Load-bearing capability of TG800 carbon fiber/polyimide resin composite cylindrical casing with flange and window under high-temperature aerodynamic load

-

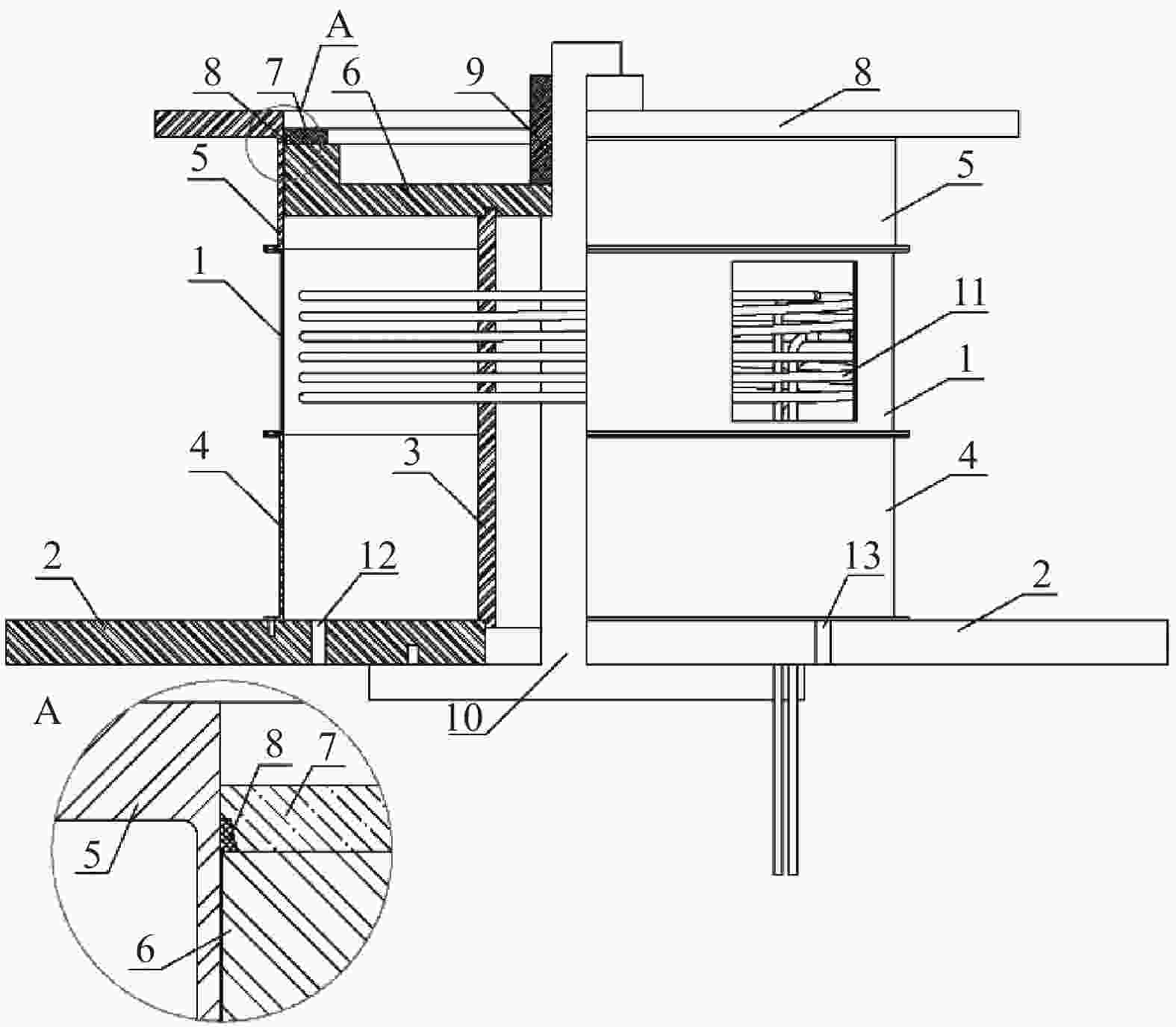

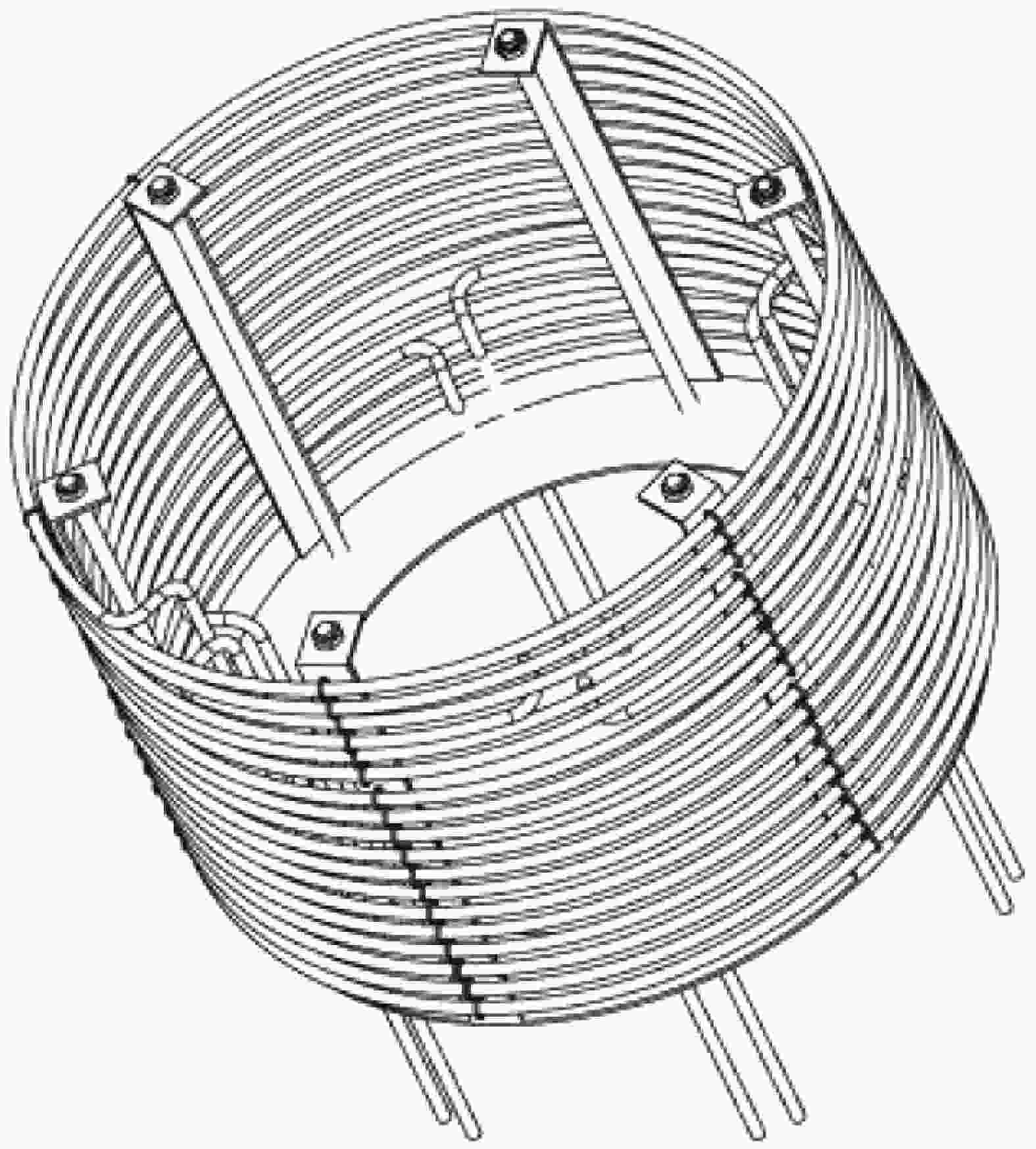

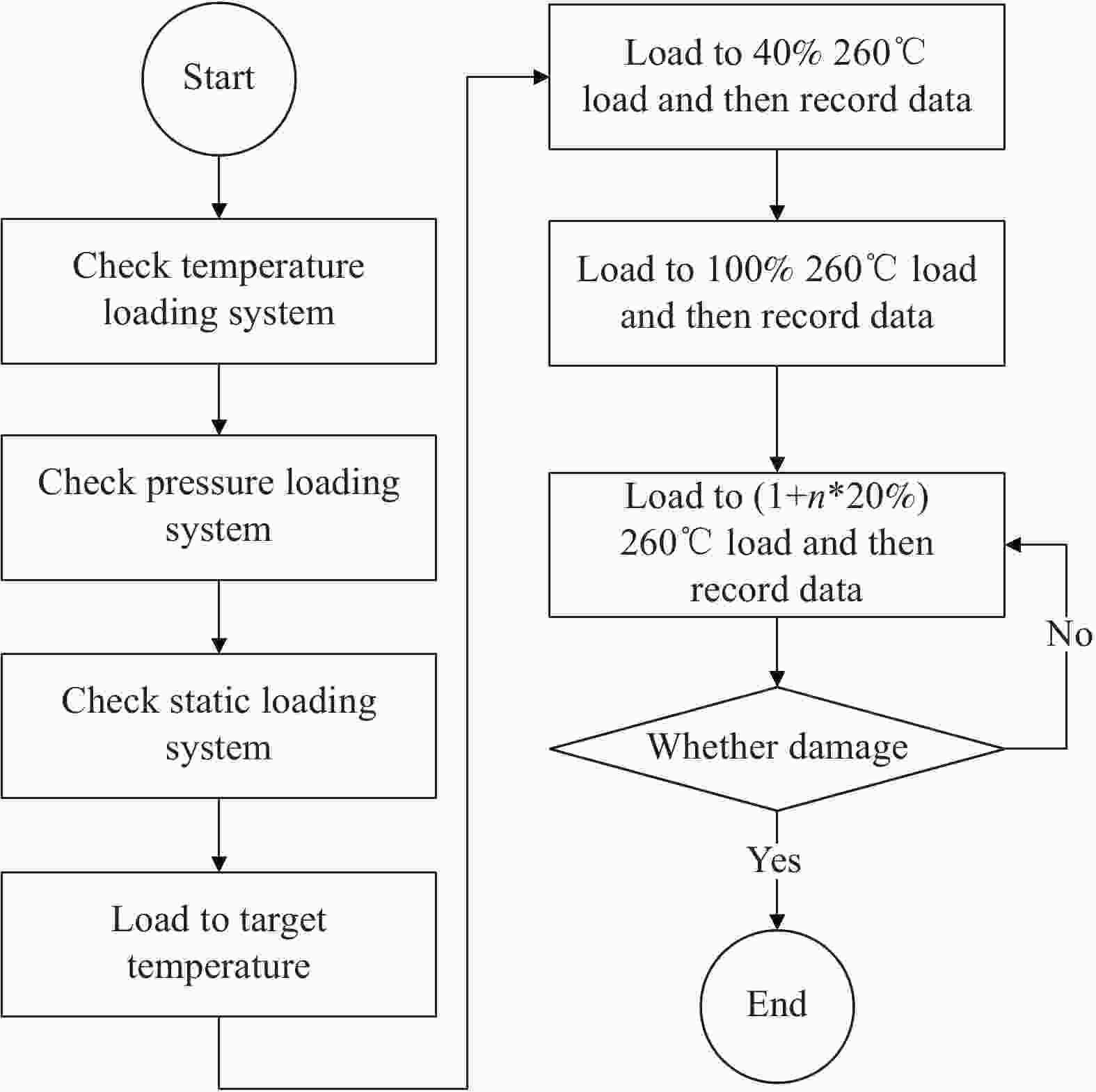

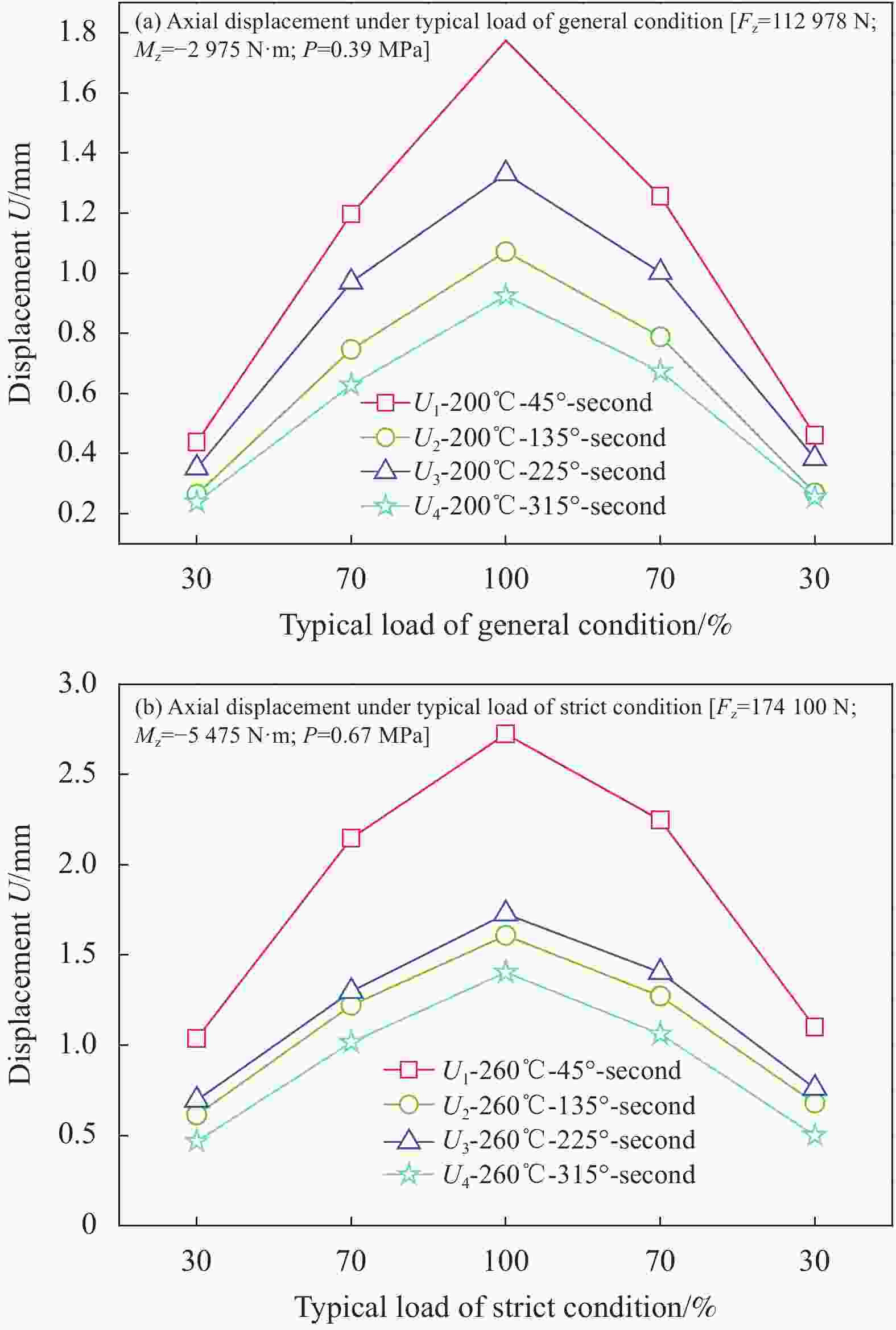

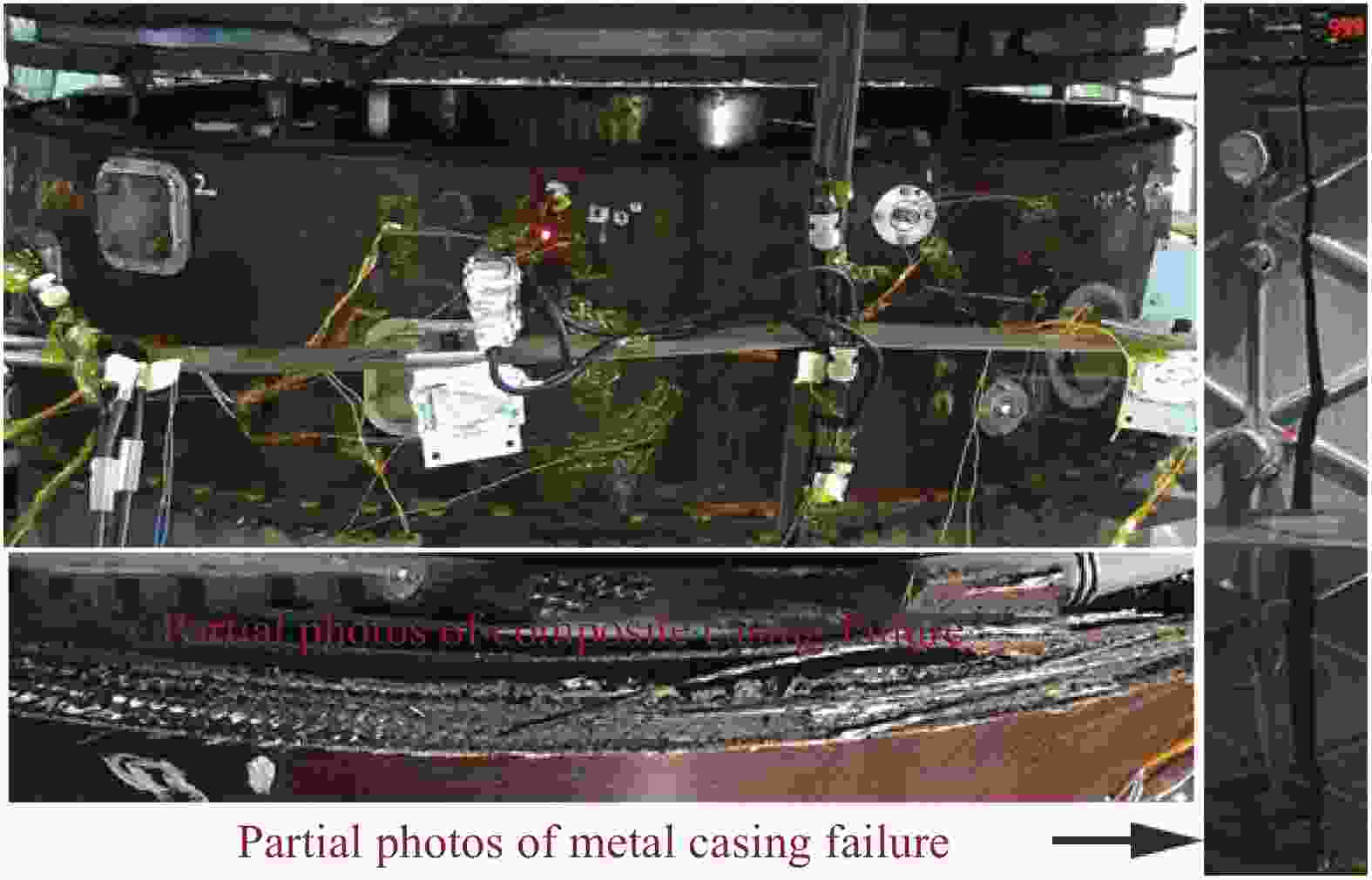

摘要: 基于航空发动机的高温气动载荷环境,对树脂传递模塑(RTM)工艺制备的TG800碳纤维/聚酰亚胺树脂复合材料带安装翻边和壳壁开口的圆柱壳机匣件开展了常温、200℃和260℃高温气动载荷下的仿真分析和承载性能试验。仿真计算得到复合材料机匣件的高应力水平发生在安装翻边和开口处。试验利用所设计的专用试验装置与机匣试验件合围成一套能够解耦内压和轴力的被试腔体结构,通过对被试腔体施加高温气体压力和机械静载联合模拟热气流载荷,相比传统的冲压胶囊加压方式,可以对机匣的翻边和开口处进行充分热压考核。常温、200℃和260℃承载试验后对机匣开口进行了无损检测,得到开口处的分层损伤区域随着载荷增大朝着正方和正圆的趋势扩大,260℃破坏试验得到TG800碳纤维/聚酰亚胺树脂复合材料机匣件的失效模式与传统金属机匣的筒体破裂不同,失效方式为安装翻边断裂。研究表明,RTM工艺TG800碳纤维/聚酰亚胺树脂复合材料结构件的力学性能在200℃以内具备良好的温度稳定性,安装翻边为复合材料机匣件在航空发动机热气流载荷下的薄弱区域,应作为机匣件减重设计的重要优化部位。Abstract: Based on the high-temperature aerodynamic load environment of aero-engines, the high temperature resistant TG800 carbon fiber/polyimide resin composite cylindrical casing test piece, which with flanges for installation and window openings on the casing wall, prepared by the resin transfer molding (RTM) process was carried out simulation analysis and load-bearing performance test under room temperature, 200℃ and 260℃ high-temperature aerodynamic load. The simulation results show that the high stress level of the composite casing occurs at the installation flange and the window of the shell wall. In the load-bearing test, the designed special test device and the composite casing test piece are combined to form a test chamber structure that can decouple the internal pressure and the axial force during loading. By applying high-temperature gas pressure and mechanical static load to the designed special test cavity to simulate the high-temperature aerodynamic load of the aero-engine, compared with the traditional pressurization method of stamping capsule, it can achieve more realistic assessment of the casing flange and window. The non-destructive testing on the window of the casing after the load-bearing test at room temperature, 200℃ and 260℃ shows that the delamination damage area at the window expands towards a larger square and circular shape as the load increases. The failure mode of the TG800 carbon fiber/polyimide resin composite casing obtained by the 260℃ destruction test is installation flanging fracture, which is different from the failure mode of the traditional metal casing cylinder rupture. The results indicate that the mechanical properties of TG800 carbon fiber/polyimide resin composite structural components prepared by RTM process have good temperature stability within 200℃. The installation flanging is the weak area of the composite casing under the high temperature aerodynamic load of the aero engine, which is an important optimization part for the weight reduction design of the casing.

-

表 1 TG800碳纤维/聚酰亚胺树脂复合材料单层板性能参数

Table 1. Performance parameters of TG800 carbon fiber/polyimide resin composite single-layer board

Sample Ambient 260℃ Density/(g·cm−3) 1.50 1.50 Poisson’s ratio ν12 0.317 0.317 0° Tension strength/MPa 2213 1821 0° Tension modulus/GPa 155 155 0° Compression strength/MPa 1431 665 0° Compression modulus/GPa 144 — 90° Tension strength/MPa 39 22.5 90° Tension modulus/GPa 7.6 4 90° Compression strength/MPa 220 96.4 90° Compression modulus/GPa 8.73 — 0° Bending strength/MPa 1881 1027 0° Bending modulus/GPa 147 149 Interlayer shear strength/MPa 106 51.3 In-plan shear strength/MPa 71 34 In-plan shear modulus/GPa 4.1 2.6 表 2 TG800碳纤维/聚酰亚胺树脂复合材料机匣试验件载荷条件

Table 2. Load condition of TG800 carbon fiber/polyimide resin composite casing test piece

Sample Temperature T/℃ Internal pressure P/MPa Mechanical load Axial load Fz/N Torque load Mz/(N·m) Load-bearing condition Ambient 0.39 112978 −2975 200 0.39 112978 −2975 260 0.67 174100 −5475 Damage condition 260 0.67~ 174100~ −5475~ Notes: The load-bearing condition is that aero-engine may occur during the flight; Damage condition is the damage test load of the aero-engine. -

[1] 沈真. 复合材料设计手册[M]. 北京: 航空工业出版社, 2001.SHEN Zhen. Composite material design manual[M]. Beijing: Aviation Industry Press, 2001(in Chinese). [2] 李映红, 赵智姝, 韩勐. 复合材料在飞机结构上的广泛应用[J]. 装备制造技术, 2011(4):138-140. doi: 10.3969/j.issn.1672-545X.2011.04.047LI Yinghong, ZHAO Zhishu, HAN Meng. The wide application of composite material in the aircraft structure[J]. Equipment Manufacturing Technology,2011(4):138-140(in Chinese). doi: 10.3969/j.issn.1672-545X.2011.04.047 [3] 梁春华. 复合材料在航空发动机上的应用[J]. 国际航空, 2005(2):60-62.LIANG Chunhua. Application of composite materials in aero-engine[J]. International Aviation,2005(2):60-62(in Chinese). [4] JULIA K. Composites for aeroengines[M]. London: Materials World, 1997. [5] 吕春光, 邱明星, 田静, 等. 航空发动机外涵机匣结构建模方法研究[J]. 航空发动机, 2012, 38(1):29-32. doi: 10.3969/j.issn.1672-3147.2012.01.010LV Chunguang, QIU Mingxing, TIAN Jing, et al. Study of modeling method for aeroengine bypass duct[J]. Aeroengine,2012,38(1):29-32(in Chinese). doi: 10.3969/j.issn.1672-3147.2012.01.010 [6] 沈尔明, 王志宏, 滕佰秋, 等. 先进树脂基复合材料在大涵道比发动机上的应用[J]. 航空制造技术, 2011(17):56-61. doi: 10.3969/j.issn.1671-833X.2011.17.009SHEN Erming, WANG Zhihong, TENG Baiqiu, et al. Advanced polymer matrix composites for high bypass ratio engines application[J]. Aeronautical Manufacturing Technology,2011(17):56-61(in Chinese). doi: 10.3969/j.issn.1671-833X.2011.17.009 [7] 赵凯, 刘鹏飞, 刘波浪, 等. 树脂基复合材料外涵道机匣的研制与应用[J]. 复合材料科学与工程, 2020(4):112-116. doi: 10.3969/j.issn.1003-0999.2020.04.018ZHAO Kai, LIU Pengfei, LIU Bolang, et al. Development and application of by-pass duct casingmade of resin matrix composite[J]. Composites Science and Engineering,2020(4):112-116(in Chinese). doi: 10.3969/j.issn.1003-0999.2020.04.018 [8] 刘振宾, 时卓, 左继成, 等. RTM工艺制备碳纤维复合材料的力学性能[J]. 沈阳理工大学学报, 2020, 39(3):16-19. doi: 10.3969/j.issn.1003-1251.2020.03.004LIU Zhenbin, SHI Zhuo, ZUO Jicheng, et al. Mechanical properties of carbon fiber composite prepared by RTM[J]. Journal of Shenyang Ligong University,2020,39(3):16-19(in Chinese). doi: 10.3969/j.issn.1003-1251.2020.03.004 [9] 李伟东, 张金栋, 刘刚, 等. 国产T800碳纤维/双马来酰亚胺复合材料的界面及力学性能[J]. 复合材料学报, 2016, 33(7):1484-1491.LI Weidong, ZHANG Jindong, LIU Gang, et al. Interfacial and mechanical properties of domestic T800 carbon fiber/bismaleimide composites[J]. Acta Materiae Compositae Sinica,2016,33(7):1484-1491(in Chinese). [10] UNTERWEGER C, DUCHOSLAV J, STIFTER D, et al. Characterization of carbon fiber surfaces and their impact on the mechanical properties of short carbon fiber reinforced polypropylene composites[J]. Composites Science & Technology,2015,108:41-47. [11] 赵文斌, 王静, 尹术帮. 固体火箭发动机壳体复合裙RTM成型技术[J]. 宇航材料工艺, 2020, 50(1):49-52. doi: 10.12044/j.issn.1007-2330.2020.01.007ZHAO Wenbing, WANG Jing, YING Shubang. RTM forming technology for composite skirts of solid rocket motor case[J]. Aerospace Materials & Technology,2020,50(1):49-52(in Chinese). doi: 10.12044/j.issn.1007-2330.2020.01.007 [12] 李晔, 张连旺, 张尧州 等. 厚度对RTM成型国产T800碳纤维增强复合材料力学性能的影响[J]. 高科技纤维与应用, 2020, 45(4):27-32. doi: 10.3969/j.issn.1007-9815.2020.04.005LI Ye, ZHANG Lianwang, ZHANG Yaozhou, et al. Effects of thickness on mechanical properties of domestic T800 carbon fiber composites by RTM[J]. Hi-Tech Fiber and Application,2020,45(4):27-32(in Chinese). doi: 10.3969/j.issn.1007-9815.2020.04.005 [13] 汪厚冰, 李新祥, 魏景超 等. 复合材料曲面帽形加筋壁板在内压-轴压联合载荷下的屈曲及承载性能[J]. 航空制造技术, 2020, 63(18):55-64, 81.WANG Houbing, LI Xinxiang, WEI Jingchao, et al. Buckling and post-buckling of curved hat-stiffened composite panels under combined internal pressure and axial compression[J]. Aeronautical Manufacturing Technology,2020,63(18):55-64, 81(in Chinese). [14] 齐红宇, 温卫东, 齐红元, 等. 航空发动机复合材料机匣屈曲特性的有限元分析[J]. 航空动力学报, 2001, 16(4):335-339. doi: 10.3969/j.issn.1000-8055.2001.04.008QI Hongyu, WEN Weidong, QI Hongyuan, et al. FEA method for the critical buckling load of aeroengine composite case[J]. Journal of Aerospace Power,2001,16(4):335-339(in Chinese). doi: 10.3969/j.issn.1000-8055.2001.04.008 [15] 李传习, 罗南海, 柯璐, 等. 胶膜连接碳纤维增强树脂复合材料板-钢搭接接头室温条件的力学性能试验[J]. 复合材料学报, 2020, 37(2):318-327.LI Chuanxi, LUO Nanhai, KE Lu, et al. Experimental study on the carbon fiber reinforced plomyer composite laminate-steel lap joints connected with a film adhesive at room temperature[J]. Acta Materiae Compositae Sinica,2020,37(2):318-327(in Chinese). [16] 解江, 宋山山, 牟浩蕾, 等. 典型螺栓连接CFRP薄壁C型柱轴压失效行为: 试验及数值模拟[J]. 复合材料学报, 2021, 38:DOI: 10.13801/j.cnki.fhclxb.20201215.001.XIE Jiang, SONG Shanshan, MOU Haolei, et al. Axial compression failure behavior of typical bolted CFRP thin-walled C-channels: Experimental and numerical simulation[J]. Acta Materiae Compositae Sinica,2021,38:DOI: 10.13801/j.cnki.fhclxb.20201215.001(in Chinese). [17] 熊美蓉, 陈琳, 刘传军. 复合材料开口有限元建模方法研究[J]. 高科技纤维与应用, 2020, 45(3):56-62. doi: 10.3969/j.issn.1007-9815.2020.03.010XIONG Meirong, CHEN Lin, LIU Chuanjun. Research on finite element modeling of composite cutout[J]. Hi-Tech Fiber and Application,2020,45(3):56-62(in Chinese). doi: 10.3969/j.issn.1007-9815.2020.03.010 [18] 熊美蓉, 陈琳, 张达, 等. 双轴载荷下复合材料开口强度分析与试验方法研究[J]. 高科技纤维与应用, 2020, 45(5):38-44. doi: 10.3969/j.issn.1007-9815.2020.05.007XIONG Meirong, CHEN Lin, ZHANG Da, et al. Stress analysis and test verification of composite laminate with a hole under biaxial loading[J]. Hi-Tech Fiber and Application,2020,45(5):38-44(in Chinese). doi: 10.3969/j.issn.1007-9815.2020.05.007 [19] 张伟, 甘健, 王志瑾. 多工况下复合材料层合板开口补强优化设计[J]. 航空工程进展, 2013, 4(2):193-198. doi: 10.3969/j.issn.1674-8190.2013.02.010ZHANG Wei, GAN Jian, WANG Zhijin. Optimization of reinforcing structure for composite laminates with cutout subject to different load cases[J]. Advances in Aeronautical Science and Engineering,2013,4(2):193-198(in Chinese). doi: 10.3969/j.issn.1674-8190.2013.02.010 [20] 周华志, 王志瑾. 复合材料层合板开口补强技术试验和仿真研究[J]. 航空工程进展, 2019, 10(4):550-561.ZHOU Huazhi, WANG Zhijin. Experimental and simulation study on opening reinforcement techniques of composite laminates[J]. Advances in Aeronautical Science and Engineering,2019,10(4):550-561(in Chinese). [21] 张瑜, 程博, 张让威, 等. 复合材料机匣整体翻边拼接结构设计与试验验证[J]. 纤维复合材料, 2019, 36(2):34-38, 48.ZHANG Yu, CHENG Bo, ZHANG Rangwei, et al. Structure design and experimental verification of integral flanged composite casing[J]. Fiber Composites,2019,36(2):34-38, 48(in Chinese). [22] SERAFINI T T, DELVIGS P, LIGHTSEY G R. Thermally stable polymides from solutions of monomeric reactants[J]. Journal of Applied Polymer Science,1972,16(4):905-915. doi: 10.1002/app.1972.070160409 [23] MICHAEL A M, MARRY B, MADOR. PMR polyimides with enhanced for high temperature application[C]//46th International SAMPE Symposium and Exhibition. California: SAMPE, 2001: 497-509. [24] 张朋, 周立正, 包建文, 等. 耐350℃ RTM聚酰亚胺树脂及其复合材料性能[J]. 复合材料学报, 2014, 31(2):345-352.ZHANG Peng, ZHOU Lizheng, BAO Jianwen, et al. Properties of 350℃ temperature-resistant RTM polyimide matrix resin and its composites[J]. Acta Materiae Compositae Sinica,2014,31(2):345-352(in Chinese). [25] 金东升, 张庆茂, 张朋, 等. RTM在耐高温复材结构中的应用问题与对策[C]//中国复合材料学会第二十一届全国复合材料学术会议(NCCM-21)论文集. 中国航空学会, 2020: 359-364.JIN Dongsheng, ZHANG Qingmao, ZHANG Peng, et al. Application problems and countermeasures of RTM in high temperature resistant composite structure[C]//NCCM-21. Chinese Society of Aeronautic and Astronautics, 2020: 359-364(in Chinese). [26] 陈卓异, 彭彦泽, 李传习, 等. 高温下双搭接钢-CFRP板胶黏界面力学性能试验[J]. 复合材料学报, 2021, 38(2):449-460.CHEN Zhuoyi, PENG Yanze, LI Chuanxi, et al. Experimental study for the adhesive interface mechanical properties of double lapped steel-CFRP plate at high temperature[J]. Acta Materiae Compositae Sinica,2021,38(2):449-460(in Chinese). [27] 高艺航, 王世勋, 石玉红, 等. MT300/KH420碳纤维增强聚酰亚胺树脂复合材料层合圆柱壳高温承载性能[J]. 复合材料学报, 2021, 38(7):2172-2183.GAO Yihang, WANG Shixun, SHI Yuhong, et al. Load-bearing capability of laminated MT300/KH420 carbon fiber reinforced polyimide resin composite cylindrical shell at high temperatures[J]. Acta Materiae Compositae Sinica,2021,38(7):2172-2183(in Chinese). -

下载:

下载: