Long term aging and failure behaviors of carbon fiber reinforced polymer composites in simulated marine environments

-

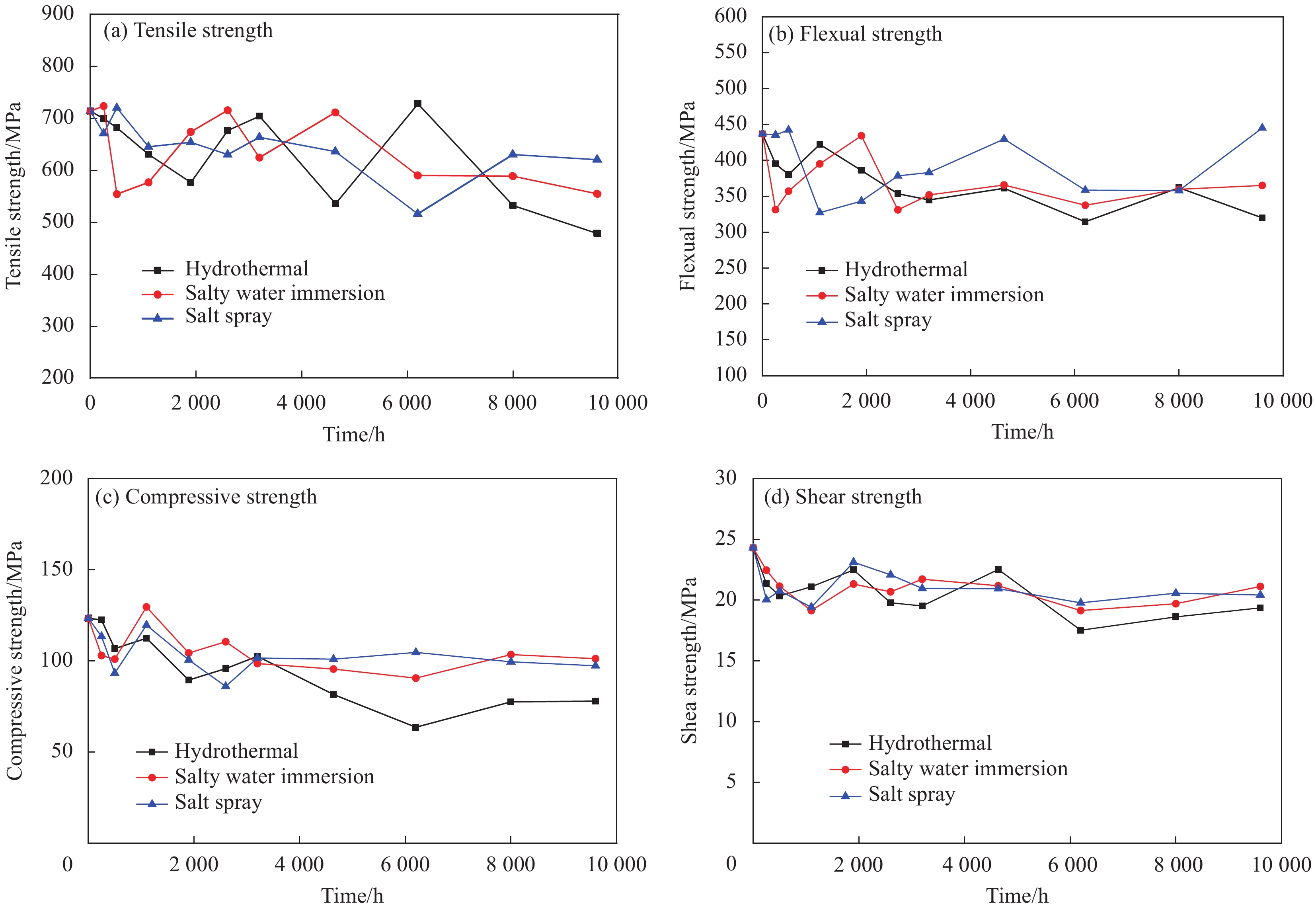

摘要: 选取两种先进轻质复合材料:碳纤维增强酚醛树脂复合材料(CF/S-157)与碳纤维增强环氧树脂复合材料(CF/TDE-85),开展模拟海洋环境实验室盐雾老化、湿热老化和盐水浸泡环境长达9600 h加速试验。基于各种力学性能(拉伸强度、弯曲强度、压缩强度及层间剪切强度)开展材料老化行为规律研究,利用傅立叶变换衰减全反射红外光谱(ATR-FTIR)分析方法对树脂基体在各种加速环境中的分子链段与官能团变化情况进行分析,得到树脂基体的失效模式;利用外观、超声扫描成像、SEM分析树脂/纤维界面的变化情况,明确了树脂/纤维界面的破坏方式;利用差示扫描量热分析(DSC)与热重分析(TG)分析各种加速老化方式对碳纤维增强树脂复合材料的玻璃化转变温度Tg与热失重的影响。结果表明,三种老化方式对树脂基体的老化影响顺序依次为70℃/95%RH (Relative humidity)湿热、35℃盐雾、常温盐水浸泡。得到了先进轻质树脂基复合材料的模拟海洋环境老化行为和失效机制、失效模式,为实现高性能树脂基复合材料的环境适应性评价和使用寿命预测奠定基础。

-

关键词:

- 碳纤维增强树脂复合材料 /

- 模拟老化 /

- 力学性能 /

- 腐蚀行为 /

- 失效模式

Abstract: Carbon fiber reinforced phenolic resin composite (CF/S-157) and carbon fiber reinforced epoxy composite (CF/TDE-85), which are widely used at present, were selected to carry out the salt spray aging, hydrothermal aging and salt water immersion environmental test in laboratory. Based on various mechanical properties (tensile strength, flexural strength, compressive strength and interlaminar shear strength), the corrosion behaviors of the composite materials were studied. The changes of molecular segments and functional groups of resin matrix in various aging environments were analyzed by attenuated total reflection flourier transformed infrared spectroscopy (ATR-FTIR), and the failure modes of various matrix resins were obtained. The failure mode of resin/fiber interface was identified based on the characterization of SEM and ultrasonic C-scanning testing and imaging system. The effects of various aging methods on glass transition temperature Tg and thermal mass loss of composites were analyzed by differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA). The results show that the deterioration severity order of the three aging methods is hydrothermal aging, salt spray and salt water immersion. The corrosion characterization, failure mechanism and failure mode of the composites in simulated marine environment are obtained, which lays a foundation for environmental adaptability evaluation and service life prediction of high-performance resin matrix composites. -

表 1 碳纤维增强树脂基复合材料(CFRP)老化试验条件

Table 1. Various artificial aging experimental conditions in lab for carbon fiber reinforced polymer (CFRP)

Aging method Aging standard Experimental condition Hydrothermal Test method for resistance of glass fiber reinforced plastics to damp heat: GB 2574—1989[29] 60℃; 95%RH (Relative humidity) Salty water immersion Test method for resistance of glass fiber reinforced plastics to water and accelerated test: GB/T 10703—1989[30] 25℃; 5% NaCl water solution Salt spray Paint and varnishes-Determination of resistance to neutral salt spray: GB/T 1771—2007[31] 5% NaCl fumes at 35℃; Solution pH: 6.8-7.2; Precipitation rate of salt spray: 1.8 mL/(h·80 cm2) 表 2 CFRP性能测试方法

Table 2. Test methods of mechanical properties for CFRP

Mechanical property Determination standard Loaded speed/(mm·min−1) Tensile strength Fiber-reinforced plastics composites-Determination of tensile properties:

GB/T 1447—2005[27]2 Flexural strength Fiber-reinforced plastics composites-Determination of flexural properties:

GB/T 1449—2005[32]2 Compressive strength Fiber-reinforced plastics composites-Determination of compressive properties: GB/T 1448—2005[28] 5 Shear strength Fiber-reinforced plastics composites-Determination of apparent interlaminar shear strength by short-beam method: JC/T 773-2010[33] 1 -

[1] FAULSTICH DE PAIVA J M, MAYER S, REZENDE M C. Comparison of tensile strength of different carbon fabric reinforced epoxy composites[J]. Materials Research,2006,9(1):83-89. doi: 10.1590/S1516-14392006000100016 [2] LEE E, BUECHER D, JANG S, et al. The characterization of discontinuous carbon fiber mat reinforced epoxy composite materials[J]. Advanced Materials Research,2015,1110:77-81. doi: 10.4028/www.scientific.net/AMR.1110.77 [3] 黄桥平, 赵桂平, 李杰. 碳纤维/环氧树脂复合材料动态拉伸试验研究与损伤分析[J]. 复合材料学报, 2009, 26(6):143-149. doi: 10.3321/j.issn:1000-3851.2009.06.024HUANG Qiaoping, ZHAO Guiping, LI Jie. Experimental study on carbon fiber/epoxy laminates under dynamic tensile and their damage analysis[J]. Acta Materiae Compositae Sinica,2009,26(6):143-149(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.06.024 [4] 李劲, 李伟, 范群, 等. 碳纤维单丝带对酚醛树脂基复合材料力学性能的增强作用[J]. 复合材料学报, 2006, 23(1):51-55. doi: 10.3321/j.issn:1000-3851.2006.01.008LI Jin, LI Wei, FAN Qun, et al. Reinforcing effect of separated carbon fiber tape on mechanicalproperties of phenolic resin composites[J]. Acta Materiae Compositae Sinica,2006,23(1):51-55(in Chinese). doi: 10.3321/j.issn:1000-3851.2006.01.008 [5] FAULSTICH DE PAIVA J M, SANTOS A D N D, REZENDE M C. Mechanical and morphological characterizations of carbon fiber fabric reinforced epoxy composites used in aeronautical field[J]. Materials Research,2009,12(3):367-374,. doi: 10.1590/S1516-14392009000300019 [6] 刘强, 马小康, 宗志坚. 斜纹机织碳纤维/环氧树脂复合材料性能及其在电动汽车轻量化设计中的应用[J]. 复合材料学报, 2011, 28(5):83-88.LIU Qiang, MA Xiaokang, ZONG Zhijian. Properties of twill-weave carbon fabric/epoxy composites and its application on light-weight design for electric vehicles[J]. Acta Materiae Compositae Sinica,2011,28(5):83-88(in Chinese). [7] 王晨阳. 碳纤维树脂基复合材料在交通装备领域的应用[J]. 中国战略新兴产业, 2019(4):189-191.WANG Chenyang. Application of carbon fiber resin matrix composites in the field of transportation equipment[J]. China Strategic Emerging Industry,2019(4):189-191(in Chinese). [8] 于海宁, 高长星, 王艳华. 碳纤维增强树脂基复合材料的应用及展望[J]. 合成纤维工业, 2020, 43(1):55-59. doi: 10.3969/j.issn.1001-0041.2020.01.012YU Haining, GAO Changxing, WANG Yanhua. Application and prospect of carbon fiber reinforced resin-based composites[J]. China Synthetic Fiber Industry,2020,43(1):55-59(in Chinese). doi: 10.3969/j.issn.1001-0041.2020.01.012 [9] EIBL S. Comparison of surface and bulk analytical techniques for the distinct quantification of a moderate thermal pre-load on a carbon fibre reinforced plastic material[J]. Polymer Degradation and Stability,2017,135:31-42. doi: 10.1016/j.polymdegradstab.2016.11.015 [10] GUO F, AL-SAADI S, SINGH RAMAN R K, et al. Durability of fiber reinforced polymer (FRP) in simulated seawater sea sand concrete (SWSSC) environment[J]. Corrosion Science,2018,141:1-13. doi: 10.1016/j.corsci.2018.06.022 [11] JOHAR M, CHONG W W F, KANG H S, et al. Effects of moisture absorption on the different modes of carbon/epoxy composites delamination[J]. Polymer Degradation and Stability,2019,165:117-125. doi: 10.1016/j.polymdegradstab.2019.05.007 [12] WANG Z K, ZHAO X L, XIAN G J, et al. Effect of sustained load and seawater and sea sand concrete environment on durability of basalt- and glass-fibre reinforced polymer (B/GFRP) bars[J]. Corrosion Science,2018,138:200-218. doi: 10.1016/j.corsci.2018.04.002 [13] WEI B, CAO H L, SONG S H. Degradation of basalt fibre and glass fibre/epoxy resin composites in seawater[J]. Corrosion Science,2011,53(1):426-431. doi: 10.1016/j.corsci.2010.09.053 [14] 孙岩, 王登霞, 刘亚平, 等. 玻璃纤维/溴化环氧乙烯基酯加速老化与自然老化的相关性[J]. 复合材料学报, 2014, 31(4):916-924.SUN Yan, WANG Dengxia, LIU Yaping, et al. Correlation of aging and natural aging of glass fiber reinforced bromide epoxy vinyl ester composites[J]. Acta Materiae Compositae Sinica,2014,31(4):916-924(in Chinese). [15] 谢可勇, 李晖, 孙岩, 等. 湿热老化对纤维增强树脂基复合材料性能的影响及其机理[J]. 机械工程材料, 2014, 38(8):1-5.XIE Keyong, LI Hui, SUN Yan, et al. Effect of hygrothermal aging on behaviors of fiber reinforced resin composites and its mechanism[J]. Meratials for Mechanical Enginnering,2014,38(8):1-5(in Chinese). [16] 樊威, 李嘉禄. 热氧老化对碳纤维织物增强聚合物基复合材料弯曲性能的影响[J]. 复合材料学报, 2015, 32(5): 1260-1270.FAN W, LI J. Effects of thermo-oxidative aging on flexural properties of carbon fiber fabric reinforced polymer matrix composites[J]. Acta Materiae Compositae Sinica, 2015, 32(5): 1260-1270. [17] FAN W, LI J L, ZHENG Y Y, et al. Influence of thermo-oxidative aging on the thermal conductivity of carbon fiber fabric reinforced epoxy composites[J]. Polymer Degradation and Stability,2016,123:162-169. doi: 10.1016/j.polymdegradstab.2015.11.016 [18] LEBLANC J, CAVALLARO P, TORRES J, et al. Low temperature effects on the mechanical, fracture, and dynamic behavior of carbon and E-glass epoxy laminates[J]. International Journal of Lightweight Materials and Manufacture,2020,3(4):344-356. doi: 10.1016/j.ijlmm.2020.05.002 [19] 隋晓东, 梁成利, 刘文博, 等. 高温老化对碳纤维增强双马来酰亚胺树脂基复合材料力学性能的影响研究[J]. 纤维复合材料, 2011, 1(1):21-23. doi: 10.3969/j.issn.1003-6423.2011.01.004SUI Xiaodong, LIANG Chengli, LIU Wenbo, et al. Effect of thermal-aging on the mechanical properties of carbon fiber reinforced bis-malaimide composite metarials[J]. Fiber Composites,2011,1(1):21-23(in Chinese). doi: 10.3969/j.issn.1003-6423.2011.01.004 [20] 王登霞, 李晖, 刘亚平, 等. 玻璃纤维/溴化环氧乙烯基酯复合材料的加速光老化研究[J]. 合成材料老化与应用, 2014, 43(1):35-40. doi: 10.3969/j.issn.1671-5381.2014.01.011WANG Dengxia, LI Hui, LIU Yaping, et al. Accelerated light aging of glass fiber /brominated epoxy vinyl ester composites[J]. Synthetic Materials Aging and Application,2014,43(1):35-40(in Chinese). doi: 10.3969/j.issn.1671-5381.2014.01.011 [21] ESLAMI S, TAHERI F. Effects of perforation size on the response of perforated GFRP composites aged in acidic media[J]. Corrosion Science,2013,69:262-269. doi: 10.1016/j.corsci.2012.12.012 [22] 代礼葵, 孙耀宁, 王国建. 玻璃纤维/环氧乙烯基酯树脂复合材料环境综合因素下的冲蚀行为及机制[J]. 复合材料学报, 2019, 36(9):2059-2066. doi: 10.13801/j.cnki.fhclxb.20181220.001DAI Likui, SUN Yaoning, WANG Guojian. Erosion behavior and mechanism of glass fiber/epoxy vinlester composites under multiple environmental factors[J]. Acta Materiae Compositae Sinica,2019,36(9):2059-2066(in Chinese). doi: 10.13801/j.cnki.fhclxb.20181220.001 [23] AN Tao, GONG Tianchen, YANG Xudong, et al. Effect of hygrothermal environment on mechanical properties and damage mechanism of CFRP[J]. Journal of Materials Engineering,2019,47(7):84-91. [24] TAO L, MIN W, QI L L, et al. The hygrothermal aging process and mechanism of CFRP papered by prepreg that may be stored at room temperature[J]. Polymer Degradation and Stability,2020,182:109395-109399. doi: 10.1016/j.polymdegradstab.2020.109395 [25] 孙旋, 童明波, 陈智, 等. 碳纤维织物布层压复合材料湿热环境疲劳后剩余压缩强度[J]. 复合材料学报, 2016, 33(3):535-544. doi: 10.13801/j.cnki.fhclxb.20150709.002SUN Xuan, TONG Mingbo, CHEN Zhi, et al. Residual compressive strength after fatigue of carbon fiber fabric composite laminates in hydrothermal environment[J]. Acta Materiae Compositae Sinica,2016,33(3):535-544(in Chinese). doi: 10.13801/j.cnki.fhclxb.20150709.002 [26] 张代军, 刘刚, 包建文, 等. T700碳纤维增强环氧树脂基复合材料自然老化性能与机制[J]. 复合材料学报, 2016, 33(7):1390-1399. doi: 10.13801/j.cnki.fhclxb.20151022.002ZHANG Daijun, LIU Gang, BAO Jianwen, et al. Environmental aging performance and mechanism of T700 carbon fiber reinforced epoxy resin matrix composites[J]. Acta Materiae Compositae Sinica,2016,33(7):1390-1399(in Chinese). doi: 10.13801/j.cnki.fhclxb.20151022.002 [27] 中国国家标准化管理委员会. GB/T 1447—2005 纤维增强塑料拉伸性能试验方法[S]. 北京: 中国标准出版社, 2005.Standardization Administration. GB/T 1447—2005 Fiber-reinforced plastics composites-Determination of tensile properties[S]. Beijing: China Standards Press, 2005(in Chinese). [28] 中国国家标准化管理委员会. GB/T 1448—2005 纤维增强塑料压缩性能试验方法[S]. 北京: 中国标准出版社, 2005.Standardization Administration. GB/T 1448—2005 Fiber-reinforced plastics composites-Determination of compressive properties[S]. Beijing: China Standards Press, 2005(in Chinese). [29] 中国国家标准化管理委员会. GB 2574—1989 玻璃纤维增强塑料湿热试验方法[S]. 北京: 中国标准出版社, 1989.Standardization Administration. GB 2574—1989 Test method for resistance of glass fiber reinforced plastics to damp heat[S]. Beijing: China Standards Press, 1989(in Chinese). [30] 中国国家标准化管理委员会. GB/T 10703—1989 玻璃纤维增强塑料耐水性加速试验方法[S]. 北京: 中国标准出版社, 1989.Standardization Administration. GB/T 10703—1989 Test method for resistance of glass fiber reinforced plastics to water and accelerated test[S]. Beijing: China Standards Press, 1989(in Chinese). [31] 中国国家标准化管理委员会. GB/T 1771—2007 色漆和清漆耐中性盐雾性能的测定[S]. 北京: 中国标准出版社, 2007.Standardization Administration. GB/T 1771—2007 Paint and varnishes-Determination of resistance to neutral salt spray[S]. Beijing: China Standards Press, 2007(in Chinese). [32] 中国国家标准化管理委员会. GB/T 1449—2005 纤维增强塑料弯曲性能试验方法[S]. 北京: 中国标准出版社, 2005.Standardization Administration. GB/T 1449—2005 Fiber-reinforced plastics composites-Determination of flexural properties[S]. Beijing: China Standards Press, 2005(in Chinese). [33] 中华人民共和国工业和信息化部. JC/T 773—2010 纤维增强塑料 短梁法测定层间剪切强度[S]. 北京: 中国标准出版社, 2010.Ministry of Industry and Information Technology of the People's Republic of China. JC/T 773—2010 Fiber-reinforced plastics composites-Determination of apparent interlaminar shear strength by short-beam method[S]. Beijing: China Standards Press, 2010(in Chinese). -

下载:

下载: