Microstructure and properties of functionalized Al2O3@SiO2/phenolic epoxy-bismaleimide composites

-

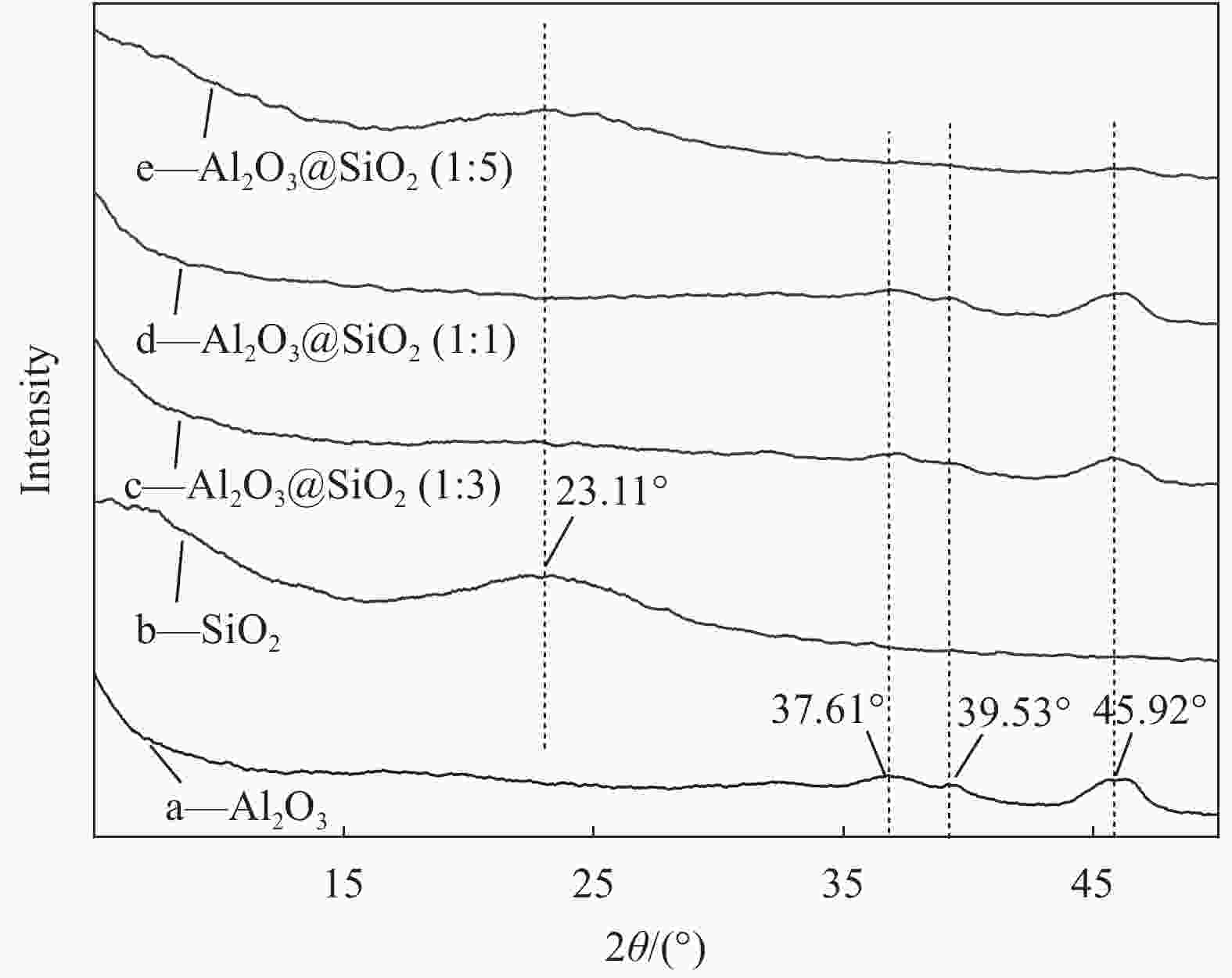

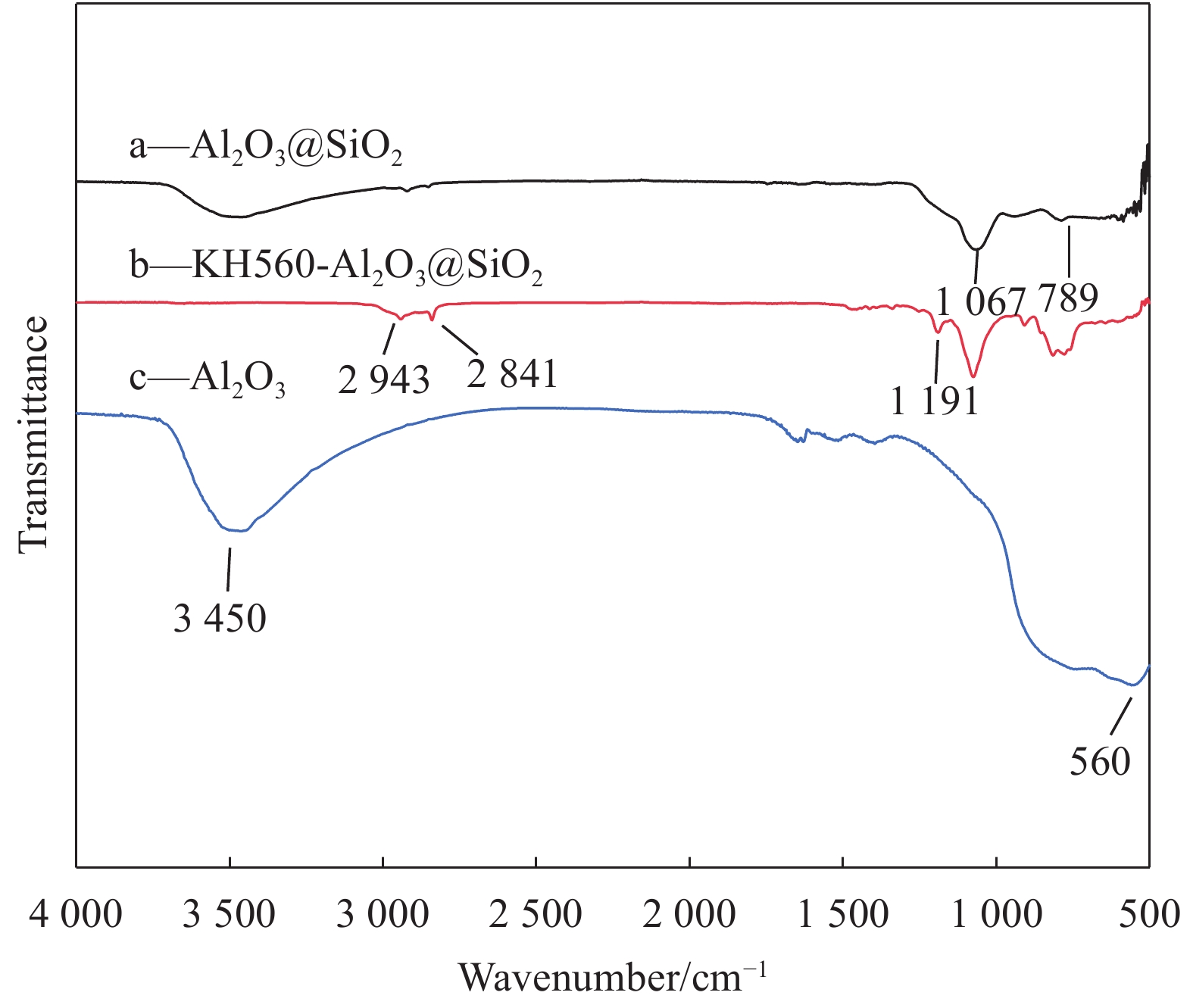

摘要: 采用溶胶-凝胶法(Sol-gel)分别制备Al2O3和SiO2,同时以KH560为架桥剂制得SiO2包覆Al2O3(KH560-Al2O3@SiO2)的增强体。以双马来酰亚胺树脂和酚醛环氧树脂(MBMI-EPN)为基体、4’4-二氨基二苯甲烷(DDM)为固化剂,采用原位聚合法制备了KH560-Al2O3@SiO2/MBMI-EPN复合材料;表征KH560-Al2O3@SiO2的微观结构及该增强体对复合材料性能的影响。结果表明:Al2O3@SiO2粒子微观结构清晰,核壳结构完整,内核为短纤维状Al2O3,外壳为无定形SiO2,二者通过化学键方式相连;Al2O3@SiO2表面成功接枝上KH560基团,粒子堆积现象减弱。KH560-Al2O3@SiO2/MBMI-EPN复合材料的微观形貌显示:KH560-Al2O3@SiO2在MBMI-EPN基体中形成多相结构、分散性较好、界面作用稳定且断面形貌呈鱼鳞状,并未发现Al2O3@SiO2粒子团聚体,整体结构完整。当KH560-Al2O3@SiO2含量为1.5wt%时,复合材料的弯曲强度与冲击强度分别为126 MPa和14.7 kJ/m2,比树脂基体分别提高了21.2%和27.8%;材料的热分解温度为392.3℃,比树脂基体提高了14.5℃,力学性能和耐热性得到明显改善。Abstract: The Al2O3 and SiO2 were obtained by sol-gel method and the KH560-Al2O3@SiO2 were prepared with KH560 as the coupling agent. The KH560-Al2O3@SiO2/MBMI-EPN composites were prepared by in-situ polymerization, using bismaleimide resin and phenolic epoxy resin (MBMI-EPN) as matrix, KH560-Al2O3@SiO2 as the reinforcement and 4’4-diaminodiphenylmethane (DDM) as curing agent. The micro-structure of KH560-Al2O3@SiO2 were characterized and the effect of the reinforcement on properties of composites were studied. The results show that the Al2O3@SiO2 particles have clear core-shell structure. The short-fiber Al2O3 is inner core, and the amorphous SiO2 is outer shell, which are connected by chemical bonds. The KH560 is successfully grafted onto the surface of Al2O3@SiO2, and the particles packing phenomenon is weakened. The micro-structure of the composites shows that KH560-Al2O3@SiO2 forms a multi-phase structure in the MBMI-EPN matrix with good dispersion and stable interface. The cross-sectional shape is fish scale, and there are no Al2O3@SiO2 nanoparticle agglomerates and the overall structure is regular. When the content of KH560-Al2O3@SiO2 is 1.5wt%, bending strength and impact strength of the composites are 126 MPa and 14.7 kJ/m2, which are 21.2% and 27.8% higher than resin matrix, respectively. And the thermal decomposition temperature of the composites is 392.3℃, which is 14.5℃ higher than that of resin matrix.

-

Key words:

- phenolic epoxy resin /

- bismaleimide /

- alumina, silicon oxide /

- mechanical properties /

- heat resistance /

-

表 1 KH560-Al2O3@SiO2/双马来酰亚胺树脂-酚醛环氧树脂(MBMI-EPN)复合材料样品的名称及组分含量

Table 1. Sample name and content of KH560-Al2O3@SiO2/bismaleimide resin and phenolic epoxy resin (MBMI-EPN) composites

Sample KH560-Al2O3@SiO2

mass ratio/wt%MBMI-EPN 0 0.5wt% KH560-Al2O3@SiO2/MBMI-EPN 0.5 1.0wt% KH560-Al2O3@SiO2/MBMI-EPN 1.0 1.5wt% KH560-Al2O3@SiO2/MBMI-EPN 1.5 2.0wt% KH560-Al2O3@SiO2/MBMI-EPN 2.0 2.5wt% KH560-Al2O3@SiO2/MBMI-EPN 2.5 -

[1] ZHANG J B, TIAN P F, YANG G P, et al. A facile preparation of pomegranate-like porous carbon by carbonization and activation of phenolic resin prepared via hydrothermal synthesis in KOH solution for high performance supercapacitor electrodes[J]. Advanced Powder Technology,2019,30(12):2900-2907. doi: 10.1016/j.apt.2019.08.036 [2] WANG K X, LIU J X, ZHANG F, et al. Primary amine-functionalized mesoporous phenolic resin-supported palladium nanoparticles as an effective and stable catalyst for water-medium suzuki-miyaura coupling reactions[J]. ACS Appied Materials & Interfaces,2019,11(44):41238-41244. [3] ZHAN S, CUI J, ZHANG G F, et al. An alternative avenue for high-performance phenolic resin/graphene composite[J]. Polymer Composites,2019,40(11):4248-4256. doi: 10.1002/pc.25286 [4] 陈兵, 王晓洁, 王喜占, 等. 环氧树脂增韧改性研究进展[J]. 中国胶黏剂, 2017, 26(2):55-58.CHEN Bing, WANG Xiaojie, WANG Xizhan, et al. Research progress of epoxy resin in toughening modification[J]. China Adhesives,2017,26(2):55-58(in Chinese). [5] SUN T, FAN H Y, ZHUO Q, et al. Covalent incorporation of aminated carbon nanotubes into epoxy resin network[J]. High Performance Polymers,2014,26(8):892-899. doi: 10.1177/0954008314533810 [6] ARIMITSU K, FUSE S, KUDO K, et al. Imidazole derivatives as latent curing agents for epoxy thermosetting resins[J]. Materials Letters,2015,161:408-410. doi: 10.1016/j.matlet.2015.08.141 [7] MASSOUMI B, ABBASIAN M, JAYMAND M, et al. Polystyrene-modified novolac epoxy resin/clay nanocomposite: Synthesis, and characterization[J]. Polymers for Advanced Technologies,2019,30(6):1484-1492. doi: 10.1002/pat.4580 [8] HUO S P, MA H L, LIU G F, et al. Synthesis and properties of organosilicon-grafted cardanol novolac epoxy resin as a novel biobased reactive diluent and toughening agent[J]. ACS Omega,2018,3(12):16403-16408. doi: 10.1021/acsomega.8b02401 [9] ICHIKAWA I, SUGIZAKI T, AKASAKA S, et al. Quantitative analysis of the phase-separated structure and mechanical properties of acrylic copolymer/epoxy thermosetting resin composites[J]. Polymer Journal,2015,47(12):779-788. doi: 10.1038/pj.2015.68 [10] 王丽萍, 郭昭华, 池君洲, 等. 氧化铝多用途开发研究进展[J]. 无机盐工业, 2015, 47(6):11-15.WANG Liping, GUO Shaohua, CHI Junzhou, et al. Progress in multipurpose research and development of multiform alumina[J]. Inorganic Chemicals Industry,2015,47(6):11-15(in Chinese). [11] 武志富, 梁柳青, 庾小酉. 纳米氧化铝的制备方法研究进展[J]. 产业与科技论坛, 2018, 17(17):97-98. doi: 10.3969/j.issn.1673-5641.2018.17.054WU Zhifu, LIANG Liuqing YU Xiaoyou. Progress in preparation of nano-alumina[J]. Industrial & Science Tribune,2018,17(17):97-98(in Chinese). doi: 10.3969/j.issn.1673-5641.2018.17.054 [12] YANG B, CHEN Y, SHI J. Mesoporous silica/organosilica nanoparticles: synthesis, biological effect and biomedical application[J]. Materials Science and Engineering: R: Reports,2019,137:66-105. doi: 10.1016/j.mser.2019.01.001 [13] 陈博, 陈学琴, 任军, 等. 纳米二氧化硅表面改性研究进展[J]. 有机硅材料, 2017, 31(5):396-400.Chen Bo, CHEN Xueqin, REN Jun, et al. Progress in surface modification of nano-silica[J]. Silicone Material,2017,31(5):396-400(in Chinese). [14] 国家质量技术监督局. 塑料试样状态调节和试验的标准环境: GB/T 2918—1998[S]. 北京: 中国标准出版社, 1998.Nation bureau of technical supervision. Standard environment for state regulation and testing of plastic samples: GB/T 2918—1998[S]. Beijing: China Standards Press, 1998 (in Chinese). [15] 国家质量监督检验检疫总局. 树脂浇铸体性能试验方法: GB/T 2567—2008[S]. 北京: 中国标准出版社, 2008.General administration of quality supervision, inspection and quarantine. Test methods for properties of resin casting boby: GB/T 2567—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [16] ZHANG L P, LI M, TIAN A L, et al. Mechanism and properties of coloured nanoscale SiO2 prepared from silica and reactive dyes[J]. Coloration Technology,2016,132(5):399-406. doi: 10.1111/cote.12231 [17] 陈宇飞, 耿成宝, 郭红缘, 等. 功能化纳米SiO2-聚醚砜/BMI-酚醛环氧树脂复合材料的固化动力学与性能[J]. 复合材料学报, 2019, 36(7):1658-1666.CHEN Yufei, GENG Chengbao, GUO hongyuan, et al. Curing reaction kinetics and properties of functionalized nano SiO2-polyethersulfone/BMI-phenolic epoxy resin composites[J]. Acta Materiae Compositae Sinica,2019,36(7):1658-1666(in Chinese). [18] LIU Z M, WANG J W, KANG M Q, et al. Synthesis of glycerol carbonate by transesterification of glycerol and dimethyl carbonate over KF/gamma-Al2O3 catalyst[J]. Journal of the Brazilian Chemical Society,2014,25(1):152-160. [19] 杨旭宇, 王安龙, 杨嵩. 氧化石墨烯与石墨烯在溶剂中的分散性能研究[J]. 炭素技术, 2014, 33(3):30-32.YANG Xuyu, WANG Anlong, YANG Song. Study on the dispersibility of GO and RGO in different solvents[J]. Carbon Techniques,2014,33(3):30-32(in Chinese). [20] 李志超, 陈宇飞, 贾锡琛. 环氧树脂改性双马来酰亚胺树脂体系的性能研究[J]. 绝缘材料, 2017, 50(1):28-31.LI Zhichao, CHEN Yufei, JIA Xichen. Study on properties of epoxy modified bismaleimide resin[J]. Insulating Materials,2017,50(1):28-31(in Chinese). -

下载:

下载: