| [1] |

黄陆军, 耿林. 网状结构钛基复合材料[M]. 北京: 国防工业出版社, 2015.HUANG L J, GENG L. Titanium matrix composites with network structure[M]. Beijing: National Defence Industry Press, 2015(in Chinese).

|

| [2] |

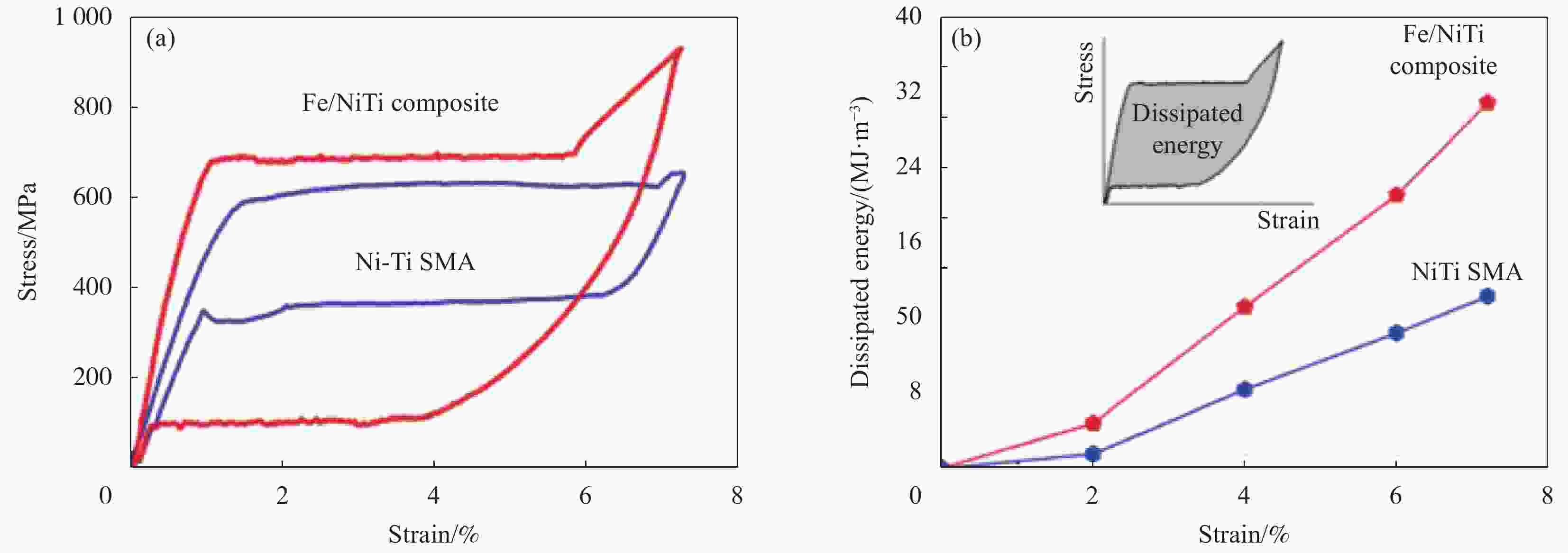

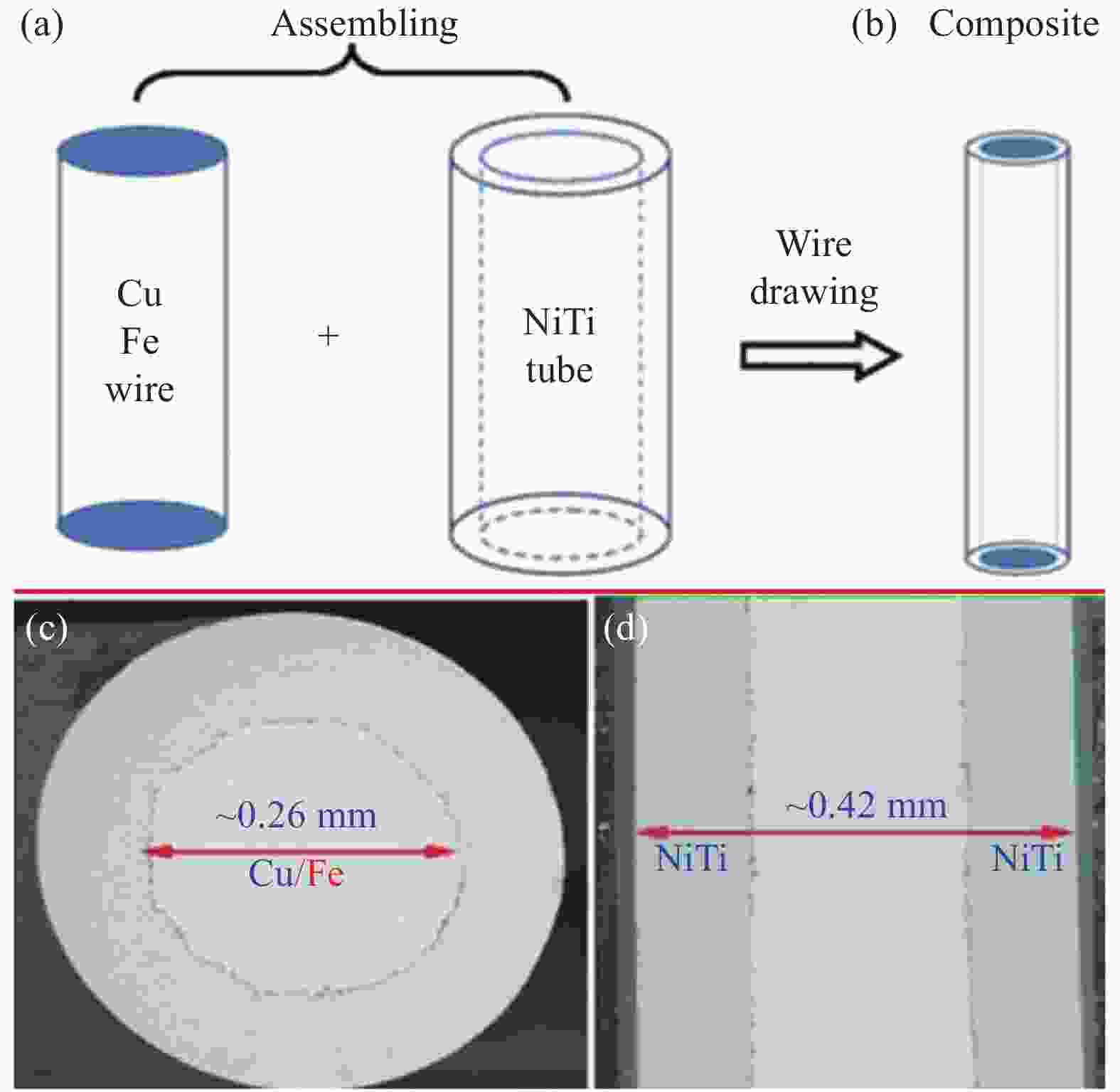

HAO S J, CUI L S, SHAO Y, et al. In situ X-ray diffraction study of deformation behavior in a Fe/NiTi composite[J]. Applied Physics Letters,2012,101(22):221904. doi: 10.1063/1.4767993

|

| [3] |

HAO S J, CUI L S, CHEN Z, et al. A novel stretchable coaxial NiTi-sheath/Cu-core composite with high strength and high conductivity[J]. Advanced Materials,2013,25(8):1199-1202. doi: 10.1002/adma.201203762

|

| [4] |

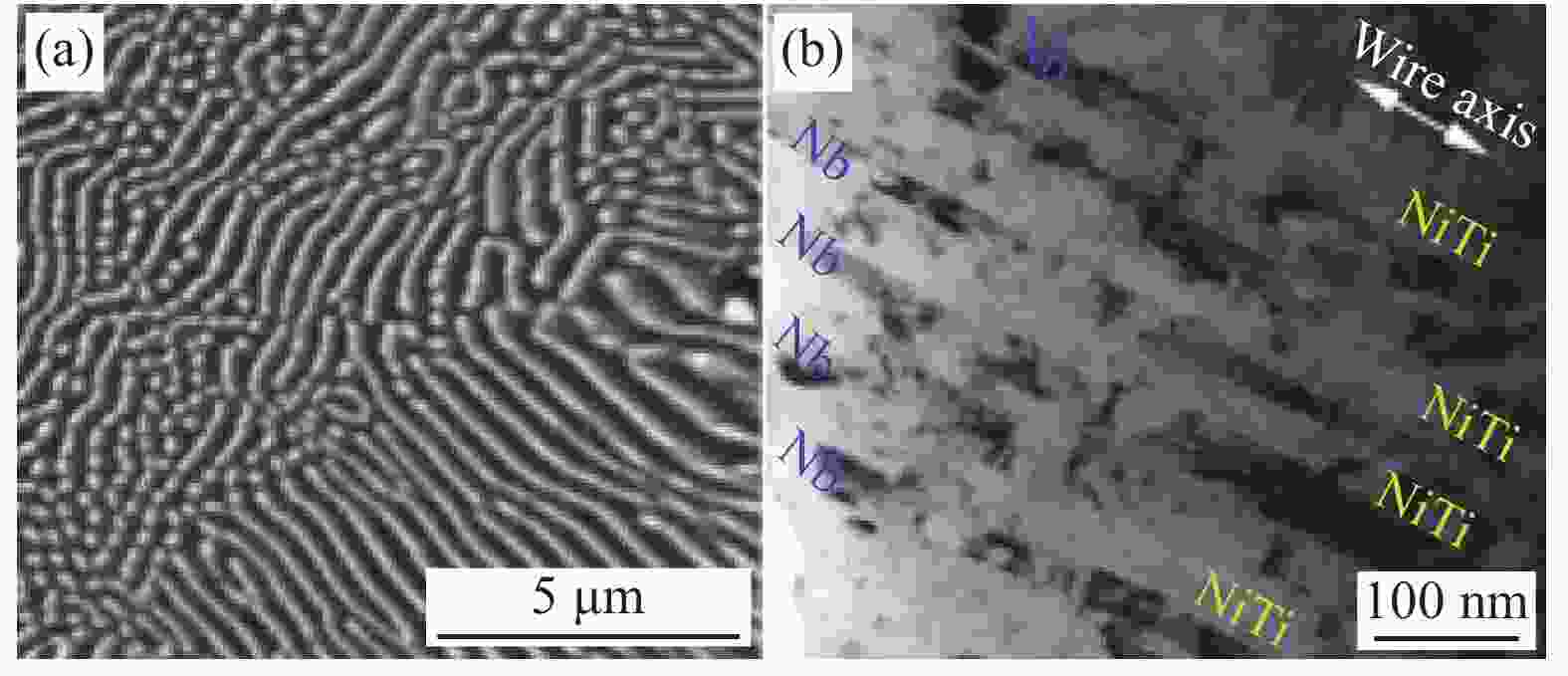

HAO S J, CUI L S, JIANG D Q, et al. Nanostructured Nb reinforced NiTi shape memory alloy composite with high strength and narrow hysteresis[J]. Applied Physics Letters,2013,102(23): 231905.

|

| [5] |

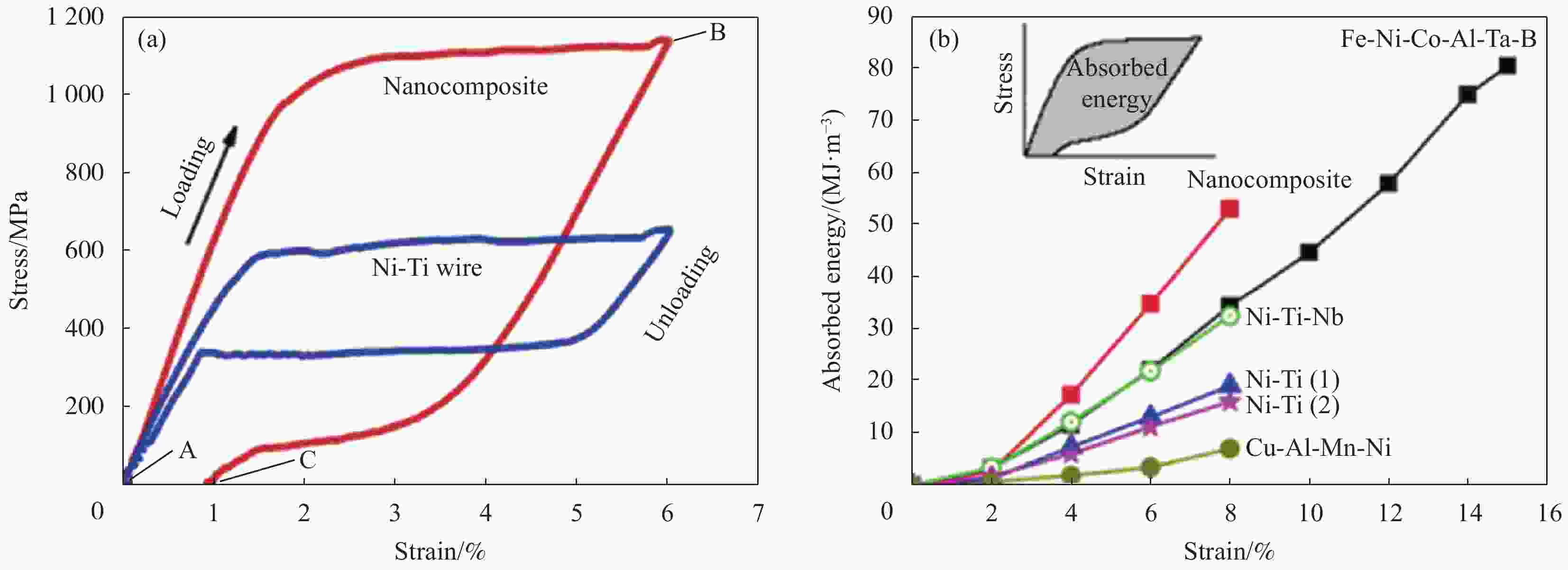

HAO S J, CUI L S, WANG Y D, et al. The ultrahigh mechanical energy-absorption capability evidenced in a high-strength NbTi/NiTi nanocomposite[J]. Applied Physics Letters,2011,99(2):024102. doi: 10.1063/1.3610562

|

| [6] |

HAO S J, CUI L S, JIANG D Q, et al. A transforming metal nanocomposite with large elastic strain, low modulus, and high strength[J]. Science,2013,339(6124):1191-1194. doi: 10.1126/science.1228602

|

| [7] |

HAO S J, CUI L S, JIANG D Q, et al. Superelastic memory effect in in-situ NbTi-nanowire-NiTi nanocomposite[J]. Applied Physics Letters,2012,101(17):173115. doi: 10.1063/1.4764538

|

| [8] |

HU M, YANG H, SHI X, et al. Transformation and superelastic characteristics of large hysteresis TiNi matrix shape memory alloys reinforced by V nanowires[J]. Materials Letters,2018,228:391-394.

|

| [9] |

ZHANG J, HAO S J, JIANG D Q, et al. In situ synchrotron high-energy X-ray diffraction study of microscopic deformation behavior of a hard-soft dual phase composite containing phase transforming matrix[J]. Acta Materialia,2017,130:297-309. doi: 10.1016/j.actamat.2017.03.052

|

| [10] |

JIANG D Q, HAO S J, ZHANG J, et al. In situ synchrotron investigation of the deformation behavior of nanolamellar Ti5Si3/TiNi composite[J]. Scripta Materialia,2014,78-79:53-56. doi: 10.1016/j.scriptamat.2014.01.034

|

| [11] |

李传吉, 林建国, 张德闯, 等. 纳米SiO2颗粒增强NiTi基复合材料的制备及组织性能研究[J]. 稀有金属材料与工程, 2012, 41(8):1385-1389. doi: 10.3969/j.issn.1002-185X.2012.08.015LI C J, LIN J G, ZHANG D C, et al. Preparation and microstructure properties of nano-SiO2 particles reinforced NiTi matrix composites[J]. Rare Metal Materials and Engineering,2012,41(8):1385-1389(in Chinese). doi: 10.3969/j.issn.1002-185X.2012.08.015

|

| [12] |

FARVIZI M, EBADZADEH T, VAEZI M R, et al. Microstructural characterization of HIP consolidated NiTi-nano Al2O3 composites[J]. Journal of Alloys and Compounds,2014,606:21-26. doi: 10.1016/j.jallcom.2014.03.184

|

| [13] |

FARVIZI M, EBADZADEH T, VAEZI M R, et al. Effect of starting materials on the wear performance of NiTi-based composites[J]. Wear,2015,334-335:35-43. doi: 10.1016/j.wear.2015.04.011

|

| [14] |

FARVIZI M, AKBARPOUR M R, AHN D H, et al. Compressive behavior of NiTi-based composites reinforced with alumina nanoparticles[J]. Journal of Alloys and Compounds,2016,688:803-807.

|

| [15] |

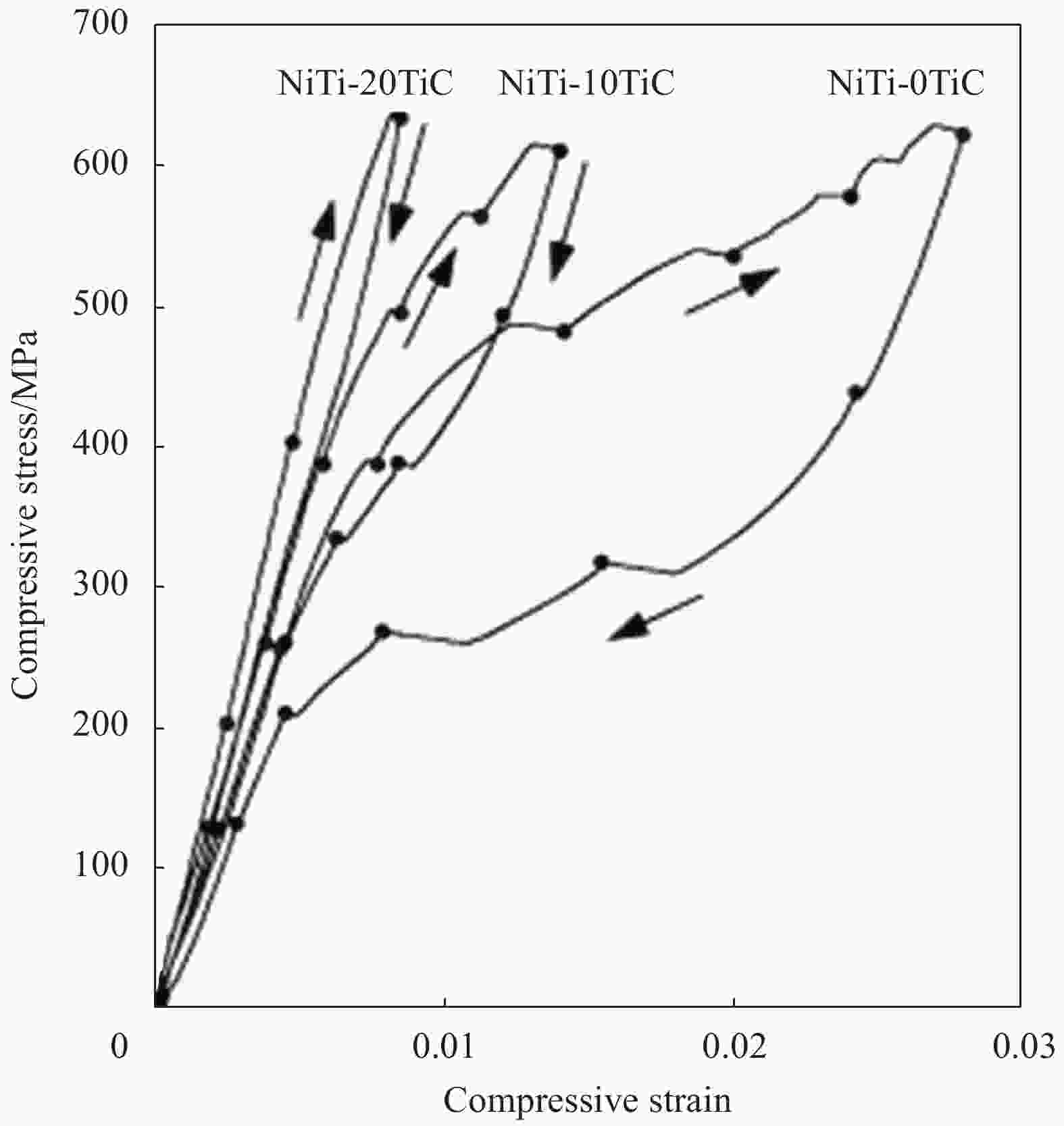

JOHANSEN K, VOGGENREITER H, EGGELER G. On the effect of TiC particles on the tensile properties and on the intrinsic two way effect of NiTi shape memory alloys produced by powder metallurgy[J]. Materials Science and Engineering A,1999,273–275:410-414.

|

| [16] |

VAIDYANATHAN R, BOURKE M A M, DUNAND D C. Stress-induced martensitic transformations in NiTi and NiTi-TiC composites investigated by neutron diffraction[J]. Office of Scientific & Technical Information Technical Reports,1999,275(99):404-409.

|

| [17] |

FUKAMI-USHIRO K L, MARI D, DUNAND D C. NiTi and NiTi-TiC composites Part II: Compressive mechanical properties[J]. Metallurgical and Materials Transactions A,1996,27(1):183-191. doi: 10.1007/BF02647758

|

| [18] |

MARI D, BATAILLARD L, DUNAND D C, et al. Martensitic transformation of NiTi and NiTi-TiC composites[J]. Journal de Physique IV,1995,5(C8):659-664.

|

| [19] |

LEE J, HWANG J, LEE D, et al. Enhanced mechanical properties of spark plasma sintered NiTi composites reinforced with carbon nanotubes[J]. Journal of Alloys and Compounds,2014,617:505-510. doi: 10.1016/j.jallcom.2014.08.091

|

| [20] |

FENG X, SUI J H, CAI W. Processing of multi-walled carbon nanotube-reinforced TiNi composites by hot pressed sintering[J]. Journal of Composite Materials,2011,45(15):1553-1557. doi: 10.1177/0021998310383734

|

| [21] |

CAI W, FENG X, SUI J H. Preparation of multi-walled carbon nanotube-reinforced TiNi matrix composites from elemental powders by spark plasma sintering[J]. Rare Metals,2012,31(1):48-50. doi: 10.1007/s12598-012-0461-3

|

| [22] |

江鸿杰. 轻质高强高阻尼Ni-Ti形状记忆合金与复合材料的制备及其性能研究[D]. 广州: 华南理工大学, 2013.JIANG H J. Fabrication and properties of lightweight, high strength and high damping Ni-Ti shape memory alloy and composites[D]. Guangzhou: South China University of Technology, 2013(in Chinese).

|

| [23] |

JIANG H J, CAO S, KE C B, et al. Nano-sized SiC particle reinforced NiTi alloy matrix shape memory composite[J]. Materials Letters,2013,100(6):74-77.

|

| [24] |

YONEZAWA T, YOSHIMURA T, UMEDA J, et al. Strengthening mechanism of TiNi shape memory sintered alloy using elemental mixtures of pre-alloyed TiNi powder and TiO2 particles[J]. Transaction of JWRI,2012,41(2):55-59.

|

| [25] |

GAO X, ZHANG X X, GENG L. Strengthening and fracture behaviors in SiCP/Al composites with network particle distribution architecture[J]. Materials Science and Engineering A,2019,740-741:353-362. doi: 10.1016/j.msea.2018.10.105

|

| [26] |

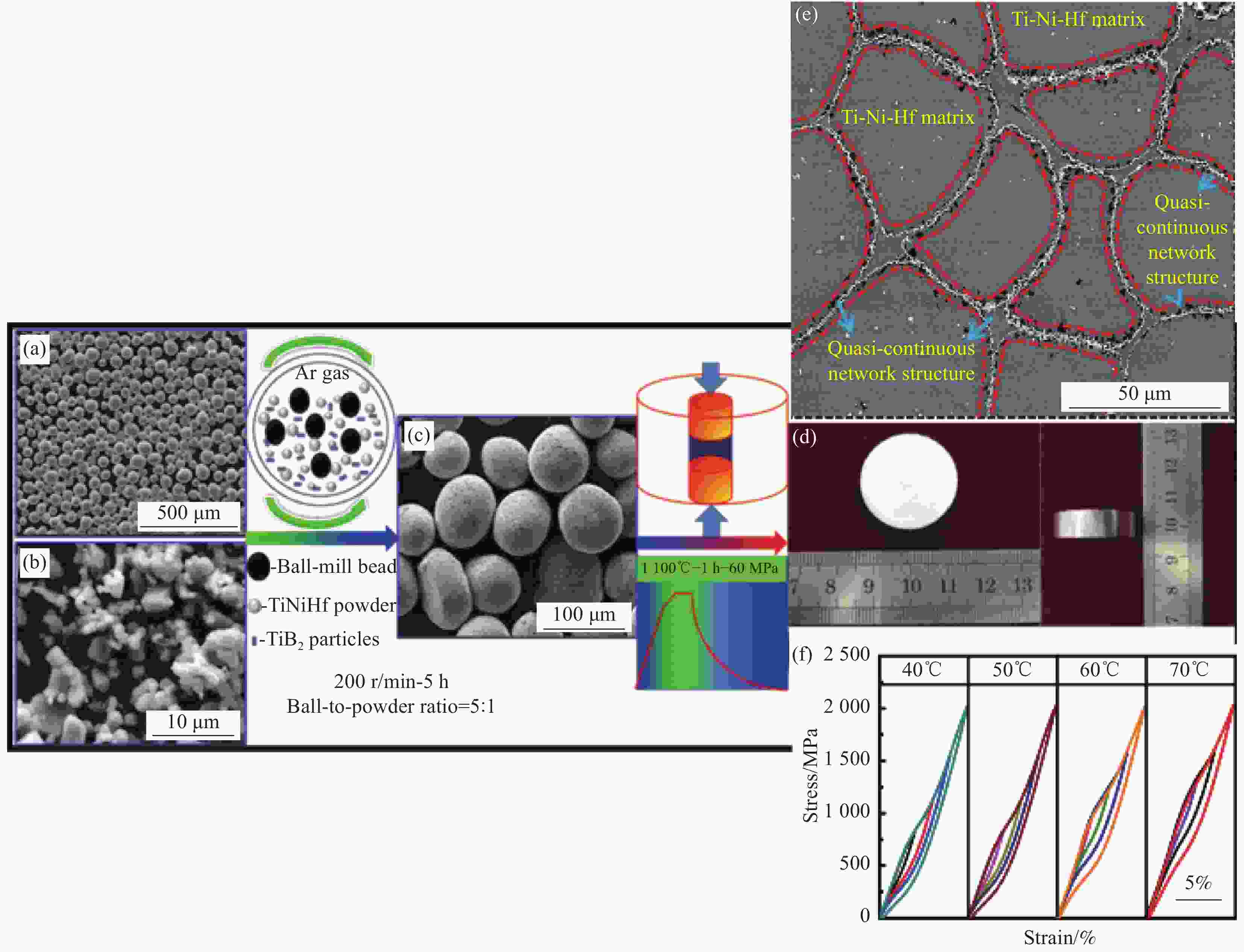

YI X Y, SUN K S, GAO W H, et al. Microstructure design of the excellent shape recovery properties in (Ti, Hf)2Ni/Ti-Ni-Hf high temperature shape memory alloy composite[J]. Journal of Alloys and Compounds,2017,729:758-763. doi: 10.1016/j.jallcom.2017.09.242

|

| [27] |

YI X Y, MENG X L, CAI W, et al. Larger strain recovery characteristics of Ti-Ni-Hf shape memory alloy composite under compression[J]. Scripta Materialia,2018,153:90-93. doi: 10.1016/j.scriptamat.2018.05.006

|

| [28] |

YI X Y, WEN G Y, SUN K S, et al. Fabrication, characterization and potential application of larger bulk Ti-Ni-Hf high temperature shape memory alloy composite reinforced by hybrid particles[J]. Journal of Alloys and Compounds,2018,764:347-358. doi: 10.1016/j.jallcom.2018.06.084

|

| [29] |

YI X Y, SHEN G J, MENG X L, et al. The higher compressive strength (TiB+La2O3)/Ti-Ni shape memory alloy composite with the larger recoverable strain[J]. Composites Communications,2021,23:100583. doi: 10.1016/j.coco.2020.100583

|

下载:

下载: