Ionic thermoelectric effect and mechanism of cement-based materials

-

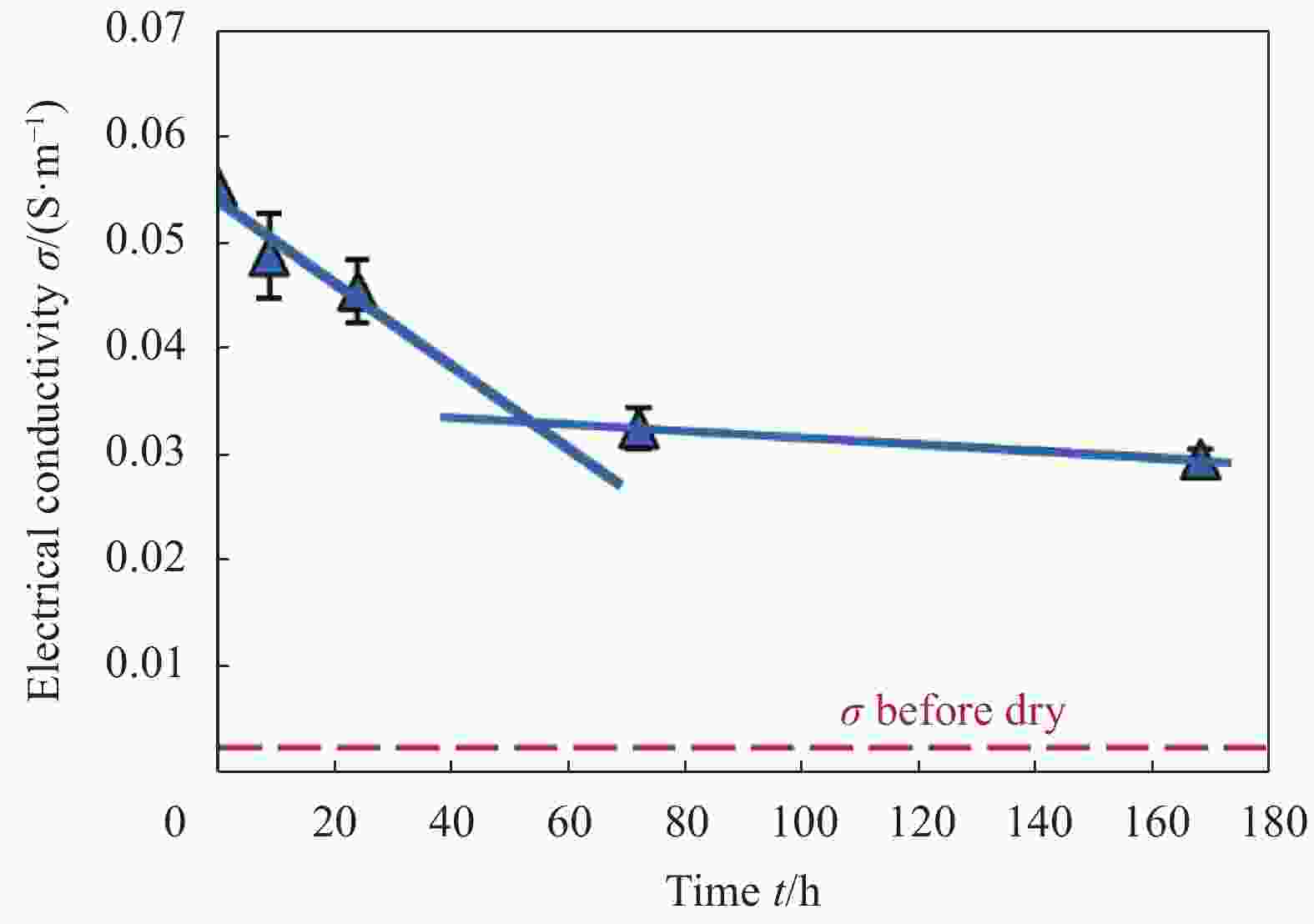

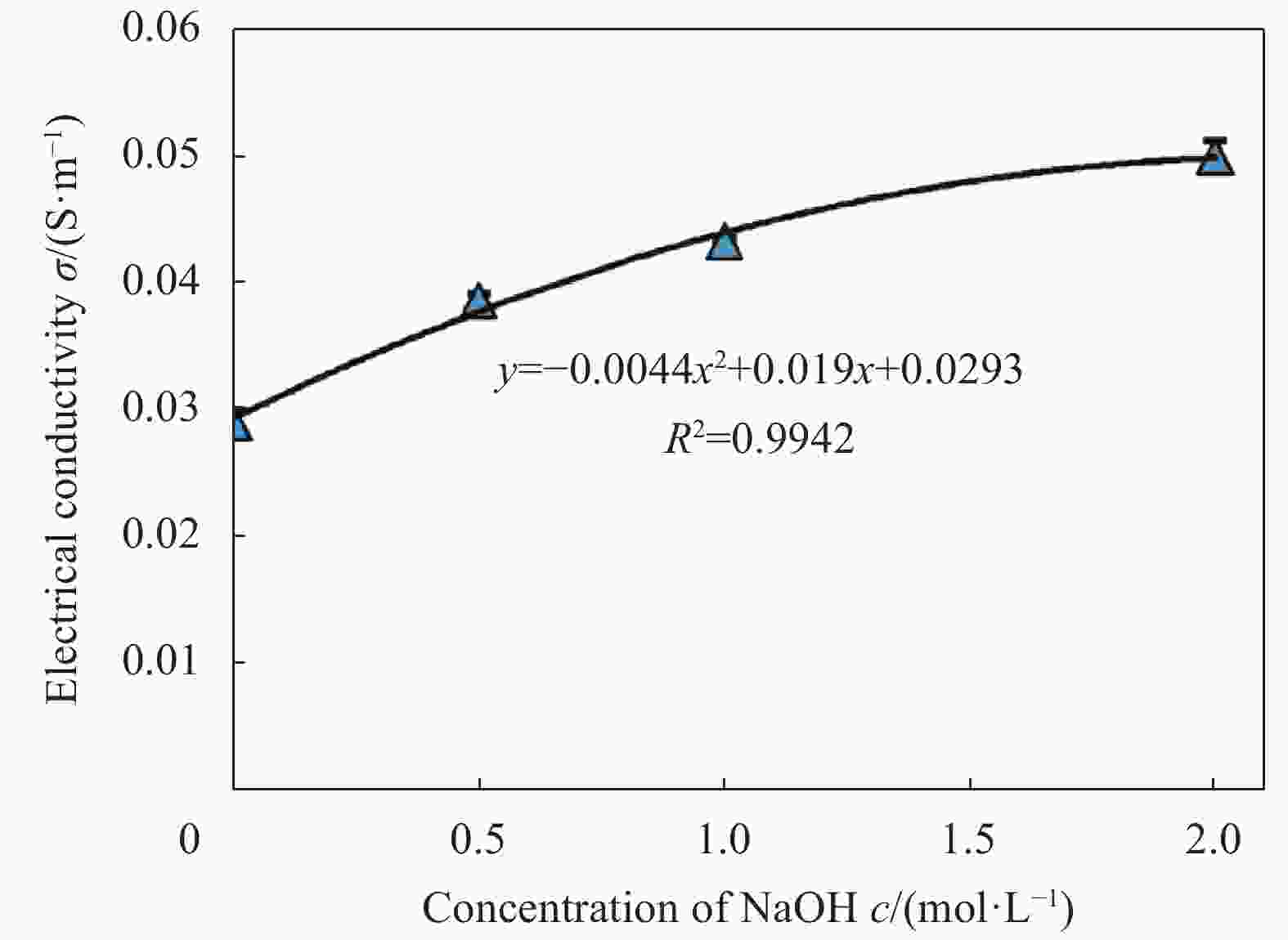

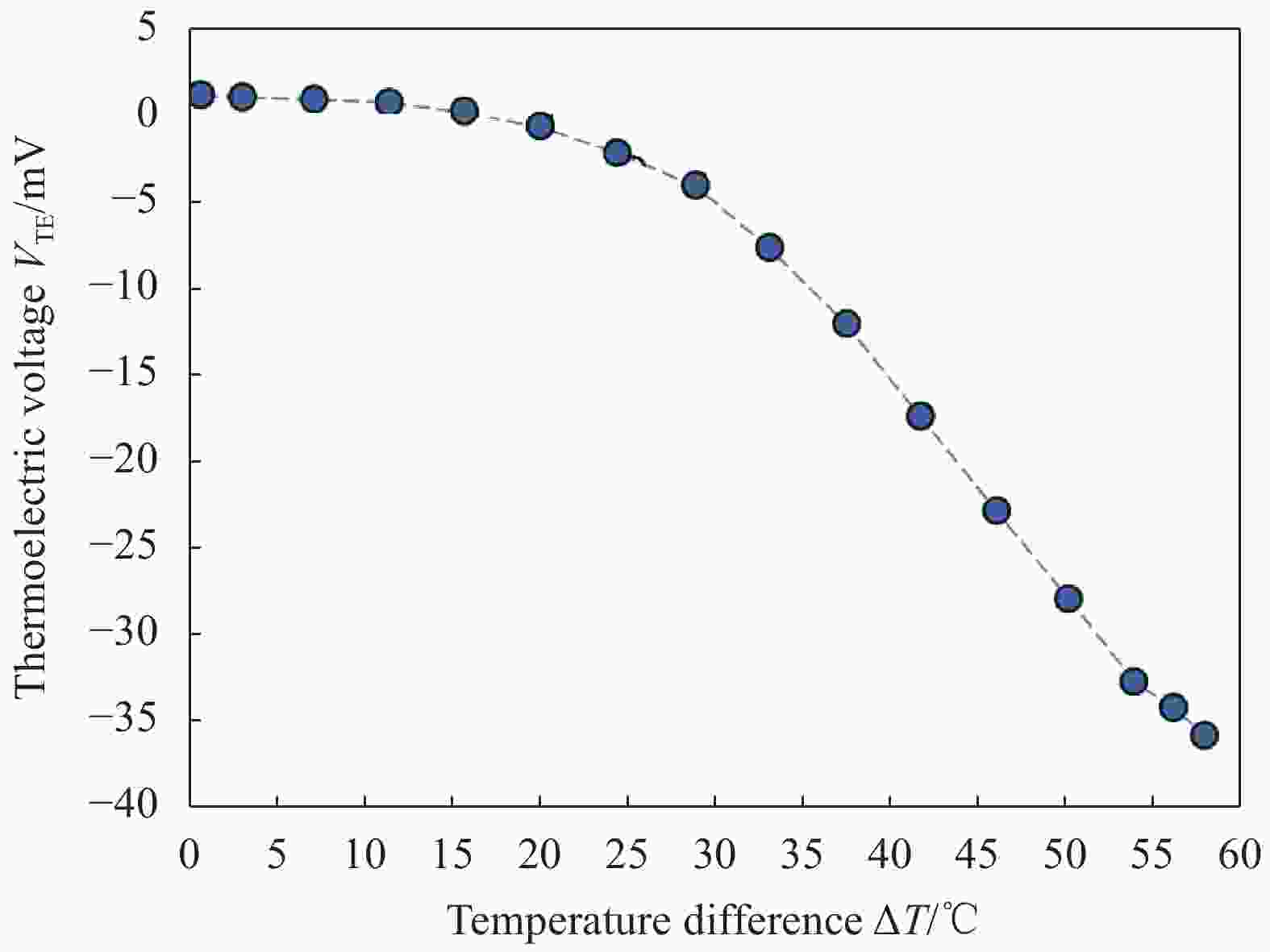

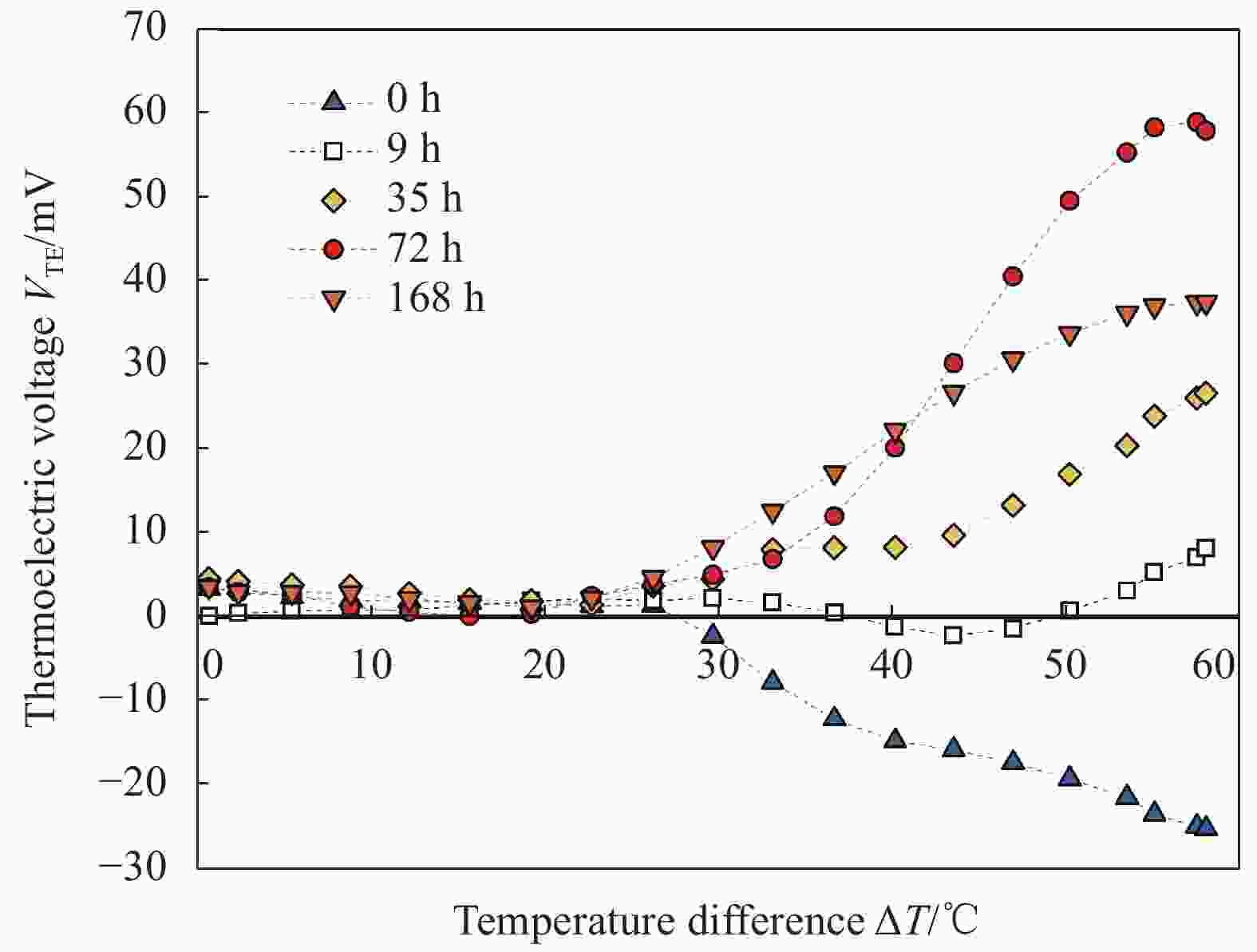

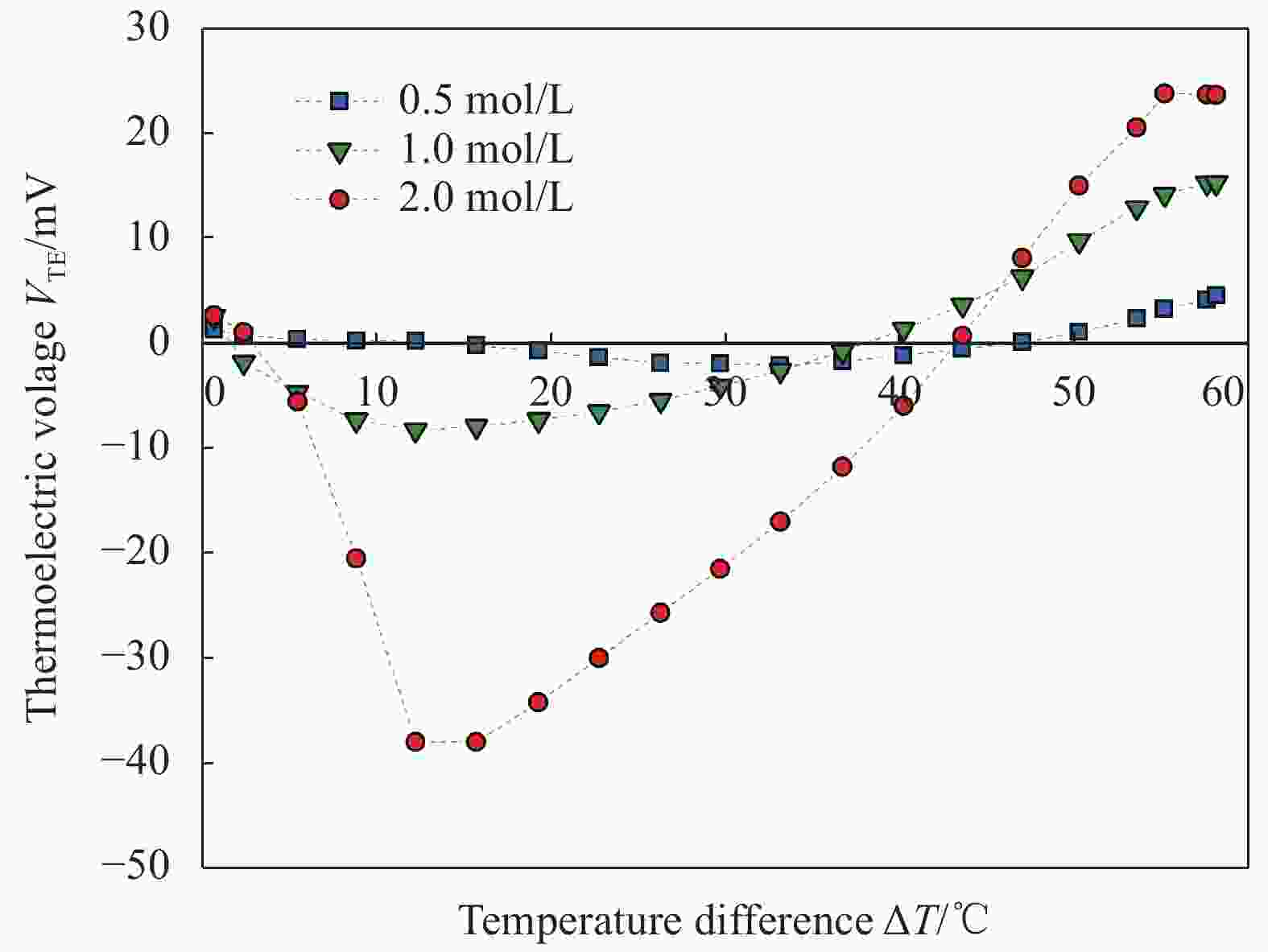

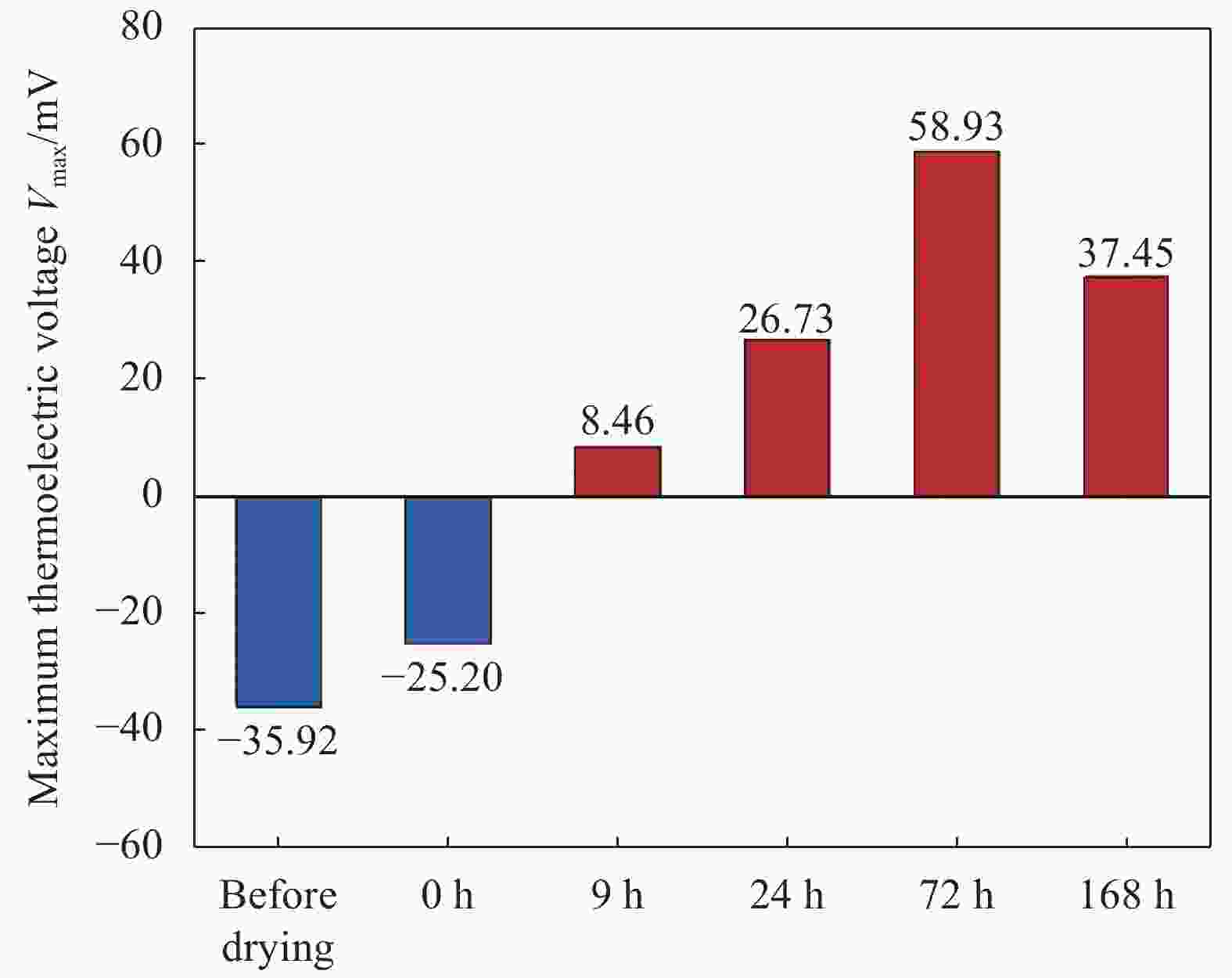

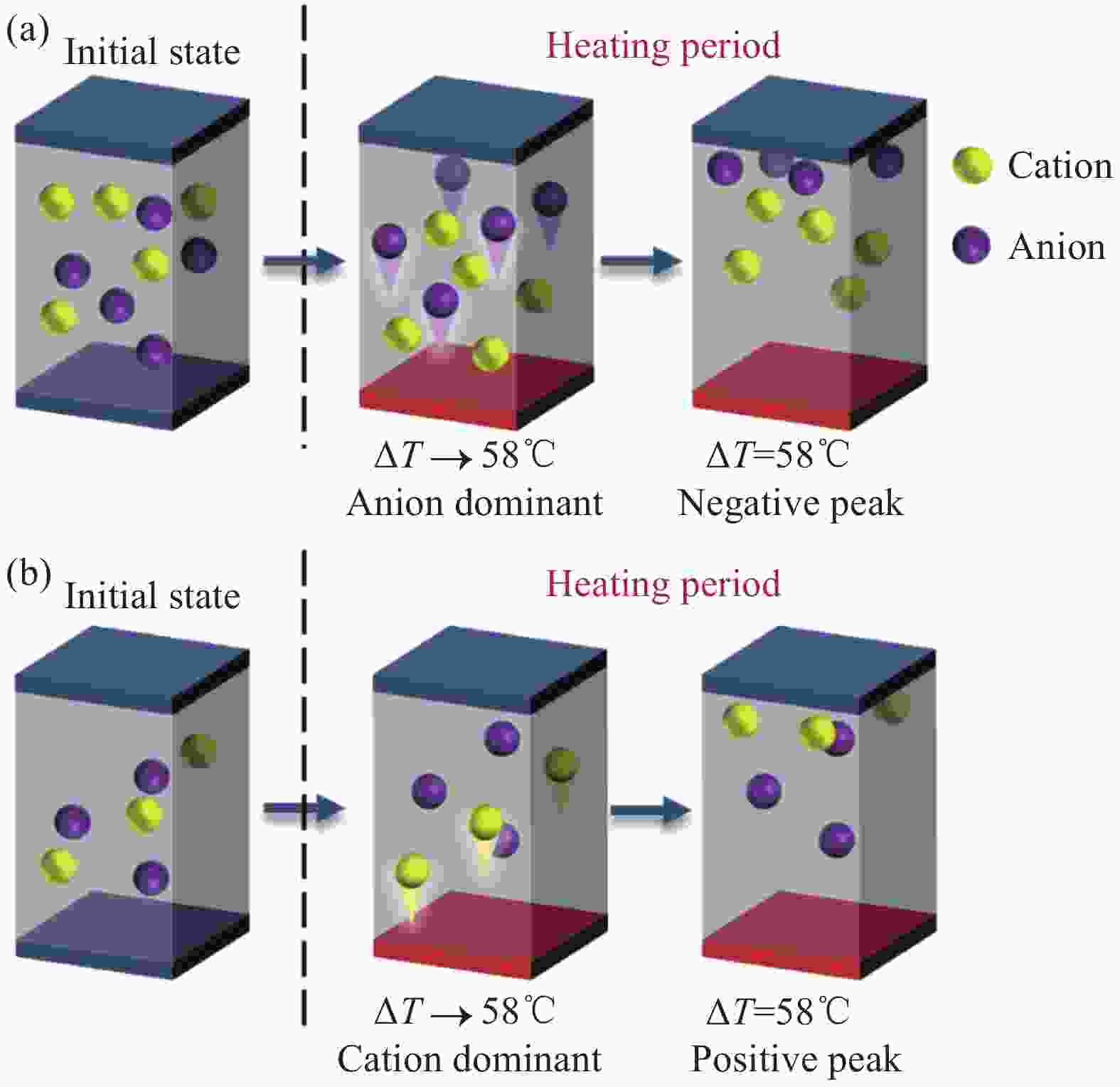

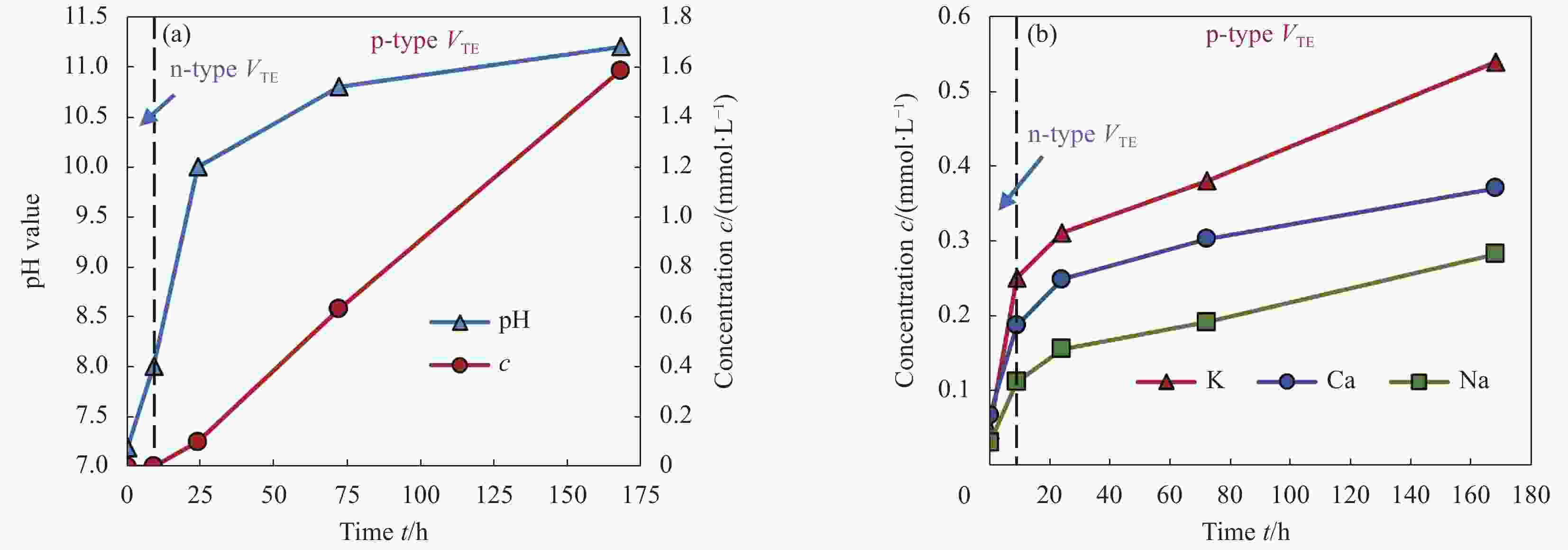

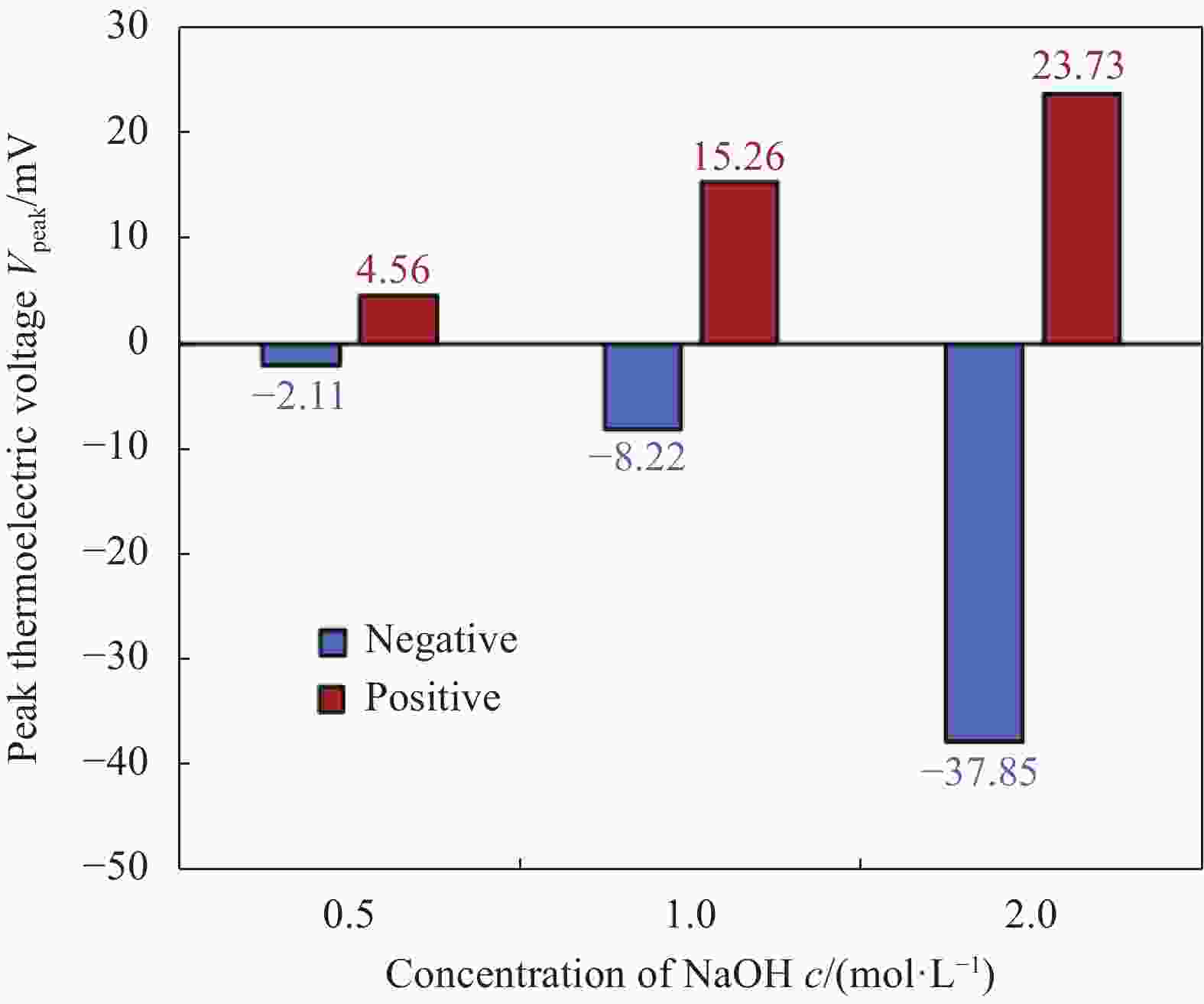

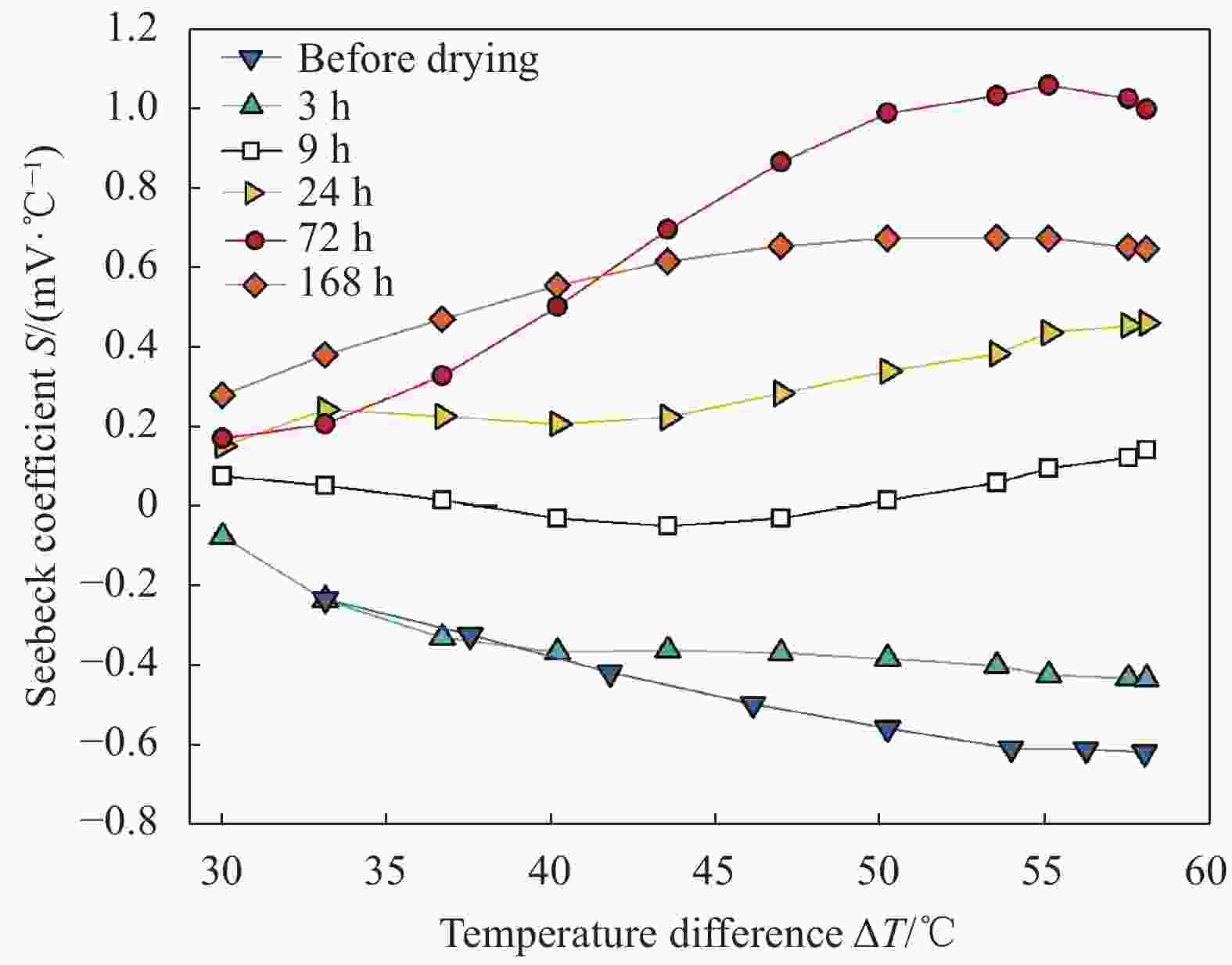

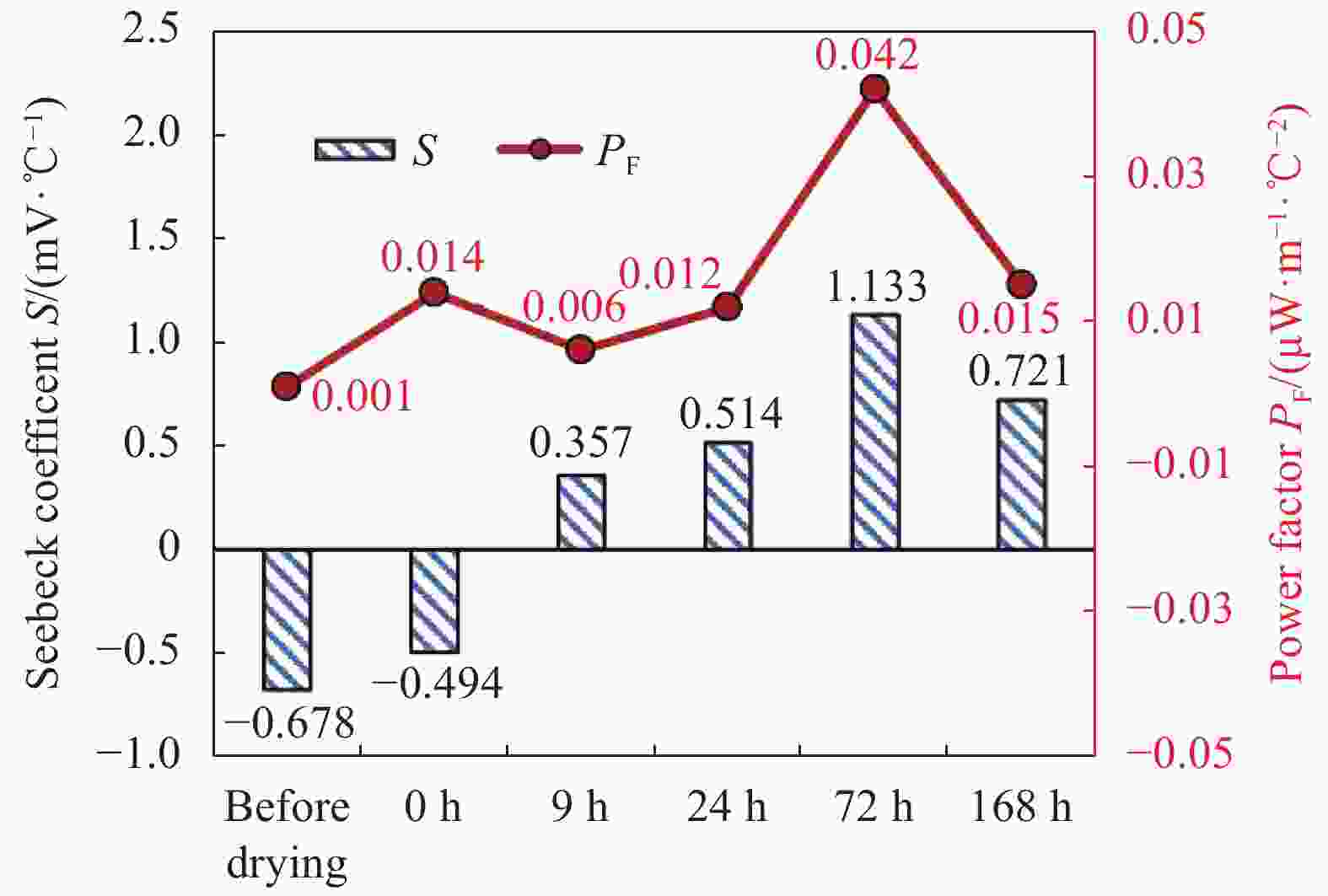

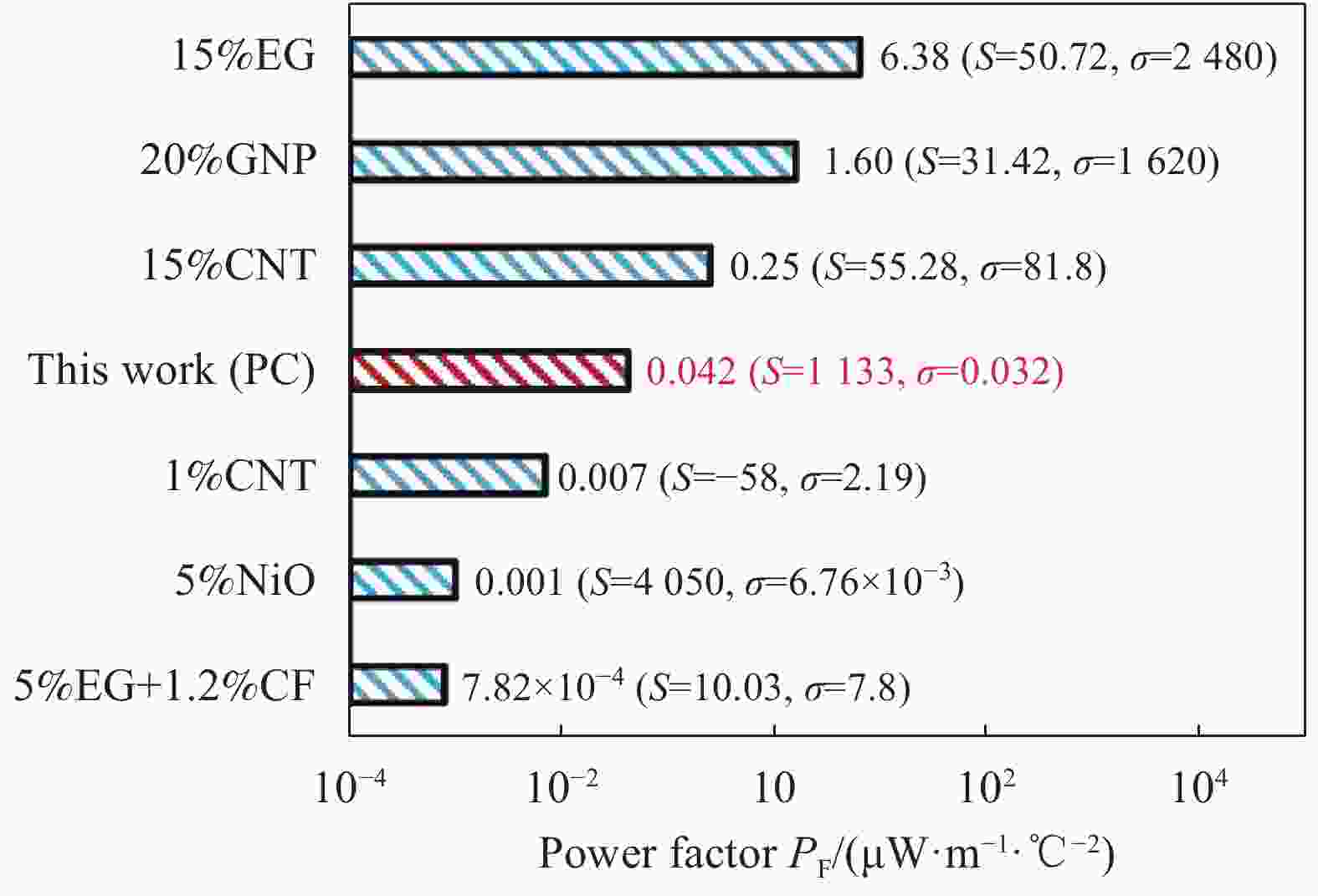

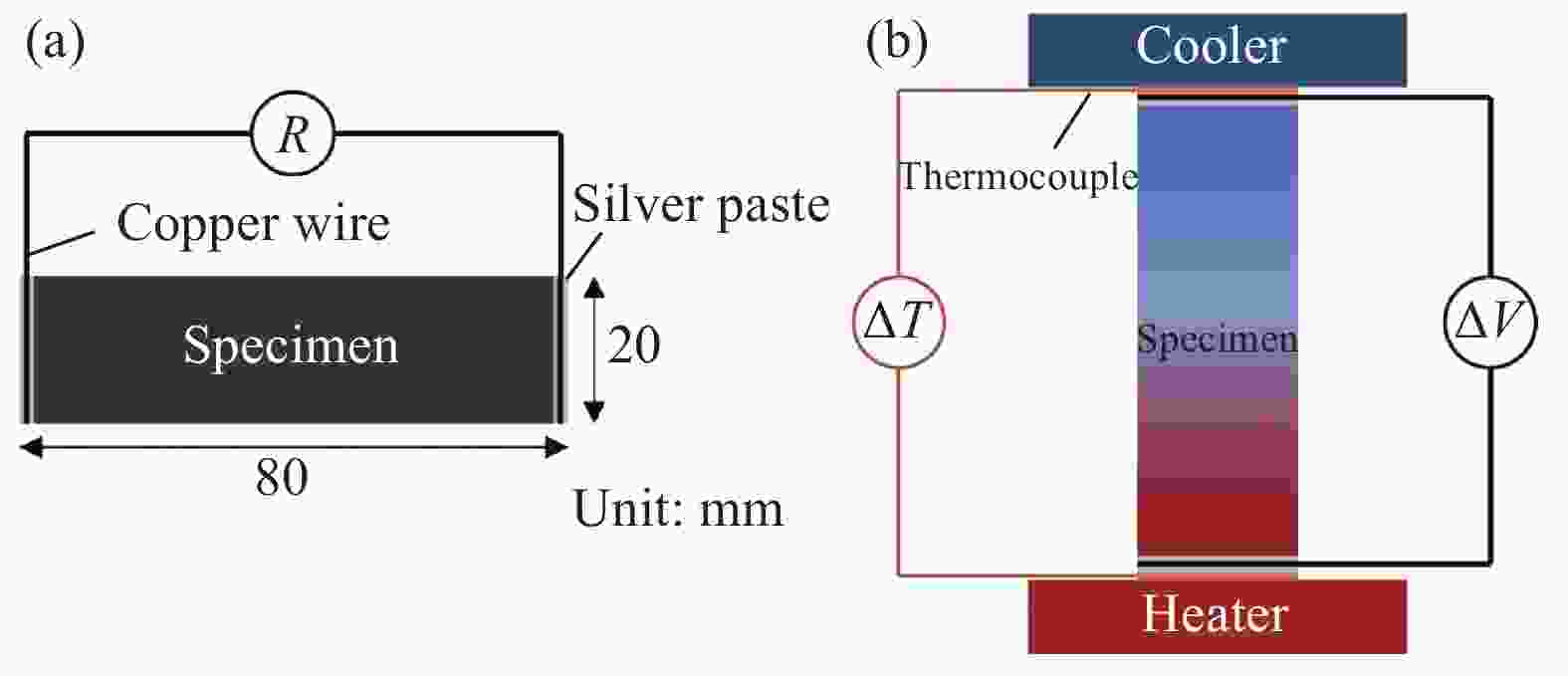

摘要: 当前水泥基材料热电效应主要通过掺入大量功能填料来增强。但掺量过高的功能填料提高了水泥基复合材料的成本,劣化了其力学性能,阻碍其大范围的应用。本研究发现,由于孔隙溶液中存在大量自由移动的离子,不掺任何功能填料的水泥净浆表现出显著的离子热电效应。本研究通过对比水泥净浆干燥前后的热电压,研究了水泥基材料的离子热电效应,并通过离子浸出与饱和碱溶液实验对水泥净浆的离子热电效应机制进行了探究。结果表明,由于孔隙溶液中OH−的热扩散,干燥前水泥净浆表现出显著的n-type离子热电效应。离子浸出过程中OH−浓度的降低导致水泥净浆的离子热电特性由n-type转变为p-type。饱和碱溶液后,在OH−浓度较大时,阳离子种类亦会对离子热电特性产生显著影响。此外,未添加功能性填料的水泥净浆的Seebeck系数可达1.133 mV·℃−1,功率因数(PF)可达0.042 μW·m−1·℃−2,高于文献中一些功能性填料掺量达5%的水泥基复合材料,具有显著的热电转换效率。Abstract: At present, the thermoelectric effect of cement-based materials is mainly enhanced by adding a large amount of functional fillers. However, the high content of the functional filler increases the cost, degrades their mechanical properties and hinders their wide application. It is found in this study that the pure cement paste without any functional fillers shows a significant ionic thermoelectric effect due to the freely moving ions in the pore solution of the cement-based materials. The ionic thermoelectric effect of the cement-based materials was studied by comparing the thermoelectric voltage of pure cement paste before and after drying, and the mechanism of the ionic thermoelectric effect of pure cement paste was further explored through ion leaching and saturated alkali solution experiments. Results show that the pure cement paste before dry shows a significant n-type ionic thermoelectric effect due to the thermal diffusion of OH−. The decrease of the concentration of OH− in the leaching process leads to the change of ionic thermoelectric voltage from n-type to p-type. After saturated in NaOH solution, the type of cations has a significant effect on the ionic thermoelectric properties even under the condition of high OH− concentration. In addition, the Seebeck coefficient of cement paste without any functional filler can reach 1.133 mV·℃−1, and the power factor PF can reach 0.042 μW·m−1·℃−2, which is higher than that of some cement-based composites with 5% functional filler in the literature.

-

表 1 采用的普通硅酸盐水泥化学成分和物理性能

Table 1. Chemical compositions and physical properties of ordinary Portland cement

SiO2/% Al2O3/% Fe2O3/% CaO/% MgO/% SO3/% Na2O/% Ignition loss/% Specific gravity Blaine fineness/(cm2·g−1) 22.00 4.40 3.43 61.75 2.49 2.83 0.56 1.77 3.14 3500 表 2 试件饱和面干质量随真空饱水时间的变化

Table 2. Saturated surface dry mass versus vacuum saturation time

ts/h m/g W/wt% 0 73.715±0.438 — 1 79.968±0.385 8.48% 2 80.120±0.381 0.19% 3 80.168±0.384 0.06% 4 80.193±0.382 0.03% Notes: ts—Vacuum saturation time; m—Saturated surface dry mass; W—Mass variation. -

[1] TZOUNIS L, LIEBSCHER M, FUGE R, et al. P- and n-type thermoelectric cement composites with CVD grown p- and n-doped carbon nanotubes: Demonstration of a structural thermoelectric generator[J]. Energy and Buildings,2019,191:151-163. doi: 10.1016/j.enbuild.2019.03.027 [2] WANG H, ZHAO D, KHAN Z U, et al. Ionic thermoelectric figure of merit for charging of supercapacitors[J]. Advanced Electronic Materials,2017,3(4):1700013. doi: 10.1002/aelm.201700013 [3] MEMON S. Advanced thermoelectric materials for energy harvesting applications[M]. London: BoD–Books on Demand, 2019 [4] HE X, CHENG H, YUE S, et al. Quasi-solid state nanoparticle/(ionic liquid) gels with significantly high ionic thermoelectric properties[J]. Journal of Materials Chemistry A,2020,8(21):10813-10821. doi: 10.1039/D0TA04100A [5] JANEK J, KORTE C. Study of the Soret effect in mixed conductors by the measurement of ionic and electronic thermopower[J]. Solid State Ionics,1996,92(3):193-204. [6] ZHAO D, WANG H, KHAN Z U, et al. Ionic thermoelectric supercapacitors[J]. Energy & Environmental Science,2016,9(4):1450-1457. [7] KYAW A K K, WONG G D H, YEMATA T A, et al. Effective ionic Seebeck component suppression in mixed ion-electron conductor via chemical treatment[J]. Organic Electronics,2019,69:7-12. doi: 10.1016/j.orgel.2019.02.014 [8] HAN C G, QIAN X, LI Q, et al. Giant thermopower of ionic gelatin near room temperature[J]. Science, 2020, 368(6495): 1091-1098. [9] 崔一纬, 魏亚. 水泥基复合材料热电效应综述: 机制、材料、影响因素及应用[J]. 复合材料学报, 2020, 37(9):2077-2093.CUI Y W, WEI Y. A review of thermoelectric effect of cement-based composites: Mechanism, material, factor and application[J]. Acta Materiae Compositae Sinica,2020,37(9):2077-2093(in Chinese). [10] SUN M, LI Z, MAO Q, et al. Study on the hole conduction phenomenon in carbon fiber-reinforced concrete[J]. Cement and Concrete Research,1998,28(4):549-554. doi: 10.1016/S0008-8846(98)00011-8 [11] WEI J, FAN Y, ZHAO L, et al. Thermoelectric properties of carbon nanotube reinforced cement-based composites fabricated by compression shear[J]. Ceramics International,2018,44(6):5829-5833. doi: 10.1016/j.ceramint.2018.01.074 [12] WEI J, ZHAO L, ZHANG Q, et al. Enhanced thermoelectric properties of cement-based composites with expanded graphite for climate adaptation and large-scale energy harvesting[J]. Energy and Buildings,2018,159:66-74. doi: 10.1016/j.enbuild.2017.10.032 [13] GHOSH S, HARISH S, ROCKY K A, et al. Graphene enhanced thermoelectric properties of cement based composites for building energy harvesting[J]. Energy and Buildings,2019,202:109419. [14] GHAHARI S, GHAFARI E, LU N. Effect of ZnO nanoparticles on thermoelectric properties of cement composite for waste heat harvesting[J]. Construction and Building Materials,2017,146:755-763. doi: 10.1016/j.conbuildmat.2017.04.165 [15] JI T, ZHANG X, LI W. Enhanced thermoelectric effect of cement composite by addition of metallic oxide nanopowders for energy harvesting in buildings[J]. Construction and Building Materials,2016,115:576-581. doi: 10.1016/j.conbuildmat.2016.04.035 [16] JI T, ZHANG X, ZHANG X, et al. Effect of manganese dioxide nanorods on the thermoelectric properties of cement composites[J]. Journal of Materials in Civil Engineering,2018,30(9):04018224. doi: 10.1061/(ASCE)MT.1943-5533.0002401 [17] 肖龙, 季涛, 廖晓, 等. 氧化镍水泥基复合材料热电性能研究[J]. 新型建筑材料, 2019, 46(3):32-35.XIAO Long, JI Tao, LIAO Xiao, et al. Thermoelectric property of cement composites with nickel oxide[J]. New Building Materials,2019,46(3):32-35(in Chinese). [18] GHOSH S, HARISH S, OHTAKI M, et al. Enhanced figure of merit of cement composites with graphene and ZnO nanoinclusions for efficient energy harvesting in buildings[J]. Energy,2020,198:117396. [19] JING G, YE Z, WU J, et al. Introducing reduced graphene oxide to enhance the thermal properties of cement composites[J]. Cement and Concrete Composites,2020,109:103559. doi: 10.1016/j.cemconcomp.2020.103559 [20] LIN Y, DU H. Graphene reinforced cement composites: A review[J]. Construction and Building Materials,2020,265:120312. doi: 10.1016/j.conbuildmat.2020.120312 [21] AGAR J N, MOU C Y, LIN J L. Single-ion heat of transport in electrolyte solutions: A hydrodynamic theory[J]. Journal of Physical Chemistry,2002,93(5):2079-2082. [22] VIGOLO D, BUZZACCARO S, PIAZZA R. Thermophoresis and thermoelectricity in surfactant solutions[J]. Langmuir,2010,26(11):7792-7801. doi: 10.1021/la904588s [23] LI T, ZHANG X, LACEY S D, et al. Cellulose ionic conductors with high differential thermal voltage for low-grade heat harvesting[J]. Nature Materials,2019,18(6):608-613. doi: 10.1038/s41563-019-0315-6 [24] WEI J, ZHANG Q, ZHAO L, et al. Effect of moisture on the thermoelectric properties in expanded graphite/carbon fiber cement composites[J]. Ceramics International,2017,43(14):10763-10769. doi: 10.1016/j.ceramint.2017.05.088 [25] WEI J, ZHANG Q, ZHAO L, et al. Enhanced thermoelectric properties of carbon fiber reinforced cement composites[J]. Ceramics International,2016,42(10):11568-11573. doi: 10.1016/j.ceramint.2016.04.014 [26] 钱锋, 刘宪昌. 石墨烯增强水泥基复合材料的制备及热电性能研究[J]. 功能材料, 2020, 51(10):10152-10156.QIAN Feng, LIU Xianchang. Preparation and thermoelectric properties of graphene-reinforced cement-based composites[J]. Journal of Functional Materials,2020,51(10):10152-10156(in Chinese). [27] ZHAO R H, TUAN C Y, XU A, et al. Conductivity of ionically-conductive mortar under repetitive electrical heating[J]. Construction and Building Materials,2018,173:730-739. doi: 10.1016/j.conbuildmat.2018.04.074 [28] 范道波. 离子导电砂浆的研发及性能研究[D]. 广州: 广州大学, 2017.FAN Daobo. Invention of ionically conductive mortar and reseach on its performance[D]. Guangzhou: Guangzhou University, 2017(in Chinese). [29] 翁余斌. 基于离子导电的水泥基复合材料性能研究[D]. 广州: 广州大学, 2019.WENG Yubin. Study on properties of cement-based compo-sites based on ion conduction[D]. Guangzhou: Guangzhou University, 2019(in Chinese). [30] CAO J, CHUNG D D L. Role of moisture in the Seebeck effect in cement-based materials[J]. Cement and Concrete Research,2005,35(4):810-812. doi: 10.1016/j.cemconres.2004.05.036 [31] GRETZ M, PLANK J. An ESEM investigation of latex film formation in cement pore solution[J]. Cement and Concrete Research,2011,41(2):184-190. doi: 10.1016/j.cemconres.2010.11.005 [32] VOLLPRACHT A, LOTHENBACH B, SNELLINGS R, et al. The pore solution of blended cements: A review[J]. Materials & Structures, 2016, 49(8): 3341-3367. -

下载:

下载: