Design and application of MOFs and derived composite materials inlithium-sulfur batteries

-

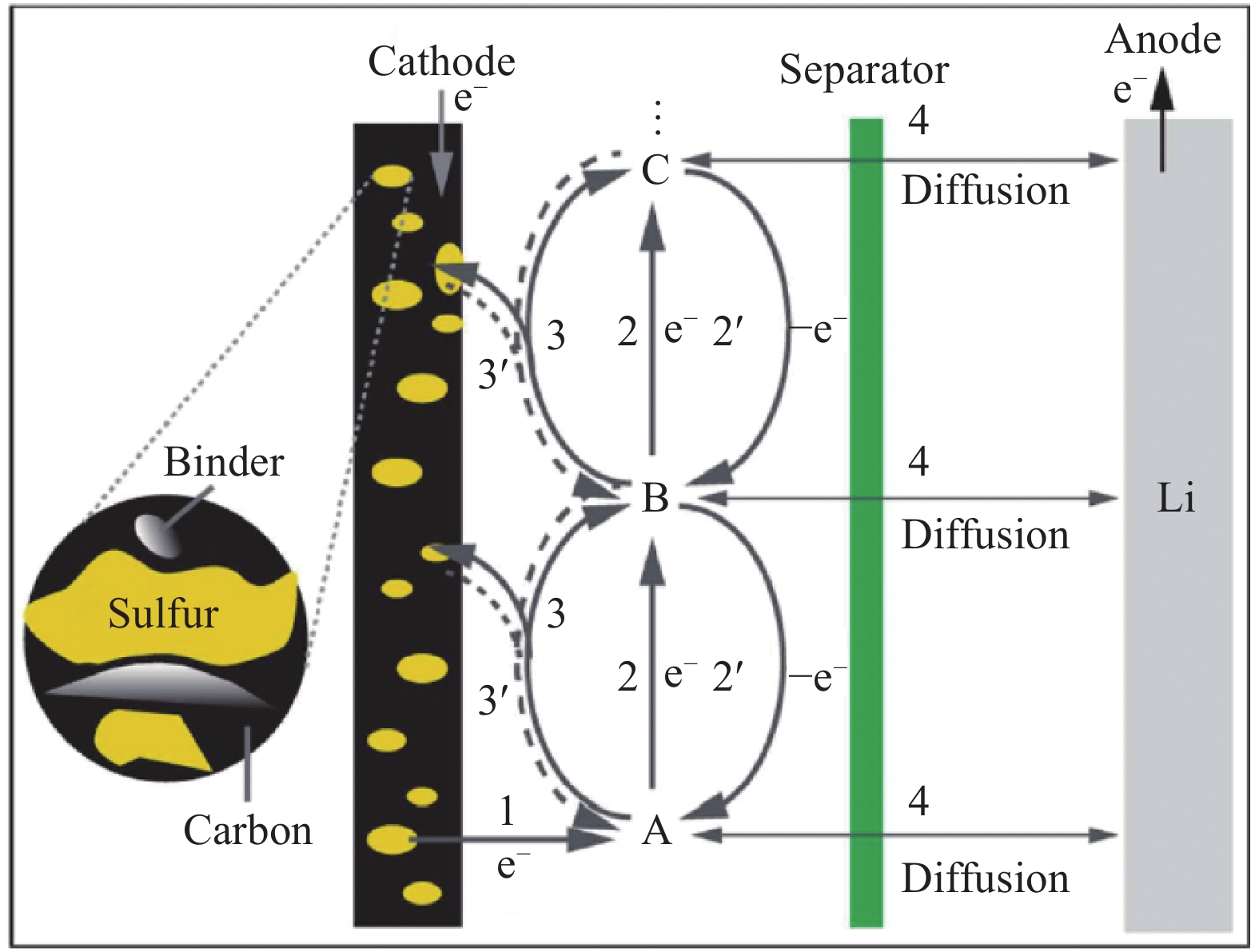

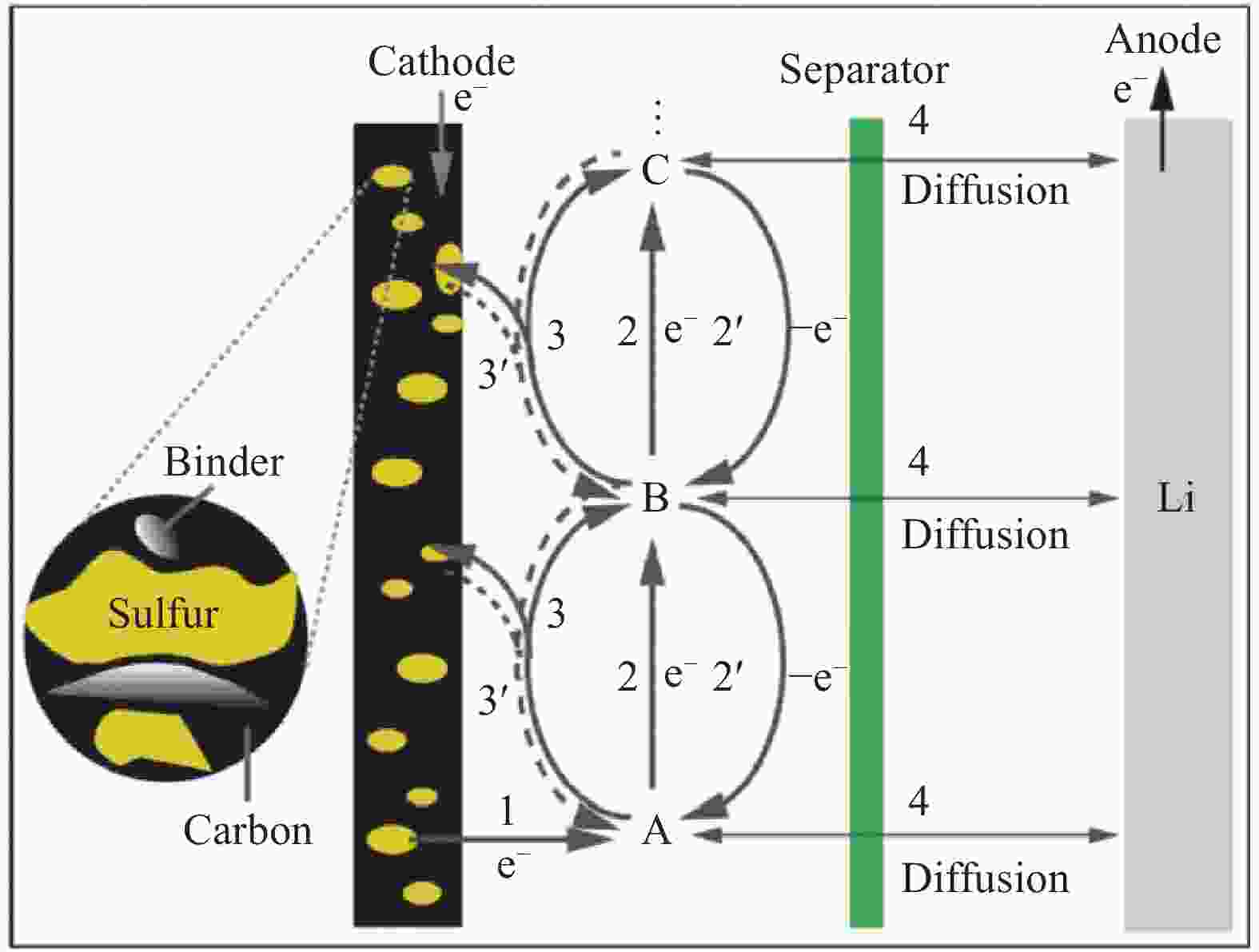

摘要: 在能源危机与环境问题日益凸显的背景下,电化学储能技术得到了迅速发展。在“超越锂”储能领域的竞争者中,锂硫电池(Li-S)因其具有高理论比容量、高质量能量密度并且环境友好、价格低廉等优点,成为最有前途的新储能技术。但是,锂硫电池的发展仍存在一些瓶颈问题需要解决,例如正极材料导电性能差、多硫化物穿梭效应及在充放电过程中电极体积膨胀等。作为锂硫电池的关键组成部分,电极和隔膜材料的设计和制备对解决这些问题及电池整体性能提升起到了重要的作用。金属有机骨架(MOFs)及衍生的复合材料作为锂硫电池电极或隔膜修饰材料,具有质量轻、电子和离子传导性好、孔道丰富和活性位点均匀分布等优势。此外,这类复合材料还具备形貌和组分可控、来源丰富和孔径可调等特性,从而便于机制研究。本文全面介绍了锂硫电池组成、工作原理并综述了近几年MOFs及衍生复合材料在锂硫电池中的研究进展,重点讨论了其在正极材料和隔膜材料中的应用,并对未来该材料在锂硫电池研究方向上的前景和突破进行了展望。Abstract: Against the background of increasingly prominent energy crisis and environmental problems, electrochemical energy storage technology has been developed rapidly. Among the competitors in the field of “beyond lithium” energy storage, lithium-sulfur batteries (Li-S) have become the most promising new energy storage technology owing to the advantages of high theoretical specific capacity, high mass energy density, environmental friendliness and low cost. However, there are still some bottleneck problems to be solved in the development of lithium-sulfur batteries, such as poor conductivity of cathode materials, polysulfide shuttle effect and electrode volume changes during charge and discharge. As the key components of lithium-sulfur batteries, the design and preparation of electrode and separator materials play the important roles in solving these problems and improving the overall performance of the batteries. Metal-organic frameworks (MOFs) and their derived composite materials exhibit the advantages of light weight, good electron and ion conductivity, abundant channels and uniform distribution of active sites to be used as electrode or separator modification materials for lithium-sulfur battery. In addition, this kind of composite material also possesses the characteristics of controllable morphology and composition, abundant source and adjustable pore size, which are convenient for mechanism research. Herein, we comprehensively introduce the composition, working mechanism and application of lithium-sulfur batteries. Importantly, we also review the research progress of MOFs and derivatives as cathode materials and separator materials in lithium-sulfur batteries in recent years. The prospects of the materials in improving the performance of lithium-sulfur batteries are also prospected.

-

Key words:

- lithium-sulfur batteries /

- metal-organic frameworks /

- composite material /

- cathode /

- separator

-

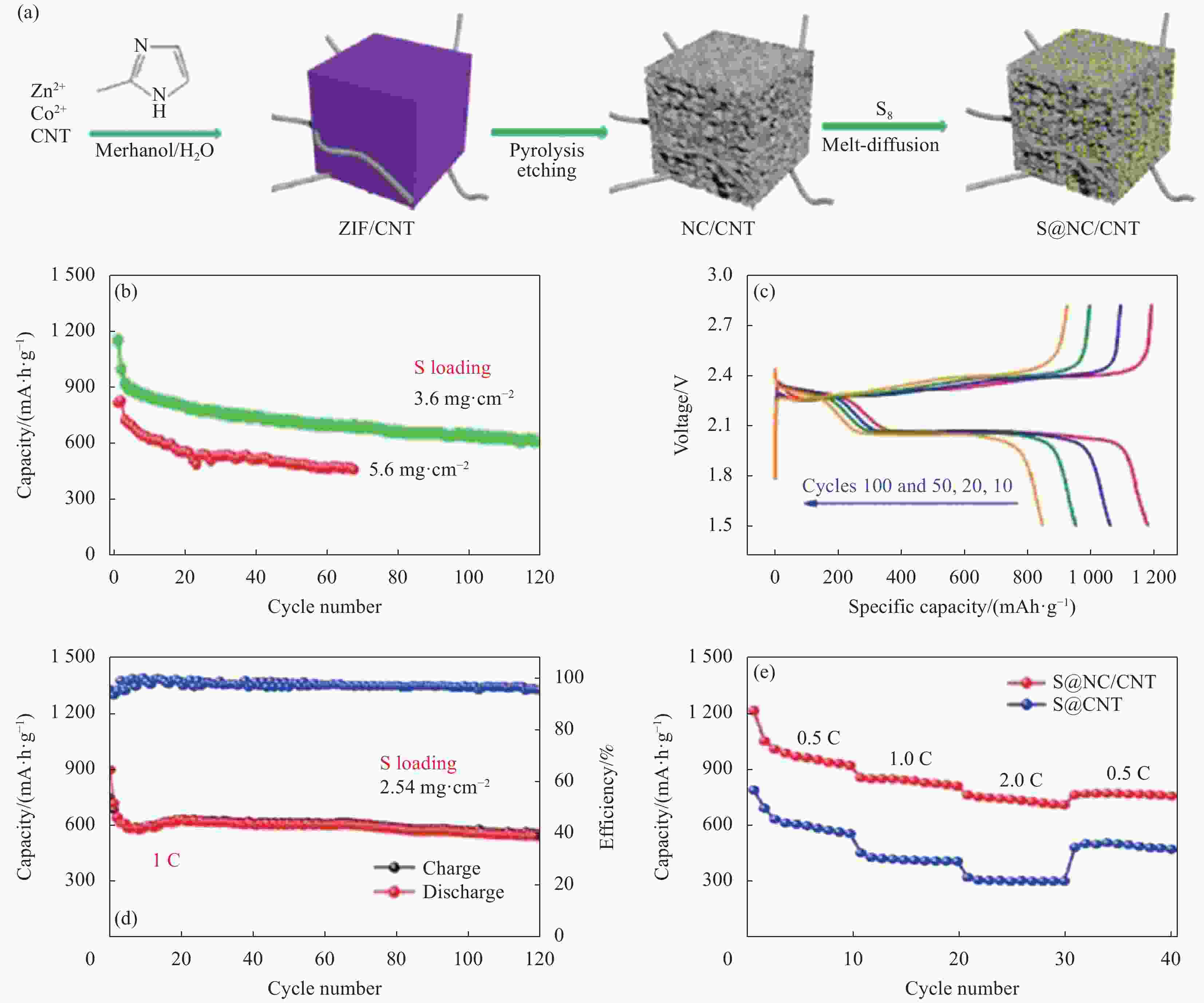

图 4 (a) S@氮掺杂碳(NC)/碳纳米管(CNT)复合材料制备过程示意图;(b) S@NC/CNT在0.5 C电流不同载硫量下的充放电性能;(c) S@NC/CNT在0.5 C电流下充放电曲线;(d) S@NC/CNT在1 C电流下充放电曲线;(e)不同电流下S@NC/CNT和S@NC的倍率性能比较[58]

Figure 4. (a) Schematic illustration of S@nitrogen doped carbon (NC)/carbon nanotube (CNT) preparation process; (b) Performance of S@NC/CNT cathode at different sulfur loading with the current rate of 0.5 C; (c) Charge-discharge profile of S@NC/CNT at the current rate of 0.5 C; (d) Cyclic performance of S@NC/CNT at 1 C; (e) Rate capability of S@NC/CNT and S@NC[58]

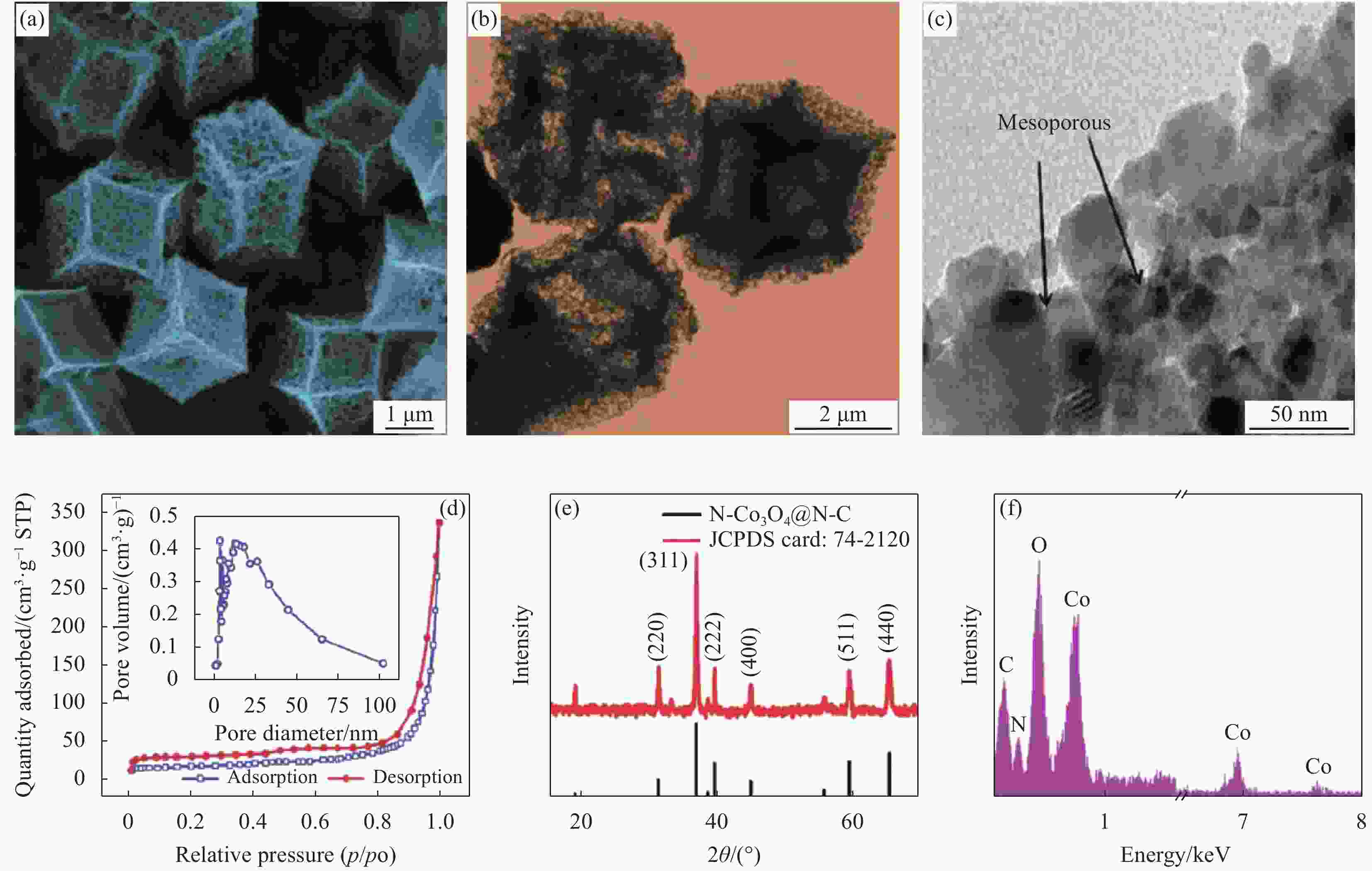

图 5 N-Co3O4@N-C的结构表征((a) SEM图像;(b) TEM图像;(c) HRTEM图像;(d) N2吸-脱附等温曲线;(e) XRD图谱;(f) EDS元素分布)[59]

Figure 5. Structure characterization of high sulfur carrier material N-Co3O4@N-C ((a) SEM image; (b) TEM image; (c) HRTEM image; (d) N2 adsorption-desorption isotherm curves; (e) XRD patterns; (f) EDS spectrum mapping)[59]

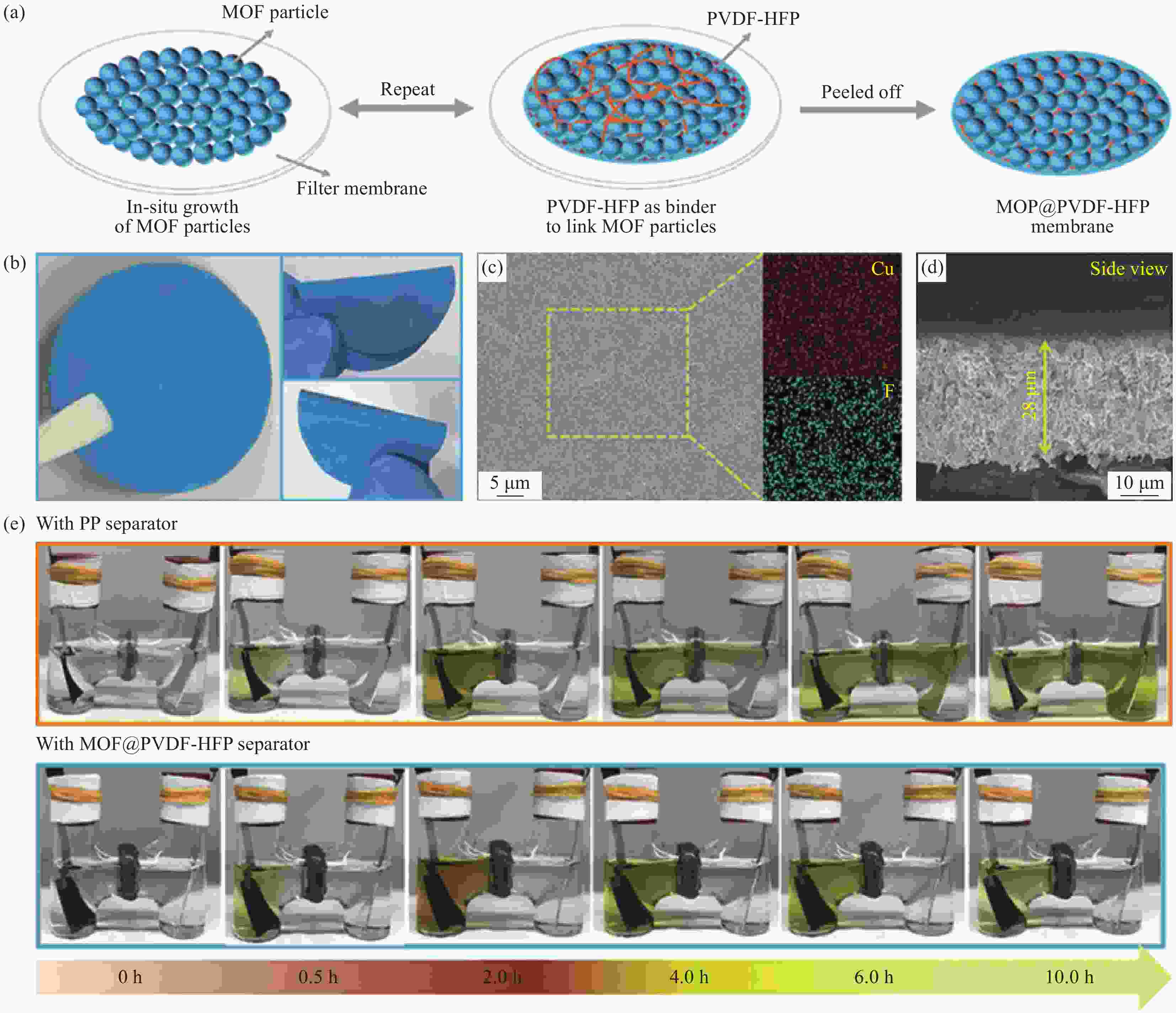

图 6 柔性MOF@PVDF-HFP隔膜((a)制备示意图;(b)光学照片;(c)俯视电镜图片及Cu、F元素分布;(d)侧视电镜图片;(e)放电过程中不同隔膜在可见H型Li-S电池中的光学图像)[68]

Figure 6. Flexible MOF@PVDF-HFP separator ((a) Schematic illustration; (b) Digital photos; (c) Top-view FE-SEM image with the corresponding elemental maps of Cu and F within the squared area; (d) Side-view FE-SEM image; (e) Optical images of visible H-type Li-S batteries with different separators during a discharging process)[68]

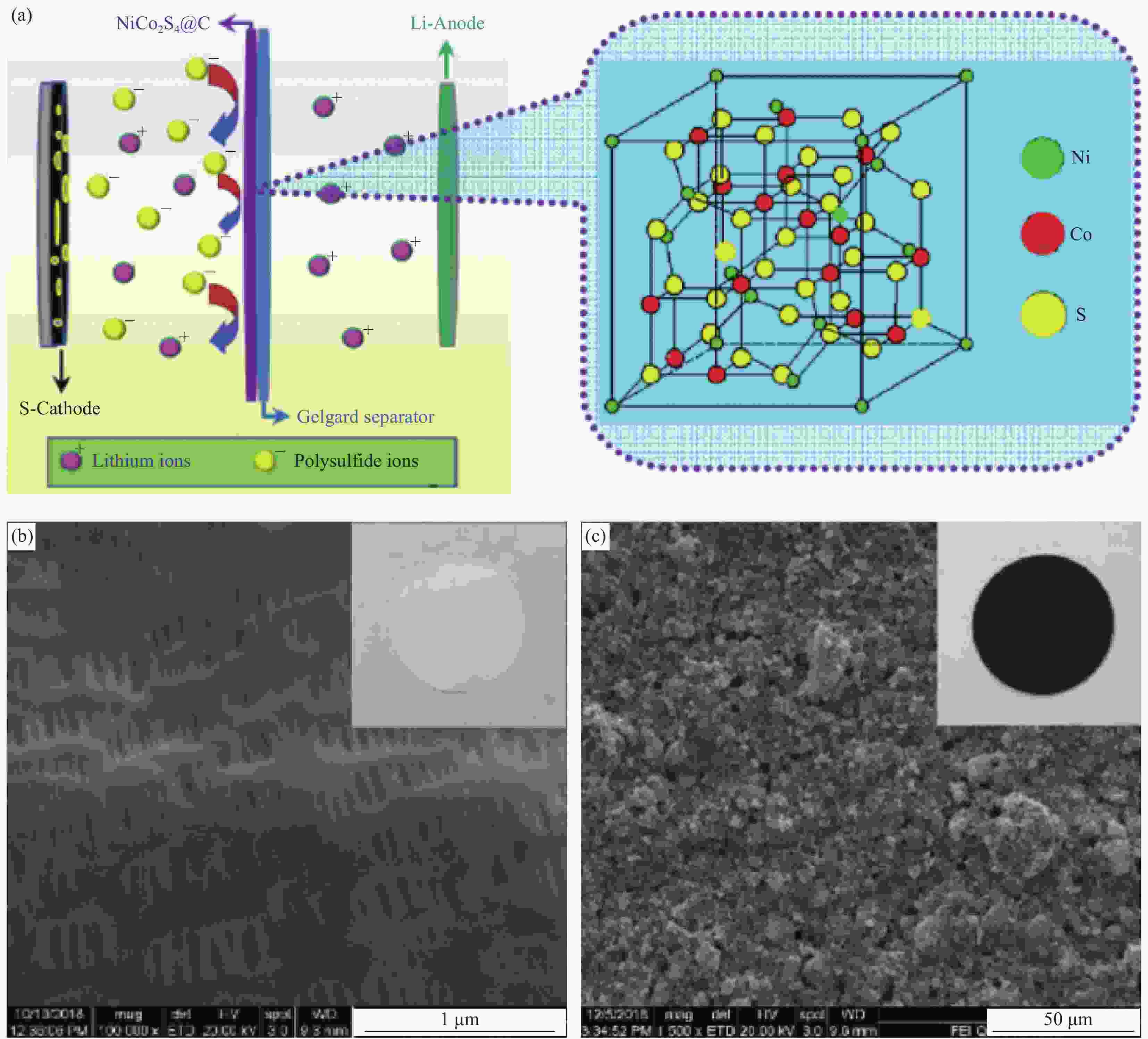

图 8 (a) NiCo2S4@C修饰的锂硫电池隔膜示意图;(b)传统Celgard隔膜表面SEM图像及插图对应光学照片;(c) NiCo2S4@C修饰的锂硫电池隔膜表面SEM图像及插图对应光学照片[73]

Figure 8. (a) Schematic configuration of Li-S battery with NiCo2S4@C-modified separator; (b) SEM image of traditional Celgard separator surface, and the inset corresponds to its optical photograph; (c) SEM image of NiCo2S4@C-modified separator surface, and the inset is its corresponding optical photograph[73]

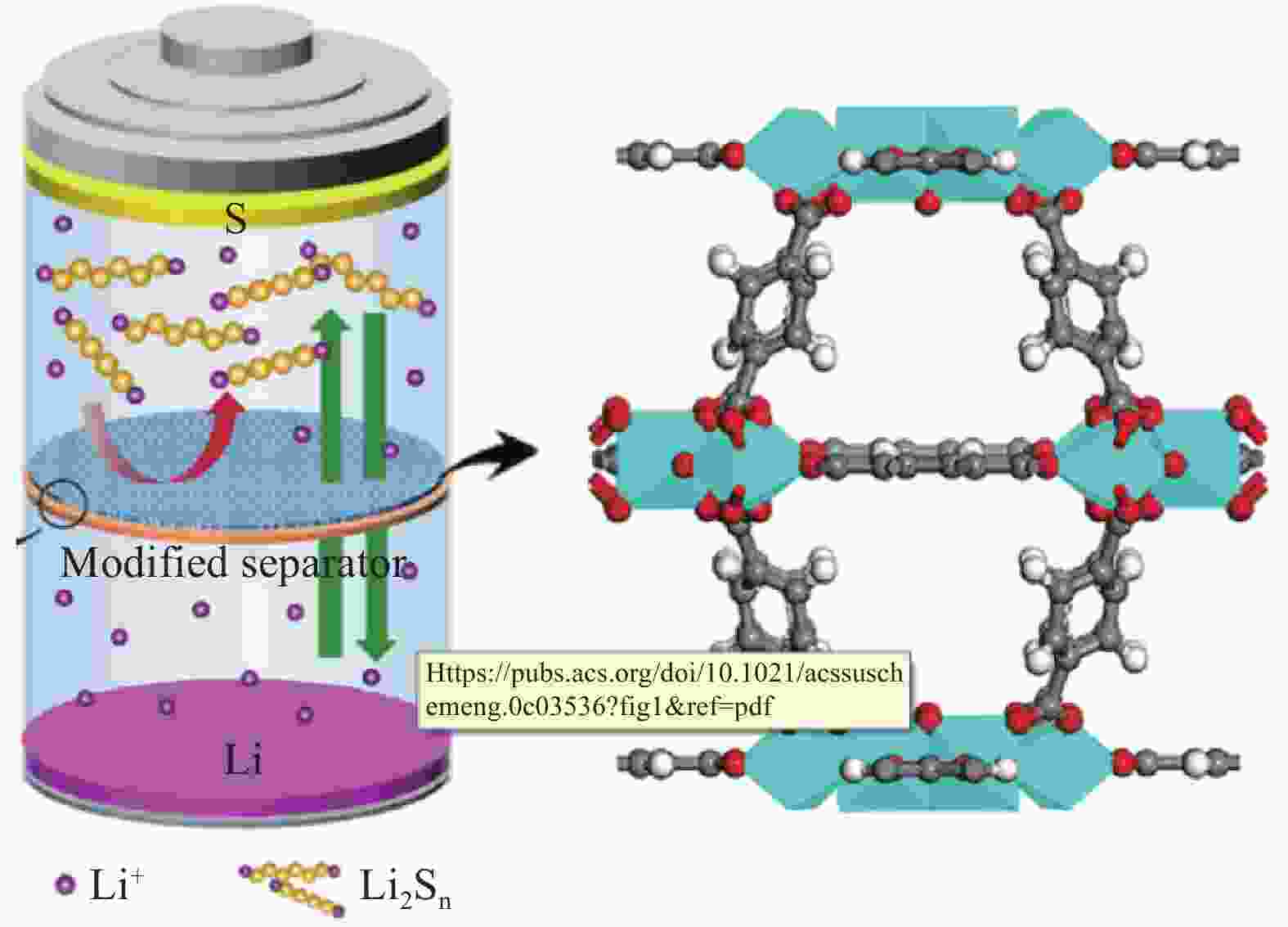

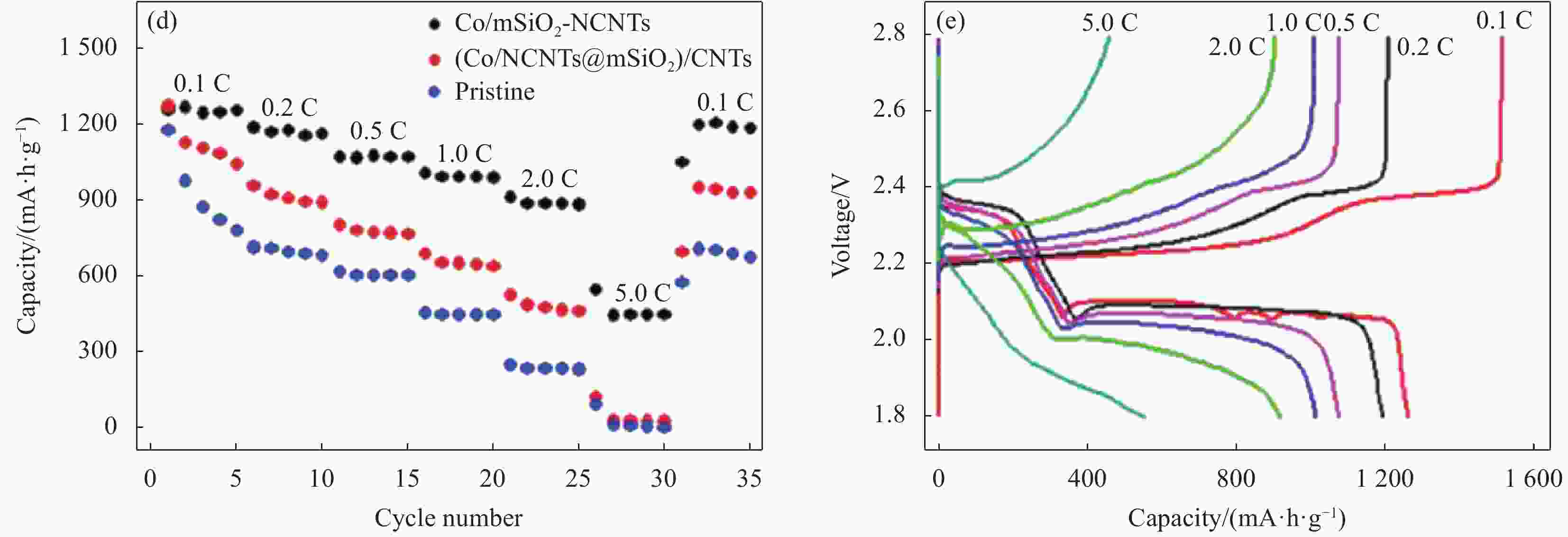

图 9 (a) Co/mSiO2-NCNTs修饰的锂硫电池隔膜示意图;传统隔膜、(Co/NCNTs@mSiO2)/CNTs修饰隔膜和Co/mSiO2-NCNTs修饰隔膜电化学性能比较:(b)在0.1 C电流下的初始充放电曲线;(c)在0.1 C电流下循环性能;(d)不同电流密度下的倍率性能;(e) Co/mSiO2-NCNTs修饰隔膜在不同电流密度下的充放电曲线[76]

Figure 9. (a) Schematic illustration of Co/mSiO2-NCNTs-Coated Separator; Electrochemical properties of pristine separator, (Co/NCNTs@mSiO2)/CNTs-coated separator and Co/mSiO2-NCNTs-coated separator: (b) Initial discharge/charge curves at 0.1 C; (c) cycling performances at 0.1 C; (d) Rate performances at different current densities; (e) Discharge/charge curves of Co/mSiO2-NCNTs-coated separator at different current densities[76]

表 1 一些金属有机骨架(MOFs)及衍生复合材料作为锂硫电池正极材料的应用

Table 1. Application of some metal-organic frameworks (MOFs) and derivative composite materials as cathode for lithium-sulfur batteries

Sample MOFs Sulfur loading

percentage/%Reversible

capacity/(mA·h·g−1)Current

density/CCycle

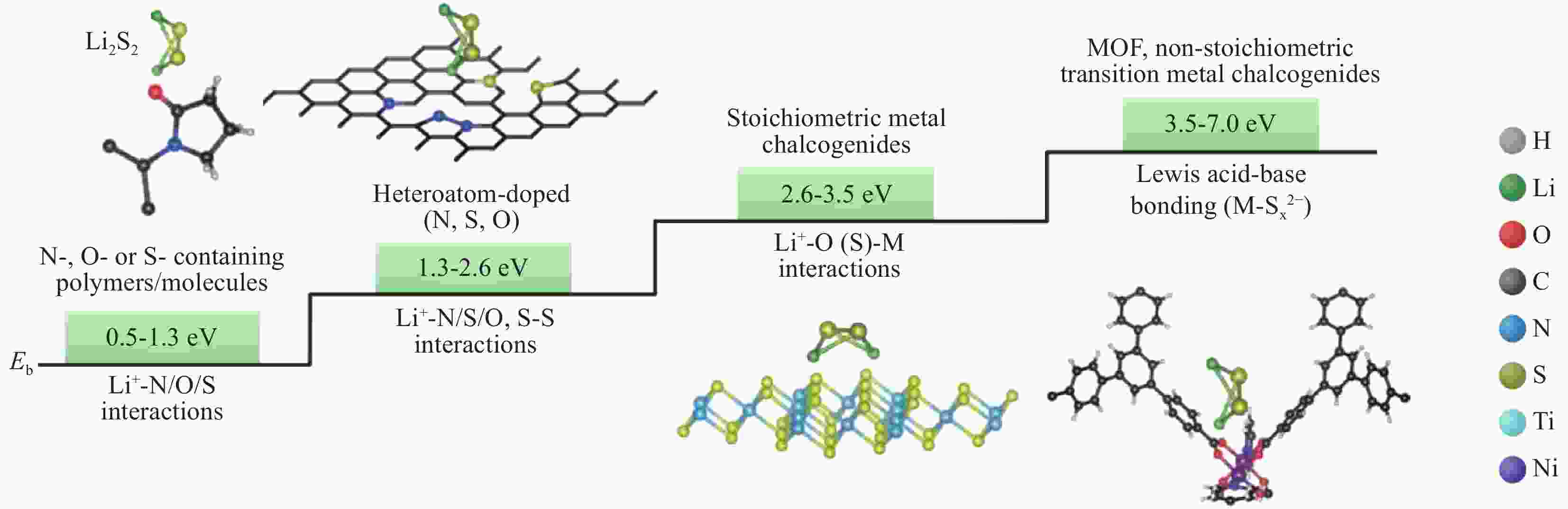

numberVoltage vs.

Li/Li+/VRefs. MOFs as cathode MIL-100(Cr)/S@155 MIL-100(Cr) 48 — — — 1.0-3.0 49 S/ZIF-8 ZIF-8 30 710 1.0 300 1.8-2.8 50 Ni-MOF/S@155 Ni-MOF 82 689 0.1 100 1.5-3.0 51 NU-1000-AQ NU-1000 45 693 0.5 100 1.6-2.9 52 MOFs derived composite

materials as cathodeHPCN–S MOF-5 60 730 0.5 50 1.2-3.0 56 Co@N−C ZIF-67 93.6 1100 0.5 850 1.7-2.7 57 S-NPC/G ZIF-8/67 50 1025 0.1 300 1.7-2.8 58 S@NC/CNT ZIF-8/67 89 1141 0.5 120 1.5-2.8 53 N–Co3O4@N–C/rGO ZIF-67 — 611 2.0 1000 1.5-3.0 59 Mo2C–C NOs@S NENU-5 NOs 80 807 0.5 600 1.7-2.8 60 Fe3O4@C MIL-53 — 760 1.0 300 1.5-2.8 61 Cr2O3@C MIL-101(Cr) — 900 0.1 100 1.8-2.8 62 表 2 一些MOFs及衍生复合材料作为锂硫电池隔膜材料的应用

Table 2. Application of some MOFs and derivative composite materials as separator for lithium-sulfur batteries

Sample MOFs Reversible

capacity/(mA·h·g−1)Current

density/CCycle

numberVoltage vs.

Li/Li+/VRefs. MOFs as separator ZIF@T-PVDF ZIF-8 1 673 1 500 1.5-3.0 68 UiO-66-NH2@SiO2 UiO-66 910 0.1 100 1.6-3.0 69 Ce-MOF-2/CNT Ce-MOF 993.5 0.1 200 1.6-2.9 70 MIL-125(Ti)-modified PP/PE MIL-125(Ti) 612 2 200 1.7-2.7 71 ZIF-8@TBAC-PVDF ZIF-8 1324.2 2 700 1.5-3.0 72 MOFs derivative composite materials as separator NiCO2S4@C NieCo-PTA MOF 700 1 200 1.6-2.8 73 ZPC ZIF-8 907.1 0.1 50 1.5-3.0 74 Co9S8–Celgard ZIF-67 530 1 1000 1.8-2.8 75 ZIF-67@mSiO2 ZIF-67 552 5 250 1.5-3.0 76 -

[1] KONG L, ZHONG M, SHUANG W, et al. Electrochemically active sites inside crystalline porous materials for energy storage and conversion[J]. Chemical Society Reviews,2020,49(8):2378-2407. doi: 10.1039/C9CS00880B [2] LI X, LIANG J, YANG X, et al. Progress and perspectives on halide lithium conductors for all-solid-state lithium batteries[J]. Energy & Environmental Science,2020,13(5):1429-1461. doi: 10.1039/C9EE03828K [3] CHEN Y, JI S, ZHAO S, et al. Enhanced oxygen reduction with single-atomic-site iron catalysts for a zinc-air battery and hydrogen-air fuel cell[J]. Nature Communications,2018,9(1):5422-5433. doi: 10.1038/s41467-018-07850-2 [4] 黄雅盼, 孙晓刚, 王杰, 等. 羟基化多壁碳纳米管掺杂抑制锂硫电池的穿梭效应[J]. 复合材料学报, 2019, 36(5):1335-1341.HUANG Yapan, SUN Xiaogang, WANG Jie, et al. Inhibiting shuttle effect of lithium sulfur batteries by introducing hydroxylated multi-walled carbon nanotube[J]. Acta Materiae Compositae Sinica,2019,36(5):1335-1341(in Chinese). [5] YANG X, LUO J, SUN X. Towards high-performance solid-state Li-S batteries: From fundamental understanding to engineering design[J]. Chemical Society Reviews,2020,49(7):2140-2195. doi: 10.1039/C9CS00635D [6] HE J, MANTHIRAM A. A review on the status and challenges of electrocatalysts in lithium-sulfur batteries[J]. Energy Storage Materials,2019,20:55-70. doi: 10.1016/j.ensm.2019.04.038 [7] 杨果, 马壮, 杨绍斌, 等. 锂硫电池硫基碳正极材料的研究进展[J]. 化工进展, 2017, 36:311-318.YANG Guo, MA Zhuang, YANG Shaobin, et al. Research progress of sulfur-based carbon cathode materials in lithium-sulfur batteries[J]. Chemical Industry and Engineering Progress,2017,36:311-318(in Chinese). [8] LIU J, CHEN H, CHEN W, et al. New insight into the “Shuttle Mechanism” of rechargeable lithium-sulfur batteries[J]. ChemElectroChem,2019,6(10):2782-2787. doi: 10.1002/celc.201900420 [9] HUANG Q, CHEN M, SU Z, et al. Rational cooperativity of nanospace confinement and rapid catalysis via hollow carbon nanospheres@Nb-based inorganics for high-rate Li-S batteries[J]. Chemical Engineering Journal,2021,411:128504-128512. doi: 10.1016/j.cej.2021.128504 [10] WANG K, JU S, GAO Q, et al. Porous sulfurized poly(acrylonitrile) nanofiber as a long-life and high-capacity cathode for lithium-sulfur batteries[J]. Journal of Alloys and Compounds,2021,860:158445-158452. doi: 10.1016/j.jallcom.2020.158445 [11] SONG Y, SUN Z, FAN Z, et al. Rational design of porous nitrogen-doped Ti3C2 MXene as a multifunctional electrocatalyst for Li-S chemistry[J]. Nano Energy,2020,70:104555-104564. doi: 10.1016/j.nanoen.2020.104555 [12] LI N, XIE Y, PENG S, et al. Ultra-lightweight Ti3C2T MXene modified separator for Li-S batteries: Thickness regulation enabled polysulfide inhibition and lithium ion transportation[J]. Journal of Energy Chemistry,2020,42:116-125. doi: 10.1016/j.jechem.2019.06.014 [13] CHEN Y, ZHANG W, ZHOU D, et al. Co-Fe mixed metal phosphide nanocubes with highly interconnected-pore architecture as an efficient polysulfide mediator for lithium-sulfur batteries[J]. ACS Nano,2019,13(4):4731-4741. doi: 10.1021/acsnano.9b01079 [14] LI Y, CAI Y, CAI Z, et al. Sulfur-infiltrated yeast-derived nitrogen-rich porous carbon microspheres@reduced graphene cathode for high-performance lithium-sulfur batteries[J]. Electrochimica Acta,2018,285:317-325. doi: 10.1016/j.electacta.2018.07.222 [15] HSIEH Y Y, ZHANG L, DEARMOND D, et al. Integrated graphene-sulfur cathode and separator with plasma enhancement for Li-S batteries[J]. Carbon,2018,139:1093-1103. doi: 10.1016/j.carbon.2018.08.025 [16] HYUN J, LEE P C, JUNG M J, et al. A simple preparation of polyaniline-coated sulfur composites for use as cathodes in Li-S batteries[J]. Electrochemistry,2016,84(11):836-841. doi: 10.5796/electrochemistry.84.836 [17] PUTHIRATH A B, BABURAJ A, KATO K, et al. High sulfur content multifunctional conducting polymer composite electrodes for stable Li-S battery[J]. Electrochimica Acta,2019,306:489-497. doi: 10.1016/j.electacta.2019.03.136 [18] MA G, HUANG F, WEN Z, et al. Enhanced performance of lithium sulfur batteries with conductive polymer modified separators[J]. Journal of Materials Chemistry A,2016,4(43):16968-16974. doi: 10.1039/C6TA07198H [19] SHI Q X, YANG C Y, PEI H J, et al. Layer-by-layer self-assembled covalent triazine framework/electrical conductive polymer functional separator for Li-S battery[J]. Chemical Engineering Journal,2021,404:127044-127055. doi: 10.1016/j.cej.2020.127044 [20] LI B, SU Q, YU L, et al. Tuning the band structure of MoS2 via Co9S8@MoS2 core-shell structure to boost catalytic activity for lithium-sulfur batteries[J]. ACS Nano,2020,14(12):17285-17294. doi: 10.1021/acsnano.0c07332 [21] KIM P J H, SEO J, FU K, et al. Synergistic protective effect of a BN-carbon separator for highly stable lithium sulfur batteries[J]. NPG Asia Materials,2017,9:375-383. doi: 10.1038/am.2017.51 [22] YANG X, QIAN X, JIN L, et al. Separator modified with Ketjenblack-In2O3 nanoparticles for long cycle-life lithium-sulfur batteries[J]. Journal of Solid State Electrochemistry,2019,23:645-656. doi: 10.1007/s10008-018-4141-6 [23] YANG X, YU Y, YAN N, et al. 1-D oriented cross-linking hierarchical porous carbon fibers as a sulfur immobilizer for high performance lithium-sulfur batteries[J]. Journal of Materials Chemistry A Materials for Energy,2016,4(16):5965-5972. doi: 10.1039/C6TA01060A [24] LI Y, WANG L, GAO B, et al. Hierarchical porous carbon materials derived from self-template bamboo leaves for lithium-sulfur batteries[J]. Electrochimica Acta,2017,229:352-360. doi: 10.1016/j.electacta.2017.01.166 [25] LI Z, HAN Y, WEI J, et al. Suppressing shuttle effect using janus cation exchange membrane for high-performance lithium-sulfur battery separator[J]. ACS Applied Materials & Interfaces,2017,9(51):44776-44781. doi: 10.1021/acsami.7b13047 [26] QIU W, LI J, ZHANG Y, et al. Carbon nanotubes assembled on porous TiO2 matrix doped with Co3O4 as sulfur host for lithium-sulfur batteries[J]. Nanotechnology,2021,32(7):75403-75410. doi: 10.1088/1361-6528/abc451 [27] AGOSTINI M, MATIC A. Designing highly conductive functional groups improving guest-host interactions in Li/S batteries[J]. Small,2020,16(2):1905585-1905593. doi: 10.1002/smll.201905585 [28] LIU M, ZHOU D, JIANG H R, et al. A highly-safe lithium-ion sulfur polymer battery with SnO2 anode and acrylate-based gel polymer electrolyte[J]. Nano Energy,2016,28:97-105. doi: 10.1016/j.nanoen.2016.08.033 [29] 樊潮江, 燕映霖, 陈利萍, 等. 过渡金属硫化物改性锂硫电池正极材料[J]. 化学进展, 2019, 31(8):1166-1176.FAN Chaojiang, YAN Yinglin, CHEN Liping, et al. Transition-metal sulfides modified cathode of Li-S batteries[J]. Progress in Chemistry,2019,31(8):1166-1176(in Chinese). [30] LI N, HE X, CHEN K, et al. Confine sulfur in urchin-like nitrogen doped carbon particles for lithium-sulfur batteries[J]. Materials Letters,2018,228:195-198. doi: 10.1016/j.matlet.2018.06.017 [31] FAN W, YUAN S, WANG W, et al. Optimizing multivariate metal-organic frameworks for efficient C2H2/CO2 separation[J]. Journal of the American Chemical Society,2020,142(19):8728-8737. doi: 10.1021/jacs.0c00805 [32] PANDEY A, DHAS N, DESHMUKH P, et al. Heterogeneous surface architectured metal-organic frameworks for cancer therapy, imaging, and biosensing: A state-of-the-art review[J]. Coordination Chemistry Reviews,2020,409:213212-213263. doi: 10.1016/j.ccr.2020.213212 [33] WANG D, WU H, LIM W Q, et al. A mesoporous nanoenzyme derived from metal-organic frameworks with endogenous oxygen generation to alleviate tumor hypoxia for significantly enhanced photodynamic therapy[J]. Advanced Materials,2019,31(27):1901893-1901901. doi: 10.1002/adma.201901893 [34] LI S, LIU X, CHAI H, et al. Recent advances in the construction and analytical applications of metal-organic frameworks-based nanozymes[J]. TrAC Trends in Analytical Chemistry,2018,105:391-403. doi: 10.1016/j.trac.2018.06.001 [35] ZHOU S, CHEN K, HUANG J, et al. Preparation of heterometallic CoNi-MOFs-modified BiVO4: A steady photoanode for improved performance in photoelectrochemical water splitting[J]. Applied Catalysis B: Environmental,2020,266:118513-118522. doi: 10.1016/j.apcatb.2019.118513 [36] DHAKSHINAMOORTHY A, ASIRI A M, GARCIA H. 2D metal-organic frameworks as multifunctional materials in heterogeneous catalysis and electro/photocatalysis[J]. Advanced Materials,2019,31(41):1900617-1900656. doi: 10.1002/adma.201900617 [37] LIAO Y T, MATSAGAR B M, WU K C W. Metal-organic framework (MOF)-derived effective solid catalysts for valorization of lignocellulosic biomass[J]. ACS Sustainable Chemistry & Engineering,2018,6(11):13628-13643. doi: 10.1021/acssuschemeng.8b03683 [38] RICE A M, MARTIN C R, GALITSKIY V A, et al. Photophysics modulation in photoswitchable metal-organic frameworks[J]. Chemical Reviews,2020,120(16):8790-8813. doi: 10.1021/acs.chemrev.9b00350 [39] LIU P, GAO S, WANG Y, et al. Core-shell CoNi@graphitic carbon decorated on B, N-codoped hollow carbon polyhedrons toward lightweight and high-efficiency microwave attenuation[J]. ACS Applied Materials & Interface,2019,11(28):25624-25635. doi: 10.1021/acsami.9b08525 [40] ZHANG Q, WANG J, KIRILLOV A M, et al. Multifunctional Ln-MOF luminescent probe for efficient sensing of Fe3+, Ce3+, and acetone[J]. ACS Applied Materials & Interface,2018,10(28):23976-23986. doi: 10.1021/acsami.8b06103 [41] WANG H F, CHEN L, PANG H, et al. MOF-derived electrocatalysts for oxygen reduction, oxygen evolution and hydrogen evolution reactions[J]. Chemical Society Reviews,2020,49(5):1414-1448. doi: 10.1039/C9CS00906J [42] ZHENG Y, ZHENG S, XUE H, et al. Metal-organic frameworks for lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2019,7(8):3469-3491. doi: 10.1039/C8TA11075A [43] DU M, LI Q, ZHAO Y, et al. A review of electrochemical energy storage behaviors based on pristine metal-organic frameworks and their composites[J]. Coordination Chemistry Reviews,2020,416:213341-213367. doi: 10.1016/j.ccr.2020.213341 [44] ZHONG Y, XU X, LIU Y, et al. Recent progress in metal-organic frameworks for lithium-sulfur batteries[J]. Polyhedron,2018,155:464-484. doi: 10.1016/j.poly.2018.08.067 [45] PANG Q, LIANG X, KWOK C Y, et al. Advances in lithium-sulfur batteries based on multifunctional cathodes and electrolytes[J]. Nature Energy,2016,1(9):16132-16142. doi: 10.1038/nenergy.2016.132 [46] SHRIVASTAV V, SUNDRIYAL S, GOEL P, et al. Metal-organic frameworks (MOFs) and their composites as electrodes for lithium battery applications: Novel means for alternative energy storage[J]. Coordination Chemistry Reviews,2019,393:48-78. doi: 10.1016/j.ccr.2019.05.006 [47] WU Q, ZHOU X, XU J, et al. Carbon-based derivatives from metal-organic frameworks as cathode hosts for Li-S batteries[J]. Journal of Energy Chemistry,2019,38:94-113. doi: 10.1016/j.jechem.2019.01.005 [48] MAO Y, LI G, GUO Y, et al. Foldable interpenetrated metal-organic frameworks/carbon nanotubes thin film for lithium-sulfur batteries[J]. Nature Communications,2017,8:14628-14635. doi: 10.1038/ncomms14628 [49] DEMIR-CAKAN R, MORCRETTE M, FARID N, et al. Cathode composites for Li-S batteries via the use of oxygenated porous architectures[J]. Journal of the American Chemical Society,2011,133:16154-16160. doi: 10.1021/ja2062659 [50] ZHOU J, LI R, FAN X, et al. Rational design of a metal-organic framework host for sulfur storage in fast, long-cycle Li-S batteries[J]. Energy & Environmental Science,2014,7(8):2715-2724. doi: 10.1039/C4EE01382D [51] ZHENG J, TIAN J, WU D, et al. Lewis acid-base interactions between polysulfides and metal organic framework in lithium sulfur batteries[J]. Nano Letters,2014,14(5):2345-2352. doi: 10.1021/nl404721h [52] LIU B, THOI V S. Improving charge transfer in metal-organic frameworks through open site functionalization and porosity selection for Li-S batteries[J]. Chemistry of Materials,2020,32(19):8450-8459. doi: 10.1021/acs.chemmater.0c02438 [53] LI W, QIAN J, ZHAO T, et al. Boosting high-rate Li-S batteries by an MOF-derived catalytic electrode with a layer-by-layer structure[J]. Advanced Science,2019,6(16):1802362-1802370. doi: 10.1002/advs.201802362 [54] RAZZAQ A A, YUAN X, CHEN Y, et al. Anchoring MOF-derived CoS2 on sulfurized polyacrylonitrile nanofibers for high areal capacity lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2020,8(3):1298-1306. doi: 10.1039/C9TA11390H [55] XU G, DING B, SHEN L, et al. Sulfur embedded in metal organic framework-derived hierarchically porous carbon nanoplates for high performance lithium-sulfur battery[J]. Journal of Materials Chemistry A,2013,1(14):4490-4496. doi: 10.1039/c3ta00004d [56] LI Y, FAN J, ZHANG J, et al. A honeycomb-like Co@N-C composite for ultrahigh sulfur loading Li-S batteries[J]. ACS nano,2017,11(11):11417-11424. doi: 10.1021/acsnano.7b06061 [57] WALLE M D, ZHANG M, ZENG K, et al. MOFs-derived nitrogen-doped carbon interwoven with carbon nanotubes for high sulfur content lithium-sulfur batteries[J]. Applied Surface Science,2019,497:143773-143781. doi: 10.1016/j.apsusc.2019.143773 [58] CHEN K, SUN Z, FANG R, et al. Metal-organic frameworks (MOFs)-derived nitrogen-doped porous carbon anchored on graphene with multifunctional effects for lithium-sulfur batteries[J]. Advanced Functional Materials,2018,28(38):1707592-1707599. doi: 10.1002/adfm.201707592 [59] XU J, ZHANG W, CHEN Y, et al. MOF-derived porous N-Co3O4@N-C nanododecahedra wrapped with reduced graphene oxide as a high capacity cathode for lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2018,6(6):2797-2807. doi: 10.1039/C7TA10272K [60] CHEN G, LI Y, ZHONG W, et al. MOFs-derived porous Mo2C-C nano-octahedrons enable high-performance lithium-sulfur batteries[J]. Energy Storage Materials,2020,25:547-554. doi: 10.1016/j.ensm.2019.09.028 [61] LIU G, FENG K, CUI H, et al. MOF derived in-situ carbon-encapsulated Fe3O4@C to mediate polysulfides redox for ultrastable Lithium-sulfur batteries[J]. Chemical Engineering Journal,2020,381:122652-122660. doi: 10.1016/j.cej.2019.122652 [62] BENITEZ A, MARANGON V, HERNANDEZ-RENTERO C, et al. Porous Cr2O3@C composite derived from metal organic framework in efficient semi-liquid lithium-sulfur battery[J]. Materials Chemistry and Physics,2020,255:123484-123493. doi: 10.1016/j.matchemphys.2020.123484 [63] GAO G K, WANG Y R, ZHU H J, et al. Rapid production of metal-organic frameworks based separators in industrial-level efficiency[J]. Advanced Science,2020,7(24):2002190-2002200. doi: 10.1002/advs.202002190 [64] LI M, WAN Y, HUANG J K, et al. Metal-organic framework-based separators for enhancing Li-S battery stability: Mechanism of mitigating polysulfide diffusion[J]. ACS Energy Letters,2017,2(10):2362-2367. doi: 10.1021/acsenergylett.7b00692 [65] FAN Y, NIU Z, ZHANG F, et al. Suppressing the shuttle effect in lithium-sulfur batteries by a UiO-66-modified polypropylene separator[J]. ACS Omega,2019,4(6):10328-10335. doi: 10.1021/acsomega.9b00884 [66] LEE D H, AHN J H, PARK M S, et al. Metal-organic framework/carbon nanotube-coated polyethylene separator for improving the cycling performance of lithium-sulfur cells[J]. Electrochimica Acta,2018,283:1291-1299. doi: 10.1016/j.electacta.2018.07.031 [67] HE Y, CHANG Z, WU S, et al. Simultaneously inhibiting lithium dendrites growth and polysulfides shuttle by a flexible MOF-based membrane in Li-S batteries[J]. Advanced Energy Materials,2018,8(34):1802130-1802138. doi: 10.1002/aenm.201802130 [68] BAI S, LIU X, ZHU K, et al. Metal-organic framework-based separator for lithium-sulfur batteries[J]. Nature Energy,2016,1(7):16094-16099. doi: 10.1038/nenergy.2016.94 [69] SURIYAKUMAR S, STEPHAN A M, ANGULAKSHMI N, et al. Metal-organic framework@SiO2 as permselective separator for lithium-sulfur batteries[J]. Journal of Materials Chemistry A,2018,6(30):14623-14632. doi: 10.1039/C8TA02259C [70] HONG X J, SONG C L, YANG Y, et al. Cerium based metal-organic frameworks as an efficient separator coating catalyzing the conversion of polysulfides for high performance lithium-sulfur batteries[J]. ACS Nano,2019,13(2):1923-1931. [71] QI C, XU L, WANG J, et al. Titanium-containing metal-organic framework modified separator for advanced lithium-sulfur batteries[J]. ACS Sustainable Chemistry and Engineering,2020,8(34):12968-12975. doi: 10.1021/acssuschemeng.0c03536 [72] FENG Y, WANG G, KANG W, et al. Taming polysulfides and facilitating lithium-ion migration: Novel electrospinning MOFs@PVDF-based composite separator with spiderweb-like structure for Li-S batteries[J]. Electrochimica Acta,2021,365:137344-137351. doi: 10.1016/j.electacta.2020.137344 [73] LI B, PAN Y, LUO B, et al. MOF-derived NiCo2S4@C as a separator modification material for high-performance lithium-sulfur batteries[J]. Electrochimica Acta,2020,344:135811-135820. doi: 10.1016/j.electacta.2020.135811 [74] 阮艳莉, 查煜澄, 张萌. 有机金属框架衍生物的制备及其在锂硫电池隔膜改性中的应用[J]. 天津工业大学学报, 2020, 39(5):56-60. doi: 10.3969/j.issn.1671-024x.2020.05.009RUAN Yanli, ZHA Yucheng, ZHANG Meng. Preparation of organometallic framework derivatives and its application in separator modification of lithium-sulfur batteries[J]. Journal of Tiangong University,2020,39(5):56-60(in Chinese). doi: 10.3969/j.issn.1671-024x.2020.05.009 [75] HE J, CHEN Y, MANTHIRAM A. Vertical Co9S8 hollow nanowall arrays grown on a Celgard separator as a multifunctional polysulfide barrier for high-performance Li-S batteries[J]. Energy & Environmental Science,2018,11(9):2560-2568. doi: 10.1039/C8EE00893K [76] FANG D, WANG Y, LIU X, et al. Spider-Web-inspired nanocomposite-modified separator: structural and chemical cooperativity inhibiting the shuttle effect in Li-S batteries[J]. ACS Nano,2019,13(2):1563-1573. -

下载:

下载: