Effect of curing agent mixing on interfacial bond behavior of glued CFRP plate-steel plate at elevated temperature

-

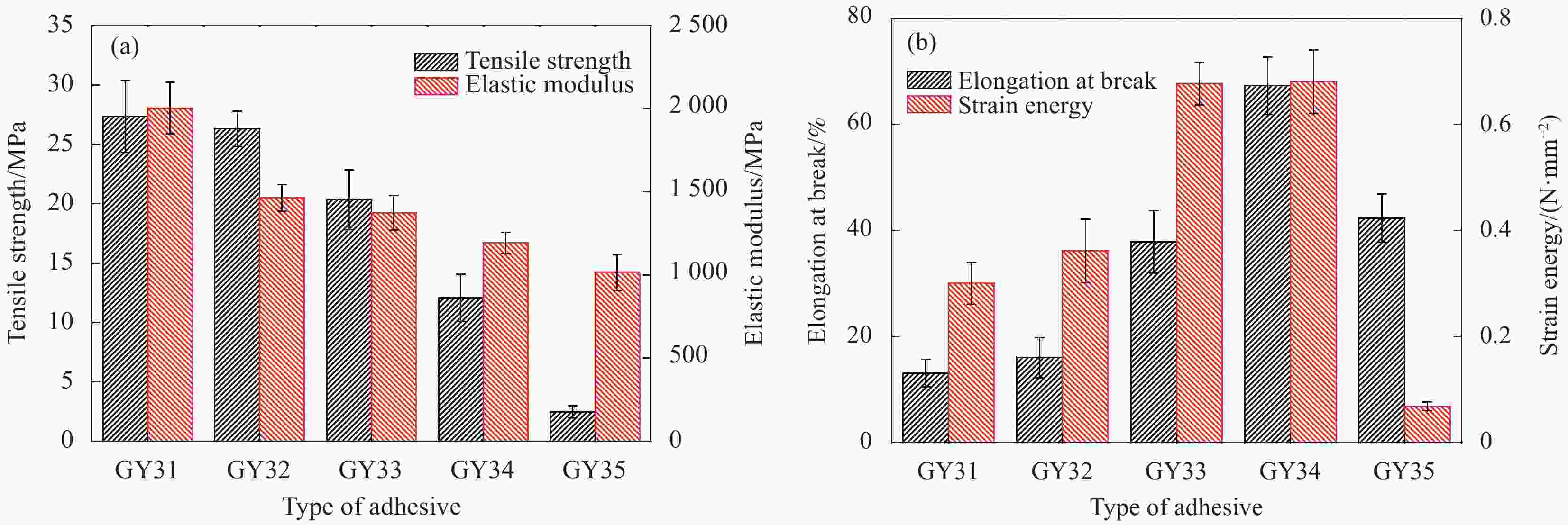

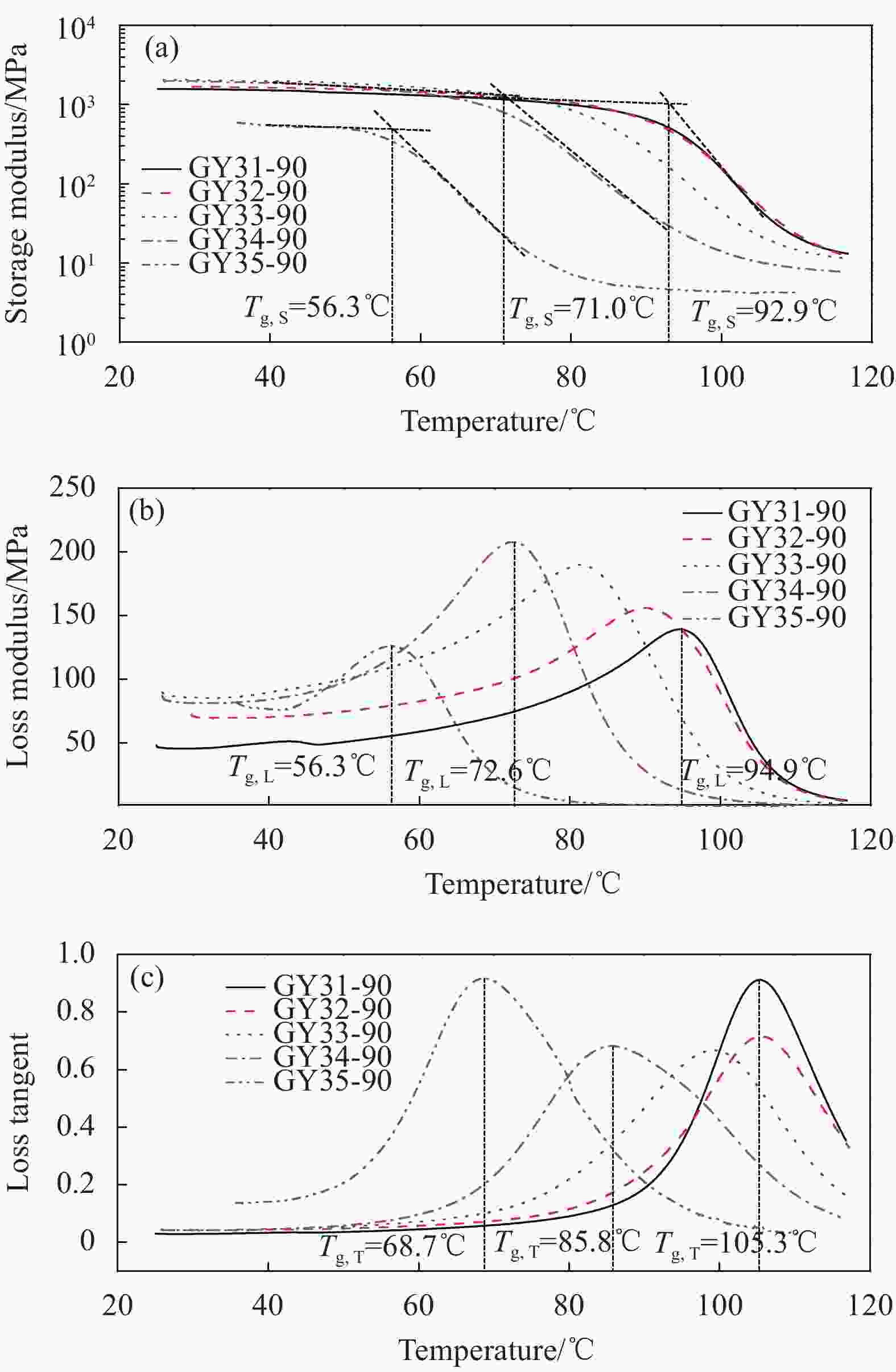

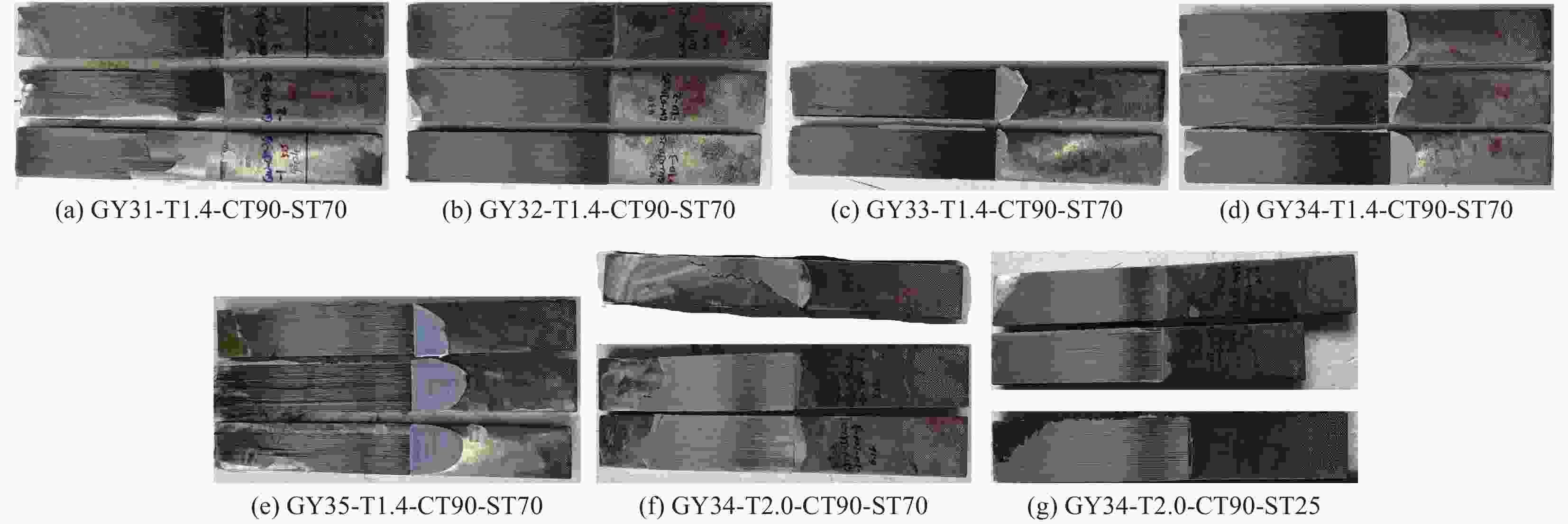

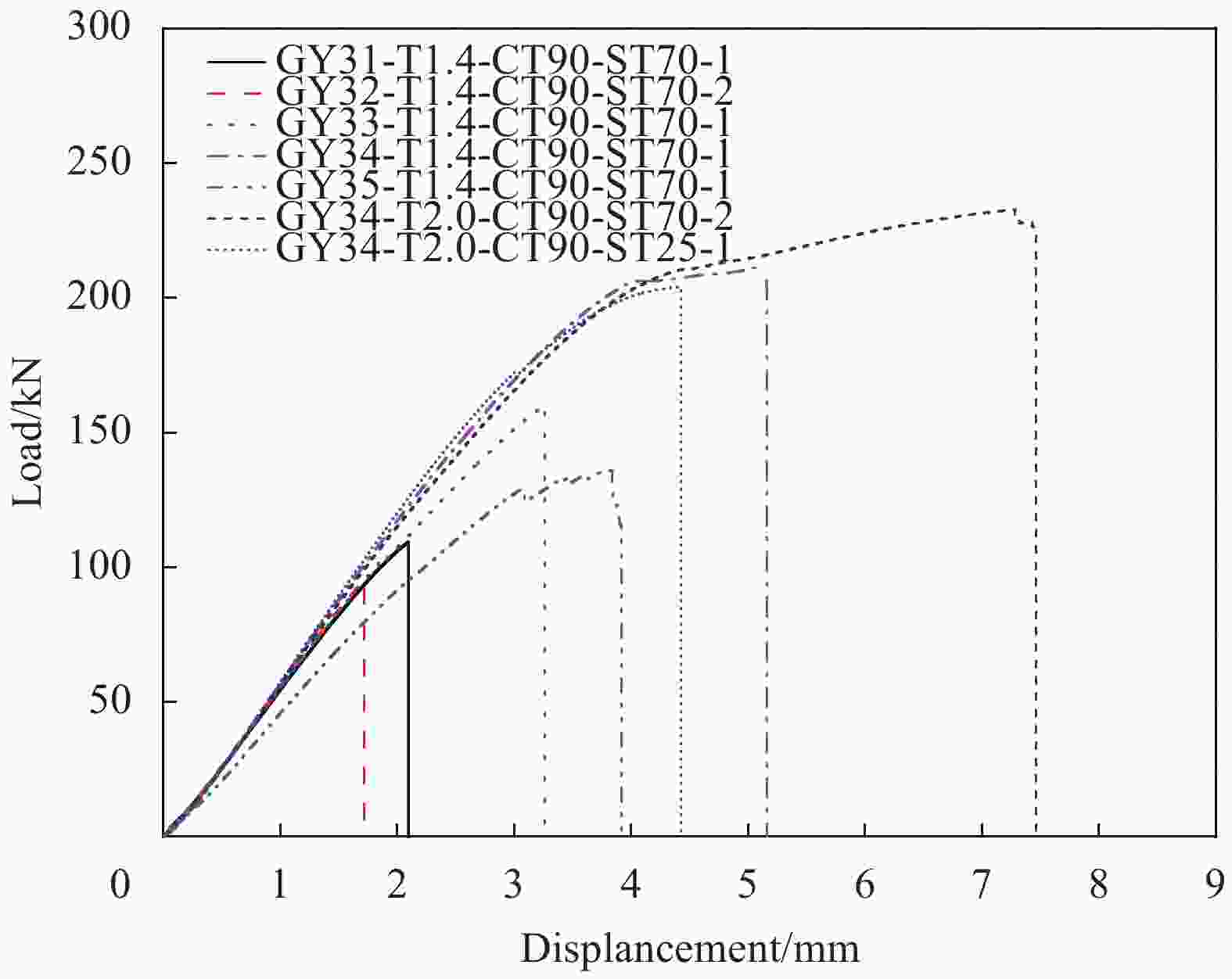

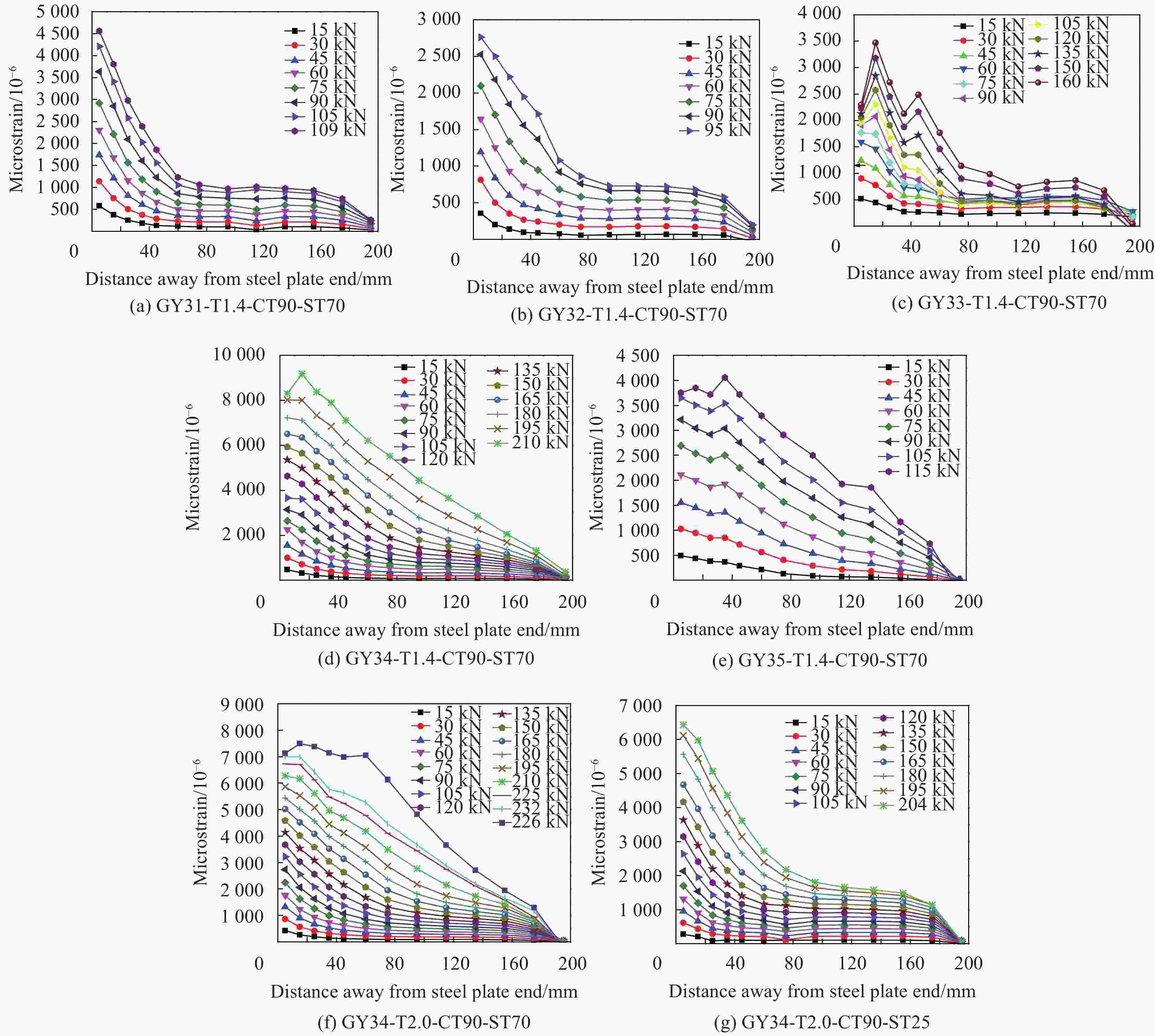

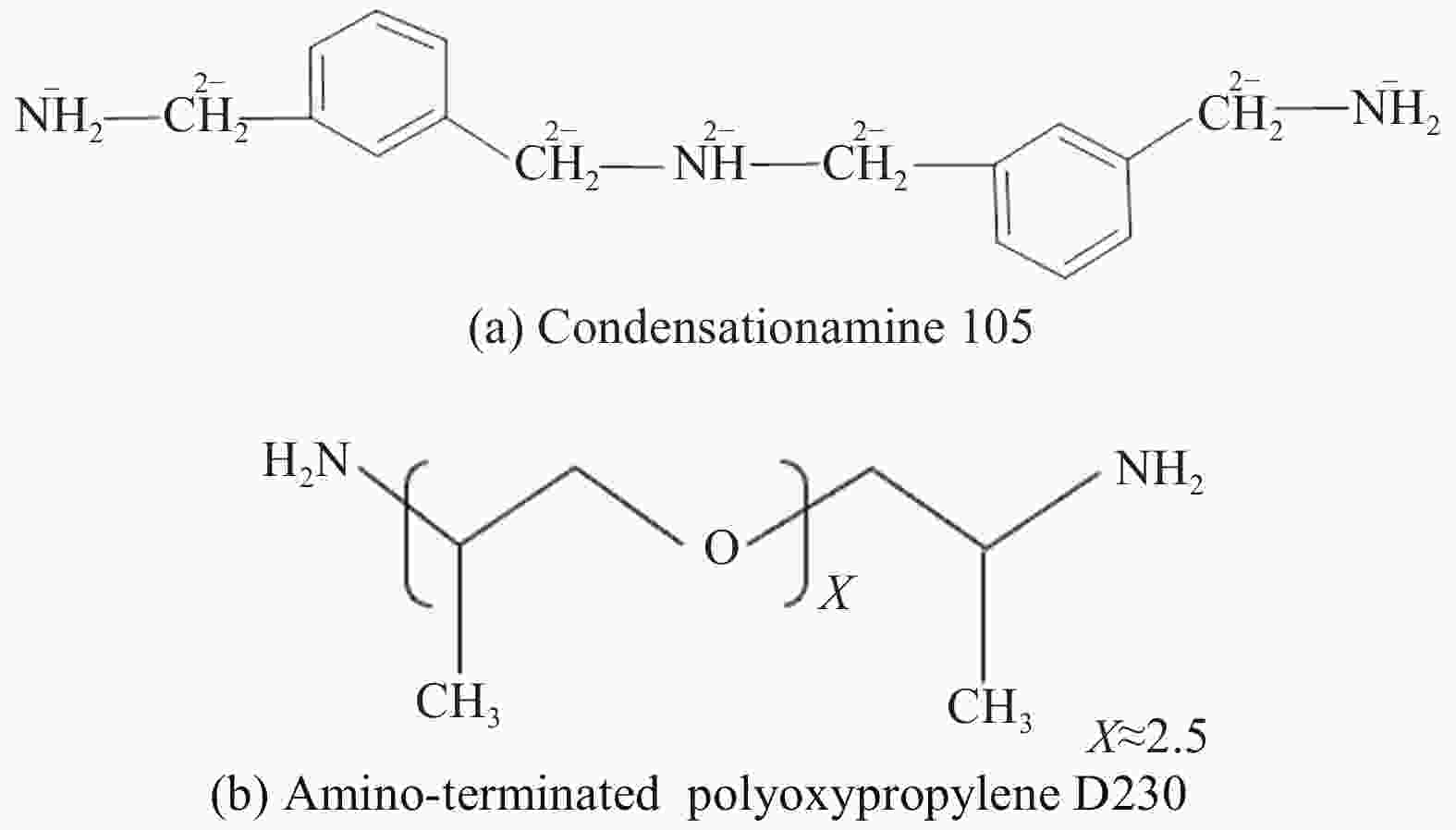

摘要: 针对单一固化剂难以兼顾耐热性和韧性的不足,研究了耐热性能较好的缩胺105和韧性较好的聚醚胺D230两种固化剂混掺对纳米SiO2环氧胶黏剂玻璃转变温度及高温下基本力学性能的影响。按一定固化条件制作了30个胶黏剂拉伸试件、21个碳纤维增强树脂复合材料(CFRP)板-钢板双搭接试件,进行了高温及常温下的准静态拉伸试验、拉伸剪切试验,测试了相应胶黏剂的动态热机械性能,并与常用商品胶的耐热性能与力学性能进行比较,得到以下结论:随混掺固化剂中聚醚胺D230比重的增加,胶黏剂高温下的拉伸强度及弹性模量逐渐降低,断裂伸长率及应变能先增加后减小,缩胺105与聚醚胺D230两种固化剂混掺的推荐比例为1∶2。随固化温度的升高,具有固化剂混掺较佳比例的胶黏剂的玻璃转变温度有所提升,综合技术与经济因素,推荐(较佳)固化条件为90℃、2 h。推荐比例与推荐固化条件的纳米SiO2环氧胶黏剂在环境温度20~70℃之间的拉伸强度及韧性均大大优于常用商品胶黏剂。基于推荐比例与推荐固化工艺的纳米SiO2胶黏剂粘结的CFRP板-钢板搭接接头,在70℃服役温度下的荷载-位移曲线存在屈服段,承载能力(较采用单一缩胺105和单一聚醚胺D230固化剂的搭接试件分别提升了104.03%、64.43%)和延性(为采用单一缩胺105固化剂的搭接试件的2.5倍以上)均大幅提升。高温和常温下的黏结-滑移本构均为三线性四边形。胶黏剂在满足耐热性的同时,需尽可能提升其韧性,才能有效提升CFRP-钢搭接界面的力学性能。相比于常用商品胶黏剂,研制的推荐胶黏剂粘结的CFRP板-钢板搭接接头具有优越得多的承载能力和界面断裂能。Abstract: Aiming at the shortcoming that it is difficult for a single curing agent to simultaneously meet the requirements of heat resistance and toughness, the influence of the mixing of two curing agents (Condensationamine 105 with excellent heat resistance and amino-terminated polyoxypropylene D230 with good toughness) on the glass transition temperature Tg and basic mechanical properties of the nano-SiO2 epoxy adhesive at elevated temperature was analyzed. According to certain curing conditions, a total of 30 adhesive tensile test pieces and 21 carbon fiber reinforced polymer (CFRP) plate-steel double lap test pieces were fabricated, and quasi-static tensile tests and shear tensile tests were performed at elevated and room temperatures. The dynamic thermodynamic properties of the corresponding adhesives were tested and compared with the heat resistance and mechanical properties of commonly used commercial adhesives. The results show that the preferred ratio of the two curing agents of condensationamine 105 and amino-terminated polyoxypropylene D230 is 1∶2. With the increase of the curing temperature, the Tg of the adhesive with the preferred ratio of two mixed curing agent is increased. Based on comprehensive technical and economic factors, the recommended (preferred) curing condition is 90℃ for 2 h. The tensile strength and toughness of the nano-SiO2 epoxy adhesive with the recommended ratio and the recommended curing conditions between ambient temperature 20~70℃ are better than the commonly used commercial adhesives. The load-displacement curve of CFRP plate-steel lap joint based on nano-SiO2 adhesive with recommended ratio and recommended curing process has a yield section at the service temperature of 70℃, and the bearing capacity (Compared with the lap joint based on nano-SiO2 adhesive with a single condensationamine 105 and a single amino-terminated polyoxypropylene 230 curing agent, the bearing capacity of the lap joint has been increased by 104.03% and 64.43%, respectively) and ductility (It is more than 2.5 times of the lap joints using a single amine 105 curing agent) are greatly improved. The bond-slip constitutive can be simplified as a trilinear quadrilateral model at elevated temperature and room temperature. Under the premise of satisfying heat resistance, the toughness of the adhesive needs to be improved as much as possible to effectively enhance the bonded behavior of the CFRP-steel lap interface. The recommended adhesive-bonded CFRP plate-steel lap joint has much superior load-bearing capacity and interface fracture energy compared with commonly used commercial adhesives.

-

表 1 胶黏剂配比

Table 1. Ratio of adhesive

g Composition Type and amount of curing agent Epoxy resin Nano-SiO2 Thixotropic agent Accelerator Defoaming agent GY31 C105 (35 g) 120 0.6 0.7 3 0.5 GY32 C105 (23.33 g)+D230 (11.67 g) 120 0.6 0.7 3 0.5 GY33 C105 (17.5 g)+D230 (17.5 g) 120 0.6 0.7 3 0.5 GY34 C105(11.67 g)+D230 (23.33 g) 120 0.6 0.7 3 0.5 GY35 D230 (35 g) 120 0.6 0.7 3 0.5 Notes: C105—Condensationamine 105; D230—Amino-terminated polyoxypropylene D230. 表 2 碳纤维增强树脂复合材料(CFRP)板及钢板材料参数

Table 2. Material parameters of carbon fiber reinforced polymer (CFRP) plate and steel plate

Material

parameterCFRP1.4

laminateCFRP2.0

laminateSteel

plateThickness/mm 1.4 2.0 12 Width/mm 50 50 50 Tensile strength/MPa 2 263 2 433 514 Elasticity modulus/GPa 161.2 162.8 206 Elongation at break/% 1.65 1.62 - 表 3 固化剂对CFRP板-钢板双搭接试件试验结果的影响

Table 3. Effect of curing agent on test results of CFRP plate-steel plate double lap test piece

Specimen

numberTa/mm Limit displacement/mm Ultimate load/kN Average bond strength/MPa Failure

mode${D_{{\rm{max}}}}$ Average ${P_{{\rm{max}}}}$ Average ${\overline p _{\max }}$ Average GY31-T1.4-CT90-ST70-1 1.09 2.29 109.30 5.5 b/d GY31-T1.4-CT90-ST70-2 1.12 2.28 2.11 92.99 101.87 4.7 5.1 b/d GY31-T1.4-CT90-ST70-3 1.05 1.76 103.32 5.2 b/d GY32-T1.4-CT90-ST70-1 1.05 2.02 96.98 4.9 d GY32-T1.4-CT90-ST70-2 1.08 1.97 1.89 95.08 90.43 4.8 4.5 d GY32-T1.4-CT90-ST70-3 1.10 1.69 79.24 4.0 d GY33-T1.4-CT90-ST70-1 1.04 3.56 160.11 8.0 d GY33-T1.4-CT90-ST70-2 1.09 4.31 4.02 179.24 171.12 9.0 8.6 d GY33-T1.4-CT90-ST70-3 1.12 4.20 174.02 8.7 d GY34-T1.4-CT90-ST70-1 1.06 5.16 211.18 10.6 d GY34-T1.4-CT90-ST70-2 1.09 4.85 4.99 205.64 207.85 10.3 10.4 d GY34-T1.4-CT90-ST70-3 1.12 4.98 206.73 10.3 d GY35-T1.4-CT90-ST70-1 1.11 3.92 135.84 6.8 d GY35-T1.4-CT90-ST70-2 1.05 3.61 3.76 115.38 126.41 5.8 6.3 d GY35-T1.4-CT90-ST70-3 1.07 3.75 128.01 6.4 b/d GY34-T2.0-CT90-ST70-1 1.06 6.71 225.40 11.3 b GY34-T2.0-CT90-ST70-2 1.09 7.46 7.06 232.59 229.15 11.6 11.5 a/b GY34-T2.0-CT90-ST70-3 1.03 7.02 229.46 11.5 a/b GY34-T2.0-CT90-ST25-1 1.02 4.42 204.20 10.2 d GY34-T2.0-CT90-ST25-2 1.10 4.69 4.01 208.99 205.10 10.5 10.3 d GY34-T2.0-CT90-ST25-3 1.06 4.11 202.11 10.1 d Notes: Specimen number GY**-**-**-**-**: GY—Initials of the phonetic alphabet of the curing agent, the character before the first “-”—Type of adhesive; Character after the first “-”—Thickness of CFRP board; Character after the second “-”—Curing temperature of specimens; Character after the third “-”—Service temperature of specimens; Character after the fourth “-”—Serial number of specimens in each group; Failure mode: a—CFRP and adhesive debonding failure; b—Steel and adhesive debonding failure; d—CFRP delamination. 表 4 CFRP-钢界面黏结-滑移本构参数

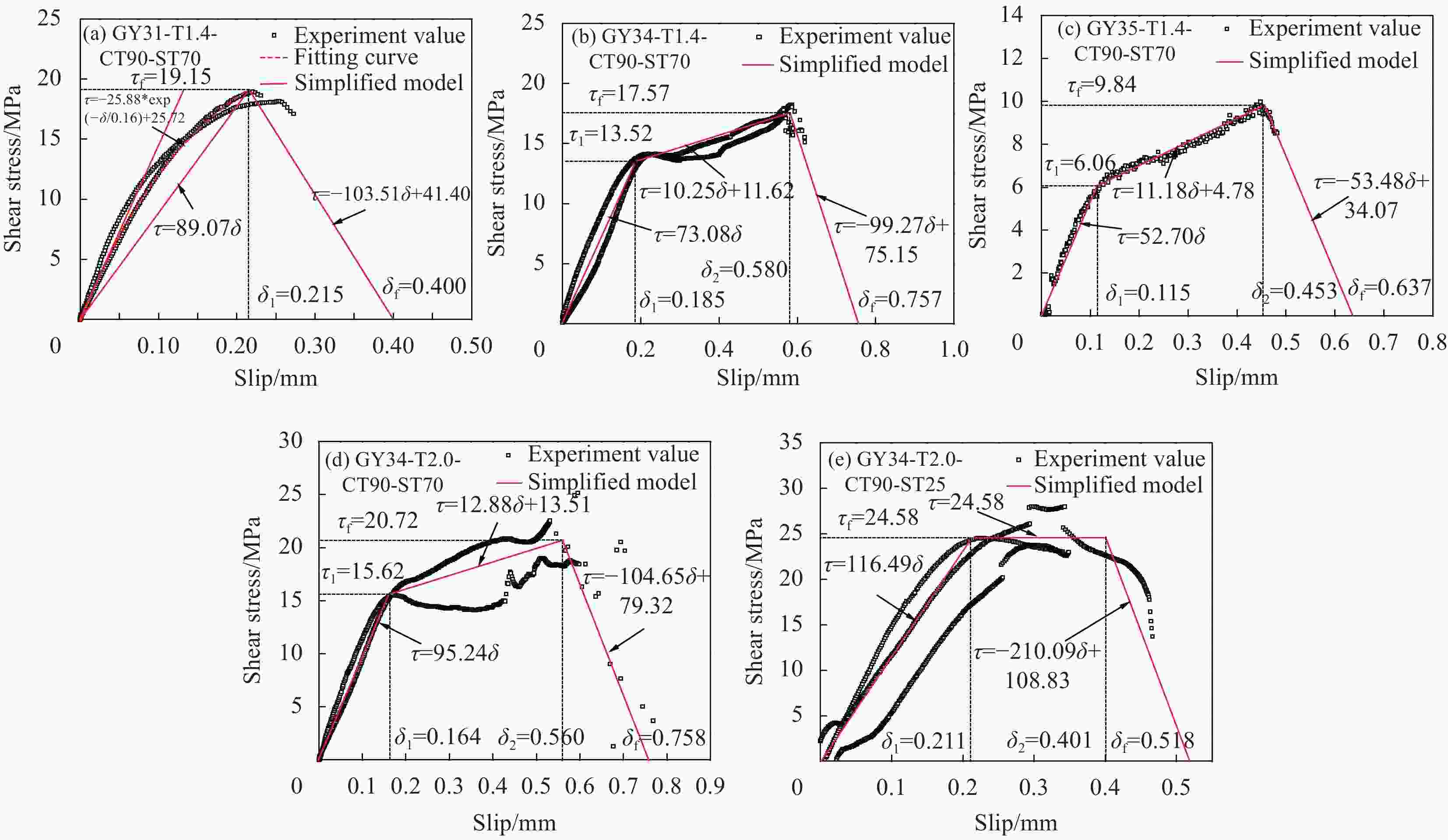

Table 4. Bond-slip constitutive parameters of CFRP-steel interface

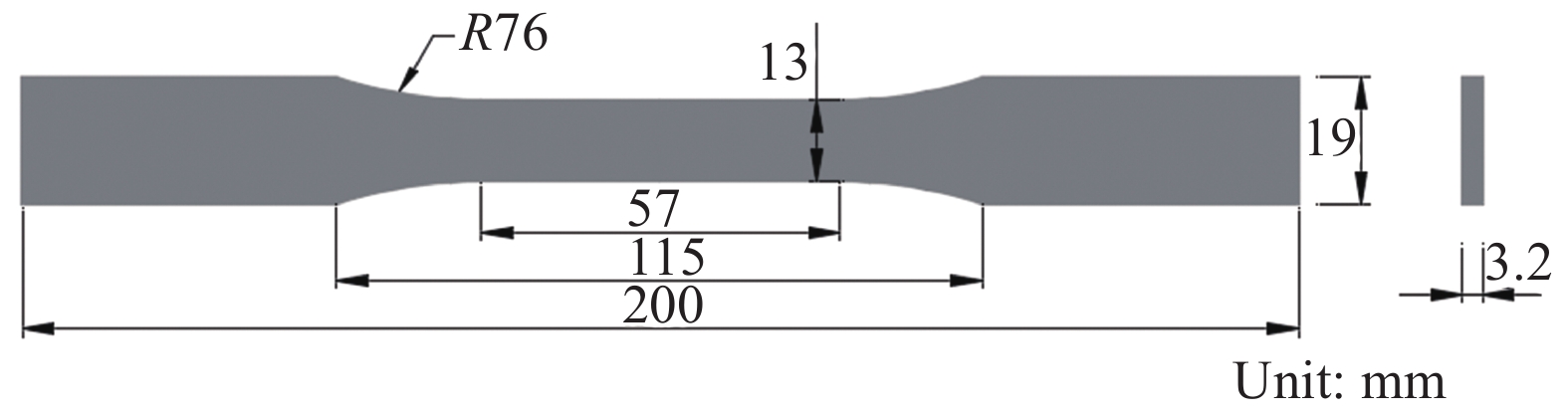

Parameter GY31-T1.4-

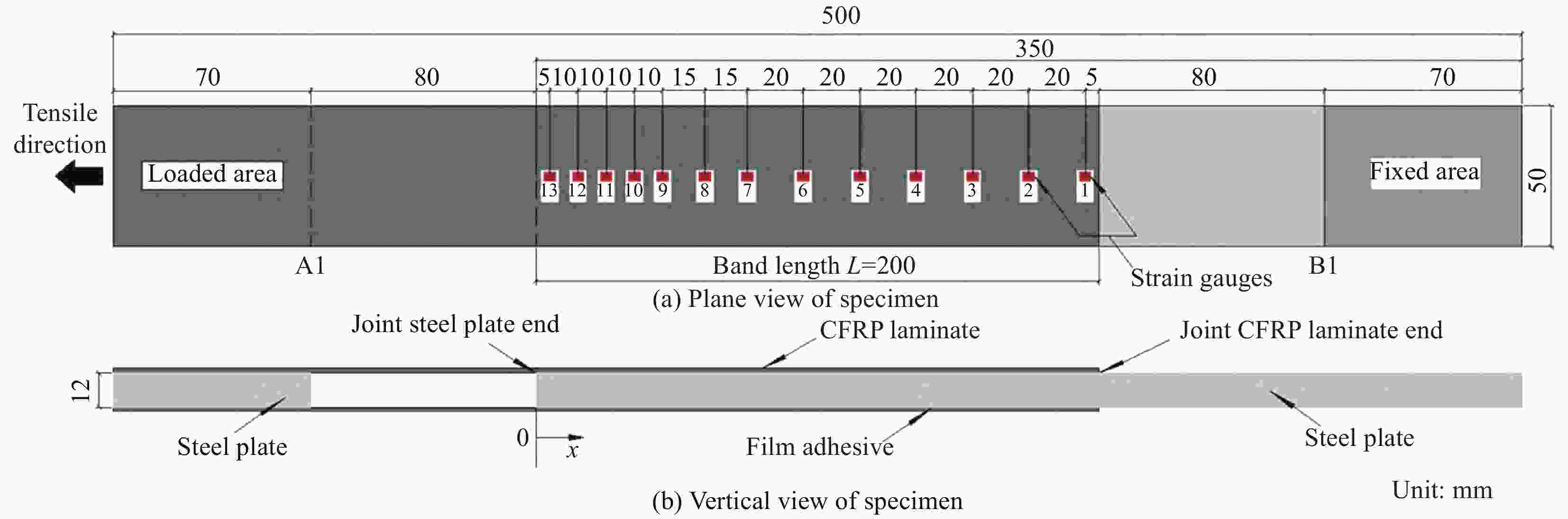

CT90-ST70GY34-T1.4-

CT90-ST70GY35-T1.4-

CT90-ST70GY34-T2.0-

CT90-ST70GY34-T2.0-

CT90-ST25${\tau _1}$/MPa − 13.52 6.06 15.62 24.58 ${\tau _{\rm{f}}}$/MPa 19.15 17.57 9.84 20.72 24.58 ${\delta _1}$/mm 0.215 0.185 0.115 0.164 0.211 ${\delta _2}$/mm − 0.580 0.453 0.560 0.401 ${\delta _{\rm{f}}}$/mm 0.400 0.575 0.637 0.758 0.518 $K$/(MPa·mm−1) 89.07 73.08 52.70 95.24 116.49 ${G_{\rm{f}}}$/(MPa·mm) 3.830 8.946 3.941 10.527 8.701 Notes: τ1—Peak elastic shear stress; τf—Peak shear stress; δ1—Maximum elastic slip; δ2—Maximum plastic slip; δf—Ultimate slip; K—Interfacial stiffness; Gf—Interfacial fracture energy. 表 5 胶黏剂GY34的玻璃化转变温度

Table 5. Glass transition temperature of adhesive GY34

Curing temperature of adhesive Tangential method Tg,S/℃ E" method Tg,L/℃ tanδ method Tg,T/℃ GY34-25(25℃ 7 days) 68.1 70.7 79.5 GY34-90(90℃ 2 h) 71.0 72.6 85.8 GY34-110(110℃ 2 h) 70.4 75.3 89.8 表 6 本文胶黏剂与商品胶黏剂的主要力学性能指标

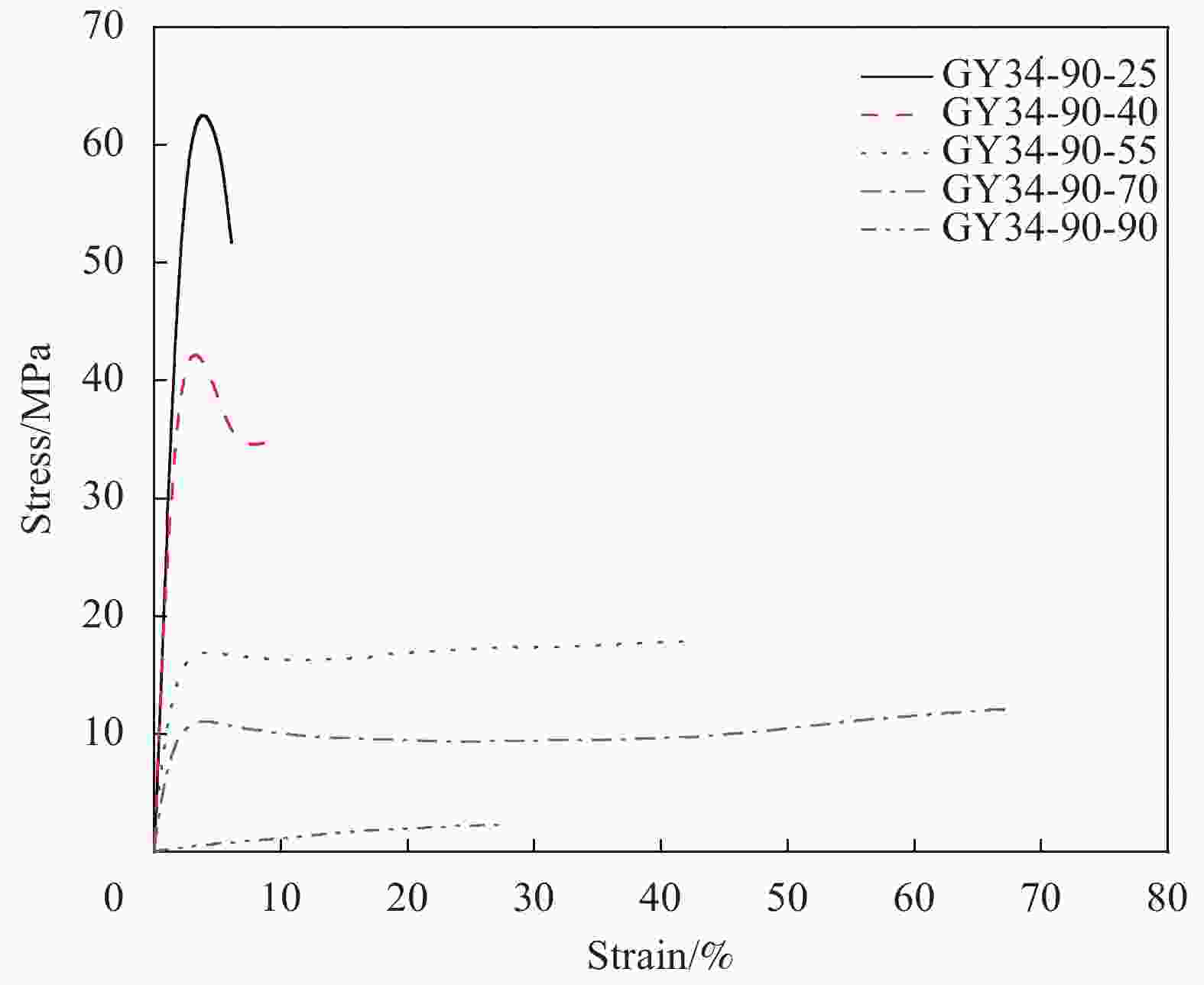

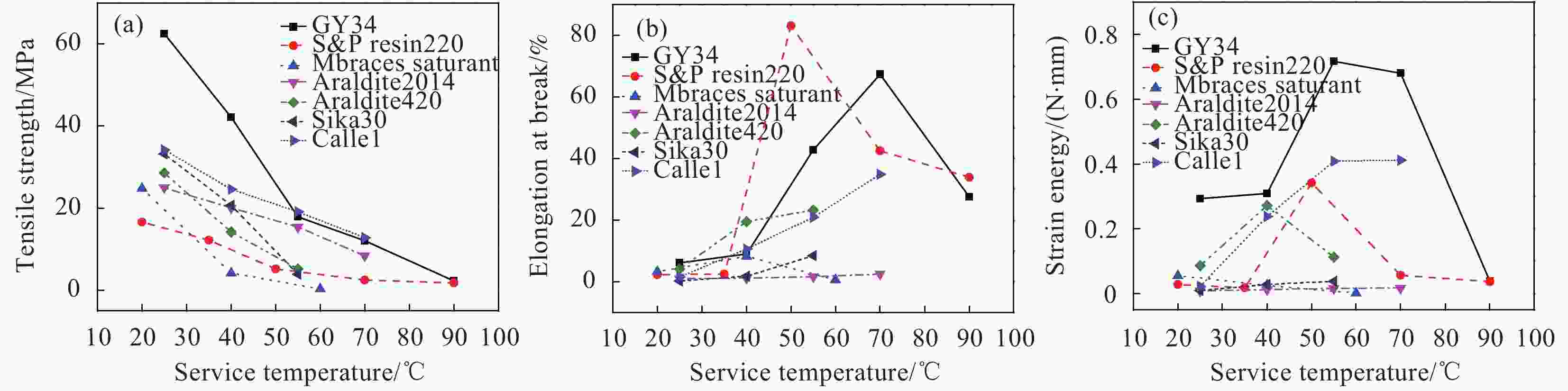

Table 6. Main mechanical properties of adhesives developed in this paper and commercial adhesives

Name of

adhesiveService

temperature/℃Tensile

strength/MPaElongation

at break/%Elastic

modulus/MPaStrain energy/

(N·mm−2)Tg,T/℃ GY34 25 62.5 6.10 3 012.3 0.2936 85.8 40 42.2 9.01 2 903.5 0.3092 55 17.9 42.80 1 733.0 0.7175 70 12.1 67.33 1 191.9 0.6806 90 2.3 27.57 71.8 0.0391 S&P Resin 220[22] 20 16.6 2.25 8 205.3 0.0284 60.0 35 12.2 2.46 6 318.2 0.0188 50 5.2 83.10 183.2 0.3421 70 2.5 42.50 82.9 0.0568 90 1.8 33.90 73.0 0.0374 Mbraces Saturant[23] 20 24.8 3.27 1 322.9 0.0552 59.2 40 4.2 8.25 283.2 0.0256 60 0.3 0.55 100.1 0.0013 Araldite2014[6] 25 25.0 0.96 4 140.0 0.0086 68.3 40 20.1 1.17 3 010.0 0.0126 55 15.4 1.60 2 320.0 0.0166 70 8.4 2.45 1 090.0 0.0169 Araldite420[6] 25 28.6 4.09 2 260.0 0.0865 43.6 40 14.2 19.50 855.0 0.2720 55 5.2 23.30 171.0 0.1130 Sika30[6] 25 33.2 0.22 11 130.0 0.0098 47.8 40 20.7 1.81 4 550.0 0.0284 55 3.9 8.40 376.0 0.0385 Calle1[6] 25 34.2 1.49 3 520.0 0.0232 63.2 40 24.6 10.60 2 360.0 0.2380 55 19.1 20.90 1 710.0 0.4090 70 12.8 34.90 752.0 0.4120 表 7 CFRP板-钢板界面黏结-滑移本构参数的比较

Table 7. Comparison of bond-slip constitutive parameters of CFRP-steel interface

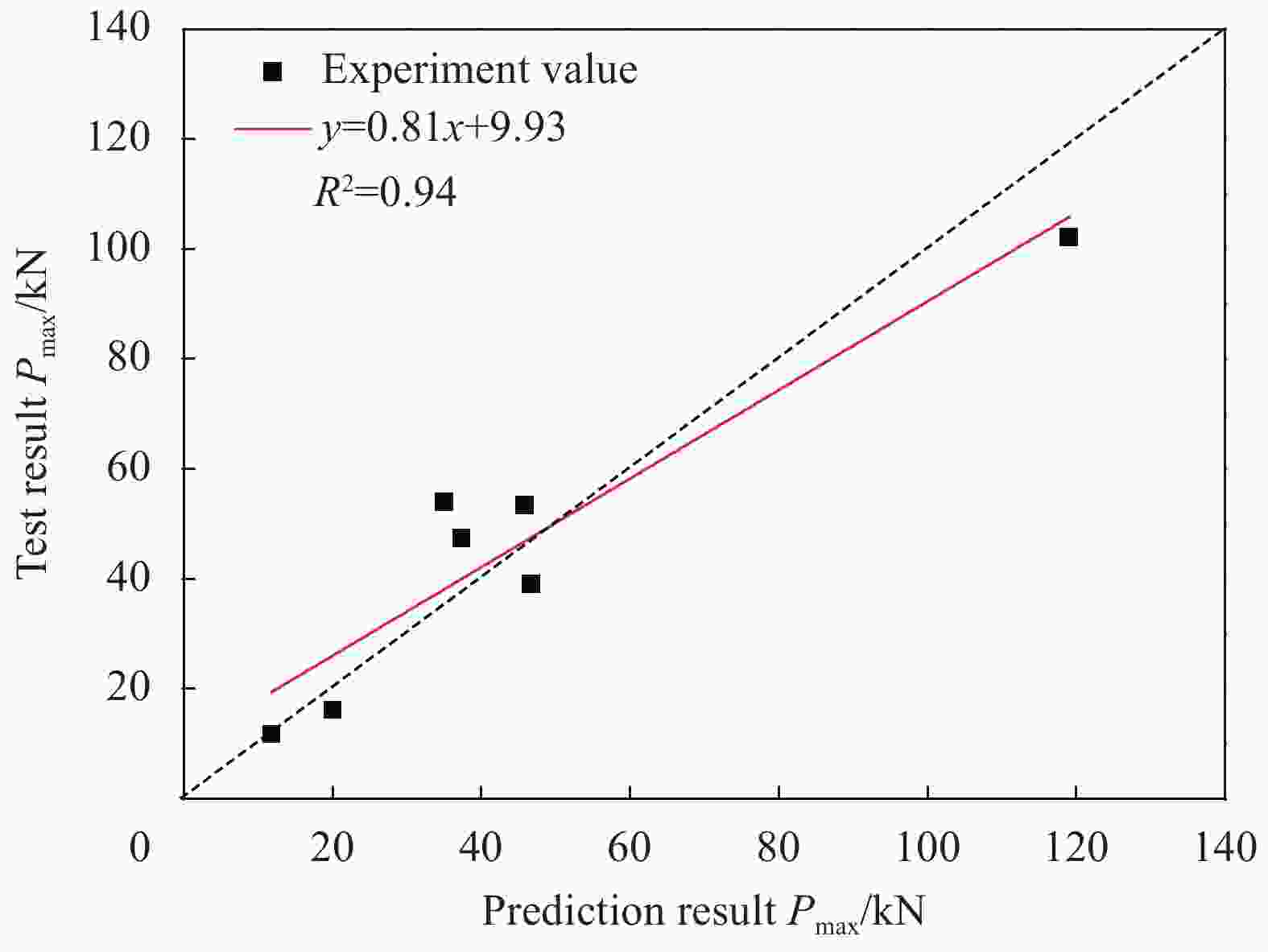

Specimen number ${\tau _1}$/MPa ${\tau _{\rm{f}}}$/MPa ${\delta _1}$/mm ${\delta _2}$/mm ${\delta _{\rm{f}}}$/mm $K$/(MPa·mm−1) ${G_{\rm{f}}}$/(MPa·mm) GY34-T2.0-CT90-ST25 24.58 24.58 0.211 0.401 0.518 116.49 8.701 GY34-T2.0-CT90-ST70 15.62 20.72 0.164 0.560 0.758 95.24 10.527 CS-35[24] - 18.90 0.068 - 0.201 277.53 0.190 CS-65[24] - 4.41 0.196 - 0.298 22.50 0.066 Sika30-22[25] - 18.00 0.046 - 0.138 388.77 1.242 Sika30-44[25] - 9.79 0.071 - 0.450 137.89 2.203 Araldite2015-23[26] 18.40 18.40 0.126 0.336 0.447 146.03 6.044 Araldite2015-42[26] 8.03 11.40 0.099 0.405 0.500 80.95 3.911 Araldite2015-82[26] 2.64 4.08 0.111 0.218 0.224 23.78 0.360 表 8 CFRP板-钢板试件极限承载力的预测值与实验值比较

Table 8. Comparison between the predicted and tested ultimate of CFRP-steel specimens

Specimen number ${b_{\rm{p}}}$/mm ${E_{\rm{p}}}$/GPa ${t_{\rm{p}}}$/mm ${G_{\rm{f}}}(T)$/(MPa·mm) ${P_{\max ,{\rm{pre}}}}$/kN ${P_{\max ,\exp }}$/kN ${P_{\max ,{\rm{pre}}}}/{P_{\max ,\exp }}$ GY34-T2.0-CT90-ST25 50 162.8 2.00 8.701 119.02 102.10 1.16 CS-35-1[24] 20 180.5 1.46 1.899 20.01 16.20 1.24 CS-65-1[24] 20 180.5 1.46 0.657 11.77 11.80 1.00 Sika30-22-1[25] 50 165.0 1.20 1.242 35.07 54.00 0.65 Sika30-44-1[25] 50 165.0 1.20 2.203 46.70 39.00 1.19 Araldite2015-23-1[26] 25 185.0 1.44 6.500 45.87 53.40 0.86 Araldite2015-42-2[26] 25 185.0 1.44 4.300 37.31 47.40 0.79 Average 0.984 Variance 0.043 Notes: bp—Width of CFRP plate; Ep—Elastic modulus of CFRP plate; tp—Thickness of CFRP plate; Pmax,pre—Predicted value of bearing capacity; Pmax,exp—Experimental value of bearing capacity. -

[1] 李传习, 李游, 陈卓异, 等. 钢箱梁横隔板疲劳开裂原因及补强细节研究[J]. 中国公路学报, 2017, 30(3):122-131.LI Chuanxi, LI You, CHEN Zhuoyi, et al. Fatigue cracking reason and detail dimension of reinforcement about transverse diaphragm of steel box girder[J]. China Journal of Highway and Transport,2017,30(3):122-131(in Chinese). [2] 李游, 李传习, 陈卓异, 等. 基于监测数据的钢箱梁U肋细节疲劳可靠性分析[J]. 工程力学, 2020, 37(2):111-123.LI You, LI Chuanxi, CHEN Zhuoyi, et al. Fatigue reliability of U-rib detail of steel box girder based on monitoring data[J]. Engineering Mechanics,2020,37(2):111-123(in Chinese). [3] 李传习, 李游, 高有为, 等. 纳米SiO2质量分数对胶粘碳纤维增强树脂复合材料板-钢搭接界面黏结性能的影响[J]. 复合材料学报, 2020, 37(10):2619-2635.LI Chuanxi, LI You, GAO Youwei, et al. Effect of nano-SiO2 mass fraction on the interface performance of glued carbon fiber reinforced polymer composite-steel specimen[J]. Acta Materiae Compositae Sinica,2020,37(10):2619-2635(in Chinese). [4] ALAA Al-Mosawe, RIADH Al-Mahaidi. Performance of CFRP-steel joints enhanced with bi-directional CFRP fabric[J]. Construction and Building Materials,2019,197(10):72-82. [5] YU Qianqian, GAO Ruixin, GU Xianglin, et al. Bond behavior of CFRP-steel double-lap joints exposed to marine atmosphere and fatigue loading[J]. Engineering Structures,2018,175(8):76-85. [6] 李传习, 曹先慧, 柯璐, 等. 高温对结构加固用环氧黏结剂力学性能的影响[J]. 建筑材料学报, 2020, 23(3):642-649.LI Chuanxi, CAO Xianhui, KE Lu, et al. Effects of high temperatures on the mechanical properties of epoxy adhesives for structural strengthening[J]. Journal of Building Materials,2020,23(3):642-649(in Chinese). [7] TANG Hongyuan, DENG Xuezhi, LIN Zhibin, et al. Analytical and experimental investigation on bond behavior of CFRP-to-stainless steel interface[J]. Composite Structures,2019,212(1):94-105. [8] YANG Yongming, HUGO Biscaia, CARLOS Chastre, et al. Bond characteristics of CFRP-to-steel joints[J]. Journal of Constructional Steel Research,2017,138(8):401-419. [9] ZHOU Helezi, LIU Hongyuan, ZHOU Huamin, et al. On adhesive properties of nano-silica/epoxy bonded single-lap joints[J]. Materials and Design,2016,95(1):212-218. [10] CHANDRATHILAKA E R K, GAMAGE J C P H, FAWZIA S. Mechanical characterization of CFRP/steel bond cured and tested at elevated temperature[J]. Composite Structures,2019,407(9):471-477. [11] CHANDRATHILAKA E R K, GAMAGE J C P H, FAWZIA S. Numerical modelling of bond shear stress slip behavior of CFRP/steel composites cured and tested at elevated temperature[J]. Composite Structures,2019,212(1):1-10. [12] BERWIS D M, COMYN J, SHALASH R J A. The effect of moisture and temperature on the properties of an epoxide-polyamide adhesive in relation to its performance in single lap joints[J]. International Journal of Adhesion and Adhesives,1982,2(4):215-222. doi: 10.1016/0143-7496(82)90028-8 [13] NGUYEN T C, BAI Y, ZHAO X L, et al. Mechanical characterization of steel/CFRP double strap joints at elevated temperatures[J]. Composite Structures,2011,93(6):1604-1612. doi: 10.1016/j.compstruct.2011.01.010 [14] YAO M, ZHU D, YAO Y, et al. Experimental study on basalt FRP/steel single-lap joints under different loading rates and temperatures[J]. Composite Structures,2016,145(2):68-79. [15] SAHIN M U, DAWOOD M. Experimental investigation of bond between high-modulus CFRP and steel at moderately elevated temperatures[J]. Journal of Composites for Construction,2016,20(6):401-409. [16] CHATAIGNER S, BENZARTI K, FORET G, et al. Design and testing of an adhesively bonded CFRP strengthening system for steel structures[J]. Engineering Structures,2018,177(10):556-565. [17] 李传习, 李游, 贺君, 等. 室温胶粘CFRP板/钢板界面性能的固化剂影响[J]. 建筑材料学报, 2021, 24(2): 339-347.LI Chuanxi, LI You, HE Jun, et al. Effect of curing agent on interfacial performance of adhesively bonded CFRP/steel cured at room temperature[J]. Journal of Building Materials, 2021, 24(2): 339-347(in Chinese). [18] American Society for Testing and Materials. Standard test method for tensile properties for plastics: ASTM D638—10[S]. West Conshohocken: ASTM International, 2010. [19] American Society for Testing and Materials. Standard test method for strength properties of double lap shear adhesive joints by tension loading: ASTM D3528—96[S]. West Conshohocken: ASTM, 2008. [20] YU T, FERNANDO D, TENG J, et al. Experimental study on CFRP-to-steel bonded interfaces[J]. Composites Part B: Engineering,2012,43(5):2279-2289. doi: 10.1016/j.compositesb.2012.01.024 [21] WANG H T, WU G. Bond-slip models for CFRP plates externally bonded to steel substrates[J]. Composite Structures,2018,184(10):1204-1214. [22] FIRMO J P, ROQUETTE M G, CORREIA J R, et al. Influence of elevated temperatures on epoxy adhesive used in CFRP strengthening systems for civil engineering applications[J]. International Journal of Adhesion and Adhesives,2019,93(1):8-18. [23] AL-SHAWAF A. Modelling wet lay-up CFRP-steel bond failures at extreme temperatures using stress-based approach[J]. International Journal of Adhesion & Adhesives,2011,31(6):416-428. [24] BISCAIA H C, RIBEIRO P. A temperature-dependent bond-slip model for CFRP-to-steel joints[J]. Composite Structures,2019,217(3):186-205. [25] ZHOU H, TORRES J P, FERNANDO D, et al. The bond behaviour of CFRP-to-steel bonded joints with varying bond properties at elevated temperatures[J]. Engineering Structures,2019,183(15):1121-1133. [26] 何俊. 胶粘剂性能对CFRP-钢界面粘结破坏行为的影响研究[D]. 哈尔滨: 哈尔滨工业大学, 2017.HE Jun. Research on the effects of adhesive properties on the failure behavior of CFRP-to-steel interface[D]. Harbin: Harbin Institute of Technology, 2017 (in Chinese). [27] LI You, LI Chuanxi, HE Jun, et al. Effect of functionalized nano-SiO2 addition on bond behavior of adhesively bonded CFRP-steel double-lap joint[J]. Construction and Building Materials,2020,244(5):1-17. -

下载:

下载: