Establishment of hyperelastic parameters and structural finite element simulation based on uniaxial tensile for silicone gel

-

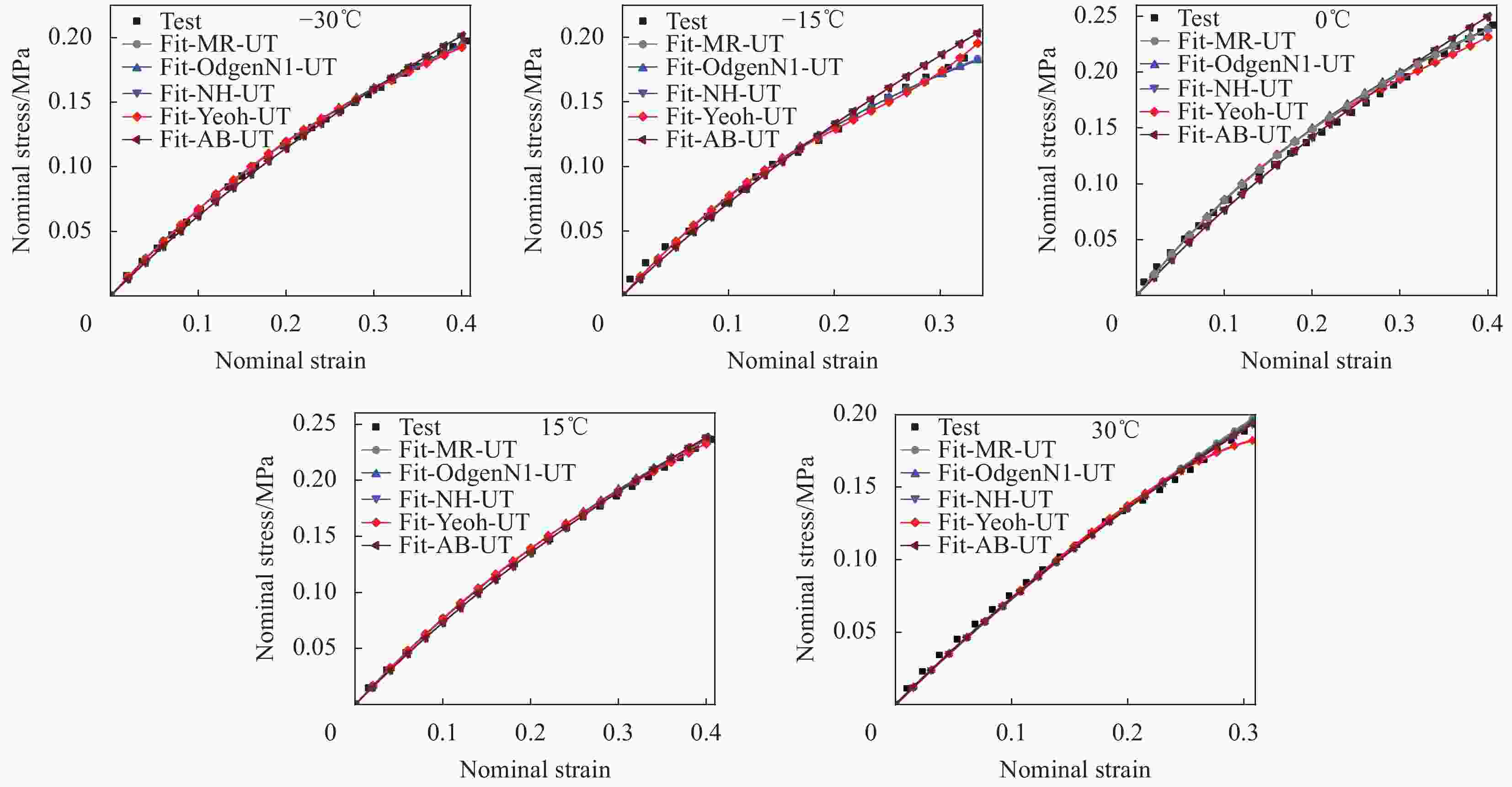

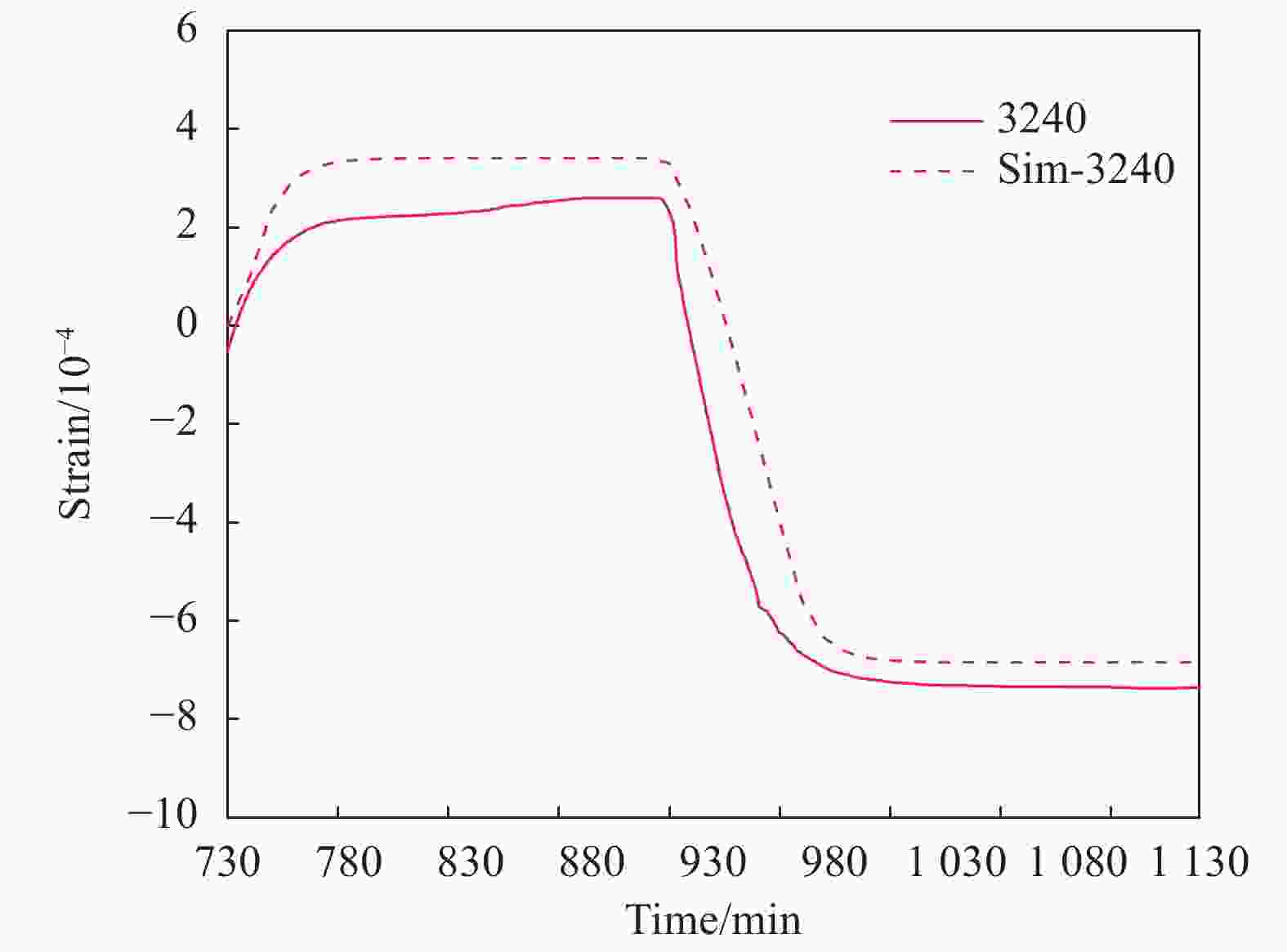

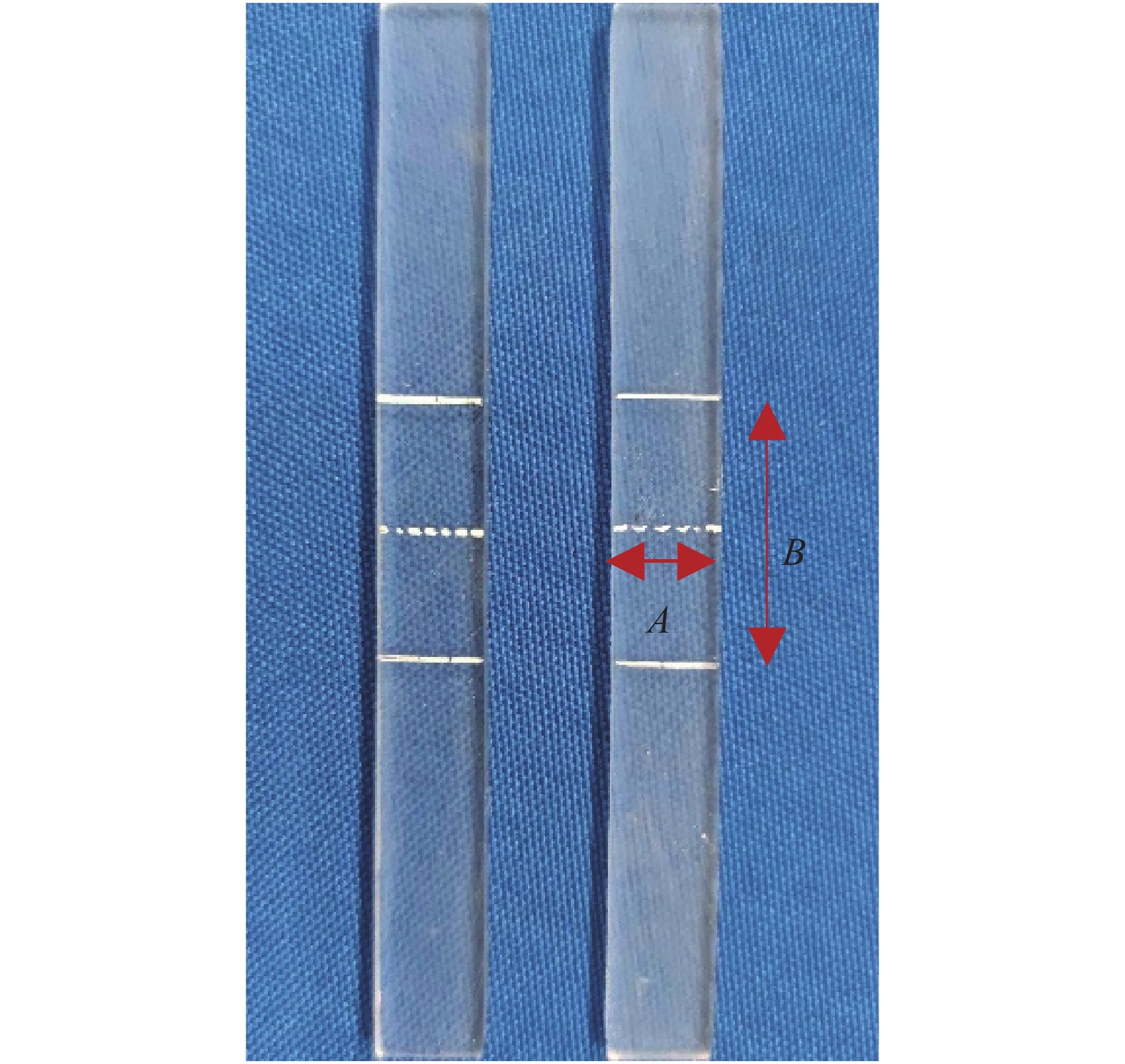

摘要: 为了研究有机硅凝胶的超弹性性能,在−30~30℃的环境温度范围内采用单轴拉伸(UT)实验,对灌封用硅凝胶的力学性能进行表征,获得了硅凝胶在不同温度下的应力-应变曲线。研究发现,硅凝胶初始弹性模量在−30~0℃的范围内与温度正相关,在0~30℃的范围内与温度负相关。随后,据UT实验数据讨论在有限元模拟中植入超弹性本构方程(Neo Hookean、Mooney-Rivlin、Yeoh、Arruda-Boyce等)的选取策略及参数确定方法,基于优选的Neo Hookean模型建立了一个温度相关超弹性本构模型,以描述硅凝胶在较大温度范围内的应力-应变响应。然后,利用商业有限元分析软件ABAQUS提供的UHYPER子程序描述与温度相关的Neo Hookean超弹性模型,结合布拉格光纤光栅监测技术(Fiber Bragg grating,FBG),选取观测点,对典型硅凝胶灌封结构在−30~30℃高低温循环进行数值模拟和实验监测。结果表明,应变的实验测试值和数值仿真结果相差7%,验证了本文建立的超弹性本构方程的可靠性和实际应用价值。Abstract: To investigate the hyperelasticity of silicone gel, its mechanical properties were characterized by uniaxial tensile (UT) test in the temperature from −30℃ to 30℃. The stress-strain curves of silicone gel at different temperatures were obtained and found that the initial elastic modulus of silicone gel is positively correlated with temperature from −30℃ to 0℃ and negatively correlated with temperature from 0℃ to 30℃. According to UT experimental data, the selection strategies and parameter determination methods of in-built hyperelastic constitutive equations (Neo Hookean, Mooney-Rivlin, Yeoh, Arruda-Boyce, etc.) were discussed in the finite element simulation. Then based on the selected Neo Hookean model, a temperature-dependent hyperelastic constitutive model was established to describe the stress-strain response of silicone gel over a wide temperature range. The temperature-dependent model was written using UHYPER subroutine of ABAQUS. In combination with fiber Bragg grating (FBG) monitoring technology, numerical simulation and experimental monitoring of silicone gel for typical encapsulation structures were carried out during high-low temperature cycles between −30℃ and 30℃. The strain results at the observation points show that the final error between experimental measurement and numerical prediction is 7%, revealing the validity of the hyperelastic constitutive equation derived in this paper and its value in practical application.

-

Key words:

- silicone gel /

- hyperelastic /

- high-low temperature cycle /

- FBG /

- potting structure

-

表 1 不同温度下各超弹性模型材料常数及确定系数R2

Table 1. Material parameters and coefficients of determination R2 of different hyperealstic models at different temperatures

Model −30℃ −15℃ 0℃ 15℃ 30℃ M-R C1=0.05825 C1=0.02064 C1=0.05401 C1=0.1028 C1=0.1545 C2=0.07124 C2=0.1306 C2=0.1119 C2=0.04166 C2=−0.02353 R2=0.9996 R2=0.9968 R2=0.9945 R2=0.9990 R2=0.9991 OdgenN1 μ1=0.2535 μ1=0.3018 μ1=0.3250 μ1=0.2830 μ1=0.2661 α1=0.7021 α1=−1.1527 α1=0.2203 α1=1.4999 α1=2.1665 R2=0.9992 R2=0.9963 R2=0.9925 R2=0.9987 R2=0.9994 N-H C1=0.1133 C1=0.1313 C1=0.1404 C1=0.1339 C1=0.1341 R2=0.9978 R2=0.9987 R2=0.9997 R2=0.9999 R2=0.9995 Yeoh C1=0.1245 C1=0.1479 C1=0.1608 C1=0.1420 C1=0.1329 C2=−0.03094 C2=−0.1330 C2=−0.07179 C2=−0.02130 C2=0.03900 C3=0.01735 C3=0.2239 C3=0.05529 C3=0.01182 C3=−0.1479 R2=0.9988 R2=0.9967 R2=0.9951 R2=0.9991 R2=0.9980 A-B μ=0.2266 μ=0.2626 μ=0.2807 μ=0.2679 μ=0.2648 λm=1 452.7355 λm=648.3473 λm=1 445.2560 λm=1 288.5382 λm=7.0010 R2=0.9978 R2=0.9987 R2=0.9997 R2=0.9999 R2=0.9995 Notes: Ci(i= 1, 2, 3), μ1, α1—Material constants of hyperelastic models; λm—Limiting drawing ratio; R2—Determining coefficient. 表 2 硅凝胶及内部器件热物理及力学性能参数值

Table 2. Parameter values for the thermophysical and mechanical properties of silicone gel and internal components

Parameter 3240 Silicone gel Material-1 Material-2 Material-3 Material-4 K/(W·(m·K)−1) K11=1.27 0.17 K11=0.77 17.3 0.4 7.0 K22=1.27 K22=0.77 K33=0.69 K33=1.77 C/(J·kg−1·K−1) 784.5 1161.2 791.6 454.6 1260.0 1000.0 ρ/(kg·m−3) 2110 1029 2090 8300 1550 4800 α α11=1.777×10−5 5.8×10−4 α11=1.936×10−5 5.60×10−6 1.25×10−5 1.00×10−6 α22=1.777×10−5 α22=1.936×10−5 α33=2.168×10−5 α33=2.726×10−5 E/Pa E11=18.89×109 E11=26.44×109 138.0×109 9.50×109 1.20×109 E22=18.89×109 E22=26.44×109 E33=7.17×109 E33=10.03×109 ν ν12=0.25 ν12=0.23 0.30 0.30 0.30 ν13=0.30 ν13=0.36 ν23=0.30 ν23=0.36 Notes: K—Thermal conductivity (subscript value 11, 22 and 33 represent values in different directions); C—Specific heat; ρ—Density; α—Coefficient of thermal expansion (subscript value 11, 22 and 33 represent values in different directions); E—Young’s modulus (subscript value 11, 22 and 33 represent values in different directions); ν—Poisson’s ratio (subscript value 12, 13 and 23 represent values in different directions). -

[1] 幸松民, 王一璐. 有机硅合成工艺及产品应用[M]. 北京: 化学工业出版社, 2000: 614-663.XING Songmin, WANG Yilu. Silicone synthesis process and product application[M]. Beijing: Chemical Industry Press, 2000: 614-663(in Chinese). [2] 王佐, 程宪涛, 吴向荣. 动力电池箱体密封用硅凝胶的研制[J]. 有机硅材料, 2019, 33(4):287-291.WANG Zuo, CHENG Xiantao, WU Xiangrong. Development of silicone gel for power battery case[J]. Silicone Material,2019,33(4):287-291(in Chinese). [3] YAO Y, LU G, BOROYEVICH D, et al. Survey of high-temperature polymeric encapsulants for power electronics packaging[J]. IEEE Transactions on Components, Packaging and Manufacturing Technology,2015,5(2):168-181. doi: 10.1109/TCPMT.2014.2337300 [4] 何泱, 耿力东, 冯传均, 等. 基于低压直流供电的100 kV重频高压电源[J]. 高电压技术, 2018, 44(9):3028-3034.HE Yang, GENG Lidong, FENG Chuanjun, et al. 100 kV repetitive high-voltage power supply based on low voltage DC input[J]. High Voltage Engineering,2018,44(9):3028-3034(in Chinese). [5] LI-TSANG C W P, LAU J C M, CHOI J, et al. A prospective randomized clinical trial to investigate the effect of silicone gel sheeting (Cica-Care) on post-traumatic hypertrophic scar among the Chinese population[J]. Burns,2006,32(6):678-683. doi: 10.1016/j.burns.2006.01.016 [6] SONG T, KIM K H, LEE K W. Randomised comparison of silicone gel and onion extract gel for post-surgical scars[J]. Journal of Obstetrics and Gynaecology,2018,38(5):702-707. doi: 10.1080/01443615.2017.1400524 [7] SCHNEIDER F A, FELLNER T B, WILDE J B, et al. Mechanical properties of silicones for MEMS[J]. Journal of Micromechanics& Microengineering,2008,18(6):065008. [8] LI H, LI Y, LAI X, et al. Investigation of ureido-attached vinyl MQ silicone resin on tracking and erosion resistance of addition-cure liquid silicone rubber[J]. Journal of Applied Polymer Science,2019,136(15):47360. doi: 10.1002/app.47360 [9] 迟庆国, 李振, 张天栋, 等. 钛酸铜钙纳米纤维/液体硅橡胶复合介质非线性电导性能[J]. 复合材料学报, 2019, 36(10):2247-2258.CHI Qingguo, LI Zhen, ZHANG Tiandong, et al. Nonlinear conductivity of copper calcium titanate nanofibers/liquid silicone rubber composite[J]. Acta Materiae Compositae Sinica,2019,36(10):2247-2258(in Chinese). [10] 尚南强, 陈庆国, 秦君. 纳米TiO2/液体硅橡胶直流电缆附件绝缘复合材料的介电性能[J]. 复合材料学报, 2019, 36(1):104-113.SHANG Nanqiang, CHEN Qingguo, QIN Jun. Dielectric properties of nano TiO2/liquid silicone rubber composites for direct current cable accessories insulation[J]. Acta Materiae Compositae Sinica,2019,36(1):104-113(in Chinese). [11] XIE C, LAI X, LI H, et al. Improvement of fluorosilicone resin on the tracking resistance of addition-cure liquid silicone rubber[J]. Journal of macromolecular science Part A, Pure and Applied Chemistry,2020,57(10):1-9. [12] OU Z, GAO F, ZHAO H, et al. Research on the thermal conductivity and dielectric properties of AlN and BN co-filled addition-cure liquid silicone rubber composites[J]. RSC Advances,2019,9(49):28851-28856. doi: 10.1039/C9RA04771A [13] FANG W, LAI X, LI H, et al. Effect of urea-containing anti-tracking additive on the tracking and erosion resistance of addition-cure liquid silicone rubber[J]. Polymer Testing,2014,37:19-27. doi: 10.1016/j.polymertesting.2014.04.007 [14] WANG J, CHEN Y, JIN Q. A novel reinforcing filler: Application to addition-type liquid silicone rubber adhesive system[J]. Journal of Adhesion Science and Technology,2006,20(2-3):261-276. doi: 10.1163/156856106775897784 [15] HUANG B, DAI L, CHEN Z, et al. Role of in-situ polymethyl-methacrylate in addition type silicone rubber with specific reference to adhesion and damping properties[J]. Journal of Applied Polymer Science,2021,138(16):50252. doi: 10.1002/app.50252 [16] 谭必恩, 张廉正, 郝志刚, 等. 加成型硅橡胶的制备及性能[J]. 高分子材料科学与工程, 2002, 18(2):180-182. doi: 10.3321/j.issn:1000-7555.2002.02.044TAN Bien, ZHANG Lianzheng, HAO Zhigang, et al. Preparation of addition type silicone rubber and its property[J]. Polymer Materials Science & Engineering,2002,18(2):180-182(in Chinese). doi: 10.3321/j.issn:1000-7555.2002.02.044 [17] 冯传均, 王传伟, 戴文峰, 等. 高压模块的有机硅凝胶灌封工艺设计与改进[J]. 电子工艺技术, 2015, 36(1):51-54.FENG Chuanjun, WANG Chuanwei, DAI Weifeng, et al. Silicone gel encapsulation process design and improvement of high-voltage module[J]. Electronics Process Technology,2015,36(1):51-54(in Chinese). [18] 罗刚. 电子器件灌封材料的现状及发展趋势[J]. 实验科学与技术, 2010(3):20-22. doi: 10.3969/j.issn.1672-4550.2010.03.008LUO Gang. Present situation and development trend of potting materials using in electron device[J]. Experiment Science and Technology,2010(3):20-22(in Chinese). doi: 10.3969/j.issn.1672-4550.2010.03.008 [19] 康峻铭, 孙亮亮, 王继辉, 等. 电子封装用环氧树脂固化温度与应变的三维有限元模拟[J]. 复合材料学报, 2019, 36(10):2330-2340.KANG Junming, SUN Liangliang, WANG Jihui, et al. Three-dimensional finite element simulation of temperature and strain in epoxy resin used to electronic packaging during curing[J]. Acta Materiae Compositae Sinica,2019,36(10):2330-2340(in Chinese). [20] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Rubber, vulcanized or thermoplastic-Determination of tensile stress-strain properties: GB/T 528—2009[S]. Beijing: China Standards Press, 2005(in Chinese). [21] LION A. On the large deformation behaviour of reinforced rubber at different temperatures[J]. Journal of the Mechanics & Physics of Solids,1997,45(11-12):1805-1834. [22] RIVLIN R S. Large elastic deformations of isotropic materials. IV. Further developments of the general theory[J]. Philosophical Transactions of The Royal Society A Mathematical Physical and Engineering Sciences,1948,241(835):379-397. [23] MARCKMANN G, VERRON E. Comparison of hyperelastic models for rubber-like materials[J]. Rubber Chemistry & Technology,2008,79(5):835-858. [24] MOONEY M. A theory of large elastic deformation[J]. Journal of Applied Physics,1940,11(9):582-592. doi: 10.1063/1.1712836 [25] OGDEN R W. Large deformation isotropic elasticity-on the correlation of theory and experiment for incompressible rubberlike solids[J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences,1972,328(1575):567-583. [26] YEOH O H. Some forms of the strain energy function for rubber[J]. Rubber Chemistry & Technology,1993,66(5):754-771. [27] GENT A N. A new constitutive relation for rubber[J]. Rubber Chemistry & Technology,1996,69(1):59-61. [28] FU X, WANG Z, MA L, et al. Temperature-dependence of rubber hyperelasticity based on the eight-chain model[J]. Polymers,2020,12(4):932-946. [29] GIORDANO M, LAUDATI A, NASSER J, et al. Monitoring by a single fiber Bragg grating of the process induced chemo-physical transformations of a model thermoset[J]. Sensors and Actuators A: Physical,2004,113(2):166-173. doi: 10.1016/j.sna.2004.02.033 -

下载:

下载: