Research progress on the application of bacterial cellulose and its composites in environmental field

-

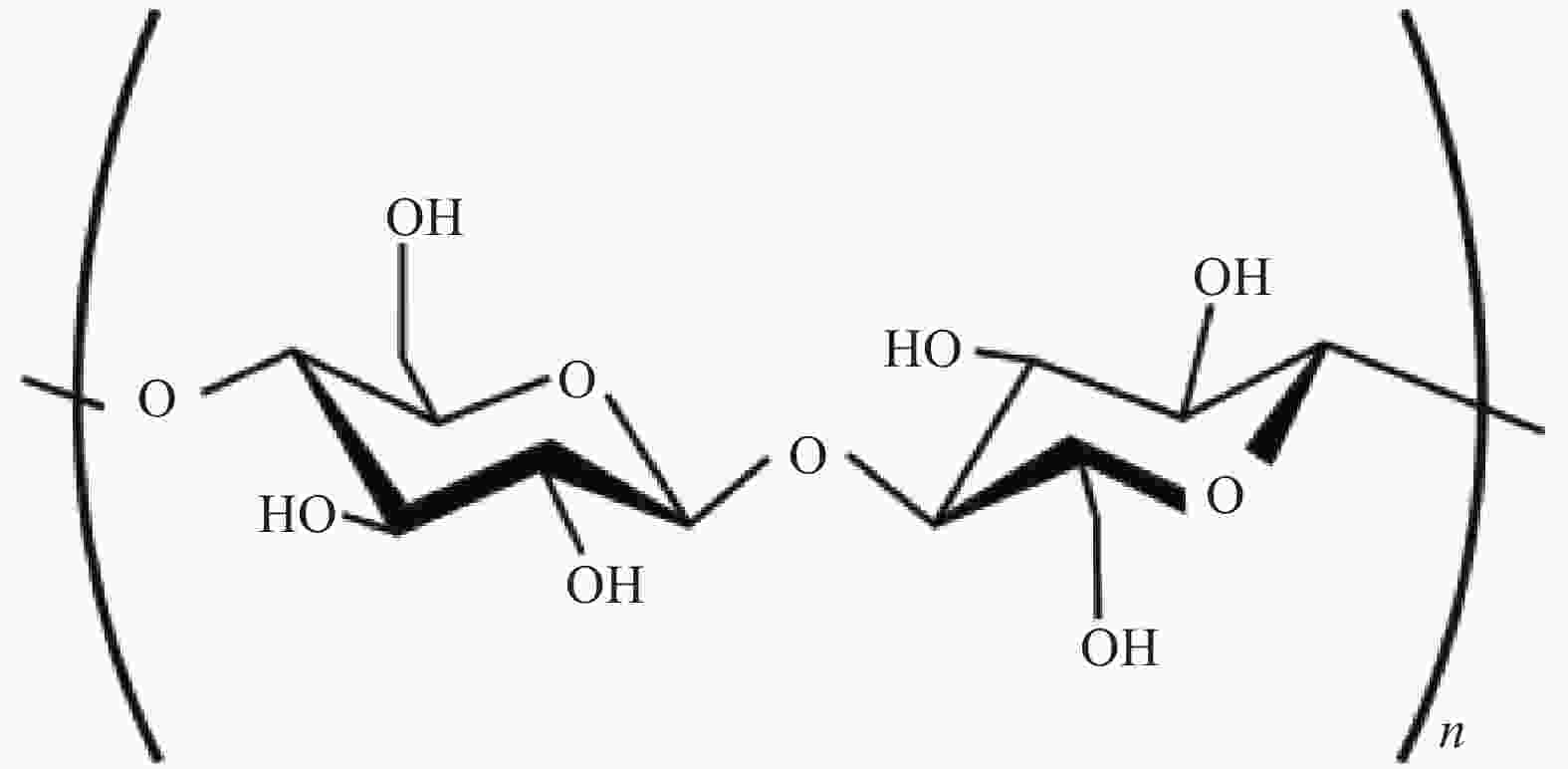

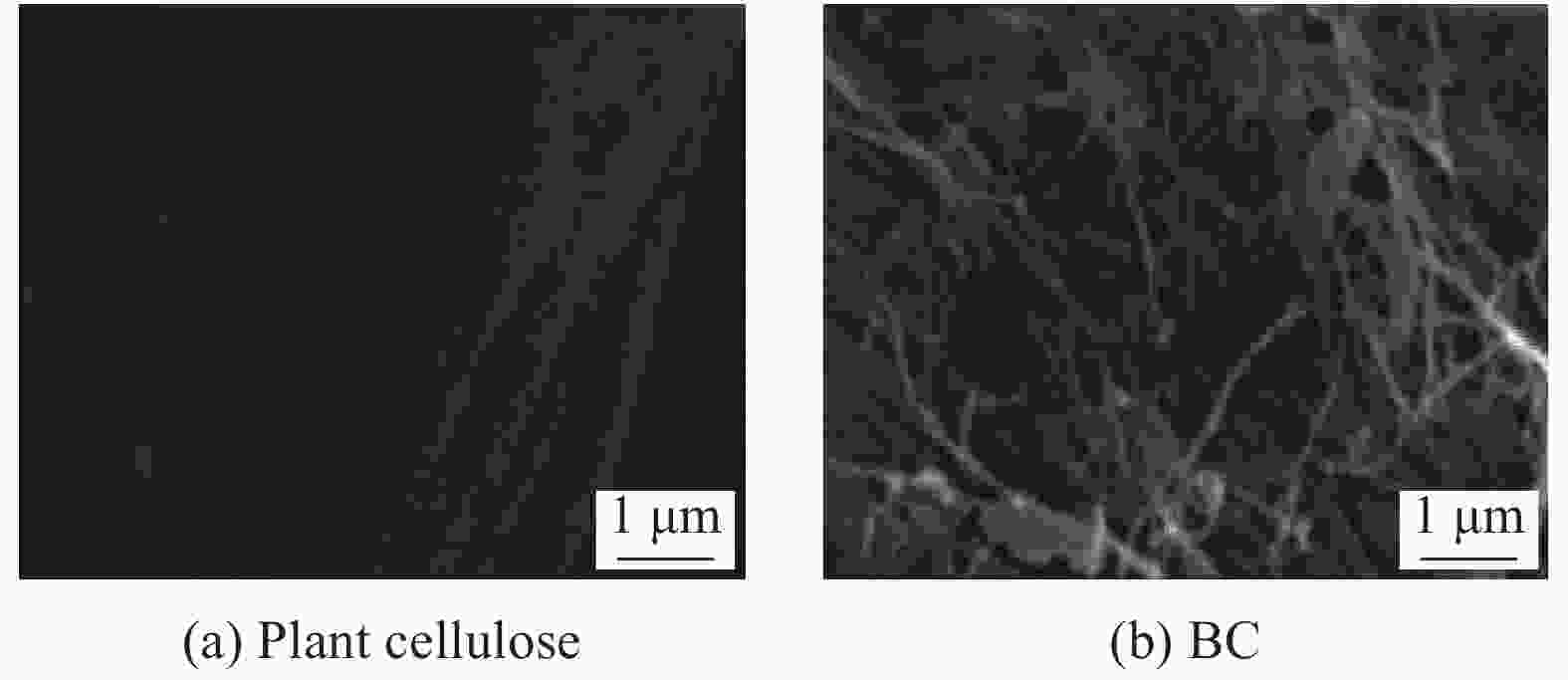

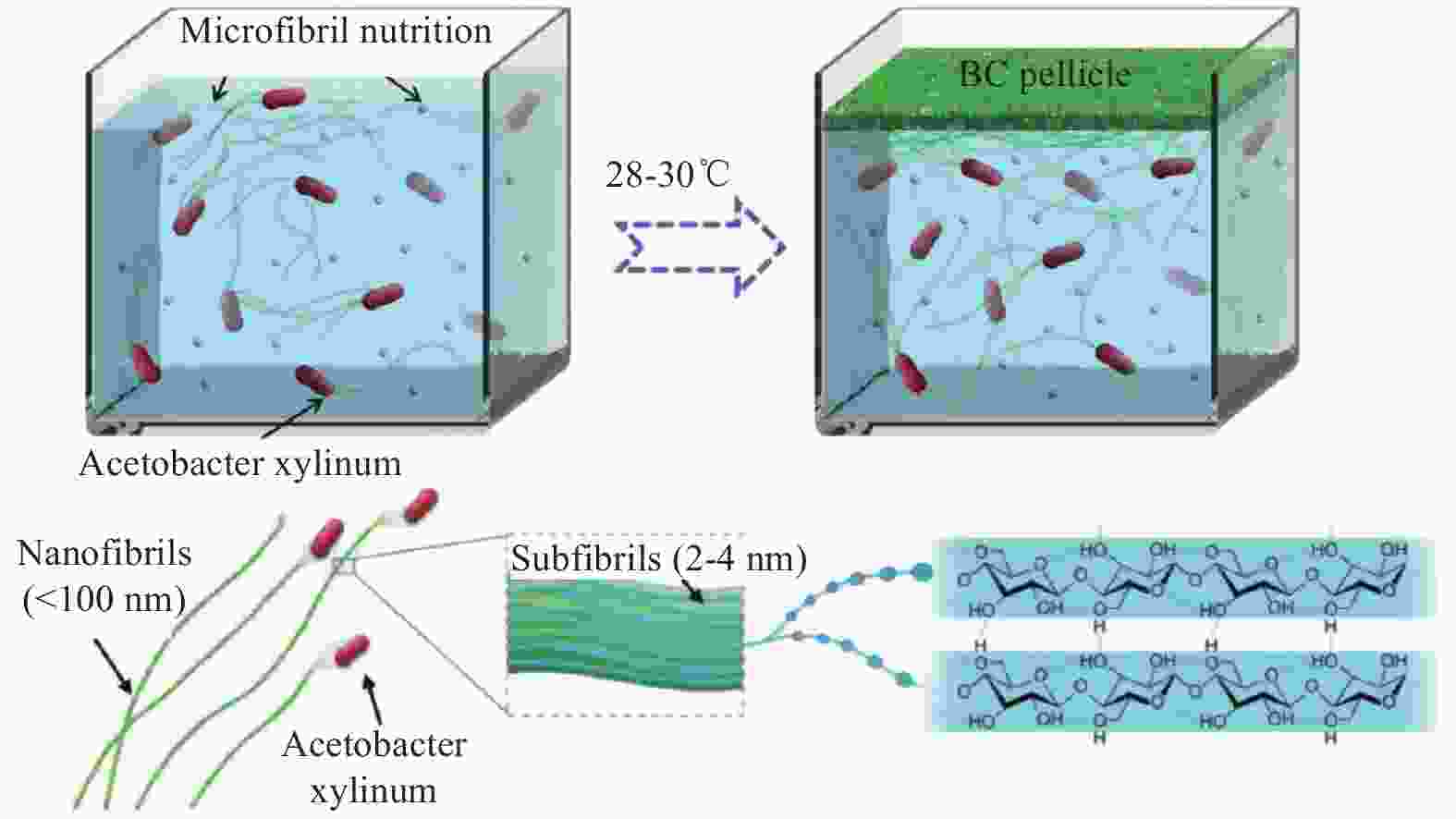

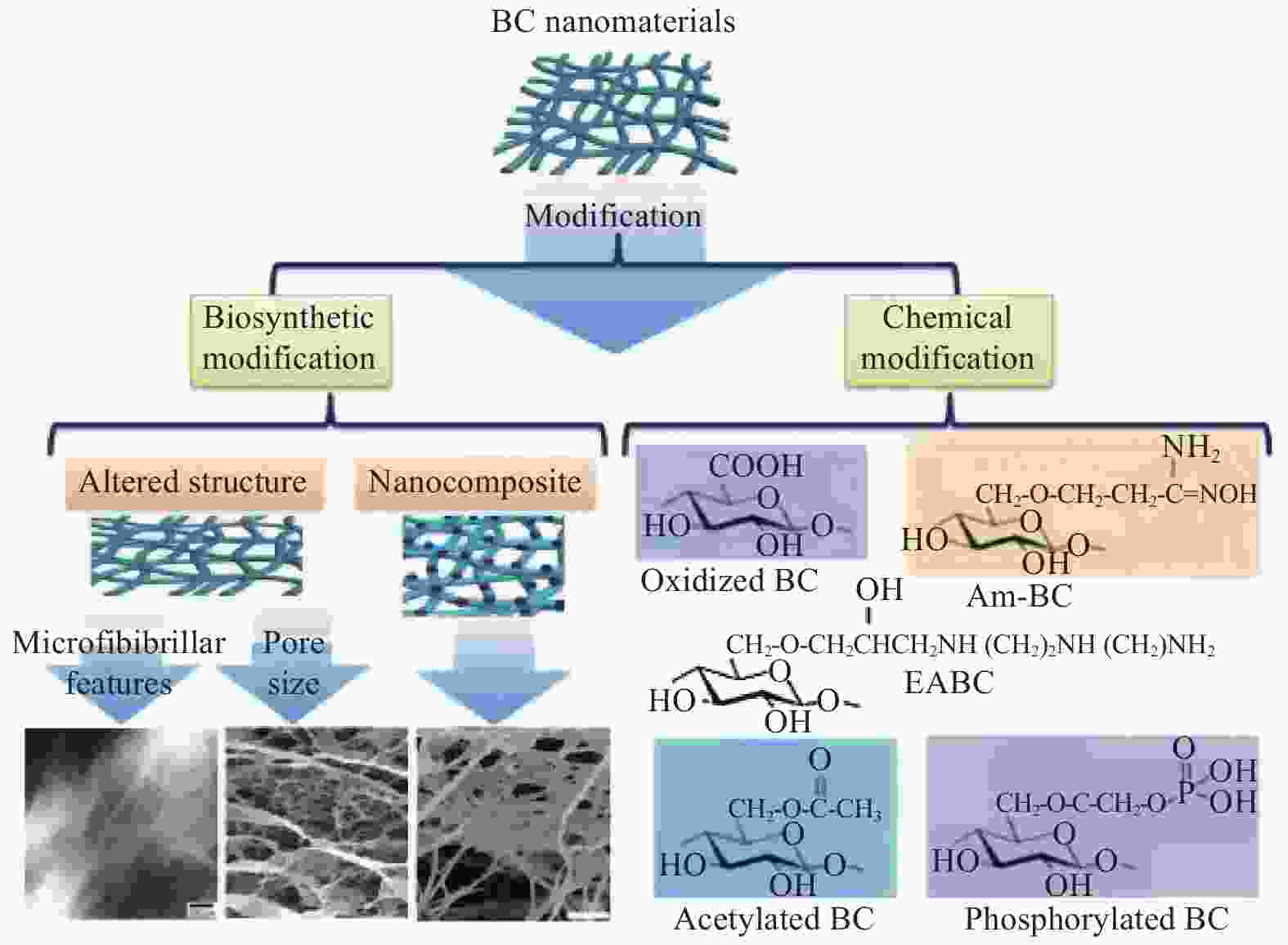

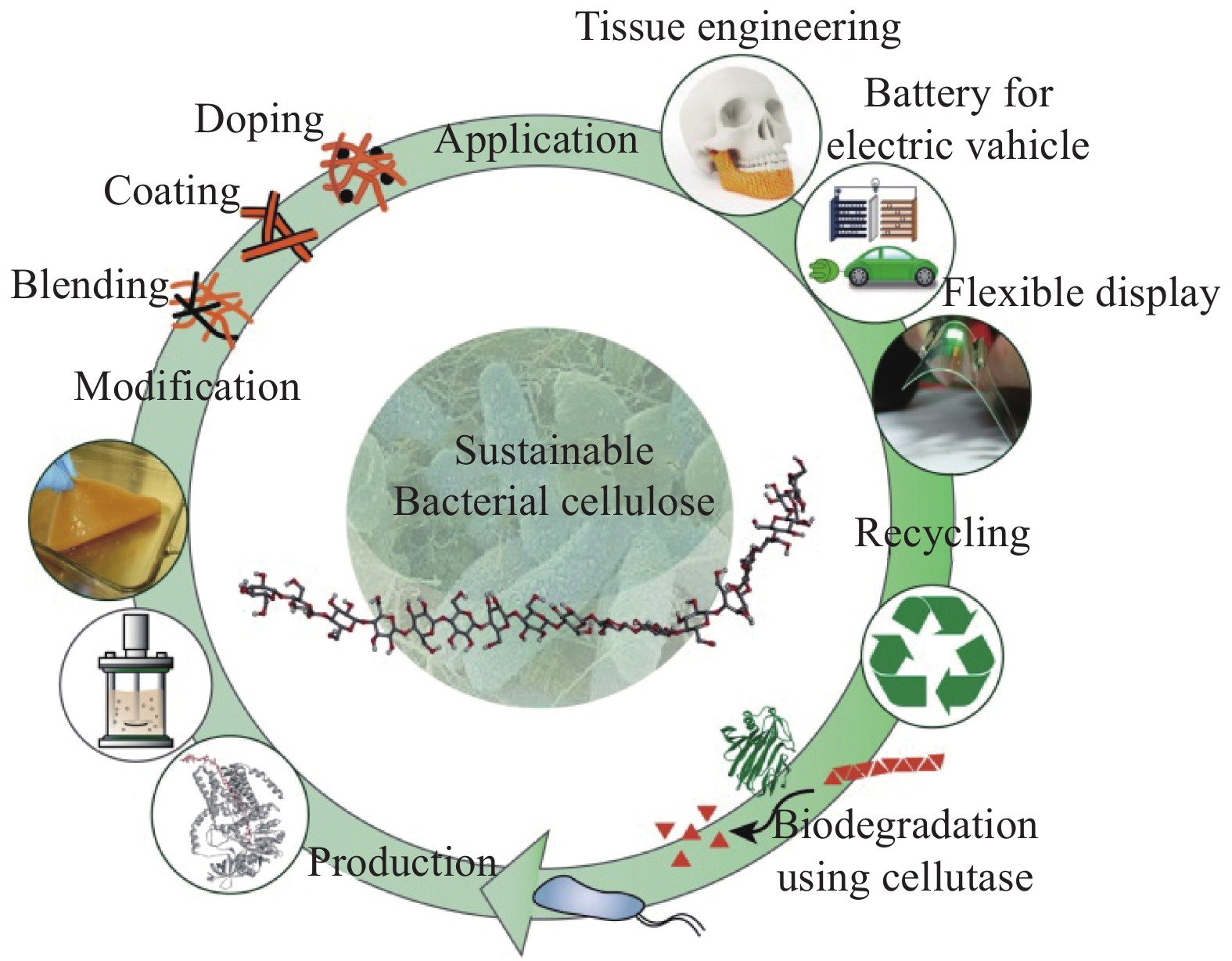

摘要: 细菌纤维素(Bacterial cellulose, BC)是一种由微生物发酵产生的细胞外多糖,作为一种新型的环境友好生物材料,细菌纤维素具有高纯度、高吸水性,优异的机械强度及生物相容性高等优点,在生物医学、化工及食品等诸多领域展现出广阔的应用前景。本文系统性地介绍了BC的结构和特性,对BC的制备工艺和影响因素进行了总结,并分析了化学改性、原位改性和纳米材料复合改性等改性方法对BC的结构与特性的影响,对BC在环境处理技术(吸附、过滤、光催化)中的应用进展进行了概述,最后对BC的研究进展及其发展方向进行了总结和展望。Abstract: Bacterial cellulose (BC), an extracellular polysaccharide obtained from microbial fermentation, is an eco-friendly bio-based material, with unique properties, including high purity, high water-holding capacity, excellent tensile strength and bio-compatibility. It shows broad application prospects of many fields such as biomedicine, chemical and food industry. In this review, the structure, unique properties, preparation and modification of BC, are respectively presented. In addition, the research progress of BC composites’ applications in environmental field (adsorption, filtration and photocatalysis) is reviewed. Finally, the existing challenges and future prospects are summarized.

-

Key words:

- bacterial cellulose /

- eco-friendly bio-based material /

- composite /

- adsorption /

- filtration /

- photocatalysis

-

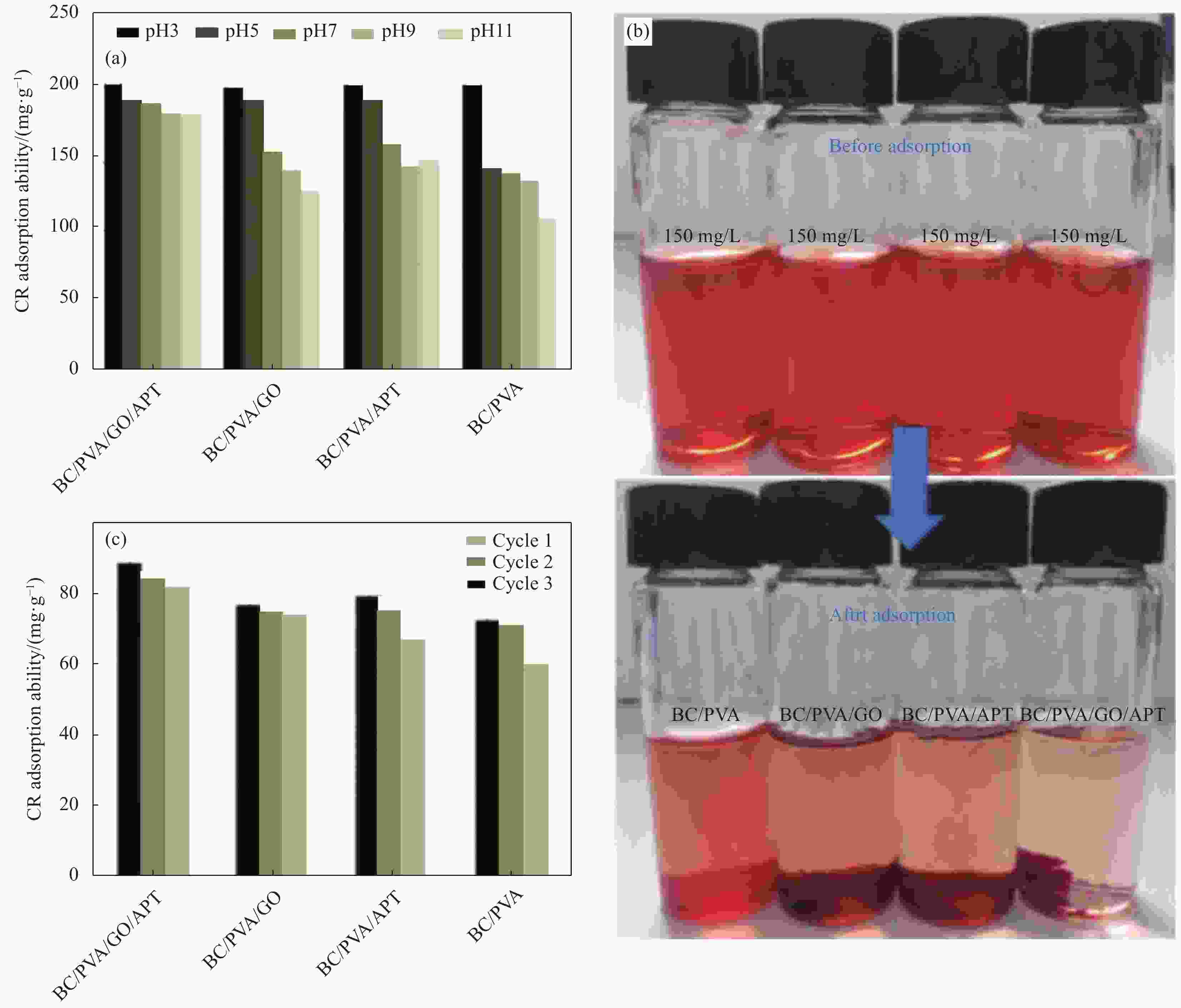

图 8 pH对制备的复合水凝胶吸附刚果红(CR)

能力的影响 (a)、制备的复合水凝胶在150 mg/L的CR溶液中吸附前后的图片 (b)和水凝胶对CR吸附的可重复使用性 (c)[41] Figure 8. Effect of pH on the congo red (CR) adsorption ability of the prepared hydrogels (a), images of 150 mg/L CR solution before adsorption by the prepared difference hydrogels (b), reusability of the prepared hydrogels (c)[41]

PVA—Polyvinyl alcohol; GO—Graphene oxide; APT—Attapulgite

-

[1] LUO H, ZHANG J, XIONG G, et al. Evolution of morphology of bacterial cellulose scaffolds during early culture[J]. Carbohydrate Polymers,2014,111:722-728. doi: 10.1016/j.carbpol.2014.04.097 [2] WOO D J, JI H H, HYUN U K, et al. Bacterial cellulose as an example product for sustainable production and consumption[J]. Microbial Biotechnology, 2017, 10(5): 1181-1185. [3] SELESTINA G. Bacterial cellulose as a versatile platform for research and development of biomedical materials[J]. Processes, 2020, 8(5): 624. [4] 税朝毅, 胡秀林, 张维, 等. 复合细菌纤维素材料研究进展[J]. 预防医学论坛, 2020, 26(10):787-792.SHUI Z Y, HU X L, ZHANG W, et al. Research progress of bacterial cellulose composite[J]. Chinese Preventive Medicine Association,2020,26(10):787-792(in Chinese). [5] BROWN, ADRIAN J. On an acetic ferment which forms cellulose[J]. Journal of the Chemical Society, Transactions,1886,49:432-439. doi: 10.1039/CT8864900432 [6] 李治明, 荣荣, 尹学琼, 等. 细菌纤维素制备及吸附金属离子的研究进展[J]. 精细化工, 2018, 35(5):721-727.LI Z M, RONG R, YIN X Q, et al. Research progress of preparation of bacterial cellulose and its adsorption for metal ions[J]. Fine Chemicals,2018,35(5):721-727(in Chinese). [7] 谭玉静. 细菌纤维素的发酵生产及其物理化学性质初探[D]. 上海: 东华大学, 2007.TAN Y J. Production of bacterial cellulose and characterization of the cellulose’s physicochemical properties[D]. Shanghai: Donghua University, 2007(in Chinese). [8] SULAEVA I, HENNIGES U, ROSENAU T, et al. Bacterial cellulose as a material for wound treatment: Properties and modifications. A review-science direct[J]. Biotechnology Advances,2015,33(8):1547-1571. doi: 10.1016/j.biotechadv.2015.07.009 [9] 刘晖. 细菌纤维素基复合材料的制备及性能研究[D]. 南京: 南京林业大学, 2016.LIU H. Study on the preparation and properties of bacterial cellulose-based composites[D]. Nanjing: Nanjing Forestry University, 2016(in Chinese). [10] HYOK K M, HAN G A. Development of artificial blood vessel using bacterial cellulose[J]. Journal of Pediatrics, 2010, 4(1): 1-66. [11] 汤卫华, 贾士儒, 贾原媛, 等. 纳米生物材料细菌纤维素在医学领域的应用研究[J]. 生物医学工程学杂志, 2014, 31(4):927-929. doi: 10.7507/1001-5515.20140174TANG W H, JIA S R, JIA Y Y, et al. Research on medical application of bacterial cellulose as Nano-biomaterials[J]. Journal of Biomedical Engineering,2014,31(4):927-929(in Chinese). doi: 10.7507/1001-5515.20140174 [12] SHLOMO, HESTRIN M, ASCHNER J, et al. Synthesis of cellulose by resting cells of acetobacter xylinum[J]. Nature,1947,159:64-65. doi: 10.1038/159064a0 [13] JONAS R, FARAH L F. Production and application of microbial cellulose[J]. Polymer Degradation and Stability, 1998, 59(1): 101-106. [14] WANG S, LI T, CHEN C J, et al. Transparent, anisotropic biofilm with aligned bacterial cellulose nanofibers[J]. Advanced Functional Materials,2018,28(24):1707491. [15] SCHRAMM M, HESTRIN S. Factors affecting production of cellulose at the air/liquid interface of a culture of acetobacter xylinum[J]. Journal of General Microbiology,1954,11(1):123-129. doi: 10.1099/00221287-11-1-123 [16] MELIH G, AKPNAR Z. Preparation and characterization of bacterial cellulose produced from fruit and vegetable peels by Komagataeibacter hansenii GA2016[J]. International Journal of Biological Macromolecules,2020,162:1597-1604. doi: 10.1016/j.ijbiomac.2020.08.049 [17] 杨光, 王彩霞. 以腐烂水果为营养源高效制备细菌纤维素[J]. 纤维素科学与技术, 2015, 23(4):67-70.YANG G, WANG C X. Cost-efficient production of bacterial cellulose by Gluconacetobacter xylinus using rotten fruits as the culture medium[J]. Journal of Cellulose Science and Technology,2015,23(4):67-70(in Chinese). [18] IRINA S, UTE H, THOMAS R, et al. Bacterial cellulose as a material for wound treatment: Properties and modifications[J]. A review,2015,33(8):1547-1571. [19] 黄小桂. 细菌纤维素的改性及其对废水的吸附行为研究[D]. 福州: 福州大学, 2017.HUANG X G. Modification and adsorption behavior of bacterial cellulose for wastewater[D]. Fuzhou: Fuzhou University, 2017(in Chinese). [20] 赵倩倩. 肠杆菌(Enterobacter sp.)FY-07发酵产细菌纤维素的原位改性研究[D]. 天津: 南开大学, 2014.ZHAO Q Q. Study on in situ modifaction of bacterial cellulose produced by Enterobacter sp. FY-07[D]. Tianjin: Nankai University, 2014(in Chinese). [21] 钱子俊, 张一瞳, 刘鹏, 等. 不同添加剂对木醋杆菌发酵细菌纤维素的影响[J]. 林业工程学报, 2018, 3(4):62-67.QIAN Z J, ZHANG Y T, LIU P, et al. Effects of different additives on bacterial cellulose production by Gluconacetobacter xylinum[J]. Journal of Forestry Engineering,2018,3(4):62-67(in Chinese). [22] 张雯, 赵秋红, 李彦军. 醋酸杆菌发酵细菌纤维素及其改性研究[J]. 食品工业科技, 2013, 34(17):181-184.ZHANG W, ZHAO Q H, LI Y J. Study on fermentation of bacterial cellulose by acetobacter xylinum and its modification[J]. Science and Technology and Food Industry,2013,34(17):181-184(in Chinese). [23] YIN N, DU R, ZHAO F, et al. Characterization of antibacterial bacterial cellulose composite membranes modified with chitosan or chitooligosaccharide[J]. Carbohydrate Polymers,2020,229:115520. [24] 朱清梅, 冯玉红, 林强, 等. 利用椰子水生物合成CMC改性细菌纤维素[J]. 精细化工, 2010, 27(7):654-658.ZHU Q M, FENG Y H, LIN Q, et al. Biosynthesis of CMC-Bacterial cellulose with coconut-water[J]. Fine Chemicals,2010,27(7):654-658(in Chinese). [25] 李玉洁, 冯玉红, 张名楠, 等. 原位生物合成中甘油醛改性细菌纤维素的研究[J]. 材料导报, 2016, 30(8):46-50.LI Y J, FENG Y H, ZHANG M N, et al. The in-situ biosynthesis of bacterial cellulose moidfied by glyceraldehyde[J]. Material Reports,2016,30(8):46-50(in Chinese). [26] 张晶. 细菌纤维素组织工程支架材料的复合改性与性能研究[D]. 天津: 天津大学, 2014.ZHANG J. Modification and properties of bacterial cellulose tissue engineering scaffolds[D]. Tianjin: Tianjin University, 2014(in Chinese). [27] 谢健健. 载纳米银细菌纤维素抗菌材料的制备及其评价[D]. 上海: 东华大学, 2012.XIE J J. Preparation and evaluation of antibacterial bacterial cellulose membranes impregnated silver nanoparticles[D]. Shanghai: Donghua University, 2012(in Chinese). [28] TRONCOSO O P, TORRES F G. Bacterial cellulose-graphene based nanocomposites[J]. International Journal of Molecular Sciences,2020,21(18):6532. doi: 10.3390/ijms21186532 [29] YAN Z Y, CHEN S Y, WANG H P, et al. Biosynthesis of bacterial cellulose/multi-walled carbon nanotubes in agitated culture[J]. Carbohydrate Polymers, 2008, 74(3): 659-665. [30] 汤莹. 纤维素化学改性研究进展与展望[J]. 科学与信息化, 2017(29): 63-65.TANG Y. Research progress and prospect of cellulose chemical modification[J]. Technology and Information, 2017(29): 63-65(in Chinese). [31] ALBERTO E L, OCAMPO A, DEPASUPIL C G, et al. Acetylation of Nata de coco (bacterial cellulose) and membrane formation[J]. MATEC Web of Conferences, 2019, 268(2): 04003. [32] 王曼, 张坤, 翟晓利, 等. 细菌纤维素和TEMPO氧化细菌纤维素对Fe(Ⅱ)的吸附[J]. 离子交换与吸附, 2016, 32(3):234-243.WANG M, ZHANG K, ZHAI X L, et al. Adsorption of Fe(Ⅱ) with bacterial cellulose and TEMPO-oxidized bacterial cellulose[J]. Ion Exchange and Adsorption,2016,32(3):234-243(in Chinese). [33] WAN N W S, ENDUD C S, MAYANAR R. Removal of copper(Ⅱ) ions from aqueous solution onto chitosan and cross-linked chitosan beads[J]. Reactive and Functional Polymers,2002,50(2):181-190. doi: 10.1016/S1381-5148(01)00113-4 [34] 鲁敏. 细菌纤维素的制备及其对重金属离子的吸附性能研究[D]. 沈阳: 东北大学, 2012.LU M. Preparation of bacterial cellulose and its adsorption propertiese to heavy metal ions[D]. Shenyang: Northeastern University, 2012(in Chinese). [35] CHEN S Y, SHEN W, YU F, et al. Preparation of amidoximated bacterial cellulose and its adsorption mechanism for Cu2+ and Pb2+[J].Journal of Applied Polymer Science, 2010, 117(1): 8-15. [36] HASINEA K, SAADET Ö, MURAT O. Modified polyacrylamide hydrogels and their application in removal of heavy metal ions[J]. Polymer, 2003, 44(6): 1785-1793. [37] ZHENG Y, WANG A Q. Granular hydrogel initiated by Fenton reagent and their performance on Cu(Ⅱ) and Ni(Ⅱ) removal[J]. Chemical Engineering Journal, 2012, 200-202: 601-610. [38] 李雅茹. PAA/纤维素复合水凝胶的制备及性能研究[D]. 天津: 天津科技大学, 2015.LI Y R. Study on the preparation and properties of PAA/cellulose composite hydrogels[D]. Tianjin: Tianjin University of Science & Technology, 2015(in Chinese). [39] 王静, 王清清, 魏取福, 等. PVA-SbQ/细菌纤维素复合气凝胶的制备及吸油性能研究[J]. 功能料, 2016, 47(3):3007-3010.WANG J, WANG Q Q, WEI Q F, et al. Study on the preparation and oil absorption of PVA-SbQ/BC composite aerogels[J]. Journal of Functional Materials,2016,47(3):3007-3010(in Chinese). [40] POURJAVADI A, NAZARI M, KABIRI B, et al. Preparation of porous graphene oxide/hydrogel nanocomposites and their ability for efficient adsorption of methylene blue[J]. RSC Advances,2016,6(13):10430-10437. [41] 焦彩珍, 丁玲, 陈鑫, 等. 增强型细菌纤维素/聚乙烯醇水凝胶的制备研究[J]. 高分子通报, 2019(2):63-74.JIAO C Z, DING L, CHEN X, et al. Studies on preparaiton of enhanced bacterial cellulose/polyvinyl alcohol hydrogels[J]. Polymer Bulletin,2019(2):63-74(in Chinese). [42] LI D W, TIAN X J, WANG Z Q, et al. Multifunctional adsorbent based on metal-organic framework modified bacterial cellulose/chitosan composite aerogel for high efficient removal of heavy metal ion and organic pollutant[J]. Chemical Engineering Journal, 2020, 383: 123127. [43] HE J, ZHAO H Y, LI X L, et al. Superelastic and superhydrophobic bacterial cellulose/silica aerogels with hierarchical cellular structure for oil absorption and recovery[J]. Journal of Hazardous Materials,2018,346:199-207. [44] 何旭敏, 何国梅, 曾碧榕, 等. 膜分离技术的应用[J]. 厦门大学学报(自然科学版), 2001, 40(2):495-502.HE X M, HE G M, ZENG B R, et al. Application of membrane-separation technology[J]. Journal of Xiamen University(Natural Science),2001,40(2):495-502(in Chinese). [45] 董丽攀, 李政, 王福迎, 等. 细菌纤维素@聚吡咯-单壁碳纳米管导电膜的制备与表征[J]. 复合材料学报, 2019, 36(3):723-729.DONG L P, LI Z, WANG F Y, et al. Preparation and characterization of bacterial cellulose@polypyrrole-single wall carbon nanotube conductive films[J]. Acta Materiae Compositae Sinica,2019,36(3):723-729(in Chinese). [46] LIU X B, HAMID S, ZHENG Y D, et al. Soy protein isolate/bacterial cellulose composite membranes for high efficiency particulate air filtration[J]. Composites Science and Technology,2017,138:124-133. [47] 胡婷婷, 贾庆明, 陕绍云. 纤维素基面膜材料的应用进展[J]. 纤维素科学与技术, 2018, 26(4):60-67.HU T T, JIA Q M, SHAN S Y. Progress in application of cellulose-based materials as facial mask[J]. Journal of Cellulose Science and Technology,2018,26(4):60-67(in Chinese). [48] 张蒙. 细菌纤维素/二醋酸纤维复合滤料制备及性能研究[D]. 无锡: 江南大学, 2019.ZHANG M. Preparation and properties of bacterial cellulose/cellulose diacetate composite filter material[D]. Wuxi: Jiangnan University, 2019(in Chinese). [49] ZHANG S, SHIM W S, KIM J. Design of ultra-fine nonwovens via electrospinning of Nylon 6: Spinning parameters and filtration efficicency[J]. Materials Design,2009,30(9):3659. doi: 10.1016/j.matdes.2009.02.017 [50] LIU C, HSU P C, LEE H W, et al. Transparent air filter for high-efficiency PM2.5 capture[J]. Nature Communications, 2015, 6: 6205. [51] 贺玮, 刘晓彤, 郑裕东, 等. 用于空气过滤的改性大豆蛋白-细菌纤维素复合材料的制备及性能[J]. 复合材料学报, 2021, 38(3): 843-853.HE W, LIU X T, ZHENG Y D, et al. Preparation and properties of modified soy protein-bacterial cellulose composite materials for air filtration[J]. Acta Materiae Compositae Sinica, 2021, 38(3): 843-853(in Chinese). [52] 范鑫. 橘渣细菌纤维素的制备及空气净化膜的构建与性能研究[D]. 武汉: 华中农业大学, 2019.FAN X. Preparation of citrus peel and pomace bacterial cellulose and fabrication and filtration of air filters[D]. Wuhan: Huazhong Agricultural University, 2019(in Chinese). [53] 宋冰, 石勇, 陆海龙, 等. 细菌纤维素纸质复合微滤膜的开发[J]. 中国造纸学报, 2015, 30(4):32-37. doi: 10.11981/j.issn.1000-6842.2015.04.32SONG B, SHI Y, LU H L, et al. Preparation and characteristics of a paper-based bacterial cellulose microfiltration membrane[J]. Transactions of China Pulp and Paper,2015,30(4):32-37(in Chinese). doi: 10.11981/j.issn.1000-6842.2015.04.32 [54] 高春涛, 蔡以兵, 王清清, 等. TiO2纳米纤维的制备及其对染料的光催化降解性能[J]. 功能材料, 2013, 44(2):240-243, 248. doi: 10.3969/j.issn.1001-9731.2013.02.020GAO C T, CAI Y B, WANG Q Q, et al. Preparation and photocatalytic degreadation properties on dyes of TiO2 nanofibers[J]. Journal of Functional Materials,2013,44(2):240-243, 248(in Chinese). doi: 10.3969/j.issn.1001-9731.2013.02.020 [55] 蒋国民, 魏静, 晁成, 等. 细菌纤维素负载TiO2用于DDNP废水光催化降解研究[J]. 功能材料, 2015, 46(2):2023-2027. doi: 10.3969/j.issn.1001-9731.2015.02.005JIANG G M, WEI J, CHAO C, et al. Study of biotemplated preparation of TiO2 nanoparticles/bacterial cellulose hybrid nanofiber for degradation of DDNP wastewater[J]. Journal of Functional Materials,2015,46(2):2023-2027(in Chinese). doi: 10.3969/j.issn.1001-9731.2015.02.005 [56] DAI B B, CHAO C, LU X Y, et al. Preparation of ZnO/CdS/BC photocatalyst hybrid fiber and research of its photocatalytic properties[J]. Journal of Nanotechnology,2015,2015:1-8. -

下载:

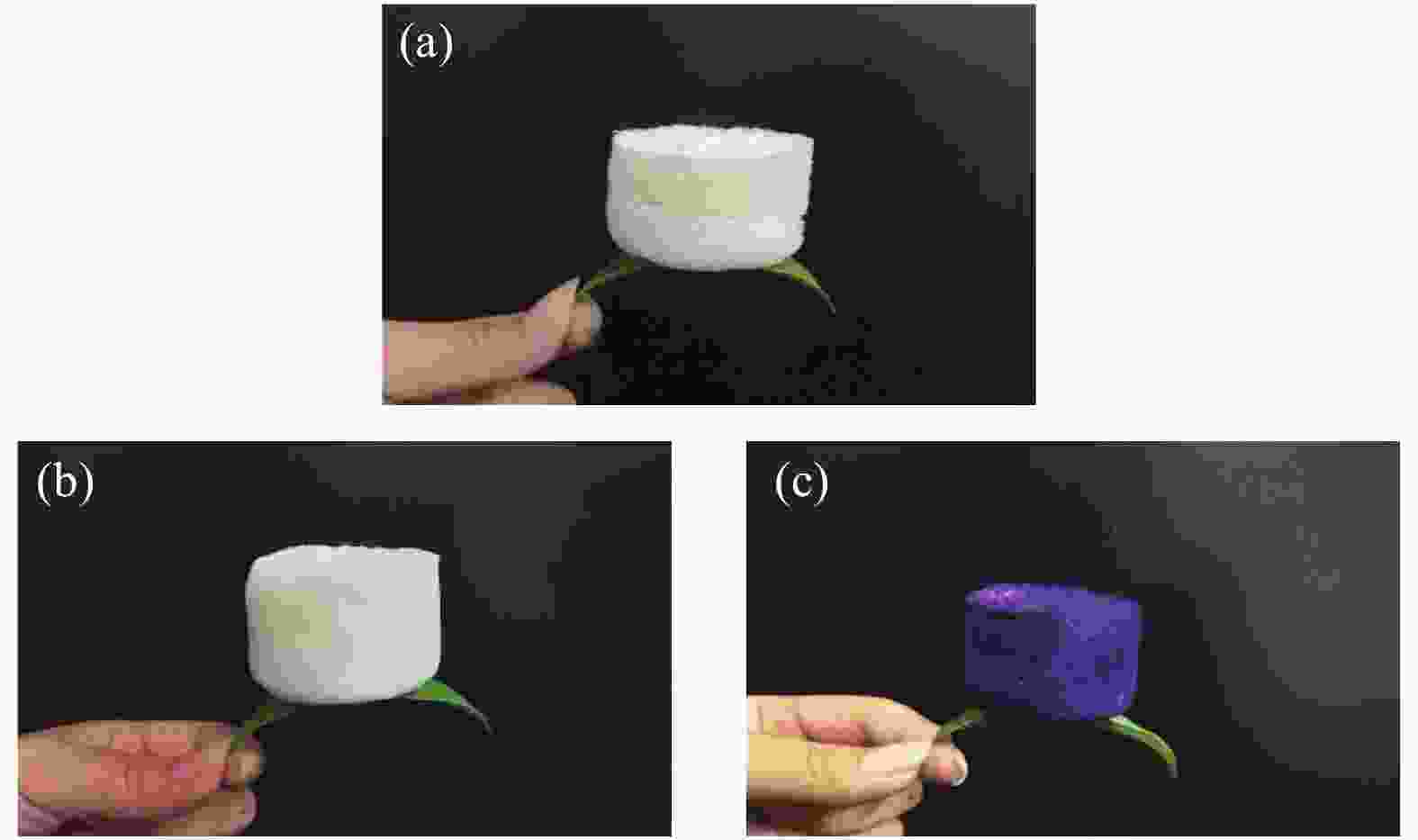

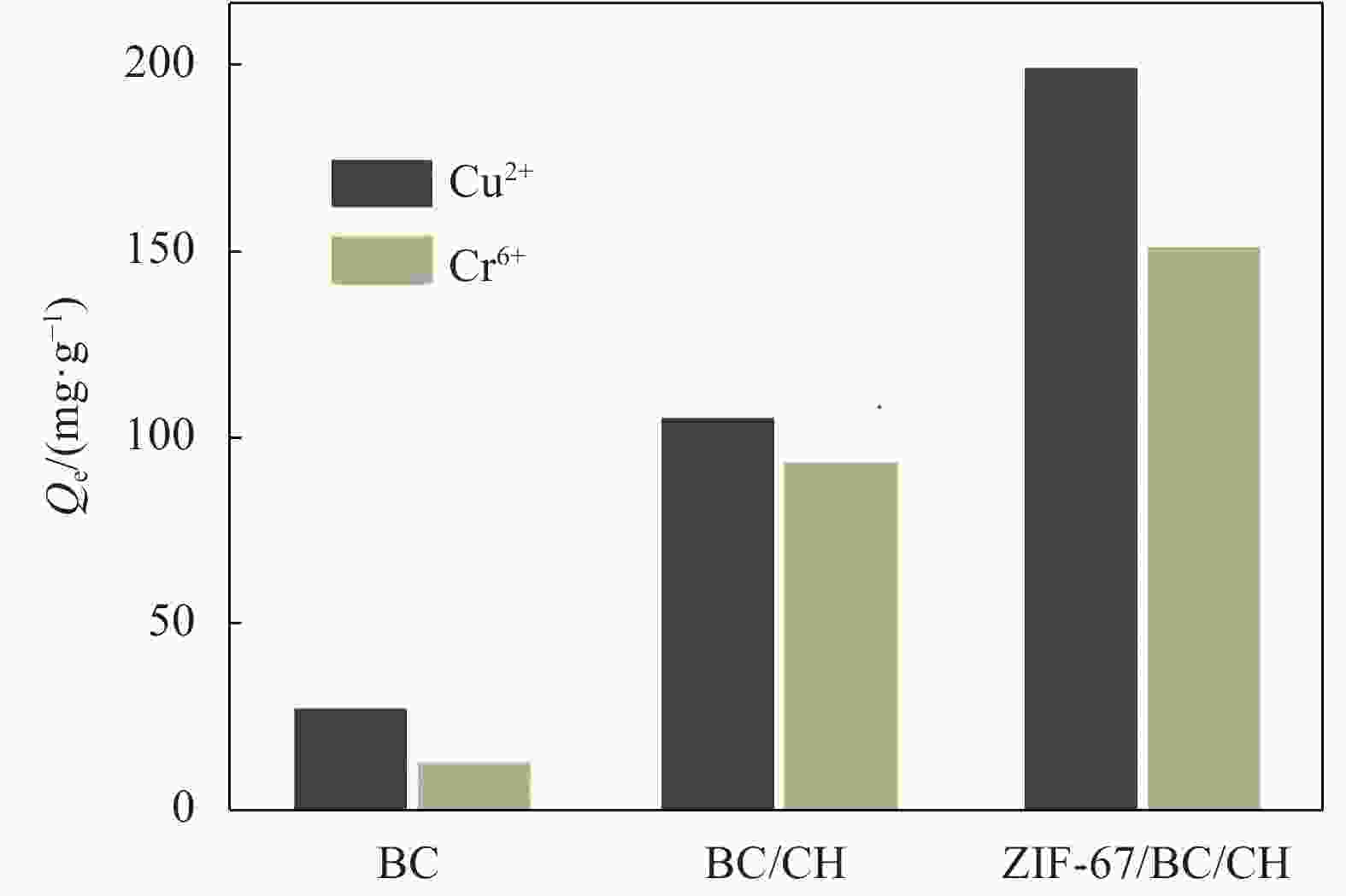

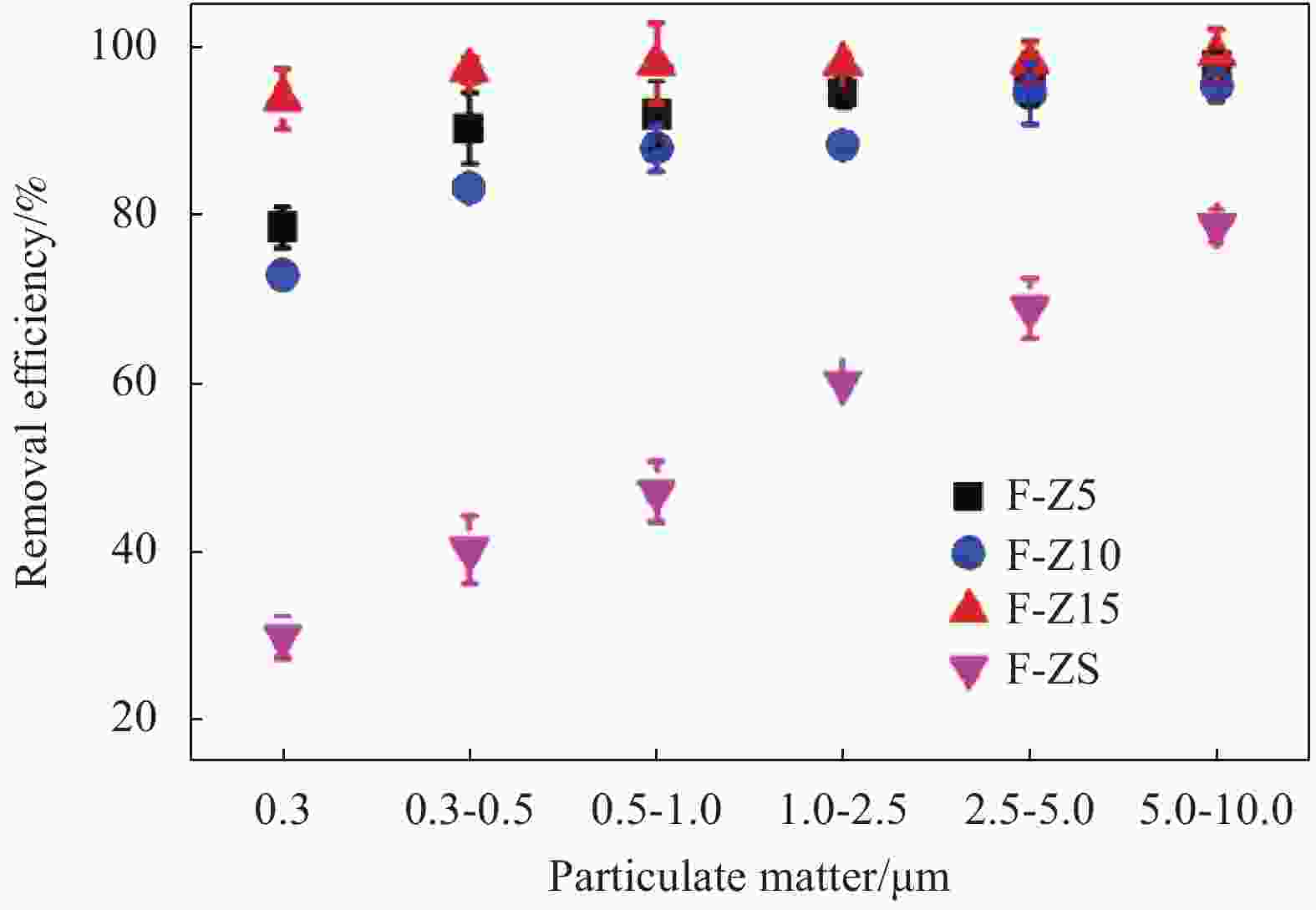

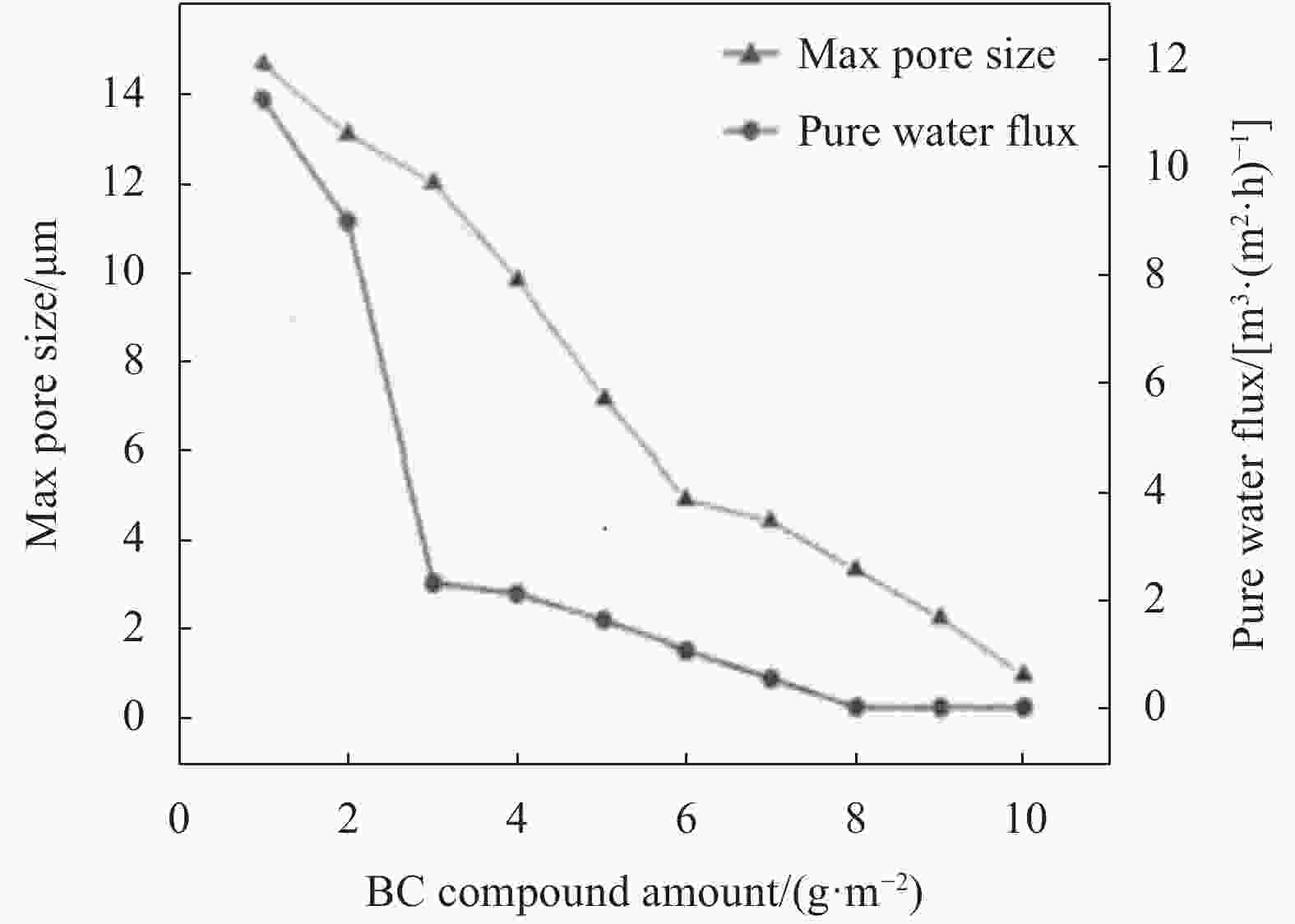

下载: