Biaxial loading verification for an in-plane failure criterion of laminates with barely visible impact damages (BVID)

-

摘要: 在复合材料飞机结构设计中,由于应力的铺层相关性,工程上通常采用应变进行结构强度预测。另外,复合材料飞机需考虑损伤容限设计,必须对含损伤,尤其是目视几乎不可见损伤(Barely visible impact damages,BVID)结构的适航符合性进行评估。因此,民用飞机结构设计上更需要基于应变的并考虑含损伤的复合材料失效准则来预测结构强度。本文介绍了一种复合应变失效判据,为验证该失效判据的保守性,设计了面内双轴加载试验,对含BVID损伤的准各向同性铺层T800级碳纤增强环氧树脂基复合材料层压板进行了各种工况的面内失效测试。通过设计双轴加载载荷比,实现了不同的拉伸、压缩、剪切复合加载工况。理论分析与试验结果对比显示,理论方法的失效载荷约为试验失效载荷的80%。此方法的保守性和准确度既满足了结构安全性需求又不会引入不必要的结构质量,适合于实际工程应用。

-

关键词:

- 复合材料层压板 /

- 面内失效 /

- 双轴加载 /

- 目视几乎不可见损伤(BVID) /

- 有限元分析(FEA)

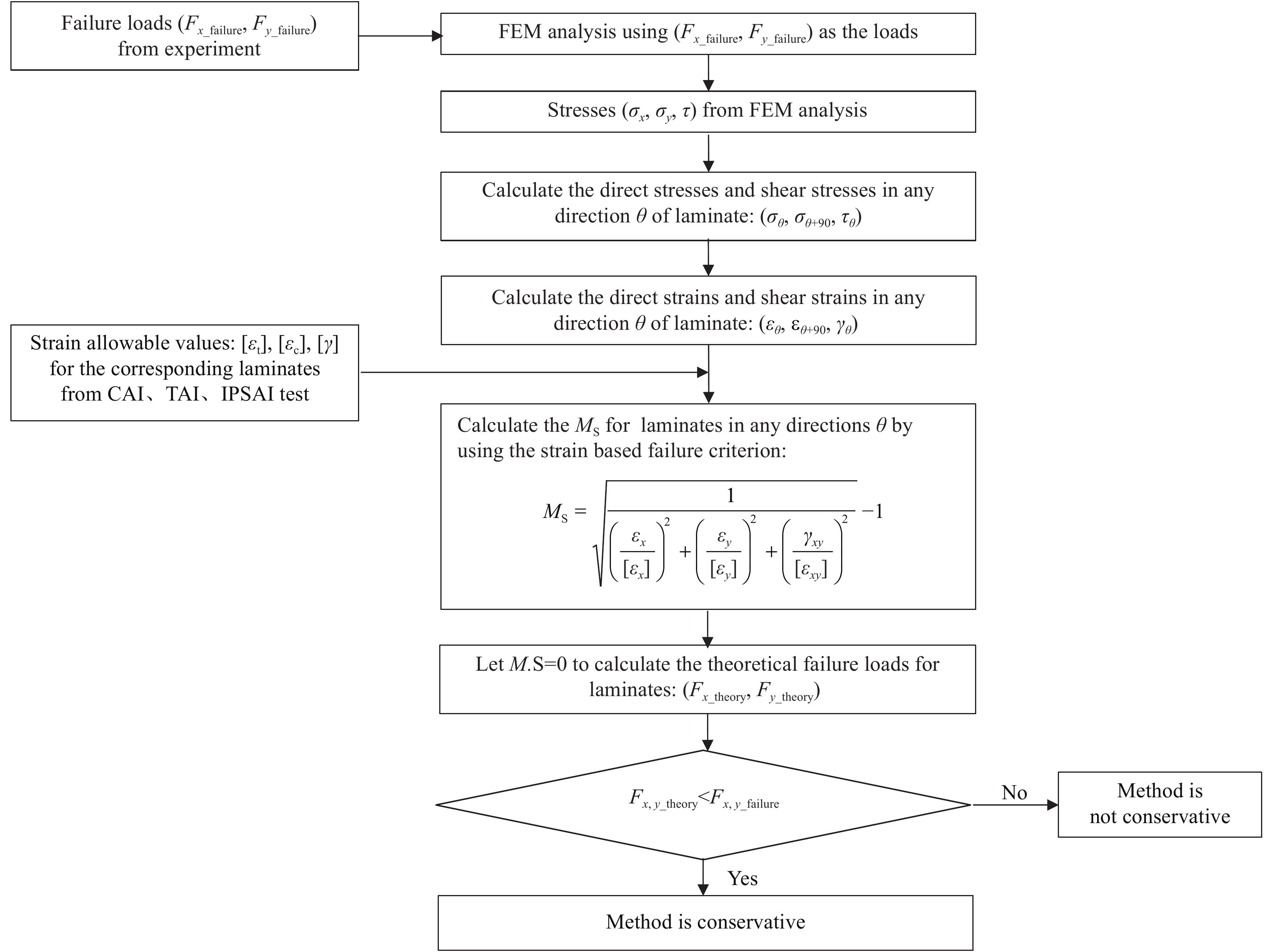

Abstract: In engineering practice, strains are used for stress analysis of composite aircraft structures, instead of stresses due to their stacking sequence dependence. Besides, for composite airplane, damage tolerant design is necessary, the compliance of airworthiness for composite structures with damages, especially barely visible impact damages (BVID) should be assessed. Thus for civil aircraft structural design, a credible strain based failure criterion for composites that containing damage is in demand for stress prediction. In this paper, a combined strain failure criterion for laminates was introduced. In order to verify the conservation of this failure criterion, biaxial loading tests were designed. Quasi-isotropic T800 carbon fiber reinforced epoxy resin matrix composite laminates with BVID were used for in-plane failure tests under various load conditions. Various load conditions with different combination of tension, compression and shearing loads were obtained through diversified design of load ratios. It is shown from the comparison of theoretical results and test results that all the theoretical failure loads are lower than experimental ones with a ratio of about 80%. The criterion is conserved to assure the safety of structures, but not too conserved to bring unnecessary weight to structures, thus it is suitable for engineering exercise. -

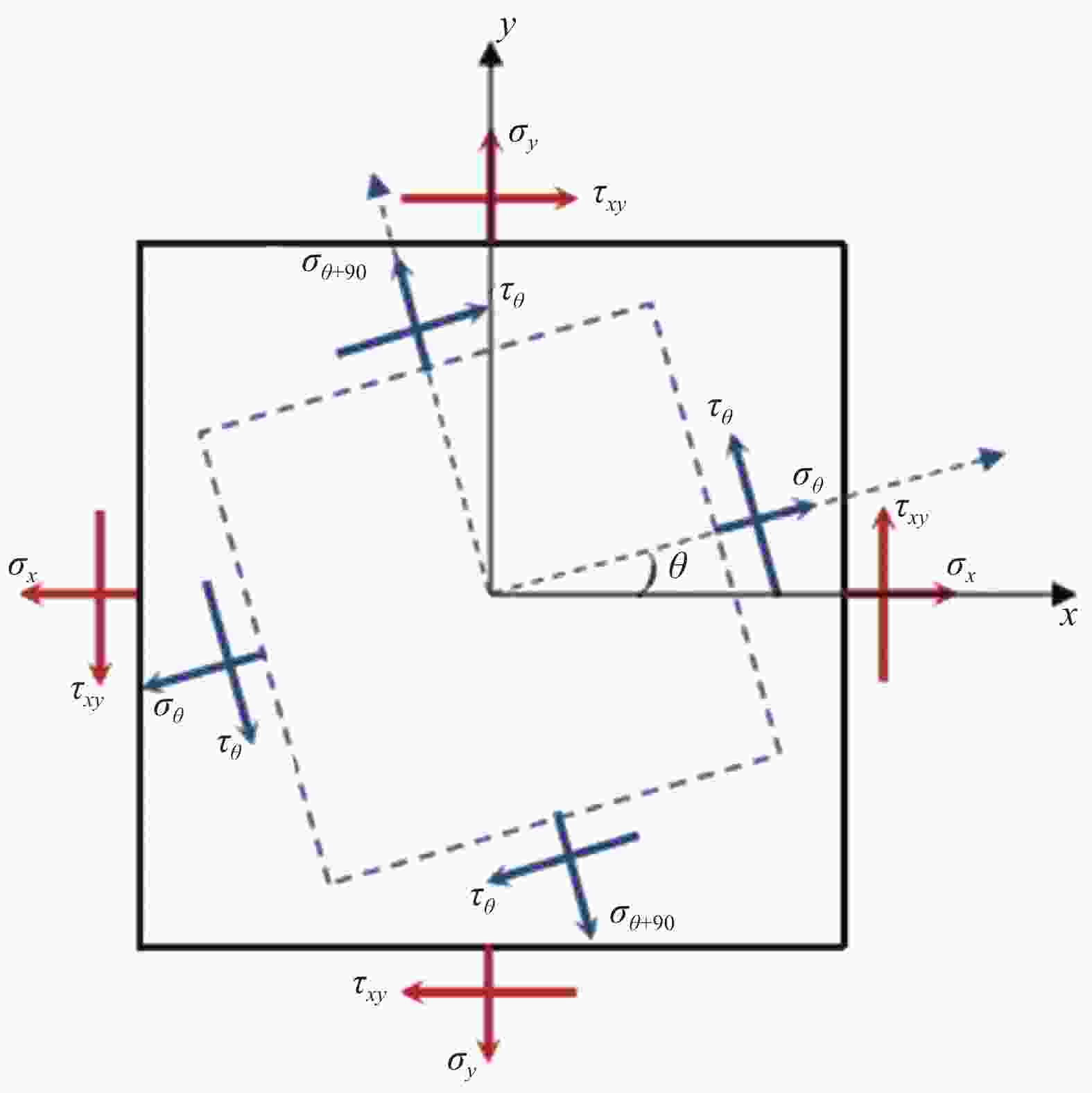

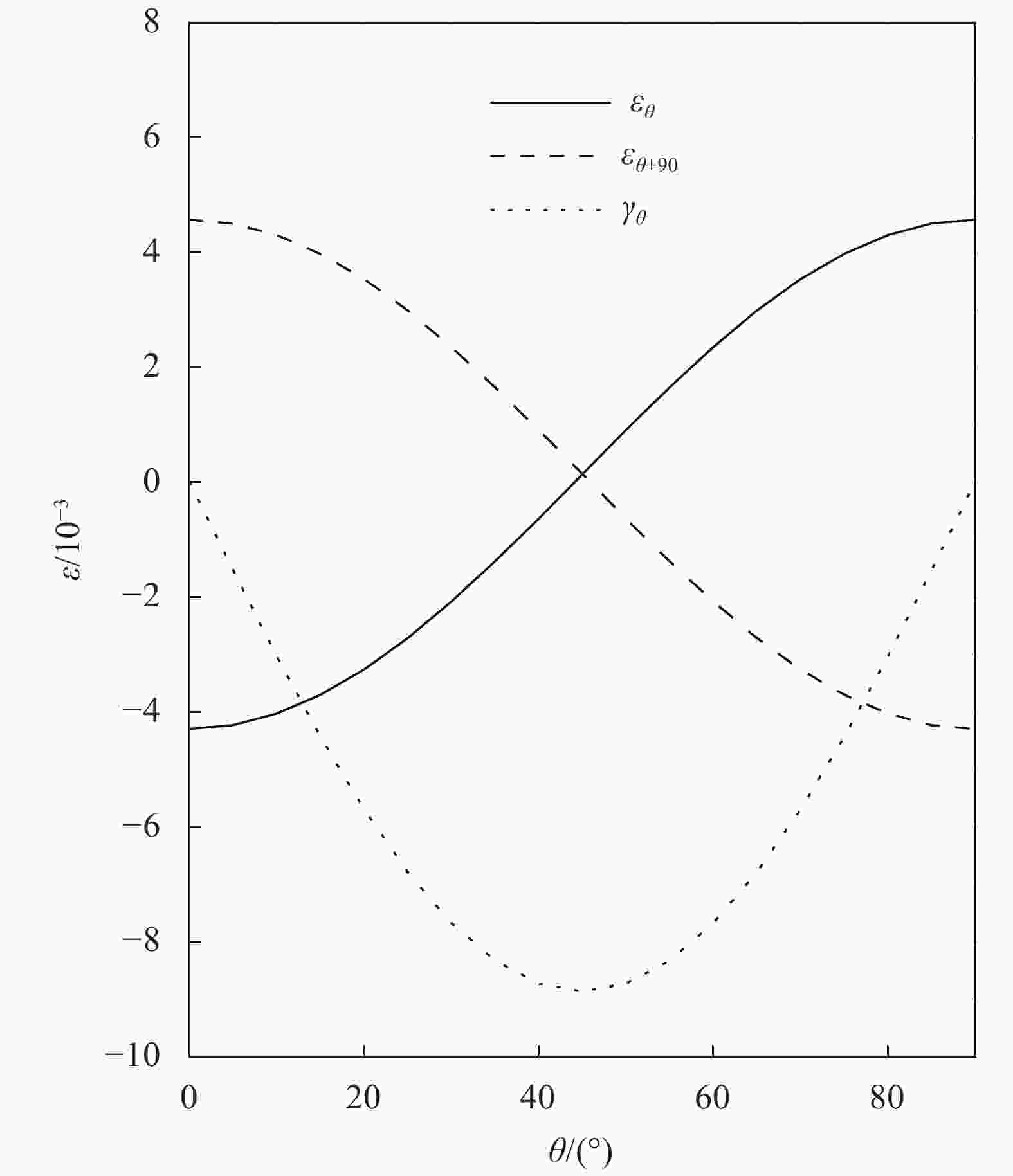

图 10 平板表面的应力分量及倾角θ斜面的应力分量示意图

Figure 10. Components of stress on the faces of a plate and on an inclined plane with inclination angle θ

σθ—Principle stress in θ direction; σθ+90—Principle stress in (θ+90) direction; τθ—Shear stress in (θ, θ+90) direction; σx—Principle stress in x direction; σy—Principle stress in y direction; τxy—Shear stress in xy direction

表 1 不同

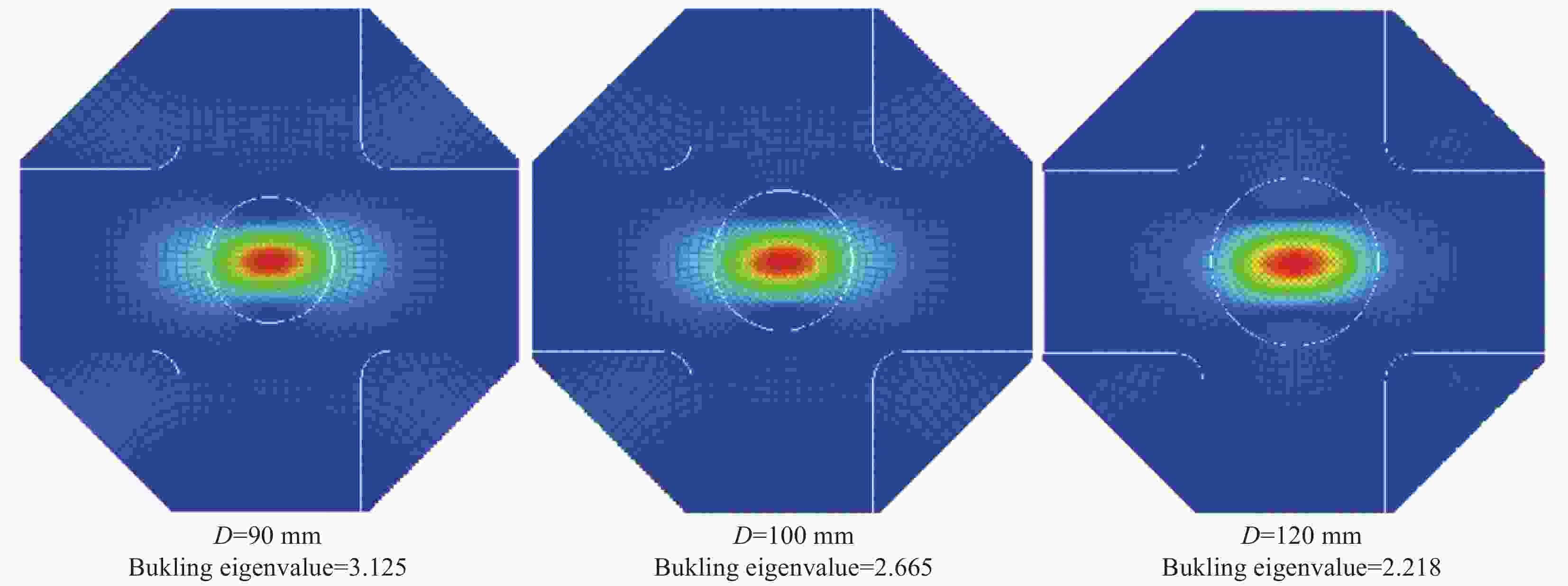

${\boldsymbol{F}}_{\boldsymbol{x}} $ ∶${\boldsymbol{F}}_{\boldsymbol{y}} $ 载荷工况下分析获得的层压板面内失效载荷与失稳载荷对比Table 1. Comparison of loads for buckling and in-plane failure of composite laminate under different

${\boldsymbol{F}}_{\boldsymbol{x}} $ ∶${\boldsymbol{F}}_{\boldsymbol{y}} $ ratiosFx∶Fy Fx_buckling/

(kN·m−1)Fx_failure/

(kN·m−1)Fx_buckling/

Fx_failure−4∶3 463.29 450.08 102.93% −3∶4 400.70 325.95 122.93% −2∶3 359.75 314.20 114.50% −3∶2 469.86 497.10 94.52% −5∶3 475.48 488.27 97.38% −3∶5 326.24 276.16 118.13% −2∶1 483.61 589.23 82.08% −1∶2 274.97 267.63 102.74% −1∶1 443.63 430.63 103.02% −5∶−1 534.88 858.04 62.34% −4∶−1 526.59 892.81 58.98% −4∶−2 473.00 996.66 47.46% −5∶−3 450.70 1028.39 43.83% 表 2 试验矩阵

Table 2. Test matrix

Specimen code Ply Fx∶Fy ratio T800 CF/EP-1 [45/−45/0/90]2s −3∶4 T800 CF/EP-2 [45/−45/0/90]2s −3∶5 T800 CF/EP-3 [45/−45/0/90]2s −1∶1 T800 CF/EP-4 [45/−45/0/90]2s −1∶2 T800 CF/EP-5 [45/−45/0/90]2s −4∶3 T800 CF/EP-6 [45/−45/0/90]2s −2∶3 T800 CF/EP-7 [45/−45/0/90]2s −5∶3 T800 CF/EP-8 [45/−45/0/90]2s −2∶1 Notes: CF—Carbon fiber; EP—Epoxy resin. 表 3 不同载荷比下层压板试件

${\boldsymbol{x}} $ 和${\boldsymbol{y}} $ 方向的失效载荷Table 3. Failure loads in

${\boldsymbol{x}} $ and${\boldsymbol{y}} $ directions of laminates under different load ratiosSpecimen code Fx/(kN·m−1) Fy/(kN·m−1) T800 CF/EP-1 −255.86 340.28 T800 CF/EP-2 −217.31 361.67 T800 CF/EP-3 −278.33 278.06 T800 CF/EP-4 −193.53 385.28 T800 CF/EP-5 −307.22 230.28 T800 CF/EP-6 −232.00 346.11 T800 CF/EP-7 −330.28 197.61 T800 CF/EP-8 −331.94 165.42 表 4 层压板理论失效载荷与试验失效载荷的比较

Table 4. Comparison of experimented and theoretical failure loads of laminates

Specimen code F_theory/F_failure T800 CF/EP-1 77.27% T800 CF/EP-2 80.66% T800 CF/EP-3 81.26% T800 CF/EP-4 81.57% T800 CF/EP-5 82.45% T800 CF/EP-6 80.26% T800 CF/EP-7 82.76% T800 CF/EP-8 86.79% -

[1] TSAI S W, WU E M. A general theory of strength for anisotropic materials[J]. Journal of Composite Materials,1971,5(1):58-80. doi: 10.1177/002199837100500106 [2] TSAI S W. Strength characteristics of composite materials[R]. Washington: NASA CR-224, 1965. [3] HOFFMAN O. The brittle strength of orthotropic materials[J]. Journal of Composite Materials,1967,1(2):200-206. doi: 10.1177/002199836700100210 [4] HASHIN Z. Failure criteria for unidirectional fiber compo-sites[J]. Journal of Applied Mechanics,1980,47(6):329-334. [5] PUCK A, SCHÜRMANN H. Failure analysis of FRP laminates by means of physically based phenomenological models[J]. Composites Science and Technology,2002,62(12-13):1633-1662. doi: 10.1016/S0266-3538(01)00208-1 [6] SUN C T, QUINN B J, TAO J, et al. Comparative evaluation of failure analysis methods for composite laminates[R]: Washington NASA, DOT/FAA/AR-95/109, 1996. [7] HART-SMITH L J. Predictions of the original and truncated maximum-strain failure models for certain fibrous composite laminates[J]. Composites Science and Technology,1998,58(7):1151-1178. doi: 10.1016/S0266-3538(97)00192-9 [8] ROTEM A. Prediction of laminate failure with the Rotem failure criterion[J]. Composites Science and Technology,1998,58(7):1083-1094. doi: 10.1016/S0266-3538(96)00143-1 [9] HINTON M J, SODEN P D. Prediction failure in composite laminates: The background to the exercise[J]. Composites Science and Technology,1998,58(7):1001-1010. doi: 10.1016/S0266-3538(98)00074-8 [10] SCHULTE K. World wide failure excercise on failure prediction in composites[J]. Composites Science and Technology,2002,62(12-13):1479. doi: 10.1016/S0266-3538(02)00126-4 [11] SODEN P D, HINTON M J, KADDOUR A S. Lamina properties and layup configurations and loading conditions of range fibre reinforced composite laminates[J]. Compo-sites Science and Technology,1998,58(7):1011-1022. doi: 10.1016/S0266-3538(98)00078-5 [12] HINTONA M J, KADDOURB A S, SODEN P D. A comparison of the predictive capabilities of current failure theories for composite laminates, judged against experimental evidence[J]. Composites Science and Technology,2002,62(12-13):1725-1797. doi: 10.1016/S0266-3538(02)00125-2 [13] HINTON M, KADDOUR A. The background to part B of the second world-wide failure exercise: Evaluation of theories for predicting failure in polymer composite laminates under three-dimensional states of stress[J]. Journal of Composite Materials,2013,47(6-7):643-652. doi: 10.1177/0021998312473346 [14] KADDOUR A S, HINTON M J, SMITH P A, et al. The background to the third world-wide failure exercise[J]. Journal of Composite Materials,2013,47(20-21):2417-2426. [15] KUMAZAWA H, TAKATOYA T. Biaxial strength investigation of CFRP composite laminates by using cruciform specimens[C]. Edinburgh, United Kingdom: 17th international Conference on Composite Materials (ICCM-17), 2009. [16] WELSH J S, ADAMS D F. An experimental investigation of the biaxial strength of IM6/3501-6 carbon/epoxy cross-ply laminates using cruciform specimens[J]. Composites Part A: Applied Science & Manufacturing,2002,33(6):829-839. [17] XU J, ASKARI A, WECKNER O, et al. Damage and failure analysis of composite laminates under biaxial loads[C]. Waikiki: 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference, 2007. [18] 王犇. 复合材料的双轴试验研究[J]. 科技创新导报, 2018(11):19-21.WANG Ben. Biaxial loading tests study for composites[J]. Science and Technology Innovation Herald,2018(11):19-21(in Chinese). [19] 史晓辉, 李真, 陈秀华, 等. 复合材料双向加载试验件形状优化设计[J]. 试验室研究与探索, 2012, 31(6):51-55.SHI Xiaohui, LI Zhen, CHEN Xiuhua, et al. Shape optimization of a composite cruciform specimen under biaxial loading condition[J]. Research and Exploration in Laboratory,2012,31(6):51-55(in Chinese). [20] 李真, 史晓辉, 陈秀华, 等. 基于改进蚁群算法的复合材料双向加载十字形试件优化设计[J]. 机械科学与技术, 2013, 32(3):462-468.LI Zhen, SHI Xiaohui, CHEN Xiuhua, et al. Optimization of a biaxial loading for cruciform specimen of composite based on modified ACO[J]. Mechanical Science and Technology for Aerospace Engineering,2013,32(3):462-468(in Chinese). [21] 蔡登安, 周光明, 曹然, 等. 双轴载荷下复合材料十字型试样几何形状对中心测试区系数的影响[J]. 复合材料学报, 2015, 32(4):1138-1144.CAI D A, ZHOU G M, CAO R, et al. Influence of geometry of composite cruciform specimen under loading on coeddicients of central testing zone[J]. Acta Materiae Compositae Sinica,2015,32(4):1138-1144(in Chinese). [22] ASTM International. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D 7136[S]. West Conhohoken: ASTM International, 2015. [23] ASTM International. Standard test method for tensile properties of polymer matrix composite materials: ASTM D 3039[S]. West Conhohoken: ASTM International, 2014. [24] ASTM International. Standard test method for compressive residual strength properties of damaged polymer matrix composite plates: ASTM D 7137[S]. West Conhohoken: ASTM International, 2012. [25] ASTM International. Standard test method for shear properties of composite materials by v-notched rail shear method: ASTM D 7078[S]. West Conhohoken: ASTM International, 2012. -

下载:

下载: