Interfacial debonding failure of CFRP-strengthened steel structures

-

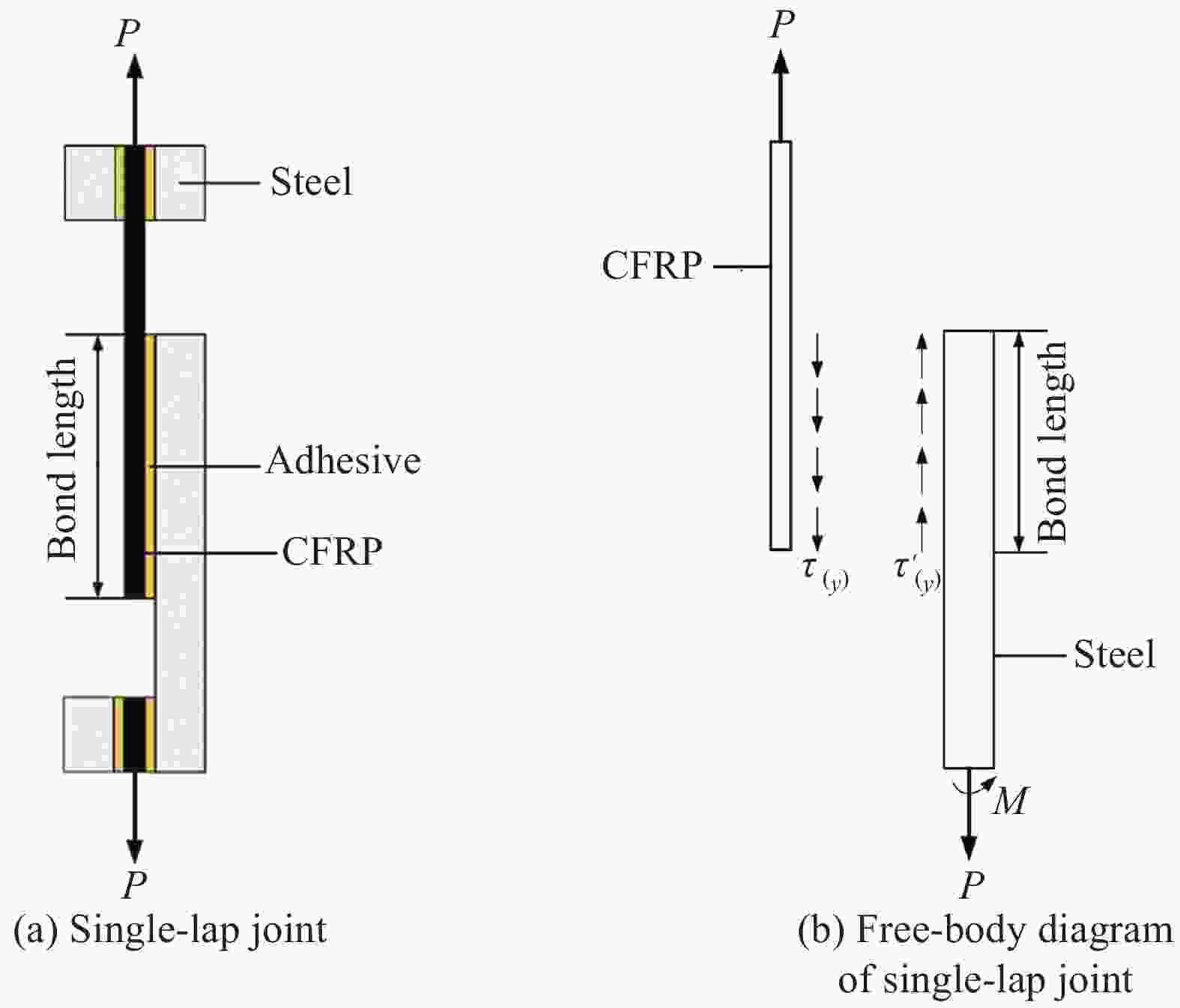

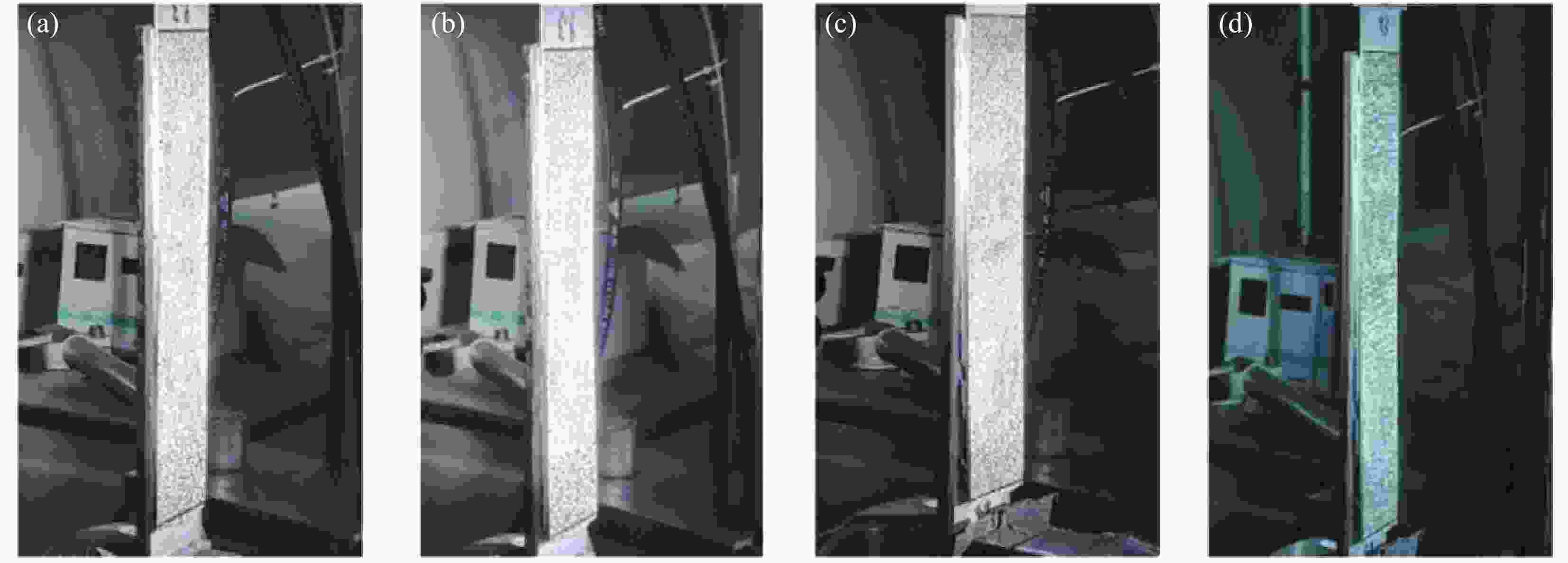

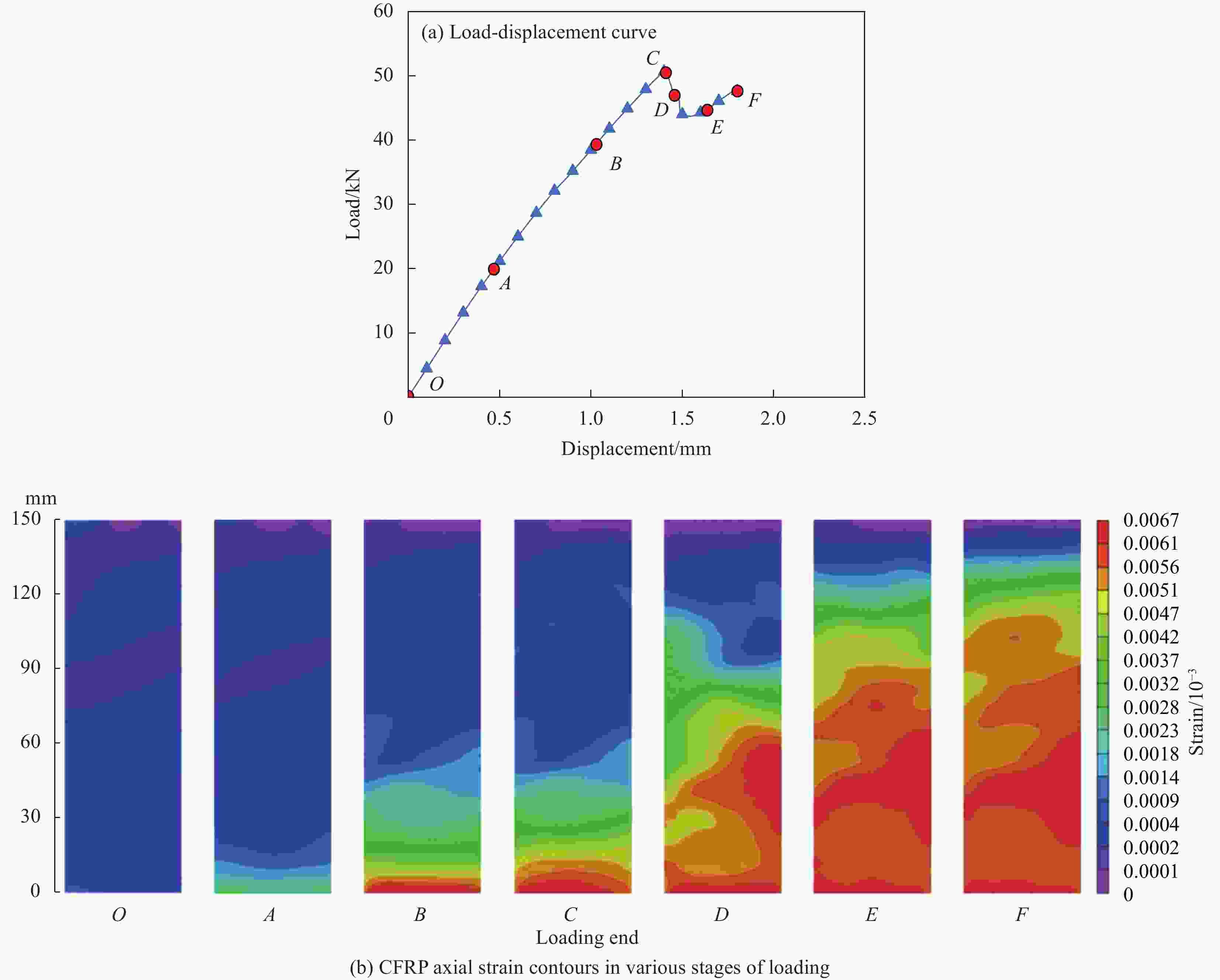

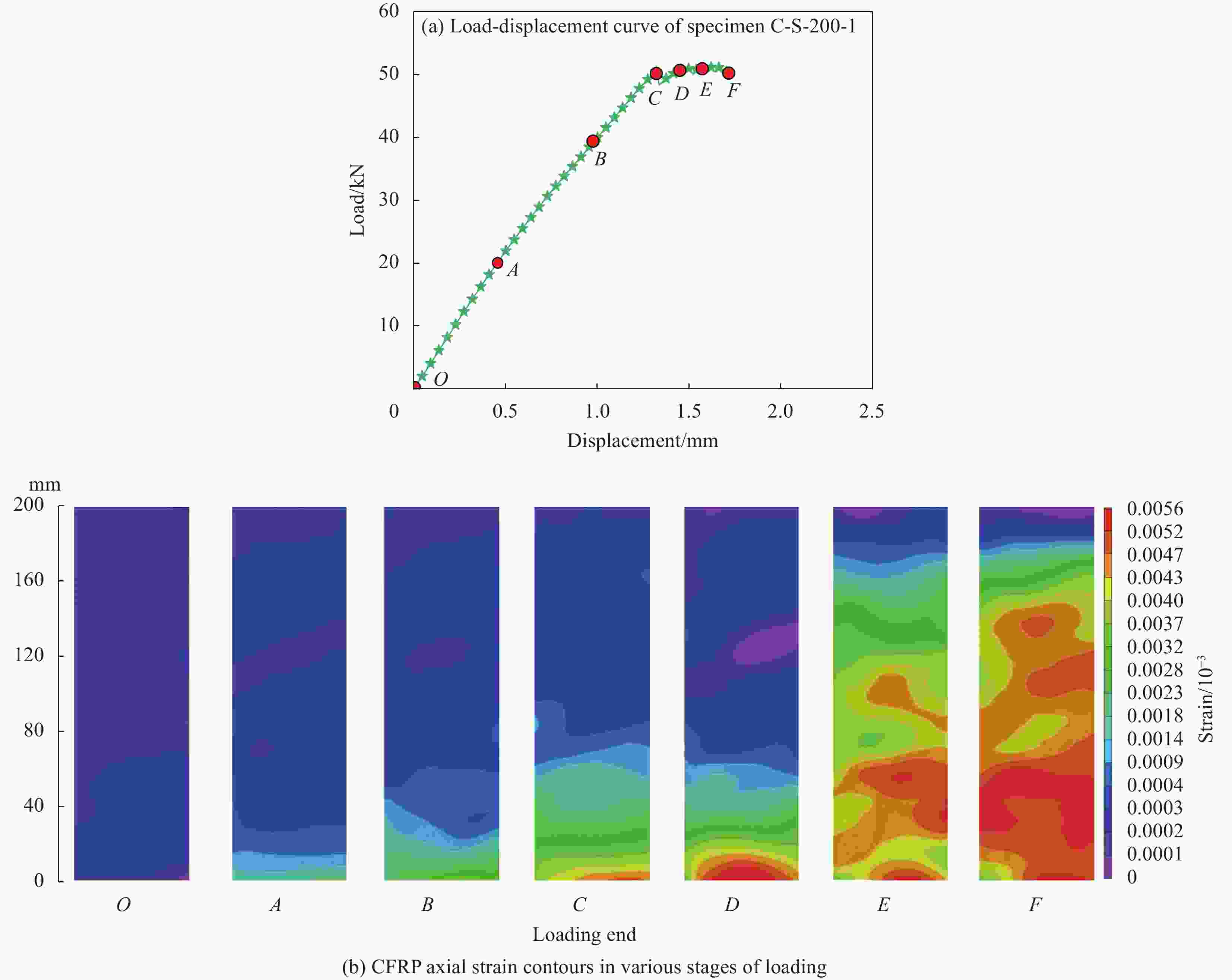

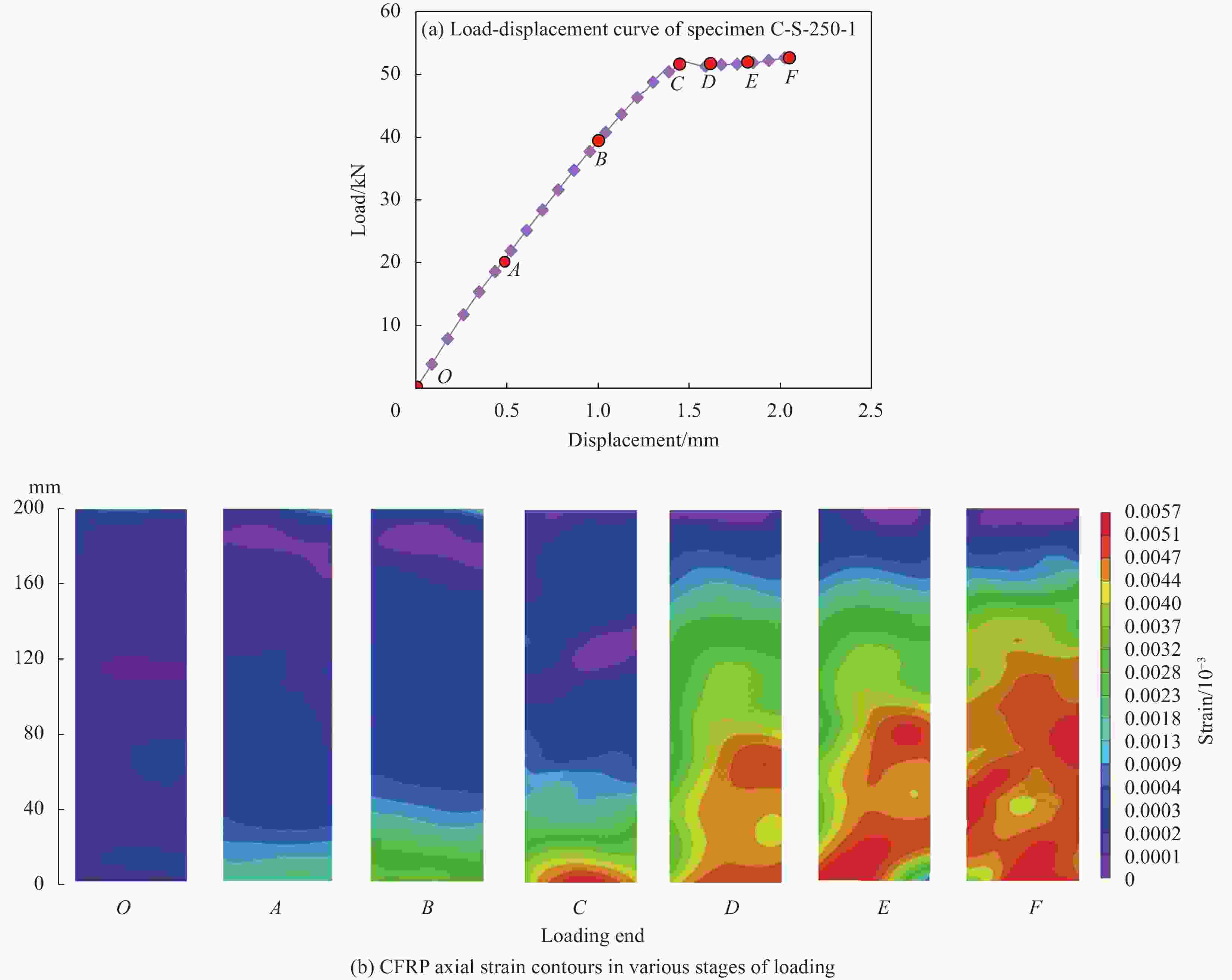

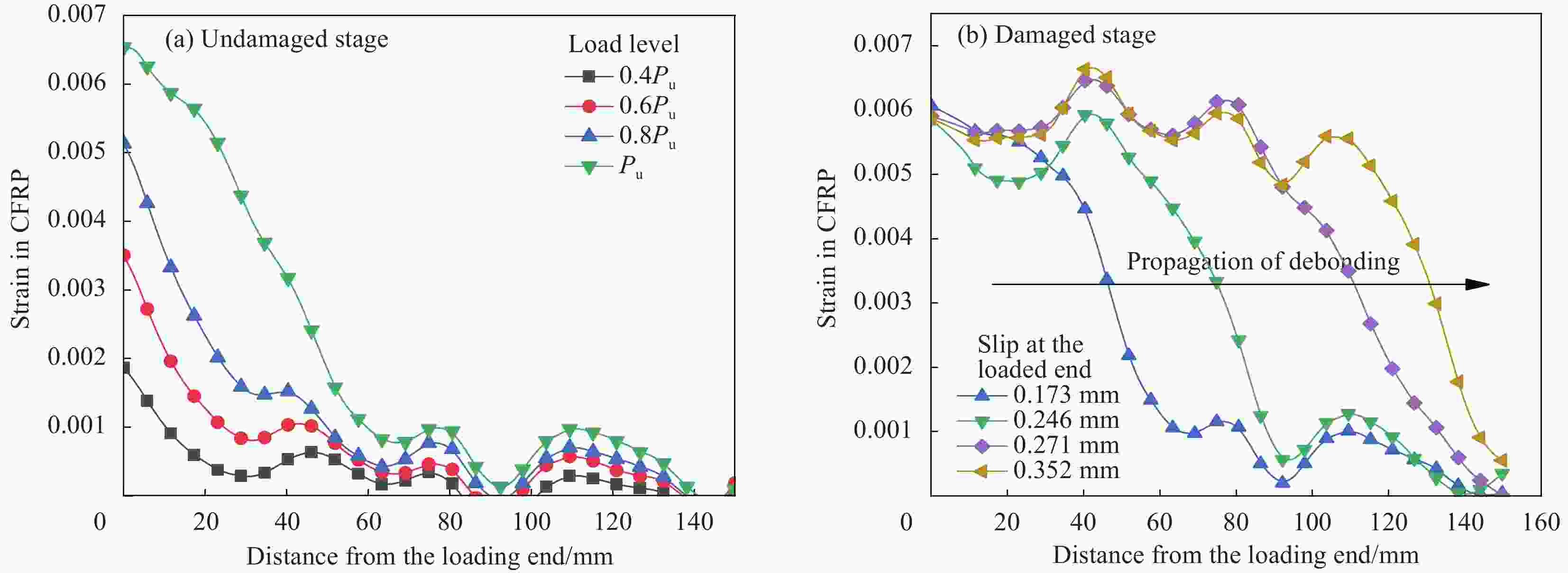

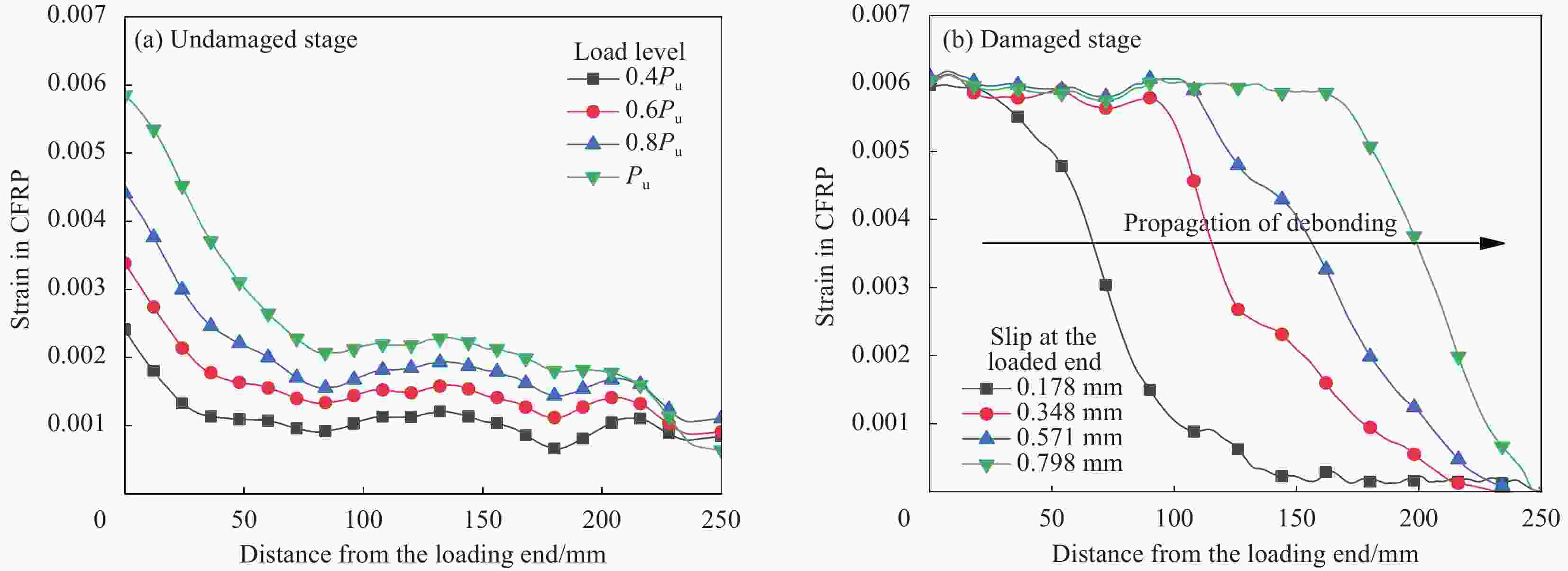

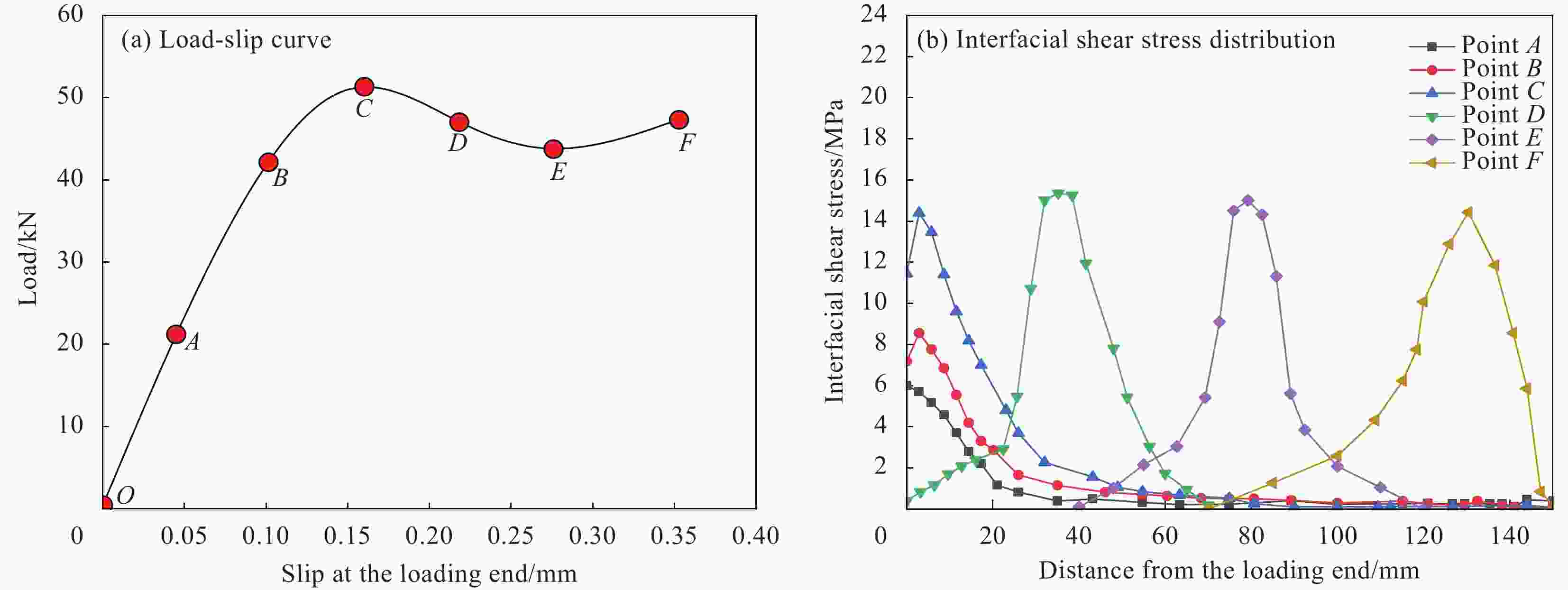

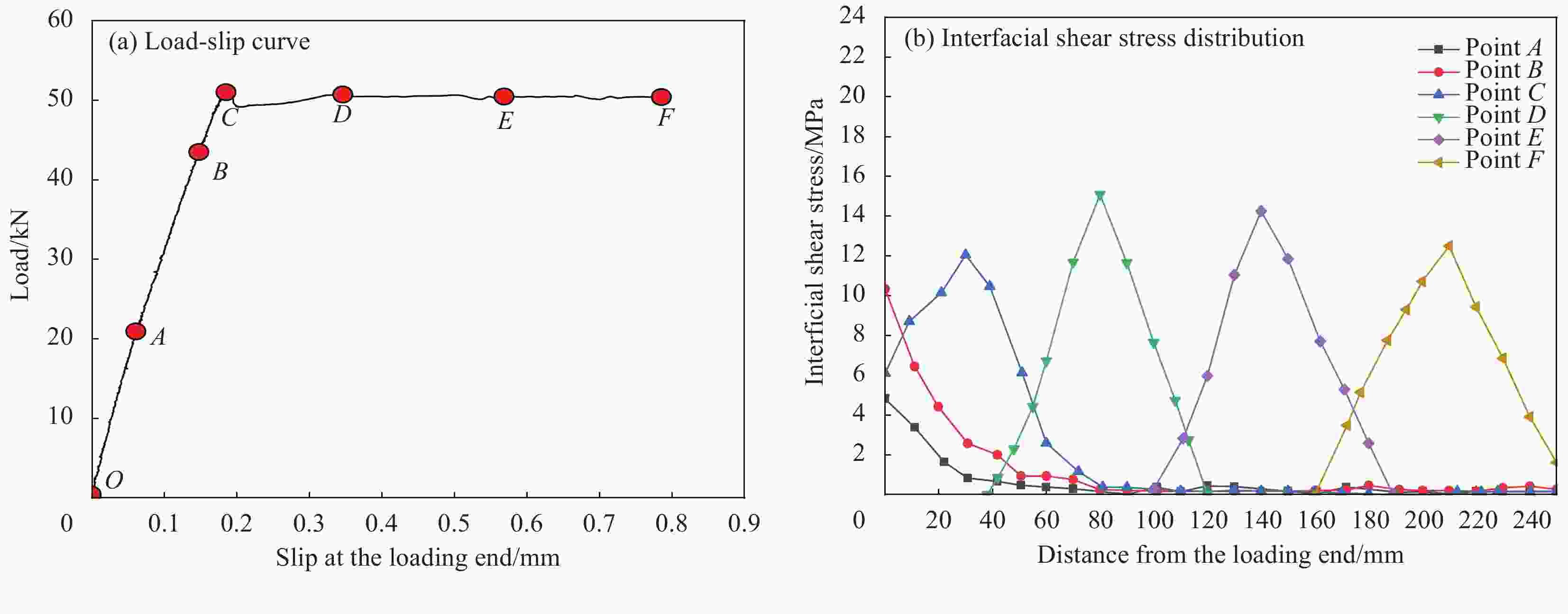

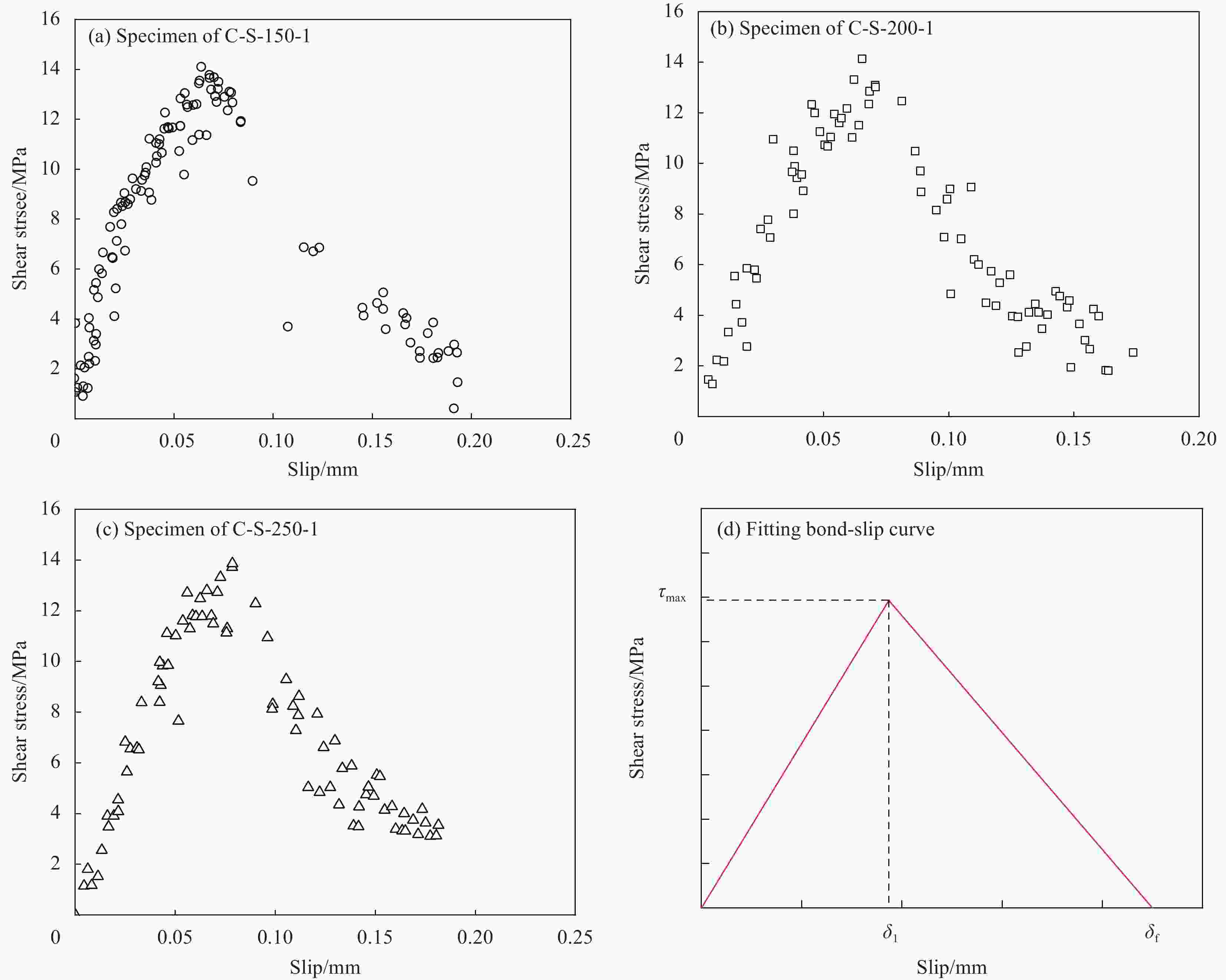

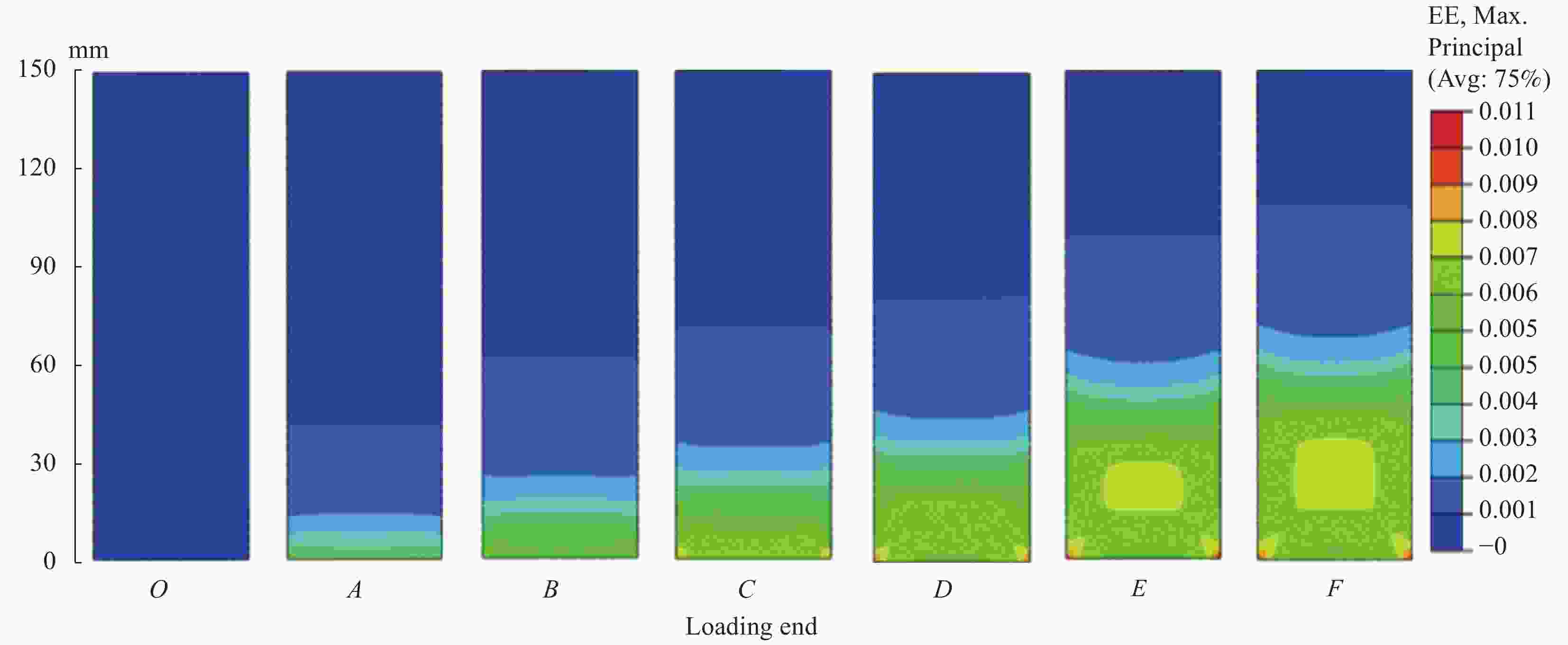

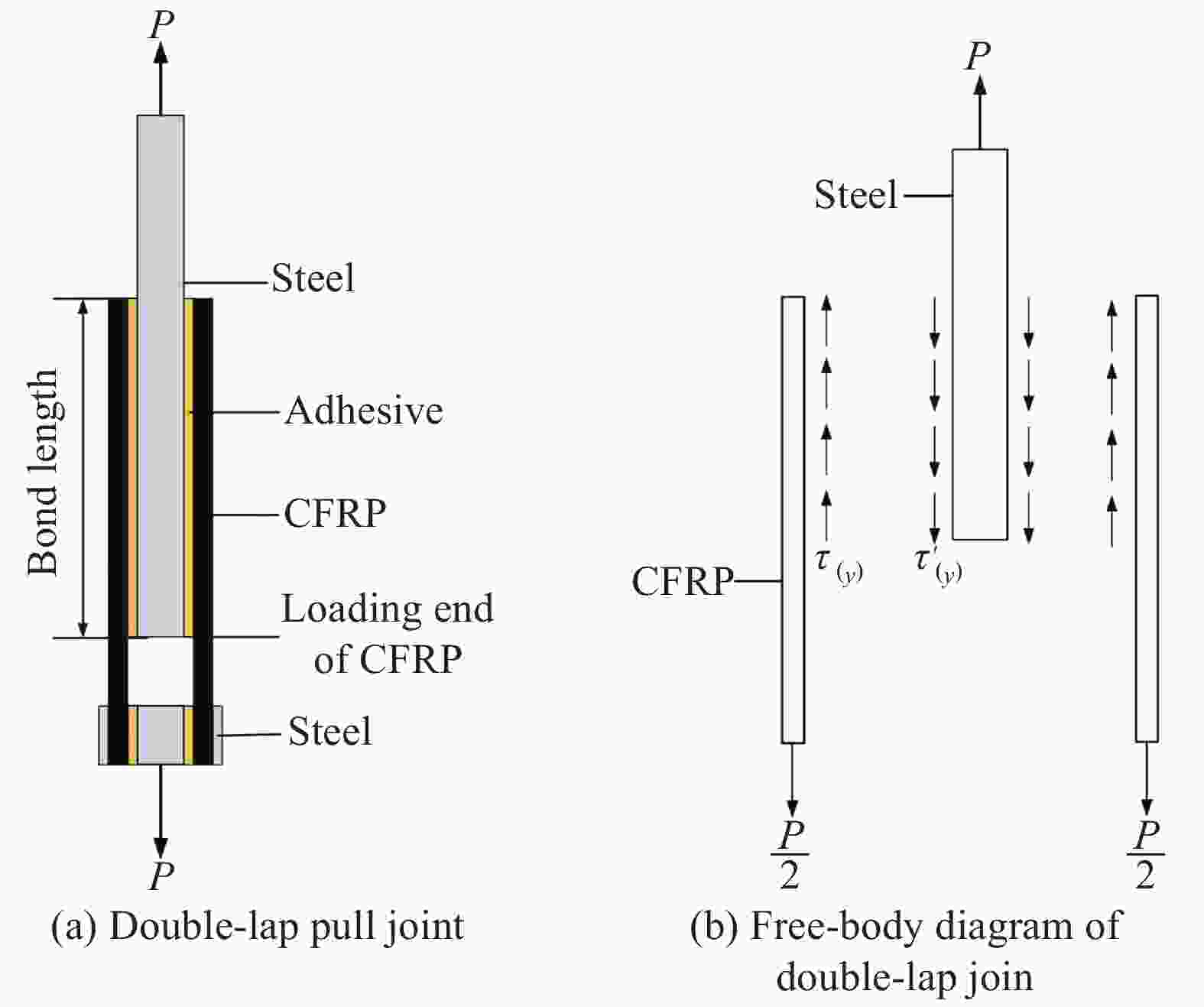

摘要: II型界面破坏是碳纤维增强树脂复合材料(CFRP)加固钢板常见的破坏方式之一。为揭示CFRP加固钢板粘结界面破坏的力学机制,开展了单剪试验和双剪试验分别研究了CFRP-钢板界面力学性能及破坏过程,并采用数字图像相关技术(DIC)对CFRP的轴向应变分布进行监测。对比两个试验的破坏模式发现,双剪试件的粘结界面主要发生II型破坏,界面破坏的主要力学原因是剪应力;而存在偏心加载的单剪试件,粘结界面上的剪应力和偏心加载引起的弯矩共同作用,使粘结界面发生I/II型混合模式失效。在II型破坏模式下,不同粘结长度的极限荷载及粘结滑移值随着粘结长度的增大而增大,但当粘结长度超过有效粘结长度后,极限荷载及极限滑移值基本保持不变。而在所讨论的偏心加载引起的界面I/II型混合破坏模式下,不同粘结长度的极限荷载基本不变。基于试验数据得到的双线性粘结-滑移关系建立了有限元模型,对CFRP加固钢板的II型界面粘结破坏行为进行分析,数值模拟结果与试验结果吻合较好。Abstract: Mode II debonding is one of the most typical failure modes on carbon fiber reinforce polymer (CFRP) plate-to-steel interface. In order to elucidate the interfacial debonding mechanism of CFRP-strengthened steel structures, single- and double-lap shear tests were conducted to investigate the mechanical behavior and debonding failure process at the FRP-to-steel plate interface. The technique of digital image correlation (DIC) was applied to measure the normal strain distribution on the surface of CFRP. Comparing the failure modes between these two joints, it can be found that a mode II fracture occurs on the interface of double-lap joint, which is caused by shear stresses. While the interface of single-lap joint subjected to eccentric loading is governed by mixed-mode I/II behavior, with the failure attributed to the combination of shear stress and bending moment. Additionally, the ultimate load and bond slip of the double-lap joints in mode II increase with the increment of bond length until an effective bond length is reached, beyond which the ultimate load remains unchanged. However, for single-lap joints subjected to eccentric loading, the ultimate loads with different bond lengths are almost the same. Based on bilinear bond-slip law obtained from experiment results, finite element model can be established to analysis the mode II interfacial debonding process of CFRP-strengthened steel structures, which shows an excellent agreement with the experimental results.

-

表 1 材料力学性能

Table 1. Material properties

Material Young’s modulus/GPa Tension strength/MPa Shear strength/MPa Yield strength/MPa Poisson’s ratio Elongation/% Q235 206 400 − 235 0.3 29.4 CFRP 150 1 230 − − 0.28 1.6 Adhesive 3.2 30 17 − 0.35 1.32 Note: CFRP—Carbon fiber reinforce polymer. 表 2 不同粘结长度CFRP加固钢板双剪试件的极限载荷及失效模式

Table 2. Ultimate load and failure modes of double-lap joint specimens of CFRP-strengthened steel plate with different bond lengths

Specimen Measured

adhesive thickness/mmBond

length/mmLength of

steel plate/mmUltimate

load/kNFailure

modeC-S-80-1 1.01 80 200 45.76 C+D C-S-80-2 0.99 80 200 45.32 C+D C-S-80-3 0.92 80 200 44.73 C+D C-S-80-4 0.91 80 200 45.12 C+D C-S-120-1 1.02 120 250 47.55 C+D+E C-S-120-2 1.03 120 250 47.87 C+D C-S-120-3 0.93 120 250 46.92 C+D C-S-120-4 0.90 120 250 47.38 C+D C-S-150-1 1.03 150 300 50.74 C+D C-S-150-2 1.02 150 300 51.42 C+D C-S-150-3 0.93 150 300 50.39 C+D C-S-150-4 0.96 150 300 50.79 C+D C-S-200-1 0.97 200 350 51.23 C+D C-S-200-2 1.09 200 350 52.21 C+D C-S-200-3 1.10 200 350 51.07 C+D C-S-200-4 0.97 200 350 51.78 C+D C-S-250-1 0.99 250 350 51.92 C+D C-S-250-2 1.03 250 350 51.08 C+D C-S-250-3 0.98 250 350 52.03 C+D C-S-250-4 0.96 250 350 51.01 C+D Notes: C—Cohesion failure in adhesive; D—Adhesion failure at adhesive/CFRP interface; E—Adhesion failure at adhesive/steel interface; C-S—CFRP-steel. 表 3 不同粘结长度CFRP加固钢板双剪试件的粘结-滑移本构参数

Table 3. Parameters in bond-slip law for double-lap joint specimens of CFRP-strengthened steel plate with different bond lengths

Specimen ${\tau _{{\rm{max}}}}$/MPa ${\delta _1}$/mm ${\delta _{\rm{f}}}$/mm ${G_{\rm{f}}}$/(N·mm−1) ${l_{\rm{e}}}$/mm C-S-150-1 14.6 0.065 0.178 1.299 78.56 C-S-150-2 14.1 0.067 0.184 1.297 81.23 C-S-150-3 13.7 0.063 0.177 1.212 80.52 C-S-150-4 13.4 0.061 0.174 1.165 80.52 C-S-200-1 14.5 0.062 0.174 1.261 77.61 C-S-200-2 14.0 0.068 0.183 1.281 81.58 C-S-200-3 13.6 0.059 0.170 1.156 78.87 C-S-200-4 13.7 0.060 0.169 1.157 78.64 C-S-250-1 14.2 0.070 0.182 1.789 81.27 C-S-250-2 14.3 0.069 0.184 1.823 81.07 C-S-250-3 13.6 0.043 0.165 1.124 74.38 C-S-250-4 13.7 0.093 0.154 1.054 83.15 Notes: Gf—Fracture energy; le—Effective bond length. -

[1] 岳清瑞, 侯兆新. 对我国钢结构发展的思考[J]. 工程建设标准化, 2017(5):48-56.YUE Qingrui, HOU Zhaoxin. Thoughts on the development of steel structures in China[J]. Standardization of Engineering Construction,2017(5):48-56(in Chinese). [2] 程璐, 冯鹏, 徐善华, 等. CFRP加固钢结构抗疲劳技术研究综述[J]. 玻璃钢/复合材料, 2013(4):58-62.CHENG Lu, FENG Peng, XU Shanhua, et al. Review on anti-fatigue technology of steel structure strengthened by CFRP[J]. Fiber Reinforced Plastics/Composites,2013(4):58-62(in Chinese). [3] HOSSEINI A, MOSTOFINEJAD D. Effective bond length of FRP-to-concrete adhesively-bonded joints: Experimental evaluation of existing models[J]. International Journal of Adhesion & Adhesives,2014,48:150-158. [4] ZHANG P, LEI D, REN Q, et al. Experimental and numerical investigation of debonding process of the FRP plate-concrete interface[J]. Construction and Building Materials,2019,235:117457. [5] 李趁趁, 于爱民, 高丹盈, 等. 侵蚀环境下FRP条带加固锈蚀钢筋混凝土圆柱轴心受压试验[J]. 复合材料学报, 2020, 37(8):2015-2028.LI Chenchen, YU Aimin, GAO Danying, et al. Experimental study on axial compression of corroded reinforced concrete columns strengthened with FRP strips under erosion environment[J]. Acta Materiae Compositae Sinica,2020,37(8):2015-2028(in Chinese). [6] SEN R. Advances in the application of FRP for repairing corrosion damage[J]. Progress in Structural Engineering & Materials,2003,5(2):99-113. [7] ZHAO X L, ZHANG L. State-of-the-art review on FRP strengthened steel structures[J]. Steel Construction,2007,29(8):1808-1823. [8] TENG J G, YU T, FERNANDO D. Strengthening of steel structures with fiber-reinforced polymer composites[J]. Journal of Constructional Steel Research,2012,78:131-143. doi: 10.1016/j.jcsr.2012.06.011 [9] BOCCIARELLI M, COLOMBI P, FAVA G, et al. Fatigue performance of tensile steel members strengthened with CFRP plates[J]. Steel Construction,2009,87(4):334-343. [10] YU T, FERNANDO D, TENG J G, et al. Experimental study on CFRP-to-steel bonded interfaces[J]. Composites Part B: Engineering,2012,43(5):2279-2289. doi: 10.1016/j.compositesb.2012.01.024 [11] WU C, ZHAO X L, CHIU W K, et al. Effect of fatigue loading on the bond behaviour between UHM CFRP plates and steel plates[J]. Composites Part B: Engineering,2013,50:344-353. doi: 10.1016/j.compositesb.2013.02.040 [12] WANG H T, WU G, JIANG J B. Fatigue behavior of cracked steel plates strengthened with different CFRP systems and configurations[J]. Journal of Composites for Construction,2016,20(3):04015078. doi: 10.1061/(ASCE)CC.1943-5614.0000647 [13] NGUYEN T C, BAI Y, ZHAO X L, et al. Curing effects on steel/CFRP double strap joints under combined mechanical load, temperature and humidity[J]. Construction & Building Materials,2013,40:899-907. [14] GRAMMATIKOS S A, JONES R G, EVERNDEN M, et al. Thermal cycling effects on the durability of a pultruded GFRP material for off-shore civil engineering structures[J]. Composite Structures,2016,153:297-310. doi: 10.1016/j.compstruct.2016.05.085 [15] MOHSEN H, REZA H, MOHAMMAD AL-E. Durability of CFRP/steel joints under cyclic wet-dry and freeze thaw conditions[J]. Composites Part B: Engineering,2017,126:211-226. doi: 10.1016/j.compositesb.2017.06.011 [16] WANG Y, ZHENG Y, LI J, et al. Experimental study on tensile behaviour of steel plates with centre hole strengthened by CFRP plates under marine environment[J]. International Journal of Adhesion and Adhesives,2018:18-26. [17] BISCAIA H C, CHASTRE C. Theoretical analysis of fracture in double overlap bonded joints with FRP composites and thin steel plates[J]. Engineering Fracture Mechanics,2018:435-460. [18] CERONI F, IANNICIELLO, et al. Bond behavior of FRP carbon plates externally bonded over steel and concrete elements: Experimental outcomes and numerical investigations[J]. Composites Part B: Engineering, 2016, 92: 434-446. [19] HE J, XIAN G. Debonding of CFRP-to-steel joints with CFRP delamination[J]. Composite Structures,2016,153:12-20. doi: 10.1016/j.compstruct.2016.05.100 [20] PANG Y, WU G, WANG H, et al. Experimental study on the bond behavior of CFRP-steel interfaces under quasi-static cyclic loading[J]. 2019, 140: 426-437. [21] LIU M, DAWOOD M. A closed-form solution of the interfacial stresses and strains in steel beams strengthened with externally bonded plates using ductile adhesives[J]. Engineering Structures,2018,154:66-77. doi: 10.1016/j.engstruct.2017.10.054 [22] YANG, Y M, SILVA, et al. CFRP-to-steel bonded joints subjected to cyclic loading: An experimental study[J]. Composites Part B: Engineering,2018,146:28-41. doi: 10.1016/j.compositesb.2018.03.039 [23] 杨怡, 黄炽辉, 吴作栋. 基于双剪实验的CFRP-钢板界面粘结性能研究[J]. 中山大学学报(自然科学版):1-9. [2020-11-05]. https://doi.org/10.13471/j.cnki.acta.snus.2020.07.14.2020B082.YANG Yi, HUANG Chihui, WU Zuodong. Study on bonding performance of CFRP-steel plate interface based on double shear test[J]. Acta Scientiarum Naturalium Universitatis Sunyatseni (Natural Science):1-9. [2020-11-05]. https://doi.org/10.13471/j.cnki.acta.snus.2020.07.14.2020B082(in Chinese). [24] CARLONI C, SUBRAMANIAM K V. Direct determination of cohesive stress transfer during debonding of FRP from concrete[J]. Composite Structures,2010,93(1):184-192. doi: 10.1016/j.compstruct.2010.05.024 [25] WANG H T, WU G, DAI Y T, et al. Experimental study on bond behavior between CFRP plates and steel substrates using digital image correlation[J]. Journal of Composites for Construction,2016,20(6):04016054. doi: 10.1061/(ASCE)CC.1943-5614.0000701 [26] YANG Y, BISCAIA H, CHASTRE C, et al. Bond characteristics of CFRP-to-steel joints[J]. Journal of Constructional Steel Research,2017,138:401-419. doi: 10.1016/j.jcsr.2017.08.001 [27] ARDALAN H, ELYAS G, MATTHIAS W, et al. Short-term bond behavior and debonding capacity of prestressed CFRP composites to steel substrate[J]. Engineering Structures,2018,176:935-947. doi: 10.1016/j.engstruct.2018.09.025 [28] LU X Z, TENG J G, YE L P, et al. Bond-slip models for FRP sheets/plates bonded to concrete[J]. Engineering Structures,2005,27(6):920-937. doi: 10.1016/j.engstruct.2005.01.014 [29] YUAN H, TENG J G, SERACINO R, et al. Full-range behavior of FRP-to-concrete bonded joints[J]. Engineering Structures,2003,26(5):553-565. -

下载:

下载: