Experimental study on picosecond laser cutting AFRP composites

-

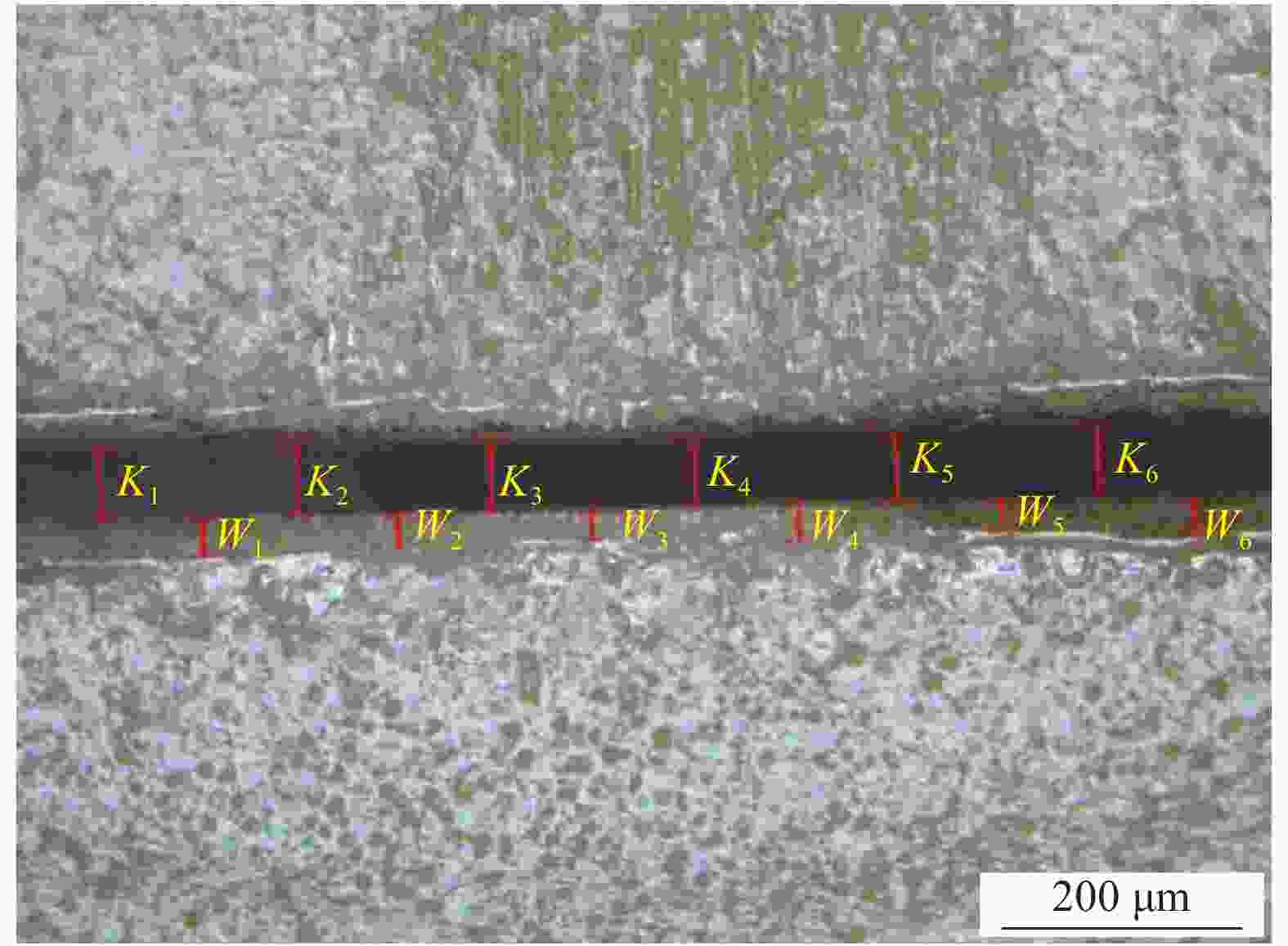

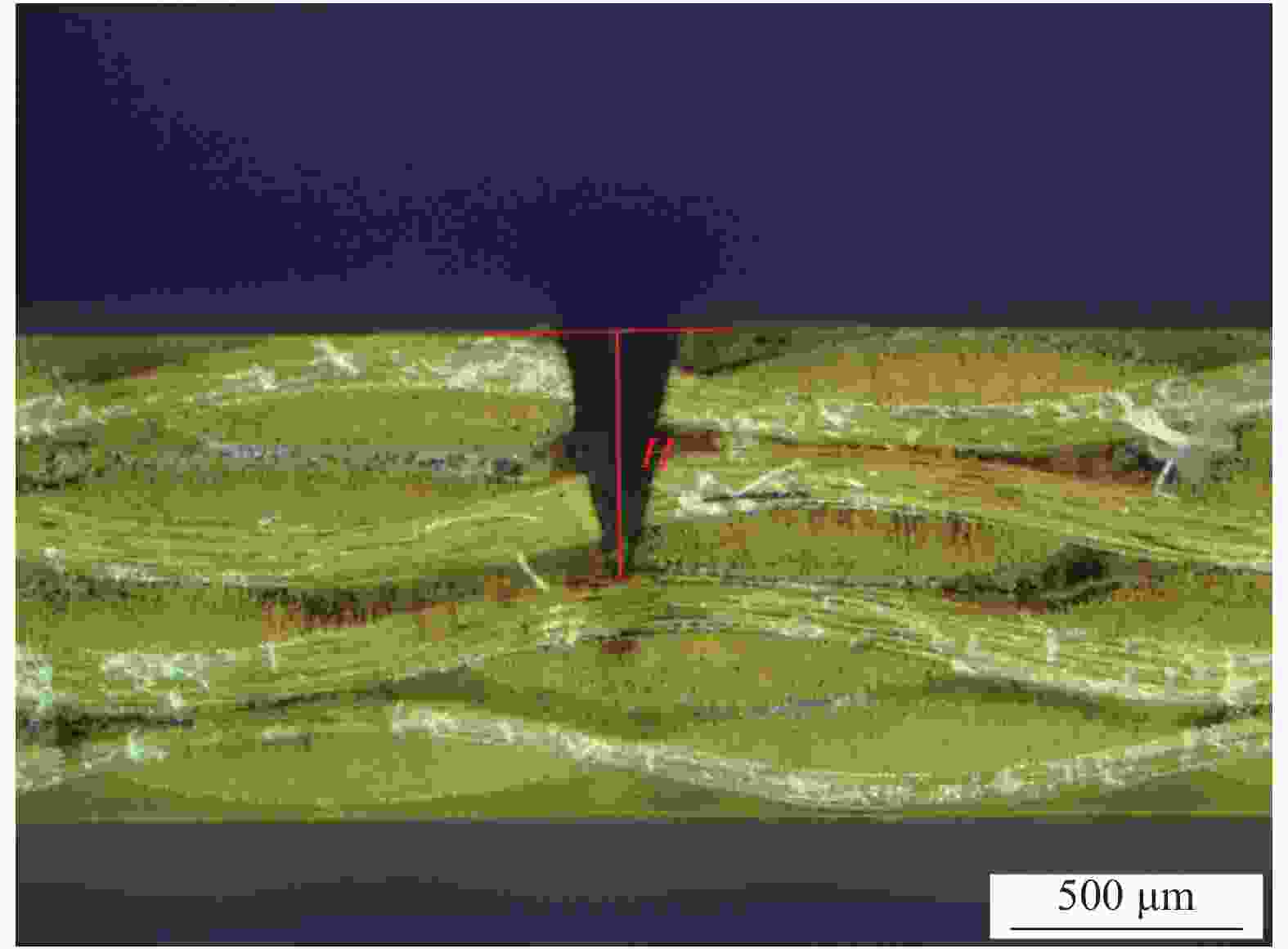

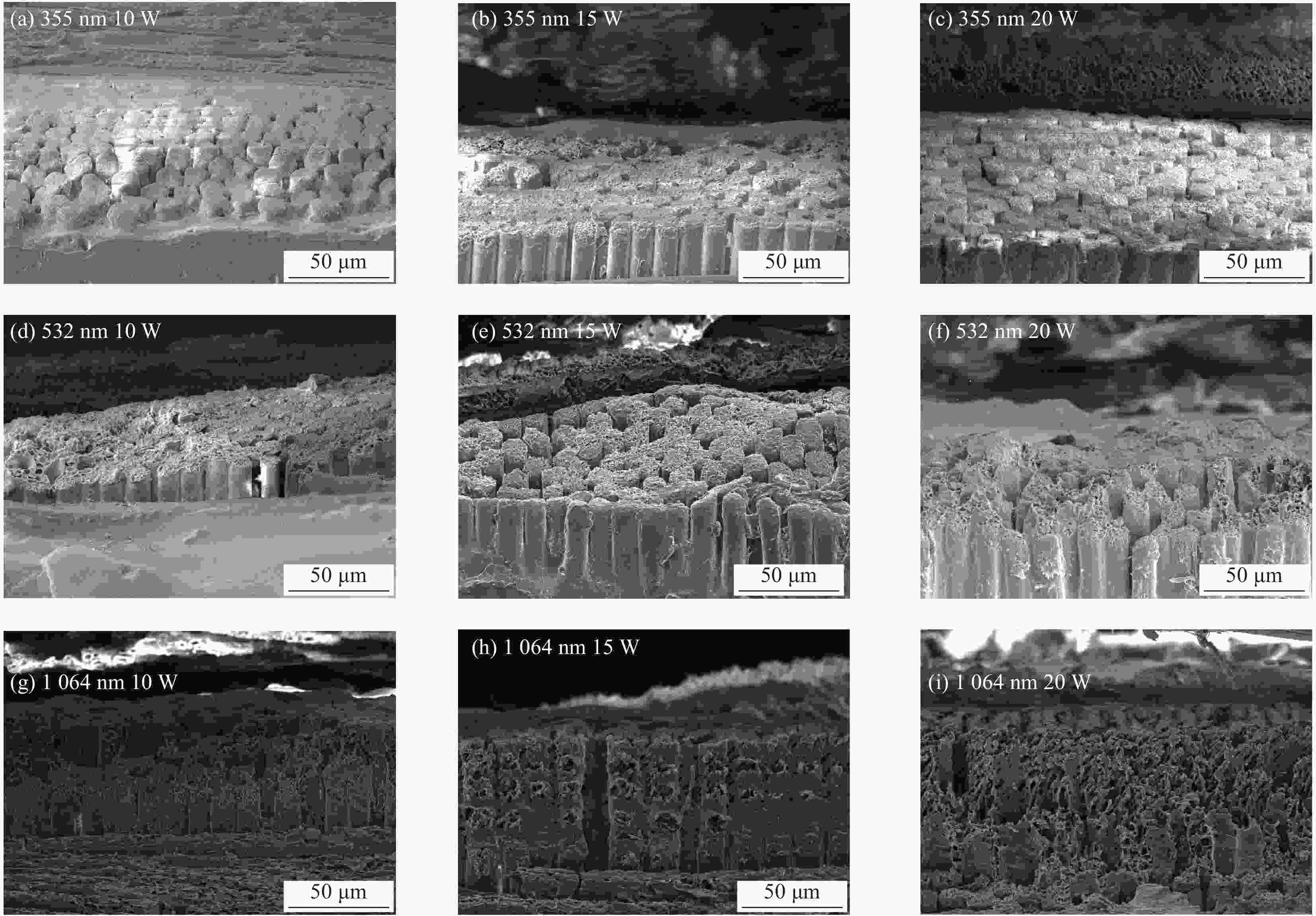

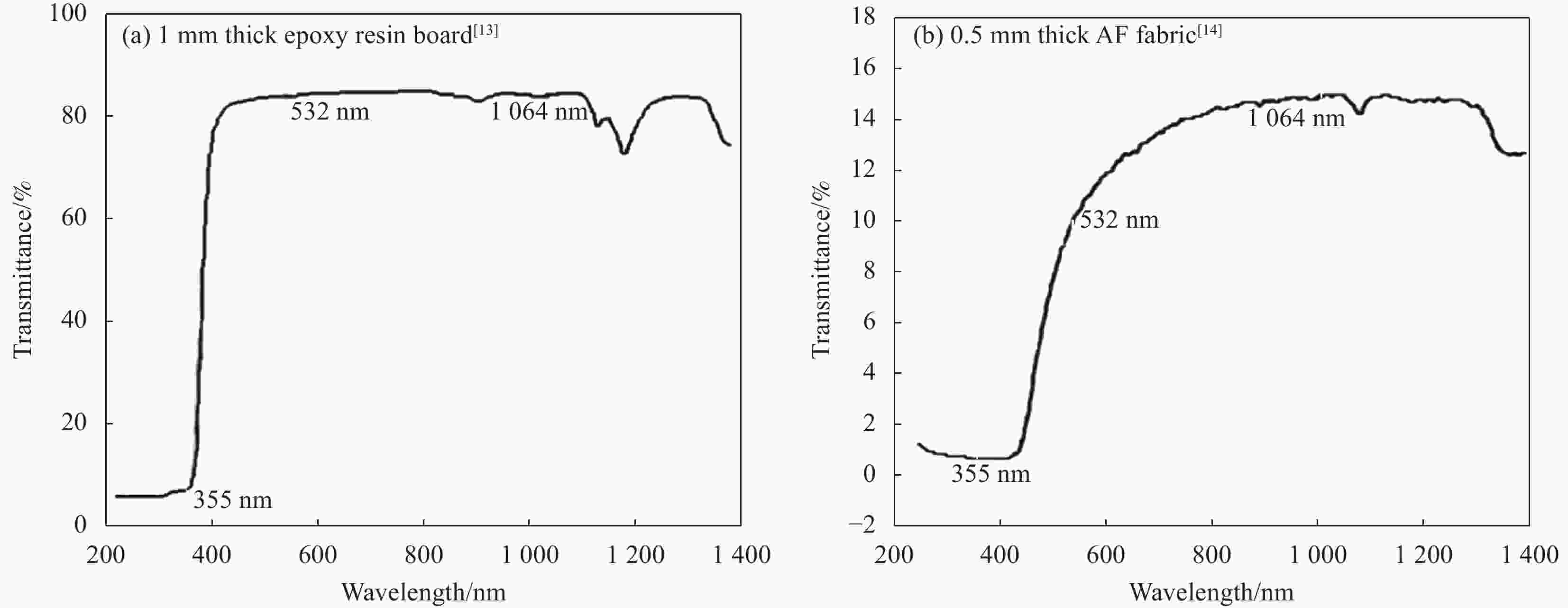

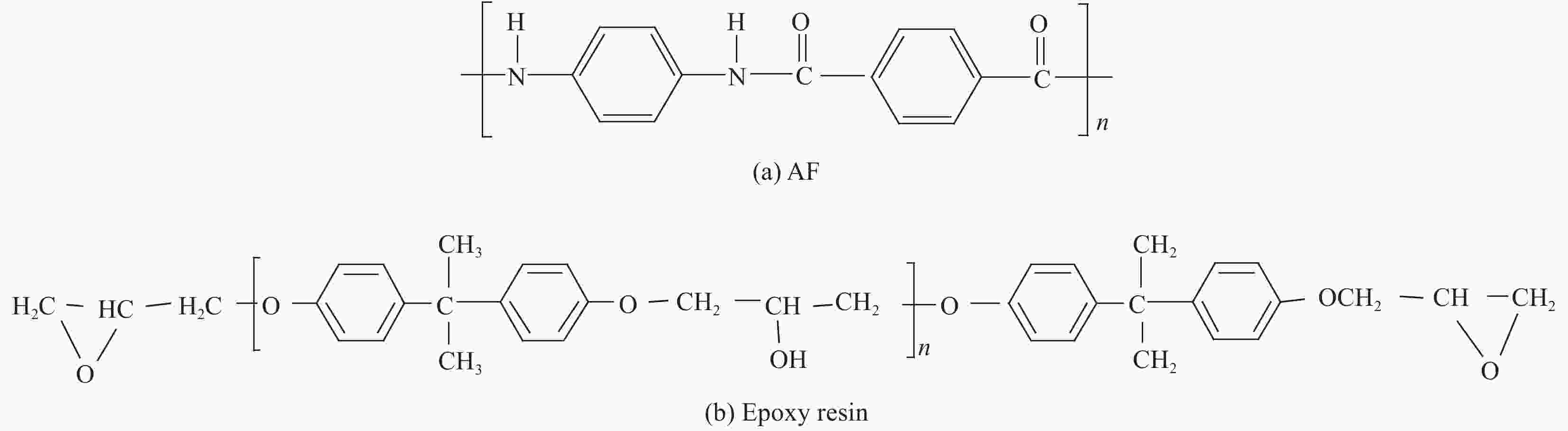

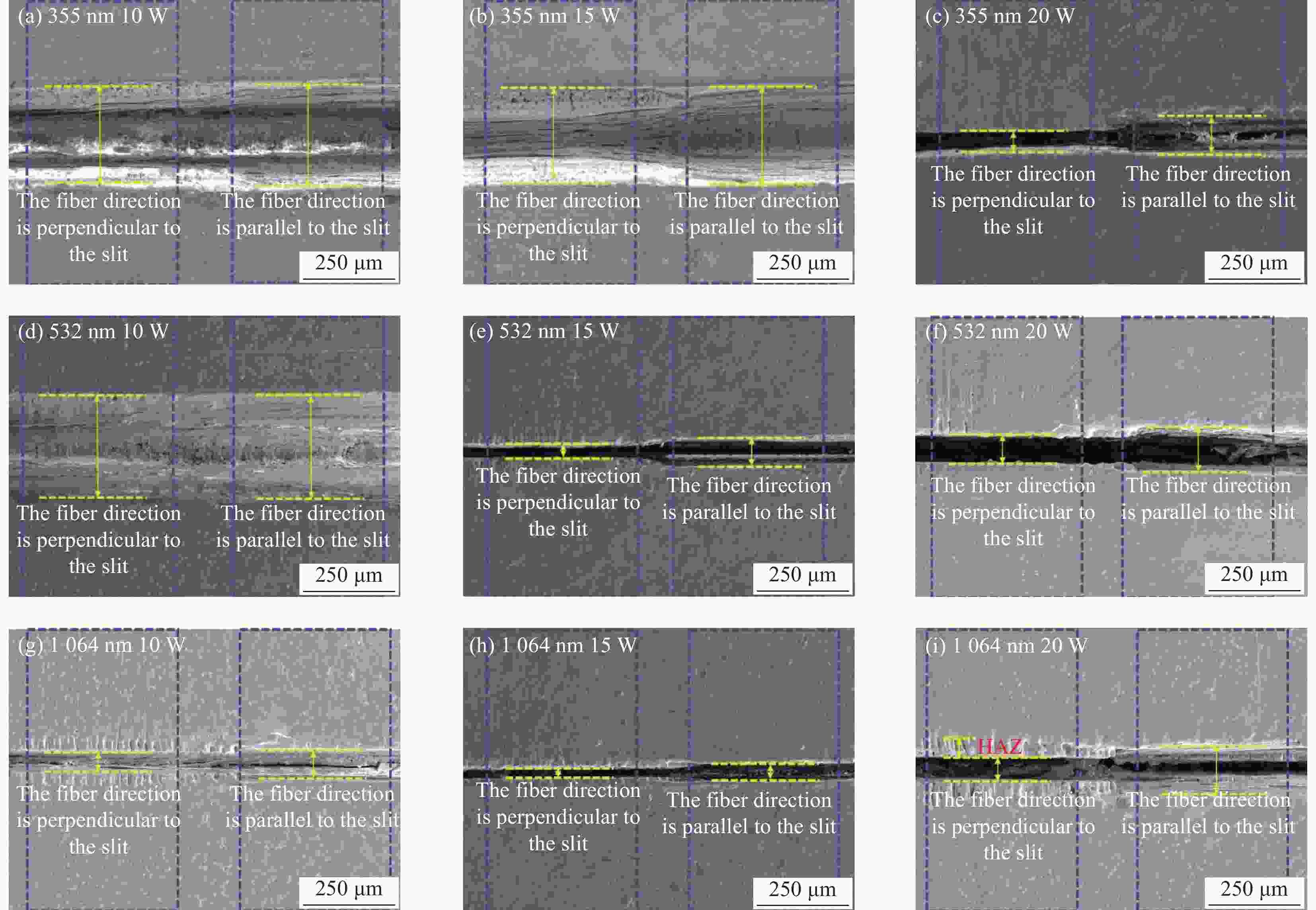

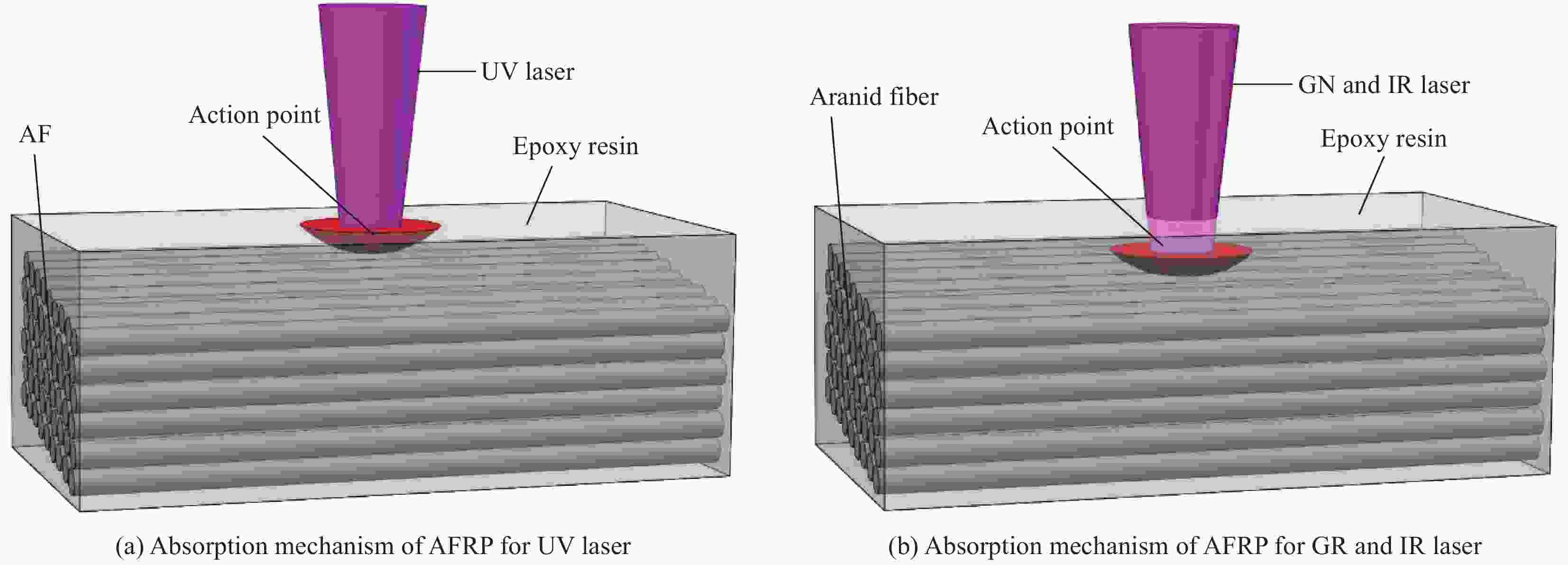

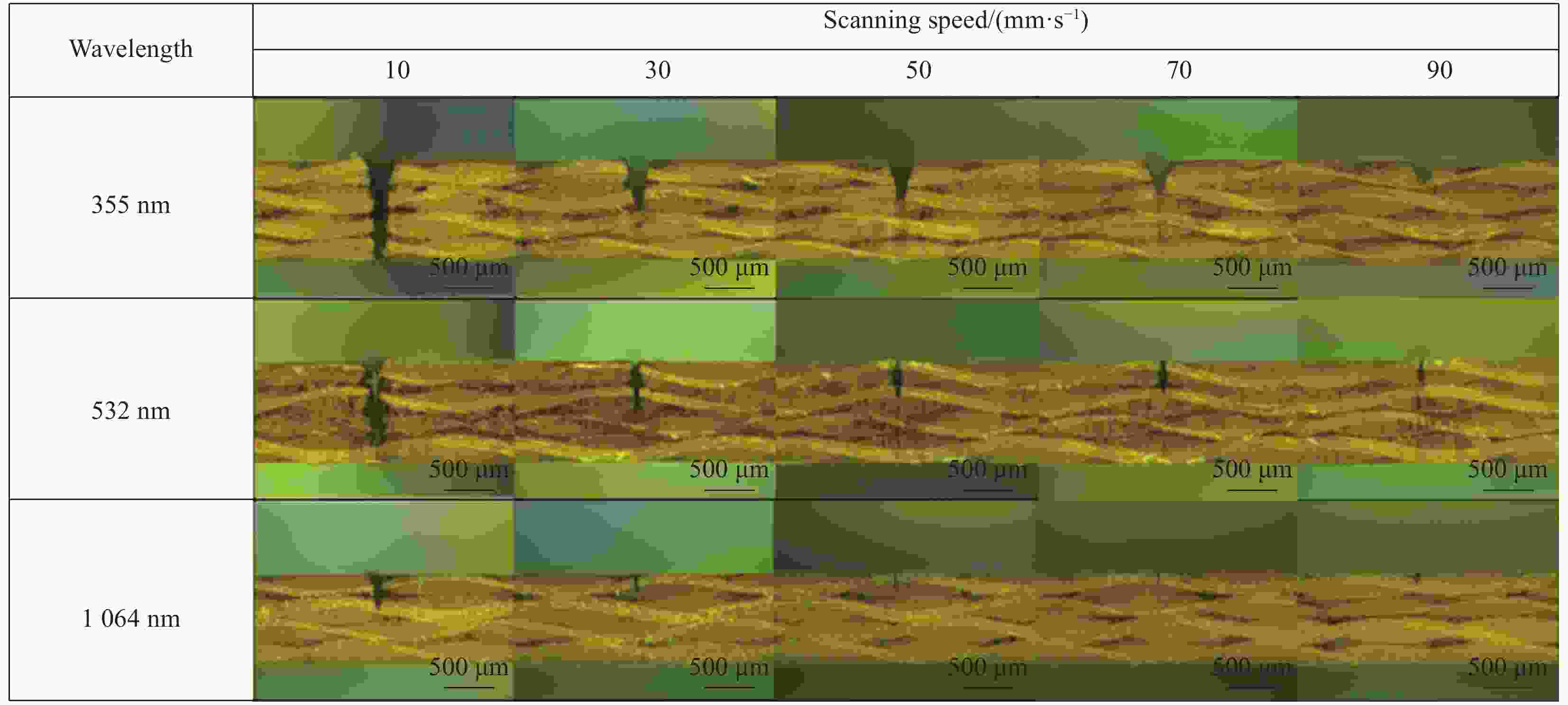

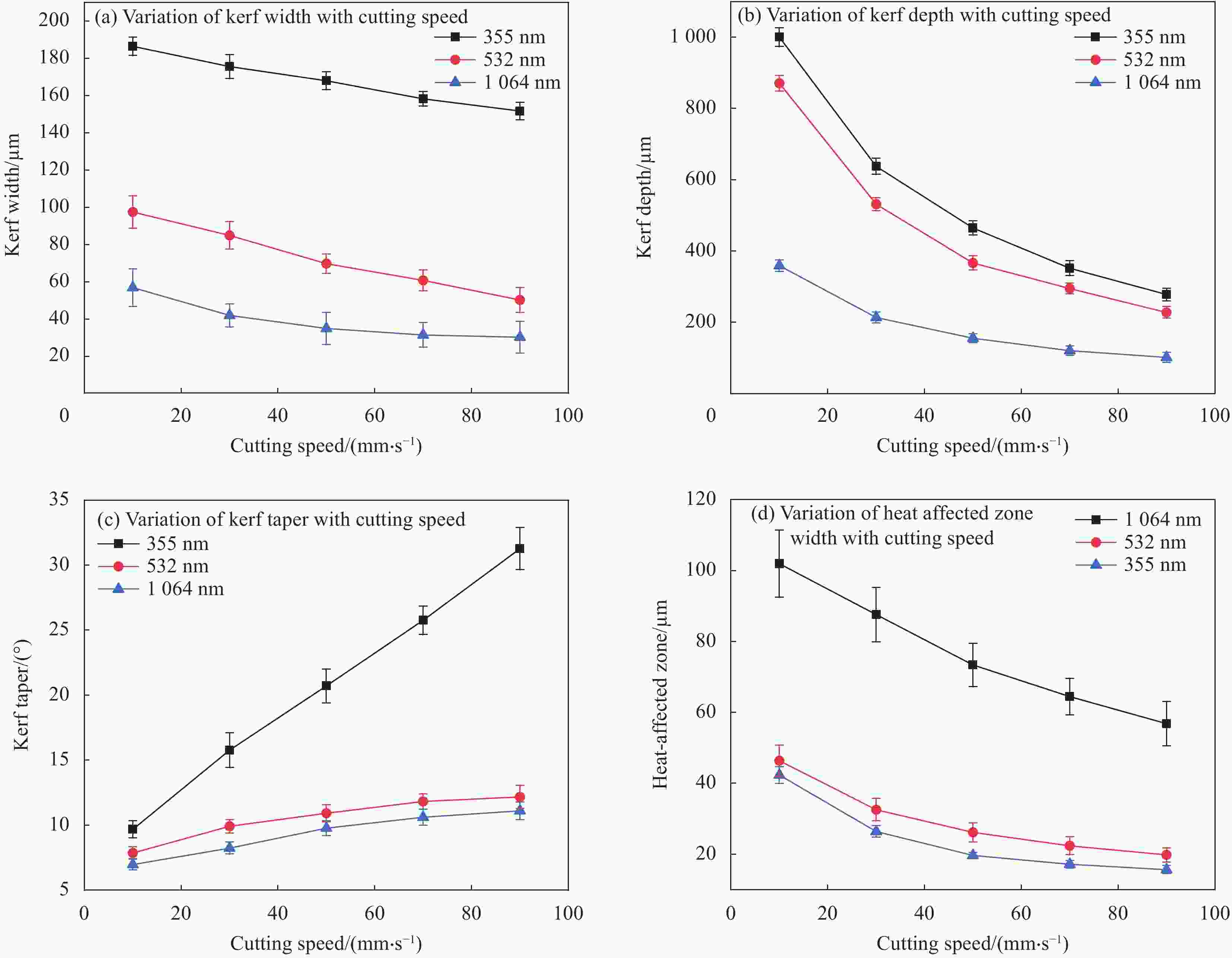

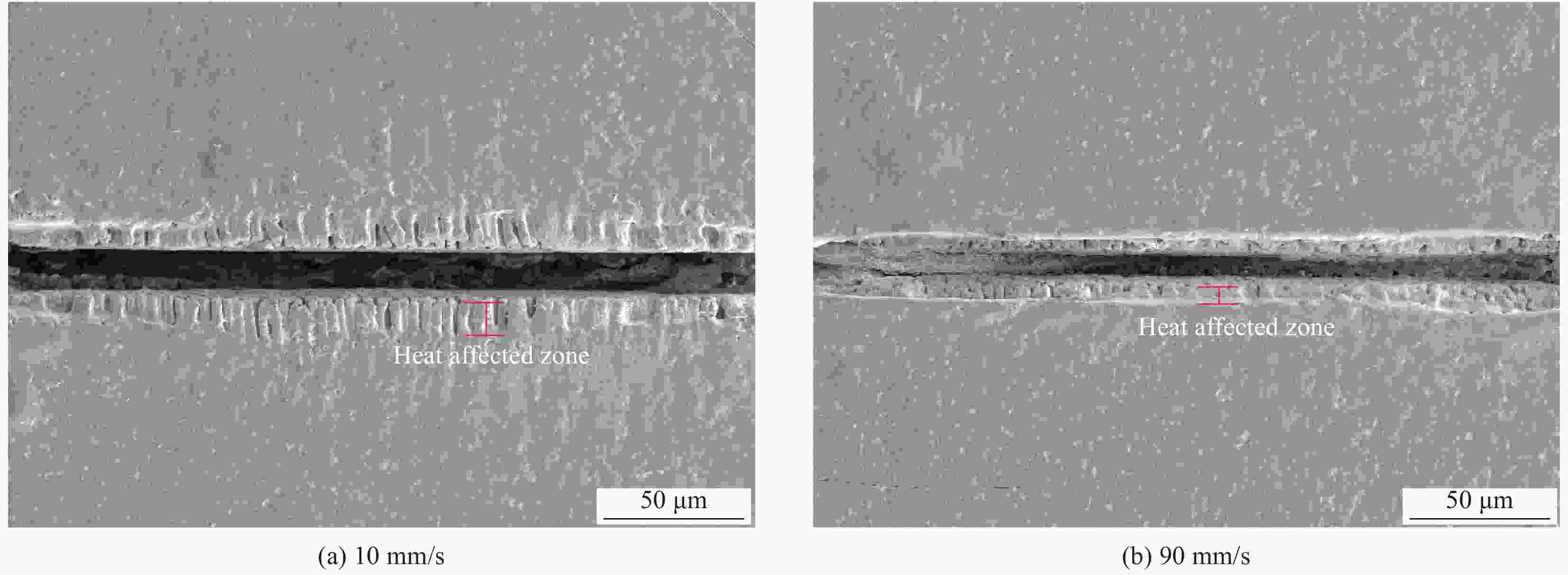

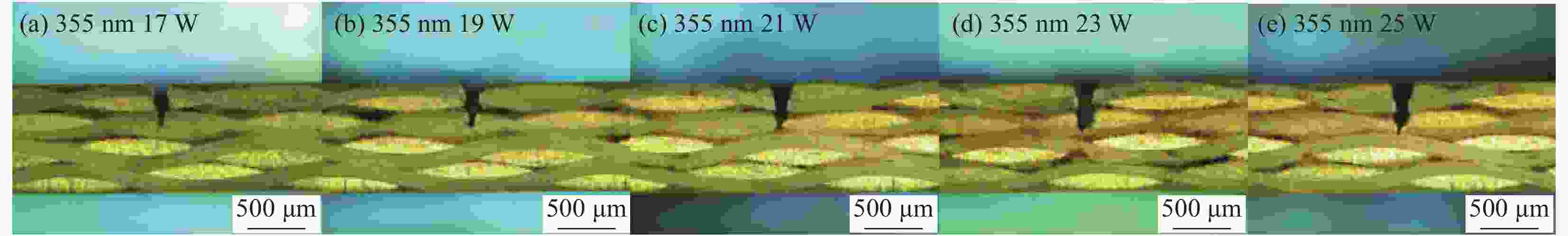

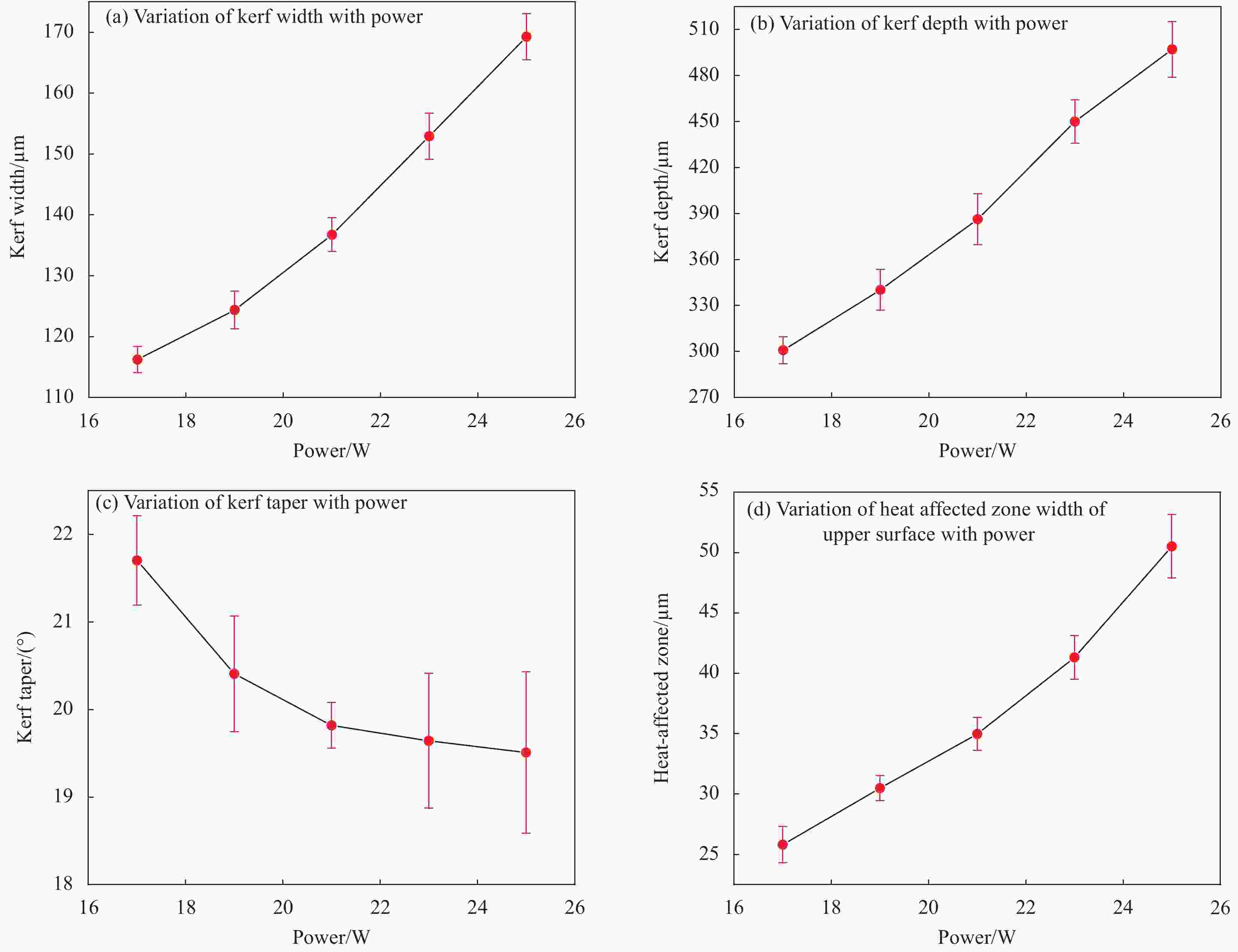

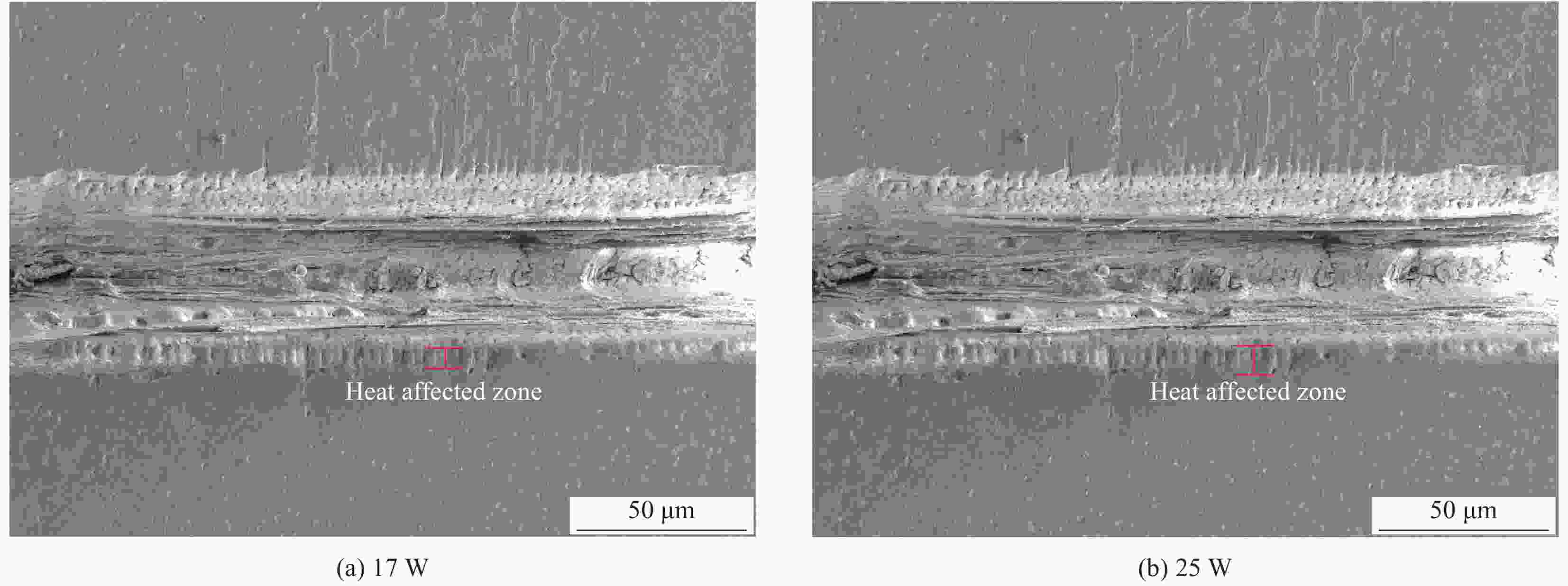

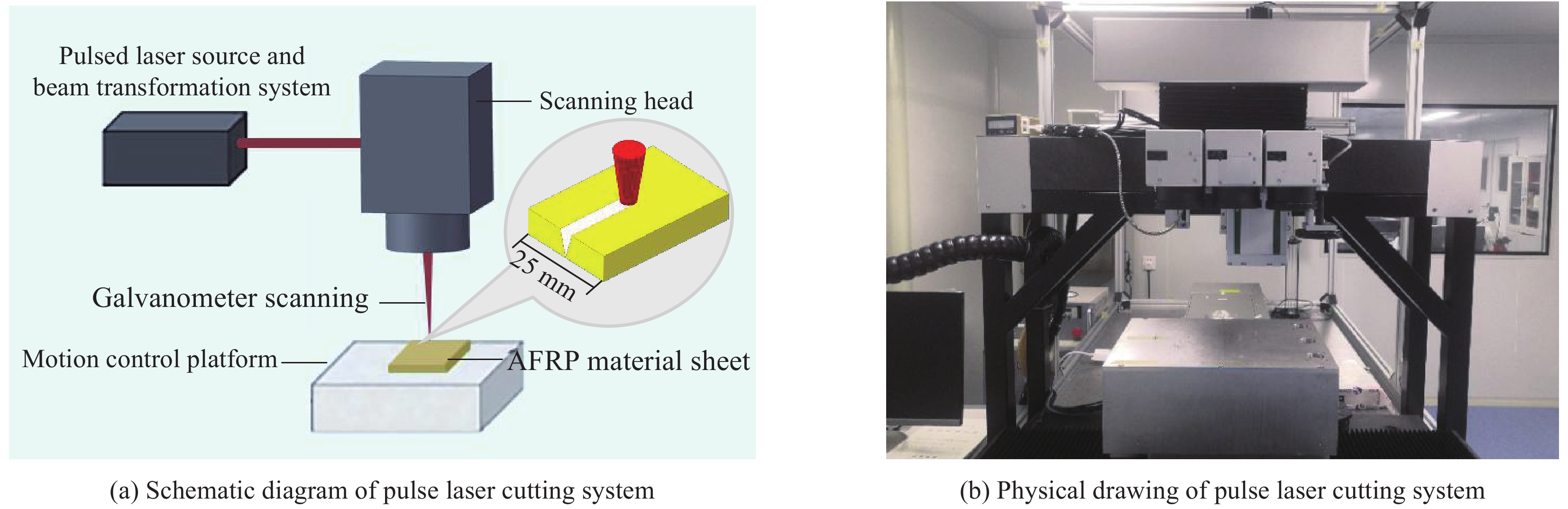

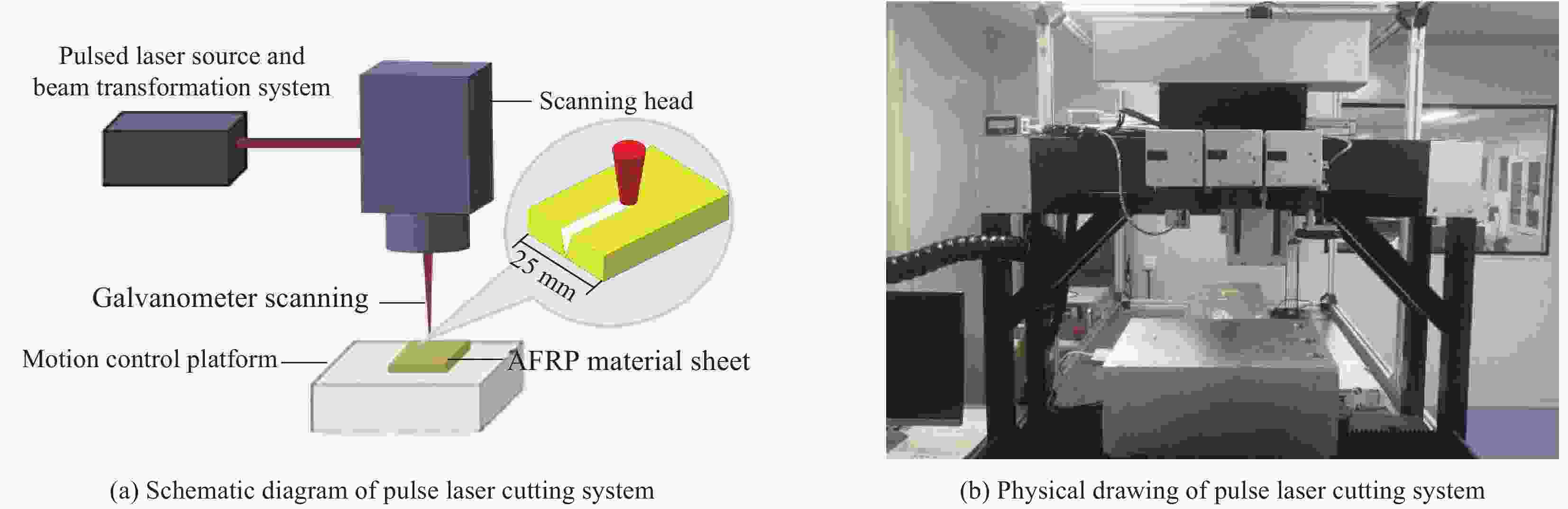

摘要: 采用紫外皮秒激光( λ=355 nm)、绿光皮秒激光( λ=532 nm)和红外皮秒激光( λ=1064 nm)的三波长皮秒脉冲固体激光器,对1 mm厚芳纶纤维增强树脂基复合材料(Aramid fiber reinforced polymer,AFRP)进行单次扫描切割实验,用光学显微镜(OM)和SEM测量了上切缝宽度、切缝深度和上表面热影响区宽度,并计算了切缝锥度,分析了激光波长、功率及扫描速度等参数对切口形貌和切缝质量的影响。结果表明:相比于红外激光和绿光激光切割AFRP,紫外激光的切割效率更高,切割质量更好;上切缝宽度、切缝深度和上表面热影响区宽度随着激光功率的增大而增大,随着激光扫描速度的增大而减小;切缝锥度随着激光功率的增大而减小,随着激光扫描速度的增大而增大;适当降低激光扫描速度,有利于提高切缝深宽比。Abstract: A three wavelength picosecond pulsed solid-state laser with ultraviolet picosecond laser ( λ=355 nm), green picosecond laser ( λ=532 nm) and infrared picosecond laser ( λ=1064 nm) was used to cut 1 mm thick aramid fiber reinforced polymer (AFRP) by a single pass scanning. The slit width, thickness and thickness were measured by optical microscope (OM) and scanning electron microscope (SEM). The effects of laser wavelength, laser power and scanning speed on the notch shape and quality were analyzed. The results show that: compared with the infrared laser and green laser cutting AFRP, the cutting efficiency of ultraviolet laser is higher, and the cutting quality is better; the width of upper slit, slit depth and the width of upper surface heat affected zone increase with the increase of laser power, and decrease with the increase of laser scanning speed; the slit taper decreases with the increase of laser power, and increases with the increase of laser scanning speed. When the laser scanning speed is reduced properly, the ratio of slit depth to width is improved.

-

Key words:

- picosecond laser /

- wavelength /

- laser cutting /

- kerf quality /

- AFRP

-

表 1 材料热学性能参数

Table 1. Thermal properties of materials

Property Kevlar-29 Epoxy resin Decomposition temperature/K 800 440 Heat conductivity/(W·m −1·K −1) 0.04 0.1 Specific heat capacity/(J·kg −1·K −1) 1400 1 884 Density/(kg·m −3) 1440 1100 表 2 激光器参数

Table 2. Laser parameters

Options Average power/W Repetition rate/kHz Pulse duration/ps Focus diameter/μm UV laser 0-25 500 15 50-60 GN laser 0-45 500 15 35-40 IR laser 0-90 500 15 25-30 -

[1] 石文天, 刘玉德, 张永安, 等. 芳纶纤维复合材料切削加工研究进展[J]. 表面技术, 2016, 45(1):28-35.SHI Wentian, LIU Yude, ZHANG Yongan, et al. Research progress in cutting of aramid fiber composites[J]. Surface Technology,2016,45(1):28-35(in Chinese). [2] AL-SULAIMAN F, YILBAS B S, AHSAN M, et al. CO 2 laser cutting of kevlar laminate: Influence of assisting gas pressure[J]. The International Journal of Advanced Manufacturing Technology,2009,45(1-2):62-70. doi: 10.1007/s00170-009-1945-7 [3] 王含妮, 谭勇, 张喜和, 等. 芳纶纤维复合材料在脉冲激光作用下的热损伤研究[J]. 光电技术应用, 2015, 30(1):6. doi: 10.3969/j.issn.1673-1255.2015.01.008WANG Hanni, TAN Yong, ZHANG Xihe, et al. Thermal damage of aramid fiber composites under pulsed laser irradiation[J]. Application of Optoelectronic Technology,2015,30(1):6(in Chinese). doi: 10.3969/j.issn.1673-1255.2015.01.008 [4] 王贵兵, 罗飞, 刘仓理, 等. 芳纶纤维复合材料激光烧蚀损伤形貌研究[J]. 激光技术, 2006(2):168-180. doi: 10.3969/j.issn.1001-3806.2006.02.002WANG Guibing, LUO Fei, LIU Cangli, et al. Laser ablation damage morphology of aramid fiber composites[J]. Laser Technology,2006(2):168-180(in Chinese). doi: 10.3969/j.issn.1001-3806.2006.02.002 [5] YILBAS B S, AL-SULAIMAN F, KARAKAS C, et al. Laser cutting of multilayered kevlar plates[J]. Journal of Materials Engineering & Performance,2007,16(6):663-671. [6] GAUTAM G D, MISHRA D R. Dimensional accuracy improvement by parametric optimization in pulsed Nd: YAG laser cutting of kevlar-29/basalt fiber-reinforced hybrid composites[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering,2019,41(7):85-99. [7] MISHRA D R, BAJAJ A, BISHT R, et al. Optimization of multiple kerf quality characteristics for cutting operation on carbon-basalt-Kevlar29 hybrid composite material using pulsed Nd: YAG laser using GRA[J]. CIRP Journal of Manufacturing Science and Technology,2020,30(4):24-35. [8] HERRMANN T, KLIMT B, SIEGEL F, et al. Micromachining with picosecond laser pulses[J]. Industrial Laser Solutions,2004,19(10):34-43. [9] 张学聪, 钱静, 付强, 等. 皮秒激光切割PBO纤维增强复合材料[J]. 中国激光, 2020, 13:1-15.ZHANG Xuecong, QIAN Jing, FU Qiang, et al. Cutting PBO fiber reinforced composites by picosecond laser[J]. Chinese Journal of Lasers,2020,13:1-15(in Chinese). [10] LI Z L, ZHENG H Y, LIM G C, et al. Study on UV laser machining quality of carbon fibre reinforced composites[J]. Composites Part A: Applied Science & Manufacturing,2010,41(10):1403-1408. [11] DELL M, ERBA, GALANTUCCI L M, et al. An experimental study on laser drilling and cutting of composite materials for the aerospace industry using excimer and CO 2 sources[J]. Composites Manufacturing,1992,3(1):14-19. doi: 10.1016/0956-7143(92)90178-W [12] HERZOG D, JAESCHKE P, MEIER O, et al. Investigations on the thermal effect caused by laser cutting with respect to static strength of CFRP[J]. International Journal of Machine Tools & Manufacture,2008,48(12-13):1464-1473. [13] TAKAHASHI K, TSUKAMOTO M, MASUNO S, et al. Heat conduction analysis of laser CFRP processing with IR and UV laser light[J]. Composites Part A: Applied Science & Manufacturing,2016,84(9):135-148. [14] CUI X, KE Q F, CAI G M, et al. Evaluation of light protective properties of high performance aramid fabrics[J]. Applied Mechanics & Materials,2014,551:28-31. [15] 贾宝申, 唐洪平, 苏春洲, 等. 脉冲激光去除树脂基复合材料表面涂层[J]. 中国激光, 2019, 46(12):1202010.JIA Baoshen, TANG Hongping, SU Chunzhou, et al. Surface coating removal of resin matrix composites by pulsed laser[J]. Chinese Journal of Lasers,2019,46(12):1202010(in Chinese). [16] AL-SULAIMAN F, YILBAS B S, KARATAS C, et al. Laser cutting of kevlar and mild steel composite structure: end product quality assessment[J]. Journal of Materials En-gineering and Performance,2007,16(1):22-29. doi: 10.1007/s11665-006-9003-1 -

下载:

下载: