Test on axial compression performance and bearing capacity calculation of GFRP bars reinforced coral aggregate marine concrete columns exposed to tidal area

-

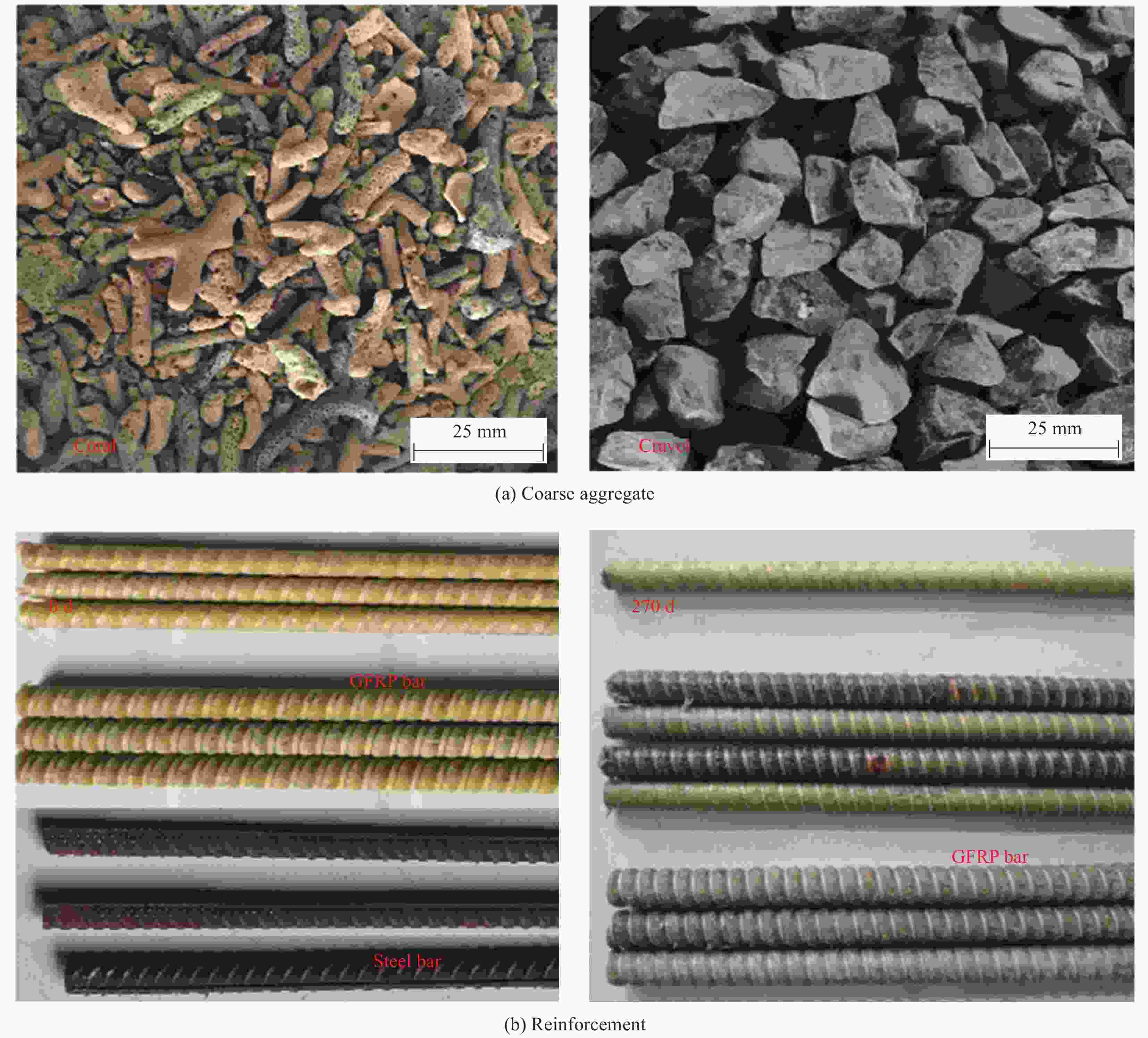

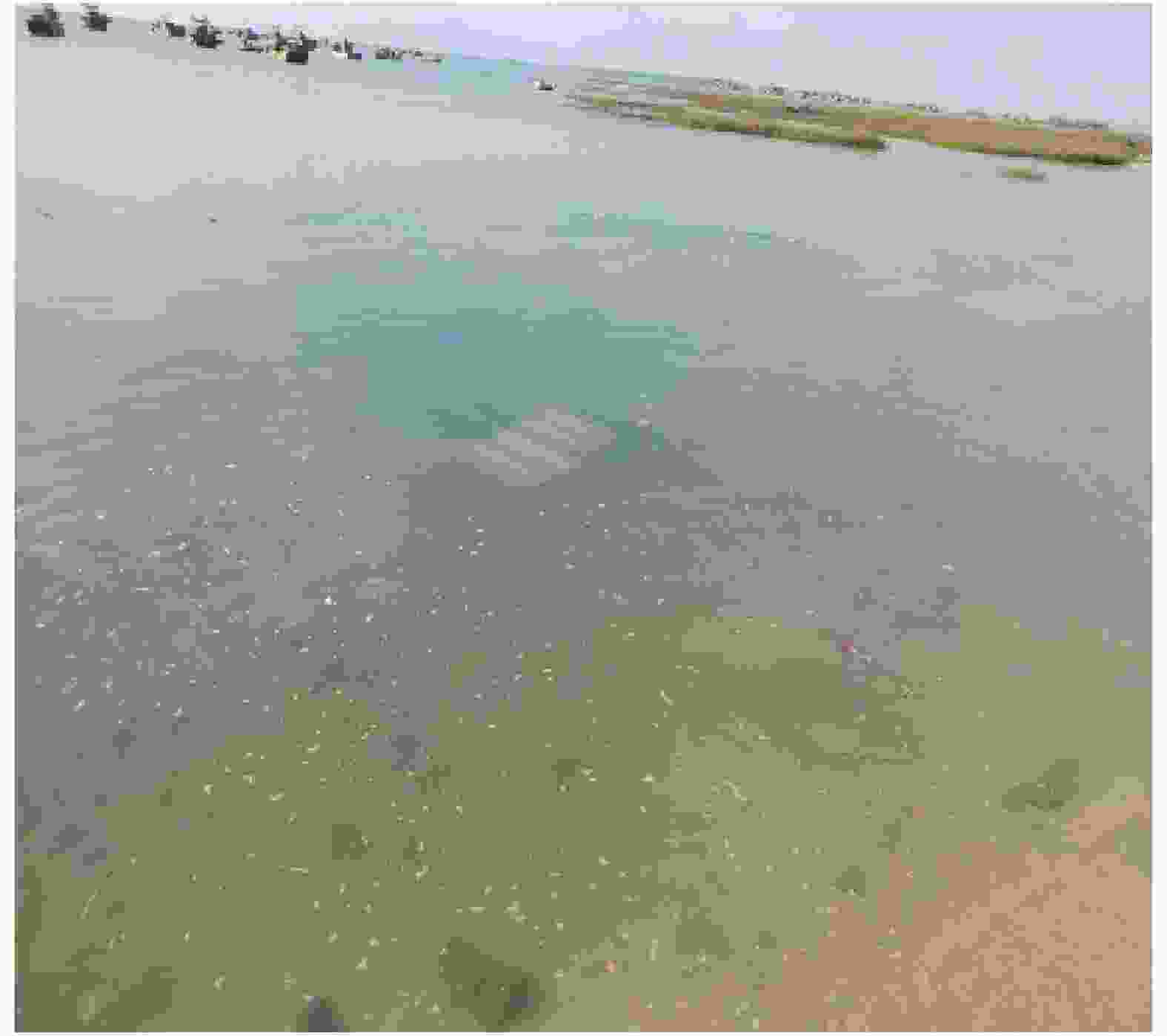

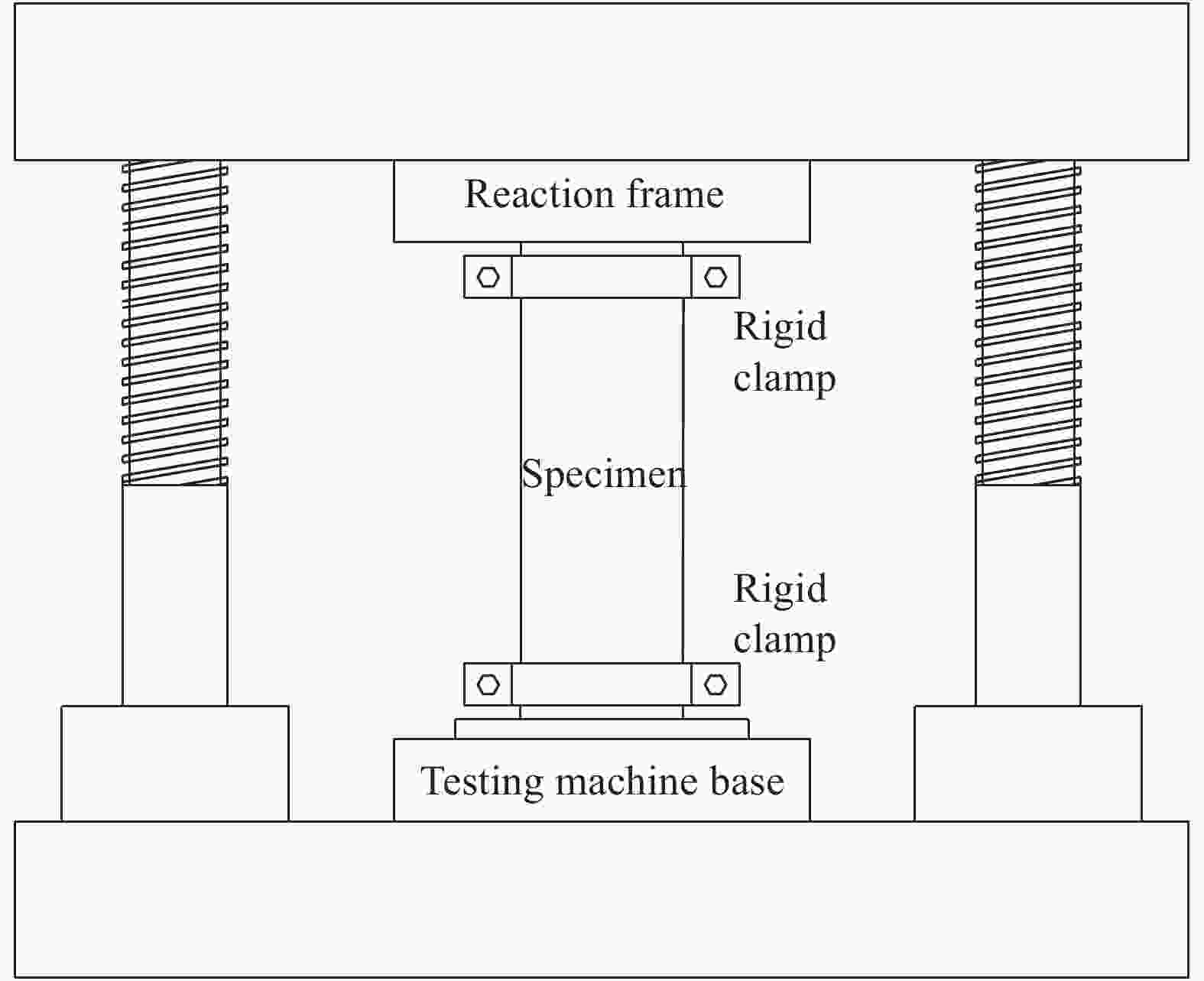

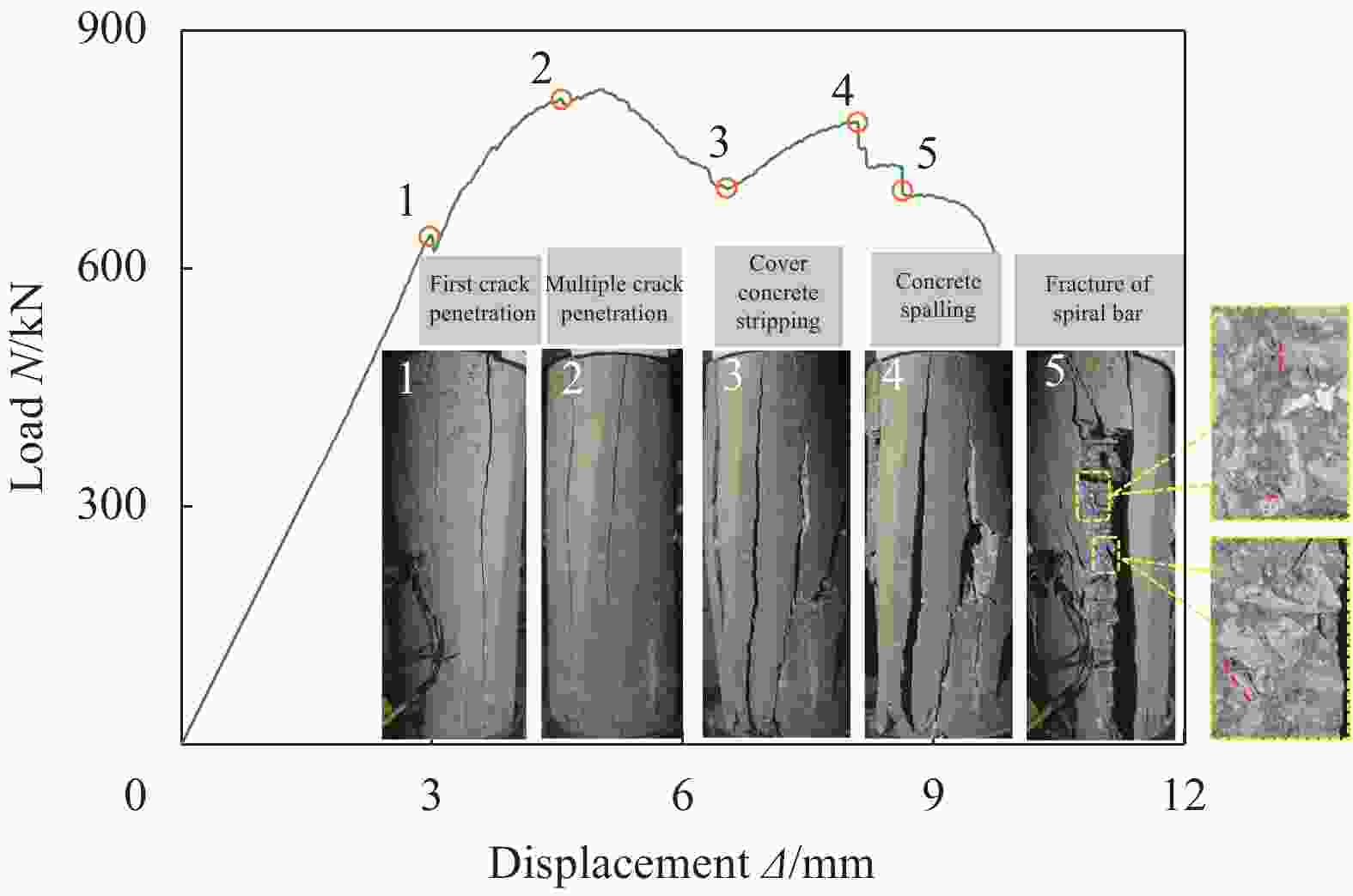

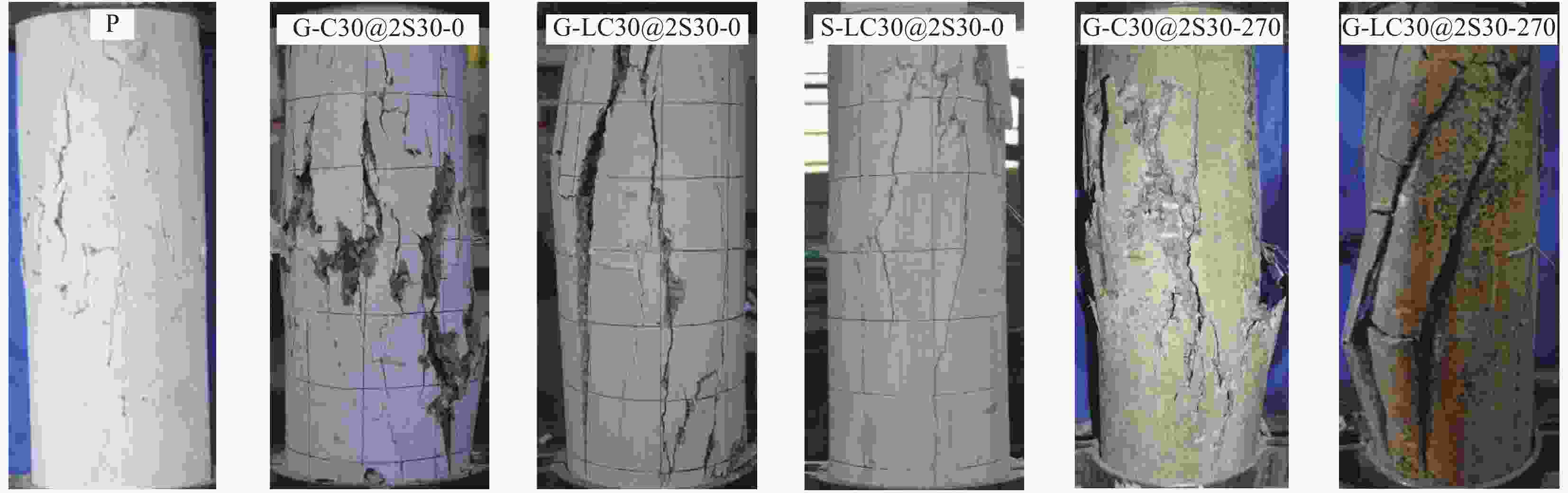

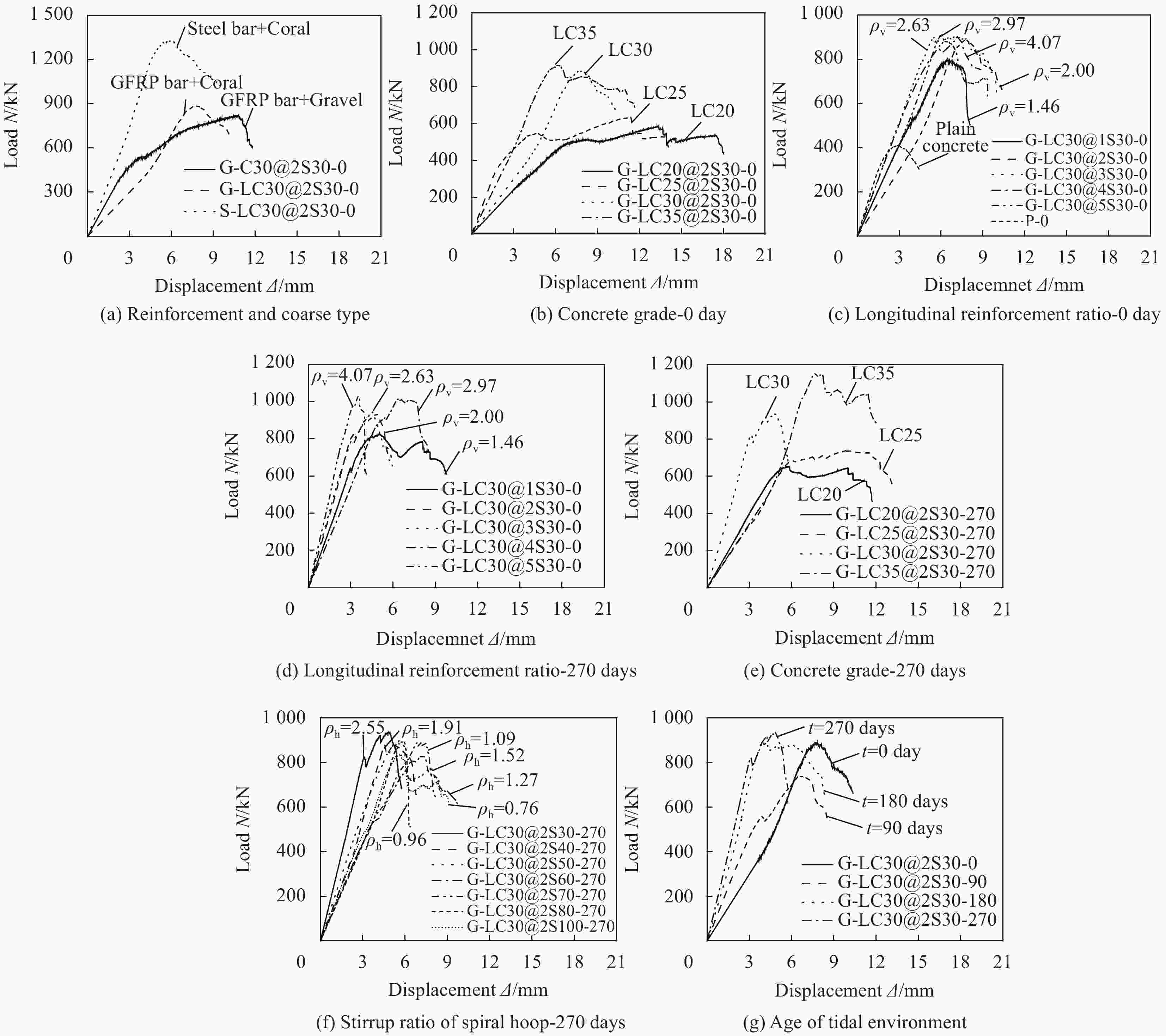

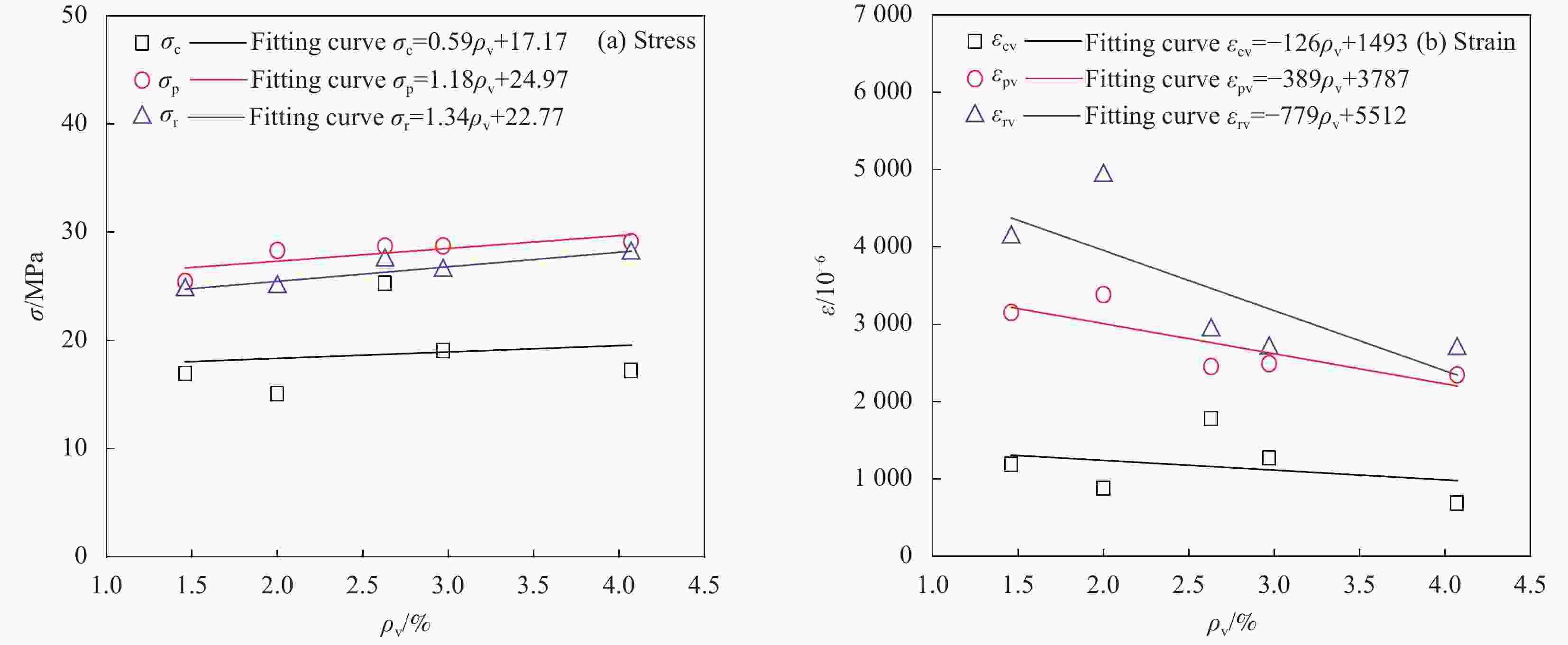

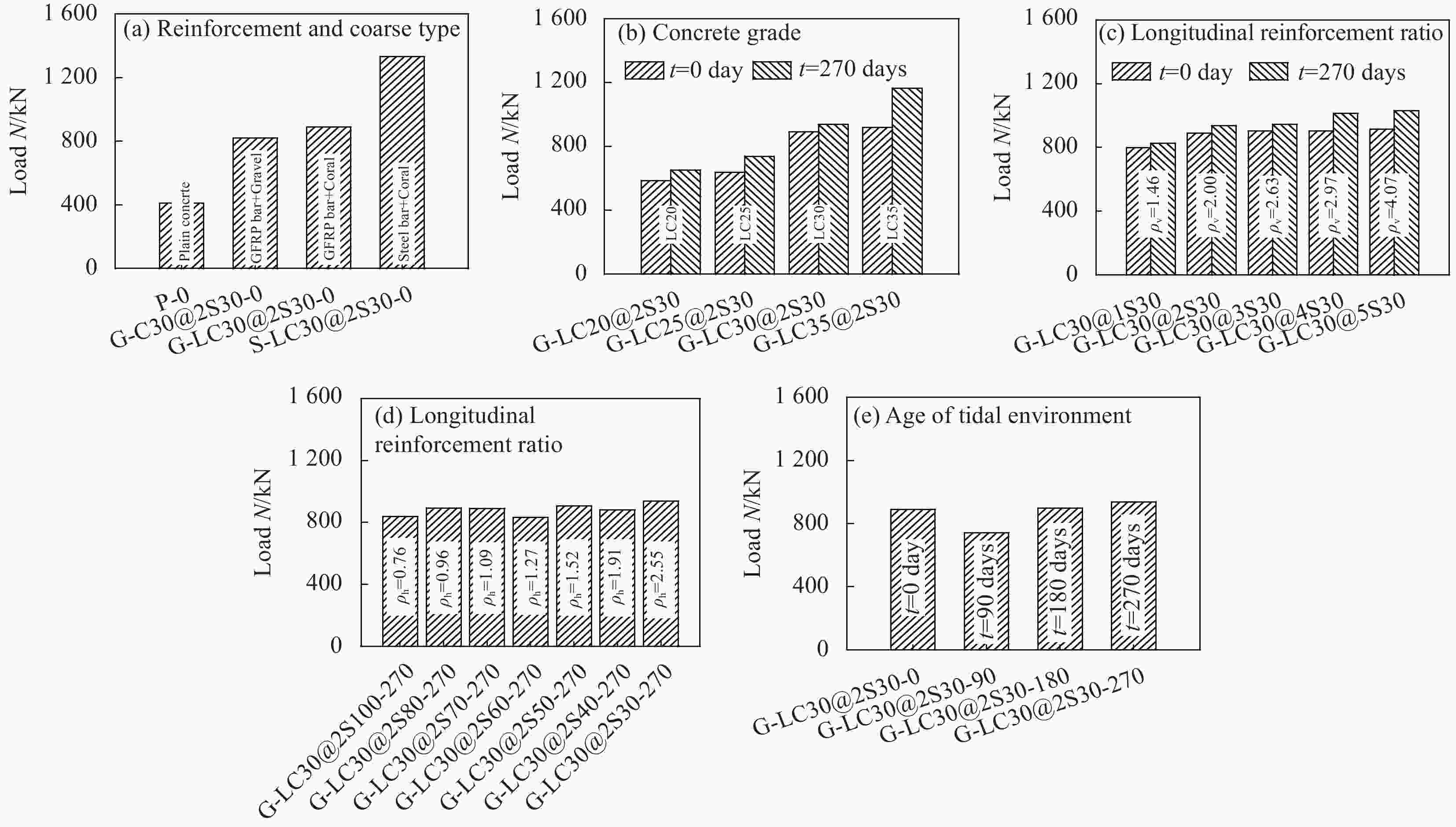

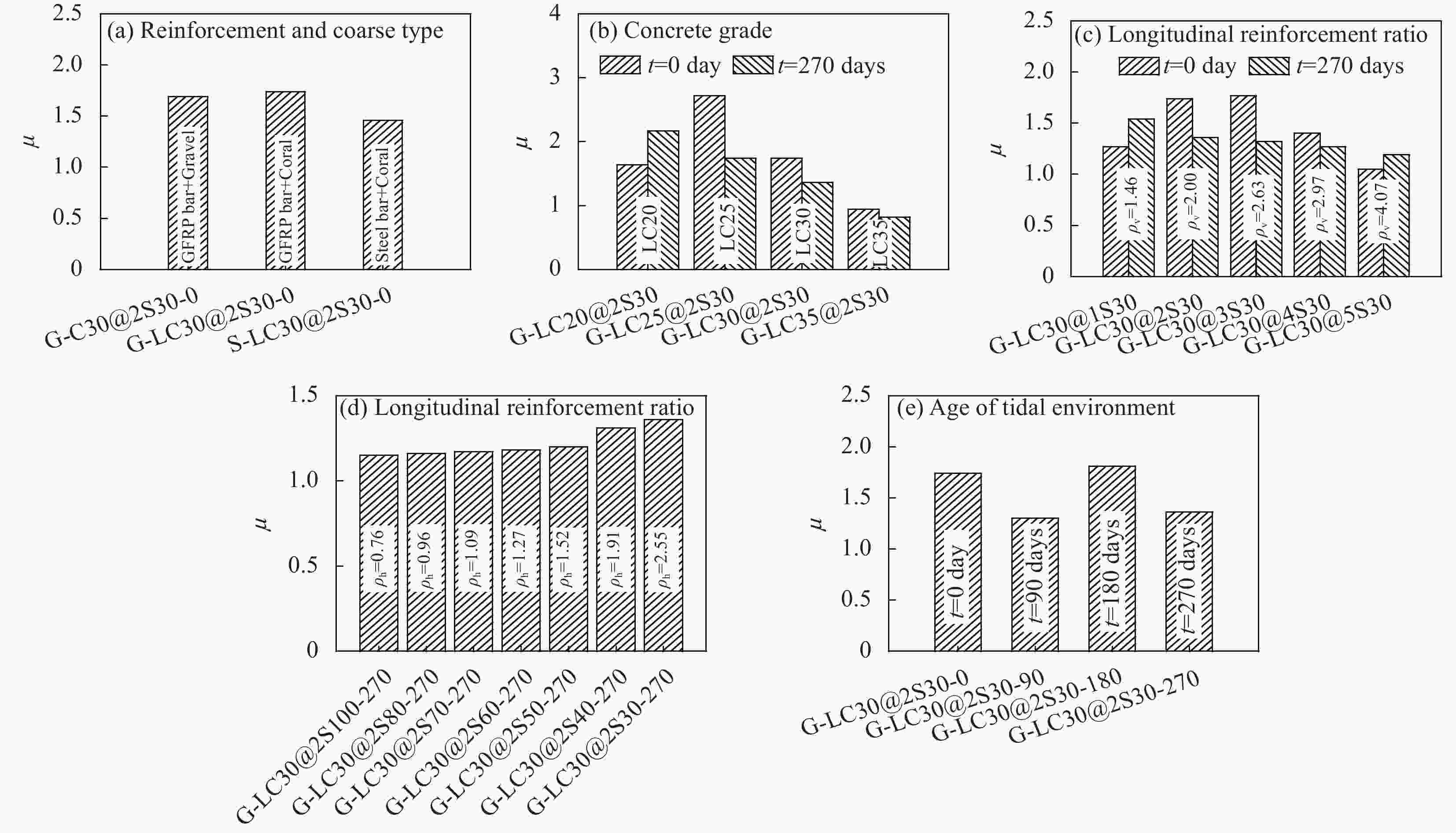

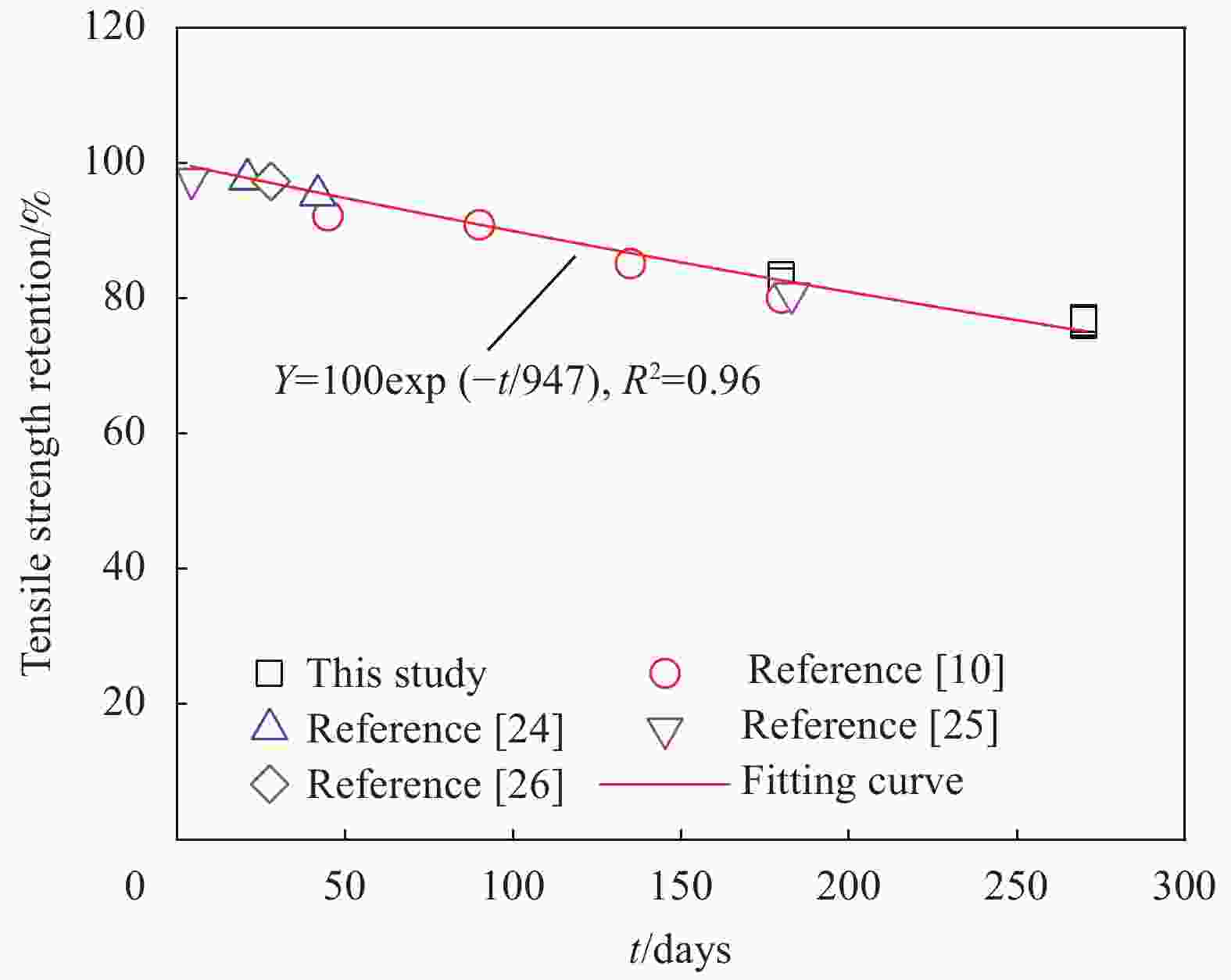

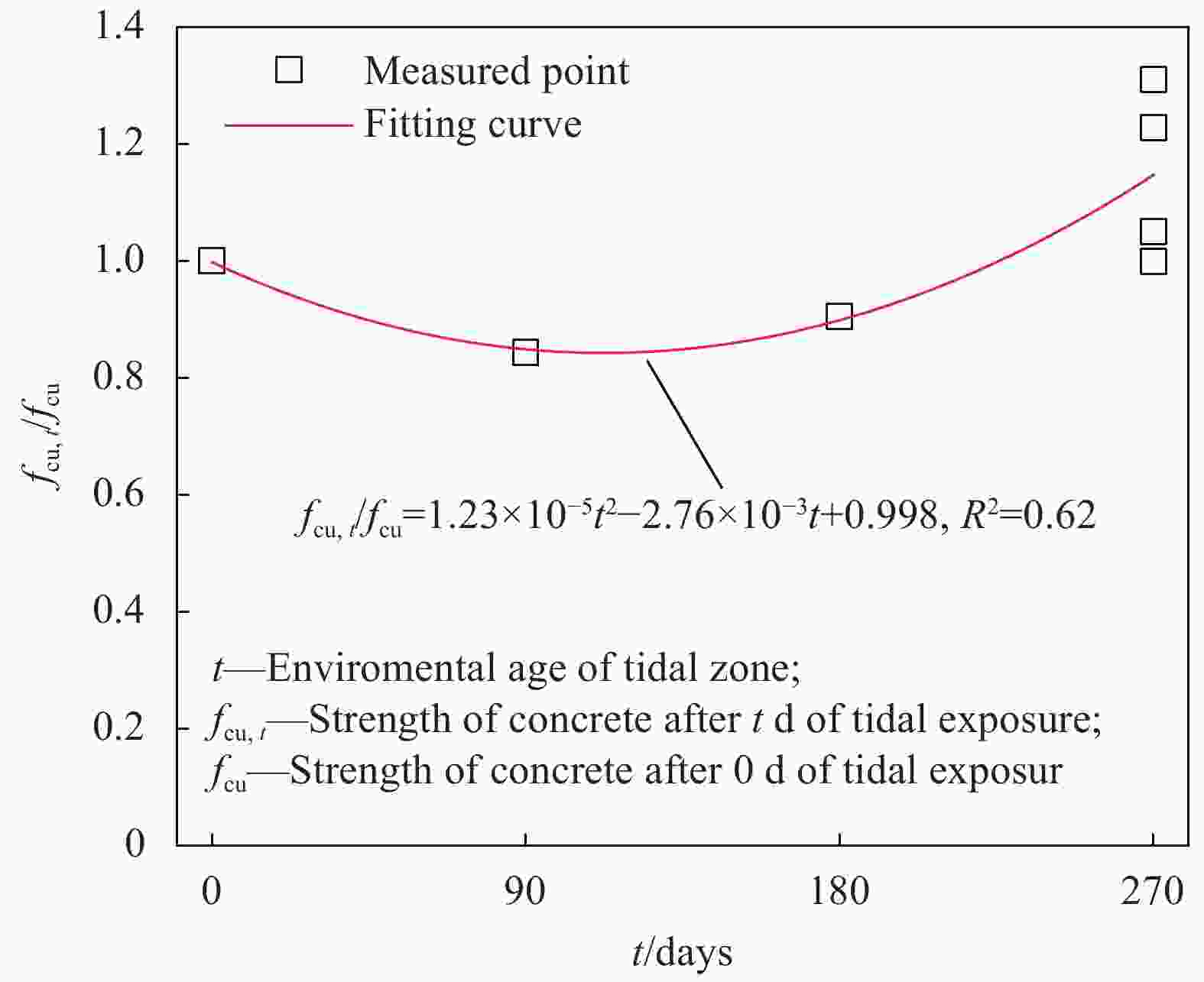

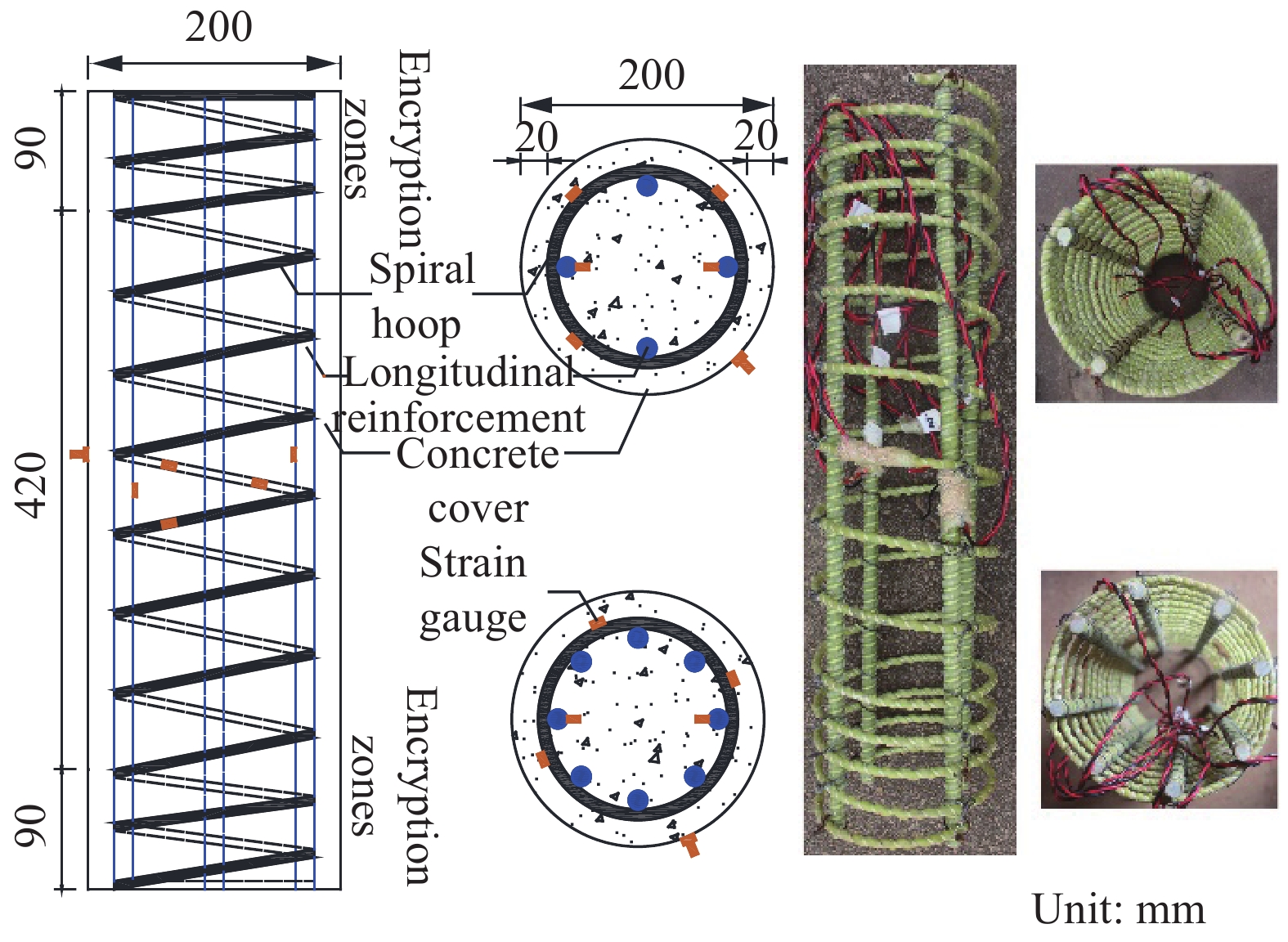

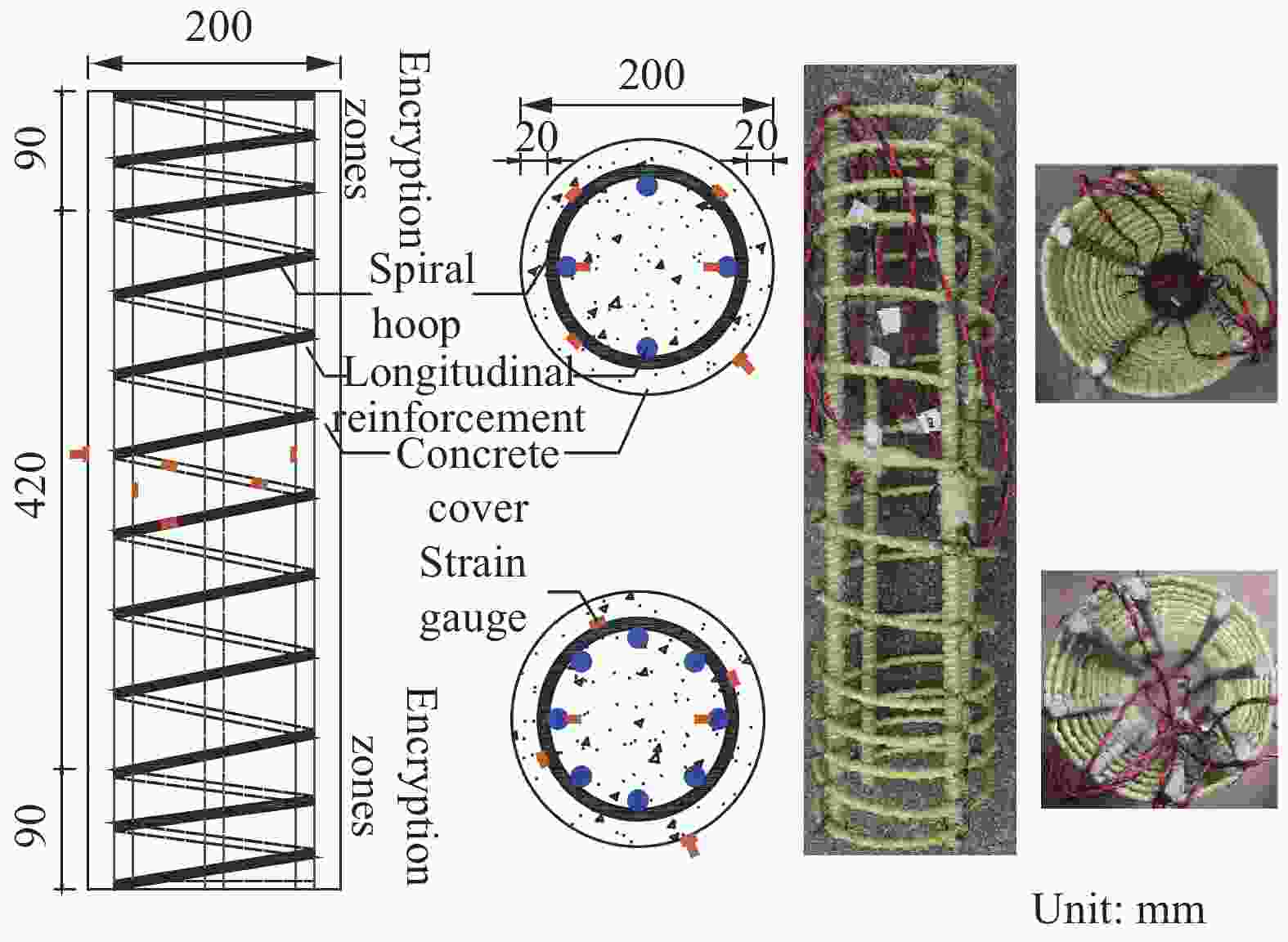

摘要: 为解决海洋工程中钢筋耐久性不足以及海上建筑材料短缺问题,提出了一种新型玻璃纤维增强树脂复合材料(GFRP)筋珊瑚海洋混凝土柱。对28个海洋潮汐区混凝土柱试件进行轴压静力加载试验,观察了受力破坏过程,获取了荷载-位移全过程曲线和特征点应力应变数据,分析了试件的受压破损机制及各参数对轴压力学性能的影响规律,并探讨了潮汐区该类新型构件的承载力计算方法。结果表明:GFRP筋珊瑚海洋混凝土柱的轴压破坏表现为表面裂缝宽而疏,粗骨料断裂,保护层混凝土被分割成条带状;与配钢筋试件相比,GFRP筋试件的承载力降低了38%,特征点应变也更小;在GFRP筋试件中,增大纵筋或螺旋箍筋配筋率并不能显著提高其承载能力,但可提高其变形性能;在270天范围内的短期潮汐环境下,试件的承载力先降低后升高,轴压延性呈波动变化趋势且变化幅值为25%。最后,拟合并引入材料性能变化参数得出潮汐区GFRP筋珊瑚海洋混凝土柱承载力计算公式。Abstract: In order to solve insufficient durability of steel bars and shortage of offshore construction materials, a new type of glass fiber reinforced polymer (GFRP) bars reinforced coral aggregate marine concrete column was proposed. 28 columns in marine tidal area were tested under axial compression. Firstly, the failure process of the specimens was observed, the load-displacement curves and the stress-strain data were obtained. Then, the failure mechanism of the specimens and the influence of various parameters on the mechanical properties were analyzed. At last, the bearing capacity calculation of this new type of member in the tidal area was discussed. The results show that the failure modes of GFRP bars reinforced coral aggregate marine concrete columns include wide and sparse cracks on the surface, coarse aggregate fracture and cover concrete divided into strips. Compared with the reinforced concrete (RC) specimen, the bearing capacity of GFRP bars reinforced coral aggregate marine concrete specimen decreases by 38%, and the strain of characteristic points is smaller. For GFRP specimens, increasing the reinforcement ratio of longitudinal bars or spiral stirrups can’t effectively improve the bearing capacity of specimens, but can improve their deformation performance. In the short-term tidal environment within 270 days, the bearing capacity of specimens first decreases and then increases, and the ductility shows a fluctuating trend with a variation amplitude of 25%. Finally, the calculation formulas for calculating the bearing capacity of the GFRP bars reinforced coral aggregate marine concrete columns in the tidal area were proposed by fitting and introducing variation parameters of material property.

-

表 1 玻璃纤维增强树脂复合材料(GFRP)筋珊瑚海洋混凝土柱参数及主要结果

Table 1. Details of specimens and main results of glass fiber reinforced polymer (GFRP) bars reinforced coral aggregate marine concrete columns

Specimen number t/d Strength grade Aggregate type RP d/mm s/mm ρv/% ρh/% Nu/kN μ P-0 0 C30 Gravel — — — — — 410.5 — G-C30@2S30-0 0 C30 Gravel 4

6 30 2.00 2.55 819 1.69 G-C30@2S30-270 270 C30 Gravel 4

6 30 2.00 2.55 801.5 2.13 S-LC30@2S30-0 0 LC30 Coral 4

6 30 2.00 2.55 1331 1.46 G-LC20@2S30-0 0 LC20 Coral 4

6 30 2.00 2.55 584.5 1.64 G-LC25@2S30-0 0 LC25 Coral 4

6 30 2.00 2.55 636.5 2.72 G-LC30@2S30-0 0 LC30 Coral 4

6 30 2.00 2.55 889.5 1.74 G-LC35@2S30-0 0 LC35 Coral 4

6 30 2.00 2.55 919 0.94 G-LC30@1S30-0 0 LC30 Coral 4

6 30 1.46 2.55 799.5 1.27 G-LC30@3S30-0 0 LC30 Coral 4

6 30 2.63 2.55 902 1.77 G-LC30@4S30-0 0 LC30 Coral 8

6 30 2.97 2.55 903 1.40 G-LC30@5S30-0 0 LC30 Coral 8

6 30 4.07 2.55 915 1.05 G-LC30@2S30-90 90 LC30 Coral 4

6 30 2.00 2.55 740.5 1.30 G-LC30@2S30-180 180 LC30 Coral 4

6 30 2.00 2.55 899 1.81 G-LC20@2S30-270 270 LC20 Coral 4

6 30 2.00 2.55 652.5 2.17 G-LC25@2S30-270 270 LC25 Coral 4

6 30 2.00 2.55 738 1.74 G-LC30@2S30-270 270 LC30 Coral 4

6 30 2.00 2.55 937 1.36 G-LC35@2S30-270 270 LC35 Coral 4

6 30 2.00 2.55 1164.5 0.82 G-LC30@1S30-270 270 LC30 Coral 4

6 30 1.46 2.55 826.5 1.54 G-LC30@3S30-270 270 LC30 Coral 4

6 30 2.63 2.55 945 1.32 G-LC30@4S30-270 270 LC30 Coral 8

6 30 2.97 2.55 1014.5 1.27 G-LC30@5S30-270 270 LC30 Coral 8

6 30 4.07 2.55 1030 1.19 G-LC30@2S40-270 270 LC30 Coral 4

6 40 2.00 1.91 880 1.31 G-LC30@2S50-270 270 LC30 Coral 4

6 50 2.00 1.52 905.5 1.20 G-LC30@2S60-270 270 LC30 Coral 4

6 60 2.00 1.27 831.5 1.18 G-LC30@2S70-270 270 LC30 Coral 4

6 70 2.00 1.09 889.5 1.17 G-LC30@2S80-270 270 LC30 Coral 4

6 80 2.00 0.96 892.5 1.16 G-LC30@2S100-270 270 LC30 Coral 4

6 100 2.00 0.76 836.5 1.15 Notes:In the specimen number, the initials P, G and S represent no reinforcement, GFRP bar and steel bar, respectively; C and LC represent ordinary aggregate concrete and coral aggregate concrete, respectively; @ represents the form of longitudinal reinforcement; S represents the spacing of spiral reinforcement; the number at the end represents the exposure age of tidal environment. t—Environmental age of tidal zone; RP—Reinforcement pattern of longitudinal bar; d—Diameter of spiral hoop; s—Spacing of spiral hoop; ρv and ρh—Longitudinal reinforcement ratio and spiral hoop ratio respectively; Nu—Peak load; μ—Ductility coefficient under axial compression. 表 2 混凝土配合比及实测性能

Table 2. Mix proportions of concrete and measured properties

SG CA/

(kg·m−3)Sand/

(kg·m−3)Cement/

(kg·m−3)Water/

(kg·m−3)AW/

(kg·m−3)PCA/

(kg·m−3)W/C Slump/

mmDensity/

(kg·m−3)Cube strength/MPa 0 day 90 days 180 days 270 days C30 1209 543 453 195 0 0 0.43 115 2506 39.9 — — 39.2 LC20 656 760 375 180 75 0.59 0.48 103 2106 17.6 — — 21.7 LC25 656 760 410 180 75 0.64 0.44 79 2153 24.0 — — 31.5 LC30 656 760 535 185 75 0.84 0.35 64 2219 39.3 33.1 35.1 39.2 LC35 656 760 625 185 75 0.98 0.30 63 2329 47.2 — — 49.6 Notes:SG—Concrete grade; CA—Coarse aggregate; AW—Additional water; PCA—Water reducing agent; W/C—Mass ratio of water to cement; C—Strength of ordinary concrete; LC—Strength of coral coarse aggregate concrete. 表 3 钢筋和GFRP筋性能

Table 3. Properties of steel and GFRP bars

Reinforcement type Diameter/mm Elastic modulus/GPa Elongation/% Yield strength/MPa Ultimate strength/MPa 0 day 180 days 270 days GFRP bar 6 40 1.30 — 670 546 509 12 40 1.32 — 662 544 511 14 40 1.28 — 618 516 472 16 40 1.30 — 672 555 517 Steel bar 6 200 — 341 438 — — 14 200 10.6 442 586 — — 表 4 GFRP筋珊瑚海洋混凝土柱特征点应力与应变

Table 4. Stress and strain on characteristic point of GFRP bars reinforced coral aggregate marine concrete columns

Specimen number First through crack Peak load Restraint enhancement σc/MPa εcv/10−6 εch/10−6 εcc/10−6 σp/MPa εpv/10−6 εph/10−6 εpc/10−6 σr/MPa εrv/10−6 εrh/10−6 εrc/10−6 G-C30@2S30-0 — — — — 26.07 4 964 2 986 2 023 — — — — G-C30@2S30-270 — — — — 25.51 4 759 2 724 1 515 — — — — S-LC30@2S30-0 23.95 988 791 — 39.37 5 178 1 423 — 42.34 8788 1734 — G-LC20@2S30-0 10.19 921 60 466 18.61 9 035 6 052 1 433 15.98 4 343 1 486 1 373 G-LC25@2S30-0 10.44 508 42 649 20.26 5 535 5 187 1 306 16.3 1 407 208 1 042 G-LC30@2S30-0 15.09 880 95 514 28.31 3 383 616 1 507 24.96 4 922 3 007 1 518 G-LC35@2S30-0 16.20 868 116 606 29.25 4 151 1 233 1 439 26.36 5 429 1 209 1 439 G-LC30@1S30-0 16.93 1 188 191 656 25.45 3 153 514 1 395 24.67 4 123 913 1 215 G-LC30@3S30-0 25.27 1 780 79 1 285 28.71 2 452 298 1 677 27.41 2 924 313 1 746 G-LC30@4S30-0 19.07 1 272 345 1 488 28.74 2 490 1 531 1 754 26.45 2 688 3 190 1 754 G-LC30@5S30-0 17.22 687 243 600 29.13 2 346 2 213 1 071 28.04 2 682 2 929 1 189 G-LC30@2S30-90 17.79 1 290 167 942 23.57 3 113 715 1 598 20.09 3 806 1 994 1 902 G-LC30@2S30-180 16.52 1 060 56 676 28.62 2 705 589 1 326 27.15 2 300 656 1 268 G-LC20@2S30-270 12.16 905 53 919 20.77 5 002 3 303 2 308 18.91 4 316 1 329 2 308 G-LC25@2S30-270 12.45 — 88 465 23.49 — 3 769 1 960 22.19 — 556 1 941 G-LC30@2S30-270 26.13 2 260 373 705 29.83 3 473 1 687 — 28.07 3 715 1 845 — G-LC35@2S30-270 17.60 1 569 156 702 37.07 3 939 429 1 433 32.91 4 005 736 2 974 G-LC30@1S30-270 20.44 600 197 — 26.31 1 576 1 927 — 22.35 1 700 2 191 — G-LC30@3S30-270 26.32 2 284 134 1 184 30.08 3 580 355 1 966 24.61 4 043 577 1 966 G-LC30@4S30-270 29.09 1 631 216 1 505 32.29 2 024 443 1 581 26.36 2 273 845 1 518 G-LC30@5S30-270 24.22 1 379 235 2 055 32.79 2 857 397 2 451 30.78 1 605 637 2 159 G-LC30@2S40-270 15.53 1 287 255 753 28.01 3 036 644 1 406 26.8 1 908 970 1 170 G-LC30@2S50-270 24.45 1 999 251 705 28.82 2 407 454 1 065 22.89 2 915 1 166 1 179 G-LC30@2S60-270 17.13 633 15 1 011 26.47 1 921 125 1 951 24.19 2 171 247 1 951 G-LC30@2S70-270 18.68 787 24 899 28.31 1 764 306 2 061 26.99 1 817 322 2 061 G-LC30@2S80-270 15.09 1 213 146 880 28.41 2 747 278 2 138 25.37 3 137 744 2 241 G-LC30@2S100-270 15.79 627 91 903 26.63 2 531 512 1 779 21.39 3 037 837 1 779 Notes:σc, σp and σr—Stress of the specimen at first through crack, peak load and restraint enhancement respectively; εxv, εxh and εxc (x=c, p, r)—Strain of longitudinal bar, spiral hoop and concrete at each characteristic point respectively. 表 5 GFRP筋珊瑚海洋混凝土柱承载力试验值与计算值比较

Table 5. Comparison between test values and calculated values of GFRP bars reinforced coral aggregate marine concrete columns bearing capacity

Specimen number Test value Nu/kN Calculated value Nu, c/kN Formula (9) Formula (10) Formula (11) Nu, c1 Nu, c1/Nu Nu, c2 Nu, c2/Nu Nu, c3 Nu, c3/Nu G-LC20@2S30-0 584.5 369.3 0.63 378.1 0.65 514.3 0.88 G-LC25@2S30-0 636.5 503.1 0.79 498.8 0.78 648.0 1.02 G-LC30@2S30-0 889.5 822.4 0.92 787.1 0.88 967.3 1.09 G-LC35@2S30-0 919.0 988.1 1.08 936.7 1.02 1133.0 1.23 G-LC30@1S30-0 799.5 826.7 1.03 775.2 0.97 924.6 1.16 G-LC30@3S30-0 902.0 817.3 0.91 800.7 0.89 1006.6 1.12 G-LC30@4S30-0 903.0 814.7 0.90 808.0 0.89 1010.4 1.12 G-LC30@5S30-0 915.0 805.9 0.88 802.6 0.88 1095.8 1.20 G-LC30@2S30-90 740.5 588.9 0.80 572.3 0.77 720.7 0.97 G-LC30@2S30-180 899.0 661.2 0.74 633.9 0.71 781.1 0.87 G-LC20@2S30-270 652.5 521.2 0.80 504.1 0.77 630.2 0.97 G-LC25@2S30-270 738.0 758.0 1.03 717.9 0.97 866.9 1.17 G-LC30@2S30-270 937.0 944.7 1.01 886.5 0.95 1053.7 1.12 G-LC35@2S30-270 1164.5 1192.9 1.02 1110.6 0.95 1301.9 1.12 G-LC30@1S30-270 826.5 949.7 1.15 877.6 1.06 1023.3 1.24 G-LC30@3S30-270 945.0 938.9 0.99 896.7 0.95 1081.2 1.14 G-LC30@4S30-270 1014.5 935.8 0.92 902.2 0.89 1083.0 1.07 G-LC30@5S30-270 1030.0 925.8 0.90 886.6 0.86 1143.7 1.11 G-LC30@2S40-270 880.0 944.7 1.07 886.5 1.01 1053.7 1.20 G-LC30@2S50-270 905.5 944.7 1.04 886.5 0.98 1053.7 1.16 G-LC30@2S60-270 831.5 944.7 1.14 886.5 1.07 1053.7 1.27 G-LC30@2S70-270 889.5 944.7 1.06 886.5 1.00 1053.7 1.18 G-LC30@2S80-270 892.5 944.7 1.06 886.5 0.99 1053.7 1.18 G-LC30@2S100-270 836.5 944.7 1.13 886.5 1.06 1053.7 1.26 Average value v 0.958 0.915 1.118 Standard deviation D 0.130 0.108 0.105 Coefficient of variation Cv 0.136 0.118 0.094 -

[1] 李哲, 金祖权, 邵爽爽. 海洋环境下混凝土中钢筋锈蚀机理及监测技术概述[J]. 材料导报, 2018, 32(23):4170-4181. doi: 10.11896/j.issn.1005-023X.2018.23.019LI Z, JIN Z Q, SHAO S S. A review on reinforcement corrosion mechanics and monitoring techniques in concrete in marine environment[J]. Materials Reports,2018,32(23):4170-4181(in Chinese). doi: 10.11896/j.issn.1005-023X.2018.23.019 [2] ZHAO Y, KARIMI A R, WONG H S. Comparison of uniform and non-uniform corrosion induced damage in reinforced concrete based on a Gaussian description of the corrosion layer[J]. Corrosion Science,2011,53(9):2803-2814. doi: 10.1016/j.corsci.2011.05.017 [3] 金伟良, 赵羽习, 鄢飞. 钢筋混凝土构件的均匀钢筋锈胀力的机理研究[J]. 水利学报, 2001(7):57-62. doi: 10.3321/j.issn:0559-9350.2001.07.010JIN W L, ZHAO Y X, YAN F. The mechanism of corroded expansion force of reinforced concrete members[J]. Journal of Hydraulic Engineering,2001(7):57-62(in Chinese). doi: 10.3321/j.issn:0559-9350.2001.07.010 [4] 金祖权, 赵铁军, 庄其昌. 劈裂裂缝混凝土在海洋潮汐区的氯离子传输[J]. 土木建筑与环境工程, 2012, 34(2):52-57.JIN Z Q, ZHAO T J, ZHUANG Q C. Chloride transport in splitting cracked concrete at marine tidal zone[J]. Journal of Civil Architectural & Environmental Engineering,2012,34(2):52-57(in Chinese). [5] ALI N M, WANG X, WU Z, et al. Integrated performance of frp tendons with fiber hybridization[J]. Journal of Composites for Construction,2014,18(3):A4013007. [6] WANG X, WANG Z, WU Z, et al. Shear behavior of basalt fiber reinforced polymer (FRP) and hybrid FRP rods as shear resistance members[J]. Construction and Building Materials,2014,73:781-789. [7] 薛伟辰, 王伟, 付凯. 碱环境下不同应力水平GFRP筋抗拉性能试验[J]. 复合材料学报, 2013, 30(6):67-75. doi: 10.3969/j.issn.1000-3851.2013.06.010XUE W C, WANG W, FU K. Experimental study on tensile properties of GFRP rebars under different stress levels as exposed to alkaline solution[J]. Acta Materiae Compositae Sinica,2013,30(6):67-75(in Chinese). doi: 10.3969/j.issn.1000-3851.2013.06.010 [8] 付凯, 王伟, 薛伟辰. 模拟混凝土环境下GFRP筋抗压性能加速老化试验研究[J]. 建筑结构学报, 2013, 34(1):117-122.FU K, WANG W, XUE W C. Accelerated aging test for evaluation of compressive properties of GFRP rebars under simulated concrete environment[J]. Journal of Building Structures,2013,34(1):117-122(in Chinese). [9] 邓宗才, 高伟男, 沈锋. 碱、盐环境下不同应力水平FRP筋抗压强度试验与理论研究[J]. 复合材料学报, 2017, 34(10):2220-2231.DENG Z C, GAO W N, SHEN F. Experimental and theoretical study on compressive strength of FRP rebars under different stress levels in alkali and salt solution[J]. Acta Materiae Compositae Sinica,2017,34(10):2220-2231(in Chinese). [10] 宣广宇, 陆春华, 徐可, 等. 不同侵蚀环境下GFRP筋抗拉性能退化试验[J]. 哈尔滨工业大学学报, 2020, 52(8): 161-168.XUAN G Y, LU C H, XU K, et al. Experiment on tensile properties of GFRP bars exposed to different aggressive environments[J]. Journal of Harbin Institute of Technology, 2020, 52(8): 161-168 (in Chinese). [11] 巩位, 余红发, 麻海燕, 等. 全珊瑚海水混凝土配合比设计及评价方法[J]. 材料导报, 2019, 33(22):3732-3737. doi: 10.11896/cldb.18100082GONG W, YU H F, MA H Y, et al. Mix proportion design and evaluation approach of coral aggregate seawater concrete[J]. Materials Reports,2019,33(22):3732-3737(in Chinese). doi: 10.11896/cldb.18100082 [12] 陈宗平, 周济, 陈宇良, 等. 珊瑚粗骨料海水混凝土力学性能试验研究[J]. 应用力学学报, 2020, 37(5):1999-2006.CHEN Z P, ZHOU J, CHEN Y L, et al. Experimental study on mechanical properties of coral coarse aggregate seawater concrete[J]. Chinese Journal of Applied Mechanics,2020,37(5):1999-2006(in Chinese). [13] 苏晨, 麻海燕, 余红发, 等. 不同珊瑚骨料对珊瑚混凝土力学性能的影响[J]. 硅酸盐学报, 2020, 48(11):1771-1780.SU C, MA H Y, YU H F, et al. Effect of different coral aggregates on mechanical properties of coral concrete[J]. Journal of the Chinese Ceramic Society,2020,48(11):1771-1780(in Chinese). [14] 吴家文, 马林建, 孔新立, 等. 冲击荷载下全珊瑚混凝土动力特性[J]. 建筑材料学报, 2020, 23(3):581-588.WU J W, MA L J, KONG X L, et al. Dynamic characteristics of coral concrete under impact load[J]. Journal of Building Materials,2020,23(3):581-588(in Chinese). [15] 刘霞, 李峰, 佘殷鹏. 玄武岩纤维增强聚合物筋增强珊瑚礁砂混凝土柱轴压试验[J]. 复合材料学报, 2020, 37(10):2428-2438.LIU X, LI F, SHE Y P. Axial compression test of basalt fiber reinforced polymer reinforced coral reef and sand aggregate concrete column[J]. Acta Materiae Compositae Sinica,2020,37(10):2428-2438(in Chinese). [16] 陈爽, 梁淑嘉, 关纪文. FRP筋-珊瑚混凝土柱轴心受压承载力[J]. 复合材料学报, 2021, 38(10): 3519-3530.CHEN S, LIANG S J, GUAN J W. Compression behaveior of FRP bars-coral concrete columns under axial compression loading[J]. Acta Materiae Compositae Sinica, 2021, 38(10): 3519-3530 (in Chinese). [17] 中华人民共和国住房和城乡建设部. 轻骨料混凝土技术规程: JGJ 51—2002[S]. 北京: 中国建筑工业出版社, 2002.Ministry of Housing and Urban-Rural Development of the Pepeple’s Republic of China. Technical specification for lightweight aggregate concrete: JGJ 51—2002[S]. Beijing: China Architecture & Building Press, 2002 (in Chinese). [18] 国家标准局. 纤维增强塑料性能试验方法总则: GB/T 1446—2005[S]. 北京: 中国标准出版社, 2005.National Bureau of Standards. Fiber-reinforced plastics composites-The generals for determination of properties: GB 1446—2005[S]. Beijing: China Standard Press, 2005 (in Chinese). [19] 国家标准局. 金属材料拉伸部分: 室温试验方法: GB/T228.1—2010[S]. 北京: 中国标准出版社, 2010.National Bureau of Standards. Metallic materials-Tensile testing-Part 1: Method of test at room temperature: GB/T 228.1—2010[S]. Beijing: China Standard Press, 2010 (in Chinese). [20] 达波, 余红发, 麻海燕. 全珊瑚海洋混凝土单轴受压应力-应变全曲线试验研究[J]. 建筑结构学报, 2017, 38(1):144-151.DA B, YU H F, MA H Y. Experimental research on whole stress-strain curves of coral aggregate seawater concrete under uniaxial compression[J]. Journal of Building Structures,2017,38(1):144-151(in Chinese). [21] MALLICK P K. Fiber-reinforced composites: materials, manufacturing, and design [M]. New York: CRC Press, 2007: 469. [22] 金祖权, 孙伟, 张云升, 等. 混凝土在硫酸盐、氯盐溶液中的损伤过程[J]. 硅酸盐学报, 2006(5):630-635. doi: 10.3321/j.issn:0454-5648.2006.05.025JIN Z Q, SUN W, ZHANG Y S, et al. Damage of concrete in sulfate and chloride solution[J]. Journal of the Chinese Ceramic Society,2006(5):630-635(in Chinese). doi: 10.3321/j.issn:0454-5648.2006.05.025 [23] DAVALOS J F, CHEN Y, RAY I, et al. Long-term durability prediction models for GFRP bars in concrete environment[J]. Journal of Composite Materials,2012,46(16):1899-1914. doi: 10.1177/0021998311427777 [24] WANG Z, ZHAO X L, XIAN G, et al. Long-term durability of basalt- and glass-fiber reinforced polymer (BFRP/GFRP) bars in seawater and sea sand concrete environment[J]. Construction and Building Materials,2017,139:467-489. [25] 代力. 持续荷载与环境作用下混凝土梁中GFRP筋抗拉性能研究[D]. 武汉: 武汉理工大学, 2017.DAI L. Study on tensile properties of GFRP bars embedded in concrete beams[D]. Wuhan: Wuhan University of Technology, 2017 (in Chinese). [26] 张新越, 欧进萍. FRP筋酸碱盐介质腐蚀与冻融耐久性试验研究[J]. 武汉理工大学学报, 2007(1):33-36. doi: 10.3321/j.issn:1671-4431.2007.01.009ZHANG X Y, OU J P. Durability experimental research on resistance of acidic, alkali, salt solutions and freeze-thaw properties of FRP bar[J]. Journal of Wuhan University of Technology,2007(1):33-36(in Chinese). doi: 10.3321/j.issn:1671-4431.2007.01.009 [27] CSA (Canadian Standards Association). Design and construction of building structures with fibre-reinforced polymers: CSA S806—12[S]. Toronto, Canada: Canadian Standards Association International, 2012. [28] 国家标准局. 纤维增强复合材料工程应用技术标准 GB 50608—2011[S]. 北京: 中国计划出版社, 2011.National Bureau of Standards. Technical code for infrastructure application of FRP composites: GB 50608—2011[S]. Beijing: China Planning Press, 2011 (in Chinese). [29] 国家标准局. 混凝土结构设计规范 GB 50010—2010[S]. 北京: 中国计划出版社, 2010.National Bureau of Standards. Code for design concrete structures: GB 50010—2010[S]. Beijing: China Planning Press, 2010 (in Chinese). [30] TOBBI H, FARGHALY A S, BENMOKRANE B. Concrete columns reinforced longitudinally and transversally with glass fiber-reinforced polymer bars[J]. ACI Structural Journal,2012,109(4):551-558. -

下载:

下载: