料学报, 2020, 37(11):2877-2888.CAI Yanzhi, WANG Yuan, CHENG Laifei, et al. High-temperature electromagnetic shielding and dielectric properties of CNT buckypaper/SiC symmetric graded laminated composite[J]. Acta Materiae Compositae Sinica,2020,37(11):2877-2888(in Chinese). [24] CAI Y, CHEN L, YANG H, et al. Mechanical and electrical properties of carbon nanotube buckypaper reinforced silicon carbide nanocomposites[J]. Ceramics International,2016,42(4):4984-4892. doi: 10.1016/j.ceramint.2015.12.011 [25] 蔡艳芝, 尹洪峰, 周媛, 等. 一种碳纳米管增强SiC基纳米复合材料膜的制备方法: 中国, ZL201410475361.1[P]. 2015-01-21.CAI Yanzhi, YIN Hongfeng, ZHOU Yuan, et al. A preparation method of carbon nanotube reinforced SiC based nanocomposite membrane: China, ZL201410475361.1[P]. 2015-01-21(in Chinese). [26] 毛全元, 黄柳宁, 梁贵超, 等. 以不同晶型二氧化锰为反应模板合成超级电容器用聚苯胺及其性能研究[J]. 功能材料, 2020, 11:11121-11127. doi: 10.3969/j.issn.1001-9731.2020.11.017MAO Quanyuan, HUANG Liuning, LIANG Guichao, et al. Synthesis and properties of polyaniline for supercapacitor using different crystal manganese dioxide as reaction template[J]. Functional Materials,2020,11:11121-11127(in Chinese). doi: 10.3969/j.issn.1001-9731.2020.11.017 [27] YIN Y, LIU C, FAN S. Well-constructed CNT mesh/PANI nanoporous electrode and its thickness effect on the supercapacitor properties[J]. The Journal of Physical Chemistry C,2012,116(50):26185-26189. doi: 10.1021/jp3083387 [28] INAMDAR A I, CHAVAN H S, KIM H, et al. Mesoporous Ni-PANI composite electrode for electrochromic energy storage applications[J]. Solar Energy Materials and Solar Cells,2019,201:110121-110128. doi: 10.1016/j.solmat.2019.110121 [29] LIU Q, BAI Z, FAN J, et al. A hydrogel-mediated scalable strategy toward core-shell polyaniline/poly(acrylic acid)-modified carbon nanotube hybrids as efficient electrodes for supercapacitor applications[J]. Applied Surface Science,2018,436:189-197. doi: 10.1016/j.apsusc.2017.11.209 [30] 李湾湾. 高强度聚苯胺导电水凝胶的设计及其在柔性超级电容器中的应用[D]. 合肥: 中国科学技术大学, 2018.LI Wanwan. Design of high intensity polyaniline conductive hydrogel and its application in flexible supercapacitors[D]. Hefei: University of Science & Technology China, 2018. (in Chinese). [31] LUO Y, LI Y, WANG D, et al. Hierarchical α-Ni(OH)2 grown on CNTs as a promising supercapacitor electrode[J]. Journal of Alloys and Compounds,2018,743:1-10. doi: 10.1016/j.jallcom.2018.01.341 [32] LIU D, DU P, WEI W, et al. Flexible and robust sandwich-structured S-doped reduced graphene oxide/carbon nanotubes/polyaniline (S-rGO/CNTs/PANI) composite membranes: Excellent candidate as free-standing electrodes for high-performance supercapacitors[J]. Electrochimica Acta,2017,233:201-209. doi: 10.1016/j.electacta.2017.03.040 [33] NATH B C, GOGOI B, BORUAH M, et al. High performance polyvinyl alcohol/multi walled carbon nanotube/polyaniline hydrogel (PVA/MWCNT/PAni) based dye sensitized solar cells[J]. Electrochimica Acta,2014,146:106-111. doi: 10.1016/j.electacta.2014.08.134 [34] WANG X, SUMBOJA A, LIN M F, et al. Enhancing electrochemicalreaction sites in nickelecobalt layered double hydroxides on zinc tin oxidenanowires: A hybrid material for an asymmetric supercapacitor device[J]. Nanoscale, 2012(22): 7266-7272. [35] YOO H D, JANG J H, RYU J H, et al. Impedance analysis of porous carbon electrodes to predict rate capability of electric double-layer capacitors[J]. Journal of Power Sources,2014,267:411-420. doi: 10.1016/j.jpowsour.2014.05.058 [36] HU J T, JIANG Y, CUI S H, et al. 3D-printed cathodes of LiMn1-x FexPO4 nanocrystals achieve both ultrahigh rate and high capacity for advanced lithium-ion battery[J]. Advanced Energy Materials,2016,6:1600856-16000864. doi: 10.1002/aenm.201600856 [37] LIU R, LIU C, FAN S. A photocapacitor based on organometal halide perovskite and PANI/CNT composites integrated using a CNT bridge[J]. Journal of Materials Chemistry A,2017,5(44):23078-23084. doi: 10.1039/C7TA06297D [38] LU Z, FOROUGHI J, WANG C, et al. Superelastic hybrid CNT/graphene fibers for wearable energy storage[J]. Advanced Energy Materials,2018,8(8):1702047-1702057. doi: 10.1002/aenm.201702047 [39] NAWWAR M, POON R, CHEN R, et al. High areal capacitance of Fe3O4-decorated carbon nanotubes for supercapacitor electrodes[J]. Carbon Energy,2019,1(1):124-133. doi: 10.1002/cey2.6 [40] ZHOU Q Q, TENG W L, JIN Y H, et al. Highly-conductive PEDOT: PSS hydrogel framework based hybrid fiber with high volumetric capacitance and excellent rate capability[J]. Electrochimica Acta,2020,334:135530. doi: 10.1016/j.electacta.2019.135530 [41] LIU T, FINN L, YU M, et al. Polyaniline and polypyrrole pseudocapacitor electrodes with excellent cycling stability[J]. Nano Letters,2014,14(5):2522-2527. doi: 10.1021/nl500255v [42] ZHOU Y, WANG X, ACAUAN L, et al. Ultrahigh-areal-capacitance flexible supercapacitor electrodes enabled by conformal P3MT on horizontally aligned carbon-nanotube arrays[J]. Advanced Materials,2019,31(30):1901916-1901924. [43] 牟晶晶. 聚苯胺基电极材料的制备及其在超级电容器中的应用研究[D]. 兰州: 西北师范大学, 2014.MOU Jingjing. Preparation of polyaniline based electrode materials and its application in supercapacitors[D]. Lanzhou: Northwest Normal University, 2014(in Chinese). [44] FARAJI M, AYDISHEH H M. Rational synthesis of a highly porous PANI-CNTs-PVC film for high performance flexible supercapacitor[J]. ChemElectroChem,2018,5(19):2882-2892. doi: 10.1002/celc.201800628 [45] HAMID HEYDARI M B G. An all-solid-state asymmetric device based on a polyaniline hydrogel for a high energy flexible supercapacitor[J]. New Journal of Chemistry,2016,41(1):237-244. [46] HE M, XU W, DONG Z, et al. Polyaniline hydrogel anchored in carbon cloth network to support Co(OH)2 as flexible electrode for high-energy density supercapacitor[J]. Inorganic Chemistry Communications, 2019, 106: 158-164. [47] LIANG K, TANG X, HU W. High-performance three-dimensional nanoporous NiO film as a supercapacitor electrode[J]. Journal of Materials Chemistry,2012,22(22):11062-11067. doi: 10.1039/c2jm31526b [48] ZHANG X, ZHANG J, CHEN Y, et al. Freestanding 3D polypyrrole@reduced graphene oxide hydrogels as binder-free electrode materials for flexible asymmetric supercapacitors[J]. Journal of Colloid & Interface Science,2019,536:291-299. doi: 10.1016/j.jcis.2018.10.044 -

下载:

下载: