Synergistic improvement of electrical conductivity and interlaminar toughness of carbon fiber resin matrix composites based on intercalation method

-

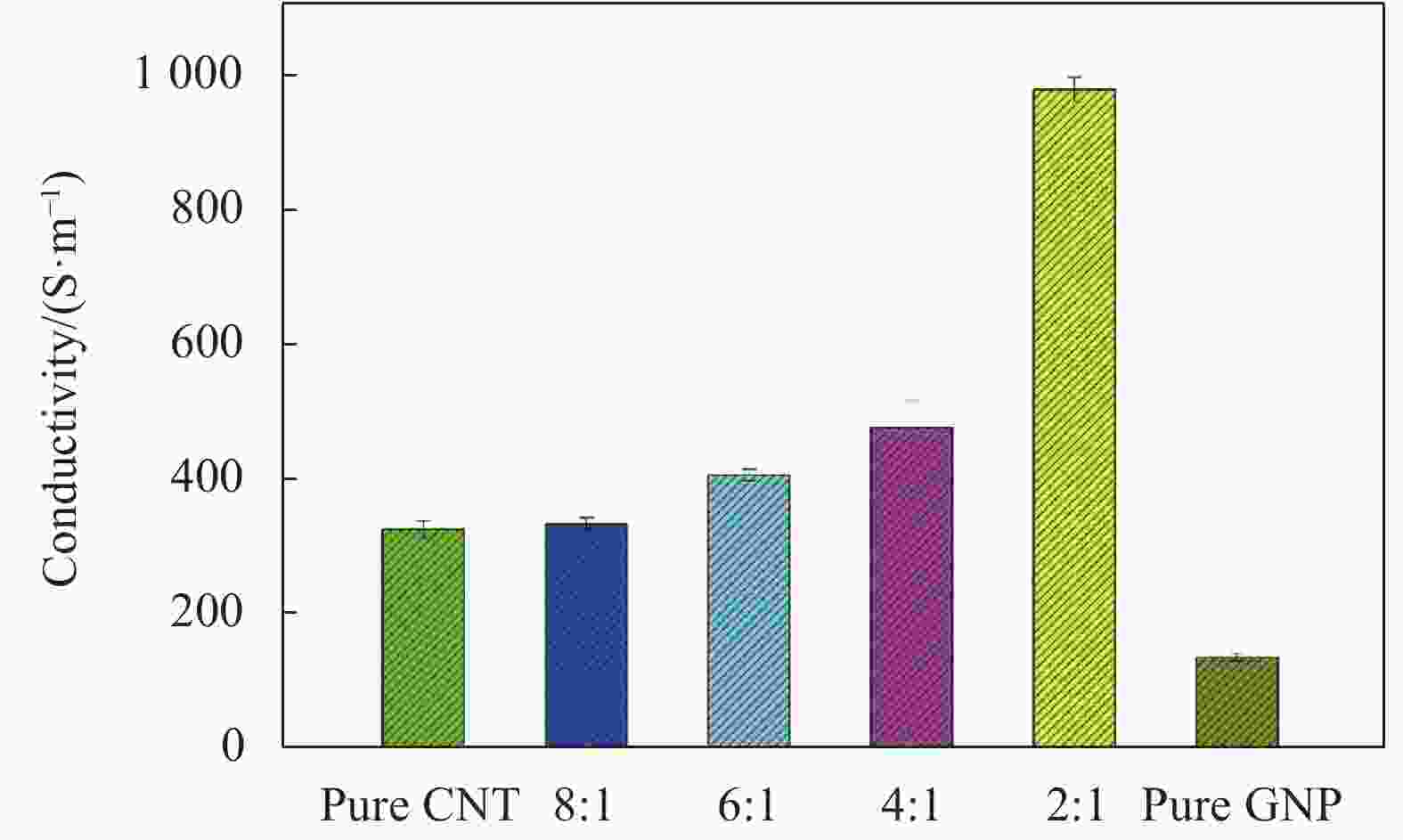

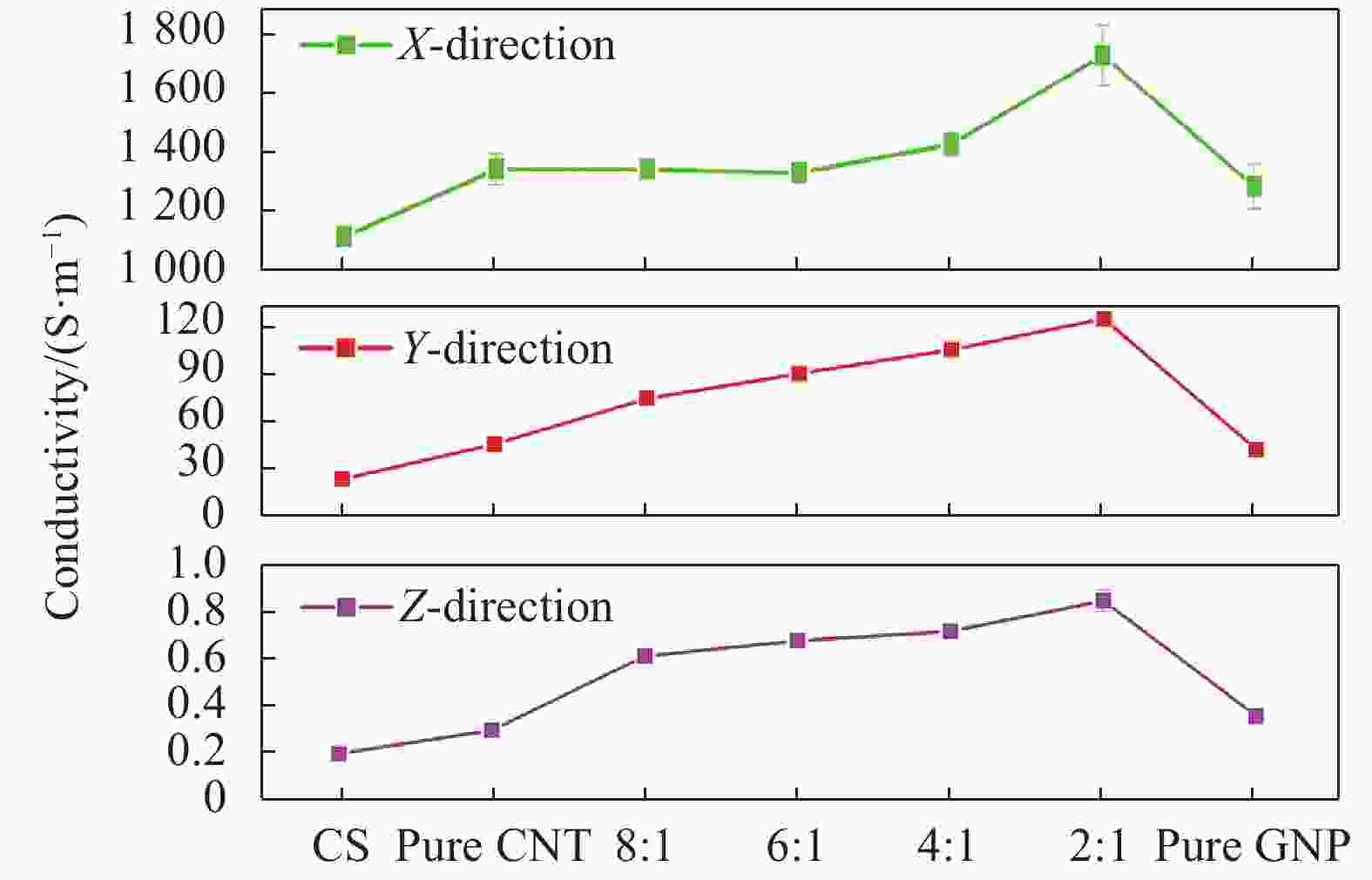

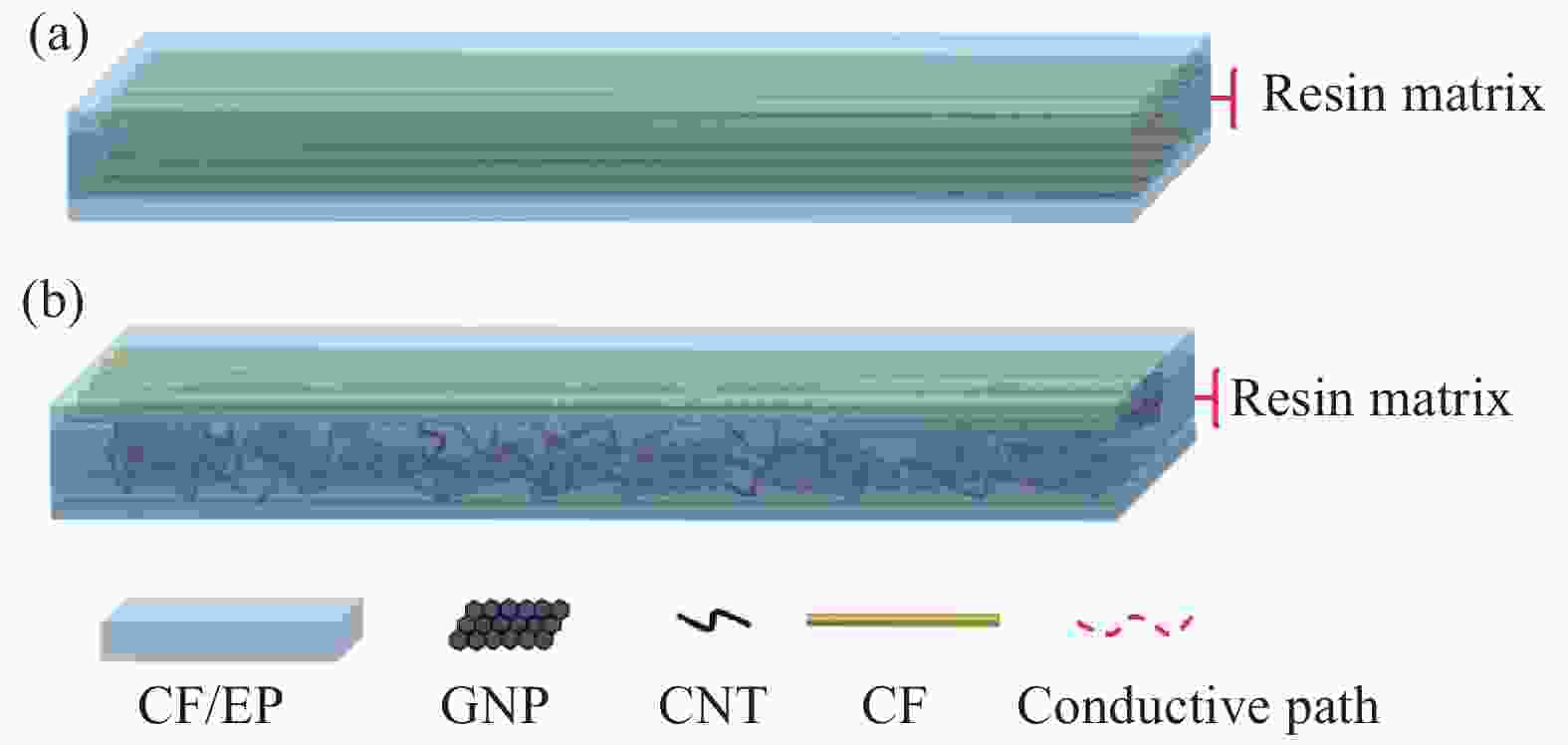

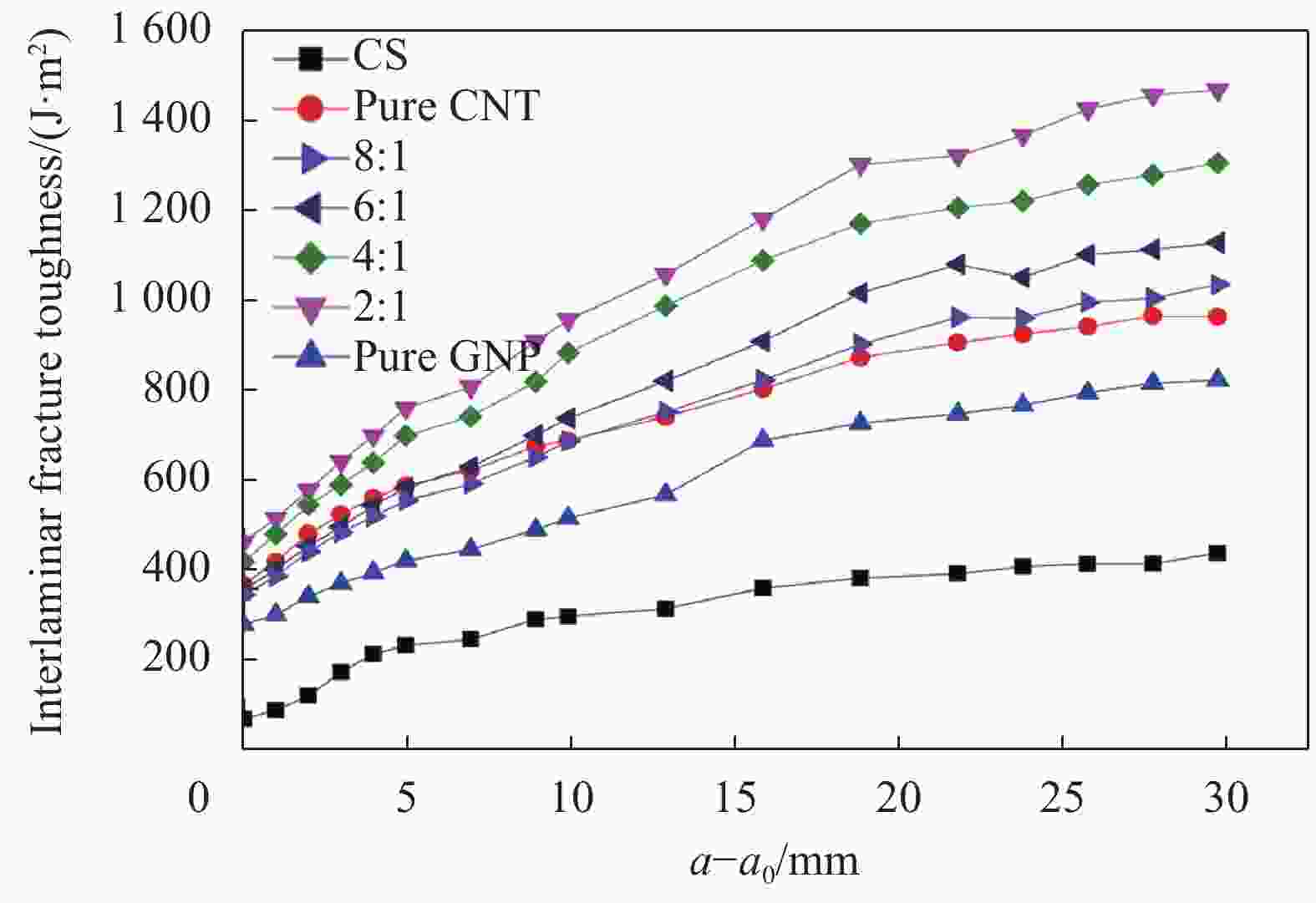

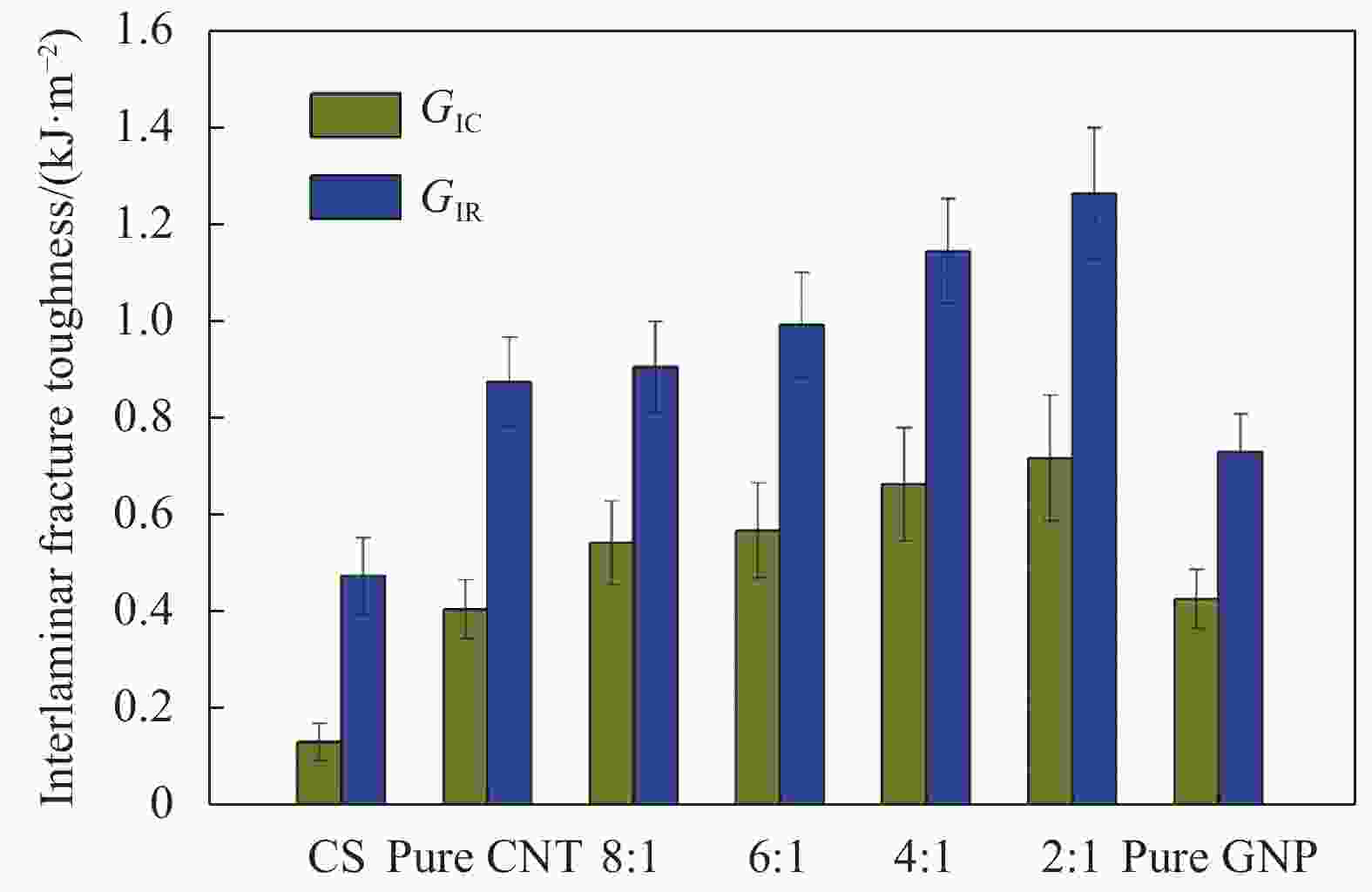

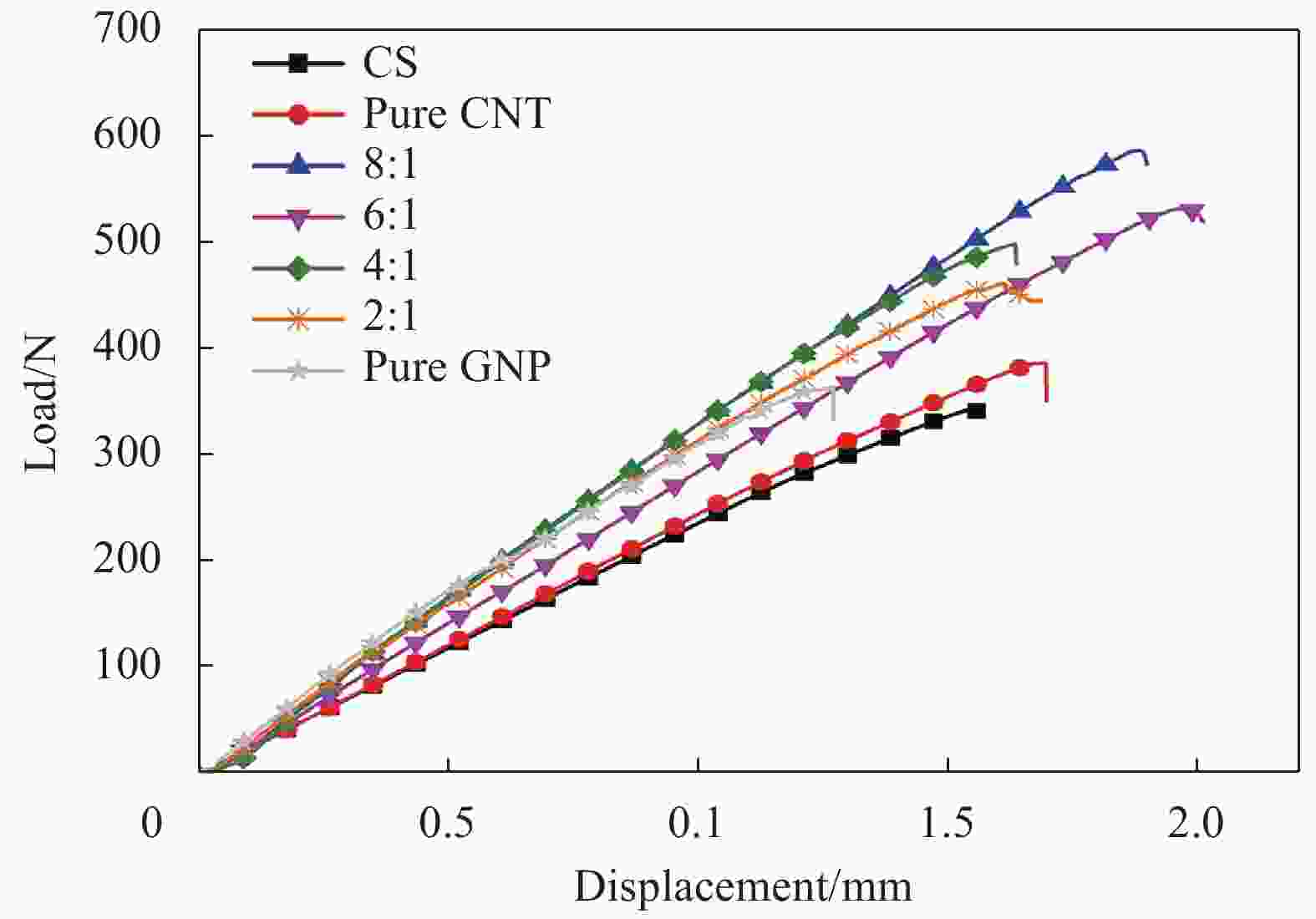

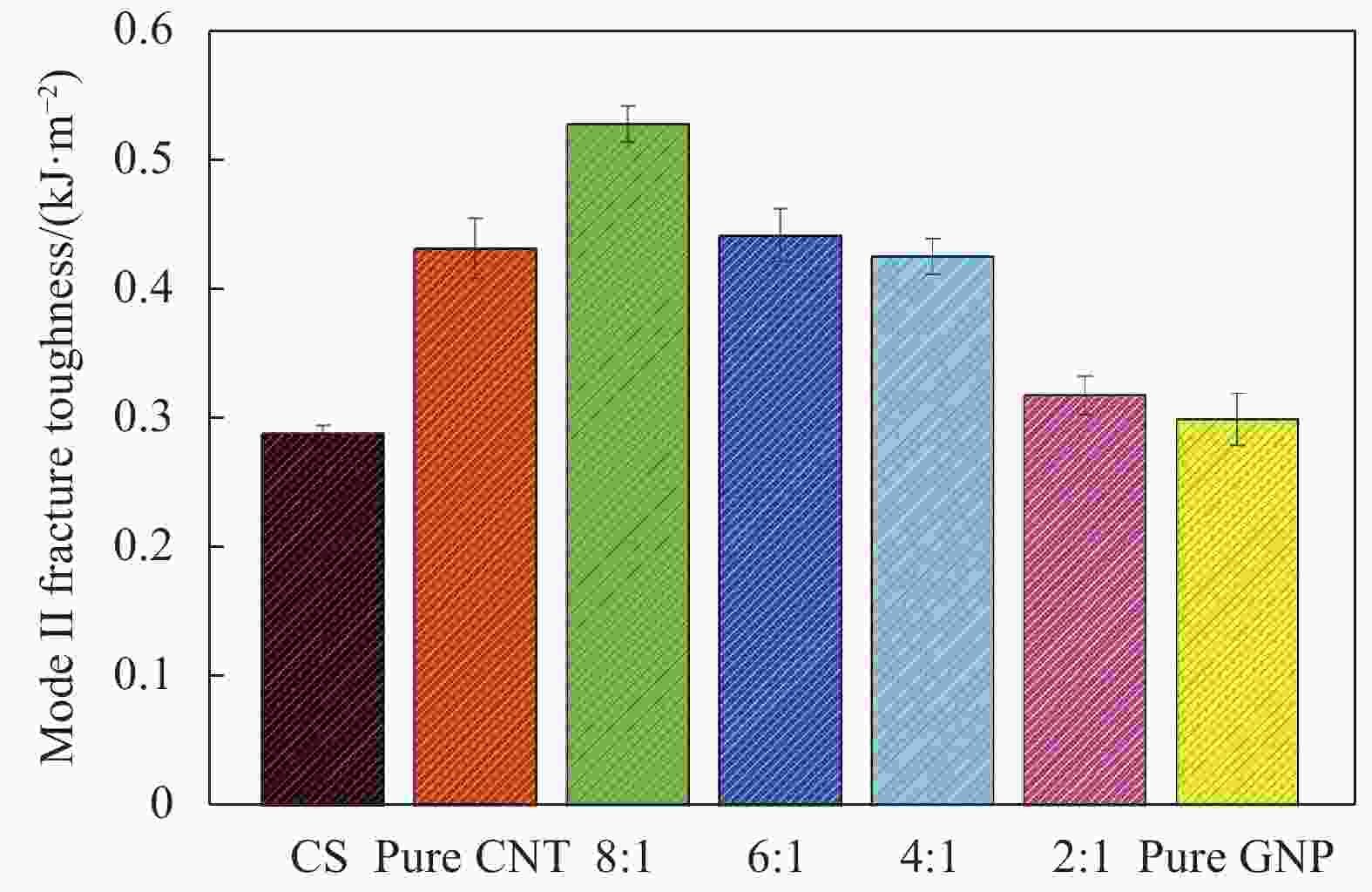

摘要: 碳纤维增强树脂基复合材料(CFRP)因其低密度、高比强度等特点,在航空航天领域得到了广泛的应用,但其导电性和层间韧性的不足降低了CFRP作为飞机结构件的使用安全性。为了改善CFRP弱的导电性和层间断裂韧性,本文采用溶液浇铸法制备了多壁碳纳米管(MWCNTs)和石墨烯纳米片(GNPs)掺杂聚醚砜(PES)的导电热塑性薄膜(CTFs)。然后将CTFs交错放入碳纤维/环氧树脂(CF/EP)预浸料中制得复合材料层压板,并对其导电性和层间断裂韧性进行了探究。结果表明,相较于对照样品(CS),在横向(Y)和厚度(Z)方向,层压板的电导率分别提高了474%和554%。采用双悬臂梁(DCB)和端口弯曲(ENF)法评估了Mode I和Mode II层间断裂韧性,当插入的CTF中纳米填料质量比为CNT∶GNP=2∶1时,复合材料层压板的Mode I层间断裂韧性(GIC)和断裂阻抗(GIR)分别提高了441%和165%,此外,纳米填料质量比CNT∶GNP=8∶1时,Mode II层间断裂韧性(GIIC)提高了79%。最后通过SEM观察了复合材料的微观结构形貌,并分析了复合材料的失效机制。

-

关键词:

- 碳纤维/环氧树脂(CF/EP)复合材料 /

- 聚醚砜(PES) /

- 协同效应 /

- 电导率 /

- 层间断裂韧性

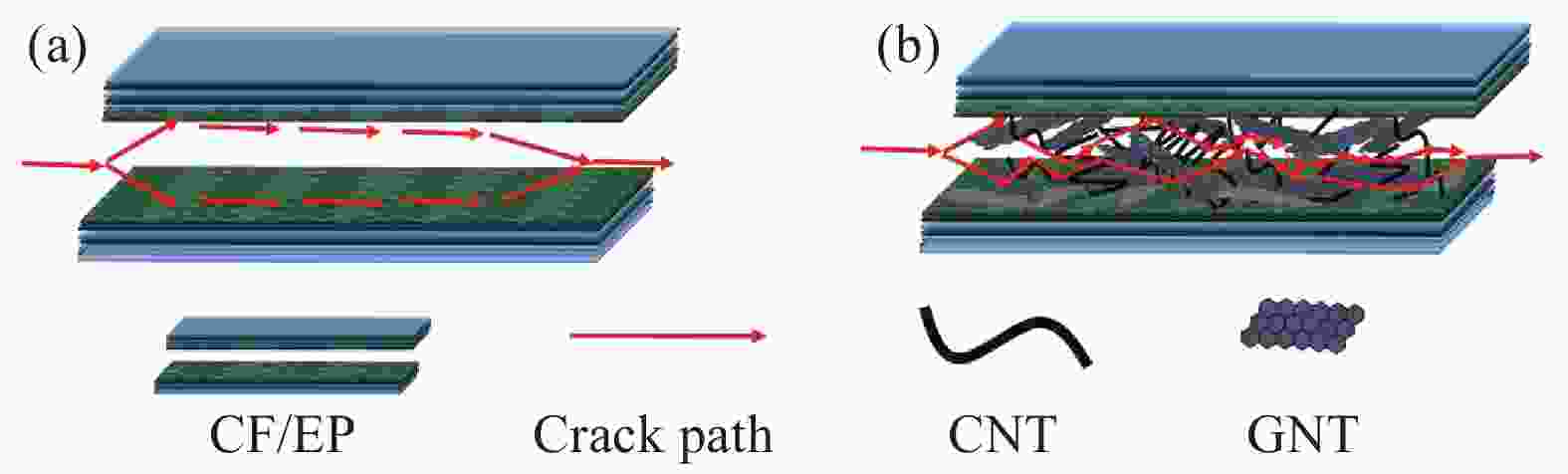

Abstract: Carbon fiber reinforced resin matrix composites (CFRP) are widely used in aerospace and is gradually replacing metal materials for aircraft structures as a result of their low density and high strength characteristics, while poor electrical conductivity and interlaminar shear fracture toughness could reduce their safety as structural components in use. In order to improve the poor electrical conductivity and interlaminar fracture toughness of CFRP, multi-walled carbon nanotubes (MWCNTs) and graphene nanoplatelets (GNPs) doped polyethersulfone (PES) conductive thermoplastic films (CTFs) were prepared by solution casting in this work. Then CTFs were interleaved into carbon fiber/epoxy resin (CF/EP) prepregs to prepare composite laminates. The electrical conductivity and interlaminar fracture toughness of the composite laminates were investigated. The results show that compared with the control sample (CS), the conductivity of the laminate increases by 474% and 554% in the transverse (Y) and thickness (Z) directions, respectively. The Mode I and Mode II interlaminar fracture toughness values were evaluated by double cantilever beam (DCB) and end-notched flexure (ENF) testing. The data show that when the nano-filler mass ratio of CNT∶GNP is 2∶1 in the interleaved CTF, the Mode I interlaminar fracture toughness and fracture impedance of the composite laminates are increased by 441% and 165%, respectively. Moreover, when the nano-filler mass ratio of CNT∶GNP is 8: 1, the Mode II interlaminar fracture toughness of the composite laminates is increased by 79%. In addition, the microstructural morphology of the composite material was observed by SEM and its failure mechanism was studied. -

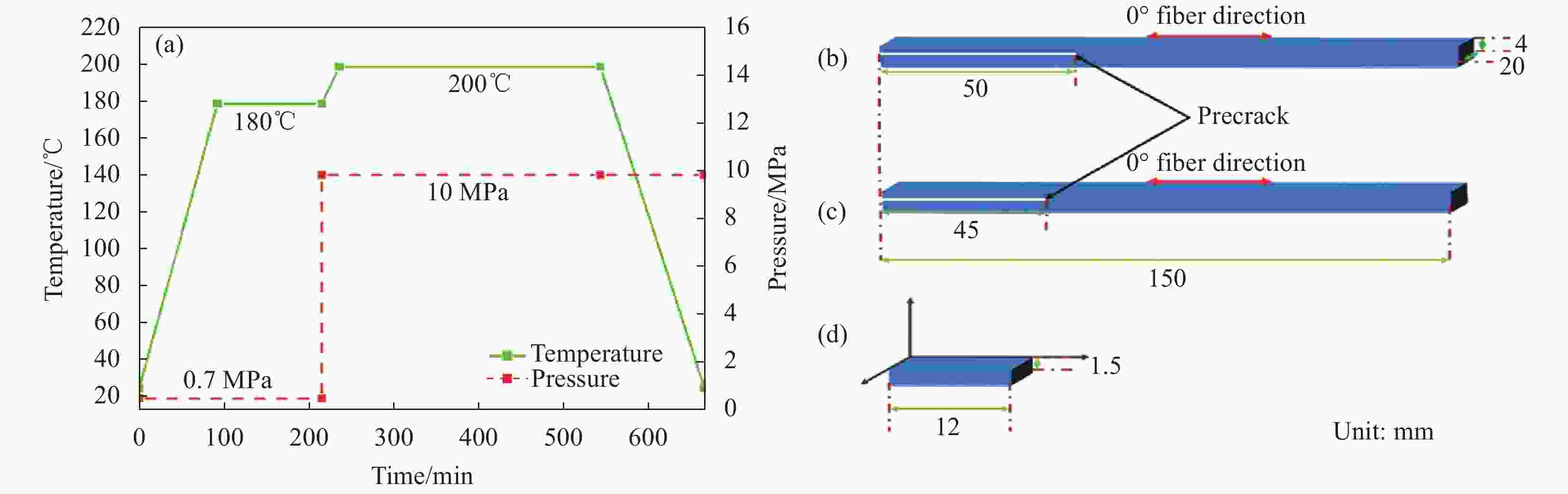

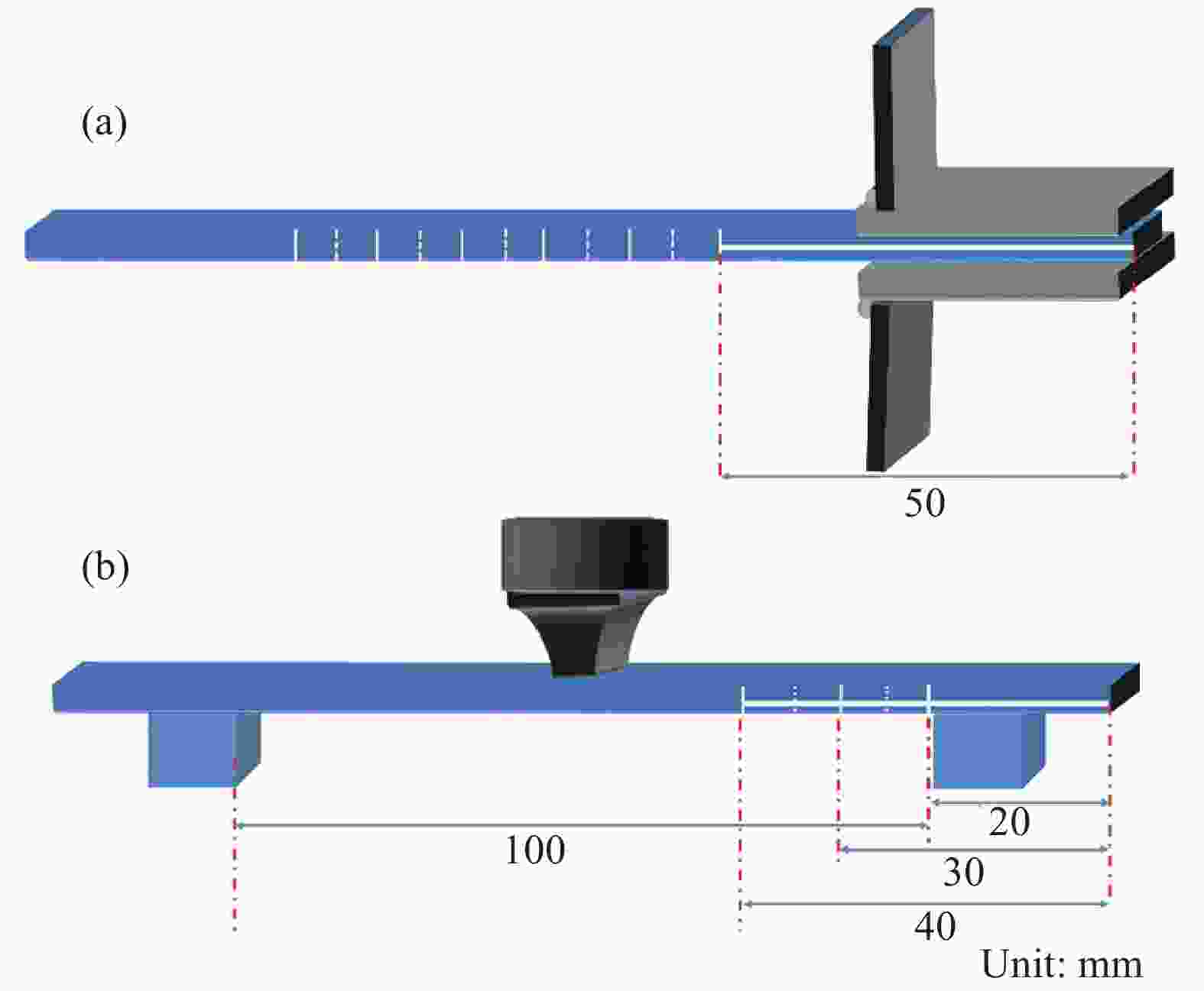

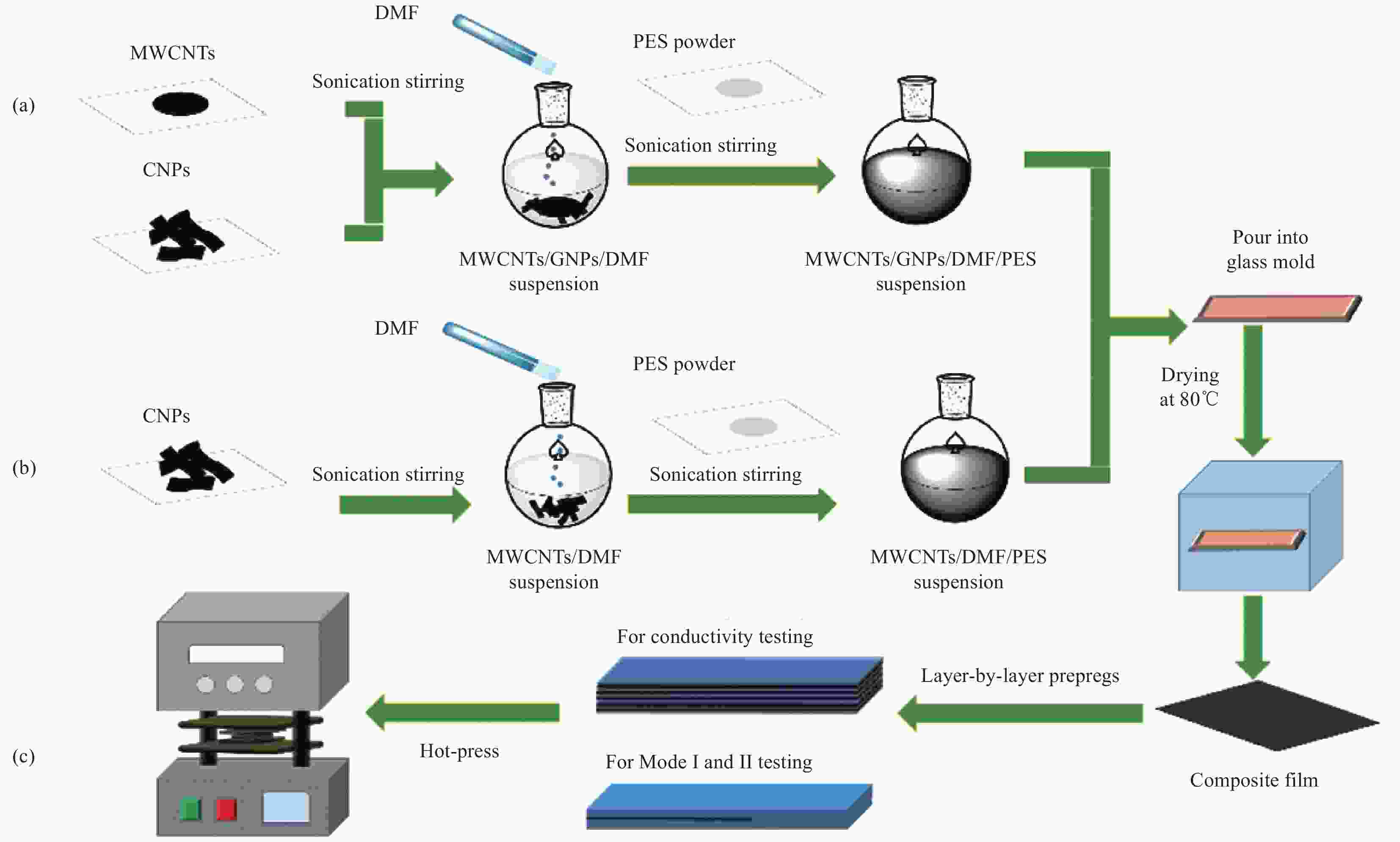

图 1 导电热塑性薄膜(CTFs)和CTF交错CF/EP复合材料层压板的制作工艺:碳纳米管(CNT)/石墨烯纳米片(GNP)/聚醚砜(PES)膜 (a)、GNP/PES膜 (b) 和层压板的热压成型 (c)

MWCNTs—Multi-walled carbon nanotubes; DMF—N, N-dimethylformamide

Figure 1. Manufacturing process of conductive thermoplastic films (CTFs) and CTFs interlaced CF/EP composite laminates: Carbon nanotube (CNT)/graphene nanoplatelets (GNP)/ polyethersulfone (PES) film (a), GNP/PES film (b) and hot-press molding of laminate (c)

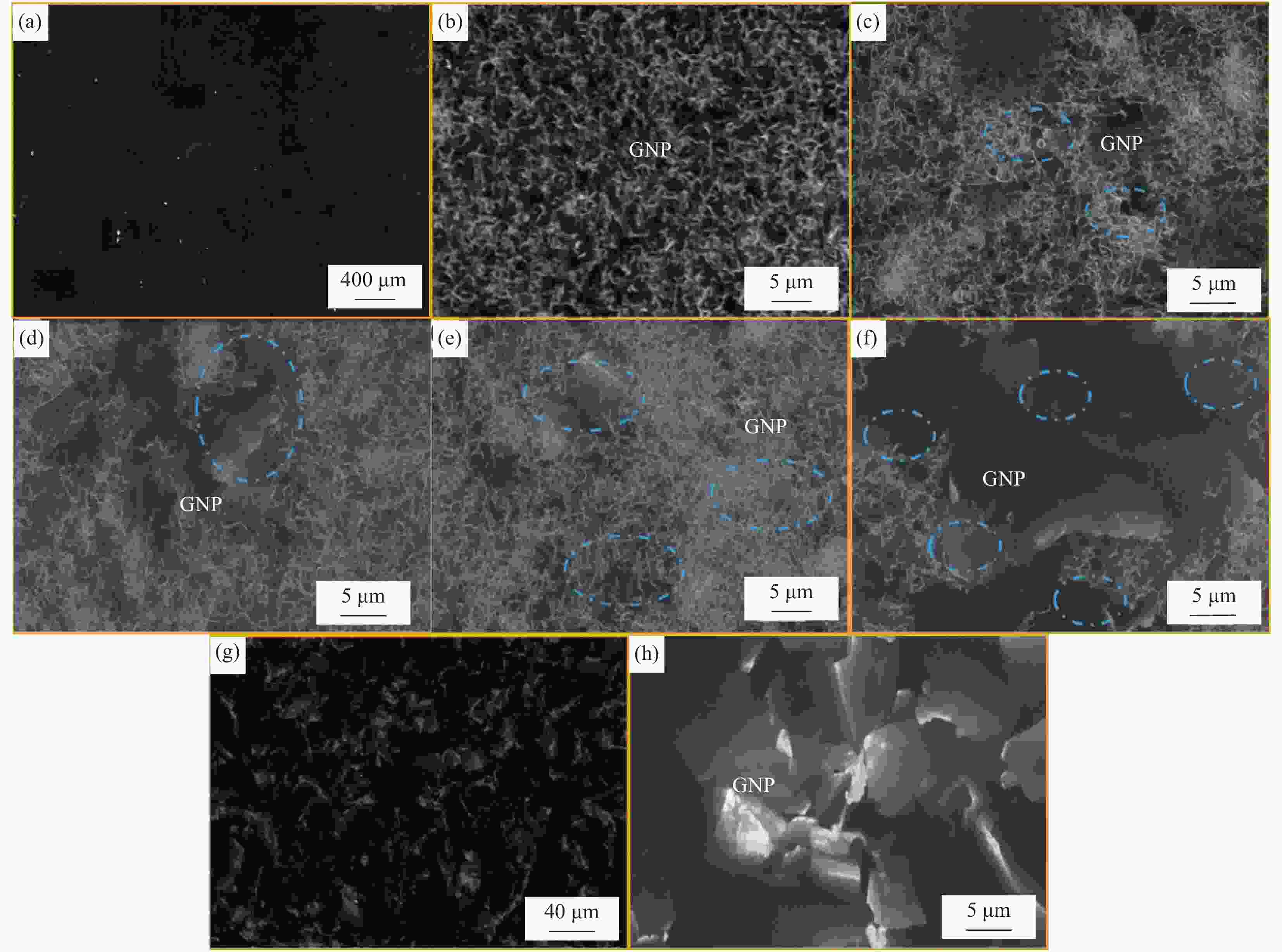

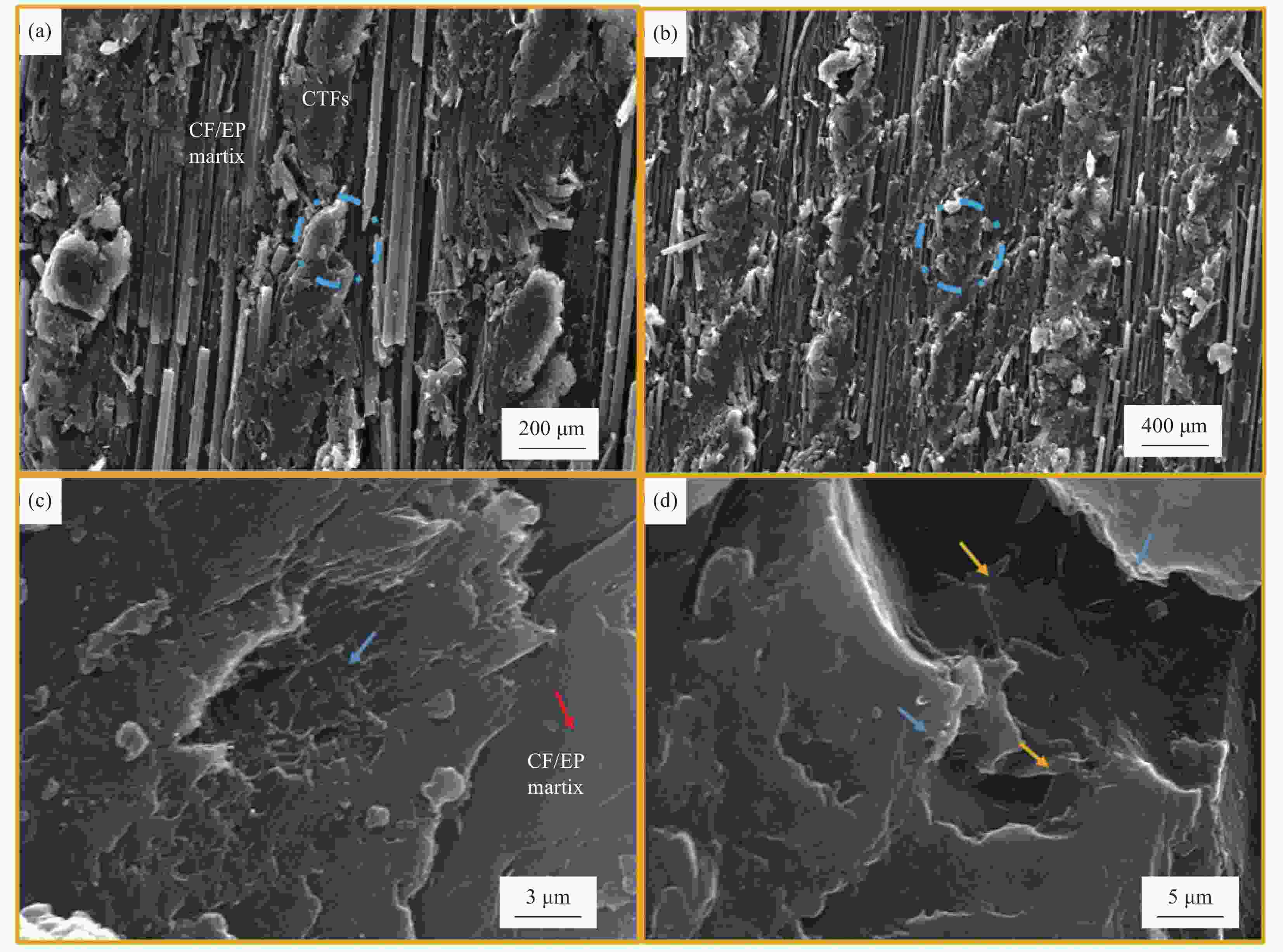

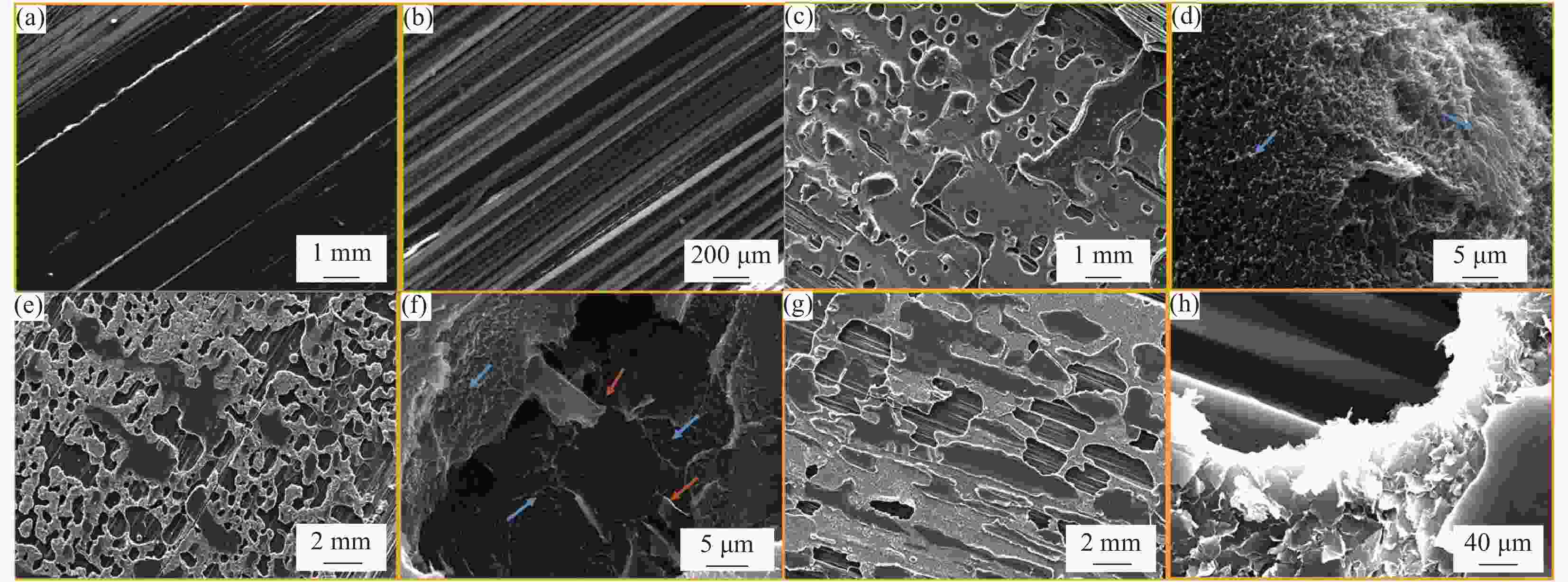

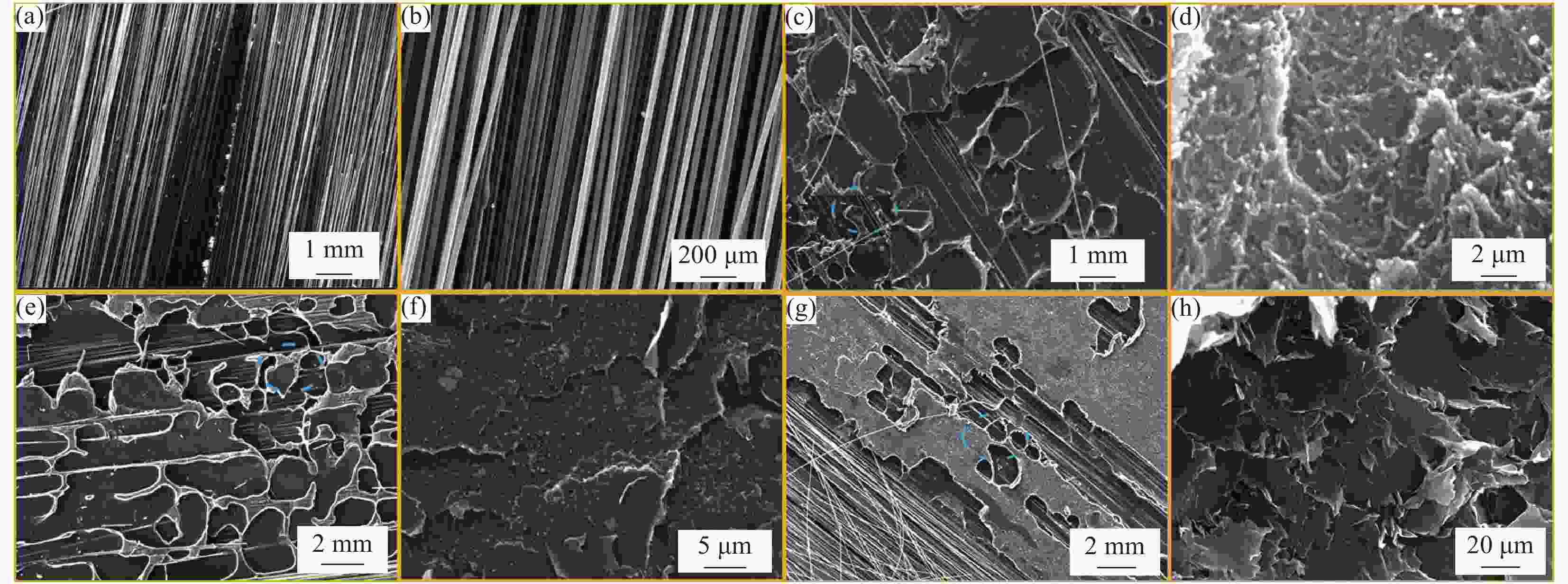

图 14 DCB测试后对照样品 ((a), (b)) 和分别插入CNT ((c), (d))、CNT/GNP=2∶1 ((e), (f)) 和GNP ((g), (h)) 的CTFs 制得的CNT/GNP复合材料层压板断裂面的SEM图像

Figure 14. SEM images of fracture surface control samples ((a), (b)) and CNT/GNP composite laminates obtained by interleaving CTFs with CNT ((c), (d)), CNT/GNP=2∶1 ((e), (f)) and GNP ((g), (h)) after DCB test

图 16 ENF测试后对照样品 ((a), (b)) 和分别插入CNT ((c), (d))、CNT∶GNP=8∶1 ((e), (f)) 和GNP ((g), (h)) 的导电热塑性薄膜制得的CNT/GNP复合材料层压板的断裂面SEM图像

Figure 16. SEM images of fracture surface control samples ((a), (b)) and CNT/GNP composite laminates obtained by interleaving CTFs with CNT ((c), (d)), CNT/GNP=8:1 ((e), (f)) and GNP ((g), (h)) after ENF test

表 1 单向碳纤维/环氧树脂(CF/EP)预浸料规格参数

Table 1. Specifications of unidirectional carbon fiber/epoxy resin (CF/EP) prepreg

Specification parameter Value Carbon fiber model T700 Fiber mass per unit area/(g·m−2) 132±4 Resin content/wt% 35±2 Monolayer prepreg thickness/mm 0.125 Epoxy resin model E1010 Tensile strength in fiber direction/MPa 2500 Bending strength/MPa 1650 -

[1] CHAND S. Review carbon fibers for composites[J]. Journal of Materials Science,2000,35(6):1303-1313. doi: 10.1023/A:1004780301489 [2] KATNAM K B, SILVA L F M D, YOUNG T M. Bonded repair of composite aircraft structures: A review of scientific challenges and opportunities[J]. Progress in Aerospace Sciences,2013,61:26-42. doi: 10.1016/j.paerosci.2013.03.003 [3] PARTRIDGE I K, CARTIÉ D D R. Delamination resistant laminates by Z-Fiber® pinning: Part I manufacture and fracture performance[J]. Composites Part A,2005,36(1):55-64. doi: 10.1016/S1359-835X(04)00180-0 [4] RAHMAN M M, ZAINUDDIN S, HOSUR M V, et al. Improvements in mechanical and thermo-mechanical properties of e-glass/epoxy composites using amino functionalized MWCNTs[J]. Composite Structures,2012,94(8):2397-2406. doi: 10.1016/j.compstruct.2012.03.014 [5] SONG Q, LI K, QI L, et al. The reinforcement and toughening of pyrocarbon-based carbon/carbon composite by controlling carbon nanotube growth position in carbon felt[J]. Materials Science and Engineering A, 2013, 564: 71-75. [6] BOROUJENI A Y, TEHRANI M, NELSON A J, et al. Hybrid carbon nanotube-carbon fiber composites with improved in-plane mechanical properties[J]. Composites Part B,2014,66:475-483. doi: 10.1016/j.compositesb.2014.06.010 [7] BRUNNER A J, NECOLA A, REES M, et al. The influence of silicate-based nano-filler on the fracture toughness of epoxy resin[J]. Engineering Fracture Mechanics,2006,73(16):2336-2345. doi: 10.1016/j.engfracmech.2006.05.004 [8] MOURITZ A P. Review of z-pinned composite laminates[J]. Composites Part A,2007,38(12):2383-2397. doi: 10.1016/j.compositesa.2007.08.016 [9] YANG Y, GUPTA M C, DUDLEY K L, et al. Novel carbon nanotube-polystyrene foam composites for electromagnetic interference shielding.[J]. Nano Letters,2005,5(11):2131-2134. doi: 10.1021/nl051375r [10] GUO M C, YI X S. The production of tough, electrically conductive carbon fiber composite laminates for use in airframes[J]. Carbon,2013,58:241-244. doi: 10.1016/j.carbon.2013.02.052 [11] TANG H, CHEN X F, TANG A Q, et al. Studies on the electrical conductivity of carbon black filled polymers[J]. Journal of Applied Polymer Science,1996,59(3):383-387. doi: 10.1002/(SICI)1097-4628(19960118)59:3<383::AID-APP1>3.0.CO;2-L [12] BAUHOFER W, KOVACS J Z. A review and analysis of electrical percolation in carbon nanotube polymer composites[J]. Composites Science and Technology,2009,69(10):1486-1498. doi: 10.1016/j.compscitech.2008.06.018 [13] VICULIS L M, MACK J J, MAYER O M, et al. Intercalation and exfoliation routes to graphite nanoplatelets[J]. Journal of Materials Chemistry,2005,15(9):974-978. doi: 10.1039/b413029d [14] 周浪, 王涛. 石墨烯/功能聚合物复合材料[J]. 复合材料学报, 2020, 37(5):997-1014.ZHOU Lang, WANG Tao. Graphene/functional polymer composites[J]. Acta Materiae Compositae Sinica,2020,37(5):997-1014(in Chinese). [15] FORSTER R J, KEANE L. Nanoparticle-metallopolymer assemblies: Charge percolation and redox properties[J]. Journal of Electroanalytical Chemistry,2003,554:345-354. [16] LONJON A, LAFFONT L, DEMONT P, et al. New highly conductive nickel nanowire-filled P(VDF-TrFE) copolymer nanocomposites: elaboration and structural study[J]. Journal of Physical Chemistry C,2009,113(28):12002-12006. doi: 10.1021/jp901563w [17] LI W, XIANG D, WANG L, et al. Simultaneous enhancement of electrical conductivity and interlaminar fracture toughness of carbon fiber/epoxy composites using plasma-treated conductive thermoplastic film interleaves [J]. RSC Advances, 2018, 8(47): 26910-26921. [18] ZHAO X, ZHANG Q, CHEN D, et al. Enhanced mechanical properties of graphene-based poly(vinyl alcohol) compo-sites[J]. Macromolecules,2011,44:2392. doi: 10.1021/ma200335d [19] 李娜, 李晓屿, 刘丽, 等. 电泳沉积氧化石墨烯的碳纤维表面改性及其增强环氧树脂复合材料界面性能[J]. 复合材料学报, 2020, 37(7):1571-1580.LI Na, LI Xiaoyu, LIU Li, et al. Surface modification of carbon fiber (CF) deposited graphene oxide (GO) by electrophorestic deposition and interfacial properties of GO-CF/epoxy composites[J]. Acta Materiae Compositae Sinica,2020,37(7):1571-1580(in Chinese). [20] ZHOU T, ZHA J W, HOU Y, et al. Surface-functionalized MWNTs with emeraldine base: preparation and improving dielectric properties of polymer nanocomposites[J]. ACS Applied Materials & Interfaces,2011,3(12):4557-4560. [21] YANG S Y, LIN W N, HUANG Y L, et al. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites[J]. Carbon,2011,49(3):793-803. doi: 10.1016/j.carbon.2010.10.014 [22] QIN W Z, VAUTARD F, DRZAL L T, et al. Mechanical and electrical properties of carbon fiber composites with incorporation of graphene nanoplatelets at the fiber-matrix interphase[J]. Composites Part B,2015,69:335-341. doi: 10.1016/j.compositesb.2014.10.014 [23] AL-SALEH M H, SUNDARARAJ U. A review of vapor grown carbon nanofiber/polymer conductive composites[J]. Carbon,2009,47(1):2-22. doi: 10.1016/j.carbon.2008.09.039 [24] LI W, DICHIARA A, BAI J. Carbon nanotube-graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites[J]. Composites Science and Technology,2013,74:221-227. doi: 10.1016/j.compscitech.2012.11.015 [25] SAFDARI M, AL-HAIK M S. Synergistic electrical and thermal transport properties of hybrid polymeric nanocomposites based on carbon nanotubes and graphite nanoplatelets[J]. Carbon,2013,64(Complete):111-121. [26] LIN Y. Functionalized interleaf technology in carbon-fibre-reinforced composites for aircraft applications[J]. National Science Review,2013,1(1):7-8. [27] GUO M C, YI X S, RUDD C, et al. Preparation of highly electrically conductive carbon-fiber composites with high interlaminar fracture toughness by using silver-plated interleaves[J]. Composites Science and Technology,2019,176(MAY 26):29-36. [28] MANDAL S, ALAM S. Studies on the mechanical, thermal, and morphological properties of poly(ether ether ketone)/poly(ether sulfone)/barium titanate nanocomposites: Correlation of experimental results with theoretical predictive models[J]. Journal of Applied Polymer Science,2012,126(2):724-733. doi: 10.1002/app.36735 [29] 申维新, 姜云龙, 朱爱萍. 聚醚砜对连续碳纤维/聚醚醚酮复合材料性能的影响[J]. 复合材料学报, 2021, 38(6):1809-1816.SHEN Weixin, JIANG Yunlong, ZHU Aiping. Effect of polyethersulfone on the properties of continuous carbon fiber/polyetheretherketone composites[J]. Acta Materiae Compositae Sinica,2021,38(6):1809-1816(in Chinese). [30] ZHOU J L, CHENG C, JIANG M Q, et al. Polyethersulfone melt-spun fibers plasticized with epoxy oligomer[J]. Materials Letters,2018,210:263-266. doi: 10.1016/j.matlet.2017.09.035 [31] ZHENG W J, YAO Z J, LIN H Y, et al. Improved fracture toughness of carbon fiber fabric/epoxy composite laminates using polyether sulfone fibers[J]. High Performance Polymers,2019,31(8):996-1005. doi: 10.1177/0954008318812151 [32] RAJASEKARAN R, ALAGAR M, CHOZHAN C K. Effect of polyethersulfone and N, N′-bismaleimido-4, 4′-diphenyl methane on the mechanical and thermal properties of epoxy systems[J]. Express Polymer Letters,2008,2(5):339-348. doi: 10.3144/expresspolymlett.2008.40 [33] LEE S, JEONG E, LEE M Y, et al. Improvement of the mechanical and thermal properties of polyethersulfone-modified epoxy composites[J]. Journal of Industrial and Engineering Chemistry,2016,33:73-79. doi: 10.1016/j.jiec.2015.09.022 [34] CHENG C, CHEN Z G, HUANG Z, et al. Simultaneously improving mode I and mode II fracture toughness of the carbon fiber/epoxy composite laminates via interleaved with uniformly aligned PES fiber webs[J]. Composites Part A,2020:129. [35] ASTM. Standard test method for mode I interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D5528-2013[S]. West conshohocken: ASTM, 2013. [36] ASTM. Standard test method for determination of the Mode II interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D7905/D7905M[S]. West conshohocken: ASTM, 2014. [37] YU A P, RAMESH P, SUN X B, et al. Enhanced thermal conductivity in a hybrid graphite nanoplatelet-carbon nanotube filler for epoxy composites[J]. Advanced Materials,2008,20(24):4740-4744. doi: 10.1002/adma.200800401 [38] WEN B, CAO M S, LU M M, et al. Reduced graphene oxides: Light-weight and high-efficiency electromagnetic interference shielding at elevated temperatures[J]. Advanced Materials,2014,26(21):3357. doi: 10.1002/adma.201470138 [39] WANG X X, CAO W Q, CAO M S, et al. Assembling nano-microarchitecture for electromagnetic absorbers and smart devices[J]. Advanced Materials,2020,32(36):2002112. [40] WEN B, CAO M S, HOU Z L, et al. Temperature dependent microwave attenuation behavior for carbon-nanotube/silica composites[J]. Carbon,2013,65:124-139. doi: 10.1016/j.carbon.2013.07.110 [41] ZHANG C, HUANG S, TJIU W W, et al. Facile preparation of water-dispersible graphene sheets stabilized by acid-treated multiwalled carbon nanotubes and their poly(vinyl alcohol) composites[J]. Journal of Materials Chemistry,2012,22:2427-2434. doi: 10.1039/C1JM13921E [42] YANG S Y, LIN W N, HUANG Y L, et al. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites[J]. Carbon,2010,49(3):793-803. [43] WONG D W Y, LIN L, MCGRAIL P T, et al. Improved fracture toughness of carbon fibre/epoxy composite laminates using dissolvable thermoplastic fibres[J]. Composites Part A,2010,41(6):759-767. doi: 10.1016/j.compositesa.2010.02.008 [44] YUE L, PIRCHERAGHI G, MONERMIAN S A, et al. Epoxy composites with carbon nanotubes and graphene nanoplatelets-dispersion and synergy effects[J]. Carbon,2014,78:268-278. doi: 10.1016/j.carbon.2014.07.003 [45] LI W, LI Y T, XIANG D, et al. Simultaneous enhancement of electrical conductivity and interlaminar shear strength of CF /EP composites through MWCNTs doped thermoplastic polyurethane film interleaves[J]. Journal of Applied Polymer Science,2019,136(39):47988. doi: 10.1002/app.47988 [46] DU X S, ZHOU H L Z, SUN W F, et al. Graphene/epoxy interleaves for delamination toughening and monitoring of crack damage in carbon fibre/epoxy composite laminates[J]. Composites Science and Technology,2017,140:123-133. doi: 10.1016/j.compscitech.2016.12.028 [47] KING J A, BARTON R L, HAUSER R A, et al. Synergistic effects of carbon fillers in electrically and thermally conductive liquid crystal polymer based resins[J]. Polymer Composites,2008,29(4):421-428. doi: 10.1002/pc.20446 [48] ZHANG X, ALLOUL O, HE Q L, et al. Strengthened magnetic epoxy nanocomposites with protruding nanoparticles on the graphene nanosheets[J]. Polymer,2013,54(14):3594-3604. doi: 10.1016/j.polymer.2013.04.062 -

下载:

下载: