Mechanical properties of alkali activated slag concrete with ultra fine dredged sand from Yangtze River

-

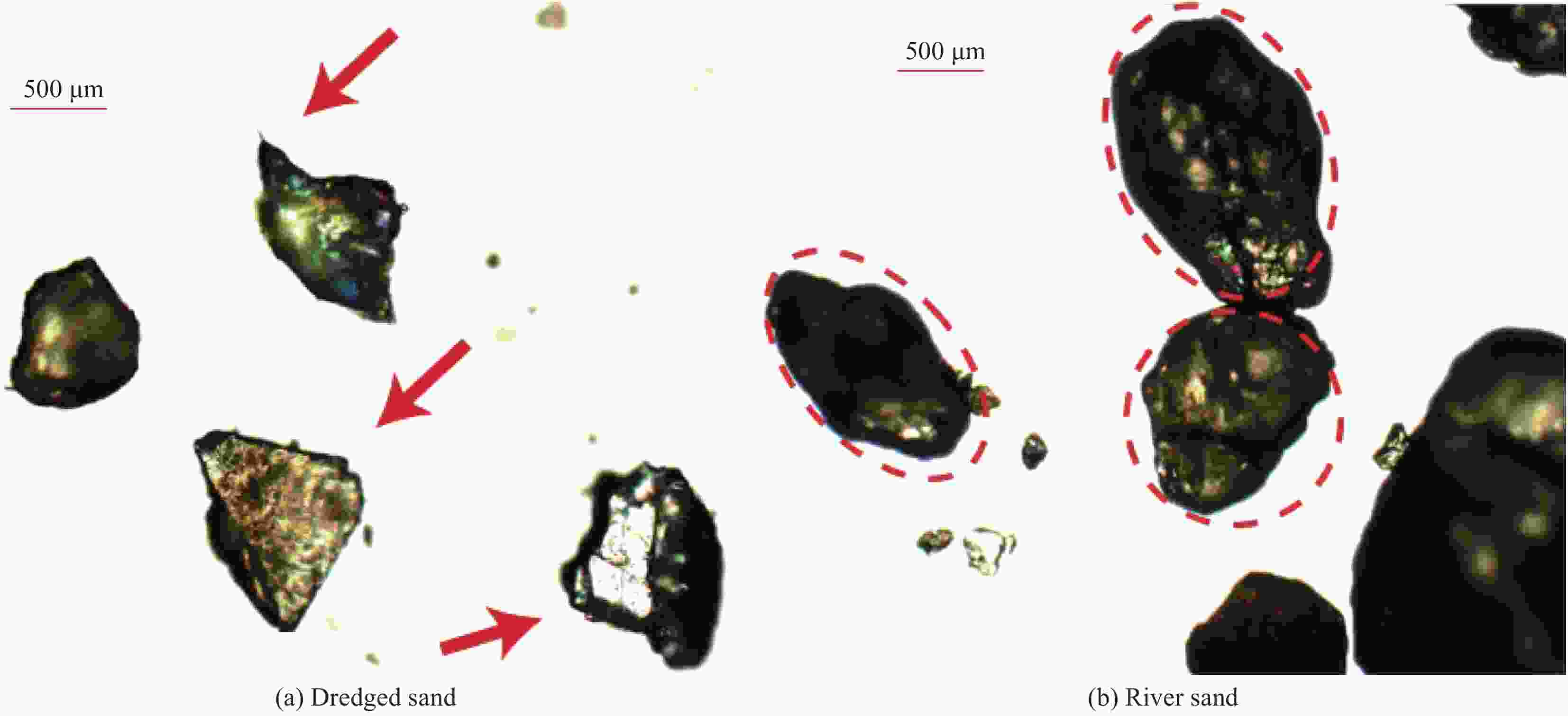

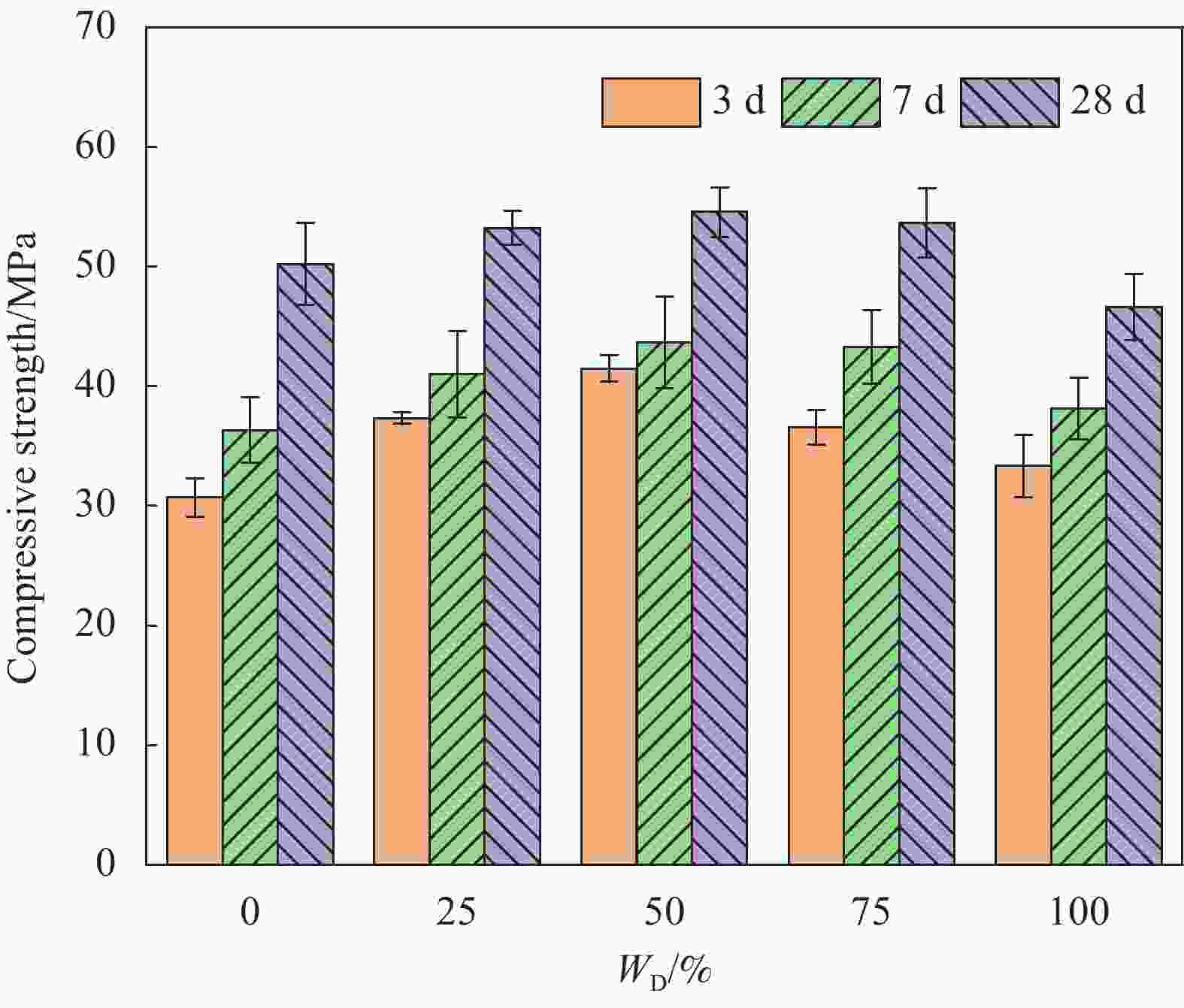

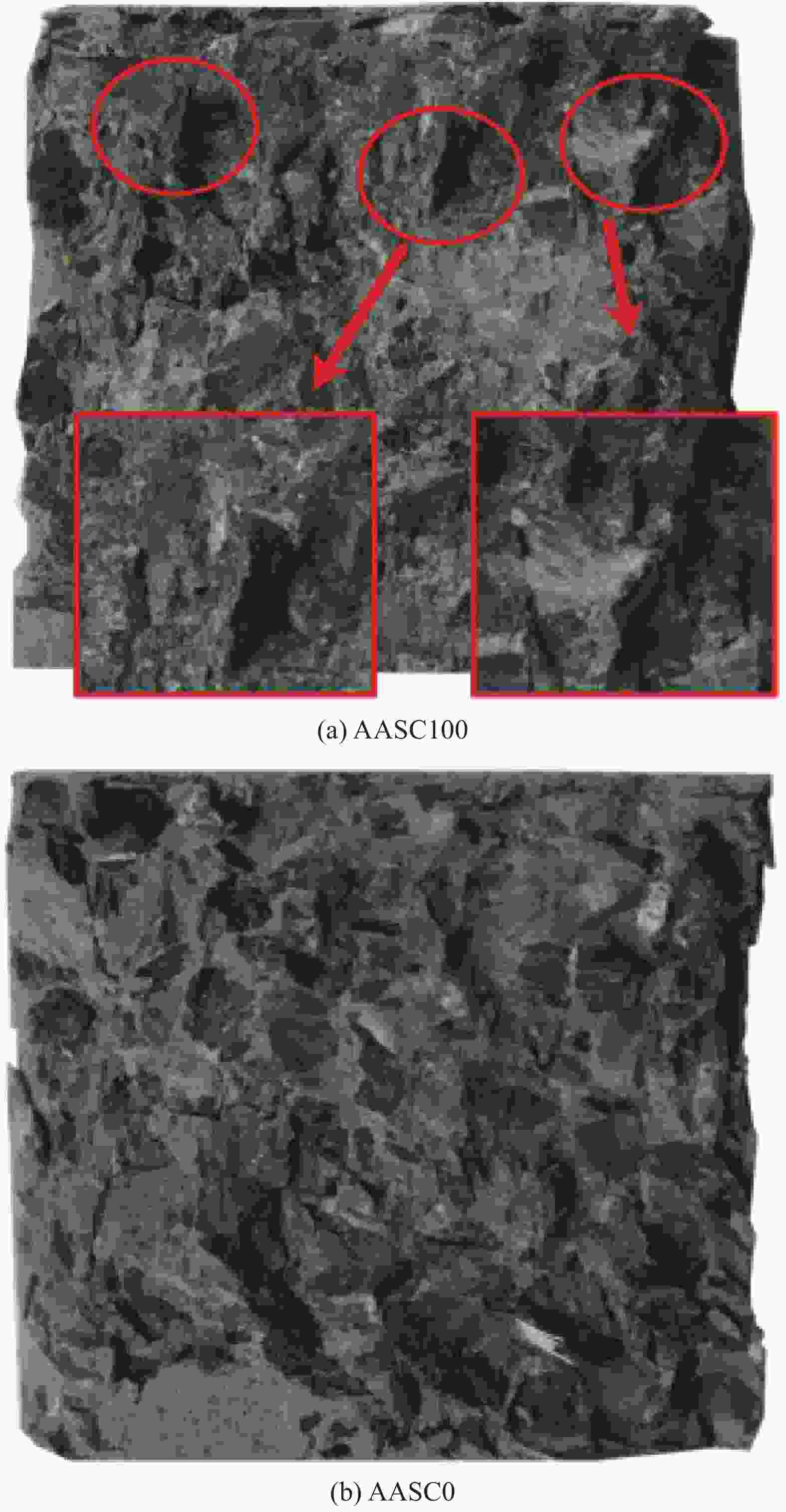

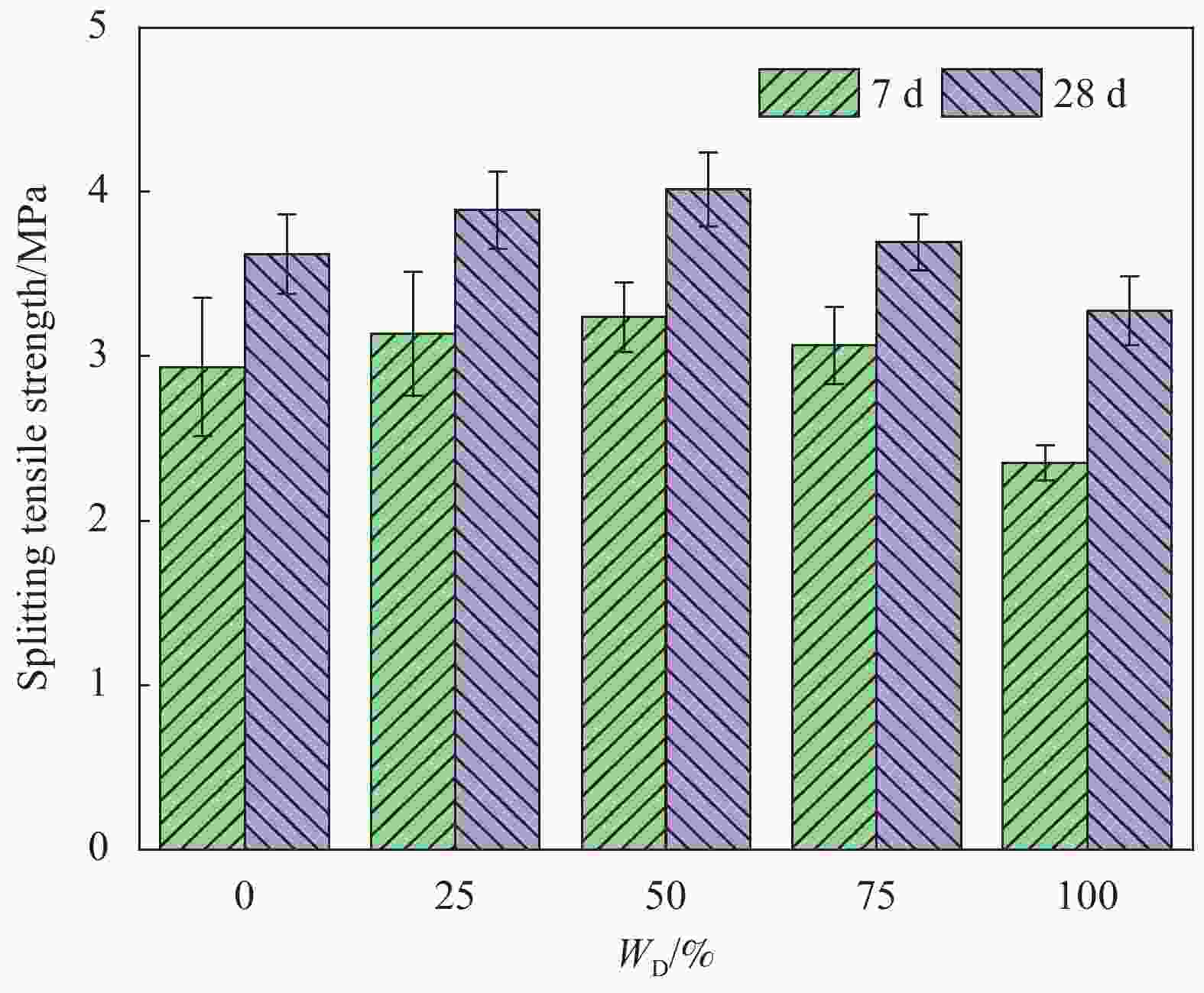

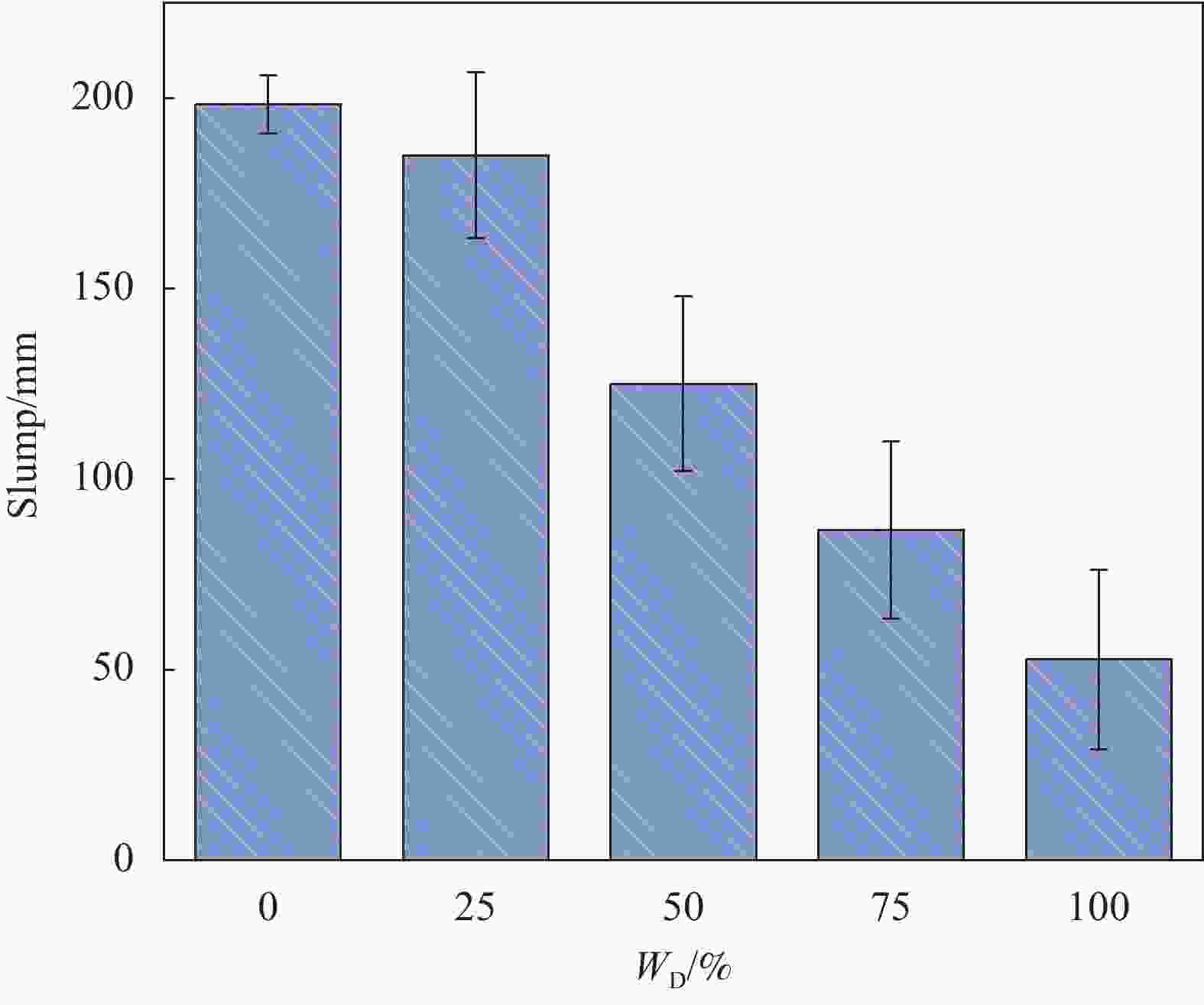

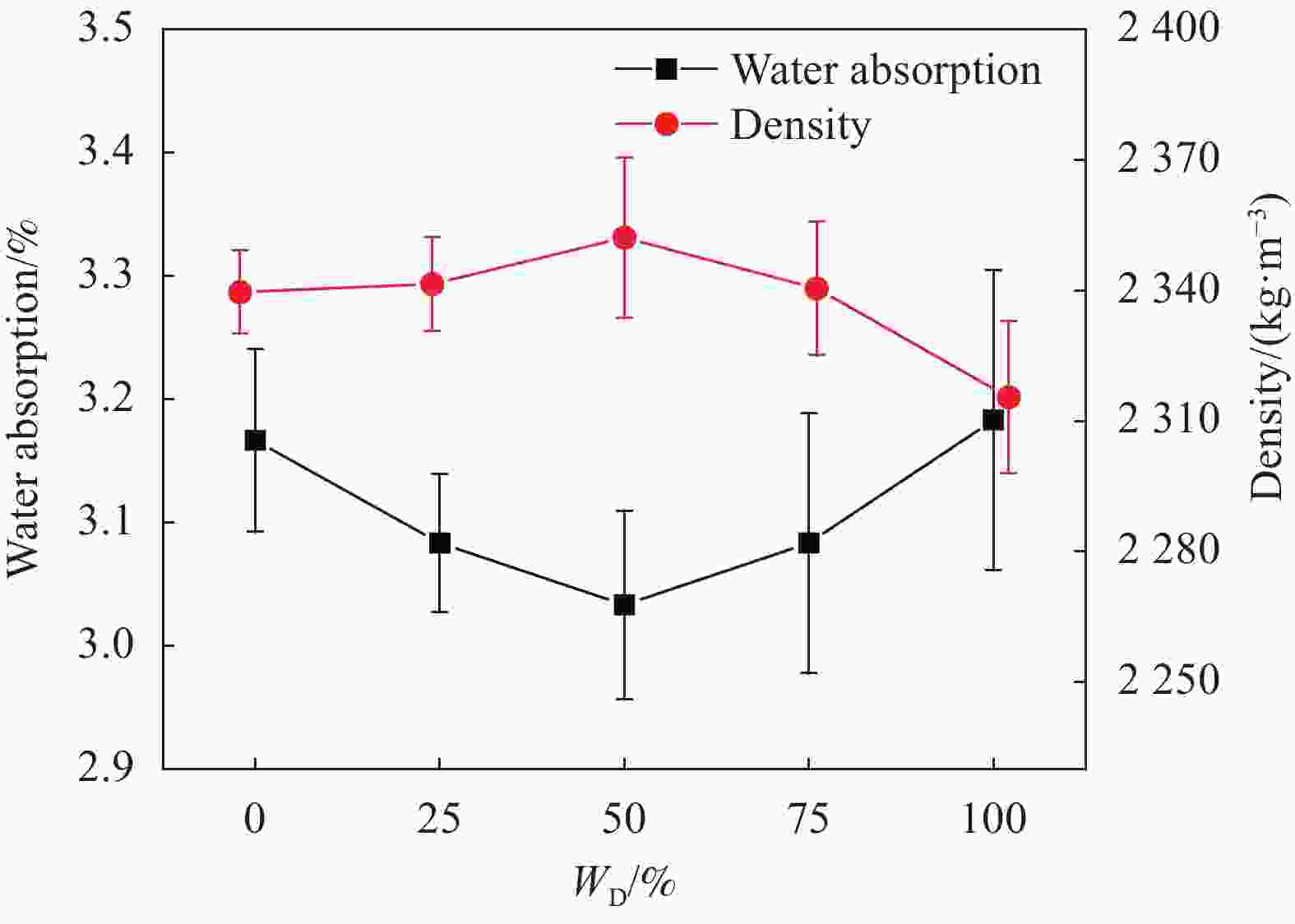

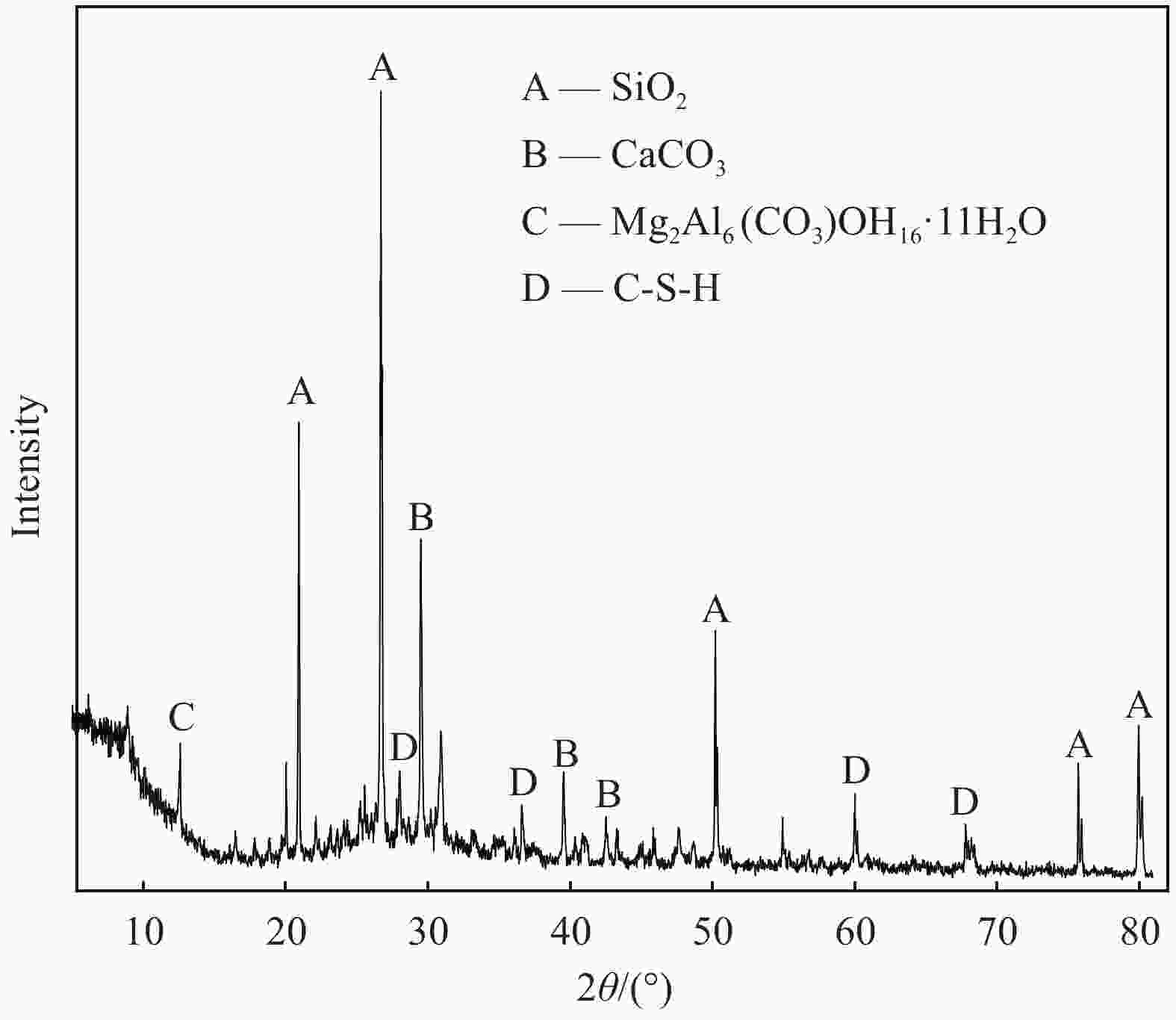

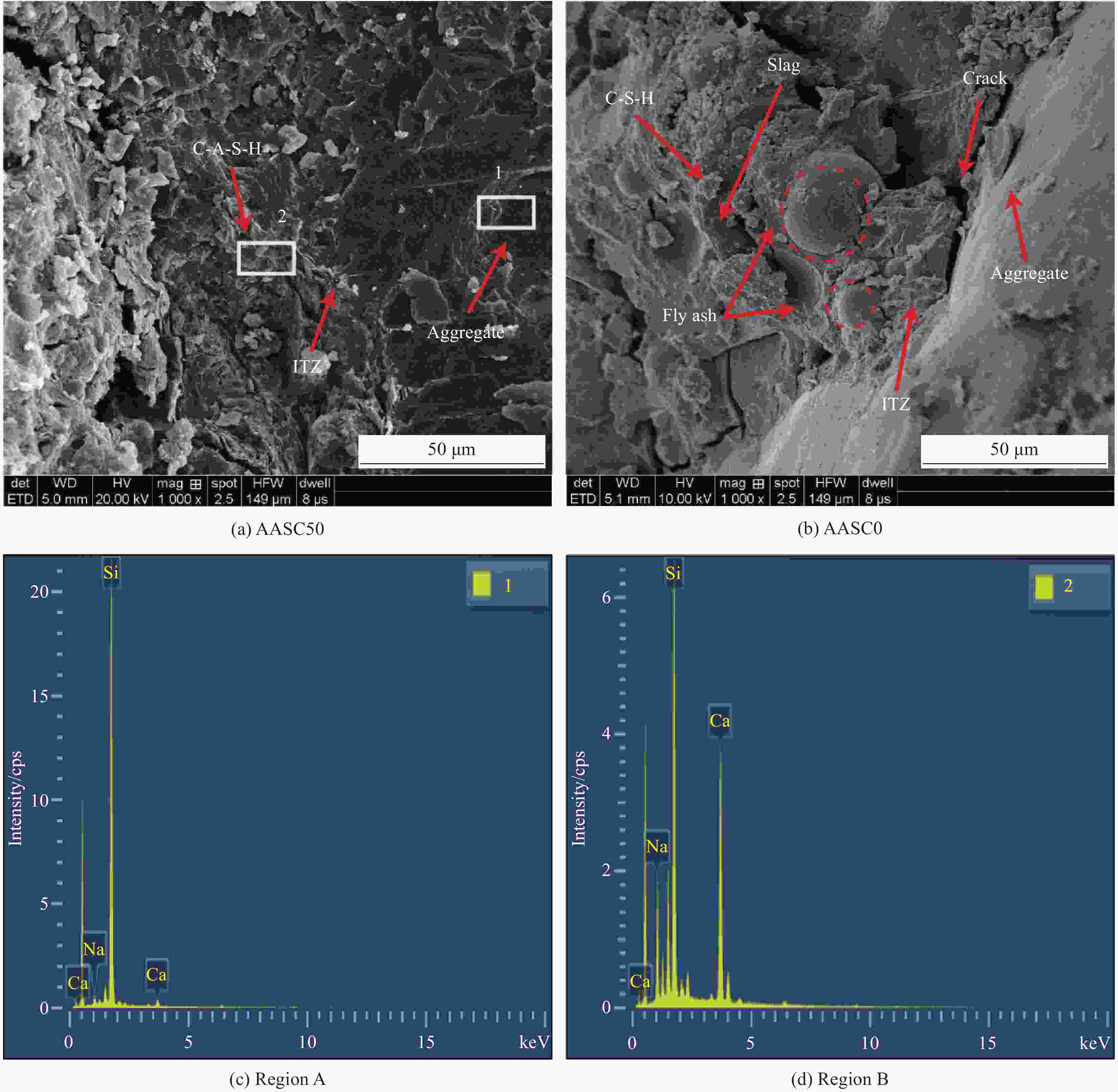

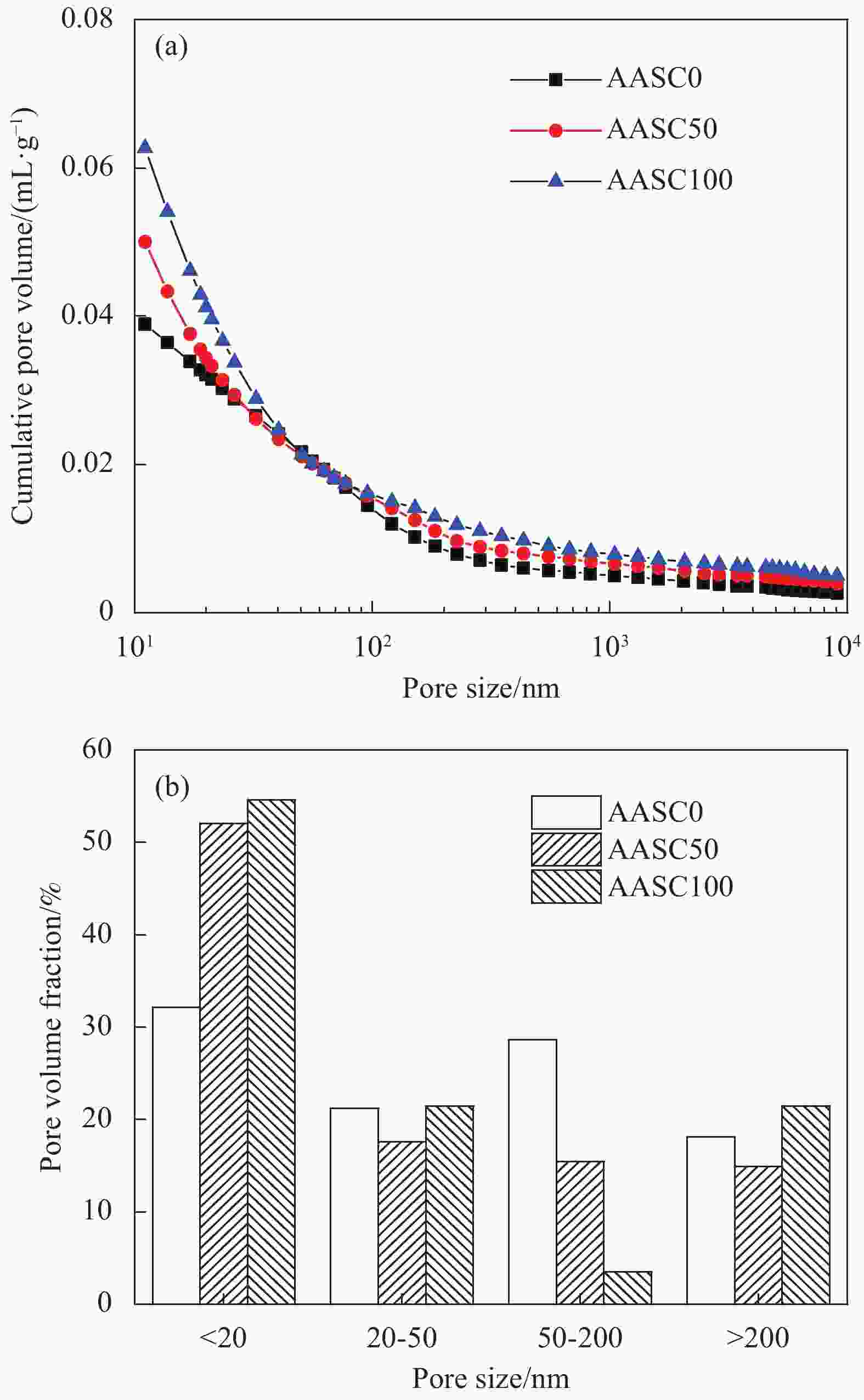

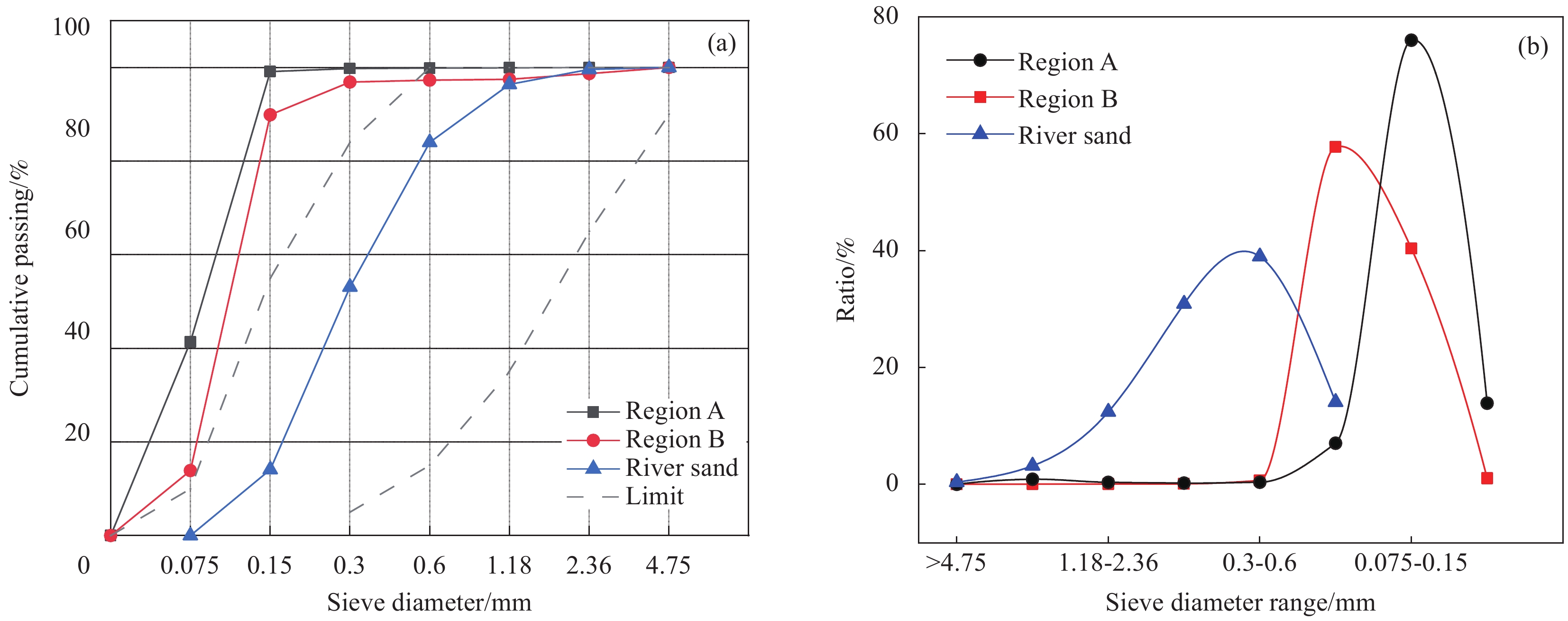

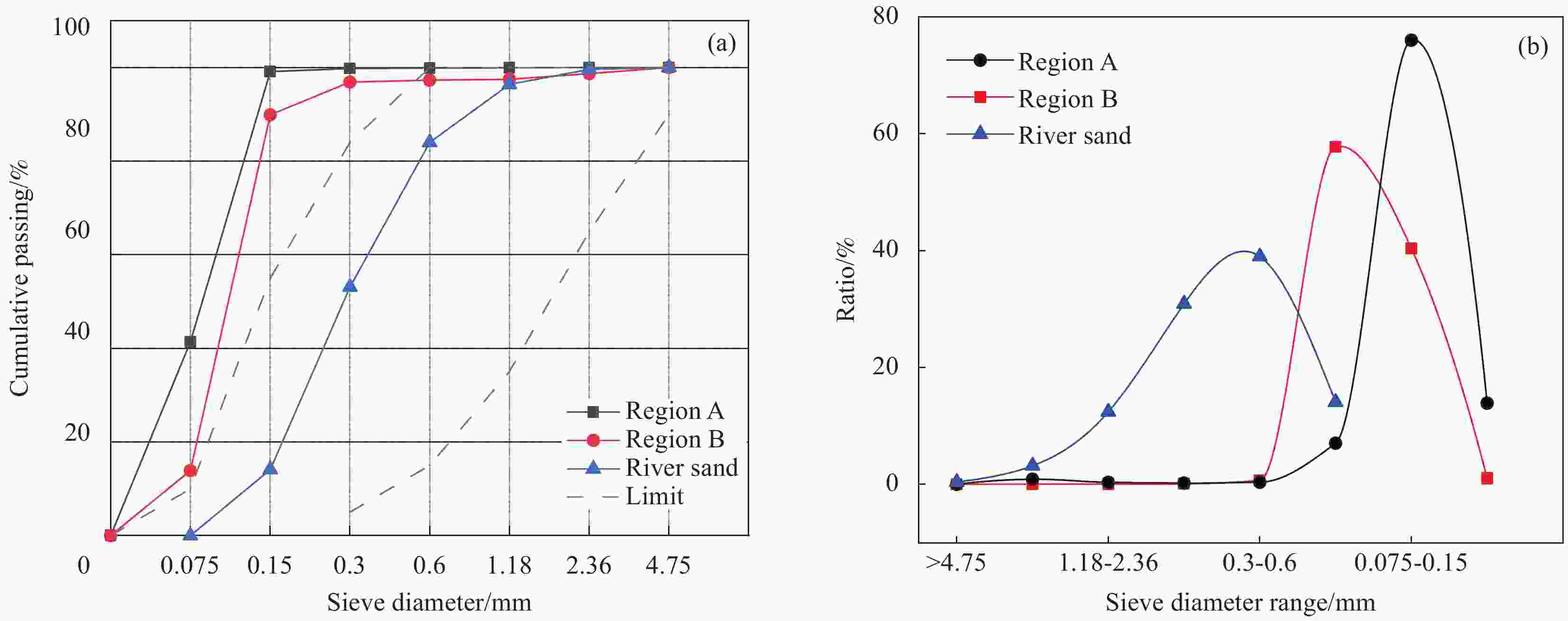

摘要: 分析了长江下游航道超细疏浚砂的理化性质,并以超细疏浚砂为原料,设计了5种不同疏浚砂掺量的碱激发矿渣混凝土(AASC)配合比,研究了其流动性、抗压强度、劈拉强度和吸水率的变化。通过SEM、XRD和压汞(MIP)技术,分析了AASC的物相组成和微观结构。研究表明:长江下游航道的超细疏浚砂颗粒细度模数在0.1~0.5之间。随着超细疏浚砂掺量的提升,试件的抗压强度和劈拉强度呈先上升后降低的趋势,而其流动性持续下降。在疏浚砂掺量(疏浚砂与细骨料的质量比)为50%时,AASC具有较好的力学性能和工作性能。试件的吸水率、密度测试以及SEM和MIP观察表明,适当掺入疏浚砂能够增加混凝土密实度,改善混凝土界面过渡区的结构,但过量疏浚砂导致混凝土流动性降低,且混凝土内的多害孔隙增加。Abstract: The physical and chemical properties of ultra-fine dredged sand in the lower reaches of the Yangtze River were analyzed. Five kinds of alkali activated slag concrete (AASC) mix proportions with different contents of ultra-fine dredged sand were designed. The fluidity, compressive strength, splitting tensile strength, density and water absorption were studied. The microstructure and phase composition of AASC were analyzed by SEM, XRD and mercury intrusion porosimetry (MIP). The results show that the fineness modulus of the ultra-fine dredged sand is between 0.1 and 0.5. With the increase of ultra-fine dredged sand content, the compressive strength and splitting tensile strength first increase and then decrease, while the fluidity continues to decline. When the dredged sand content (mass ratio to fine aggregate) reaches 50%, AASC obtains proper mechanical properties and workability. The results of water absorption, density test, SEM observation and MIP test show that the appropriate addition of dredged sand can increase the compactness of concrete and improve the structure of interface transition zone, but excessive dredged sand can reduce the fluidity of concrete and increase the porosity of concrete.

-

表 1 矿渣化学成分

Table 1. Chemical composition of slag

Component CaO SiO2 Al2O3 MgO TiO2 S Na2O K2O Ratio/wt% 39.42 33.04 15.64 7.80 1.28 1.05 0.61 0.39 表 2 长江疏浚砂具体物理性能参数

Table 2. Physical properties of dredged sand from Yangtze River

Apparent density/

(kg·m−3)Bulk density/

(kg·m−3)Higher feed density/

(kg·m−3)Water

content/wt%Clay

content/wt%Porosity/

vol%Fineness

modulus2686-2695 1331-1404 2400-2800 11.4-17.8 1.9-3.2 9.7-18.5 0.1-0.5 表 3 不同疏浚砂掺量的碱激发矿渣混凝土(AASC)配合比 WD

Table 3. Mix proportion of alkali activated slag concrete (AASC) with different dredged sand contents

$ {{W}}_{\rm{D}} $ (kg·m−3) Group Stone Dredged sand River sand Fly ash Slag Sodium silicate Water Water reducer AASC0 1125 0 606 150 350 140 155 0.87 AASC25 1125 151.5 454 150 350 140 155 0.87 AASC50 1125 189 189 150 350 140 155 0.87 AASC75 1125 454 151.5 150 350 140 155 0.87 AASC100 1125 606 0 150 350 140 155 0.87 -

[1] LIRER S, LIGUORI B, CAPASSO I, et al. Mechanical and chemical properties of composite materials made of dredged sediments in a fly-ash based geopolymer[J]. Journal of Environmental Management,2017,191:1-7. [2] 李青云. 推进长江航道疏浚砂综合利用[N]. 中国水运报, 2020-04-01(1).LI Qingyun. Promoting comprehensive utilization of dredged sand in Yangtze River[N]. China Water Transport News, 2020-04-01(1). (in Chinese). [3] 丁慧, 孙秀丽, 刘文化, 等. 固化疏浚淤泥作路基材料工程特性试验研究[J]. 土木建筑与环境工程, 2017, 39(2):11-18.DING Hui, SUN Xiuli, LIU Wenhua, et al. Experimental analysis of engineering properties of solidified sludge as roadbed filling material[J]. Journal of Civil, Architectural & Environmental Engineering,2017,39(2):11-18(in Chinese). [4] SIHAM K, FABRICE B, EDINE A N, et al. Marine dredged sediments as new materials resource for road construction[J]. Waste Management,2008,28(5):919-928. doi: 10.1016/j.wasman.2007.03.027 [5] 何宁, 沈雪松, 周彦章, 等. 大型疏浚土充填袋筑堤技术研究[J]. 岩土工程学报, 2015, 37(3):440-445.HE Ning, SHEN Xuesong, ZHOU Yanzhang, et al. Study on large dredged soil filling bag embankment technology[J]. Journal of Geotechnical Engineering,2015,37(3):440-445(in Chinese). [6] AMAR M, BENZERZOUR M, SAFHI A E M, et al. Durability of a cementitious matrix based on treated sediments[J]. Case Studies in Construction Materials,2018,8:258-276. doi: 10.1016/j.cscm.2018.01.007 [7] CHEN H J, YANG M D, TANG C W, et al. Producing synthetic lightweight aggregates from reservoir sediments[J]. Construction and Building Materials,2012,28(1):387-394. doi: 10.1016/j.conbuildmat.2011.08.051 [8] HUANG X, LI G, PAN X, et al. Kinetic characteristics of lightweight aggregates obtained from dredged sediment[J]. Journal of Thermal Analysis and Calorimetry,2016,126(3):1201-1209. doi: 10.1007/s10973-016-5610-8 [9] 刘霞, 李峰, 佘殷鹏. 玄武岩纤维增强聚合物筋增强珊瑚礁砂混凝土柱轴压试验[J]. 复合材料学报, 2020, 37(10):2428-2438.LIU Xia, LI Feng, SHE Yinpeng. Axial compression test of basalt fiber reinforced polymer reinforced coral reef and sand aggregate concrete column[J]. Acta Materiae Compositae Sinica,2020,37(10):2428-2438(in Chinese). [10] PENG X, ZHOU Y, JIA R, et al. Preparation of non-sintered lightweight aggregates from dredged sediments and modification of their properties[J]. Construction and Building Materials,2017,132:9-20. doi: 10.1016/j.conbuildmat.2016.11.088 [11] TANG C W, CHEN H J, WANG S Y, et al. Production of synthetic lightweight aggregate using reservoir sediments for concrete and masonry[J]. Cement and Concrete Composites,2011,33(2):292-300. doi: 10.1016/j.cemconcomp.2010.10.008 [12] BERNAL S A, RUBY M D G, PEDRAZA A L, et al. Effect of binder content on the performance of alkali-activated slag concretes[J]. Cement and Concrete Research,2011,41(1):1-8. doi: 10.1016/j.cemconres.2010.08.017 [13] FANG G, ZHANG M. Multiscale micromechanical analysis of alkali-activated fly ash-slag paste[J]. Cement and Concrete Research,2020,135:106141. doi: 10.1016/j.cemconres.2020.106141 [14] SEO J, BAE S J, JANG D I, et al. Thermal behavior of alkali-activated fly ash/slag with the addition of an aerogel as an aggregate replacement[J]. Cement and Concrete Composites,2020,106:103462. [15] ADESANYA E, OHENOJA K, DI MARIA A, et al. Alternative alkali-activator from steel-making waste for one-part alkali-activated slag[J]. Journal of Cleaner Production,2020,274:123020. doi: 10.1016/j.jclepro.2020.123020 [16] 黄鑫, 姜景山, 孙天洋, 等. 玄武岩-碳纤维/矿渣混凝土力学性能正交试验[J]. 复合材料学报, 2020, 37(7):1743-1753.HUANG Xin, JIANG Jingshan, SUN Tianyang. et al. Orthogonal test on mechanical properties of basalt carbon fiber / slag concrete[J]. Acta Materiae Compositae Sinica,2020,37(7):1743-1753(in Chinese). [17] 中华人民共和国水利部. 水工混凝土试验规程: SL 352—2006[S]. 北京: 中国水利水电出版社, 2006.Ministry of Water Resources of the People's Republic of China. Test code for hydraulic concrete: SL 352—2006[S]. Beijing: China Water & Power Press, 2006 (in Chinese). [18] 中华人民共和国住房和城乡建设部. 普通混凝土力学性能试验方法标准: GB/T 50081—2002[S]. 北京: 中国建筑工业出版社, 2003.Ministry of Housing and Urban-Rural Development of the People's Republic of China. Standard for test method of mechanical properties on ordinary concrete: GB/T 50081—2002[S]. Beijing: China Architecture & Building Press, 2003 (in Chinese). [19] 郑文忠, 邹梦娜, 王英. 碱激发胶凝材料研究进展[J]. 建筑结构学报, 2019, 40(1):28-39.ZHENG Wenzhong, ZOU Mengna, WANG Ying. Research progress of alkali activated cementitious materials[J]. Journal of Building Structure,2019,40(1):28-39(in Chinese). [20] SIDDIQUE R, SCHUTTER G D, NOUMOWE A. Effect of used-foundry sand on the mechanical properties of concrete[J]. Construction and Building Materials,2009,23(2):976-980. doi: 10.1016/j.conbuildmat.2008.05.005 [21] 郭东, 苏春义, 彭自强, 等. 海水拌和珊瑚礁砂混凝土力学性能及微观结构[J]. 建筑材料学报, 2018, 21(1):41-46. doi: 10.3969/j.issn.1007-9629.2018.01.007GUO Dong, SU Chunyi, PENG Ziqiang. et al. Mechanical properties and microstructure of coral reef sand concrete mixed with seawater[J]. Journal of Building Materials,2018,21(1):41-46(in Chinese). doi: 10.3969/j.issn.1007-9629.2018.01.007 [22] 李玉根, 张慧梅, 刘光秀, 等. 风积砂混凝土基本力学性能及影响机理[J]. 建筑材料学报, 2020, 23(5):1212-1221. doi: 10.3969/j.issn.1007-9629.2020.05.030LI Yugen, ZHANG Huimei, LIU Guangxiu, et al. Basic mechanical properties and influence mechanism of aeolian sand concrete[J]. Journal of Building Materials,2020,23(5):1212-1221(in Chinese). doi: 10.3969/j.issn.1007-9629.2020.05.030 [23] SIDDIQUE R, AGGARWAL Y, AGGARWAL P, et al. Strength, durability and micro-structural properties of concrete made with used-foundry sand (UFS)[J]. Construction and Building Materials,2011,25(4):1916-1925. doi: 10.1016/j.conbuildmat.2010.11.065 [24] JOSE I E G, FUENTES A F, GOROKHOVSKY A, et al. Hydration products and reactivity of blast-furnace slag activated by various alkalis[J]. Journal of the American Ceramic Society,2010,86(12):2148-2153. [25] ZHANG J, SHI C, ZHANG Z. Carbonation induced phase evolution in alkali-activated slag/fly ash cements: The effect of silicate modulus of activators[J]. Construction and Building Materials,2019,223:556-582. [26] GRUSKOVNJAK A, LOTHENBACH B, HOLZER L, et al. Hydration of alkali-activated slag: Comparison with ordinary Portland cement[J]. Advances in Cement Research,2006,18(3):119-128. doi: 10.1680/adcr.2006.18.3.119 [27] 吴中伟, 廉慧珍. 高性能混凝土[M]. 北京: 中国铁道出版社, 1999: 120-125.WU Zhongwei, LIAN Huizhen. High performance concrete[M]. Bejjing: China Railway Publishing House, 1999: 120-125 (in Chinese). -

下载:

下载: