| [1] |

CHEN L, JIA Y M, ZHAO J H, et al. Strong piezocatalysis in barium titanate/carbon hybrid nanocomposites for dye wastewater decomposition[J]. Journal of Colloid and Interface Science,2020,586:758-765.

|

| [2] |

尚建平, 刘锐, 覃孝平, 等. 改性凹凸棒土负载铜和稀土催化氧化印染废水[J]. 化工进展, 2020, 39(S2):434-439.SHANG Jianping, LIU Rui, QIN Xiaoping, et al. Modified attapulgite clay with copper and rare earth catalytic oxidation printing and dyeing wastewater[J]. Chemical Industry and Engineering Progress,2020,39(S2):434-439(in Chinese).

|

| [3] |

SONU K, SOGANI M, SYED Z, et al. Enhanced decolorization and treatment of textile dye wastewater through adsorption on acid modified corncob derived biochar[J]. Chemistry Select,2020,5(39):12287-12297.

|

| [4] |

石健, 万杨, 黄鑫, 等. 聚合铁钛混凝剂对印染废水的处理[J]. 环境工程学报, 2019, 13(5):1021-1029.SHI Jian, WAN Yang, HUANG Xin, et al. Treating dyeing wastewater with a kind of polyferric titanium sulfate[J]. Journal of Environmental Engineering,2019,13(5):1021-1029(in Chinese).

|

| [5] |

皇甫志杰, 张维, 姚继明. 电化学高级氧化工艺降解印染废水的研究进展[J]. 毛纺科技, 2020, 48(9):40-45.HUANGFU Zhijie, ZHANG Wei, YAO Jiming. Research progress on degradation of printing and dyeing wastewater by electrochemical advanced oxidation process[J]. Wool Textile Journal,2020,48(9):40-45(in Chinese).

|

| [6] |

陈康, 赵孔银, 张志箭, 等. 海藻酸钙/聚丙烯无纺布复合过滤膜的制备及性能[J]. 复合材料学报, 2019, 36(1):7-12.CHEN Kang, ZHAO Kongyin, ZHANG Zhijian, et al. Preparation and properties of calcium alginate/polypropylene non-woven composite filtration membrane[J]. Acta Materiae Compositae Sinica,2019,36(1):7-12(in Chinese).

|

| [7] |

HUANG Y F, ZHOU Y K, WANG K G. A kind of NiO nanofilm photocatalyst supported on nano-PAA substrate for efficient degradation of organic dye wastewater.[J]. Environmental Science and Pollution Research International,2020,27(33):41503-41514. doi: 10.1007/s11356-020-10131-5

|

| [8] |

柏源, 张超智, 孙红旗, 等. 氮、银共掺杂TiO2可见光催化剂的制备及表征[J]. 材料工程, 2020, 48(11):32-38. doi: 10.11868/j.issn.1001-4381.2019.000151BAI Yuan, ZHANG Chaozhi, SUN Hongqi, et al. Preparation and characterization of nitrogen and silver co-doped TiO2 nanocatalyst for visible light photocatalysis[J]. Journal of Materials Engineering,2020,48(11):32-38(in Chinese). doi: 10.11868/j.issn.1001-4381.2019.000151

|

| [9] |

任保胜, 王瑞, 任金芝, 等. 纳米TiO2/碳化植物纤维复合材料的制备与光催化性能[J]. 复合材料学报, 2020, 37(5):1138-1147.REN Baosheng, WANG Rui, REN Jinzhi, et al. Preparation and photocatalytic properties of nano TiO2/carbonized plant fiber composites[J]. Acta Materiae Compositae Sinica,2020,37(5):1138-1147(in Chinese).

|

| [10] |

王想. 不锈钢纤维毡负载纳米TiO2光催化剂的制备及染料降解性能研究[D]. 杭州: 浙江理工大学, 2017.WANG Xiang. Study on preparation of Nano-TiO2 photocatalyst coatedon stainless steel felts and its dye degradation[D]. Hangzhou: Zhejiang Sci-Tech University, 2017(in Chinese).

|

| [11] |

LIU Y, LIU Z F, HUANG D L, et al. Metal or metal-containing nanoparticle@MOF nanocomposites as a promising type of photocatalyst[J]. Coordination Chemistry Reviews,2019,388:63-78. doi: 10.1016/j.ccr.2019.02.031

|

| [12] |

WU T, LIU X J, LIU Y, et al. Application of QD-MOF composites for photocatalysis: Energy production and environmental remediation[J]. Coordination Chemistry Reviews,2020,403:213097. doi: 10.1016/j.ccr.2019.213097

|

| [13] |

WANG C C, YI X H, WANG P. Powerful combination of MOFs and C3N4 for enhanced photocatalytic performance[J]. Applied Catalysis B: Environmental,2019,247:24-48.

|

| [14] |

LIU X M, TANG B, LONG J L, et al. The development of MOFs-based nanomaterials in heterogeneous organocatalysis[J]. Science Bulletin,2018,63(8):502-524. doi: 10.1016/j.scib.2018.03.009

|

| [15] |

CHEN D, FENG P F, WEI F H. Preparation of Fe(Ⅲ)-MOFs by microwave-assisted ball for efficiently removing organic dyes in aqueous solutions under natural light[J]. Chemical Engineering and Processing:Process Intensification,2018,135:63-67.

|

| [16] |

GUO T, WANG K, ZHANG G K, et al. A novel α-Fe2O3@g-C3N4 catalyst: Synthesis derived from Fe-based MOF and its superior photo-Fenton performance[J]. Applied Surface Science,2019,469:331-339. doi: 10.1016/j.apsusc.2018.10.183

|

| [17] |

ZHAO D F, HAMADA H, YANG Y Q. Influence of polyurethane dispersion as surface treatment on mechanical, thermal and dynamic mechanical properties of laminated woven carbon-fiber-reinforced polyamide 6 composites[J]. Composites Part B,2019,160:535-545. doi: 10.1016/j.compositesb.2018.12.105

|

| [18] |

MA Y Y, YAN C, XU H B, et al. Enhanced interfacial properties of carbon fiber reinforced polyamide 6 composites by grafting graphene oxide onto fiber surface[J]. Applied Surface Science,2018,452:286-298. doi: 10.1016/j.apsusc.2018.04.274

|

| [19] |

PLOYCHOMPOO S, CHEN J D, LUO H J, et al. Fast and efficient aqueous arsenic removal by functionalized MIL-100(Fe)/rGO/δ-MnO2 ternary composites: Adsorption performance and mechanism[J]. Journal of Environmental Sciences,2020,91:22-34. doi: 10.1016/j.jes.2019.12.014

|

| [20] |

DONG R F, CHEN D Y, LI N J, et al. Enhancement of organic pollutants bio-decontamination from aqueous solution using newly-designed Pseudomonas putida-GA/MIL-100(Fe) bio-nanocomposites[J]. Environmental Research,2019,173:237-245. doi: 10.1016/j.envres.2019.03.052

|

| [21] |

王爱静, 吴腾飞, 彭啸, 等. TiO2/PC-CS的制备及光催化降解甲苯增溶废水的研究[J]. 功能材料, 2020, 51(9):9193-9200. doi: 10.3969/j.issn.1001-9731.2020.09.029WANG Aijing, WU Tengfei, PENG Xiao, et al. Preparation of TiO2/PC-CS and photocatalytic degradation of solubilized toluene in wastewater[J]. Jorunal of Functional Materials,2020,51(9):9193-9200(in Chinese). doi: 10.3969/j.issn.1001-9731.2020.09.029

|

| [22] |

ZHONG H, WANG Y H, YANG H X. A novel transparent thermal insulation bilayer coating based on ATO/Black TiO2[J]. Energy Procedia,2019,158:1072-1079. doi: 10.1016/j.egypro.2019.01.260

|

| [23] |

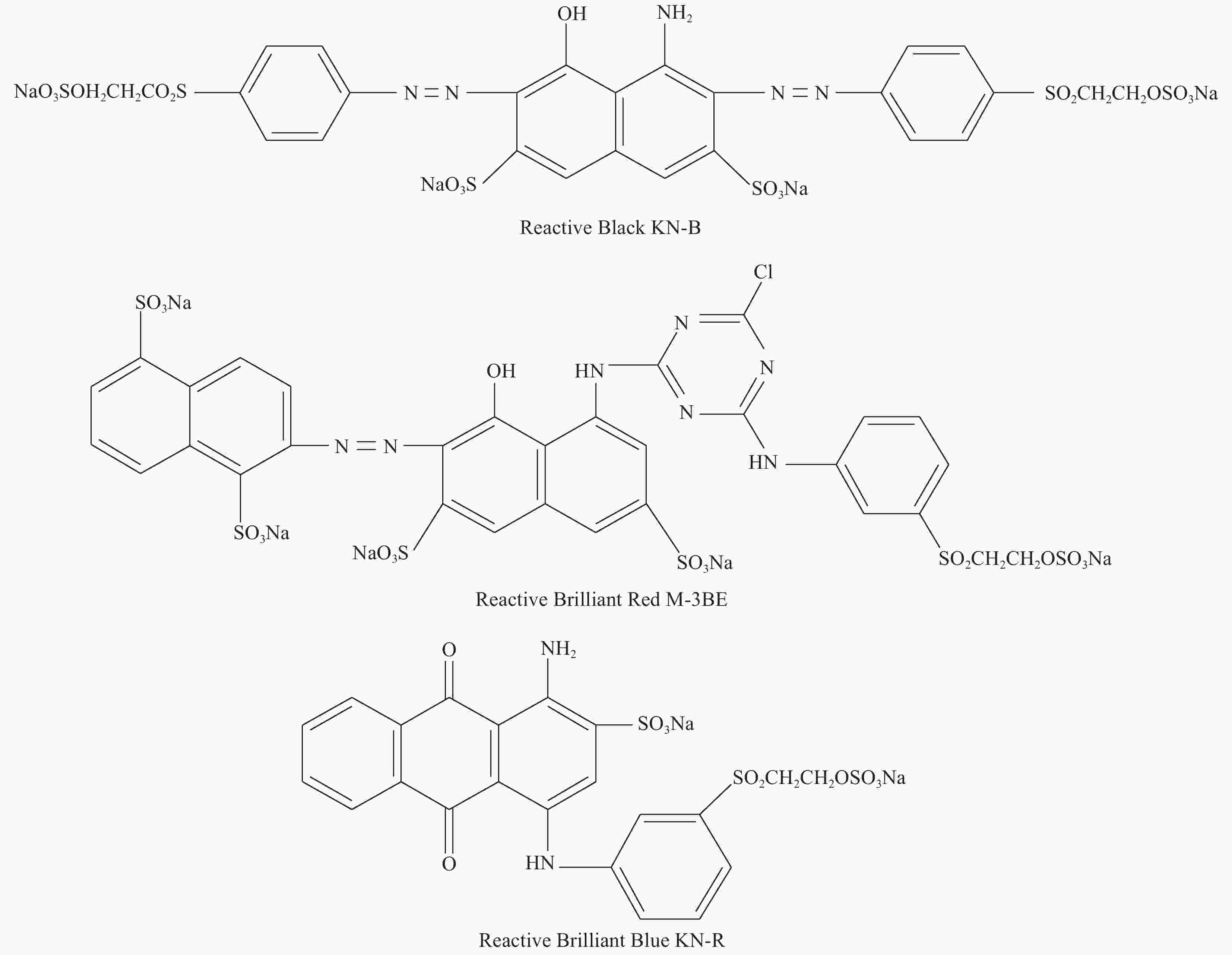

MARTORELL M M, PAJOT H F, FIGUEROA L. Biological degradation of Reactive Black 5 dye by yeast Trichosporon akiyoshidainum[J]. Journal of Environmental Chemical Engineering,2017,5(6):5987-5993. doi: 10.1016/j.jece.2017.11.012

|

| [24] |

MENDEZMARTINE Z, ANA J, DAVILAJIMENEZ, et al. Electrochemical reduction and oxidation pathways for Reactive Black 5 dye using nickel electrodes in divided and undivided cells[J]. Electrochimica Acta,2011,59:140-149.

|

| [25] |

DONG Y C, WANG P, LI B. Fe complex immobilized on waste polypropylene fibers for fast degradation of Reactive Red 195 via enhanced activation of persulfate under LED visible irradiation[J]. Journal of Cleaner Production,2019,208:1347-1356. doi: 10.1016/j.jclepro.2018.10.211

|

| [26] |

宿程远. 海泡石/多相类芬顿—厌氧组合技术降解蒽醌类污染物的研究[D]. 哈尔滨: 哈尔滨工业大学, 2015.SU Chengyuan. Degradation of anthraquinones by combination of sepiolite/heterogeneous Fenton-like oxidation and anaerobic biological processes[D]. Harbin: Harbin Institute of Technology, 2015(in Chinese).

|

| [27] |

熊重铎. 蒽醌染料茜素绿模拟废水的微波无极紫外光催化氧化降解过程的研究[D]. 上海: 东华大学, 2015.XIONG Zhongduo. Study on photocatalytic degradation process of anthraquinone dye alizarin green simulate wastewater using microwave powered electrodeless discharged UV lamp[D]. Shanghai: Donghua University, 2015(in Chinese).

|

| [28] |

SIMSEK E B, TUNA Ö, BALTA Z. Construction of stable perovskite-type LaFeO3 particles on polymeric resin with boosted photocatalytic Fenton-like decaffeination under solar irradiation[J]. Separation and Purification Technology,2020,237:116384. doi: 10.1016/j.seppur.2019.116384

|

| [29] |

CARLA S, ANA Z, SIXTO M, et al. Formation of chlorinated by-products during photo-Fenton degradation of pyrimethanil under saline conditions. Influence on toxicity and biodegradability[J]. Journal of Hazardous Materials,2012,217-218:217-223. doi: 10.1016/j.jhazmat.2012.03.017

|

| [30] |

MUSTAPHA M B, ABDUL A A R, ANAM A. A review on approaches for addressing the limitations of Fenton oxidation for recalcitrant wastewater treatment[J]. Process Safety and Environmental Protection,2019,126:119-140. doi: 10.1016/j.psep.2019.03.028

|

| [31] |

ANGAMUTHU M, SATISHKUMAR G, LANDAU M V. Precisely controlled encapsulation of Fe3O4 nanoparticles in mesoporous carbon nanodisk using iron based MOF precursor for effective dye removal[J]. Microporous and Mesoporous Materials,2017,251:58-68. doi: 10.1016/j.micromeso.2017.05.045

|

下载:

下载: