Lateral impact resistance of BFRP tendon under different pretensions and impact energies

-

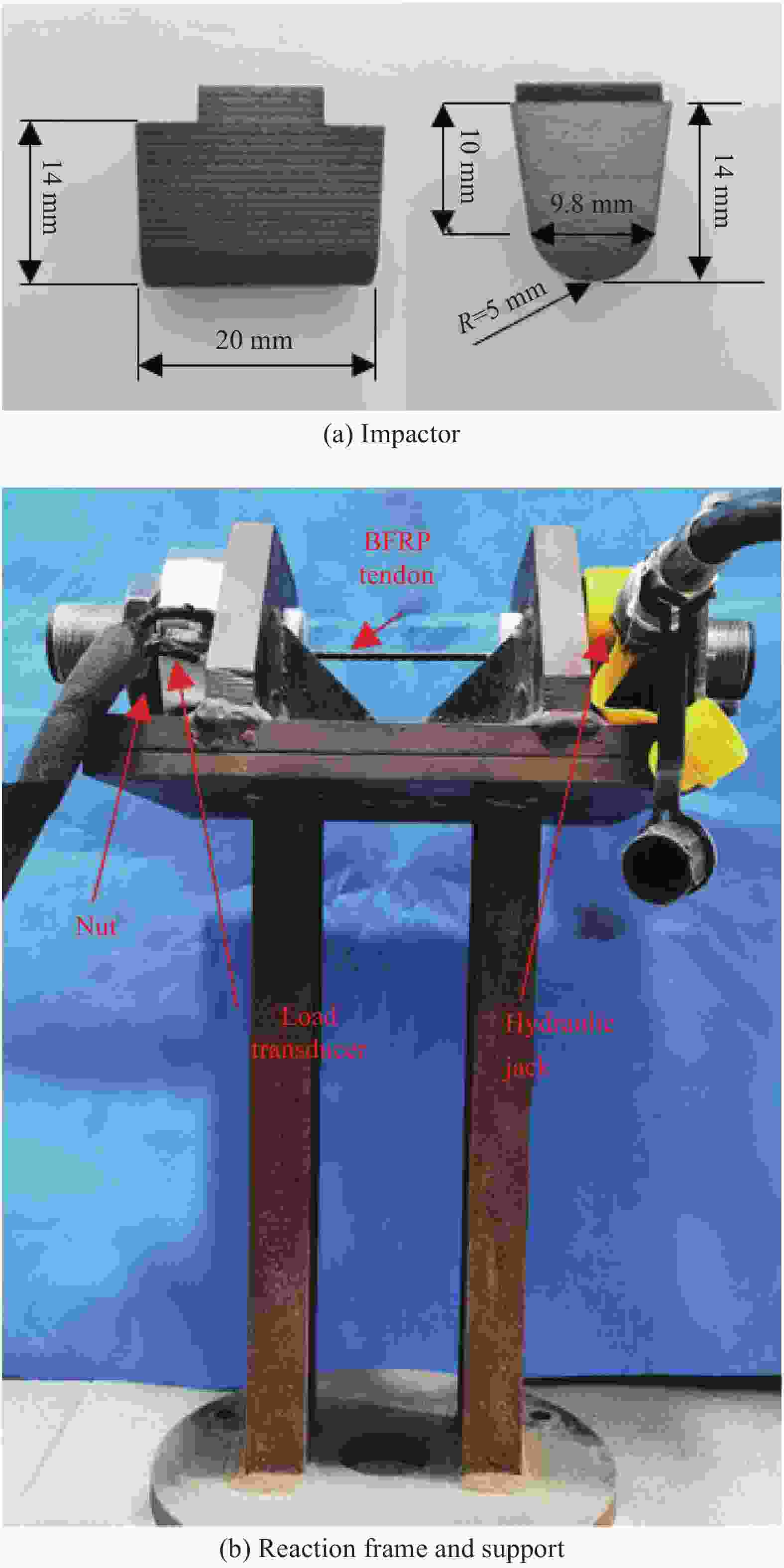

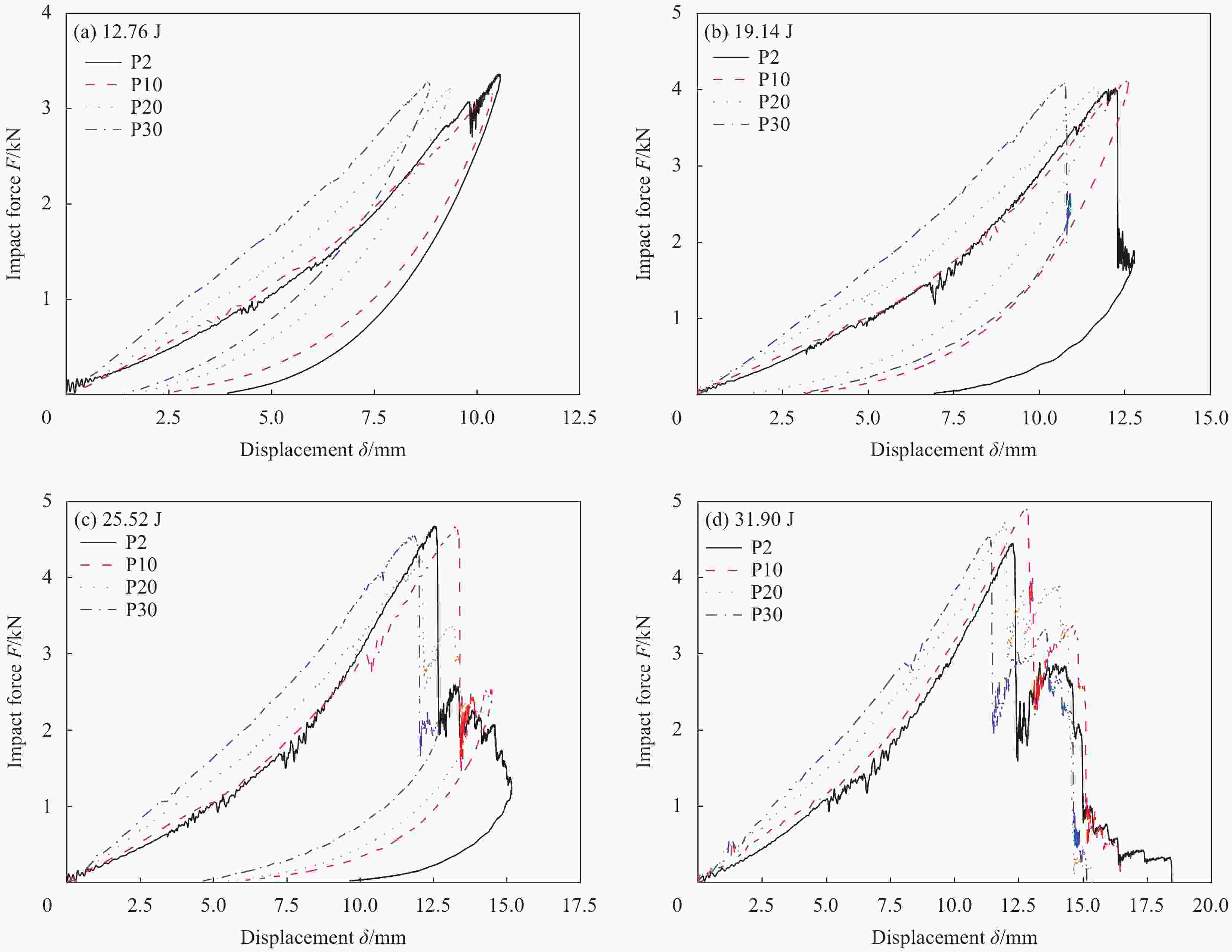

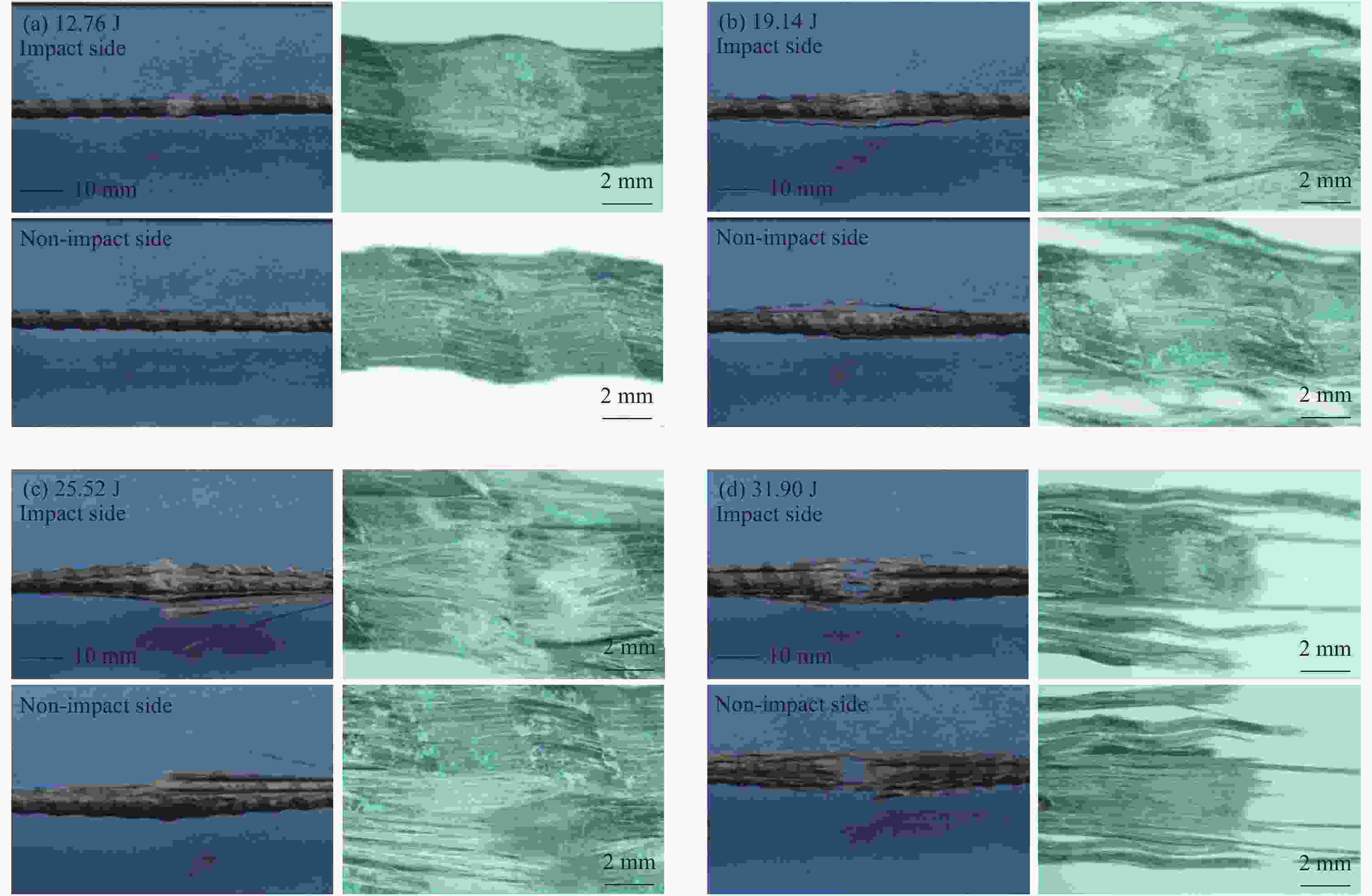

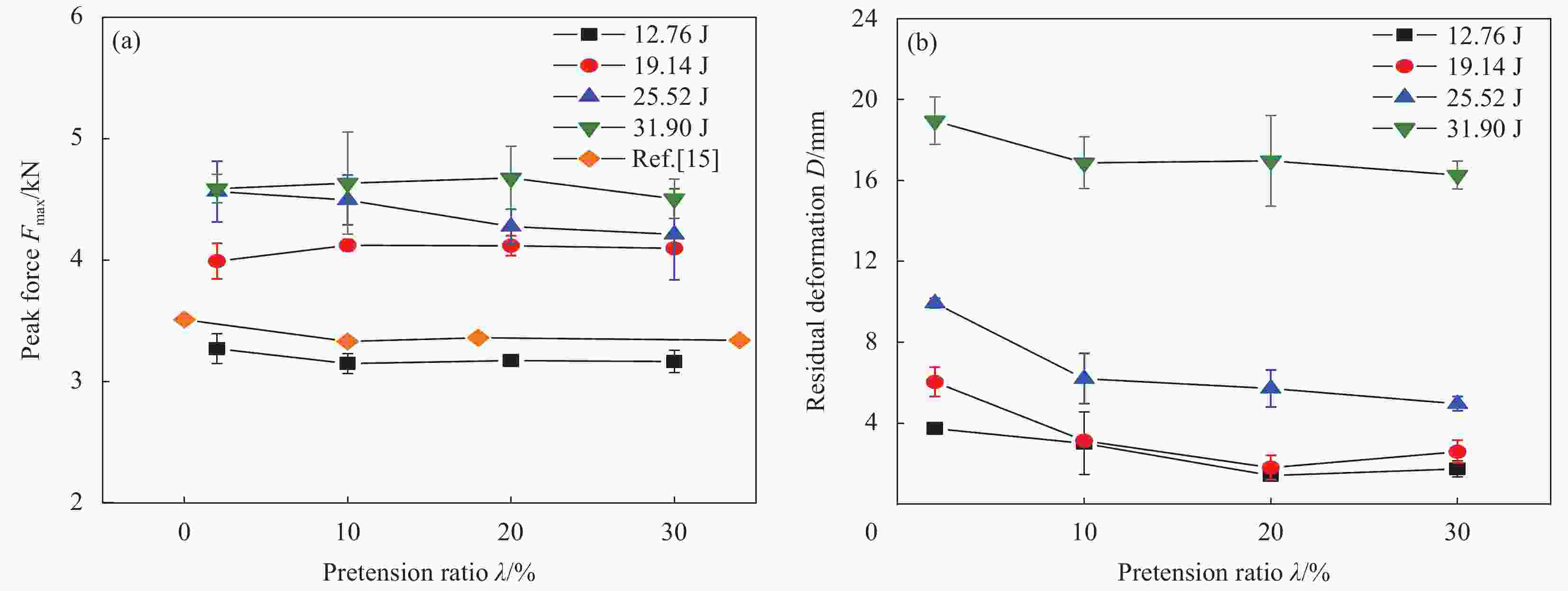

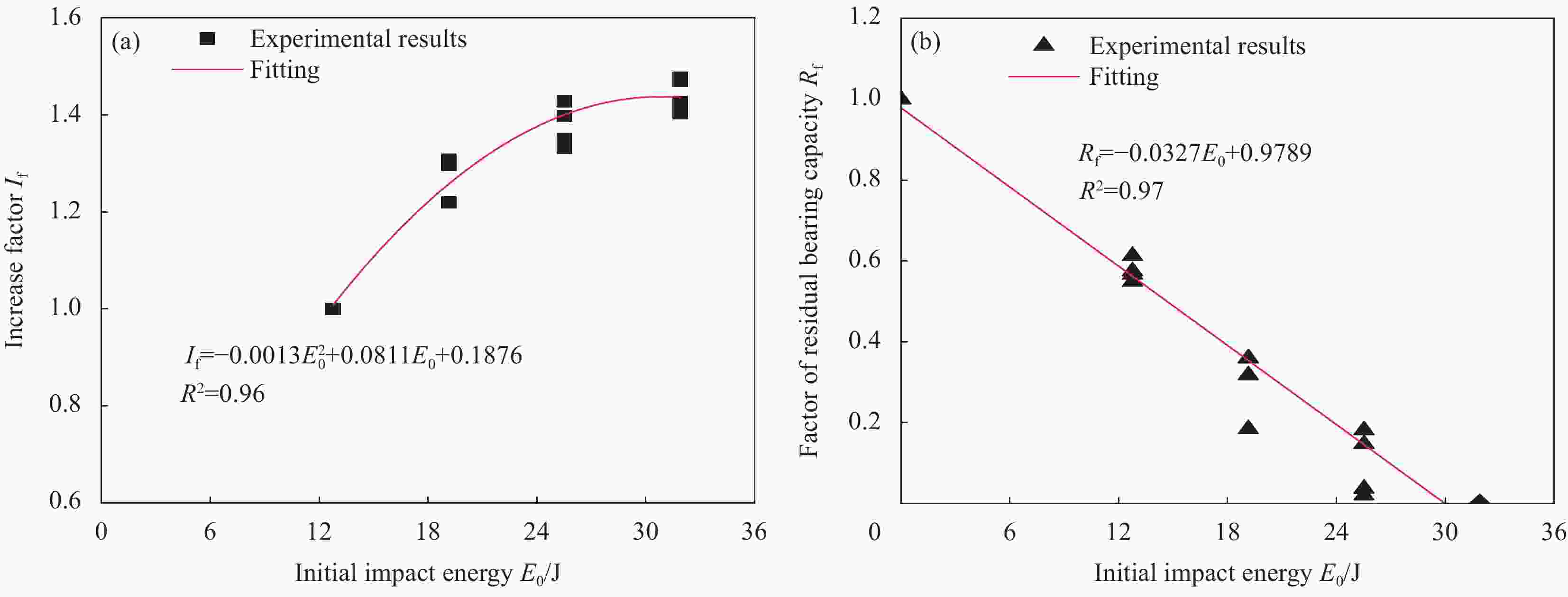

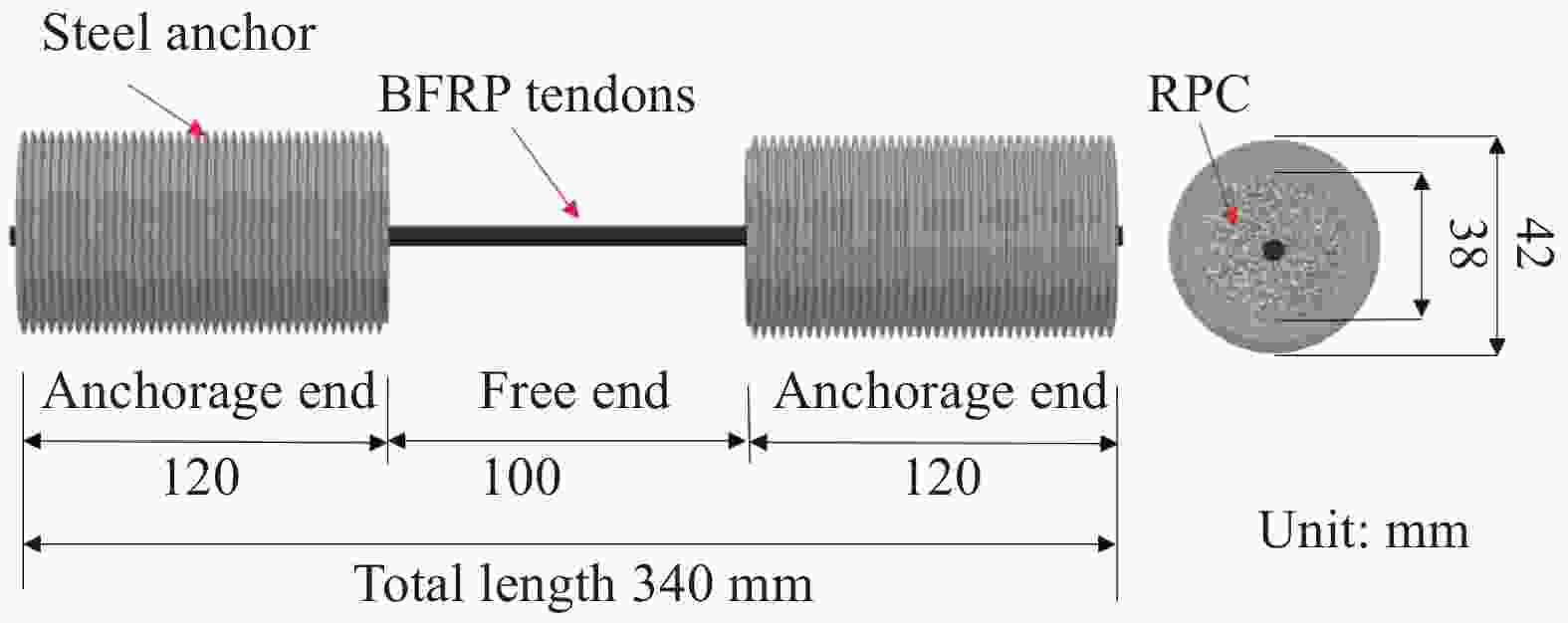

摘要: 为研究玄武岩纤维增强树脂基复合材料(Basalt fiber reinforced polymer,BFRP)筋的低速冲击性能,通过落锤冲击试验测试了不同预拉力比值(2%、10%、20%和30%)和不同能量(12.76~31.90 J)作用下BFRP筋的低速冲击响应,同时测试了未完全断裂试件的残余拉伸承载力。结果表明:BFRP筋的损伤破坏模式包括冲击面树脂破碎、部分纤维断裂和BFRP筋完全断裂。在冲击能量为19.14 J,预拉力从2%增大到10%和20%时,BFRP筋的破坏模式从冲击面树脂破碎转变为部分纤维断裂。施加预拉力提高了BFRP筋断裂时的耗能,但对峰值荷载影响较小。BFRP筋未完全断裂时,试件的残余变形、耗能和冲击时间与预拉力呈负相关;当BFRP筋完全断裂时,冲击后试样的残余变形随预拉力的增大而减小,耗能和冲击时间先增大后减小。BFRP筋的残余拉伸承载力随冲击能量的增大而减小。研究发现BFRP筋的残余拉伸承载力和试件耗能/总冲击能量(耗能比)都能较好地评估BFRP筋的损伤程度。本研究成果可以为预应力BFRP筋抗冲击设计提供重要参考。Abstract: In order to study the low-velocity impact performance of basalt fiber reinforced polymer (BFRP) tendon, the drop-weight impact test of the BFRP tendon was conducted to examine the low-velocity impact response under different pretension ratios (2%, 10%, 20%, and 30%) and impact energies (12.76 -31.90 J). Meanwhile, the residual tensile loading capacity of the incompletely broken specimens was further measured. Experimental results indicate that the failure modes of BFRP tendon include resin failure on the impact side, partial fracture of the fiber and complete fracture of the BFRP tendon. Under 19.14 J impact energy, the failure mode of the BFRP tendon changes from resin failure on the impact side to partial fracture of the fiber when the pretension ratio is increased from 2% to 10% and 20%. Meanwhile, the applied pre-tension enhances energy consumption, but the influence on the peak force is minimal. When the BFRP tendon is not completely broken, the residual deformation, energy consumption and the impact contact time of the specimen are negatively related to the pretension ratio. When the BFRP tendon is completely broken, the residual deformation of BFRP tendon decreases with the pretension ratio while the energy consumption and impact time first increases and then decreases with the pretension ratio. And the residual tensile loading capacity of the BFRP tendon decreases with the increase of impact energy. The impact damage level of BFRP tendon can be appropriately assessed with both the residual tensile loading capacity and the ratio between energy consumption and total impact energy (energy absorption ratio) of the specimen. The results of this study can provide important reference for the impact resistance design of the pre-tensioned BFRP tendon.

-

Key words:

- BFRP tendon /

- low-velocity impact /

- failure modes /

- energy absorption ratio /

- impact damage

-

表 1 玄武岩纤维增强树脂基复合材料(BFRP)筋的力学性能[25]

Table 1. Mechanical properties of basalt fiber reinforced polymer (BFRP) tendon[25]

Type Tensile strength/MPa Load bearing capacity/kN Elastic modulus/GPa Ultimate strain/% Shear strength/MPa BFRP 1113.40 17.64 50.81 2.23 169.10 表 2 不同预拉力和冲击能量下BFRP试件耗能

Table 2. Energy consumption of BFRP specimens under different impact energies and pretension ratios

$\lambda $/% ${E_0}$/J ${E_{{\rm{tot}}}}$/J ${E_{{\rm{ab}}}}$/J ${E_{{\rm{ab}}}}/{E_{{\rm{tot}}}}$ 2 12.76 13.32(0.79) 6.96(0.60) 0.52(0.01) 19.14 20.15(0.12) 15.91(1.26) 0.79(0.06) 25.52 26.94(0.20) 25.75(0.43) 0.96(0.01) 31.90 34.33(0.15) 30.96(2.24) 0.90(0.06) 10 12.76 13.97(0.08) 6.66(0.14) 0.48(0.01) 19.14 20.69(0.11) 10.76(0.41) 0.52(0.02) 25.52 27.40(0.18) 22.31(1.67) 0.81(0.06) 31.90 34.06(0.16) 31.18(1.66) 0.92(0.05) 20 12.76 13.79(0.01) 6.06(0.25) 0.44(0.02) 19.14 20.49(0.04) 10.67(1.78) 0.52(0.09) 25.52 27.29(0.19) 23.94(2.54) 0.88(0.09) 31.90 34.07(0.29) 33.72(1.77) 0.99(0.05) 30 12.76 13.88(0.63) 5.83(0.29) 0.42(0.00) 19.14 20.50(0.10) 13.90(2.17) 0.68(0.11) 25.52 27.21(0.23) 24.28(2.31) 0.89(0.08) 31.90 33.98(0.09) 32.70(1.80) 0.96(0.05) Notes: $\lambda $—Ratio of the initial pretension to the load bearing capacity of the BFRP tendon; ${E_{\rm{0}}}$, ${E_{{\rm{tot}}}}$, ${E_{{\rm{ab}}}}$ and ${E_{{\rm{ab}}}}/{E_{{\rm{tot}}}}$—Initial impact energy, total impact energy, absorbed energy and energy absorption ratio of BFRP tendon, respectively; Values in the parentheses—Standard deviations. 表 3 不同冲击能量及预拉力下BFRP的抗冲击性能

Table 3. Impact performance of BFRP under different impact energies and pretension ratios

$\lambda $/% ${E_0}$/J ${F_{\max }}$/kN ${I_{\rm{f}}}$ $D$/mm ${t_{\rm{d}}}$/ms ${T_{\rm{r}}}$/kN ${R_{\rm{f}}}$ 2 12.76 3.27(0.12) 1.00 3.73(0.25) 21.01(0.92) 9.68(0.69) 0.55 19.14 3.99(0.15) 1.22 6.04(0.72) 25.11 (0.35) 3.25(0.09) 0.18 25.52 4.57(0.25) 1.40 9.94(0.23) 34.53 (2.17) 0.35(0.05) 0.02 31.90 4.59(0.12) 1.40 18.94(1.18) 11.72 (0.40) 0(0) 0 10 12.76 3.15(0.08) 1.00 3.00(1.55) 22.37 (0.59) 9.99(0.62) 0.57 19.14 4.12(0.05) 1.31 3.14(0.21) 21.21(0.53) 6.35(0.75) 0.36 25.52 4.50(0.2) 1.43 6.20(1.25) 26.05 (0.65) 3.20(0.45) 0.18 31.90 4.63(0.42) 1.47 16.87(1.28) 12.75 (2.37) 0(0) 0 20 12.76 3.17(0.04) 1.00 1.41(0.02) 21.06 (0.30) 10.14(0.50) 0.57 19.14 4.12(0.08) 1.30 1.80(0.60) 20.71 (0.57) 6.33(0.78) 0.36 25.52 4.28(0.14) 1.35 5.72(0.92) 27.82 (2.49) 2.62(0.83) 0.15 31.90 4.68(0.26) 1.48 16.97(2.24) 13.69 (2.26) 0(0) 0 30 12.76 3.16(0.09) 1.00 1.74(0.40) 19.90 (0.24) 10.81(0.47) 0.61 19.14 4.10(0.02) 1.30 2.59(0.56) 21.38 (1.47) 5.60(0.42) 0.32 25.52 4.21(0.37) 1.33 4.96(0.34) 24.10 (4.79) 0.65(0.27) 0.04 31.90 4.51(0.16) 1.43 16.27(0.70) 11.95 (0.73) 0(0) 0 Note: ${F_{\max }}$, ${I_{\rm{f}}}$, $D$, ${t_{\rm{d}}}$, ${T_{\rm{r}}}$ and ${R_{\rm{f}}}$—Peak force, peak force increase factor, residual deformation, impact time, residual load bearing capacity and factor of residual bearing capacity of BFRP tendon, respectively. -

[1] WANG X, WU Z. Evaluation of FRP and hybrid FRP cables for super long-span cable-stayed bridges[J]. Composite Structures,2010,92(10):2582-2590. doi: 10.1016/j.compstruct.2010.01.023 [2] KAO C S, KOU C H, XIE X. Static instability analysis of long-span cable-stayed bridges with carbon fiber composite cable under wind load[J]. Journal of Applied Science and Engineering,2006,9(2):89-95. [3] ZHANG K, FANG Z, NANNI A, et al. Experimental study of a large-scale ground anchor system with frp tendon and RPC grout medium[J]. Journal of Composites for Construction,2015,19(4):04014073. doi: 10.1061/(ASCE)CC.1943-5614.0000537 [4] YANG Y, WANG X, WU Z. Long-span cable-stayed bridge with hybrid arrangement of FRP cables[J]. Composite Structures,2020,237:111966. doi: 10.1016/j.compstruct.2020.111966 [5] FANG Z, ZHANG K, TU B. Experimental investigation of a bond-type anchorage system for multiple FRP tendons[J]. Engineering Structures,2013,57:364-373. doi: 10.1016/j.engstruct.2013.09.038 [6] ZHOU J, LIAO B, SHI Y, et al. Low-velocity impact behavior and residual tensile strength of CFRP laminates[J]. Composites Part B: Engineering,2019,161:300-313. doi: 10.1016/j.compositesb.2018.10.090 [7] CAPRINO G, LOPRESTO V, SCARPONI C, et al. Influence of material thickness on the response of carbon-fabric/epoxy panels to low velocity impact[J]. Composites Science and Technology,1999,59(15):2279-2286. doi: 10.1016/S0266-3538(99)00079-2 [8] AKTAŞ M, ATAS C, İçTEN B M, et al. An experimental investigation of the impact response of composite laminates[J]. Composite Structures,2009,87(4):307-313. doi: 10.1016/j.compstruct.2008.02.003 [9] ATAS C, SAYMAN O. An overall view on impact response of woven fabric composite plates[J]. Composite Structures,2008,82(3):336-345. doi: 10.1016/j.compstruct.2007.01.014 [10] KHALILI S M R, MITTAL R K, MOHAMMAD P N. Analysis of fiber reinforced composite plates subjected to transverse impact in the presence of initial stresses[J]. Composite Structures,2007,77(2):263-268. doi: 10.1016/j.compstruct.2005.08.027 [11] KÖRBELIN J, DERRA M, FIEDLER B. Influence of temperature and impact energy on low velocity impact damage severity in CFRP[J]. Composites Part A: Applied Science and Manufacturing,2018,115:76-87. doi: 10.1016/j.compositesa.2018.09.010 [12] CANTWELL W J, MORTON J. Comparison of the low and high velocity impact response of cfrp[J]. Composites,1989,20(6):545-551. doi: 10.1016/0010-4361(89)90913-0 [13] CANTWELL W J, MORTON J. The influence of varying projectile mass on the impact response of CFRP[J]. Composite Structures,1989,13(2):101-114. doi: 10.1016/0263-8223(89)90048-2 [14] HEIMBS S, BERGMANN T, SCHUELER D, et al. High velocity impact on preloaded composite plates[J]. Composite Structures,2014,111:158-168. doi: 10.1016/j.compstruct.2013.12.031 [15] FANG Y, FANG Z, JIANG R, et al. Transverse static and low-velocity impact behavior of CFRP wires under pretension[J]. Journal of Composites for Construction,2019,23(5):04019041. doi: 10.1061/(ASCE)CC.1943-5614.0000970 [16] WHITTINGHAM B, MARSHALL I H, MITREVSKI T, et al. The response of composite structures with pre-stress subject to low velocity impact damage[J]. Composite Structures,2004,66(1):685-698. [17] XIANG Y, FANG Z, WANG C, et al. Experimental investigations on impact behavior of CFRP cables under pretension[J]. Journal of Composites for Construction,2017,21(2):04016087. doi: 10.1061/(ASCE)CC.1943-5614.0000745 [18] SAGHAFI H, MINAK G, ZUCCHELLI A. Effect of preload on the impact response of curved composite panels[J]. Composites Part B: Engineering,2014,60:74-81. doi: 10.1016/j.compositesb.2013.12.026 [19] SCHUELER D, TOSO-PENTECÔTE N, VOGGENREITER H. Effects of static preloads on the high velocity impact response of composite plates[J]. Composite Structures,2016,153:549-556. doi: 10.1016/j.compstruct.2016.06.062 [20] GUILLAUD N, FROUSTEY C, DAU F, et al. Impact response of thick composite plates under uniaxial tensile preloading[J]. Composite Structures,2015,121:172-181. doi: 10.1016/j.compstruct.2014.11.021 [21] 王计真, 刘小川. 考虑面内载荷的复合材料层合板冲击性能[J]. 复合材料学报, 2020, 37(8):1868-1874.WANG Jizhen, LIU Xiaochuan. Impact resistance of composite panels under in-plane preloading[J]. Acta Materiae Compositae Sinica,2020,37(8):1868-1874(in Chinese). [22] MINES R A W, LI Q M. Static behaviour of transversely loaded CFRP laminate panels subject to in-plane tension[J]. Strain,2000,36(2):71-80. doi: 10.1111/j.1475-1305.2000.tb01176.x [23] 向宇, 方志, 王常林. 碳纤维拉索及其锚固系统抗冲击性能试验研究[J]. 土木工程学报, 2015, 48(12):82-90.XIANG Yu, FANG Zhi, WANG Changlin. Experimental study on impact behaviors of CFRP cable and its anchoring system[J]. China Civil Engineering Journal,2015,48(12):82-90(in Chinese). [24] ASTM Committee. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136/D7136M—2015[S]. US: West Conshohocken, 2015. [25] 徐旭锋. BFRP拉索筋的动态及高温力学性能研究[D]. 长沙: 湖南大学, 2020.XU Xufeng. Mechanical properties of basalt fiber reinforced polymer (BFRP) tendon at varying strain rates and elevated temperatures[D]. Changsha: Hunan University, 2020(in Chinese). -

下载:

下载: