Ply optimization of carbon fiber reinforced plastic control arm based on grey relational analysis

-

摘要: 采用碳纤维增强树脂复合材料(CFRP)对悬架控制臂进行轻量化设计,为了充分发挥CFRP优异的力学性能,对CFRP控制臂进行多目标铺层优化。基于CFRP力学性能试验结果构建控制臂有限元模型,并通过有限元仿真对比分析钢质控制臂和CFRP控制臂结构性能。综合考虑质量、模态频率、刚度和强度等性能,基于正交试验设计方法,并结合灰色关联分析和主成分分析,对CFRP控制臂铺层参数进行多目标优化,确定最优铺层方案。结果表明,相比于原钢质控制臂,除纵向刚度略有下降外,CFRP控制臂其余结构性能指标均有所改善,并且质量降低40.23%,减重效果显著。

-

关键词:

- 碳纤维增强树脂复合材料 /

- 控制臂 /

- 正交试验设计 /

- 灰色关联分析 /

- 轻量化

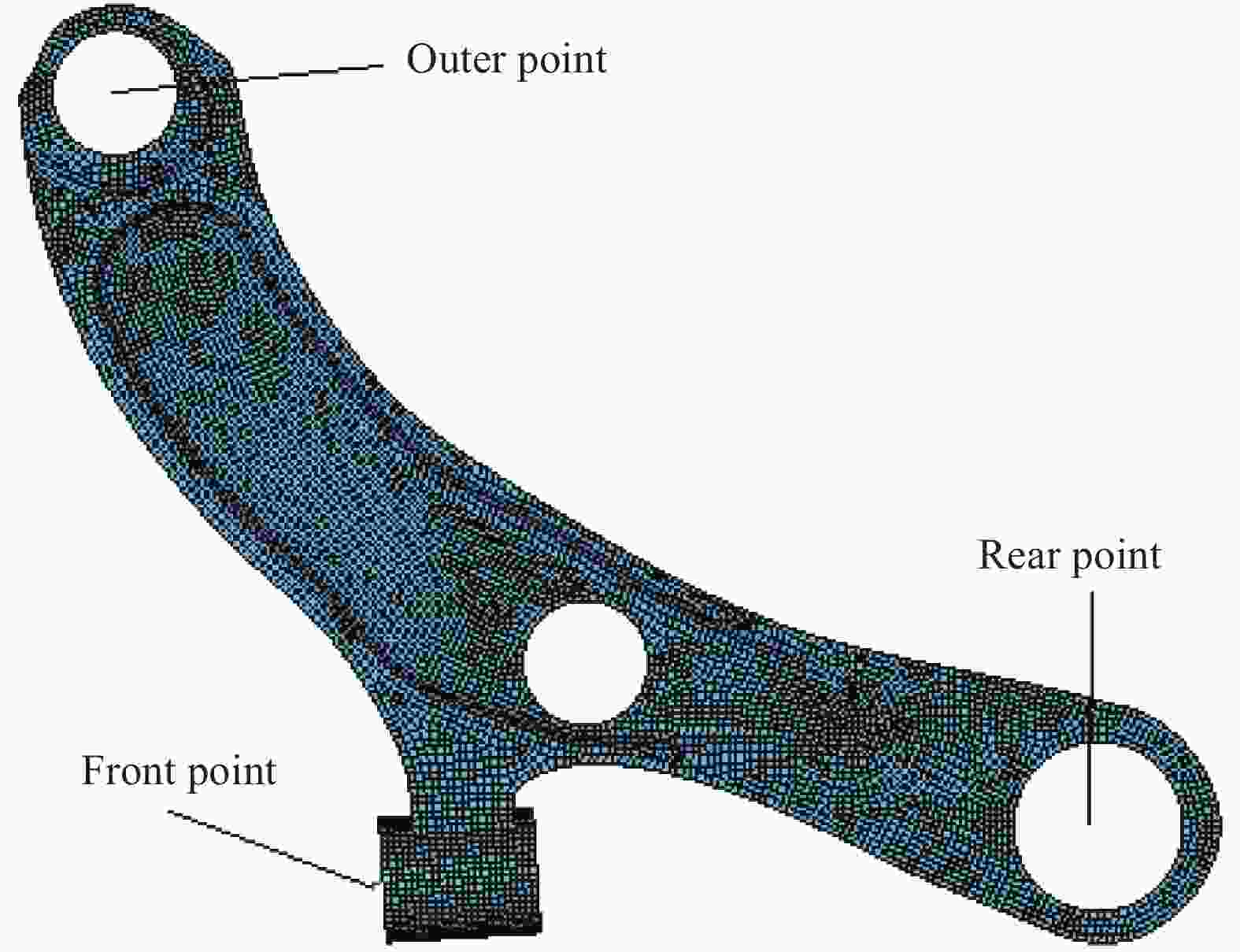

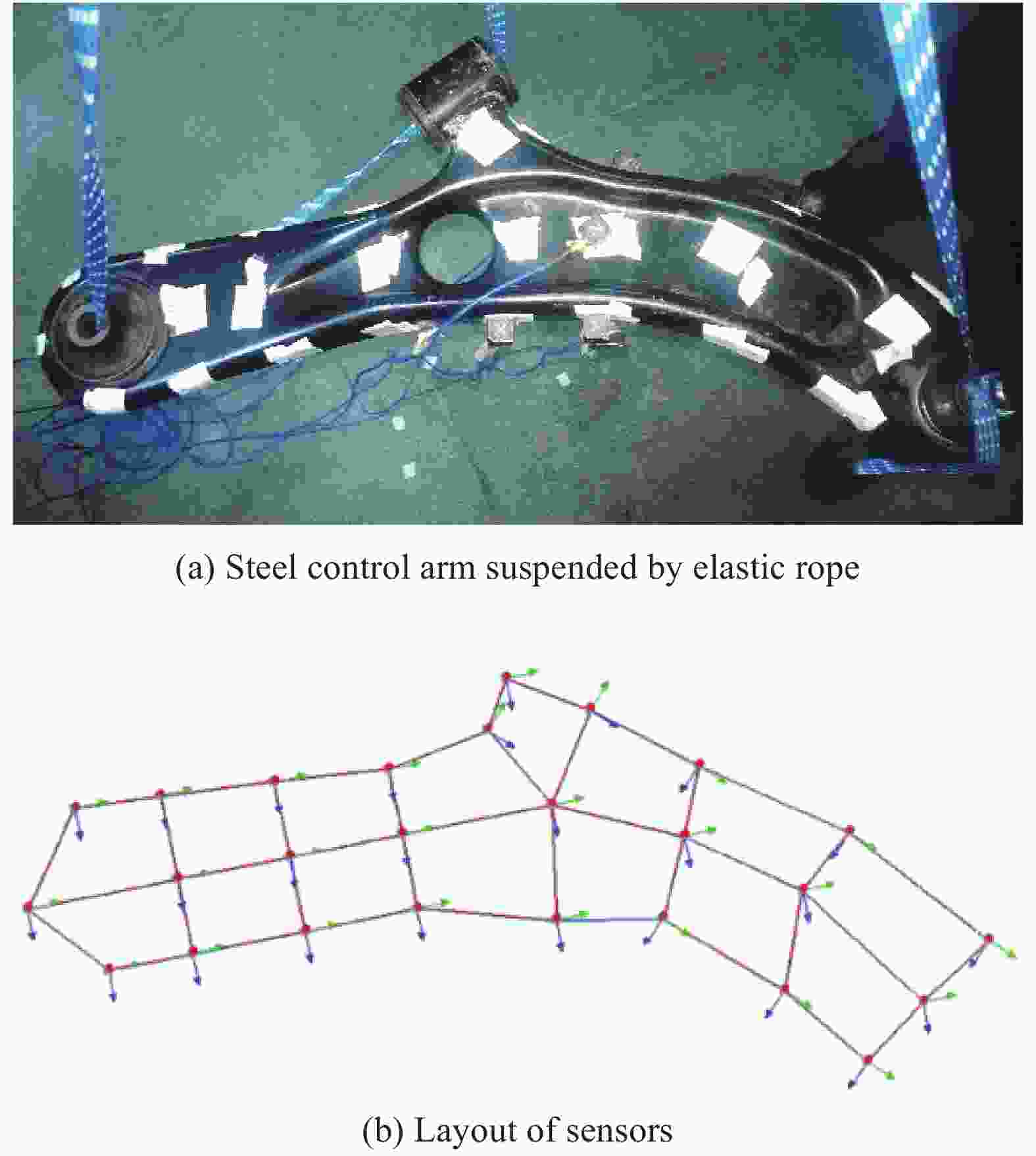

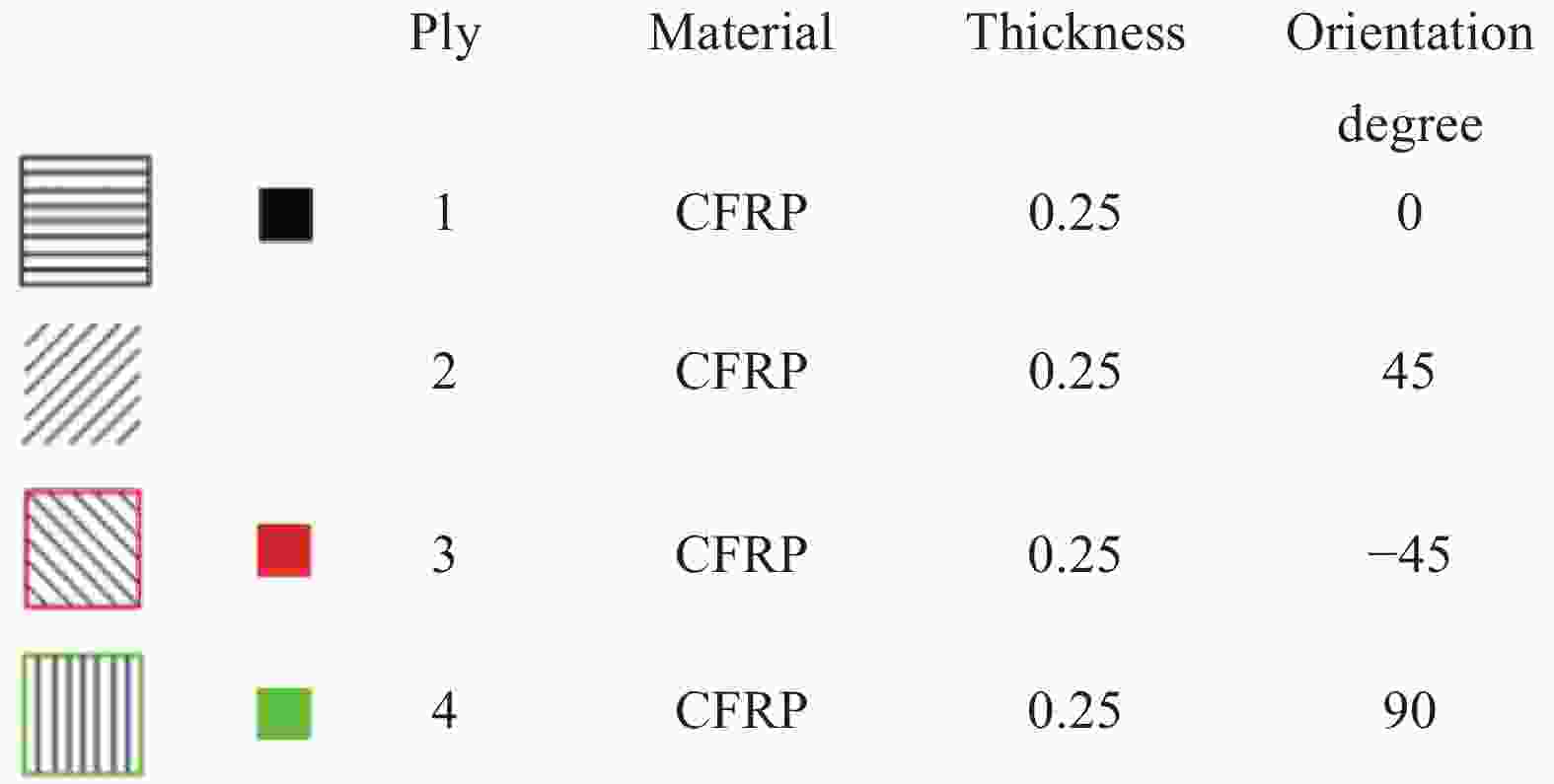

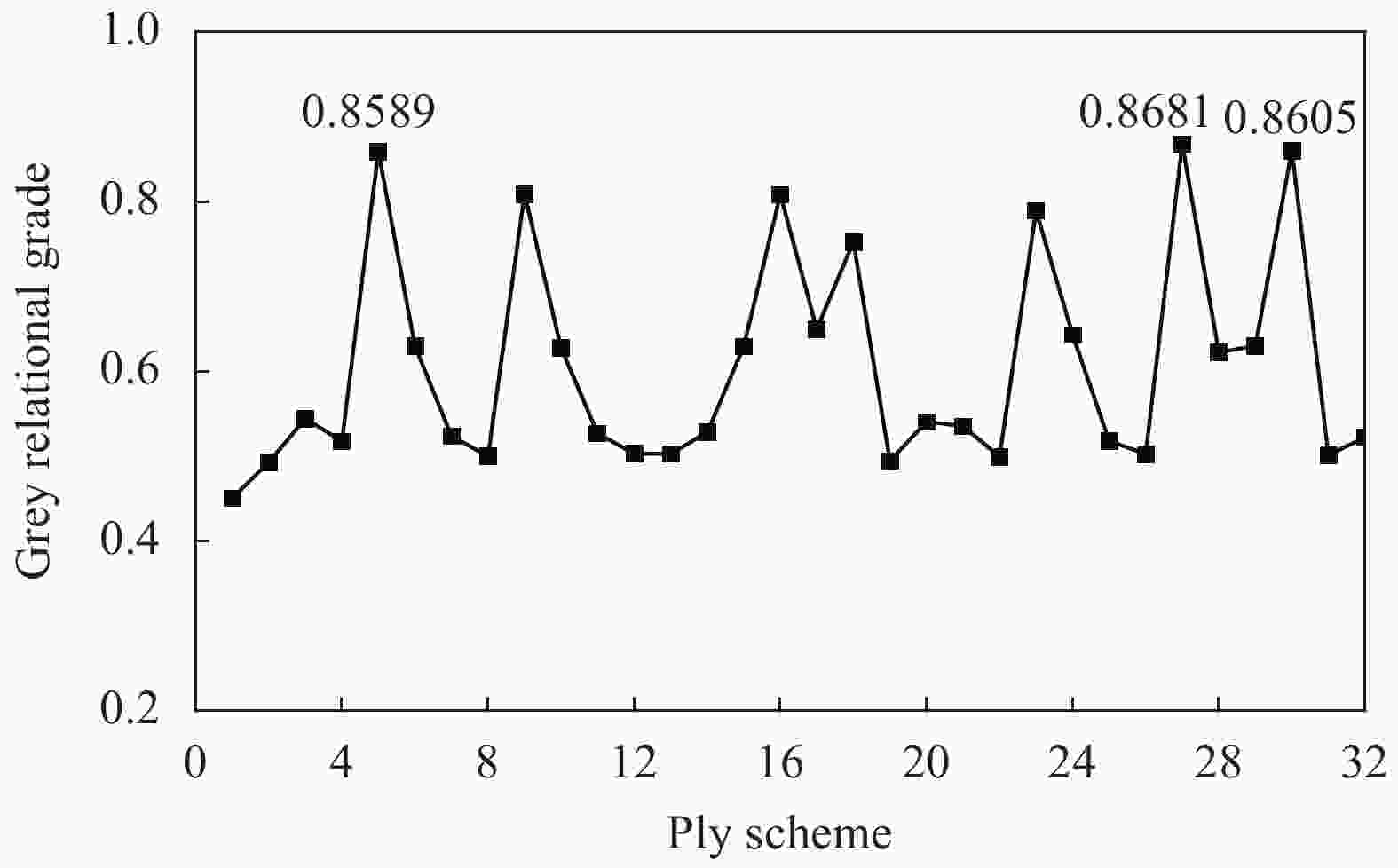

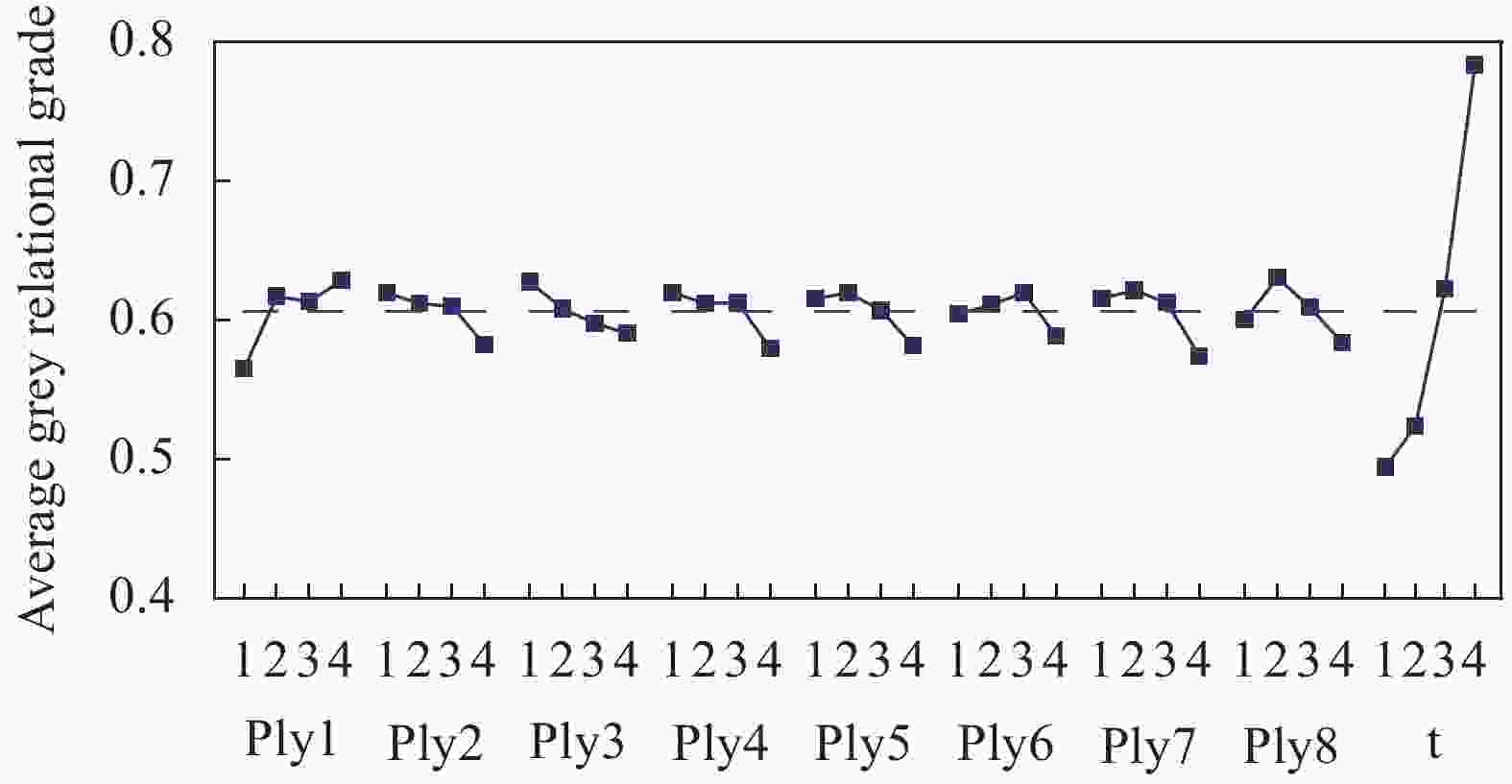

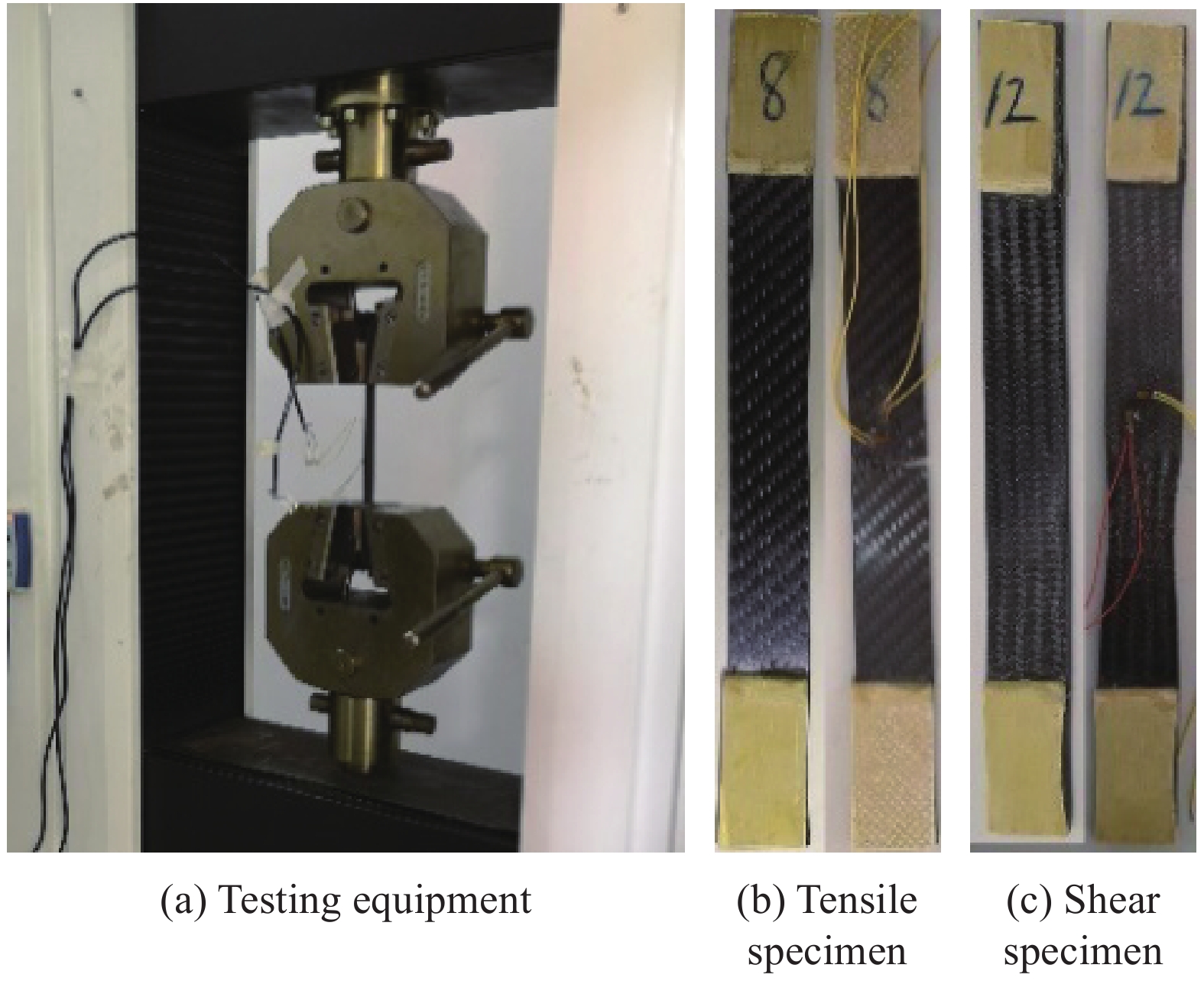

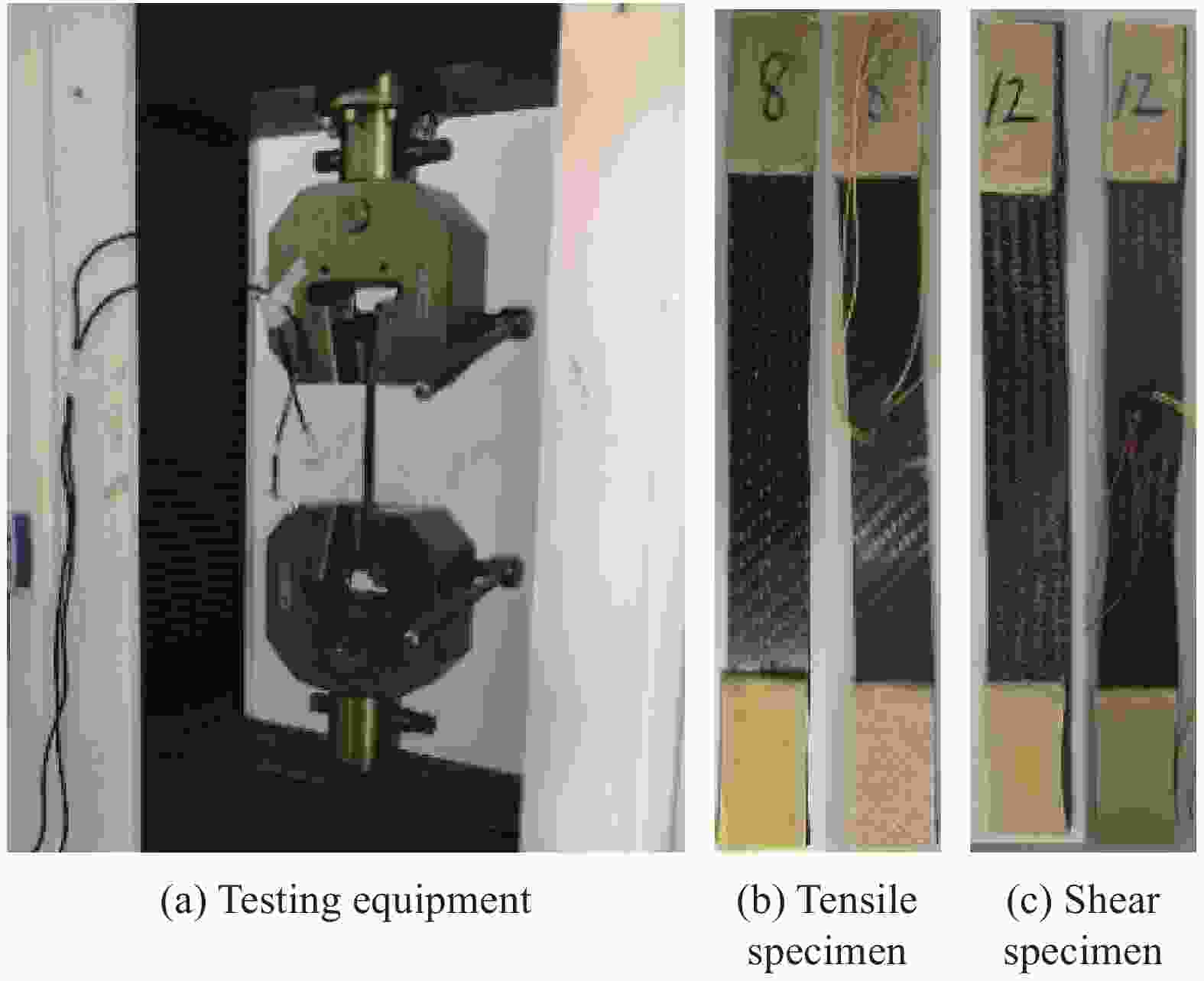

Abstract: Carbon fiber reinforced plastic (CFRP) was used for lightweight design of suspension control arm. In order to perform the excellent mechanical properties of CFRP, the multi-objective ply optimization of CFRP control arm was carried out. The finite element model of the control arm was constructed based on the test results of material mechanical properties of CFRP. And the structural properties of the steel control arm and the CFRP control arm were compared by finite element simulations. Considering the mass, modal frequency, stiffness and strength, the orthogonal experiment design method combined with grey relational analysis and principal component analysis were used to optimize the CFRP control arm ply parameters for determining the optimal ply scheme. The results show that the mass of the optimized CFRP control arm is reduced by 40.23% compared with the original steel control arm, which achieves a significant weight reduction. Meanwhile, the structural performance indexes of the optimized CFRP control arm are improved, except for a slight decrease in longitudinal stiffness. -

表 1 CFRP力学参数

Table 1. Mechanical parameters of CFRP

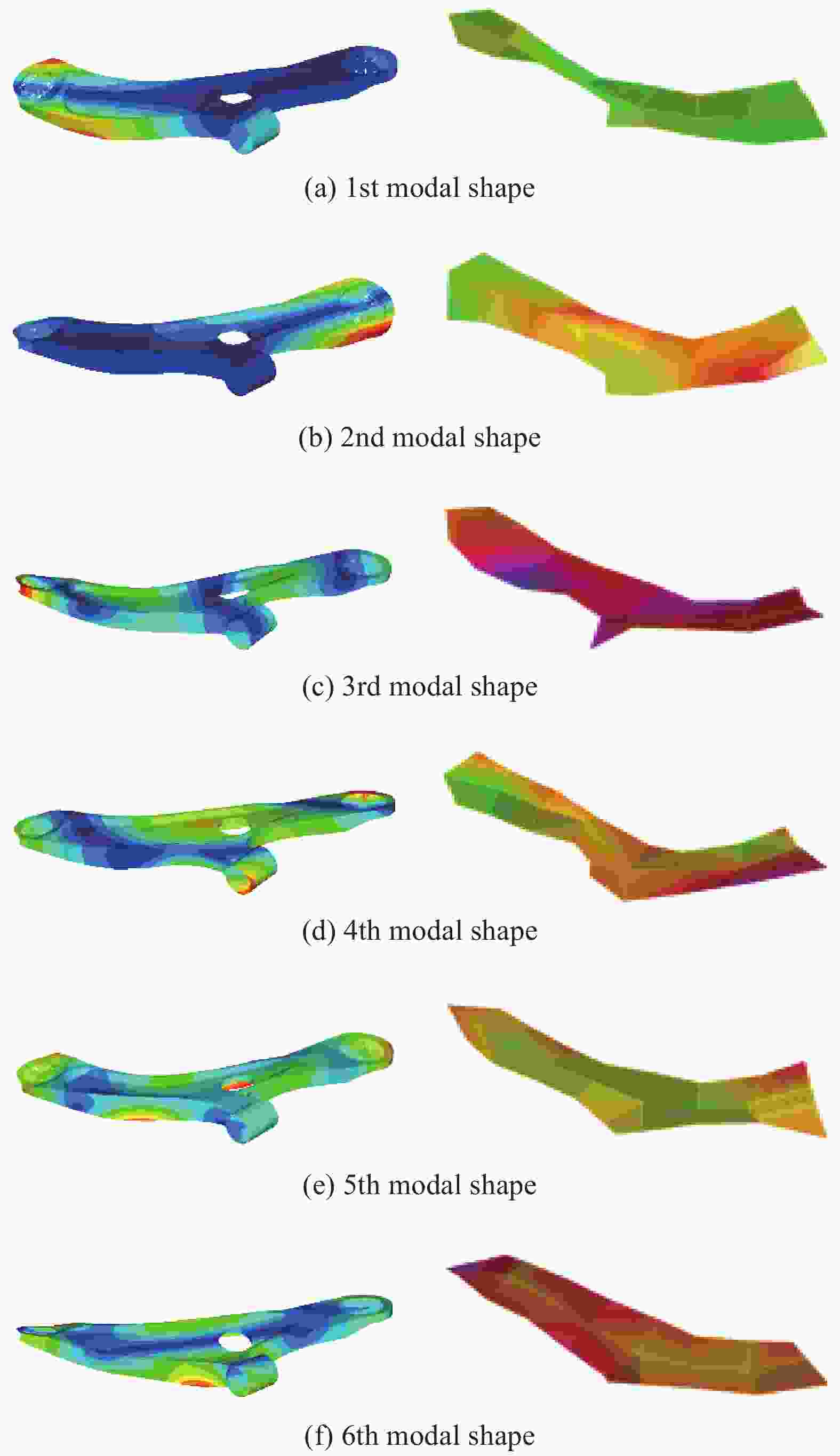

Property Value Density ρ/(g·cm−3) 1.65 Longitudinal elastic modulus E1/GPa 51.77 Transverse elastic modulus E2/GPa 51.77 Poisson’s ratio ν12 0.0369 Longitudinal tensile strength Xt/MPa 757.08 Transverse tensile strength Yt/MPa 757.08 Shear modulus G12/GPa 2.07 Shear strength S/MPa 39.02 表 2 钢质控制臂固有频率仿真与试验结果对比

Table 2. Comparison of simulation and test results of natural frequency for steel control arm

Modal

orderNatural frequency /Hz Relative

error/%Simulation value Experimental value 1 211.9 204.7 3.4 2 246.0 235.7 4.2 3 396.0 378.8 4.3 4 714.2 674.1 5.6 5 927.0 909.5 1.9 6 993.2 970.2 2.3 表 3 控制臂载荷条件

Table 3. Load cases of control arm

Position Direction Braking/N Steering/N Top speed/N Outer point Fx −739.9 638.9 −2338.7 Fy −1086.6 2613.7 −3481.7 Fz −67.6 −175.9 143.4 Front point Fx 221.8 −573.5 527.5 Fy −1886.2 2287.9 −6234.5 Fz −293.9 −407.4 −858.8 Rear point Fx 116.5 73.8 166.7 Fy 752.1 −551.7 2406.7 Fz 293.7 407.1 856.8 表 4 控制臂初始性能分析

Table 4. Initial performance analysis of control arm

Property Ply-16 Ply-34 Ply-32 Steel m/kg 1.17 1.44 1.71 2.66 f/Hz 201.8 279.7 343.5 211. 9 Kx/(kN·mm−1) 1.49 3.64 9.52 5.65 Ky/(kN·mm−1) 2.94 7.41 15.38 10.36 σb/MPa 58.8 26.3 15 92.6 σs/MPa 52.9 28.9 18.2 77.4 σv/MPa 184.65 88 50.1 295.1 Notes: m—Mass; f—The first order frequency; Kx—Longitudinal stiffness; Ky—Transverse stiffness; σb —Maximum braking stress; σs—Maximum steering stress; σv—Maximum top speed stress. 表 5 CFRP控制臂正交试验表

Table 5. Orthogonal array for CFRP control arm simulation

No. 1 2 3 4 5 6 7 8 9 1 1 1 1 1 1 1 1 1 1 2 1 2 2 2 2 2 2 2 2 3 1 3 3 3 3 3 3 3 3 4 1 4 4 4 4 4 4 4 4 5 1 1 1 2 2 3 3 4 4 6 1 2 2 1 1 4 4 3 3 7 1 3 3 4 4 1 1 2 2 8 1 4 4 3 3 2 2 1 1 9 2 1 2 3 4 1 2 3 4 10 2 2 1 4 3 2 1 4 3 11 2 3 4 1 2 3 4 1 2 12 2 4 3 2 1 4 3 2 1 13 2 1 2 4 3 3 4 2 1 14 2 2 1 3 4 4 3 1 2 15 2 3 4 2 1 1 2 4 3 16 2 4 3 1 2 2 1 3 4 17 3 1 4 1 4 2 3 2 3 18 3 2 3 2 3 1 4 1 4 19 3 3 2 3 2 4 1 4 1 20 3 4 1 4 1 3 2 3 2 21 3 1 4 2 3 4 1 3 2 22 3 2 3 1 4 3 2 4 1 23 3 3 2 4 1 2 3 1 4 24 3 4 1 3 2 1 4 2 3 25 4 1 3 3 1 2 4 4 2 26 4 2 4 4 2 1 3 3 1 27 4 3 1 1 3 4 2 2 4 28 4 4 2 2 4 3 1 1 3 29 4 1 3 4 2 4 2 1 3 30 4 2 4 3 1 3 1 2 4 31 4 3 1 2 4 2 4 3 1 32 4 4 2 1 3 1 3 4 2 Notes: In the first row of the table, the factors 1-8 represent ply angle and the factor 9 represents ply thickness; The levels 1-4 of the factors 1-8 represent 0°, 45°, −45° and 90°, respectively; The level 1-4 of the factor 9 denotes 0.15 mm, 0.2 mm, 0.25 mm and 0.3 mm, respectively. 表 6 CFRP控制臂性能指标仿真结果

Table 6. Simulation results of CFRP control arm performance

No. m/kg f/Hz Kx/(kN·mm−1) Ky/(kN·mm−1) σv/MPa 1 1.10 127.4 1.486 3.058 202.0 2 1.27 246.1 2.006 4.287 101.0 3 1.43 277.6 2.690 5.696 71.9 4 1.59 208.5 3.675 7.111 79.0 5 1.59 316.8 5.206 10.777 46.9 6 1.43 268.0 4.126 8.591 66.5 7 1.27 225.0 3.057 6.470 98.5 8 1.10 183.7 2.029 4.406 155.0 9 1.59 328.5 4.806 9.999 47.0 10 1.43 278.9 3.941 8.272 64.9 11 1.27 234.5 2.922 6.229 94.5 12 1.10 194.7 1.886 4.096 148.0 13 1.10 194.1 1.886 4.097 148.0 14 1.27 235.3 2.924 6.230 93.8 15 1.43 279.9 3.943 8.273 64.5 16 1.59 328.0 4.807 10.003 47.0 17 1.43 282.5 4.102 8.561 61.5 18 1.59 320.3 4.533 9.499 49.5 19 1.10 190.0 1.791 3.929 157.0 20 1.27 237.3 3.036 6.430 87.8 21 1.27 236.6 2.990 6.352 90.4 22 1.10 193.4 1.847 4.028 152.0 23 1.59 325.9 4.693 9.793 46.8 24 1.43 281.6 4.037 8.448 62.0 25 1.27 220.6 3.042 6.460 102.0 26 1.10 186.5 2.035 4.407 152.0 27 1.59 320.8 5.215 10.776 46.3 28 1.43 262.9 4.107 8.578 68.0 29 1.43 264.1 4.155 8.663 66.6 30 1.59 320.6 5.177 10.710 46.2 31 1.10 186.5 2.023 4.387 154.0 32 1.27 221.5 3.075 6.518 99.4 表 7 CFRP控制臂主成分分析结果

Table 7. Principal component analysis results of CFRP control arm

Property Eigenvector w PC1 PC2 PC3 PC4 PC5 m −0.4195 0.7900 0.2013 0.3954 −0.0557 0.1759 f 0.4472 0.2075 0.7976 −0.3474 −0.0088 0.2000 Kx 0.4526 0.3711 −0.4201 −0.1430 −0.6786 0.2049 Ky 0.4536 0.3819 −0.3469 −0.0029 0.7267 0.2057 σv 0.4620 −0.2221 0.1627 0.8382 −0.0906 0.2135 Eigenvalue 4.5813 0.3022 0.1100 0.0061 0.0005 − Contribution/% 91.63 6.04 2.20 0.12 0.01 − Notes: PC1-PC5—The first to fifth principal components, respectively; w—Mass coefficient of the performance indicators. 表 8 控制臂优化前后性能对比

Table 8. Performance comparison of original and optimized control arm

Property Scheme No. 27 Optimal combination Steel Relative variation/% m/kg 1.59 1.59 2.66 40.23 f/Hz 320.8 321.5 211. 9 51.72 Kx/(kN·mm−1) 5.21 5.22 5.65 −7.61 Ky/(kN·mm−1) 10.78 10.84 10.36 4.63 σb/MPa 25.1 25.5 92.6 72.46 σs/MPa 13.8 14.2 77.4 81.65 σv/MPa 46.3 47.5 295.1 83.90 -

[1] 徐建全, 杨沿平. 纯电动汽车与传统汽车轻量化全生命周期多目标优化研究[J]. 汽车工程, 2019, 41(8):885-891.XU Jianquan, YANG Yanping. A multi-objective lightweight optimization study on fulllife cycle of electric and conventional vehicles[J]. Automotive Engineering,2019,41(8):885-891(in Chinese). [2] LIU Zhao, LI Han, ZHU Ping. Diversity enhanced particle swarm optimization algorithm and its application in vehicle lightweight design[J]. Journal of Mechanical Science and Technology,2019,33(2):695-709. doi: 10.1007/s12206-019-0124-5 [3] 陈静, 彭博, 王登峰, 等. 碳纤维增强复合材料电池箱轻量化设计[J]. 汽车工程, 2020, 42(2): 257-263, 277.CHEN Jing, PENG Bo, WANG Dengfeng, et al. Lightweight design of carbon fiber reinforced composite battery box[J]. Automotive Engineering, 2020, 42(2): 257-263, 277 (in Chinese). [4] 王禹琪, 刘昕晖, 陈晋市, 等. 钢制组装式车轮的轻量化设计及多目标优化[J]. 哈尔滨工业大学学报, 2020, 52(7):170-178.WANG Yuqi, LIU Xinhui, CHEN Jinshi, et al. Lightweight design and multi-objective optimization of steel assembled wheel[J]. Journal of Harbin Institute of Technology,2020,52(7):170-178(in Chinese). [5] 刘强, 马小康, 宗志坚. 斜纹机织碳纤维/环氧树脂复合材料性能及其在电动汽车轻量化设计中的应用[J]. 复合材料学报, 2011, 28(5):83-88.LIU Qiang, MA Xiaokang, ZONG Zhijian. Properties of twill-weave carbon fabric/epoxy composites and its application on light-weight design for electric vehicles[J]. Acta Materiae Compositae Sinica,2011,28(5):83-88(in Chinese). [6] 马芳武, 熊长丽, 杨猛, 等. 碳纤维复合材料汽车B柱加强板的优化与性能分析[J]. 湖南大学学报(自然科学版), 2019, 46(8):36-44.MA Fangwu, XIONG Changli, YANG Meng, et al. Optimization and performance analysis of CFRP automotive b-pillar reinforced plate[J]. Journal of Hunan University(Natural Sciences),2019,46(8):36-44(in Chinese). [7] 庄蔚敏, 王楠, 吴迪, 等. 碳纤维复合材料层合板三点弯曲损伤仿真研究[J]. 机械工程学报, 2019, 55(10):109-114.ZHUANG Weimin, WANG Nan, WU Di, et al. Simulation and analysis of the damage of carbon fiber composite laminates under three point bending load[J]. Journal of Mechanical Engineering,2019,55(10):109-114(in Chinese). [8] YANG Haiyang, LEI Hongshuai, LU Guoxing, et al. Energy absorption and failure pattern of hybrid composite tubes under quasi-static axial compression[J]. Composites Part B: Engineering,2020,198:108217. [9] 王爽, 王登峰. 灰色关联及熵权法对碳纤维增强树脂复合材料防撞梁的耐撞性优化设计[J]. 复合材料学报, 2020, 37(2):345-355.WANG Shuang, WANG Dengfeng. Optimization design of carbon fiber reinforced polymer anti-collision beam crashworthiness by grey relational analysis with entropy method[J]. Acta Materiae Compositae Sinica,2020,37(2):345-355(in Chinese). [10] WU Chi, GAO Yunkai, FANG Jianguang, et al. Discrete topology optimization of ply orientation for a carbon fiber reinforced plastic (CFRP) laminate vehicle door[J]. Materials & Design,2017,128:9-19. [11] LIU Zhao, ZHU Chao, ZHU Ping, et al. Reliability-based design optimization of composite battery box based on modified particle swarm optimization algorithm[J]. Composite Structures,2018,204:239-255. doi: 10.1016/j.compstruct.2018.07.053 [12] 肖志, 杜庆勇, 莫富灏, 等. 连续碳纤维增强复合材料汽车顶盖铺层优化[J]. 汽车工程, 2017, 39(6):722-728.XIAO Zhi, DU Qingyong, MO Fuhao, et al. Ply optimization on vehicle roof of continuous carbon fiber reinforced polymer[J]. Automotive Engineering,2017,39(6):722-728(in Chinese). [13] 张君媛, 姜哲, 李仲玉, 等. 基于抗撞性的汽车B柱碳纤维加强板优化设计[J]. 汽车工程, 2018, 40(10): 1166-1171, 1178.ZHANG Junyuan, JIANG Zhe, LI Zhongyu, et al. Optimization design of vehicle cfrp b-pillar stiffening panel for crashworthiness[J]. Automotive Engineering, 2018, 40(10): 1166-1171, 1178 (in Chinese). [14] 叶辉, 刘畅, 闫康康. 纤维增强复合材料在汽车覆盖件中的应用[J]. 吉林大学学报(工学版), 2020, 50(2):417-425.YE Hui, LIU Chang, YAN Kangkang. Application of fiber reinforced composite in auto-body panel[J]. Journal of Jilin University (Engineering and Technology Edition),2020,50(2):417-425(in Chinese). [15] KIM Dohyoung, CHOI Donghoon, KIM Haksung. Design optimization of a carbon fiber reinforced composite automotive lower arm[J]. Composites Part B: Engineering,2014,58:400-407. doi: 10.1016/j.compositesb.2013.10.067 [16] 王红民, 谢锋, 郑国峰, 等. 汽车悬架控制臂拉压溃分析及疲劳寿命预测[J]. 振动与冲击, 2016, 35(20):41-46.WANG Hongmin, XIE Feng, ZHENG Guofeng, et al. The collapse analysis of the vehicle suspension control arm and fatigue life prediction[J]. Journal of Vibration and Shock,2016,35(20):41-46(in Chinese). [17] 杨绍勇, 雷飞, 陈园. 基于铺层设计特征的碳纤维增强复合材料悬架控制臂结构优化[J]. 工程设计学报, 2016, 23(6):600-605, 619.YANG Shaoyong, LEI Fei, CHEN Yuan. Structure optimization of a carbon fiber reinforced composite suspension control arm based on the lay up design features[J]. Chinese Journal of Engineering Design,2016,23(6):600-605, 619(in Chinese). [18] MESSANA A, FERRARIS A, AIRALE A G, et al. Enhancing vibration reduction on lightweight lower control arm[J]. Shock and Vibration,2020,2020:8891831. [19] XIONG Feng, WANG Dengfeng, ZHANG Shuai, et al. Lightweight optimization of the side structure of automobile body using combined grey relational and principal component analysis[J]. Structural and Multidisciplinary Optimization,2018,57(1):441-461. doi: 10.1007/s00158-017-1749-6 [20] WANG Dengfeng, JIANG Rongchao, LU Wenchao, et al. Optimization of cab suspension parameters of self-dumping trucks using grey relational analysis[J]. Journal of Grey System,2016,28(2):76-89. [21] 张志飞, 陈仁, 徐中明, 等. 面向多目标的汽车悬架控制臂拓扑优化研究[J]. 机械工程学报, 2017, 53(4):114-121. doi: 10.3901/JME.2017.04.114ZHANG Zhifei, CHEN Ren, XU Zhongming, et al. Research on multi-objective topology optimization of vehicle suspension control arm[J]. Journal of Mechanical Engineering,2017,53(4):114-121(in Chinese). doi: 10.3901/JME.2017.04.114 [22] 邱小明, 王银雪, 姚汉伟, 等. 基于灰色关联的DP1180/DP590异质点焊接头工艺参数优化[J]. 吉林大学学报(工学版), 2018, 48(4):1147-1152.QIU Xiaoming, WANG Yinxue, YAO Hanwei, et al. Multi-objective optimization of resistance spot welding parameters for DP1180/DP590 using grey relational analysis based Taguchi[J]. Journal of Jilin University (Engineering and Technology Edition),2018,48(4):1147-1152(in Chinese). [23] ASTM International. Standard test method for in-plane shear response of polymer matrix composite materials by tensile test of a ± 45° laminate: ASTM D3518/D3518M—2013[S]. US: West Conshohocken, 2013. [24] ASTM International. Standard test method for tensile properties of polymer matrix composite materials: ASTM D3039/D3039M—2014[S]. US: West Conshohocken, 2014. [25] WANG Dengfeng, JIANG Rongchao, WU Yinchong. A hybrid method of modified NSGA-II and TOPSIS for lightweight design of parameterized passenger car sub-frame[J]. Journal of Mechanical Science and Technology,2016,30(11):4909-4917. doi: 10.1007/s12206-016-1010-z -

下载:

下载: