Effect of corrosion on the surface properties of steel plate and interfacial bonding properties between CFRP plate and corroded steel plate

-

摘要: 为研究锈蚀对钢板表面特性及碳纤维增强树脂复合材料(CFRP)板-锈蚀钢板界面黏结性能的影响,开展了6批次锈蚀钢板表面特性测试及22个CFRP板-锈蚀钢板双搭接试件的拉伸试验,揭示了锈蚀对钢板表面形貌与粗糙度、表观接触角与表面自由能以及CFRP板-钢板黏结界面破坏模式、有效黏结长度、极限荷载的影响。研究结果表明:随着腐蚀龄期不断增大,均匀腐蚀与点蚀交替主导钢板表面形貌特征变化,钢板表面粗糙度与表面自由能均出现周期性上下波动;CFRP板-锈蚀钢板黏结界面主要呈钢板/胶层界面剥离与CFRP板/胶层界面剥离混合破坏模式,腐蚀龄期仅对混合破坏类型的面积占比有一定影响;胶层厚度相同时,锈蚀钢板对应界面有效黏结长度明显大于未锈蚀钢板对应界面,腐蚀龄期0~12个月、胶层厚度0.21~0.7 mm的CFRP板-锈蚀钢板界面有效黏结长度为63.75~91.5 mm;随着腐蚀龄期不断增大,CFRP板-锈蚀钢板界面极限荷载呈先增大后稳定趋势,锈蚀引起的钢板表面面积、表面自由能及表面粗糙度增加,对CFRP板-钢板黏结界面极限承载力有利。Abstract: In order to investigate the effect of corrosion on the surface properties of steel plate and interfacial bonding properties between CFRP plate and corroded steel plate, surface characteristic test of corroded steel plates with six kinds of corrosion duration and tensile test of thirty-four double-lap specimens with CFRP plates and corroded steel plates were carried out. The effects of corrosion duration on the morphology and surface roughness, apparent contact angle and surface free energy of steel plate, and the failure mode, effective bond length and ultimate load of bonding interface between CFRP plate and corroded steel plate were revealed. Test results show that with the increase of corrosion duration, pitting corrosion and uniform corrosion alternately play the dominant role on the surface topography, the surface roughness and surface free energy of the corroded steel plates fluctuate up and down continuously. The failure mode of bonding interface between CFRP plate and corroded steel plate is mainly the mixed of steel/adhesive interfacial debonding and CFRP/adhesive interfacial debonding, and the corrosion duration only has a certain influence on the area proportion of the mixed failure type. As for the specimens with the si-milar adhesive thickness, the effective bond length of the corroded specimens is significantly larger than that of the un-corroded ones, the effective bond length for the specimens with the corrosion duration of 0-12 months and the adhesive thickness of 0.21-0.7 mm are approximately 63.75-91.5 mm. With the increase of corrosion duration, the ultimate bearing capacity of the bonding interface increases at first and tends to be stable afterwards, the increase of surface area, surface free energy and surface roughness caused by corrosion plays the favorable factor on the ultimate bearing capacity.

-

Key words:

- corrosion /

- steel structure /

- surface properties /

- CFRP plate /

- interface /

- bond characteristic

-

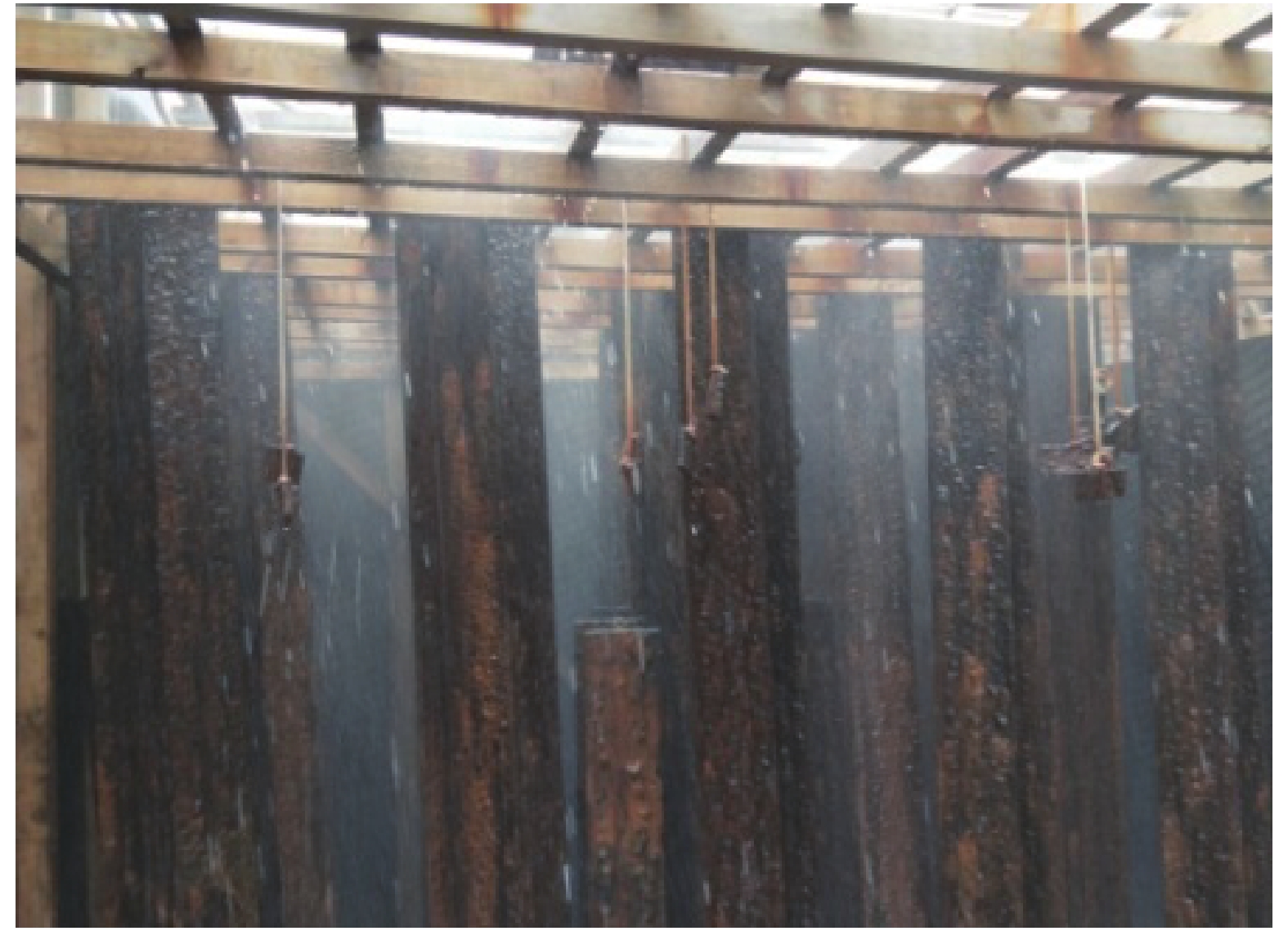

图 6 不同腐蚀龄期锈蚀钢板表面形貌:(a) C0外侧;(b) C0内侧;(c) C3外侧;(d) C3内侧;(e) C4外侧;(f) C4内侧;(g) C6外侧;(h) C6内侧;(i) C8外侧;(j) C8内侧;(k) C12外侧;(l) C12内侧

Figure 6. Surface topographies of steel plates with different corrosion durations: (a) C0 front side; (b) C0 back side; (c) C3 front side; (d) C3 back side; (e) C4 front side; (f) C4 back side; (g) C6 front side; (h) C6 back side; (i) C8 front side; (j) C8 back side; (k) C12 front side; (l) C12 back side

图 12 不同荷载水平下CFRP-钢板界面剪应力分布:(a) CFRP-S(C0-B150)试件正面;(b) CFRP-S(C8-B150)试件背面

Figure 12. Interfacial shear stress distribution of CFRP-corroded steel plate under different load levels: (a) Front side of specimen CFRP-S(C0-B150); (b) Back side of specimen CFRP-S(C8-B150)

Leff—Effective bonding length of interface

表 1 试验用材料属性

Table 1. Material properties

Material Thickness/

mmElasticity modulus/

GPaYield strength/

MPaTensile strengt/

MPaElongation at

break/%CFRP plate 1.4 165a N/A 2400a 1.61a Adhesive N/A 5.3 N/A 41.75 1.13 Steel plate 10.75b 181.9 275.6 421.18 20.78 Notes: aAccording to the manufacturer′s instructions; bThickness of steel plate which cut from the flange of the un-corroded H beams; N/A—Not applicable. 表 2 CFRP板-锈蚀钢板双搭接试件参数与主要试验结果汇总

Table 2. Summary of parameters and results of quasi-static loading tests of double-lap joint specimens of CFRP-corroded steel plate

Specimen No. Cd/month ξ/% L1/mm tf/mm tb/mm tave/mm Fu/kN Lf/mm Lb/mm Failure mode CFRP-S(C0-B30) 0 0.00 30 0.54 0.49 0.52 37.00 — — a+c (Back) CFRP-S(C0-B50) 50 0.46 0.47 0.47 39.80 — — a+d (Front)/

a+b+c (Back)CFRP-S(C0-B80) 80 0.52 0.44 0.48 48.80 — — a+c+d (Back) CFRP-S(C0-B120) 120 0.63 0.42 0.52 49.90 67.75 67.75 a+c(Front) CFRP-S(C0-B150) 150 0.52 0.41 0.46 48.00 63.75 73.00 a+c (Back) CFRP-S(C3-B150) 3 5.08 150 0.37 0.44 0.41 52.00 91.50 91.50 a+c (Front) CFRP-S(C4-B30) 4 6.15 30 0.47 0.43 0.45 39.10 — — a+c (Front)/

c+d (Back)CFRP-S(C4-B50) 50 0.51 0.45 0.48 43.30 — — a+c (Back) CFRP-S(C4-B80) 80 0.44 0.58 0.51 50.90 — — a+c (Back) CFRP-S(C4-B120) 120 0.51 0.31 0.41 53.00 — — a+c (Front) CFRP-S(C4-B150) 150 0.70 0.24 0.47 52.30 82.25 73.00 a (Front) CFRP-S(C6-B150) 6 7.92 150 0.40 0.24 0.32 54.30 82.25 73.00 a+c (Back) CFRP-S(C8-B30) 8 10.07 30 0.30 1.72 1.01 23.28 — — c+d (Front)/

a (Back)CFRP-S(C8-B50) 50 0.30 0.42 0.36 40.76 — — a+c+d (Front) CFRP-S(C8-B80) 80 0.30 0.32 0.31 52.88 — — a+c+d (Back) CFRP-S(C8-B120) 120 0.40 0.57 0.49 53.64 82.25 91.50 a+c (Front)/

c+d (Back)CFRP-S(C8-B150) 150 0.42 0.57 0.50 53.90 91.50 73.00 a+b+c+d (Front)/

a+c (Back)CFRP-S(C12-B30) 12 15.02 30 0.54 0.43 0.49 40.00 — — a+c (Back) CFRP-S(C12-B50) 50 0.30 0.64 0.47 45.60 — — a+b (Back) CFRP-S(C12-B80) 80 0.70 0.53 0.62 52.70 — — a+c (Front) CFRP-S(C12-B120) 120 0.40 0.53 0.46 56.00 91.50 91.50 a+c+d (Back) CFRP-S(C12-B150) 150 0.70 0.39 0.54 55.00 82.25 91.50 a+c+d (Front)/

a+c (Back)Notes: CFRP-S—CFRP-steel plate; C—Corrosion durations; B—Bond length; Cd—Corrosion duration; ξ—Mass loss rate; L1—Bond length of CFRP plate on the testing side of specimen; tf and tb—Measured thickness of the adhesive layer on the front and back side of corroded steel plate; tave—Average thickness of both side of adhesive layers. Fu—Ultimate load; Lf and Lb—Effective bond length of the front and back side of the double-lap joint; a—Steel/adhesive interfacial debonding; b—Cohesive failure; c—CFRP/adhesive interfacial debonding; d—CFRP delamination; Front and Back—Outer and inner edges of the flange plate, respectively. 表 3 加速腐蚀试验及锈蚀钢板表面特性测试结果

Table 3. Accelerated corrosion test results and morphologies of corroded steel plates

Specimen No. Cd / month ξ/% Location Sa/μm Sq/μm Sz/μm Sdr/% θ1,ave θ2,ave γs/(mJ·m−2) C0 0 0 Front 13.0 21.6 134.9 0.02 79.1 46.1 40.9 Back 15.9 20.4 179.8 0.04 78.3 44.0 42.0 C3 3 5.08 Front 70.3 110.3 1 293.9 5.32 67.6 40.9 47.9 Back 78.1 116.2 1 309.5 5.25 69.3 37.1 48.4 C4 4 6.15 Front 120.5 144.6 903.9 4.91 65.0 39.5 49.6 Back 84.6 116.3 788.0 3.54 63.5 39.1 50.5 C6 6 7.92 Front 95.8 130.9 808.3 4.10 65.7 39.0 49.4 Back 101.6 143.1 941.2 5.07 61.0 38.5 52.0 C8 8 10.07 Front 136.4 170.3 1 008.6 4.05 69.4 41.0 46.9 Back 98.5 135.0 866.8 4.35 67.6 37.7 49.0 C12 12 15.02 Front 117.8 146.5 913.1 5.60 67.0 37.8 49.2 Back 113.9 146.4 1 073.5 6.32 63.7 37.9 50.8 Notes: Sa, Sq, Sz and Sdr—Arithmetic mean height, root mean square height, maximum height, and developed interfacial area ratio of the scale-limited surface, respectively; θ1,ave and θ2,ave—Average static contact angles corresponding to the first and second measuring liquid, respectively; γs—Calculated surface free energy for corroded steel plates. -

[1] LEPRETRE E, CHATAIGNER S, DIENG L, et al. Fatigue strengthening of cracked steel plates with CFRP laminates in the case of old steel material[J]. Construction and Building Materials,2018,174:421-432. doi: 10.1016/j.conbuildmat.2018.04.063 [2] YU Qianqian, WU Yufei. Fatigue retrofitting of cracked steel beams with CFRP laminates[J]. Composite Structures,2018,192:232-244. doi: 10.1016/j.compstruct.2018.02.090 [3] EL-TAWIL S, EKIZ E, GOEL S, et al. Retraining local and global buckling behavior of steel plastic hinges using CFRP[J]. Journal of Constructional Steel Research,2011,67(3):261-269. doi: 10.1016/j.jcsr.2010.11.007 [4] 李安邦. CFRP板加固锈蚀钢板疲劳性能及其设计方法研究[D]. 西安: 西安建筑科技大学, 2020.LI Anbang. Fatigue behavior and design method of corroded steel plate strengthened with CFRP plates[D]. Xi’an: Xi’an University of Architecture & Technology, 2020(in Chinese). [5] 杨勇新, 岳清瑞, 彭福明. 碳纤维布加固钢结构的黏结性能研究[J]. 土木工程学报, 2006, 39(10):1-5. doi: 10.3321/j.issn:1000-131X.2006.10.001YANG Yongxin, YUE Qingrui, PENG Fuming. Study on the bond behavior of CFRP sheets to steel[J]. China Civil Engineering Journal,2006,39(10):1-5(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.10.001 [6] 黎文婧, 黄辉, 贾彬, 等. 碳纤维布-钢界面黏结性能试验研究[J]. 工业建筑, 2019, 49(3):24-28.LI Wenjing, HUANG Hui, JIA Bin, et al. Research on the bond behavior of CFRP-steelinterface[J]. Industrial construction,2019,49(3):24-28(in Chinese). [7] FAWZIA S, AL-MAHAIDI R, ZHAO X L. Experimental and finite element analysis of a double strap joint between steel plates and normal modulus CFRP[J]. Composite Structures,2006,75(1-4):156-162. doi: 10.1016/j.compstruct.2006.04.038 [8] WU C, ZHAO X, DUAN WH, et al. Bond characteristics between ultra high modulus CFRP laminates and steel[J]. Thin-Walled Structures,2012,51:147-157. doi: 10.1016/j.tws.2011.10.010 [9] YU T, FERNANDO D, TENG J, et al. Experimental study on CFRP-to-steel bonded interfaces[J]. Composites Part B: Engineering,2012,43(5):2279-2289. doi: 10.1016/j.compositesb.2012.01.024 [10] AL-MOSAWE A, AL-MAHAIDI R, ZHAO X L. Effect of CFRP properties, on the bond characteristics between steel and CFRP laminate under quasi-static loading[J]. Construction and Building Materials,2015,98:489-501. doi: 10.1016/j.conbuildmat.2015.08.130 [11] 李传习, 李游, 高有为, 等. 纳米SiO2质量分数对胶粘碳纤维增强树脂复合材料板-钢搭接界面黏结性能的影响[J]. 复合材料学报, 2020, 37(10):2619-2635.LI Chuanxi, LI You, GAO Youwei, et al. Effect of nano-SiO2 mass fraction on the interface performance of glued carbon fiber reinforced polymer composite-steel specimen[J]. Acta Materiae Compositae Sinica,2020,37(10):2619-2635(in Chinese). [12] FERNANDO D, TENG J G, YU T, et al. Preparation and characterization of steel surfaces for adhesive bonding[J]. Journal of Composites for Construction,2013,17(6):04013012. doi: 10.1061/(ASCE)CC.1943-5614.0000387 [13] HARRIS AF, BEEVERS A. The effects of grit-blasting on surface properties for adhesion[J]. International Journal of Adhesion & Adhesives,1999,19(6):445-452. [14] WU C, ZHAO X L, CHIU W K, et al. Effect of fatigue loading on the bond behaviour between UHM CFRP plates and steel plates[J]. Composites Part B: Engineering,2013,50:344-353. doi: 10.1016/j.compositesb.2013.02.040 [15] AL-MOSAWE A, AL-MAHAIDI R, ZHAO X L. Bond behaviour between CFRP laminates and steel members under different loading rates[J]. Composite Structures,2016,148:236-251. doi: 10.1016/j.compstruct.2016.04.002 [16] 邓军, 黄培彦. CFRP板与钢梁粘接的疲劳性能研究[J]. 土木工程学报, 2008, 41(5):20-24.DENG Jun, HUANG Peiyan. Fatigue behaviour of adhesive bonding in steel beams strengthened with a CFRP plate[J]. China Civil Engineering Journal,2008,41(5):20-24(in Chinese). [17] HESHMATI M, HAGHANI R, AL-EMRANI M. Durability of bonded FRP-to-steel joints: Effects of moisture, de-icing salt solution, temperature and FRP type[J]. Composites Part B: Engineering,2017,119:153-167. doi: 10.1016/j.compositesb.2017.03.049 [18] NGUYEN T C, BAI Y, ZHAO X L, et al. Durability of steel/CFRP double strap joints exposed to sea water, cyclic temperature and humidity[J]. Composite Structures,2012,94(5):1834-1845. doi: 10.1016/j.compstruct.2012.01.004 [19] 韦芳芳, 朱德昌, 王海涛, 等. 冻融环境下CFRP板-钢界面黏结性能试验研究[J]. 东南大学学报(自然科学版), 2020, 50(5):803-807.WEI Fangfang, ZHU Dechang, WANG Haitao, et al. Experimental study on bond behavior of CFRP plate-steel interface in freeze-thaw environment[J]. Journal of Southeast University (Natural Science Edition),2020,50(5):803-807(in Chinese). [20] NGUYEN T C, BAI Y, ZHAO X L, et al. Curing effects on steel/CFRP double strap joints under combined mechanical load, temperature and humidity[J]. Construction and Building Materials,2013,40:899-907. doi: 10.1016/j.conbuildmat.2012.11.035 [21] YU Q Q, GAO R X, GU X L, et. al. Bond behavior of CFRP-steel double-lap joints exposed to marine atmosphere and fatigue loading[J]. Engineering Structures,2018,175:76-85. doi: 10.1016/j.engstruct.2018.08.012 [22] 任慧韬, 李杉, 高丹盈. 荷载和恶劣环境共同作用对CFRP-钢结构黏结性能的影响[J]. 土木工程学报, 2009, 42(3):36-41. doi: 10.3321/j.issn:1000-131X.2009.03.006REN Huitao, LI Shan, GAO Danying. Bond behavior of CFRP and steel under dry-wet cyclic conidtion and loading[J]. China Civil Engineering Journal,2009,42(3):36-41(in Chinese). doi: 10.3321/j.issn:1000-131X.2009.03.006 [23] XIA S, TENG J. Behaviour of FRP-to-steel bonded joints[C]//Proceedings of the International Symposium on Bond Behaviour of FRP in Structures (BBFS 2005). Hong Kong: International Institute for FRP in Construction, 2005: 411–418. [24] HE J, XIAN G. Bond-slip behavior of fiber reinforced polymer strips-steel interface[J]. Construction & Building Materials,2017,155:250-258. [25] WANG H T, WU G. Bond-slip models for CFRP plates externally bonded to steel substrates[J]. Composite Structures,2018,184:1204-1214. doi: 10.1016/j.compstruct.2017.10.033 [26] CHOTICKAI P. Effect of pre-installed corrosion on steel plate-CFRP bond characteristics[J]. International Journal of Adhesion and Adhesives,2018,84:431-437. doi: 10.1016/j.ijadhadh.2018.05.010 [27] 中国国家标准化管理委员会. 金属和合金的腐蚀户外周期喷淋暴露试验方法: GB/T 24517—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Corrosion of metals and alloys, outdoors exposure test methods for periodic water spray: GB/T 24517—2009[S]. Beijing: Standards Press of China, 2009(in Chinese). [28] 中国国家标准化管理委员会. 人造气氛腐蚀试验盐雾试验: GB/T 10125—2012[S]. 北京: 中国标准出版社, 2012.Standardization Administration of the People’s Republic of China. Corrosion tests in artificial atmospheres—Salt spray tests: GB/T 10125—2012[S]. Beijing: Standards Press of China, 2012(in Chinese). [29] ISO. Geometrical product specifications (GPS)—Surface texture: Areal—Part 2: Terms, definitions and surface texture parameters: ISO 25178-2[S]. Geneva: International Organization of Standardization, 2012. [30] ASAMI K, KIKUCHI M. In-depth distribution of rusts on a plain carbon steel and weathering steels exposed to coastal-industrial atmosphere for 17 years[J]. Corrosion Science,2003,45(11):2671-2688. doi: 10.1016/S0010-938X(03)00070-2 [31] ZHAO X L, ZHANG L. State-of-the-art review on FRP strengthened steel structures[J]. Steel Construction,2007,29(8):1808-1823. [32] 彭福明. 纤维增强复合材料加固修复金属结构界面性能研究[D]. 西安: 西安建筑科技大学, 2005.PENG Fuming. Research on the interfacial performance of metaliic struetures strengthened with fiber reinforced polymers[D]. Xi’an: Xi’an University of Architecture & Technology, 2005(in Chinese). -

下载:

下载: