Preparation and thermoelectric properties of N type Ag2Te@PEDOT:PSS composite films

-

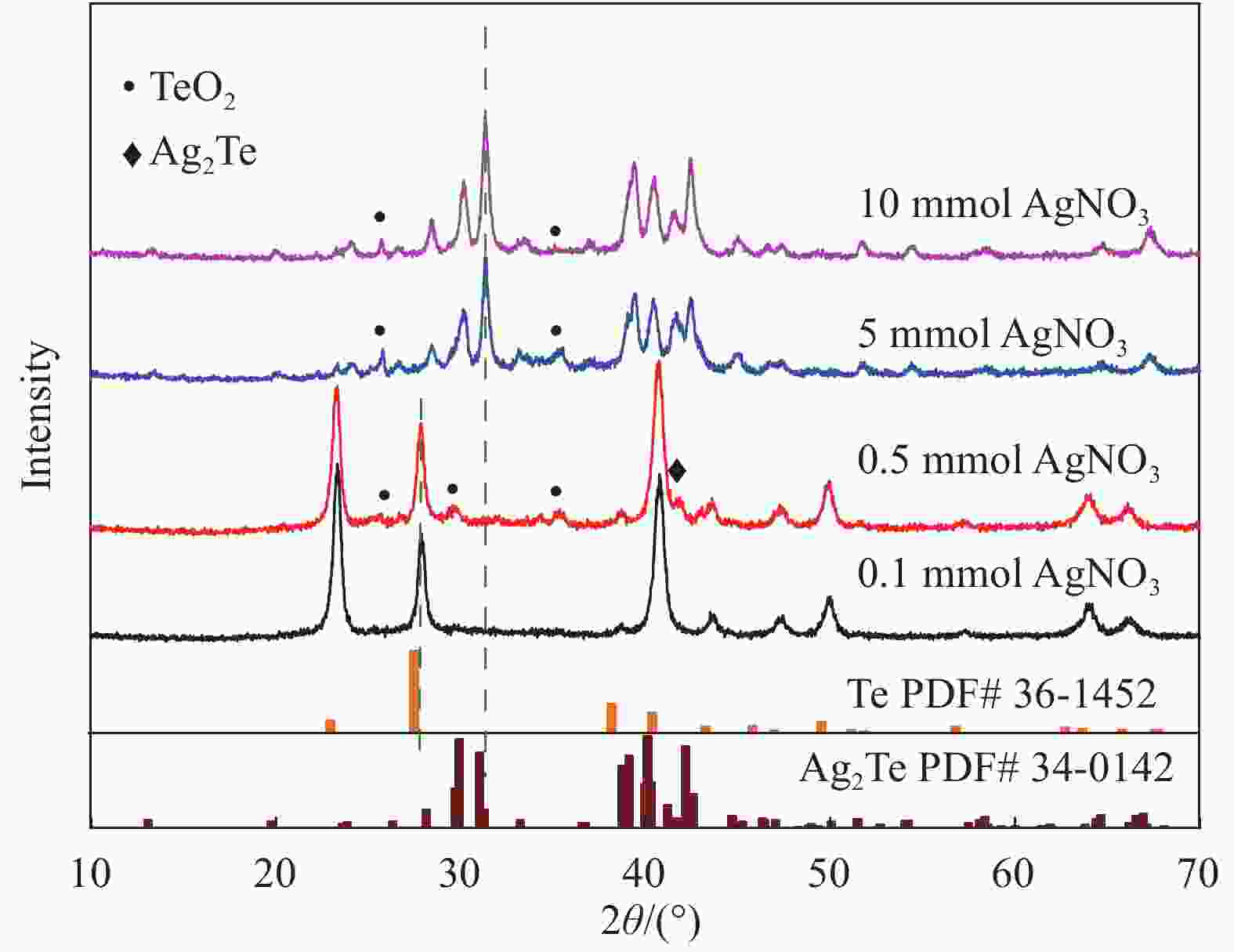

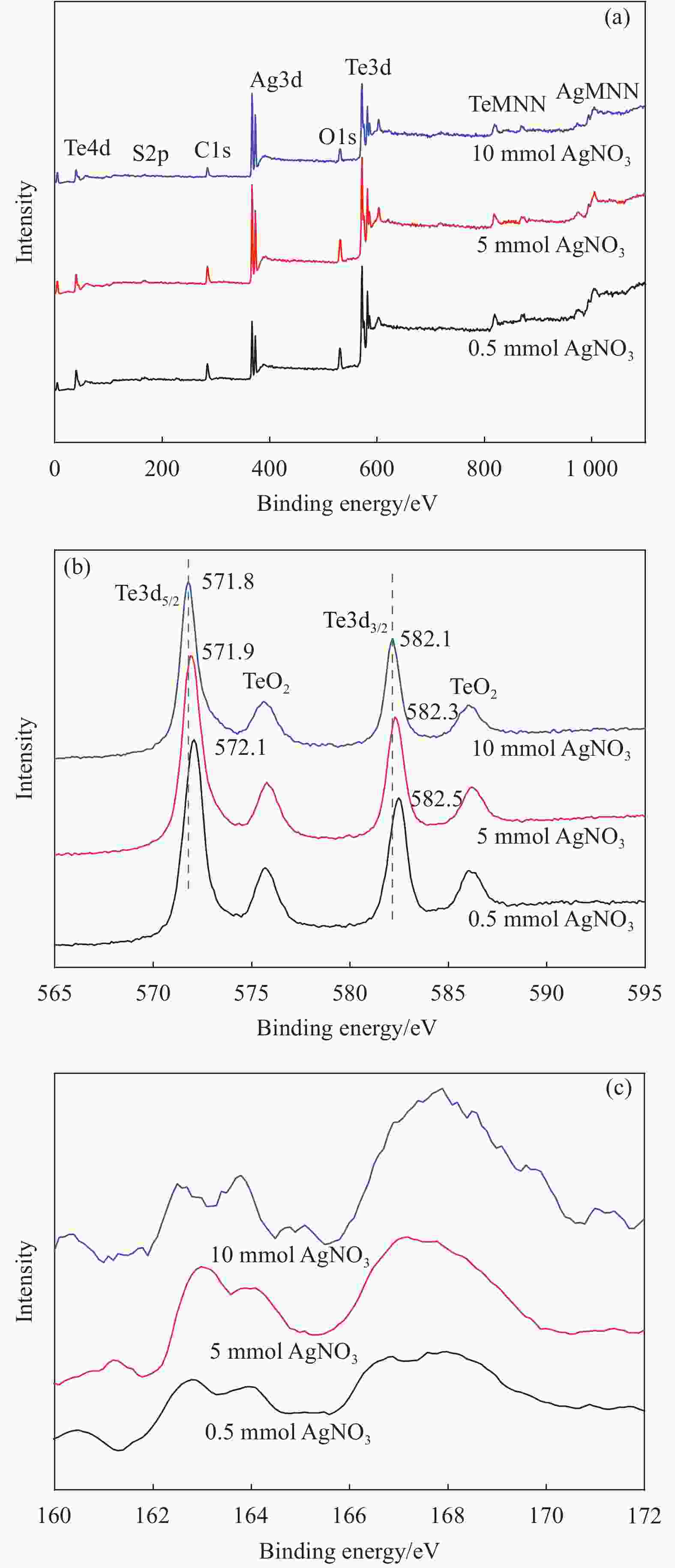

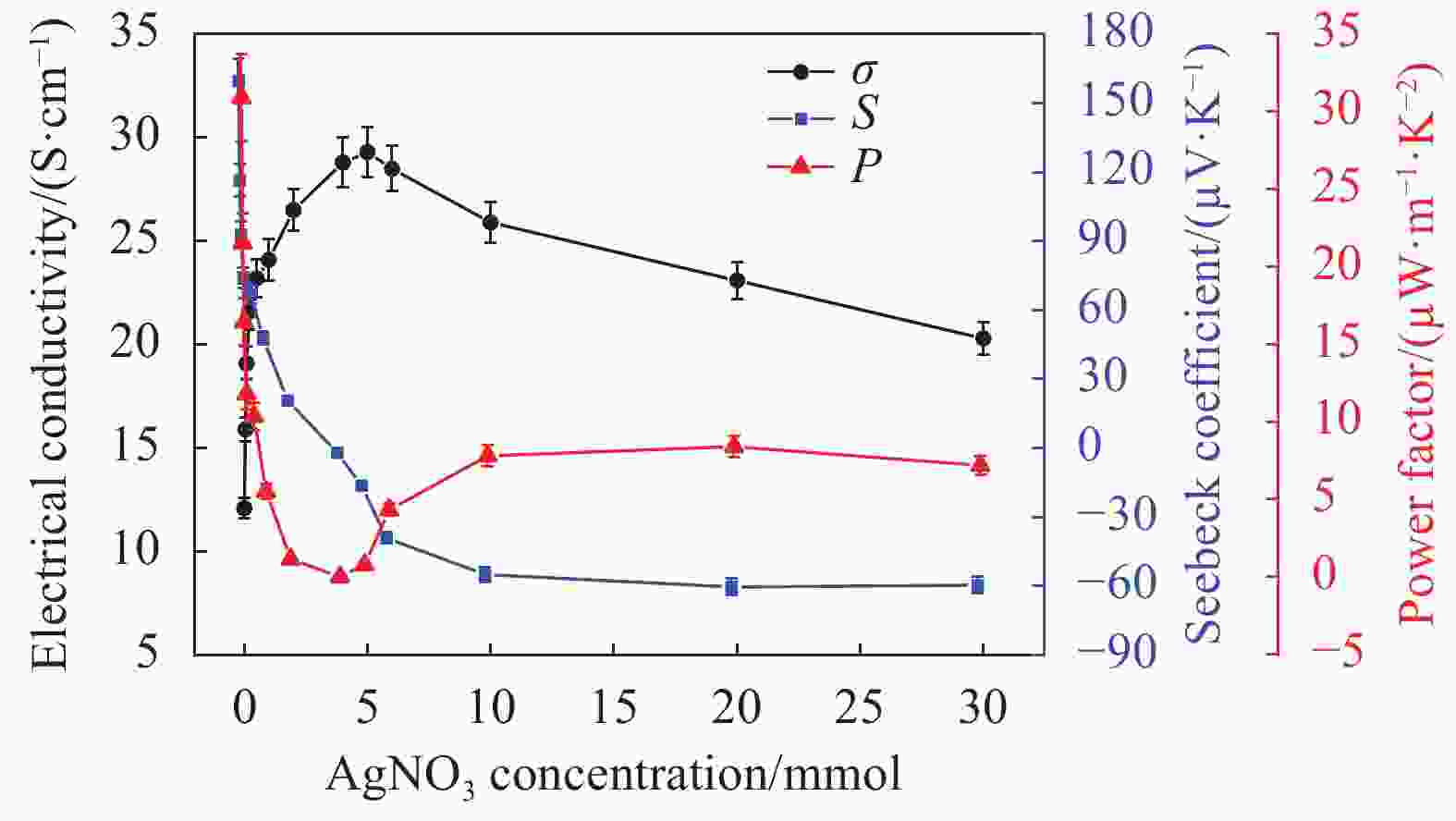

摘要: 利用一步热还原法制备了聚3, 4-乙烯二氧噻吩:聚苯乙烯磺酸包覆的Te纳米线(Te@PEDOT:PSS)复合膜,然后将其浸入不同浓度的AgNO3溶液中,通过Ag+与Te的反应使Te向Ag2Te转变,从而使热电材料由P型的Te@PEDOT:PSS复合膜转化为N型的Ag2Te@PEDOT:PSS复合膜。通过FESEM、TEM、XPS、XRD等表征手段揭示了掺杂过程中AgNO3与Te@PEDOT:PSS复合膜的作用机制,探究了掺杂浓度对Ag2Te@PEDOT:PSS复合膜热电性能的影响。反应中Ag2Te@PEDOT:PSS复合膜的电导率随着AgNO3溶液浓度的增加呈先增大后减小的趋势,主要是由于AgNO3浓度较大时生成TeO2造成的,Seebeck系数随着AgNO3浓度增大而迅速减小,主要是由于反应生成的Ag2Te为N型传导,当Ag2Te所提供的电子数量超过Te提供的空穴数量时,材料的传导机制由P型变为N型,即Seebeck系数由正变负,随着AgNO3浓度的增大,Seebeck系数的绝对值变大,当AgNO3溶液浓度为10 mmol时,Seebeck系数为(−55.9±3.3) μV/K。当AgNO3溶液浓度为20 mmol时,N型Ag2Te@PEDOT:PSS复合膜的功率因子达最大值,为(8.4±0.7) μW/(m·K2)。Abstract: The poly(3,4-ethyl-enedioxythiophene): polystyrenesulfonate functionalized Te nanowires (Te@PEDOT:PSS) composite films were in situ synthesized using a one-step thermal reduction process. Then the Te@PEDOT:PSS composite films were immersed into AgNO3 solutions with different concentration to prepare Ag2Te@PEDOT:PSS composite films. By introducing Ag+ into the Te@PEDOT:PSS composite films, P type Te@PEDOT:PSS composite films was transformed to N type Ag2Te@PEDOT:PSS composite films. FESEM, TEM, XPS, and XRD were used to analysis the reaction mechanism between AgNO3 and Te@PEDOT:PSS composite films. Also, the thermoelectric properties of the Ag2Te@PEDOT:PSS composite films as a function of AgNO3 concentration were measured. The electrical conductivity of Ag2Te@PEDOT:PSS composite films first increases as the increasing AgNO3 concentration, and then decreases due to the formation of TeO2. The Seebeck coefficient of the Ag2Te@PEDOT:PSS composite films decreases significantly with the increasing concentration of AgNO3. The phenomenon can be contributed to the N type conduction of Ag2Te, and when the amount of electron provided by Ag2Te is larger than the amount of hole from Te, the conduction mechanism changes from P type to N type. As the further increasing concentration of AgNO3, the absolute value of Seebeck coefficient of the Ag2Te@PEDOT:PSS composite films increases. And the value reaches (−55.9±3.3) μV/K when the concentration of AgNO3 is 10 mmol. The N type Ag2Te@PEDOT:PSS composite film shows a maximum power factor of (8.4±0.7) μW/(m·K2) with 20 mmol AgNO3.

-

Key words:

- PEDOT:PSS /

- Ag2Te /

- composites /

- thermoelectric properties /

- film /

- Seebeck coefficient

-

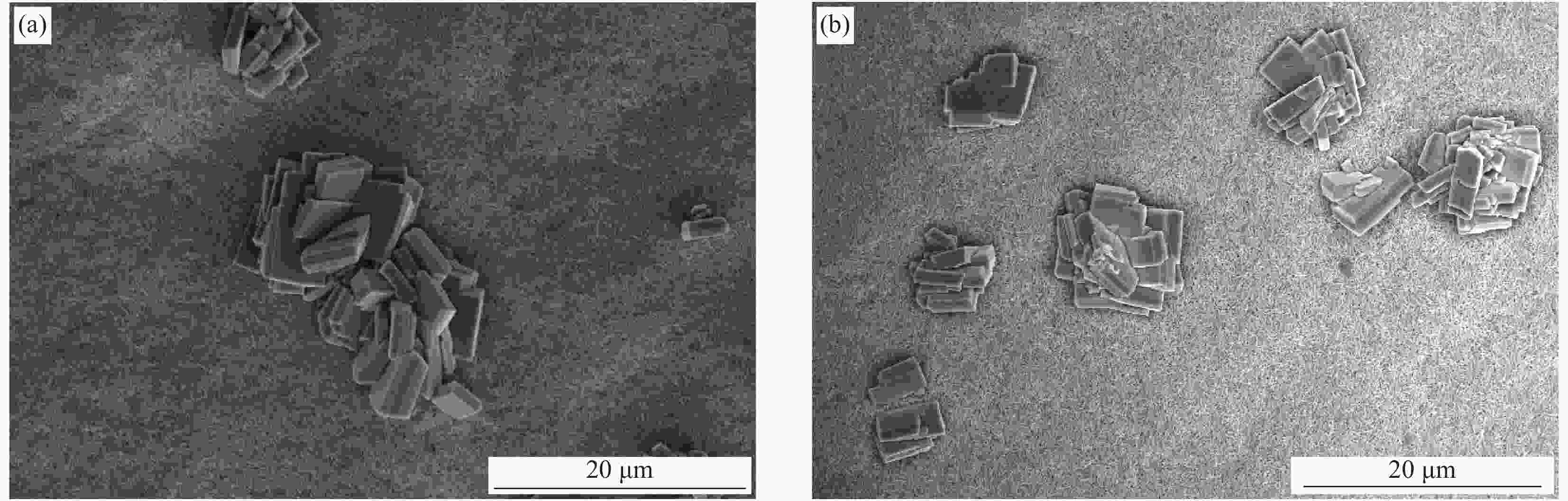

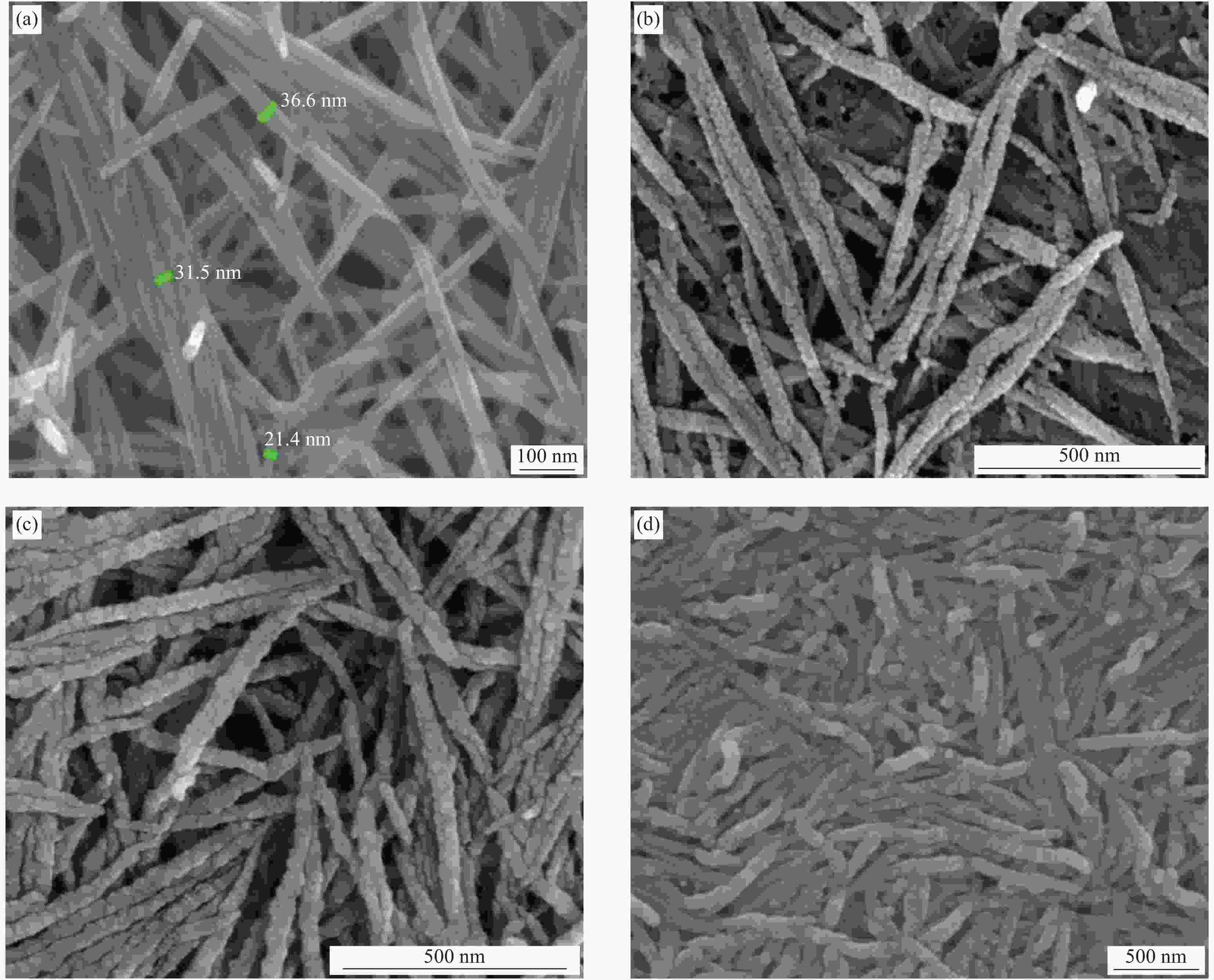

图 1 聚3, 4-乙烯二氧噻吩:聚苯乙烯磺酸包覆的Te纳米线(Te@PEDOT:PSS)复合膜及不同AgNO3浓度的Ag2Te@PEDOT:PSS复合膜的FESEM图像: (a) Te@PEDOT:PSS; (b) 0.1 mmol AgNO3; (c) 5 mmol AgNO3; (d) 10 mmol AgNO3

Figure 1. FESEM images of poly(3,4-ethyl-enedioxythiophene): polystyrenesulfonate functionalized Te nanowires (Te@PEDOT:PSS) composite film and Ag2Te@PEDOT:PSS composite films immersed in different concentration of AgNO3:(a) Te@PEDOT:PSS; (b) 0.1 mmol AgNO3; (c) 5 mmol AgNO3; (d) 10 mmol AgNO3

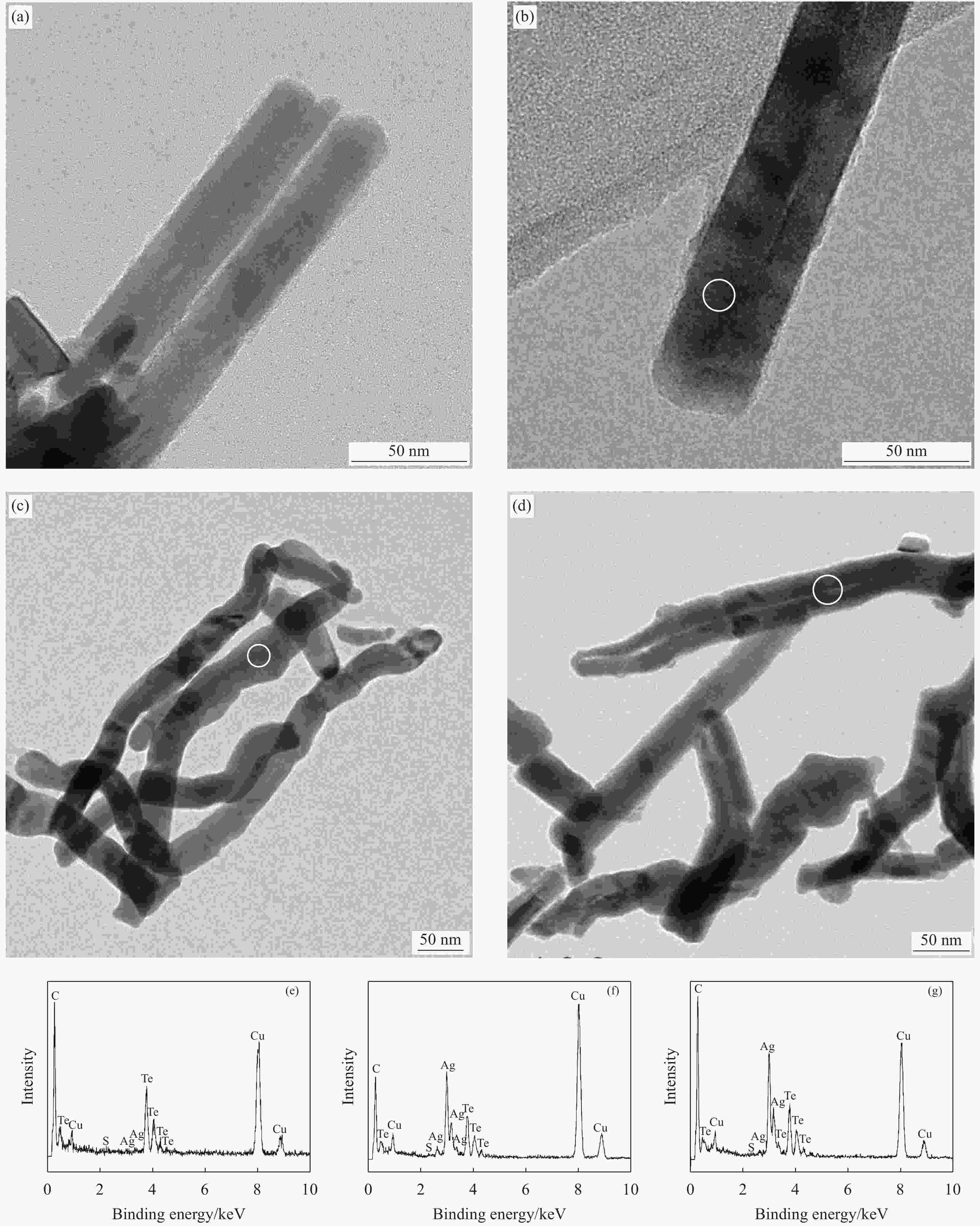

图 4 Te@PEDOT:PSS复合膜(a)和不同浓度AgNO3溶液掺杂后Ag2Te@PEDOT:PSS复合膜((b) 0.1 mmol AgNO3, (c) 5 mmol AgNO3,(d) 10 mmol AgNO3)的TEM图像及不同浓度AgNO3溶液掺杂后Ag2Te@PEDOT:PSS复合膜的EDS图谱((e) 0.1 mmol AgNO3, (f) 5 mmol AgNO3, (g) 10 mmol AgNO3; 对应 TEM图像中(b), (c), (d)的圈内成分)

Figure 4. TEM images of Te@PEDOT:PSS composite film (a) and Ag2Te@PEDOT:PSS composite films doped by AgNO3 with different concentration ((b) 0.1 mmol AgNO3, (c) 5 mmol AgNO3, (d) 10 mmol AgNO3) and EDS spectra of Ag2Te@PEDOT:PSS composite films doped by AgNO3 with different concentration ((e) 0.1 mmol AgNO3, (f) 5 mmol AgNO3, (g) 10 mmol AgNO3; Corresponding to circle part of TEM images in (b), (c) and (d))

表 1 5 mmol AgNO3浸泡后Ag2Te@PEDOT:PSS复合膜表层结晶物元素含量

Table 1. Element contents of crystal on surface of Ag2Te@ PEDOT:PSS composite film immersed in 5 mmol AgNO3

Element Mass fraction/% Atomic fraction/% O 7.80 40.10 Ag 3.95 3.01 Te 88.25 56.89 表 2 0.1 mmol AgNO3浸泡后Ag2Te@PEDOT:PSS复合膜的元素含量

Table 2. Element contents of Ag2Te@PEDOT:PSS composite film immersed in 0.1 mmol AgNO3

Element Mass fraction/% Atomic fraction/% S 0.5 2.1 Ag 2.8 3.3 Te 96.6 94.6 表 3 5 mmol AgNO3浸泡后Ag2Te@PEDOT:PSS复合膜的元素含量

Table 3. Element contents of Ag2Te@PEDOT:PSS composite film immersed in 5 mmol AgNO3

Element Mass fraction/% Atomic fraction/% S 0.4 1.5 Ag 57.6 60.9 Te 42.0 37.6 表 4 10 mmol AgNO3浸泡后Ag2Te@PEDOT:PSS复合膜的元素含量

Table 4. Element contents of Ag2Te@PEDOT:PSS composite film immersed in 10 mmol AgNO3

Element Mass fraction/% Atomic fraction/% S 0.3 1.0 Ag 59.9 63.4 Te 39.9 35.7 -

[1] 刘祎, 张荔. 聚3,4-乙烯二氧噻吩: 聚苯乙烯磺酸盐基柔性复合热电材料研究进展[J]. 复合材料学报, 2021, 38(2):1-11. doi: 10.13801/j.cnki.fhclxb.20201016.001LIU Y, ZHANG L. Recent progress on poly(3,4-ethyl-enedioxythiophene): polystyrenesulfonate-based flexible composite thermoelectric materials[J]. Acta Materiae Compositae Sinica,2021,38(2):1-11(in Chinese). doi: 10.13801/j.cnki.fhclxb.20201016.001 [2] GAO X, UEHARA K, KLUG D D, et al. Theoretical studies on the thermopower of semiconductors and low-band-gap crystalline polymers[J]. Physical Review B,2005,72(12):125202. doi: 10.1103/PhysRevB.72.125202 [3] DARGUSCH M, LIU W D, CHEN Z G. Thermoelectric generators: Alternative power supply for wearable electrocardiographic systems[J]. Advanced Science,2020,7(18):2001362. doi: 10.1002/advs.202001362 [4] XU K, CHEN G, QIU D. Convenient construction of poly(3,4-ethylenedioxythiophene)-graphene pie-like structure with enhanced thermoelectric performance[J]. Journal of Materials Chemistry A,2013,1(40):12395-12399. doi: 10.1039/c3ta12691a [5] SONG H, MENG Q, LU Y, et al. Progress on PEDOT:PSS/nanocrystal thermoelectric composites[J]. Advanced Electronic Materials,2019,5(11):1800822. doi: 10.1002/aelm.201800822 [6] BHARTI M, SINGH A, SAMANTA S, et al. Conductive polymers for thermoelectric power generation[J]. Progress in Materials Science,2018,93:270-310. doi: 10.1016/j.pmatsci.2017.09.004 [7] ZHAO D, FABIANO S, BERGGREN M, et al. Ionic thermoelectric gating organic transistors[J]. Nature Communications,2017,8(1):1-7. doi: 10.1038/s41467-016-0009-6 [8] HUANG D, YAO H, CUI Y, et al. Conjugated-backbone effect of organic small molecules for n-type thermoelectric materials with ZT over 0.2[J]. Journal of the American Chemical Society,2017,139(37):13013-13023. doi: 10.1021/jacs.7b05344 [9] HUEWE F, STEEGER A, KOSTOVA K, et al. Low-cost and sustainable organic thermoelectrics based on low-dimensional molecular metals[J]. Advanced Materials,2017,29(13):1605682. doi: 10.1002/adma.201605682 [10] ZHAO X, MADAN D, CHENG Y, et al. High conductivity and electron-transfer validation in an n-type fluoride-anion-doped polymer for thermoelectrics in air[J]. Advanced Materials,2017,29(34):1606928. doi: 10.1002/adma.201606928 [11] BUBNOVA O, KHAN ZU, MALTI A, et al. Optimization of the thermoelectric figure of merit in the conducting polymer poly(3,4-ethylenedioxythiophene)[J]. Nature Materials,2011,10(6):429-433. doi: 10.1038/nmat3012 [12] JIANG Q, LAN X, LIU C, et al. High-performance hybrid organic thermoelectric SWNTs/PEDOT:PSS thin-films for energy harvesting[J]. Materials Chemistry Frontiers,2018,2(4):679-685. doi: 10.1039/C7QM00515F [13] KIM G H, SHAO L, ZHANG K, et al. Engineered doping of organic semiconductors for enhanced thermoelectric efficiency[J]. Nature Materials,2013,12(8):719-723. doi: 10.1038/nmat3635 [14] WANG L, ZHANG Z, LIU Y, et al. Exceptional thermoelectric properties of flexible organic-inorganic hybrids with monodispersed and periodic nanophase[J]. Nature Communications,2018,9(1):3817. doi: 10.1038/s41467-018-06251-9 [15] SCHLITZ R A, BRUNETTI F G, GLAUDELL A M, et al. Solubility-limited extrinsic n-type doping of a high electron mobility polymer for thermoelectric applications[J]. Advanced Materials,2014,26(18):2825-2830. doi: 10.1002/adma.201304866 [16] RUSS B, ROBB M J, BRUNETTI F G, et al. Power factor enhancement in solution-processed organic n-type thermoelectrics through molecular design[J]. Advanced Materials,2014,26(21):3473-3477. doi: 10.1002/adma.201306116 [17] SHI K, ZHANG F, DI C A, et al. Toward high performance n-type thermoelectric materials by rational modification of BDPPV backbones[J]. Journal of the American Chemical Society,2015,137(22):6979-6982. doi: 10.1021/jacs.5b00945 [18] CHANI M T S, KARIMOV K S, ASIRI A M, et al. Temperature gradient measurements by using thermoelectric effect in CNTs-silicone adhesive composite[J]. Plos One,2014,9(4):e95287. doi: 10.1371/journal.pone.0095287 [19] SARABIA-RIQUELME R, CRADDOCK J, MORRIS E A, et al. Simple, low-cost, water-processable n-type thermoelectric composite films from multiwall carbon nanotubes in polyvinylpyrrolidone[J]. Synthetic Metals,2017,225:86-92. doi: 10.1016/j.synthmet.2016.11.014 [20] SONG H, QIU Y, WANG Y, et al. Polymer/carbon nanotube composite materials for flexible thermoelectric power generator[J]. Composites Science and Technology,2017,153:71-83. doi: 10.1016/j.compscitech.2017.10.006 [21] SUN Y, SHENG P, DI C, et al. Organic thermoelectric materials and devices based on p- and n-type poly(metal 1,1,2,2-ethenetetrathiolate)s[J]. Advanced Materials,2012,24(7):932-937. doi: 10.1002/adma.201104305 [22] SUN Y, QIU L, TANG L, et al. Flexible n-type high-performance thermoelectric thin films of poly(nickel-ethylenetetrathiolate) prepared by an electrochemical method[J]. Advanced Materials,2016,28(17):3351-3358. doi: 10.1002/adma.201505922 [23] LI F Y, HU C G, XIONG Y F, et al. Phase-transition-dependent conductivity and thermoelectric property of silver telluride nanowires[J]. The Journal of Physical Chemistry C,2008,112(41):16130-16133. doi: 10.1021/jp804053c [24] SULAEV A, ZHU W, TEO K L, et al. Gate-tuned quantum oscillations of topological surface states in β-Ag2Te[J]. Scientific Reports,2015,5(1):1-7. doi: 10.9734/JSRR/2015/14076 [25] LEE S, IN J, YOO Y, et al. Single crystalline β-Ag2Te nanowire as a new topological insulator[J]. Nano Letters,2012,12(8):4194-4199. doi: 10.1021/nl301763r [26] SUN Y, FANG H, PAN L, et al. Impact of surface-bound small molecules on the thermoelectric property of self-assembled Ag2Te nanocrystal thin films[J]. Nano Letters,2015,15(6):3748-3756. doi: 10.1021/acs.nanolett.5b00255 [27] CHANG Y, GUO J, TANG Y Q, et al. Facile synthesis of Ag2Te nanowires and thermoelectric properties of Ag2Te polycrystals sintered by spark plasma sintering[J]. CrystEngComm,2018,21(11):1718-1727. [28] PEI J, CHEN G, JIA D, et al. Crooked Ag2Te nanowires with rough surfaces: Facile microwave-assisted solution synthesis, growth mechanism, and electrical performances[J]. New Journal of Chemistry,2014,38(1):59-62. doi: 10.1039/C3NJ01303K [29] SAMAL A K, PRADEEP T. Room-temperature chemical synthesis of silver telluride nanowires[J]. The Journal of Physical Chemistry C,2009,113(31):13539-13544. doi: 10.1021/jp901953f [30] CRISPIN X, JAKOBSSON F L E, CRISPIN A, et al. The origin of the high conductivity of poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonate) (PEDOT-PSS) plastic electrodes[J]. Chemistry of Materials,2006,18(18):4354-4360. doi: 10.1021/cm061032+ [31] BALA M, BHOGRA A, KHAN S A, et al. Enhancement of thermoelectric power of PbTe thin films by Ag ion implantation[J]. Journal of Applied Physics,2017,121(21):215301. doi: 10.1063/1.4984050 [32] BERTRAME J R, PENN A, NEE M J, et al. A Novel n-type organosilane-metal ion hybrid of Rhodamine B and copper cation for low-temperature thermoelectric materials[J]. ACS Applied Materials & Interfaces,2017,9(12):10946-10954. doi: 10.1021/acsami.6b15857 -

下载:

下载: