Preparation and thermophysical properties of graphite flake-carbon fiber co-reinforced copper matrix composites

-

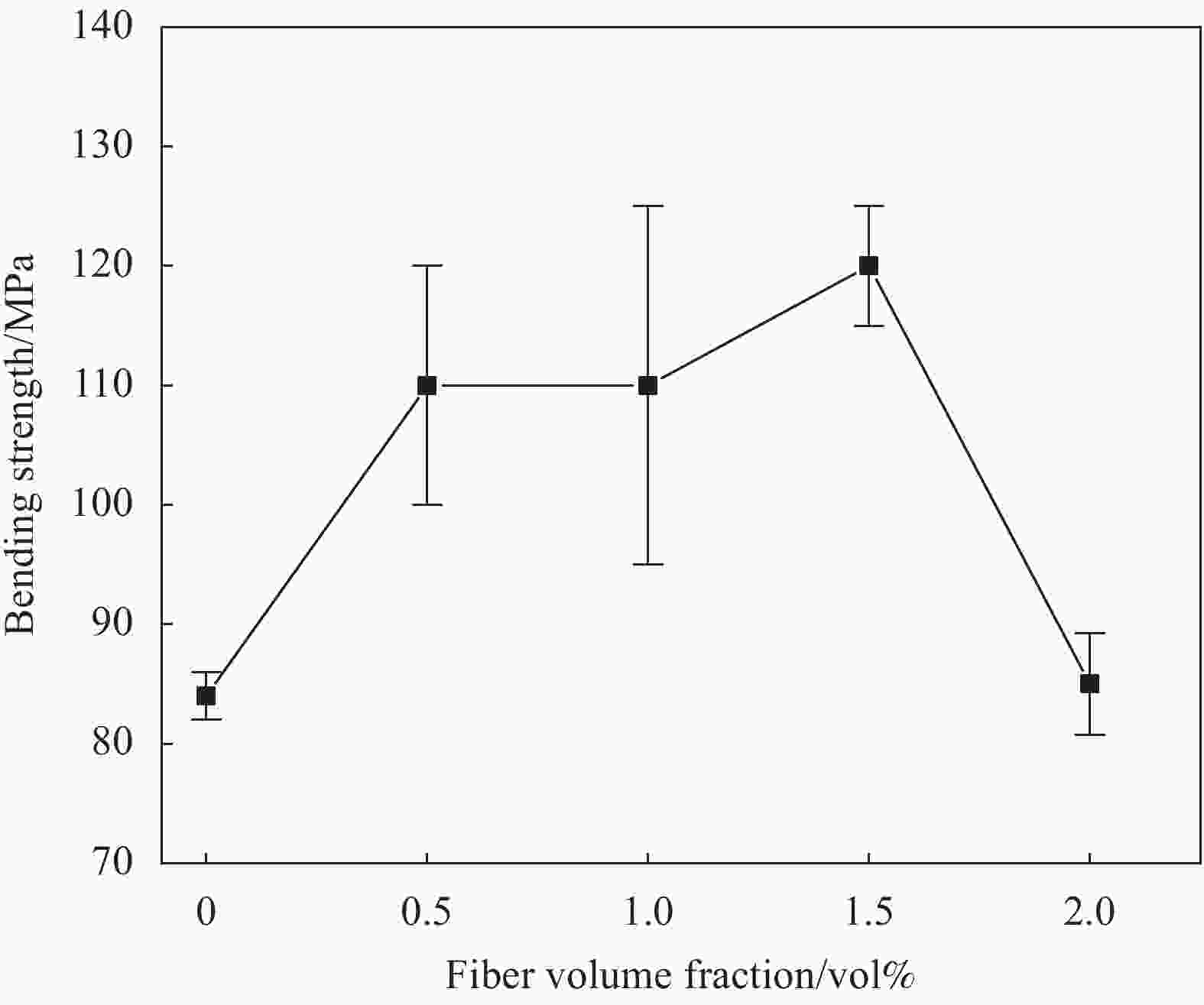

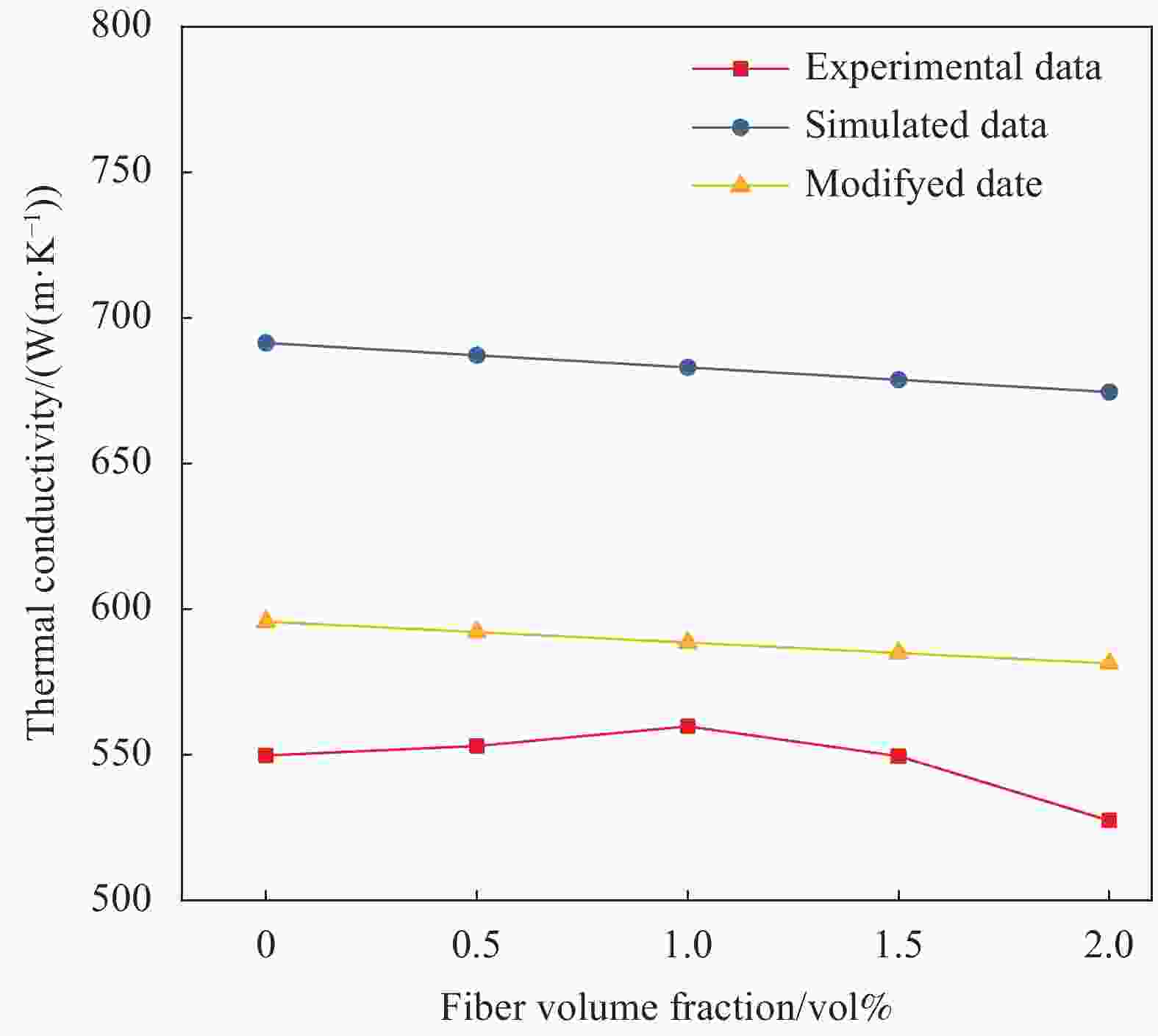

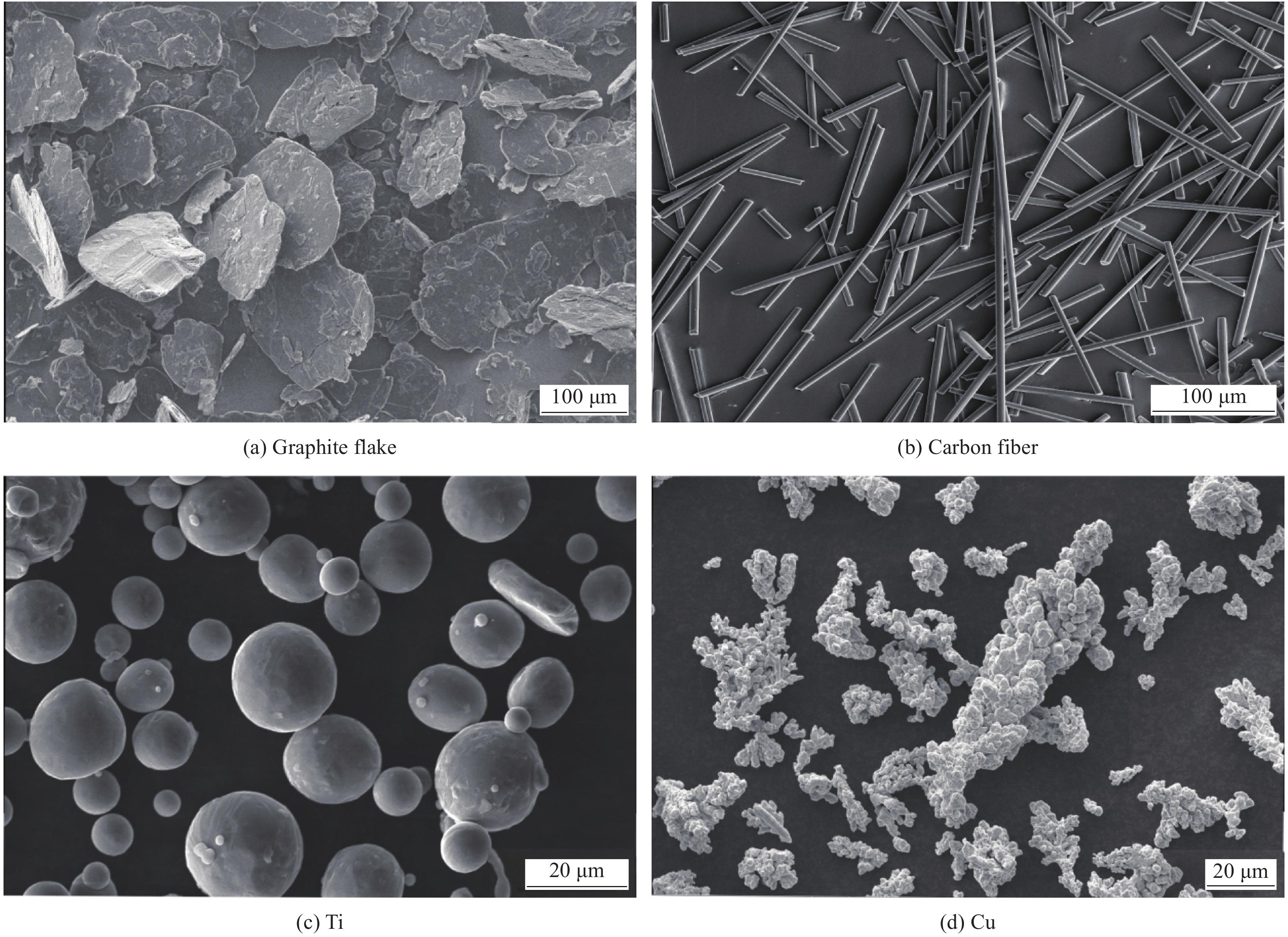

摘要: 采用真空热压技术制备了石墨鳞片-碳纤维协同增强铜基复合材料,研究了碳纤维含量对复合材料的组织结构、抗弯强度与热导率的影响。结果表明,石墨鳞片-碳纤维/铜基复合材料界面结合良好;当碳纤维体积分数为0.5vol%~1.5vol%时,碳纤维能够均匀分散在基体中,并有效提升复合材料的抗弯强度。当碳纤维体积分数为1.5vol%时,抗弯强度达到最大值126 MPa,相比未添加碳纤维的复合材料提高了46%;但过量加入碳纤维(2vol%及以上)时,碳纤维出现团聚,使抗弯强度下降。碳纤维的加入会使复合材料的热导率小幅下降,复合材料的热导率从549 W/(m·K)降低到527 W/(m·K)。使用声子失配模型(Acoustic mismatch model,AMM)结合Digimat软件的MF模块对多相复合材料的热导率进行有效预测。Abstract: The copper-matrix composites reinforced by graphite flake and carbon fiber were prepared by vacuum hot pressing technique. The effects of carbon fiber content on the microstructure, mechanical properties and thermal properties of the composites were discussed. The results show that the prepared graphite flake-carbon fiber/copper matrix composites have good interface bonding. The carbon fibers can be uniformly dispersed in the matrix and the bending strength of the composites can be improved when the volume fraction of 0.5vol%-1.5vol% carbon fibers is added. When the content of carbon fiber is 1.5vol%, the bending strength reaches the maximum of 126 MPa, which is increased by 46% compared with that without carbon fiber. However, the excessive addition of carbon fiber (2vol% or more) leads to an uneven distribution of carbon fiber, and the bending strength of composites decreases. The thermal conductivity of the composite decreases slightly with the addition of carbon fiber, from 549 W/(m·K) to 527 W/(m·K). The acoustic mismatch model (AMM) was used in conjunction with Digimat’s MF module to effectively predict the thermal conductivity of multiphase composites.

-

Key words:

- graphite/copper /

- metal matrix composites /

- bending strength /

- model analysis /

- vacuum hot pressing

-

表 1 样品各组分的含量

Table 1. Content of each component of the sample

Sample Cu/

vol%Ti/

vol%Graphite

flake/vol%Carbon

fiber/vol%0vol%fiber 48 2 50.0 0 0.5vol%fiber 48 2 49.5 0.5 1vol%fiber 48 2 49.0 1.0 1.5vol%fiber 48 2 48.5 1.5 2vol%fiber 48 2 48.0 2.0 Phase Density/

(kg·m−3)Thermal conductivity/

(W(m·K)−1)Specific heat/

(J·kg−1·K−1)Phonon velocity/

(m·s−1)Cu 8960 390 385 2500 Transversal

4910 LongitudinalTiC 4930 36.4 562 6977 Graphite flake 2260 1000 Transversal

10 Longitudinal710 22160 Longitudinal

14660 Transversal

4140 Out-planeFiber 1800 150 Longitudinal

10 Transversal710 22160 Longitudinal

14660 Transversal

4140 Out-plane -

[1] 张晓辉, 王强. 电子封装用金属基复合材料的研究现状[J]. 微纳米电子技术, 2018, 55(1):18-25, 44.ZHANG X H, WANG Q. Research status of metal matrix composites for electronic packaging[J]. Micronanoelectronic Technology,2018,55(1):18-25, 44(in Chinese). [2] 刘猛, 李顺, 白书欣, 等. SiCP/Cu电子封装材料研究进展[J]. 材料导报, 2013, 27(19):130-134.LIU M, LI S, BAI S X, et al. Progress in SiCp/Cu electronic packaging materials[J]. Materials Review,2013,27(19):130-134(in Chinese). [3] 申胜飞, 李茜. 5G通信技术关键材料发展研究[J]. 科技中国, 2019(8):50-59.SHEN S F, LI Q. Research on key materials development of 5G communication technology[J]. Science and Technology of China,2019(8):50-59(in Chinese). [4] MALLIK S, EKERE N, BEST C, et al. Investigation of thermal management materials for automotive electronic control units[J]. Applied Thermal Engineering,2011,31(2):355-362. [5] 王俊伟, 张现周, 薛晨, 等. 石墨表面镀Si对石墨/Al复合材料热物理性能的影响[J]. 复合材料学报, 2017, 34(4):608-615.WANG J W, ZHANG X Z, XUE C, et al. Effects of Si coated on graphite surface on the thermal and mechanical properties of graphite/Al composites[J]. Acta Materiae Compo-sitae Sinica,2017,34(4):608-615(in Chinese). [6] LIU Q, ZHANG C, CHEN J, et al. Modeling of interfacial design and thermal conductivity in graphite flake/Cu composites for thermal management applications[J]. Applied Thermal Engineering,2019,156:351-358. doi: 10.1016/j.applthermaleng.2019.04.063 [7] SOHN Y, HAN T, HAN J H. Effects of shape and alignment of reinforcing graphite phases on the thermal conductivity and the coefficient of thermal expansion of graphite/copper composites[J]. Carbon,2019,149:152-164. [8] LIU B, ZHANG D Q, LI X, et al. Effect of graphite flakes particle sizes on the microstructure and properties of graphite flakes/copper composites[J]. Journal of Alloys and Compounds,2018,766:S0925838818322503. [9] LIU Q, HE X B, REN S B, et al. Thermophy-sical properties and microstructure of graphite flake/copper composites processed by electroless copper coating[J]. Journal of Alloys & Compounds,2014,587:255-259. [10] BAI H, XUE C, LYU J L, et al. Thermal conductivity and mechanical properties of flake grap-hite/copper composite with a boron carbide-boron nano-layer on graphite surface[J]. Composites Part A: Applied Science and Manufacturing,2017:S1359835X17304256. [11] REN S B, HONG Q, CHEN J, et al. The influence of matrix alloy on the microstructure and properties of (flake graphite+diamond)/Cu composites by hot pressing[J]. Journal of Alloys & Compounds,2015,652:351-357. [12] ZHU Y, BAI H, XUE C, et al. Thermal conductivity and mechanical properties of a flake graphite/Cu composite with a silicon nano-layer on a graphite surface[J]. RSC Advances,2016,6(100):98190-98196. doi: 10.1039/C6RA17804A [13] ZHANG R, HE X, LIU Q, et al. Improvement in mechanical and thermal properties of graphite flake/Cu composites by introducing TiC coating on graphite flake surface[J]. Metals-Open Access Metallurgy Journal,2019,9(5):519. [14] 王晗. 多相协同增强铜基复合材料的制备与强化机理研究[D]. 秦皇岛: 燕山大学, 2020.WANG H. Study on preparation and strengthening mechanism of multiphase cooperatively reinforced copper matrix composites[D]. Qinhuangdao: Yanshan University, 2020(in Chinese). [15] 陈达, 赵炜康, 武世文, 等. 纤维长度对碳纤维/铜基复合材料组织及力学性能的影响[J]. 矿冶工程, 2017, 37(6):105-108+112.CHEN D, ZHAO W K, WU S W, et al. Effects of carbon fiber length on microstructures and mechanical properties of carbon fibers/Cu composite[J]. Mining and Metallurgical Engineering,2017,37(6):105-108+112(in Chinese). [16] 刘建秀, 宋阳, 樊江磊, 等. 碳纤维增强铜基复合材料研究进展[J]. 材料科学与工程学报, 2018, 36(2):173, 175-179.LIU J X, SONG Y, FAN J L, et al. Research progress of carbon fiber reinforced copper matrix composites[J]. Journal of Materials Science& Engineering,2018,36(2):173, 175-179(in Chinese). [17] LIU L, TANG Y, ZHAO H, et al. Fabrication and properties of short carbon fibers reinforced copper matrix composites[J]. Journal of Materials Science,2008,43(3):974-979. doi: 10.1007/s10853-007-2089-5 [18] CUI Q, CHEN C, YU C, et al. Effect of molybdenum particles on thermal and mechanical properties of graphite flake/copper composites[J]. Carbon,2020,161:169-180. doi: 10.1016/j.carbon.2020.01.059 [19] 陈文革, 王娇娇, 马佳, 等. 镀铬碳纤维增强铜基复合材料的组织与性能[J]. 兵器材料科学与工程, 2017, 40(2):42-47.CHEN W G, WANG J J, MA Jia, et al. Microstructure and properties of Cr-coated carbon fiber-reinforced copper matrix composites[J]. Ordnance Material Science and Engineering,2017,40(2):42-47(in Chinese). [20] LIANG Y H, WANG H Y, YANG Y F, et al. Evolution process of the synthesis of TiC in the Cu-Ti-C system[J]. Journal of Alloys & Compounds,2008,452(2):298-303. [21] ZHANG R, HE X, CHEN Z, et al. Influence of Ti content on the microstructure and properties of graphite flake/Cu-Ti composites fabricated by vacuum hot pressing[J]. Vacuum,2017,141:265-271. doi: 10.1016/j.vacuum.2017.04.026 [22] XIONGN, BAO R, YI J, et al. CNTs/Cu-Ti composites fabrication through the synergistic reinforcement of CNTs and in situ generated nanoTiC particles[J]. Journal of Alloys& Compounds,2018:S092583881832989X. [23] 曾凡坤, 马洪兵, 江南. 高定向石墨/铜复合材料的制备和热物理性能[J]. 复合材料学报, 2020, 37(8):1951-1959.ZENG F K, MA H B, JIANG N. Preparation and thermophysical properties of aligned graphite flake/Cu composites[J]. Acta Materiae Compositae Sinica,2020,37(8):1951-1959(in Chinese). [24] LIU Q, TANG S W, HUANG J C, et al. Microstructure and thermal conductivity of graphite flake/Cu composites with a TiC or Cu coating on graphite flakes[J]. Materials Research Express,2019,6(12):125632 (12pp). [25] ZHANG Y, ZHANG H L, WU J H, et al. Enhanced thermal conductivity in copper matrix composites reinforced with titanium-coated diamond particles-sciencedirect[J]. Scripta Materialia,2011,65(12):1097-1100. doi: 10.1016/j.scriptamat.2011.09.028 [26] KUNIYA K, ARAKAWA H, KANAI T, et al. Thermal conductivity, electrical conductivity and specific heat of copper-carbon fiber composites[J]. Transactions of the Japan Institute of Metals,1987,28(10):819-826. [27] PRASHER R. Thermal boundary resistance and thermal conductivity of multiwalled carbon nanotubes[J]. Physical Review B, Condensed Matter,2008,77(7):439-446. [28] MORATH C J, MARIS H J, CUOMO J J, et al. Picosecond optical studies of amorphous diamond and diamondlike carbon: Thermal conductivity and longitudinal sound velocity[J]. Journal of Applied Physics,1994,76(5):2636-2640. doi: 10.1063/1.357560 [29] YUAN M Y, TAN Z Q, FAN G L, et al. Theoretical modelling for interface design and thermal conductivity prediction in diamond/Cu composites[J]. Diamond and Related Materials,2018,81:38-44. doi: 10.1016/j.diamond.2017.11.010 [30] 刘骞. 非连续石墨/铜复合材料的制备与热性能研究[D]. 北京: 北京科技大学, 2016.LIU Q. Research of preparation and thermal properties of discontinuous graphite/copper[D]. Beijing: University of Science and Technology Beijing, 2016(in Chinese). -

下载:

下载: