Effect of compound field on microstructure and properties of SiCp/AZ91D magnesium matrix composites

-

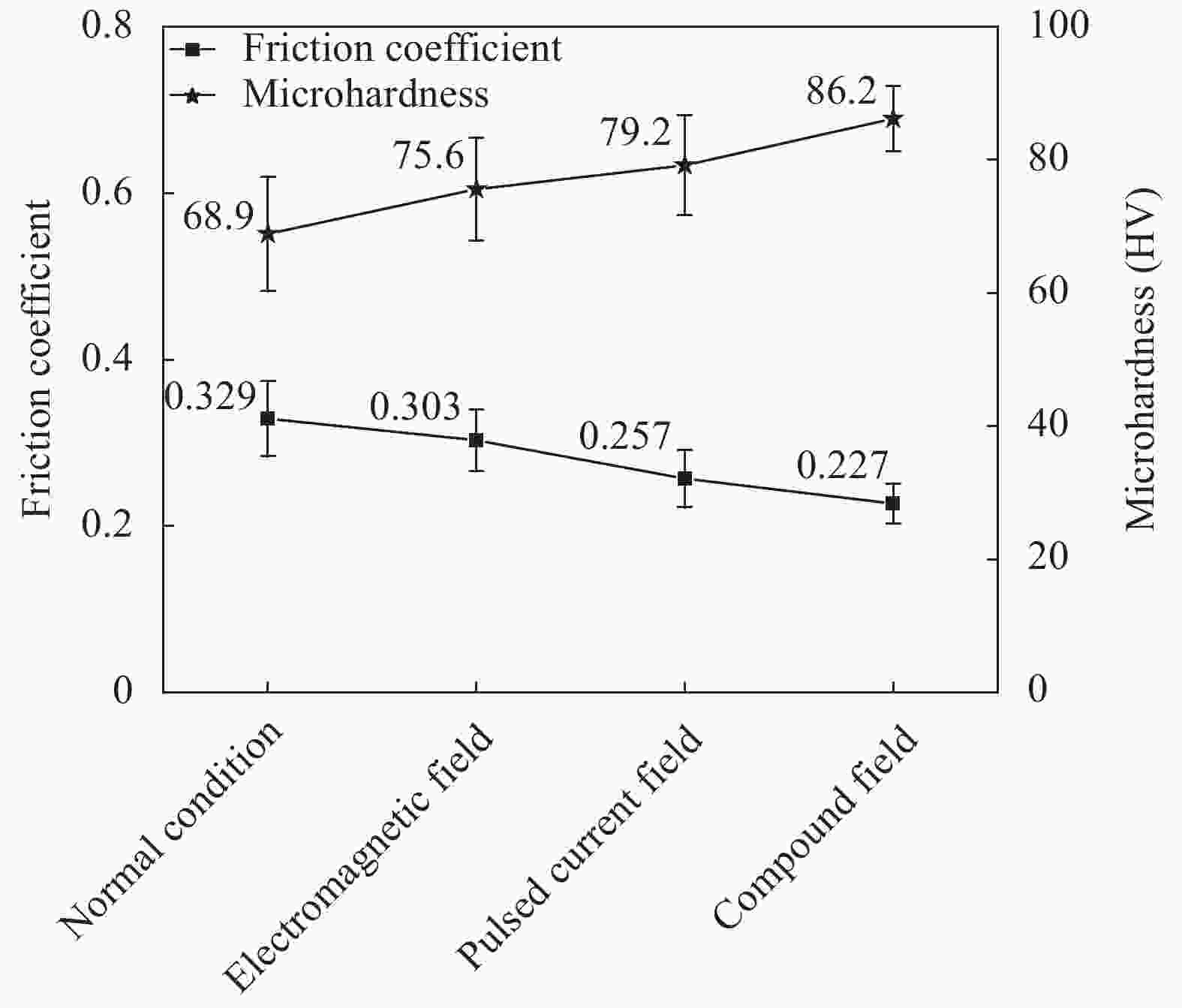

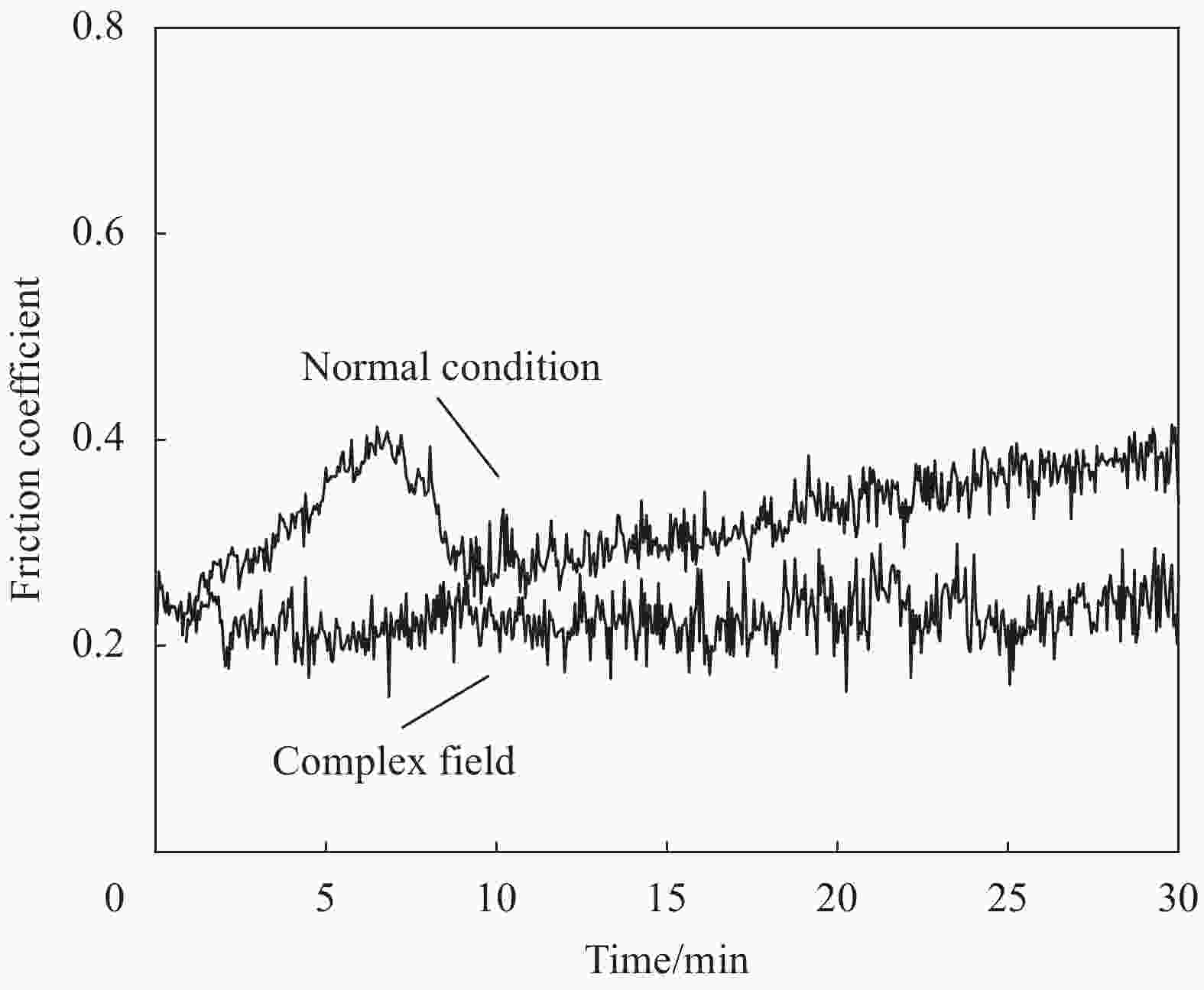

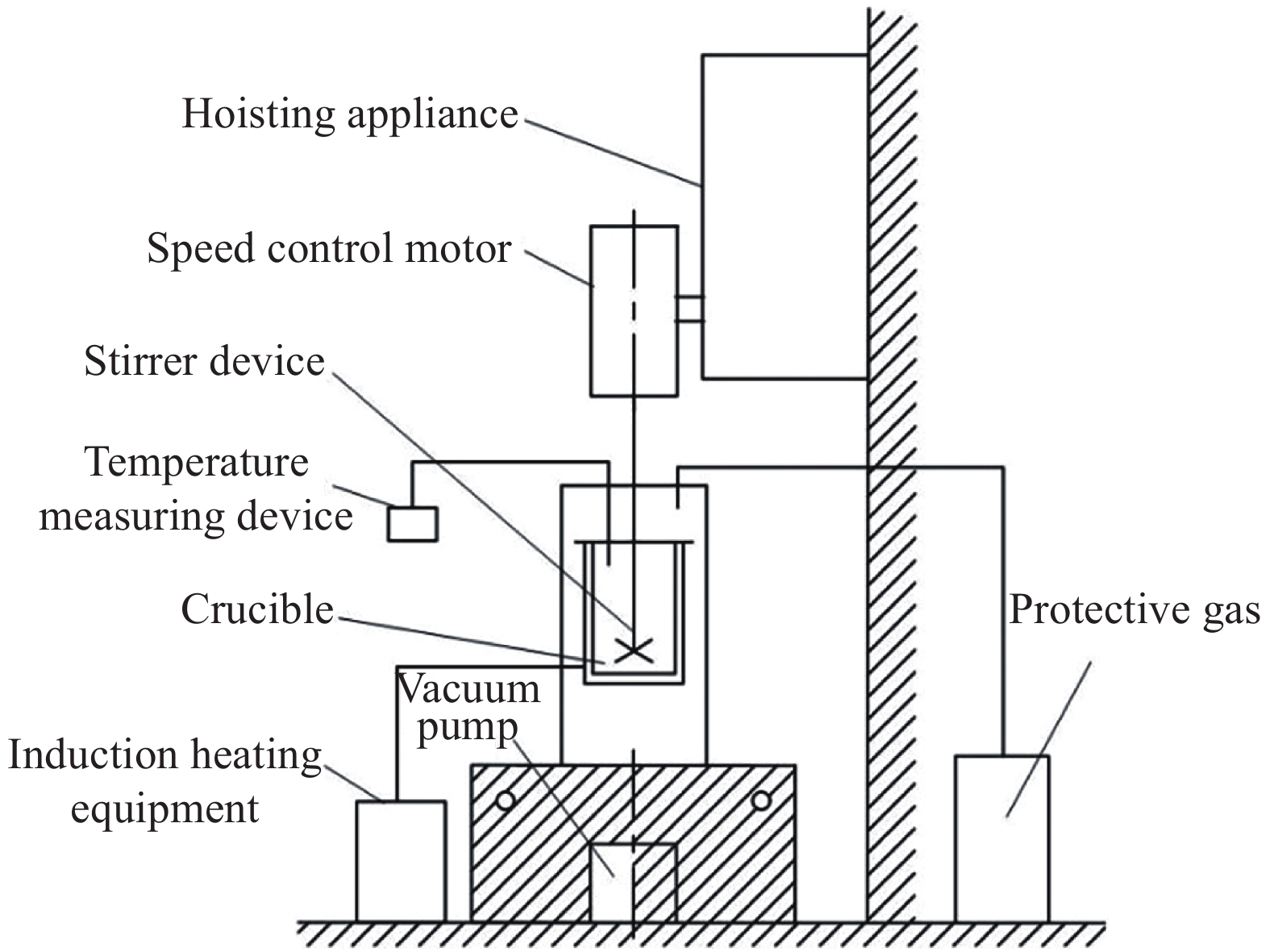

摘要: 在常规条件、电磁模拟微重力场、脉冲电流场和“电磁模拟微重力+脉冲电流”复合场四种外场条件下制备出SiCp含量5wt%的SiCp/AZ91D镁基复合材料,分析测试结果表明:在常规条件下,样品晶粒粗大,β-Mg17Al12相呈现出无规律的网格状结构,新生相Mg2Si以颗粒状的初生相和树枝状的共晶相存在;在电磁模拟微重力场条件下,β-Mg17Al12相细化为零散分布的短棒状和颗粒状,Mg2Si全部转化为花纹状的共晶相;在脉冲电流场条件下,β-Mg17Al12相呈现出规律分布的矩形网格状,Mg2Si以方向性明显的树枝状共晶相存在;“电磁模拟微重力+脉冲电流”复合场则兼具前述两种外场的优点,样品中的晶粒明显细化,β-Mg17Al12相呈现为颗粒状、短棒状和矩形网格状,Mg2Si转变为花纹状和树枝状的共晶组织贯穿组织晶粒,相比常规条件下的样品,其显微硬度提高了25.1%,摩擦性能提高了31%。

-

关键词:

- 镁基复合材料 /

- SiCp/AZ91D /

- 微重力 /

- 脉冲电流 /

- 显微组织

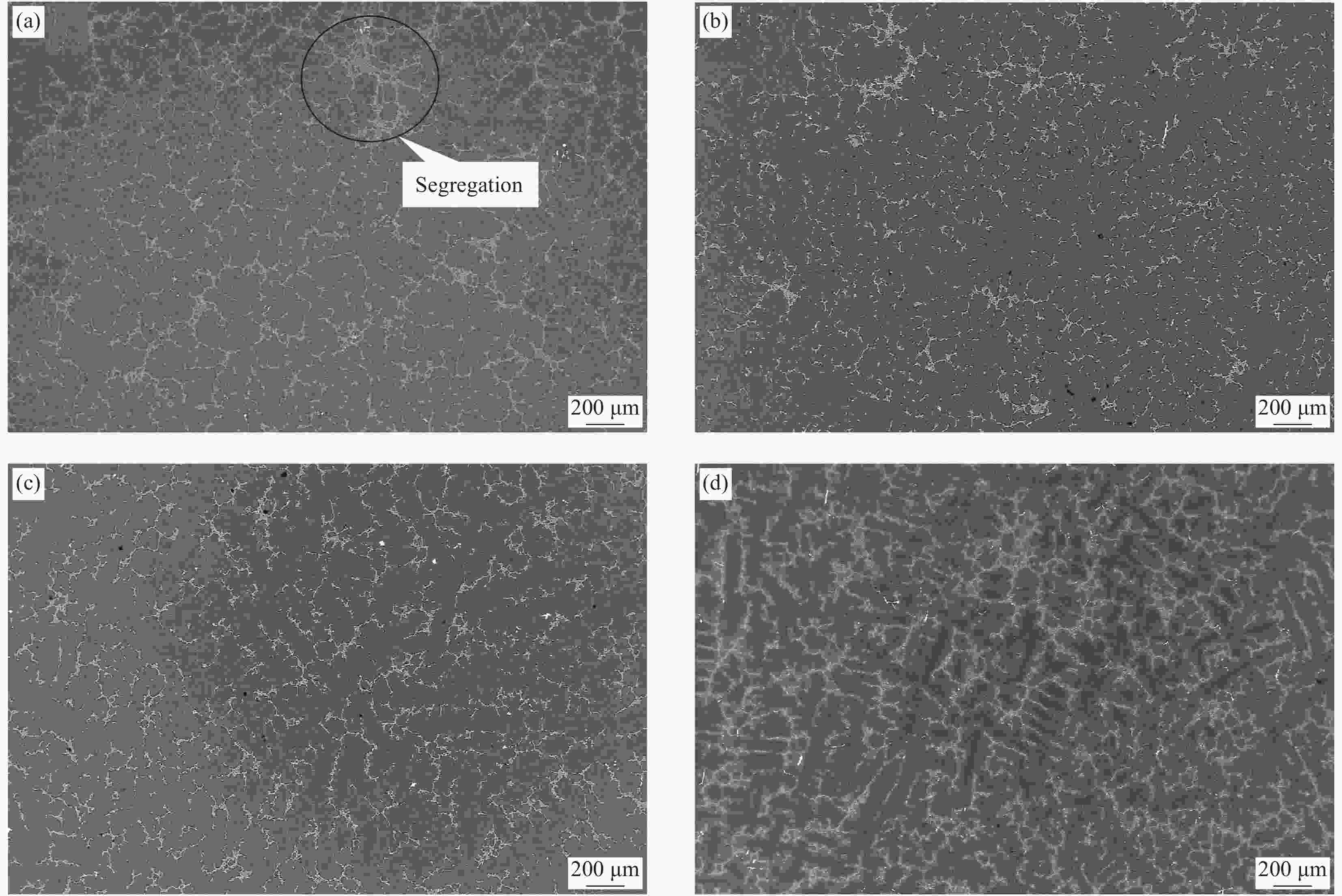

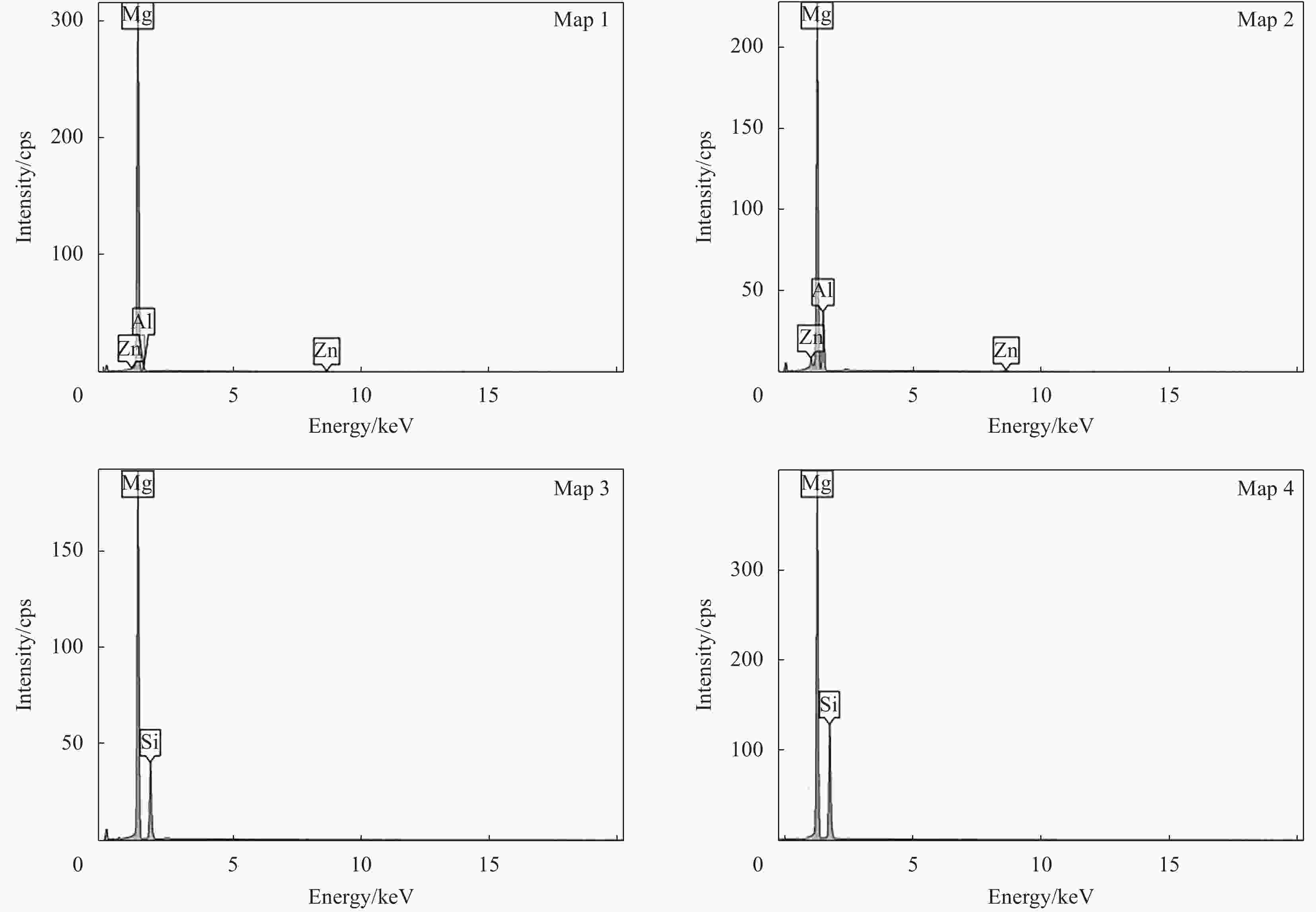

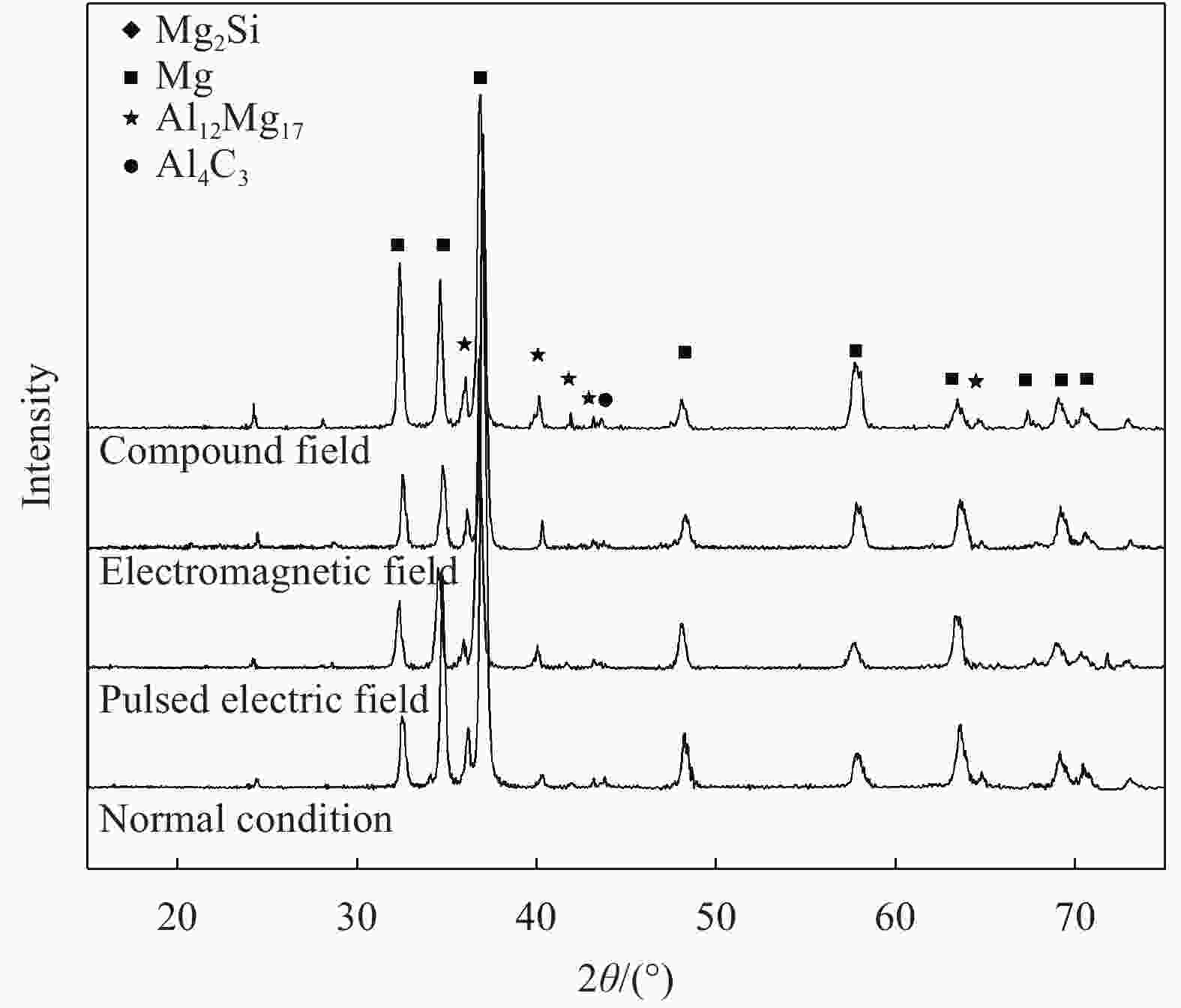

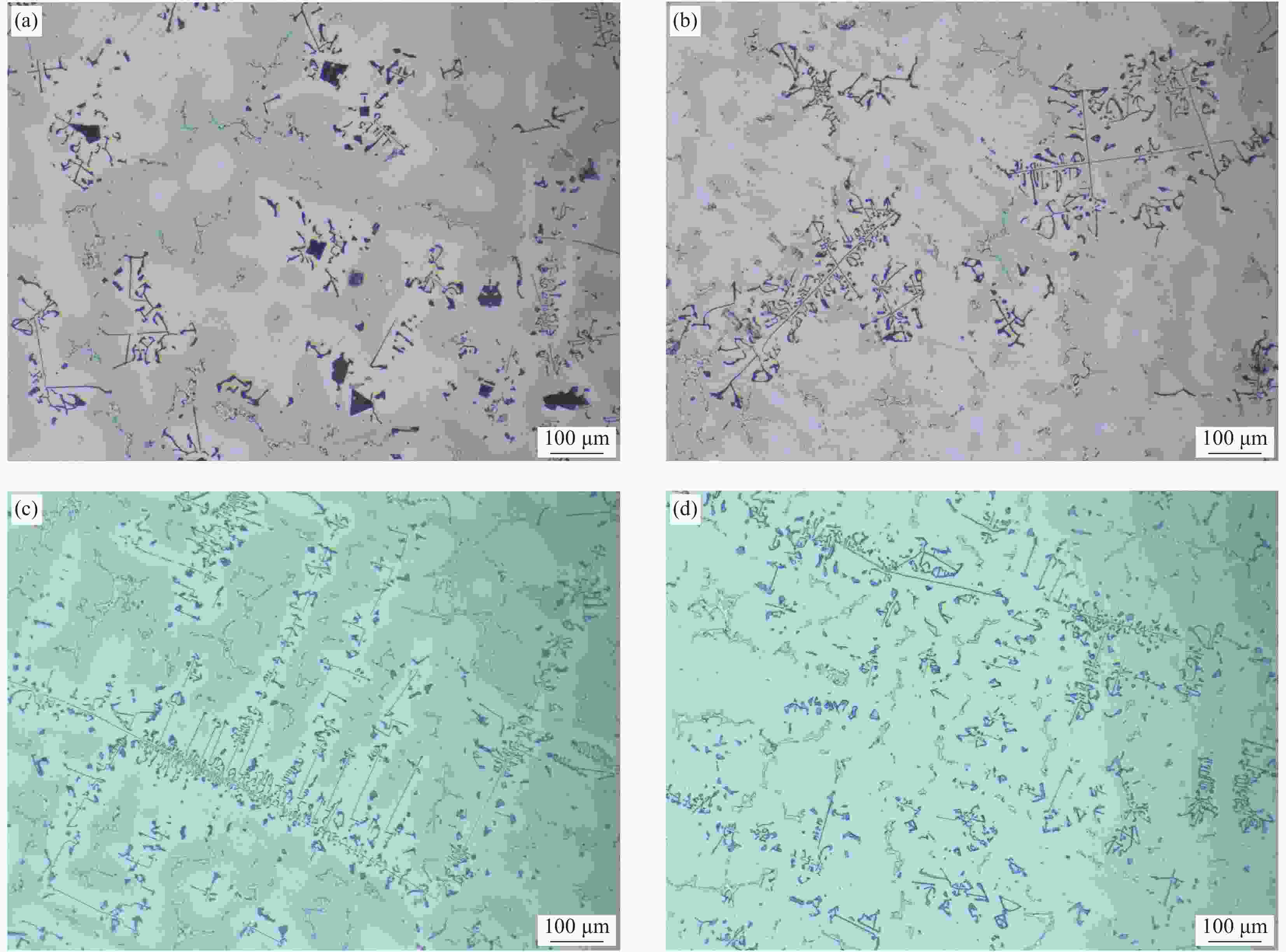

Abstract: SiCp/AZ91D magnesium matrix composites were prepared under four kinds of external field conditions: normal condition, electromagnetic simulated microgravity field condition, pulse current field condition and "electromagnetic simulated microgravity + pulse current" condition. The test results indicate that: In the normal condition, the grain size of the sample is coarse, the β-Mg17Al12 phase shows an irregular grid structure, and Mg2Si exists in the granular primary phase and dendritic eutectic phase. In the electromagnetic simulation microgravity field condition, the β-Mg17Al12 phase transforms into short rods and granules, and Mg2Si is transformed into patterned eutectic phase. In the pulse current field condition, the β-Mg17Al12 phase transforms into regular distribution of rectangular grid, and Mg2Si exists in dendritic eutectic phase with obvious directivity. The "electromagnetic simulated microgravity + pulse current" condition combines the advantages of the first two kinds of external field conditions, the grain size of the sample is obviously refined, the β-Mg17Al12 phase presents granular, short rod and rectangular grid structures and the Mg2Si is transformed into the pattern and dendritic eutectic structure throughout the grain. Compared with the sample under normal condition, the microhardness is improved by 25.1% and the friction property is improved by 31%.-

Key words:

- magnesium matrix composites /

- SiCp/AZ91D /

- microgravity /

- pulse current /

- microstructure

-

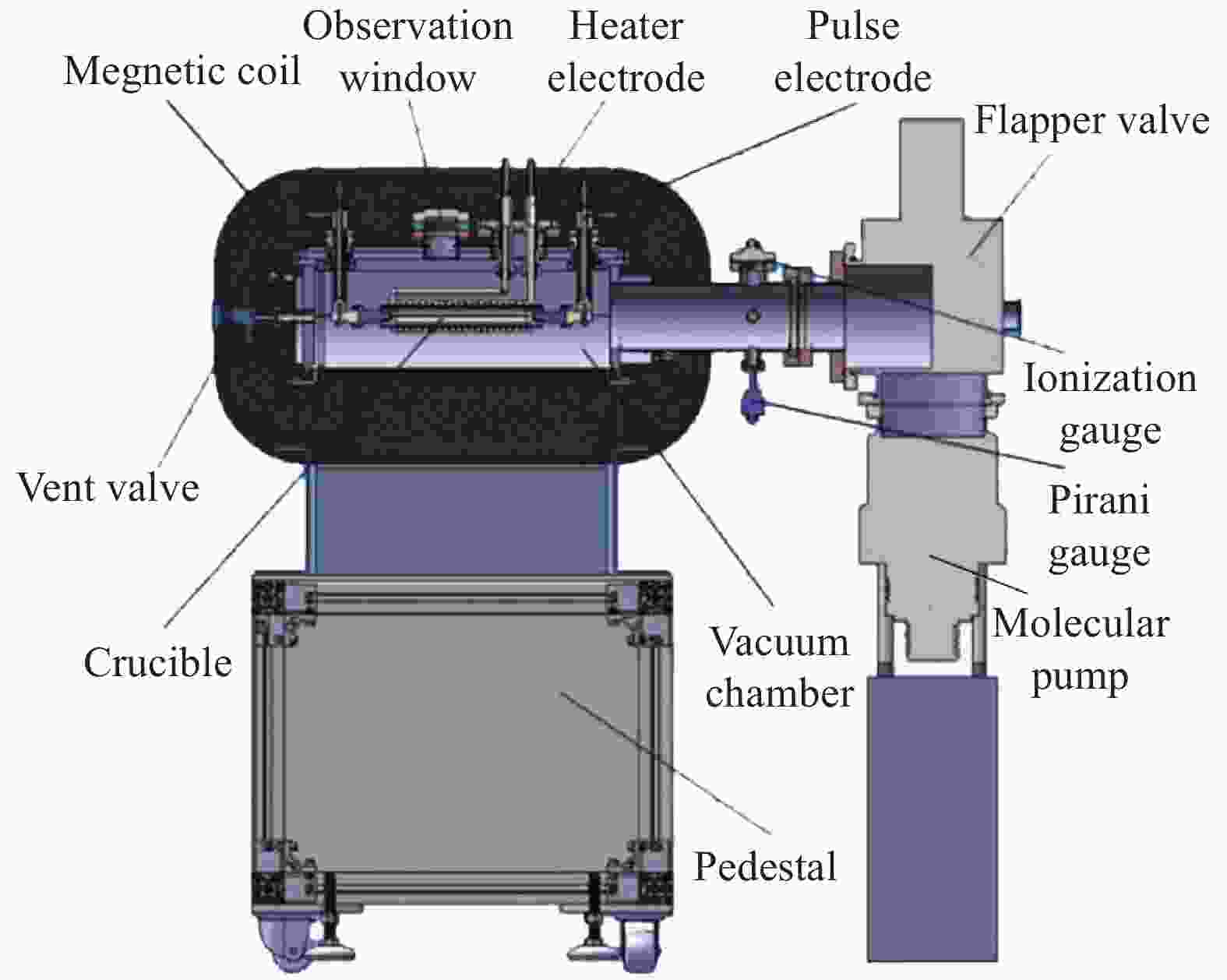

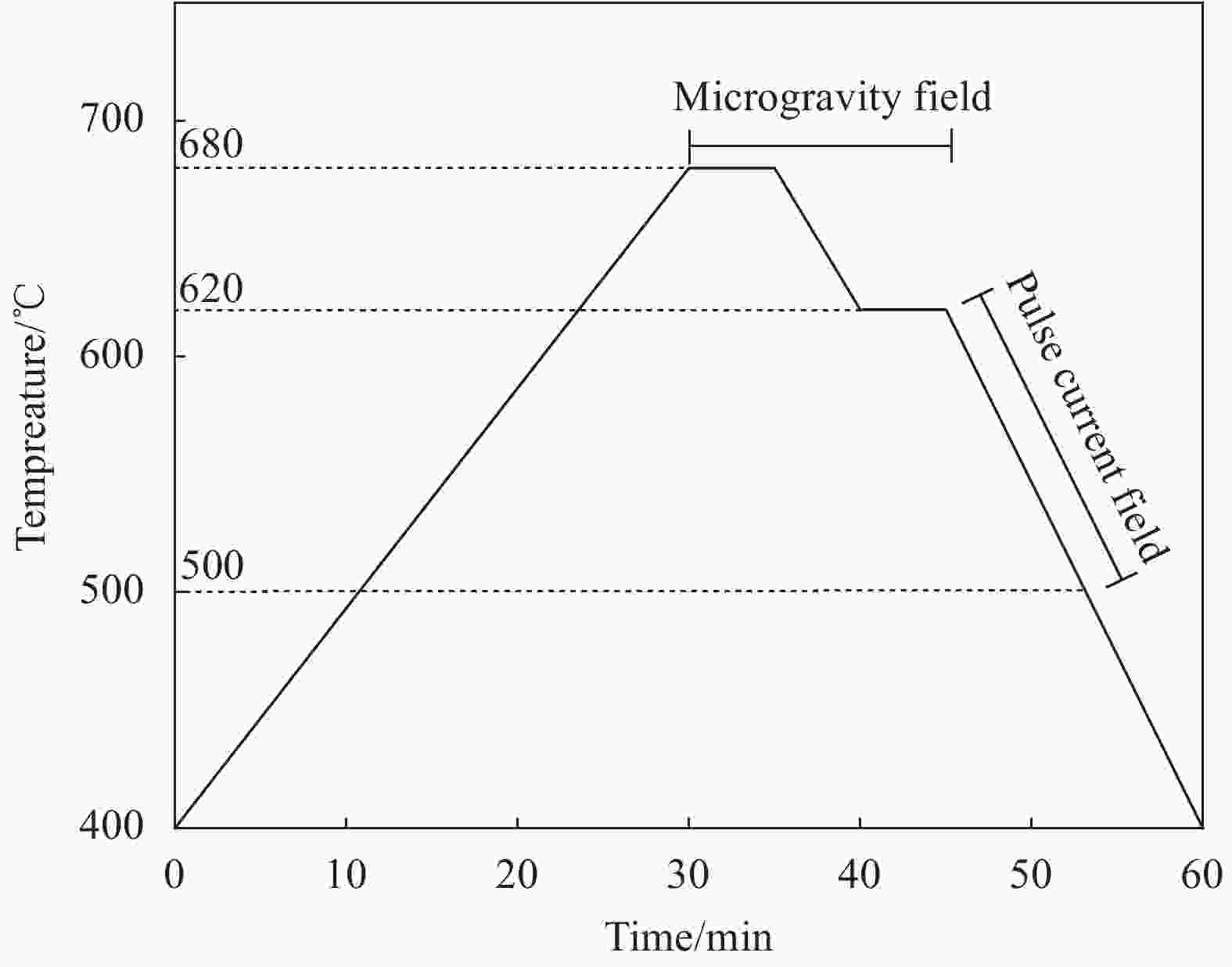

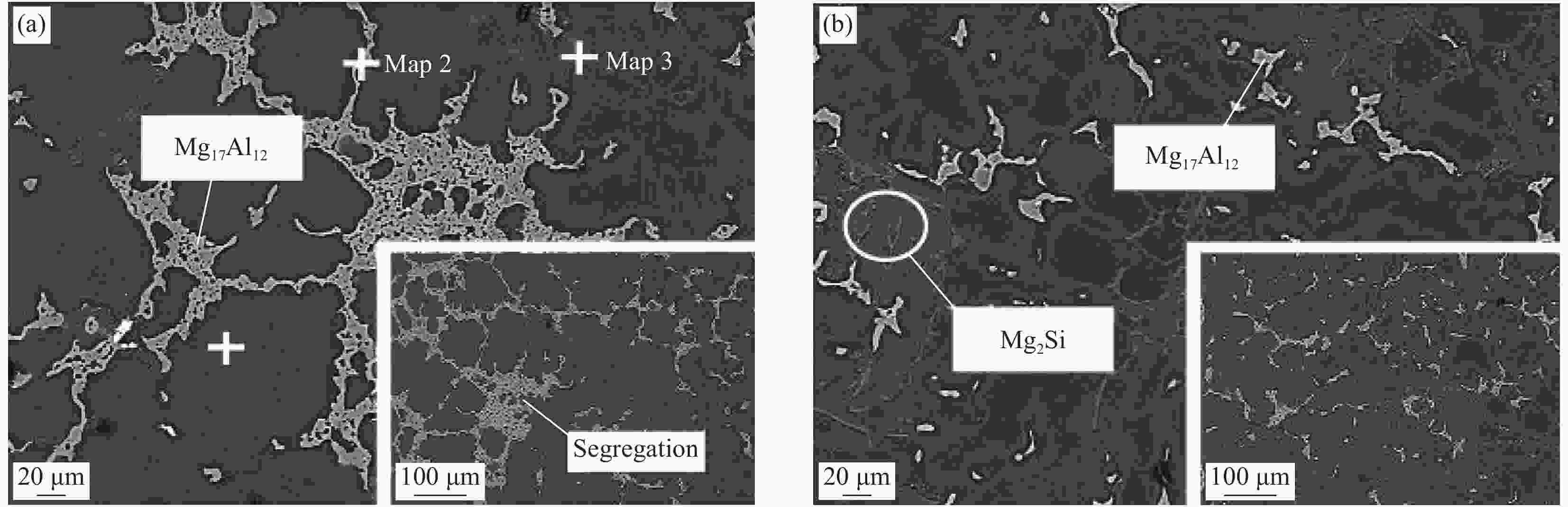

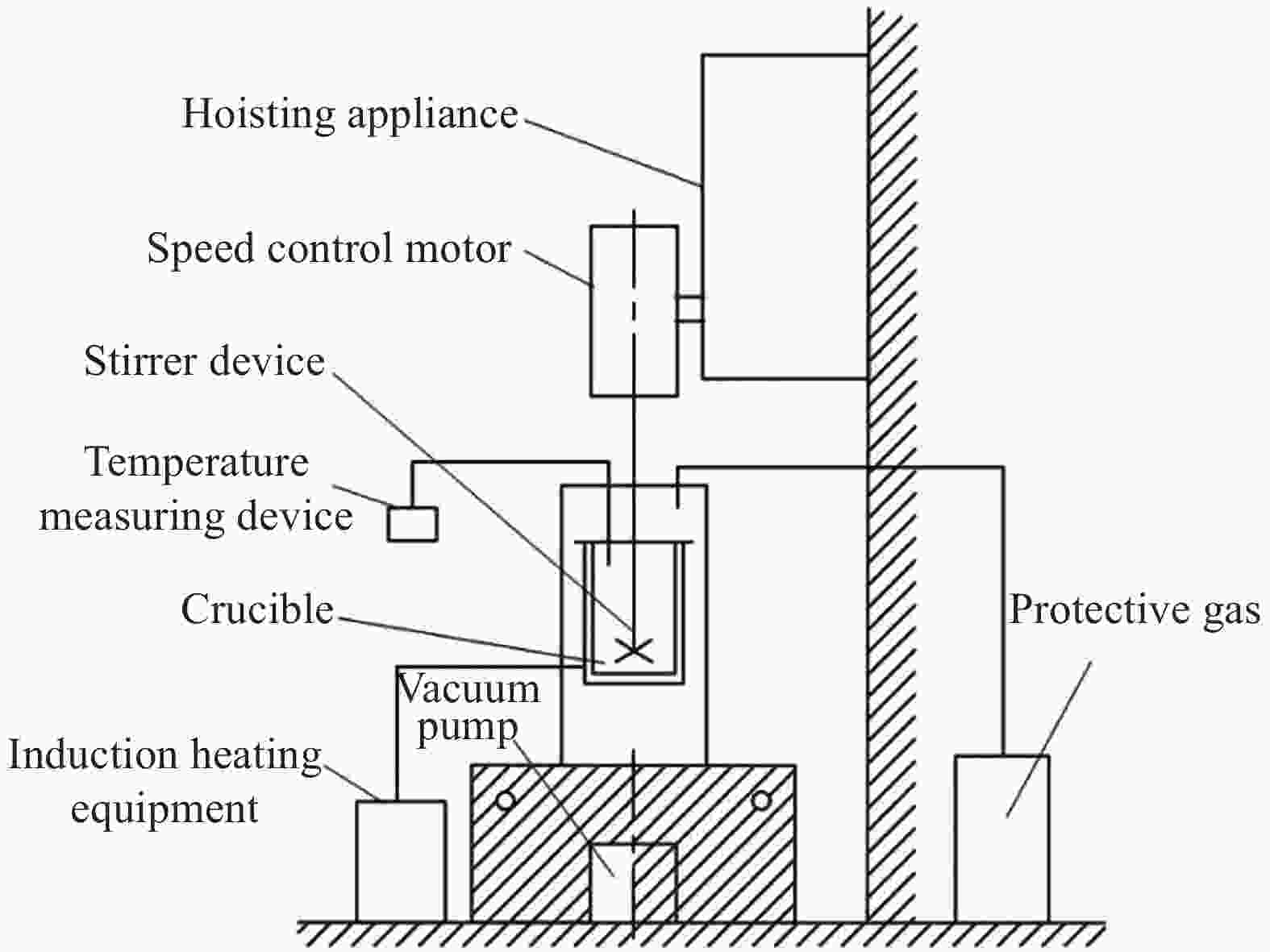

图 5 在不同外场条件下制备的铸态SiCp/AZ91D镁基复合材料的低倍SEM图像

Figure 5. Low magnification SEM images of the as-cast SiCp/AZ91D composites under different field conditions ((a) Normal solidification condition; (b) Electromagnetic simulation of microgravity field condition; (c) Pulsed current field condition; (d) Compound field condition)

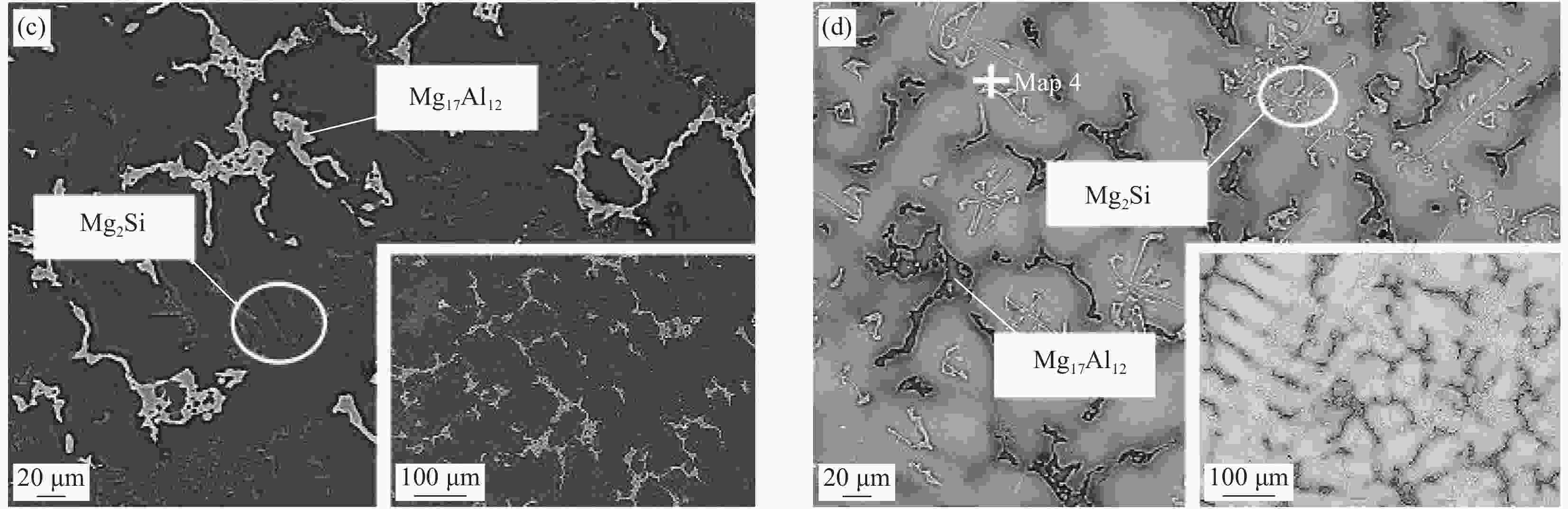

图 6 在不同外场条件下铸态SiCp/AZ91D镁基复合材料的高倍SEM图像

Figure 6. High magnification SEM images of the as-cast SiCp/AZ91D composites under different field conditions ((a) Normal solidification condition; (b) Electromagnetic simulation of microgravity field condition; (c) Pulsed current field condition; (d) Compound field condition)

表 1 AZ91D镁合金的主要成分

Table 1. Chemical composition of AZ91D alloy

Element Al Zn Mn Si Cu Mg Content/wt% 9 0.67 0.25 0.05 0.015 Balance -

[1] 丁文江. 镁合金科学与技术[M]. 北京: 科学出版社, 2007.DING W J. Magnesium alloy science and technology[M]. Beijing: Science Press, 2007(in Chinese). [2] MALAKI M, XU W, ASHISH K. K, et al. Advanced metal matrix nanocomposites[J]. Metals,2019,9(3):330. [3] 吴国华, 陈玉狮, 丁文江. 镁合金在航空航天领域研究应用现状与展望[J]. 载人航天, 2016, 22(3):281-292. doi: 10.3969/j.issn.1674-5825.2016.03.002WU G H, CHEN Y S, DING W J. Current research application and future prospect of magnesium alloys in aerospace industry[J]. Manned Spaceflight,2016,22(3):281-292(in Chinese). doi: 10.3969/j.issn.1674-5825.2016.03.002 [4] 曾小勤, 朱庆春, 李扬欣等. 镁合金中的第二相颗粒强化[J]. 中国材料进展, 2019, 38(3):193-204, 250.ZENG X Q, ZHU Q C, LI Y X, et al. Second phase particle strengthening in magnesium alloys[J]. Materials China,2019,38(3):193-204, 250(in Chinese). [5] KARAKULAK E. A review: Past, present and future of grain refining of magnesium castings[J]. Journal of Magnesium and Alloys,2019,7(3):15. [6] CHEN L Y, XU J Q, CHOI H, et al. Processing and properties of magnesium containing a dense uniform dispersion of nanoparticles[J]. Nature, 2015, 528: 539-543. [7] 赵聪铭, 邓坤坤, 聂凯波, 等. 挤压包覆轧制对SiCp增强镁合金 (AZ91) 复合板显微组织和力学性能的影响[J]. 复合材料学报, 2020, 37(1) ; 164-172.ZHAO C M, DENG K K, NIE K B, et al. Effect of extrusion-cladding rolling on microstructure and mechanical property of SiCp reinforced magnesium alloy(AZ91) clad plate[J]. Acta Materiae Compositae Sinica, 2020, 37(1): 164-172(in Chinese). [8] CHEN T J, JIANG X D, MA Y, et al. Grain refinement of AZ91D magnesium alloy by SiC[J]. Journal of Alloys and Compounds,2010,496(1):218-225. [9] HEMANTH J. Development and property evaluation of alu minum alloy reinforced with nano-ZrO, metal matrix composites (NMMCs)[J]. Materials Science and Engineering A, 2009, 507: 110-113. [10] HAMEDAN A D, SHAHMIRI M. Production of A356-1 wt% SiC nanocomposite by the modified stir casting method[J]. Materials Science and Engineering A, 2012, 556: 921-926. [11] SAIIADI S A, EZATPOUR H, BEYGI H. Microstructure and mechanical properties of Al-Al203 micro and nano composites fabricated by stir casting[J]. Materials Science and Engineering A, 2011, 528: 8765-8771. [12] 常海, 黄勇, 胡小石. 搅拌铸造法制备短碳纤维/AZ91复合材料的组织与性能[J]. 复合材料学报, 2019, 36(1):159-166.HANG H, HUANG Y, HU X S. Microstructure and mechanical properties of short carbon fiber/AZ91 composite fabricated by stir-casting[J]. Acta Materiae Compositae Sinica,2019,36(1):159-166(in Chinese). [13] 金培鹏, 韩丽, 王金辉. 轻金属基复合材料[M]. 北京: 国防工业出版社, 2013.JIN P P, HAN L, WANG J H. Light metal matrix composites[M]. Beijng: National Defence Industry Press, 2013(in Chinese). [14] 杨院生, 付俊伟, 罗天骄, 等. 镁合金低压脉冲磁场晶粒细化[J]. 中国有色金属学报, 2011, 21(10):2639-2649.YANG Y S, FU J W, LUO T J, et al. Grain refinement of magnesium alloys under low-voltage pulsed magnetic field[J]. The Chinese Journal of Nonferrous Metals,2011,21(10):2639-2649(in Chinese). [15] ZHAO Y T, ZHANG S L, CHEN G. Alu minum matrix composites reinforced by in situ Al2O3 and Al3Zr particles fabricated via magneto chemistry reaction[J]. Nonferrous Metals Society China,2010,20:2129-2133. doi: 10.1016/S1003-6326(09)60429-5 [16] 余挺, 王东新, 秦春, 等. 强脉冲电流对Cu-SiCp/AZ91D组织和性能的影响[J]. 真空科学与技术学报, 2018, 38(10):906-912.YU T, WANG D X, QIN C, et al. Modification of Mg-Alloy AZ91D by adding Cu-coated SiC powder and by passing pulse current[J]. Chinese Journal of Vacuum Science and Technology,2018,38(10):906-912(in Chinese). [17] 余挺, 王东新, 秦春, 等. 微重力磁场对Cu-SiCp/AZ91D复合材料组织及性能的影响[J]. 特种铸造及有色合金, 2018, 38(10):1112-1115.YU T, WANG D X, QIN C, et al. Effects of the microgravity on microstructure and performance of Cu-SiCp/AZ91D composites[J]. Special Casting & Nonferrous Alloys,2018,38(10):1112-1115(in Chinese). [18] 耿桂宏, 郝维新. 金属熔体块体纳米材料制备系统: 中国, ZL201410816445.7[P]. 2017-06-06.GENG G H, HAO W X. Preparation system of metal melt bulk nanomaterials: China, ZL201410816445.7[P]. 2017-06-06(in Chinese). [19] CHEN T J, MA Y, LV W B, et al. Grain refinement of AM60B magnesium alloy by SiC particles[J]. Journal of Materials Science,2010,45(6):6732-6738. [20] SHENG S D, CHEN D, CHEN Z H. Effects of Si addition on microstructure and mechanical properties of RS/PM (rapid solidification and powder metallurgy) AZ91 alloy[J]. Journal of Alloys and Compounds,2008,470(1):L17-L20. [21] 郭学锋. 细晶镁合金制备方法及组织与性能[M]. 北京: 冶金工业出版社, 2010.GUO X F. Preparation method, microstructure and properties of fine grain magnesium alloy[M]. Beijing: Metallurgical Industry Press, 2010(in Chinese). [22] 李凡国, 于思荣, 袁明. Mg2Si/AZ91D复合材料阻尼性能[J]. 复合材料学报, 2017, 34(9):1997-2004.LI F, YU S, YUAN M. Damping capacity of Mg2Si/AZ91D composites[J]. Acta Materiae Compositae Sinica,2017,34(9):1997-2004(in Chinese). [23] 韩秋华. AZ91D热处理中β相的析出特征对合金组织及力学性能的影响[D]. 兰州: 兰州理工大学, 2011.HAN Q H. Effect of precipitation morphology of β phase on microstructure and mechanical properties of AZ91D magnesium alloys[D]. Lanzhou: Lanzhou University of Technology, 2011(in Chinese). [24] BARNAK J P, SPRECHER A F, CONRAD H. Colony (grain) size reduction in eutectic Pb-Sn castings by electroplusing[J]. Scripta Metall,1995,32(6):879-884. doi: 10.1016/0956-716X(95)93218-S [25] JIANG H X, HE J, ZHAO J Z. Influence of electric current pulses on the solidification of Cu-Bi-Sn immiscible alloys[J]. Scientific Reports,2015,5(1):12680. doi: 10.1038/srep12680 [26] AHMED T, JIANG H X, LI W, et al. Solidification of Pb-Al Alloys under the influence of electric current pulses[J]. Acta Metallurgica Sinica (English Letters),2018,31(8):842-852. doi: 10.1007/s40195-017-0685-1 [27] 张荣生, 刘海洪. 快速凝固技术[M]. 北京: 冶金工业出版社, 1994.ZHANG R S, LIU H H. Rapid solidification technique[M]. Beijing: Metallurgical Industry Press, 1994(in Chinese). [28] LI Z Y, YU T, WANG D, et al. Effect of the electromagnetic compound field on the grain growth and wear resistance of a Cu-Pb monotectic alloy[J]. Materiali in Tehnologije,2020,54(2):243-249. doi: 10.17222/mit.2019.115 -

下载:

下载: