Electromagnetic absorption properties and mechanical properties of Fe-Ni alloy/polylactic acid composites fabricated by fused deposition modeling

-

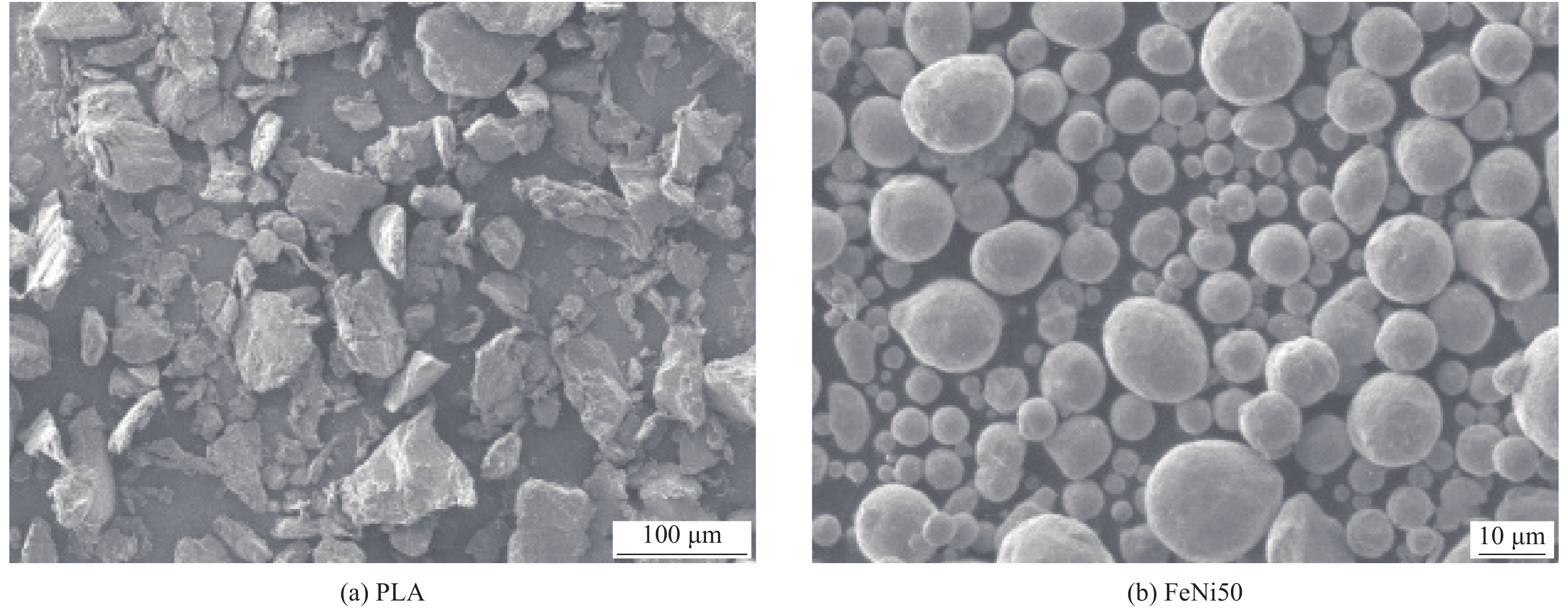

摘要: 在制备铁镍合金(FeNi50)/聚乳酸(PLA)复合线材的基础上,利用熔融沉积成形(FDM)制备出FeNi50/PLA复合材料。采用SEM、振动样品磁强计、矢量网络分析仪和万能试验机研究了FeNi50对复合材料微观形貌、磁性、电磁性能和力学性能的影响,并讨论了其反射损耗。研究发现,复合材料的饱和磁化强度和电磁性能随着FeNi50含量的增加而增加,使其反射损耗得到改善并向低频偏移。采用两步混合工艺使FeNi50颗粒相对均匀地分布在聚乳酸基体中,形成了类似海岛状的结构。这种结构阻止了FeNi50团聚并隔离了涡流,从而改善了吸波性能;得益于上述分散结构,球形颗粒分布在裂纹扩展方向上,吸收了断裂能量,使复合材料的断裂延伸率相比纯PLA提高了31.7%。表明这种基于FDM的FeNi50/PLA复合材料在吸波和承载方面具有较好的应用潜力。Abstract: The Fe-Ni alloy/polylactic acid (FeNi50/PLA) composite was prepared using fused deposition modeling (FDM) by PLA/FeNi50 composite filaments with different contents of FeNi50. Effects of FeNi50 on the micromorphology, magnetic properties, electromagnetic properties and mechanical properties of the composites were investigated using SEM, vibrating sample magnetometer, vector network analyzer and universal testing machine, and the reflection loss of composites were discussed. The results show that the saturation magnetisation strength and electromagnetic properties of the composites gradually increase as the FeNi50 content, resulting in improved reflection loss and a shift towards to low-frequency. The two-step mixing process enables FeNi50 particles to be distributed relatively uniformly in the PLA matrix, forming an island-like structure, which prevents FeNi50 agglomeration and isolates eddy currents, thus improving microwave absorption performance. Thanks to the above dispersion structure, the spherical particles are distributed in the crack extension direction, which absorbs the fracture energy and increases the elongation at break of the composites by 31.7% compared with the pure PLA. It is shown that the FDM-based FeNi50/PLA composites have good potential for microwave absorption and load-bearing applications.

-

图 8 7个不同FeNi50含量同轴环的电磁参数:在2~18 GHz频率范围内,复介电常数的实部(a)、虚部(b);复磁导率的实部(c)、虚部(d);介电损耗角正切(e)和磁损耗角正切(f)

Figure 8. Electromagnetic parameters of seven coaxial rings with different FeNi50 contents: Real (a) and imaginary (b) part of the complex permittivity; Real (c) and imaginary (d) part of the complex permeability; Tangent dielectric loss (e) and tangent magnetic loss (f) in the frequency range of 2–18 GHz

表 1 FeNi50/PLA复合粉末DSC曲线对应的数据

Table 1. DSC data of FeNi50/PLA composite powders

Sample number FeNi50 content/wt% ${T_{\rm{m}}}$/℃ ${T_{\rm{c}}}$/℃ ${T_{\rm{g}}}$/℃ Pure PLA 0 114.03 96.03 69.03 10%FeNi50/PLA 10 113.00 96.00 67.00 20%FeNi50/PLA 20 113.02 96.00 68.00 30%FeNi50/PLA 30 113.01 96.01 66.97 40%FeNi50/PLA 40 112.97 95.97 67.00 50%FeNi50/PLA 50 113.00 96.00 67.00 60%FeNi50/PLA 60 112.99 96.99 66.49 Notes: Tm—Melting temperature; Tc—Crystallization temperature; Tg—Glass transition temperature. 表 2 FeNi50/PLA复合材料的组分

Table 2. Components of FeNi50/PLA composites

Sample number Mass fraction/wt% PLA FeNi50 Pure PLA 100 0 10%FeNi50/PLA 90 10 20%FeNi50/PLA 80 20 30%FeNi50/PLA 70 30 40%FeNi50/PLA 60 40 50%FeNi50/PLA 50 50 60%FeNi50/PLA 40 60 表 3 不同FeNi50含量的FeNi50/PLA复合材料的拉伸强度和断裂延伸率

Table 3. Tensile strength and elongation at break of FeNi50/PLA composites with different FeNi50 contents

Sample

numberTensile strength/

MPaElongation at

break/%Pure PLA 37.0 14.2 10%FeNi50/PLA 27.7 13.2 20%FeNi50/PLA 26.8 13.0 30%FeNi50/PLA 25.7 14.2 40%FeNi50/PLA 24.2 15.2 50%FeNi50/PLA 24.4 17.8 60%FeNi50/PLA 23.3 18.7 -

[1] LEI Q I, HE J K, LI D C. Electrohydrodynamic 3D printing of layer-specifically oriented, multiscale conductive scaffolds for cardiac tissue engineering[J]. Nanoscale,2019,32(11):15195-15205. [2] AZAROV A V, KOLESNIKOV V A, KHAZIEW A R. Development of equipment for composite 3D printing of structural elements for aerospace applications[J]. IOP Conference Series: Materials Science and Engineering,2020,934(1):12047-12049. [3] CAMINERO M A, CHACON J M, GARCIA-MORENO I, et al. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling[J]. Composites Part B Engineering,2018,148:93-103. doi: 10.1016/j.compositesb.2018.04.054 [4] OLIVERI G, WERNER D H, MASSA A. Reconfigurable electromagnetics through metamaterials—A review[J]. Proceedings of the IEEE,2015,103(7):1034-1056. doi: 10.1109/JPROC.2015.2394292 [5] TIAN X Y, YIN L P, LI D C. 3D printing: a useful tool for the fabrication of artificial electromagnetic (EM) medium[J]. Rapid Prototyping Journal,2016,22(2):251-257. doi: 10.1108/RPJ-09-2014-0122 [6] ARBAOUI Y, LAUR V, MAALOUF A, et al. 3D printing for microwave: Materials characterization and application in the field of absorbers[C]. Phoenix: IEEE, 2015. [7] KRONBERGER R, SOBOLL P. New 3D printed microwave metamaterial absorbers with conductive printing materials[C]. London: European Microwave Association, 2016. [8] PADDUBSKAVA A, VALYNETS N, KUZHIR P, et al. Electromagnetic and thermal properties of three-dimensional printed multilayered nano-carbon/poly(lactic) acid structures[J]. Journal of Applied Physics,2016,119(13):135102. doi: 10.1063/1.4945576 [9] JIANG W, YAN L, MA H, et al. Electromagnetic wave absorption and compressive behavior of a three-dimensional metamaterial absorber based on 3D printed honeycomb[J]. Scientific Reports,2018,8(1):4817. doi: 10.1038/s41598-018-23286-6 [10] HU C, LI Z, WANG Y, et al. Comparative assessment of the strain-sensing behaviors of polylactic acid nanocompo-sites: reduced graphene oxide or carbon nanotubes[J]. Journal of Materials Chemistry C,2017,5(9):2318-2328. doi: 10.1039/C6TC05261D [11] PORRAS A, MARANON A, ASHCROFT I A. Thermo-mechanical characterization of Manicaria Saccifera natural fabric reinforced poly-lactic acid composite lamina[J]. Composites. Part A, Applied science and manufacturing,2016,81:105-110. doi: 10.1016/j.compositesa.2015.11.008 [12] MADHAVAN NAMPOOTHIRI K, NAIR N R, John R P. An overview of the recent developments in polylactide (PLA) research[J]. Bioresource technology,2010,101(22):8493-8501. doi: 10.1016/j.biortech.2010.05.092 [13] PARK K, HAN J, LEE S, et al. Fabrication and electromagnetic characteristics of microwave absorbers containing carbon nanofibers and magnetic metals[J]. Proceedings of SPIE-The International Society for Optical Engineering,2008,6929:69292G. [14] HWANG S, REYES E I, MOON K, et al. Thermo-mechanical characterization of metal/polymer composite filaments and printing parameter study for fused deposition modeling in the 3D printing process[J]. Journal of Electronic Materials,2015,44(3):771-777. doi: 10.1007/s11664-014-3425-6 [15] GUAN X N, XU X N, KUNIYOSHI R, et al. Electromagnetic and mechanical properties of carbonyl iron powders-PLA composites fabricated by fused deposition modeling[J]. Materials Research Express,2018,5(11):115303. doi: 10.1088/2053-1591/aadce4 [16] WANG Y B, CASTLES F, GRANT P. 3D printing of NiZn ferrite/ABS magnetic composites for electromagnetic devices[J]. Mrs Proceedings,2015,1788:29-35. doi: 10.1557/opl.2015.661 [17] ARBAOUI Y, AGACIAK P, CHEVALIER A, et al. 3D printed ferromagnetic composites for microwave applications[J]. Journal of Materials Science,2017,52(9):4988-4996. doi: 10.1007/s10853-016-0737-3 [18] 王晓茹, 陈支泽. 乳酸低聚物改性的纳米碳酸钙对聚乳酸性能的影响[J]. 复合材料学报, 2021, 38(9):2786-2794.WANG X R, CHEN Z Z. Effect of g-calcium carbonate modified by lactic oligomers on the properties of polylactic acid composites[J]. Acta Materiae Compositae Sinica,2021,38(9):2786-2794(in Chinese). [19] 袁彩霞, 罗卫华, 袁光明, 等. 增容纳米纤维素/聚乳酸复合材料的制备与性能[J]. 复合材料学报, 2016, 33(12):2718-2724.YUAN C X, LUO W H, YUAN G, et al. Preparation and properties of compatibilized cellulose nanocrystal/poly(lactic acid) composites[J]. Acta Materiae Compositae Sinica,2016,33(12):2718-2724(in Chinese). [20] 中国国家标准化管理委员会. 塑料拉伸性能的测定: GB/T 1040—2006[S]. 北京: 中国标准出版社, 2006.Standardization Administration of the People’s Republic of China. Plastics: Determination of tensile properties: GB/T 1040—2006[S], Beijing: China Standards Press, 2006(in Chinese). [21] XU D, YANG S, CHEN P, et al. 3D nitrogen-doped porous magnetic graphene foam-supported Ni nanocomposites with superior microwave absorption properties[J]. Jour-nal of Alloys and Compounds,2019,782(25):600-610. [22] LIU J R, ITHO M, HORIKAWA T, et al. Iron based carbon nanocomposites for electromagnetic wave absorber with wide bandwidth in GHz range[J]. Applied Physics A,2006,82(3):509-513. doi: 10.1007/s00339-005-3417-8 [23] SUGIMOTO S, MAEDA T, BOOK D, et al. GHz microwave absorption of a fine a-Fe structure produced by the disproportionation of Sm Fe in hydrogen217[J]. Journal of Alloys and Compounds,2002(330-332):301-306. [24] SOHN J C, BYUN D J, LIM S H. Theoretical and experimental permeability spectra of nano-granular Co-Fe-Al-O films for GHz magnetoelastic device applications[J]. Physica Status Solidi (A),2004,201(8):1946-1950. doi: 10.1002/pssa.200304686 [25] WEI H, CHENG L, SHCHUKIN D. Effect of porous structure on the microwave absorption capacity of soft magnetic connecting network Ni/Al2O3/Ni film[J]. Materials,2020,13(7):1764. doi: 10.3390/ma13071764 [26] HUANG B, YUE J, WEI Y, et al. Enhanced microwave absorption properties of carbon nanofibers functionalized by FeCo coatings[J]. Applied Surface Science,2019,483:98-105. doi: 10.1016/j.apsusc.2019.03.301 [27] CHEN X, SHI T, WU G, et al. Design of molybdenum disulfide@polypyrrole compsite decorated with Fe3O4 and superior electromagnetic wave absorption performance[J]. Journal of Colloid and Interface Science,2020,572:227-235. doi: 10.1016/j.jcis.2020.03.089 [28] YU J, PAN S, CHENG L, et al. Effect of Fe doping on microwave absorption performance of magnetic powder NdNi5[J]. Applied Physics A,2020,126(5):348. doi: 10.1007/s00339-020-03521-6 [29] ZAHAROV Y A, PUGACHEV V M, OVCHARENKO V I, et al. Phase composition and magnetic properties of nanostructured Fe-Co-Ni powders[J]. Physica Status Solidi (B),2018,255(3):1700175. doi: 10.1002/pssb.201700175 [30] WASEE S M, ANJUM S, MUSTAFA L. Structural, magnetic and optical investigations of Fe and Ni co-doped TiO2 dilute magnetic structural, magnetic and optical investigations of Fe and Ni co-doped TiO2 dilute magnetic semiconductors[J]. Ceramics International,2018,44(15):17767-17774. doi: 10.1016/j.ceramint.2018.06.244 [31] CHEN S, TAN G, GU X, et al. Microwave absorbing properties of FeCrMoNiPbCSi amorphous powders composite[J]. Journal of Alloys and Compounds,2017,705:309-313. doi: 10.1016/j.jallcom.2017.02.089 [32] QIAO M, LEI X, MA Y. Dependency of tunable microwave absorption performance on morphology-controlled hierarchical shells for core-shell Fe3O4@MnO2 composite microspheres[J]. Chemical Engineering Journal,2016,304:552-562. doi: 10.1016/j.cej.2016.06.094 [33] MA Z, ZHANG Y, CAO C, et al. Attractive microwave absorption and the impedance match effect in zinc oxide and carbonyl iron composite[J]. Physica B: Condensed Matter,2011,406(24):4620-4624. doi: 10.1016/j.physb.2011.09.039 [34] GUO X, YAO Z, LIN H. Epoxy resin addition on the microstructure, thermal stability and microwave absorption properties of core-shell carbonyl iron@epoxy composites[J]. Journal of Magnetism and Magnetic Materials,2019,485:244-250. doi: 10.1016/j.jmmm.2019.04.059 [35] 林坷升, 刘洁, 张媛玲, 等. 聚乳酸/羟基磷灰石复合材料激光选区烧结工艺优化与性能研究[J]. 中国机械工程, 2020, 31(19):2355-2362.LIN K S, LIU J, ZHANG Y L, et al. Study on process optimization and properties of polylactic acid/hydroxyapatite composites by selective laser sintering[J]. China Mechanical Engineering,2020,31(19):2355-2362(in Chinese). [36] 石倩. 氮化硼/环氧树脂导热复合材料的制备与性能研究[D]. 贵阳: 贵州大学, 2019.SHI Q. Preparation and properties of boron nitride/epoxy resin thermal conductive composites[D]. Guiyang: Guizhou University, 2019(in Chinese). -

下载:

下载: