Meso-scale study on damage performance of resin mineral composite material for machine tool bed based on PFC3D

-

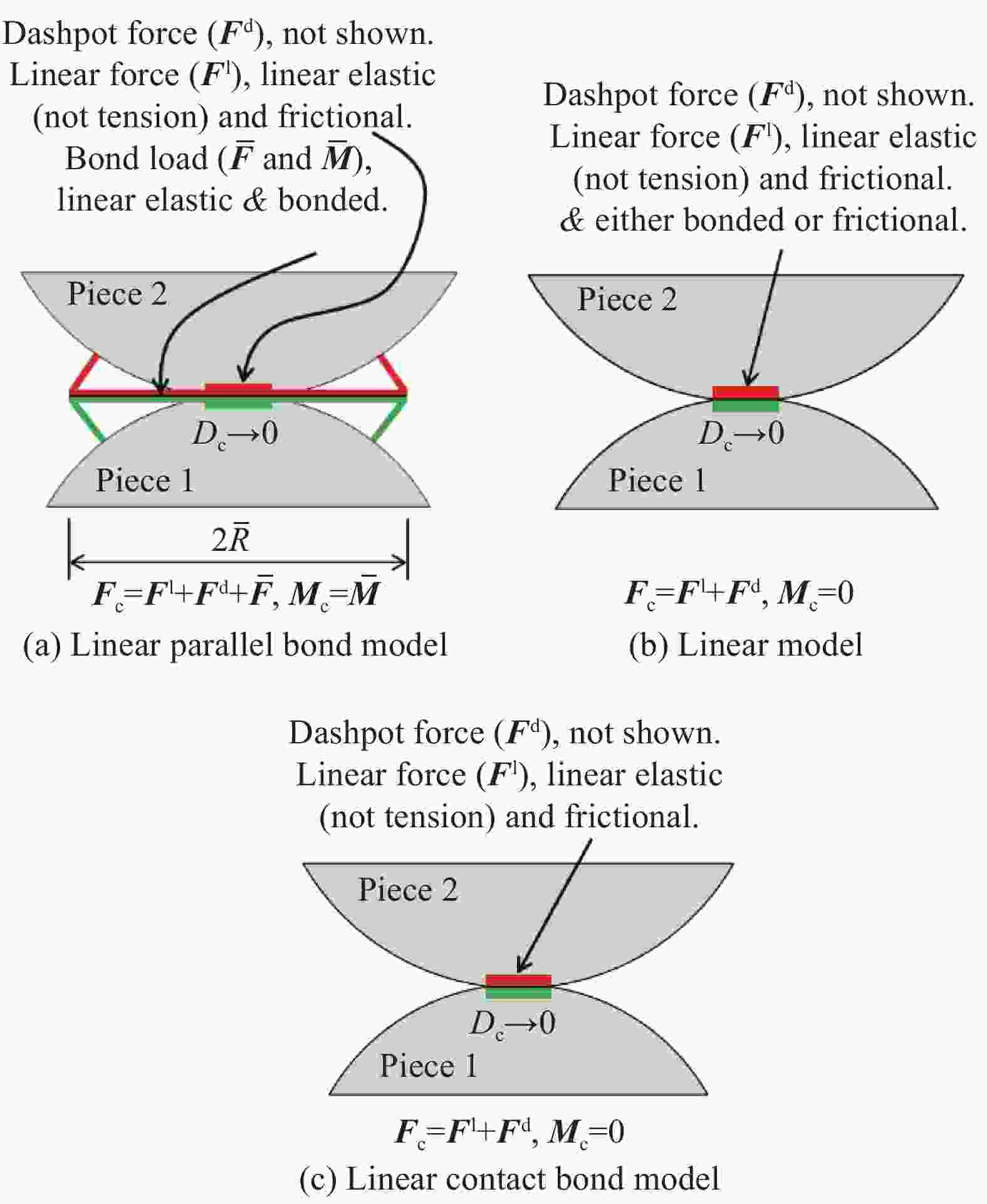

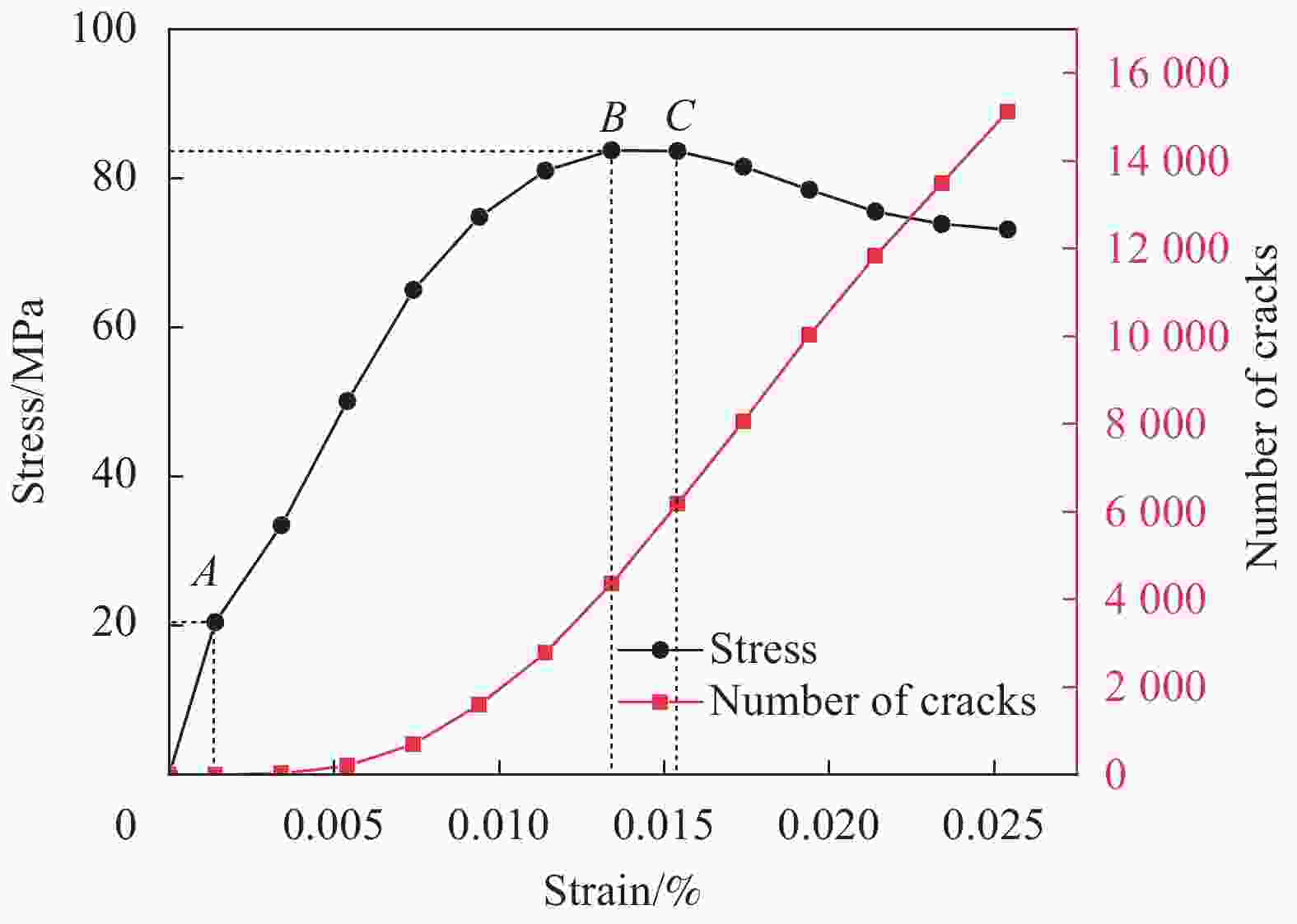

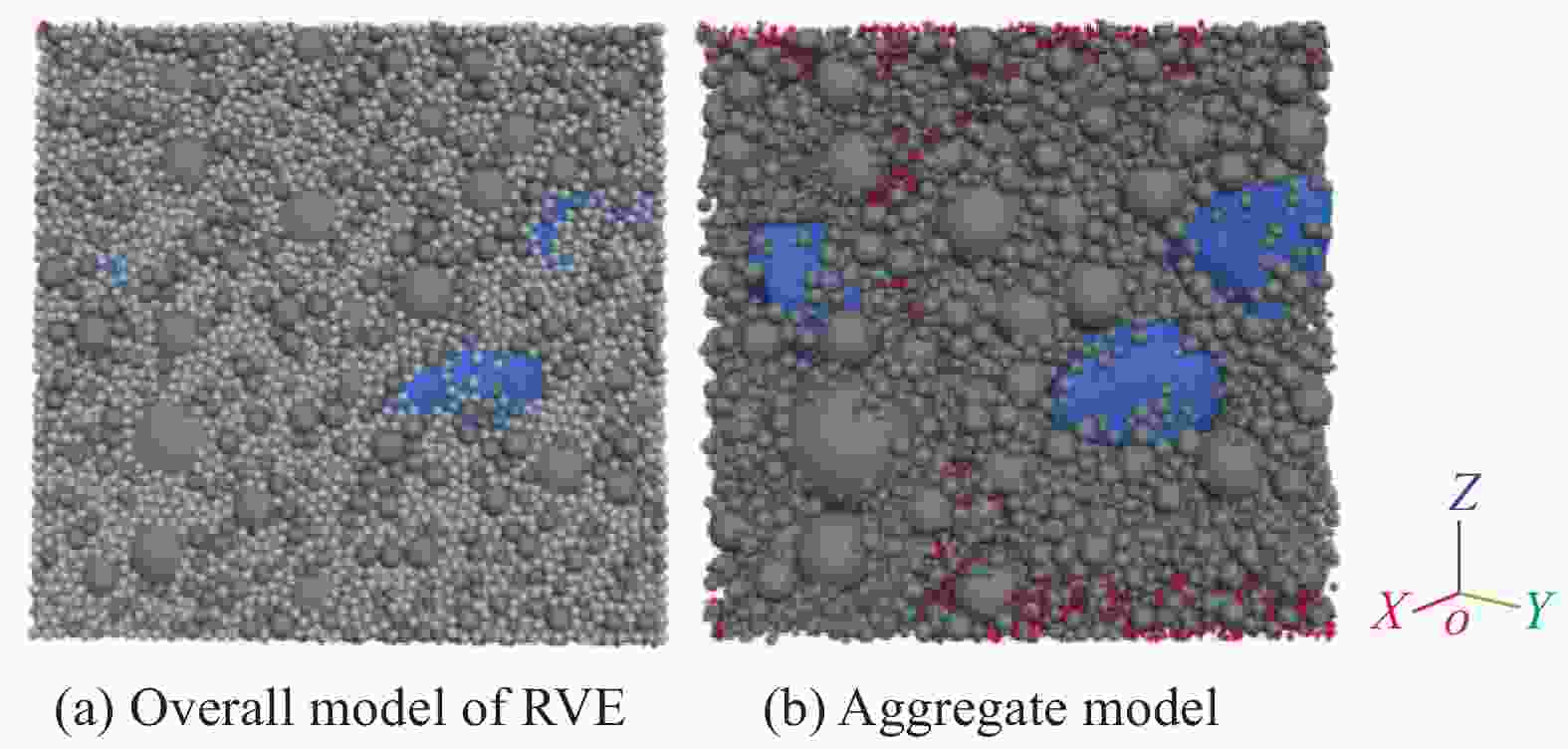

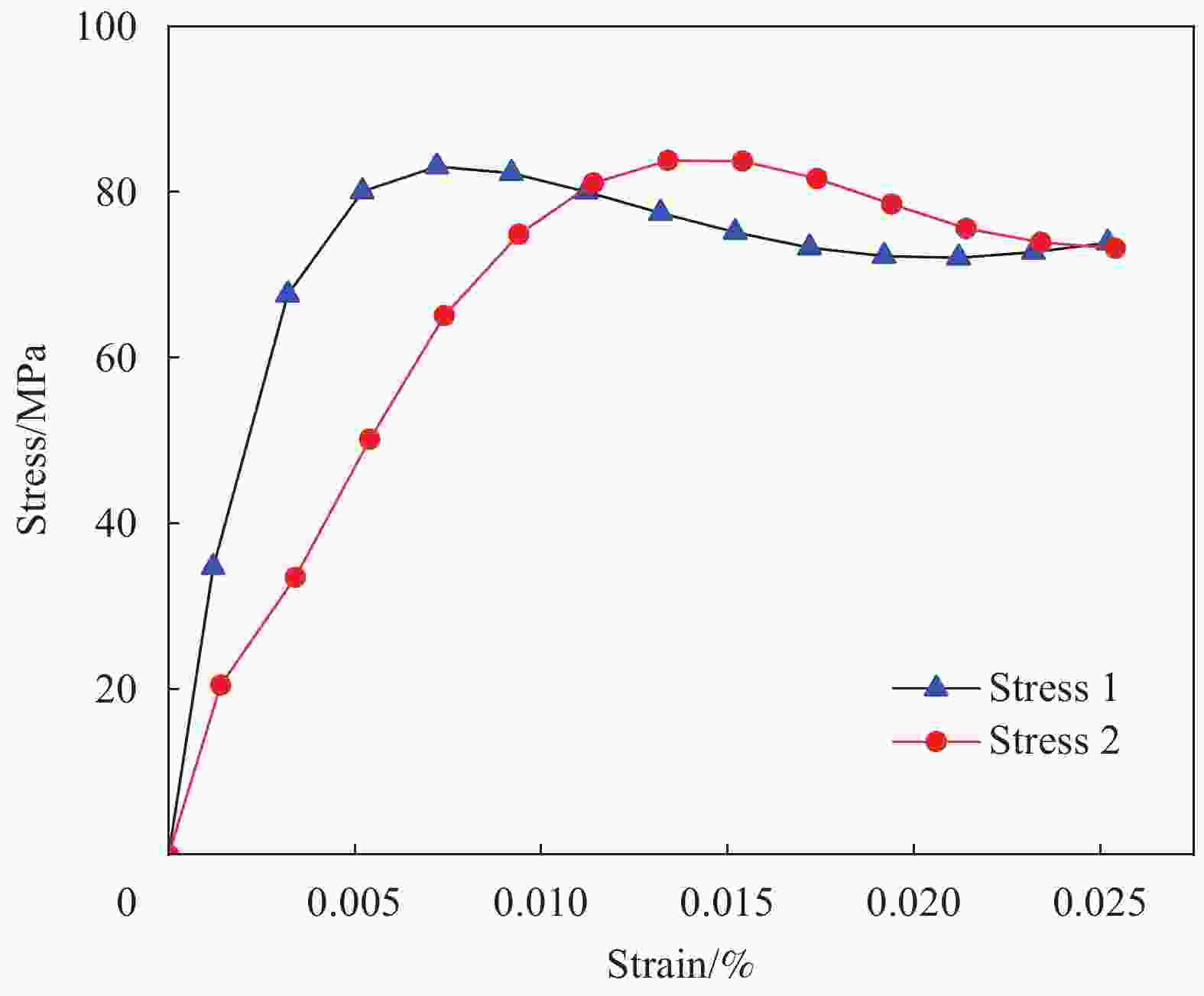

摘要: 为研究机床床身用树脂矿物复合材料在典型工况下的损伤演化过程、破坏失效形式,基于颗粒流数值模拟技术(Three-dimensional particle flow code,PFC3D),考虑级配和随机骨料形状,建立了包含骨料、界面过渡区、树脂基质、孔隙的树脂矿物复合材料四项介质离散元模型。结合机床典型工况下的受力情况,研究了树脂矿物复合材料损伤演化过程及裂纹分布规律,并从细观角度研究了裂纹萌生、扩展、贯穿的形成机制。研究结果表明:(1) 树脂矿物复合材料损伤演化过程可以明显分为四个阶段;(2) 骨料与树脂基质的界面过渡区首先起裂,并在与加载平行且无大骨料支撑的薄弱位置出现试件的压溃现象。该项研究为树脂矿物复合材料作为机床基础件材料的损伤性能细观研究提供参考依据。Abstract: This subject mainly studies the damage evolution process and failure mode of the resin-mineral composite material used for the machine bed under typical working conditions. In this study, a four media discrete element model was established based on particle flow numerical simulation technology (Three-dimensional particle flow code, PFC3D), as well as grading and random aggregate shape. The model includes aggregate, interfacial transition zone, resin matrix and porous resin mineral composites. The failure evolution and crack distribution of resin mineral composites were studied under the typical working conditions of machine tool and the formation mechanism of crack initiation, propagation and penetration was studied from a meso-level perspective. The results show that: (1) Damage evolution of resin mineral composites can be divided into four stages. (2) Cracks appeared earlier in the interface between aggregate and resin matrix. In addition, the crushing phenomenon occurs at the weak position with parallel loading and no large aggregate support. This study provides an important reference for the study of damage properties of resin mineral composites as basic parts of machine tools.

-

表 1 树脂矿物复合材料骨料级配配方

Table 1. Aggregate grading formula of resin mineral composite

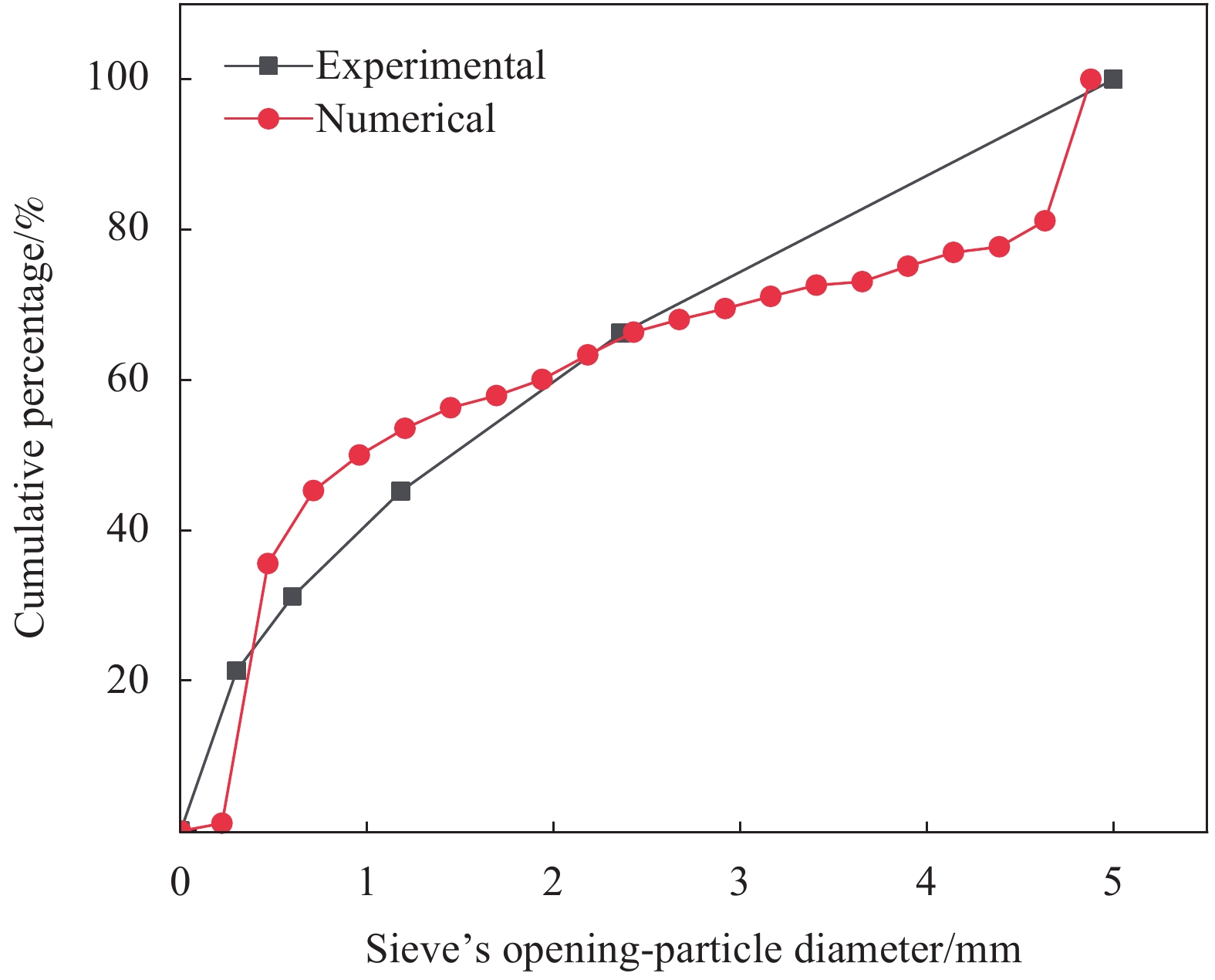

Particle diameter/mm 0.1-0.3 0.3-0.6 0.6-1.18 1.18-2.36 2.36-5 Content/wt% 21.3 9.9 14 21 33.8 表 2 随机刚性颗粒Clump填充控制参数的取值

Table 2. Random rigid particle clump filling control parameters

Number of iteration First Second Third Fourth Fifth Sixth Ratio 0.5 0.4 0.3 0.2 0.2 0.2 Distance 100 110 120 130 150 180 表 3 树脂矿物复合材料内平行黏结模型细观参数标定值

Table 3. Calibration values of mesoscopic parameters of linear parallel bond model of resin mineral composite

Parameter name Calibration

valueContact elastic modulus Ec/GPa 46.08 Stiffness ratio k 1.15 Normal critical damping ratio dn 0 Tangential critical damping ratio ds 0 Coefficient of friction fc 0.15 Bond normal strength Pten/MPa 130 Bond tangential strength Pshear/MPa 130 Friction angle fa/(°) 45 表 4 树脂矿物复合材料内接触黏结模型细观参数标值

Table 4. Calibration values of mesoscopic parameters of linear contact bond model of resin mineral composite

Parameter name Calibration

valueEffective modulus Em/GPa 55 Stiffness ratio k 5 Normal critical damping ratio dn 0 Tangential critical damping ratio ds 0 Coefficient of friction fc 0.4 Tensile strength S/MPa 24 Adhesion a/MPa 24 表 5 树脂矿物复合材料三轴压缩数值计算结果

Table 5. Numerical calculation results of triaxial compression for resin mineral composites

Working

conditionSpecimen

typePeak stress

σp/MPaPeak strain

εp/%Tangential

modulus/GPaInitiation

stress σi/MPaDamage

stress σd/MPaσi/σp σd/σp Typical working

conditionsRegular

hexahedron83.8 0.0134 14.416 20.46 83.8 0.244 1 -

[1] YIN J, ZHANG J, WANG T, et al. Mechanical properties optimization of resin mineral composite for machine tool bed[J]. Journal of Reinforced Plastics and Composites,2015,34(4):329-340. doi: 10.1177/0731684415571781 [2] 尹纪财. 机床用树脂矿物复合材料力学性能及其湿热老化机理研究[D]. 济南: 山东大学, 2016.YIN Jicai. Research on the mechanical properties and damp-heat aging mechanism of resin-mineral composite materials for machine tools[D]. Ji’nan: Shandong University, 2016(in Chinese). [3] 任娜娜. 机床用树脂矿物复合材料的制备及性能研究[D]. 南京: 南京理工大学, 2015.RAN Na’na. Research on preparation and performance of resin mineral composite material for machine tool[D]. Nanjing: Nanjing University of Science and Technology, 2015(in Chinese). [4] SHENG P, ZHANG J, JI Z. An advanced 3D modeling method for concrete-like particle-reinforced composites with high volume fraction of randomly distributed particles[J]. Composites Science and Technology,2016,134:26-35. doi: 10.1016/j.compscitech.2016.08.009 [5] ZHAO K, WAN S M, LIN B. Visualization of random particle packing model for resin concrete[J]. Applied Mechanics and Materials,2012,215-216:1483-1487. [6] 李晓周. 新型环氧树脂混凝土轴心受压构件的受力性能研究[D]. 长春: 吉林建筑大学, 2019.LI Xiaozhou. Study on mechanical properties of new type epoxy resin concrete members under axial compression[D]. Changchun: Jilin University of Architecture 2019(in Chinese). [7] 田会文, 周臻, 陆纪平, 等. 纤维增强树脂复合材料约束超高性能混凝土轴压性能的细观数值模拟[J]. 复合材料学报, 2020, 37(7):1629-1638.TIAN Huiwen, ZHOU Zhen, LI Jiping, et al. Micro-numerical simulation of axial compression properties of ultra high performance concrete confined by fiber reinforced resin composite[J]. Acta Materiae Compositae Sinica,2020,37(7):1629-1638(in Chinese). [8] 屈瑾, 娄宗科, 刘兆松. 基于细观层次的混凝土随机骨料建模[J]. 长江科学院院报, 2015, 32(4):129-132. doi: 10.3969/j.issn.1001-5485.2015.04.025QU Jin, LOU Zongke, LIU Zhaosong. Random aggregate modeling of concrete based on meso-level[J]. Journal of Yangtze River Scientific Research Institute,2015,32(4):129-132(in Chinese). doi: 10.3969/j.issn.1001-5485.2015.04.025 [9] 乔倩倩. 基于细观力学方法的混凝土多尺度损伤力学行为研究[D]. 大连: 大连理工大学, 2015.QIAO Qianqian. Research on multi-scale damage mechanical behavior of concrete based on mesomechanics method[D]. Dalian: Dalian University of Technology, 2015(in Chinese). [10] 肖诗云, 乔倩倩. 混凝土等效弹性模量细观影响因素[J]. 沈阳建筑大学学报 (自然科学版), 2015, 31(4):637-643.XIAO Shiyun, QIAO Qianqian. Microscopic influencing factors of concrete equivalent elastic modulus[J]. Journal of Shenyang Jianzhu University (Natural Science Edition),2015,31(4):637-643(in Chinese). [11] AI S G, TANG L Q, MAO Y Q, et al. Effect of aggregate distribution and shape on failure behavior of polyurethane polymer concrete under tension[J]. Computational Materials Science,2013,67(12):133-139. [12] Ai S, TANG L, MAO Y, et al. Numerical analysis on failure behaviour of polyurethane polymer concrete at high strain rates in compression[J]. Computational Materials Science,2013,69(3):389-395. [13] 郭晓辉, 张新乐, 曹海, 等. 聚合物混凝土抗局部破坏效应试验研究[C]//第 20 届全国结构工程学术会议论文集 (第Ⅰ册), 北京: 中国力学学会工程力学编辑部, 2011: 494-498.GUO Xiaohui, ZHANG Xinle, CAO Hai, et al. Experimental study on the anti-local damage effect of polymer concrete[C]// Proceedings of the 20th National Structural Engineering Conference (Volume I), Beijing: Engineering Mechanics Editorial Department of Chinese Society of Mechanics, 2011: 494-498(in Chinese). [14] 石崇, 张超, 王盛年. 颗粒流(PFC5.0)数值模拟技术与应用[M]. 北京: 中国建筑工业出版社, 2018: 1-462.SHI Chong, ZHANG Chao, WANG Shengnian. Particle flow (PFC5.0) numerical simulation technology and application[M]. Beijing: China Construction Industry Press, 2018: 1-462(in Chinese). [15] 汪杰, 付建新, 宋卫东, 等. 岩石-充填体组合模型力学特性及微裂纹演化特征颗粒流模拟[J]. 中国矿业大学学报, 2020(3):453-462.WANG Jie, FU Jianxin, SONG Weidong, et al. Particle flow simulation of mechanical properties and microcrack evolution characteristics of rock-backfill combined model[J]. Journal of China University of Mining & Technology,2020(3):453-462(in Chinese). [16] 邓树新, 郑永来, 冯利坡, 等. 试验设计法在硬岩 PFC 3D 模型细观参数标定中的应用[J]. 岩土工程学报, 2019, 41(4):655-664.DENG Shuxin, ZHENG Yonglai, FENG Lipo, et al. Application of design of experiments in the calibration of meso-parameters of hard rock PFC 3D model[J]. Chinese Journal of Geotechnical Engineering,2019,41(4):655-664(in Chinese). [17] 朱月风. 自愈型微胶囊在沥青路面中的力学行为及性能需求研究[D]. 西安: 长安大学, 2017.ZHU Yuefeng. Research on mechanical behavior and performance requirements of healing microcapsules in asphalt pavement[D]. Xi’an: Chang’an University, 2017(in Chinese). [18] 黄华, 李典伦, 邓文强, 等. 混凝土数控机床支承件组合结构设计与优化研究[J]. 机械科学与技术, 2021, 40(3): 394-402.HUANG Hua, LI Dianlun, DENG Wenqiang, et al. Research on design and optimization of combined structure of supports for concrete CNC machine tools[J]. Mechanical Science and Technology, 2021, 40(3): 394-402(in Chinese). [19] TOUFIGH V, ABYANEH M J, JAFARI K. Study of behavior of concrete under axial and triaxial compression[J]. ACI Materials Journal,2017,114(4):619-629. [20] 尹大伟, 陈绍杰, 刘兴全, 等. 节理特性对花岗岩起裂应力和损伤应力影响规律颗粒流模拟[J]. 应用基础与工程科学学报, 2018, 26(4):808-820.YIN Dawei, CHEN Shaojie, LIU Xingquan, et al. Particle flow simulation of the influence of joint characteristics on the initiation and damage stress of granite[J]. Journal of Applied Foundation and Engineering Science,2018,26(4):808-820(in Chinese). -

下载:

下载: