Influence of polar interface on the morphology and degradation performance of calcium alginate gel units

-

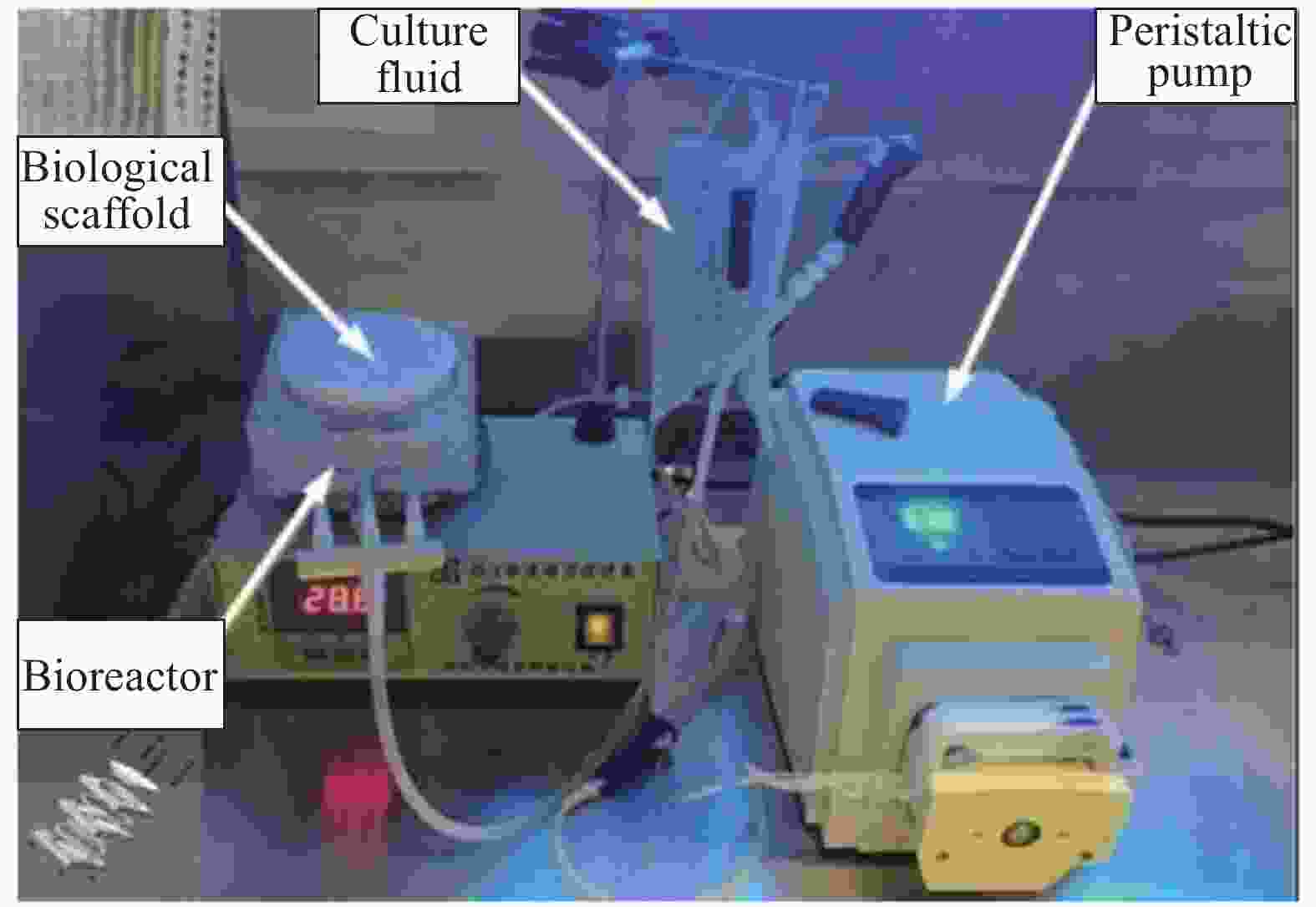

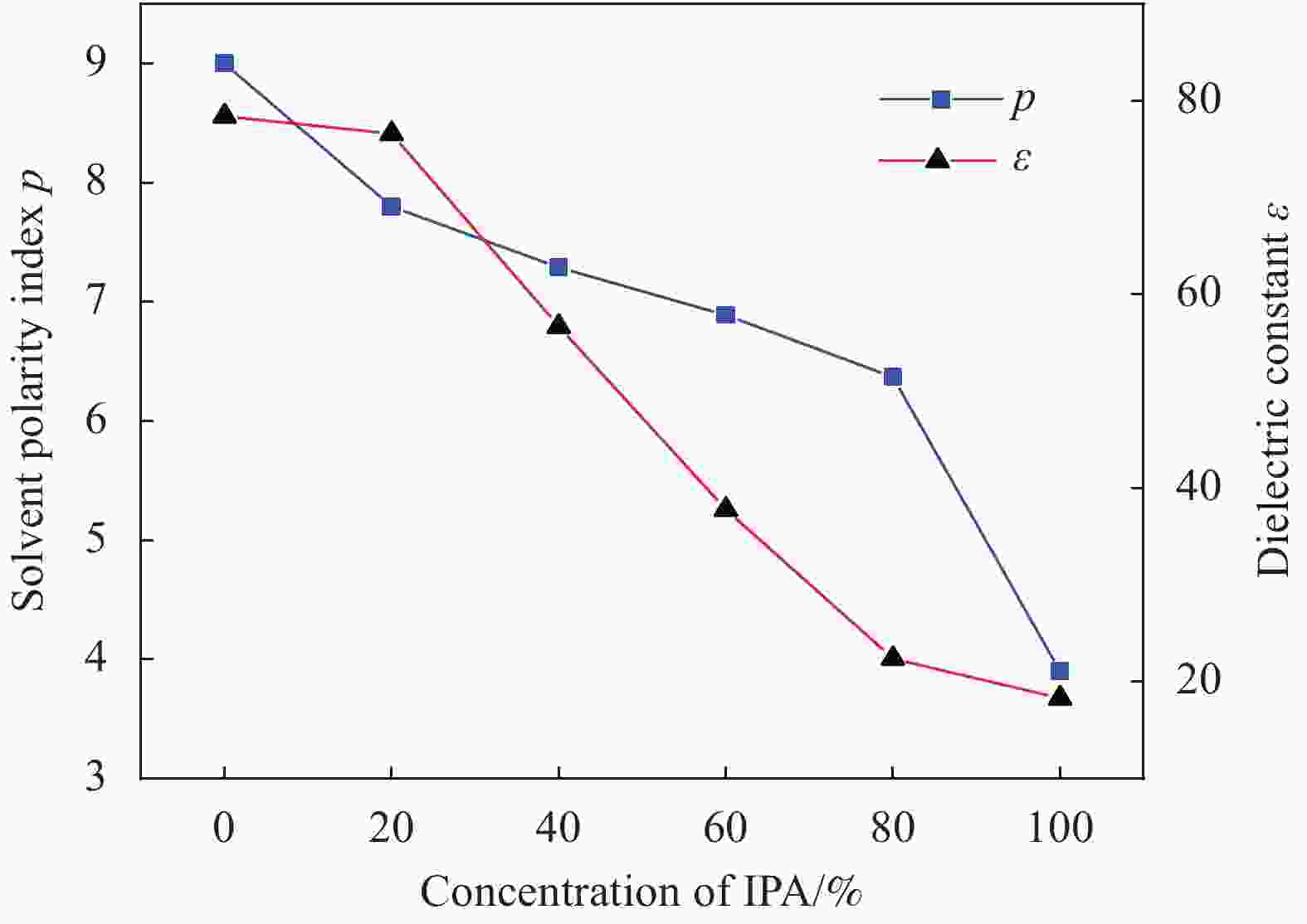

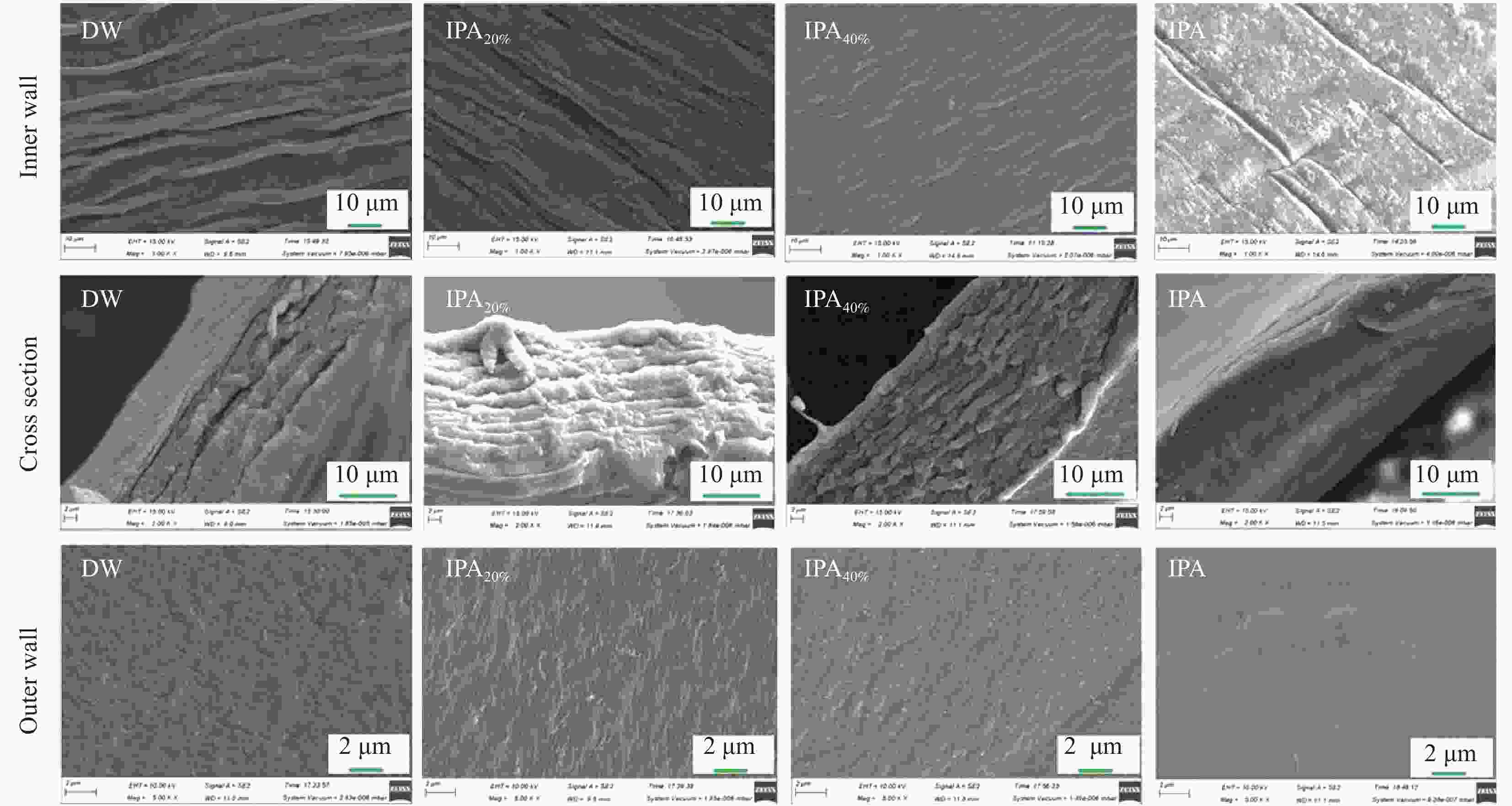

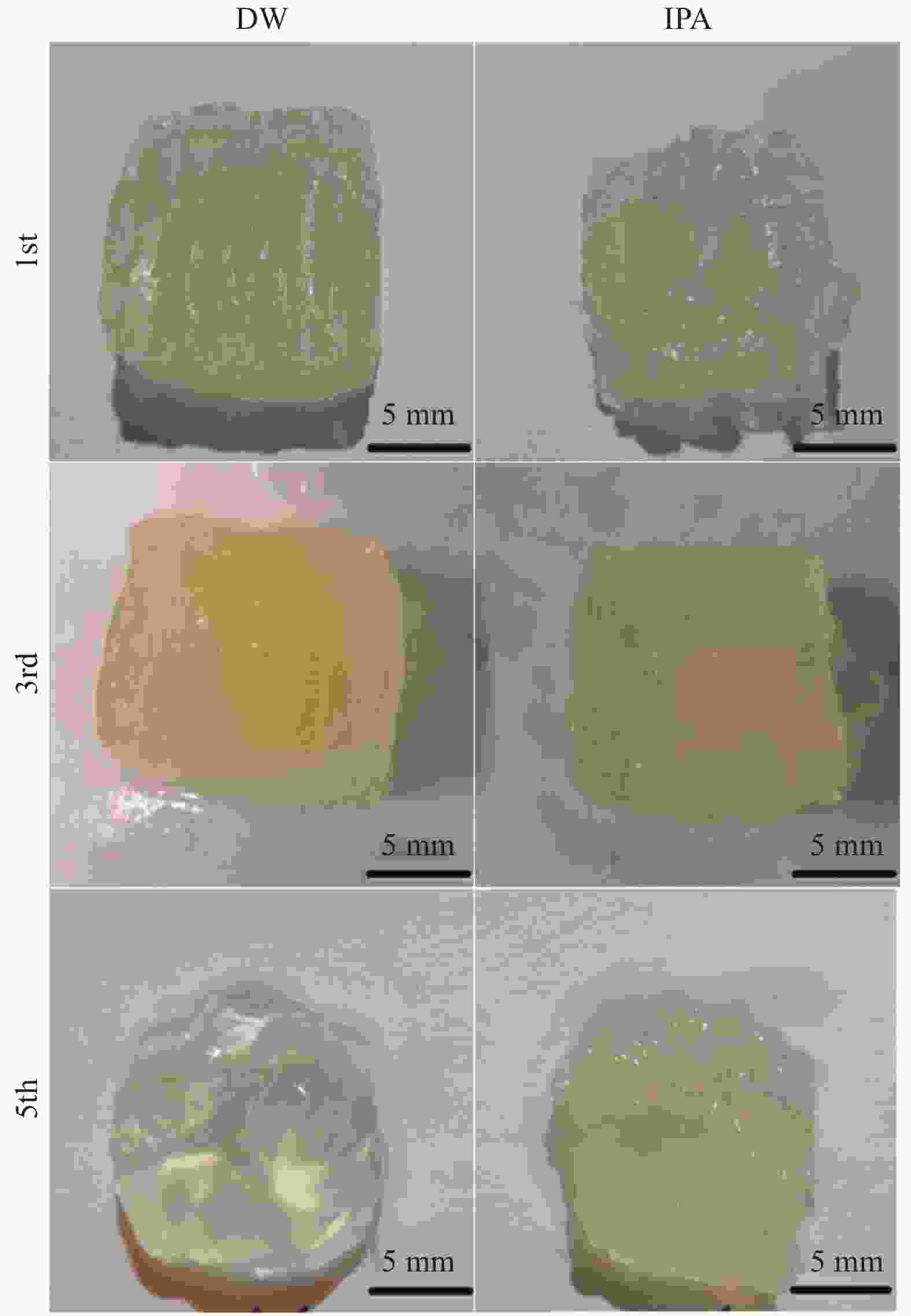

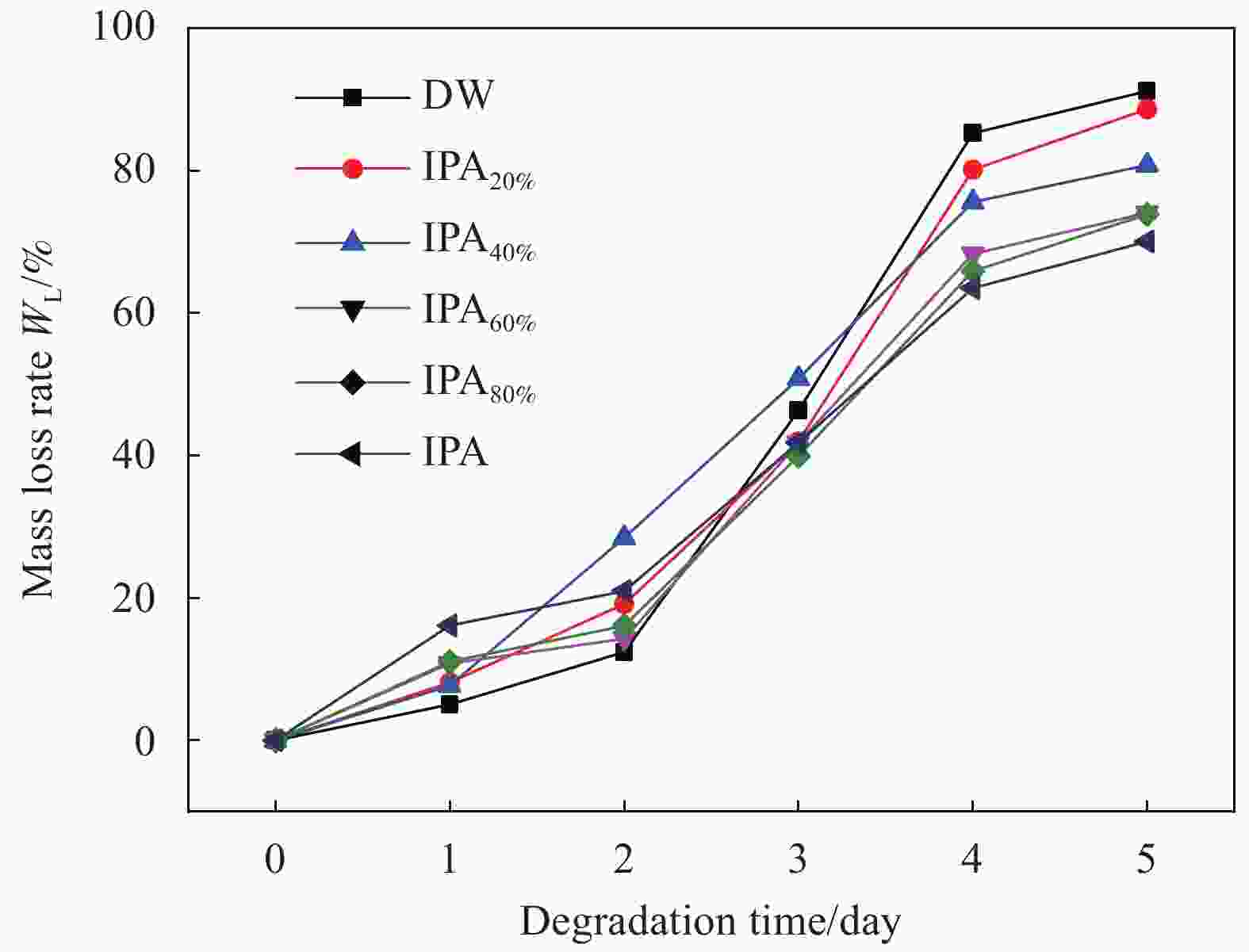

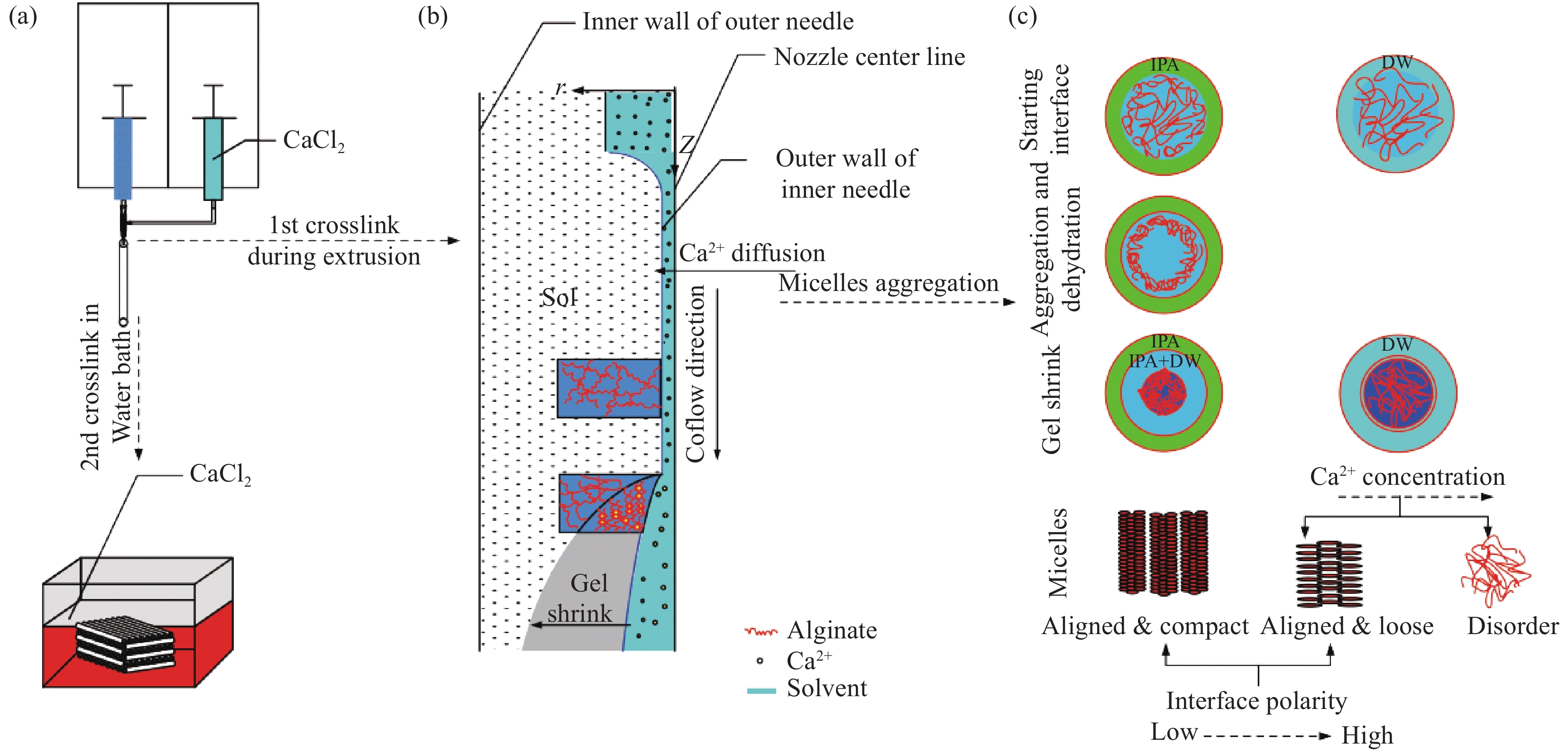

摘要: 生物支架的降解直接影响其结构、功能及所装载细胞的存活率。以海藻酸钠为原料,氯化钙为交联剂,制备海藻酸钙水凝胶生物支架;通过交联剂溶剂中异丙醇(IPA)与去离子水(DW)比例的变化,获得不同极性条件的同轴反应流界面,从而影响海藻酸钙凝胶的凝胶单元聚集形态,考察界面极性对其降解进程的调控能力。结果表明,随着交联剂中IPA比例的增加,溶剂极性指数由9.0渐变至3.9;随着界面极性的减弱,所制备纤维的微观凝胶单元,越呈现有序性;有序而密实的凝胶单元形态减缓海藻酸盐纤维的降解速率,第5天DW基纤维支架的质量损失率为91.16%,而IPA纤维支架为73.86%;凝胶单元越致密,溶胀度越低,而溶胀平衡对降解进程有迟滞作用。Abstract: The degradation of the bio-scaffold directly affects its structure, function and survival rate of the loaded cells. Sodium alginate as the raw material and calcium chloride as the cross-linking agent were used to prepare calcium alginate hydrogel bio-scaffold; by changing the ratio of iso-propyl alcohol (IPA) to deionized water (DW) in the crosslinking solvent, coaxial reaction flow interfaces with different polarity conditions were obtained, which affected the aggregation morphology of gel units of calcium alginate gel. The regulation ability of interface polarity on the degradation process of calcium alginate gel was investigated. The results show that the polarity index of the solvent changes from 9.0 to 3.9 with the increase of the proportion of IPA in the crosslinking agent; as the polarity of the interface decreases, the microscopic gel unit of the prepared fiber becomes more orderly; the degradation rate of alginate fibers is slowed down by the ordered and dense morphology of gel units; the mass-loss rate of DW-based fiber scaffold on the fifth day is 91.16% while that of IPA-based fiber scaffold is 73.86%; the denser the gel unit, the lower the swelling degree, and the swelling balance has a retarding effect on the degradation process.

-

Key words:

- sodium alginate /

- hydrogel /

- isopropanol (IPA) /

- polarity /

- micelle /

- degradation

-

图 1 中空纤维同轴交联直写原理图: (a)海藻酸钙支架制备;(b)交联原理过程图;(c)不同界面极性条件下海藻酸链聚集情况

Figure 1. Hollow fiber coaxial crosslinking directly written schematic diagram: (a) Preparation of Sodium alginate scaffolds; (b) Cross-linking schematic process; (c) Aggregation of sodium alginate molecular chains under various polarity conditions

IPA—Iso-propyl alcohol; DW—Deionized water

表 1 IPA与DW混合比例所制备的溶剂极性指数p与介电常数ε (25℃)

Table 1. Solvent polarity index p and dielectric constant ε with different mixing ratio of IPA and DW (25℃)

DW IPA20% IPA40% IPA60% IPA80% IPA p 9.00 7.80 7.29 6.89 6.37 3.90 ε 78.4 76.6 56.7 37.8 22.4 18.3 Notes: DW—Deionized water; IPA—Iso-propyl alcohol; IPAx%—x concentration of IPA. -

[1] BYROM D. Biomaterials: novel materials from biological sources[J]. Bioresource Technology,1991,43(1):309-331. [2] REES A. Polysaccharide shapes and their interactions-some recent advances[J]. Pure & Applied Chemistry,2009,53(1):1-14. [3] MELCHELS F, DOMINGOS M, KLEIN T J, et al. Additive manufacturing of tissues and organs[J]. Progress in Polymer Science,2012,37(8):1079-1104. doi: 10.1016/j.progpolymsci.2011.11.007 [4] HUANG Y, HUANG Z, LIU H, et al. Photoluminescent biodegradable polyorganophosphazene: A promising scaffold material for in vivo application to promote bone regeneration[J]. Bioactive Materials,2020,5(1):102-109. doi: 10.1016/j.bioactmat.2020.01.008 [5] ENTEKHABI E, NAZARPAK M H, SEDIGHI M, et al. Predicting degradation rate of genipin cross-linked gelatin scaffolds with machine learning[J]. Materials Science & Engineering C,2020,107:110362.1-110362.11. [6] CHEN H, XIE S, YANG Y, et al. Multiscale regeneration scaffold in vitro and in vivo[J]. Journal of Biomedical Materials Research Part B Applied Biomaterials,2017,106(3):1218-1225. [7] VALENTIN T M, LEGGETT S E, CHEN P Y, et al. Stereolithographic printing of ionically-crosslinked alginate hydrogels for degradable biomaterials and microfluidics[J]. Lab on a Chip,2017,17(20):3474-3488. doi: 10.1039/C7LC00694B [8] 贺美, 向廷生, 谢瑶, 等. 影响有机化学品快速生物降解性的分子结构参数研究进展[J]. 生态科学. 2015, 3(34): 1871-1878.HE Mei, XIANG Tingshneg, XIE Yao, et al. A review on molecular structural descriptors affecting ready biodegradation of organic chemicals [J]. 2015, 3(34): 1871-1878. (in Chinese). [9] TRIPATHI R, MISHRA B. Development and evaluation of sodium alginate–polyacrylamide graft–co-polymer-based stomach targeted hydrogels of famotidine[J]. Aaps Pharmscitech,2012,13(4):1091-1102. doi: 10.1208/s12249-012-9824-1 [10] WONG T W. Alginate graft copolymers and alginate–co-excipient physical mixture in oral drug delivery[J]. Journal of Pharmacy & Pharmacology,2011,63(12):1497-1512. [11] 许冠哲, 刘袖洞, 于炜婷, 等. 海藻酸钠疏水改性研究进展[J]. 材料导报, 2013(7):76-80. doi: 10.3969/j.issn.1005-023X.2013.07.017XU Guanzhe, LIU Xiudong, YU Weiting, et al. Research progress on hydrophobic modification of sodium alginate[J]. Materials Review,2013(7):76-80(in Chinese). doi: 10.3969/j.issn.1005-023X.2013.07.017 [12] BOUHADIR K H, MOONY D J. Promoting angiogenesis in engineered tissues[J]. Journal of Drug Targeting,2001,9(6):397-406. doi: 10.3109/10611860108998775 [13] MUN C H, HWANG J Y, LEE S H. Microfluidic spinning of the fibrous alginate scaffolds for modulation of the degradation profile[J]. Tissue Engineering & Regenerative Medicine,2016,13(2):140-148. [14] CHAE S K, KANG E, KHADE A, et al. Micro/Nanometer-scale fiber with highly ordered structures by mimicking the spinning process of silkworm[J]. Advanced Materials,2013,25(22):3071-3078. doi: 10.1002/adma.201300837 [15] AHN S Y, MUN C H, LEE S H. Microfluidic spinning of fibrous alginate carrier having highly enhanced drug loading capability and delayed release profile[J]. RSC Advances,2015,5(20):15172-15181. doi: 10.1039/C4RA11438H [16] ZHANG X L, CHEN H, YI Z, et al. Ampicillin-incorporated alginate-chitosan fibers from microfluidic spinning and for vitro release[J]. Journal of Biomaterials Science Polymer Edition,2017,28(13):1408-1425. [17] ANTONIOU E, ALEXANDRIDIS P. Polymer conformation in mixed aqueous-polar organic solvents[J]. European Polymer Journal,2010,46(2):324-335. doi: 10.1016/j.eurpolymj.2009.10.005 [18] ZHANG Y, YU Y, CHEN H, et al. Characterization of printable cellular micro-fluidic channels for tissue engineering[J]. Biofabrication,2013,5(2):25004. doi: 10.1088/1758-5082/5/2/025004 [19] GAO Q, HE Y, FU J. Coaxial nozzle-assisted 3D bioprinting with built-in microchannels for nutrients delivery[J]. Biomaterials,2015,61:203-215. doi: 10.1016/j.biomaterials.2015.05.031 [20] 李瑜, 刘媛媛, 李帅, 等. 交联直写海藻酸盐水凝胶中空纤维的凝胶率与溶胀度[J]. 化工学报, 2014, 65(12):5090-5096.LI Yu, LIU Yuanyuan, LI Shuai, et al. Gel fraction and swelling degree of hollow alginate fiber fabricatied by direct writing and crosslinking[J]. Ciesc Journal,2014,65(12):5090-5096(in Chinese). [21] 毛伟, 连芩, 李涤尘, 等. 立体空心血管网水凝胶支架的3D打印工艺研究[J]. 机械工程学报, 2017, 53(9):180-186. doi: 10.3901/JME.2017.09.180MAO Wei, LIAN Qin, LI Dichen, et al. 3D printing process for hydro gel with the three-dimensional micro tubes to mimic vascular network[J]. Journal of Mechanical Engineering,,2017,53(9):180-186(in Chinese). doi: 10.3901/JME.2017.09.180 [22] LI N N, XIE M E, SUO H, et al. Coaxial printed double crosslinked alginate/silk fibroin vascular network scaffold[J]. Chinese Journal of Tissue Engineering Research,2019,23(18):2865-2870. [23] WU Y G, TABATA M. Characterization of solvent polarity of aqueous mixed solvents by using solvatochromic indicators[J]. Analytical Sciences/Supplements,2007,17:a311-a312. [24] KATRITZKYA R, FARA D C, YANG H, et al. Quantitative measures of solvent polarity.[J]. Chemical Reviews,2004,104(1):175-198. doi: 10.1021/cr020750m [25] BARAI B K, SINGHALR S, KULKARNI P R. Optimization of a process for preparing carboxymethyl cellulose from water hyacinth (Eichornia crassipes)[J]. Carbohydrate Polymers,1997,32(3–4):229-231. [26] 华乃震. 水基性透明液体剂型的加工、性能和差异[J]. 世界农药, 2012, 34(2):5-8. doi: 10.3969/j.issn.1009-6485.2012.02.002HUA Naizhen. Processing properties and differences of water-basedtransparent liquid, formulations[J]. World Pesticides,2012,34(2):5-8(in Chinese). doi: 10.3969/j.issn.1009-6485.2012.02.002 [27] RINAUDO M. Non-covalent interactions in polysaccharide systems[J]. Macromolecular Bioscience,2006,6(8):590-610. doi: 10.1002/mabi.200600053 [28] 胡桂香, 骆成才, 殷开梁, 等. 溶剂效应对手性咪唑衍生物对映异构体与固定相相互作用的影响[J]. 高等学校化学学报, 2013(6):202-209.HU Guixiang, LUO Chengcai, YIN Kailiang, et al. Influence of solvent effect on interaction between chiral imidazole derivates enantiomer and stationary phase[J]. Chemical Journal of Chinese Universities,2013(6):202-209(in Chinese). [29] DENA S, KOFFLER J, LYNAM D A, et al. Characterizing the degradation of alginate hydrogel for use in multilumen scaffolds for spinal cord repair[J]. Journal of Biomedical Materials Research Part A,2016,104(3):611-619. doi: 10.1002/jbm.a.35600 [30] 何淑兰, 尹玉姬, 张敏, 等. 组织工程用海藻酸盐水凝胶的研究进展[J]. 化工进展, 2004(11):24-28.HE Shulan, YIN Yuji, ZHANG Min, et al. Research progress of alginate brine gel for tissue engineeing[J]. Chemical Industry and Engneering Progress,2004(11):24-28(in Chinese). [31] SAHOTA P S, BUM J L, HEATON M, et al. Development of a reconstructed human skin model for angiogenesis[J]. Wound Repair and Regeneration,2010,11(4):275-284. [32] SHANDALOV Y, EGOIZ D, FREIMAN A, et al. A method for constructing vascularized muscle flap[J]. Methods,2015,84:70-75. doi: 10.1016/j.ymeth.2015.03.021 -

下载:

下载: