Uncertainty analysis of natural vibration characteristics of composite laminated plates with spatially varied stochastic volume fractions

-

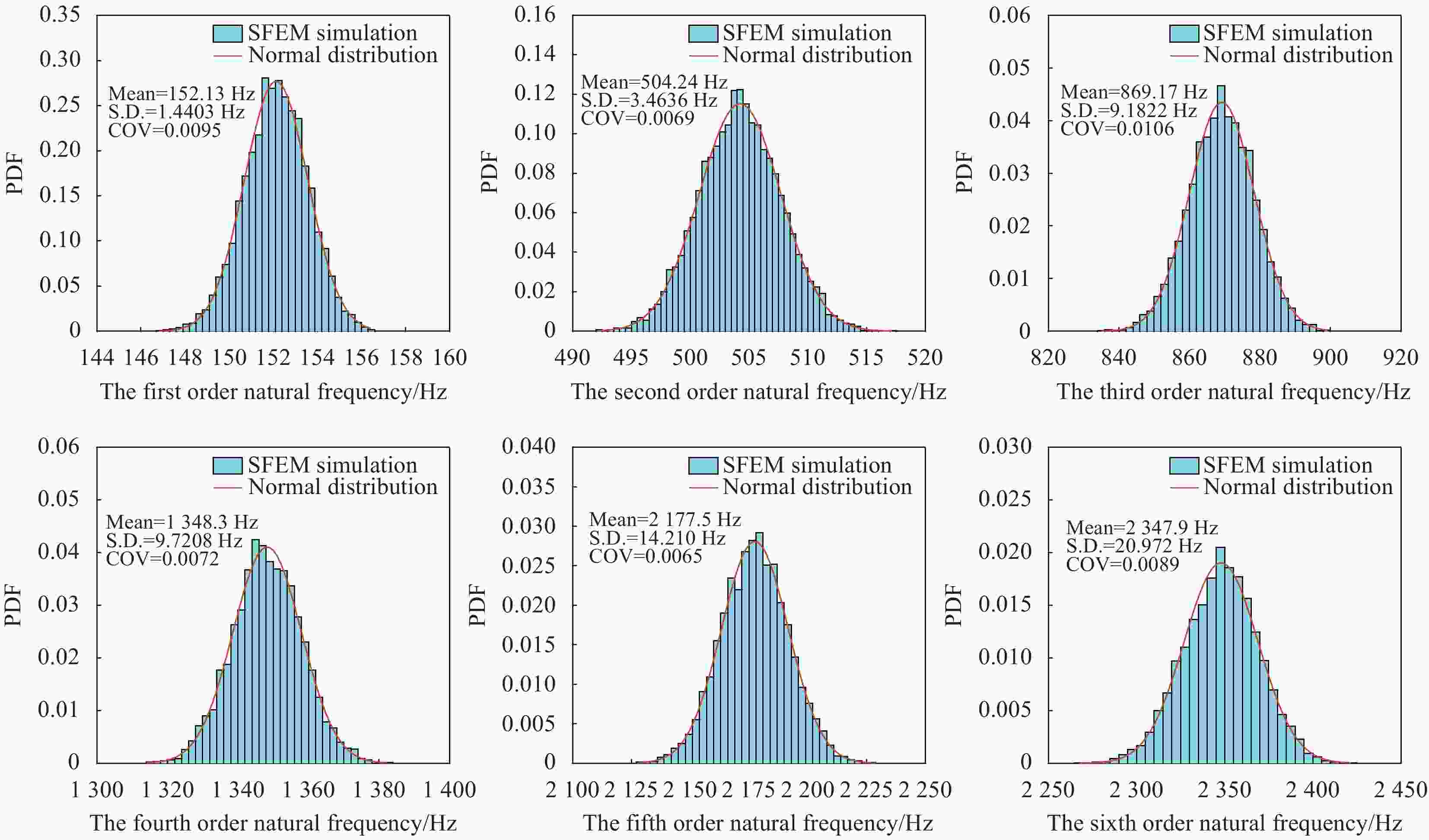

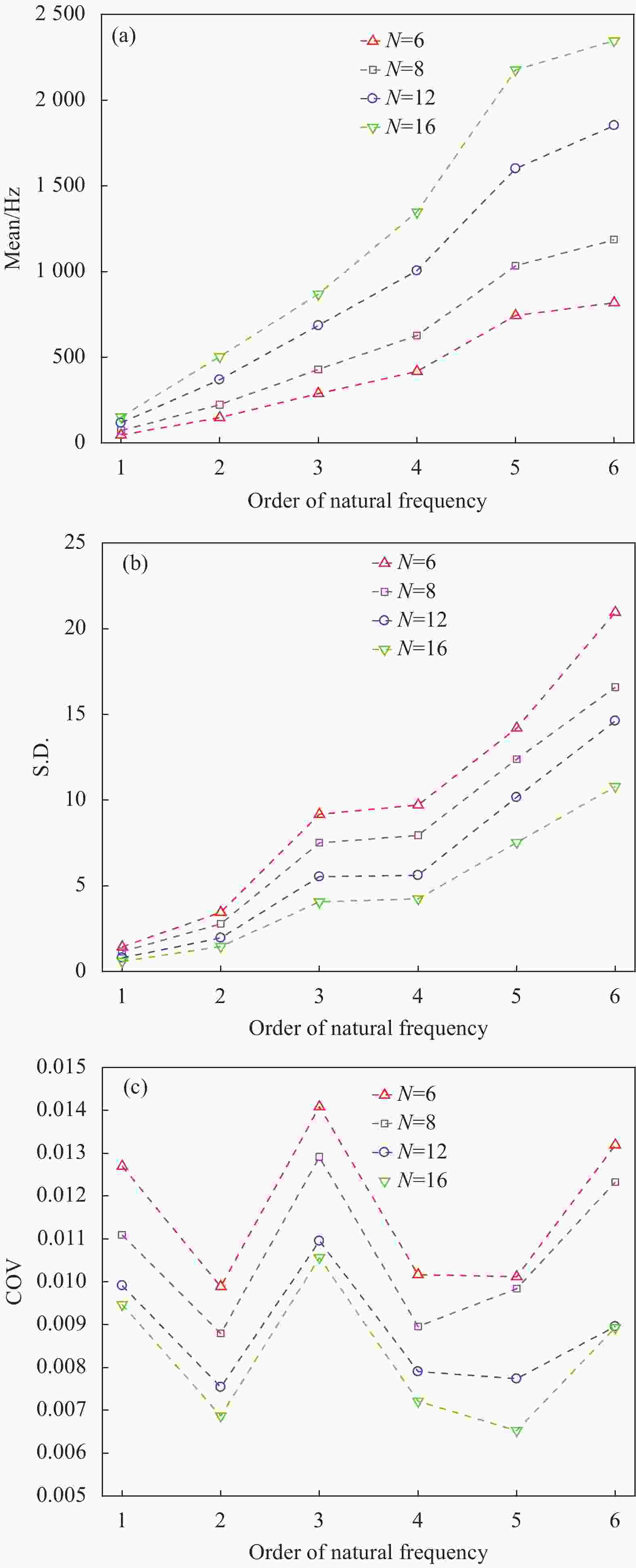

摘要: 考虑复合材料层合板中每层体积分数空间不确定性的影响,采用指数型自相关函数模拟每层体积分数同空间位置的依赖关系,结合伽辽金-里兹正交多项式逼近和K-L展开方法,研究了体积分数随机场的自相关长度特征对材料属性随机场离散精度的影响;进而通过体积分数随机场作用下复合材料层合板的随机有限元模型,研究了T300碳纤维/QY8911环氧树脂复合材料垂尾蒙皮结构的固有频率均值、标准差和变异系数与层合板层数之间的关系,基于Monte-Carlo模拟方法验证了采用本文方法开展复合材料层合板固有振动特性分析的有效性。数值结果表明:复合材料层合板结构固有频率的变异系数随铺层数减少而增大,层数越少,纤维体积分数的不确定性对固有振动特性分散性的影响越大。Abstract: In each layer of the composite laminate, the spatial uncertainty effect of the volume fraction was considered. Using exponential autocorrelation function, the relationship between the volume fraction of each layer and the spatial position was simulated. Combining the Galerkin-Riza discretization and K-L series expansion methods, the influence of autocorrelation length on the discretization accuracy was carried out. The stochastic finite element model of composite laminates with spatially random material properties was established. Taking the T300 carbon fiber/QY8911 epoxy aircraft vertical tail thin-gauge skin structure as an example, the relationships between the mean value, standard deviation and coefficient of variation of the natural frequency and the number of laminate layers were obtained. And the Monte-Carlo simulation method was used to verify the effectiveness of the method in this paper to carry out the natural frequency and mode uncertainty analysis of composite laminates. The results show that: the coefficient of variation of the natural frequency of the composite laminate structure increases with the decrease of the number of layers, and the less the number of layers, the greater influence of uncertainty of the fiber volume fraction on dispersion of the natural vibration characteristics.

-

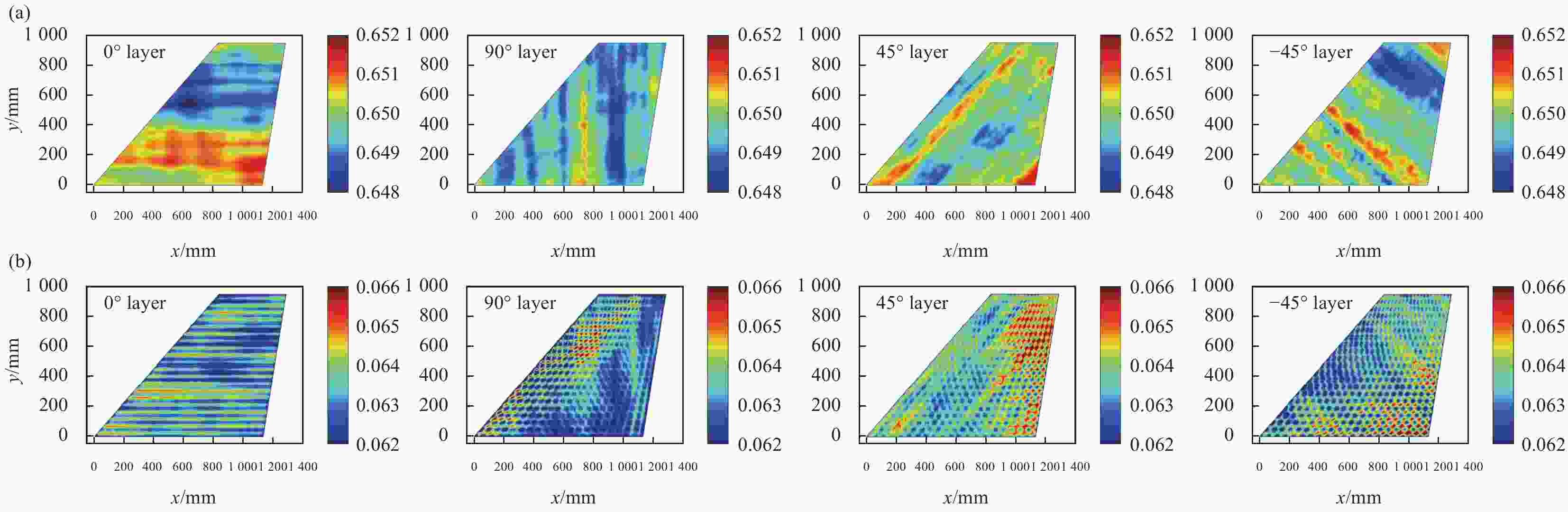

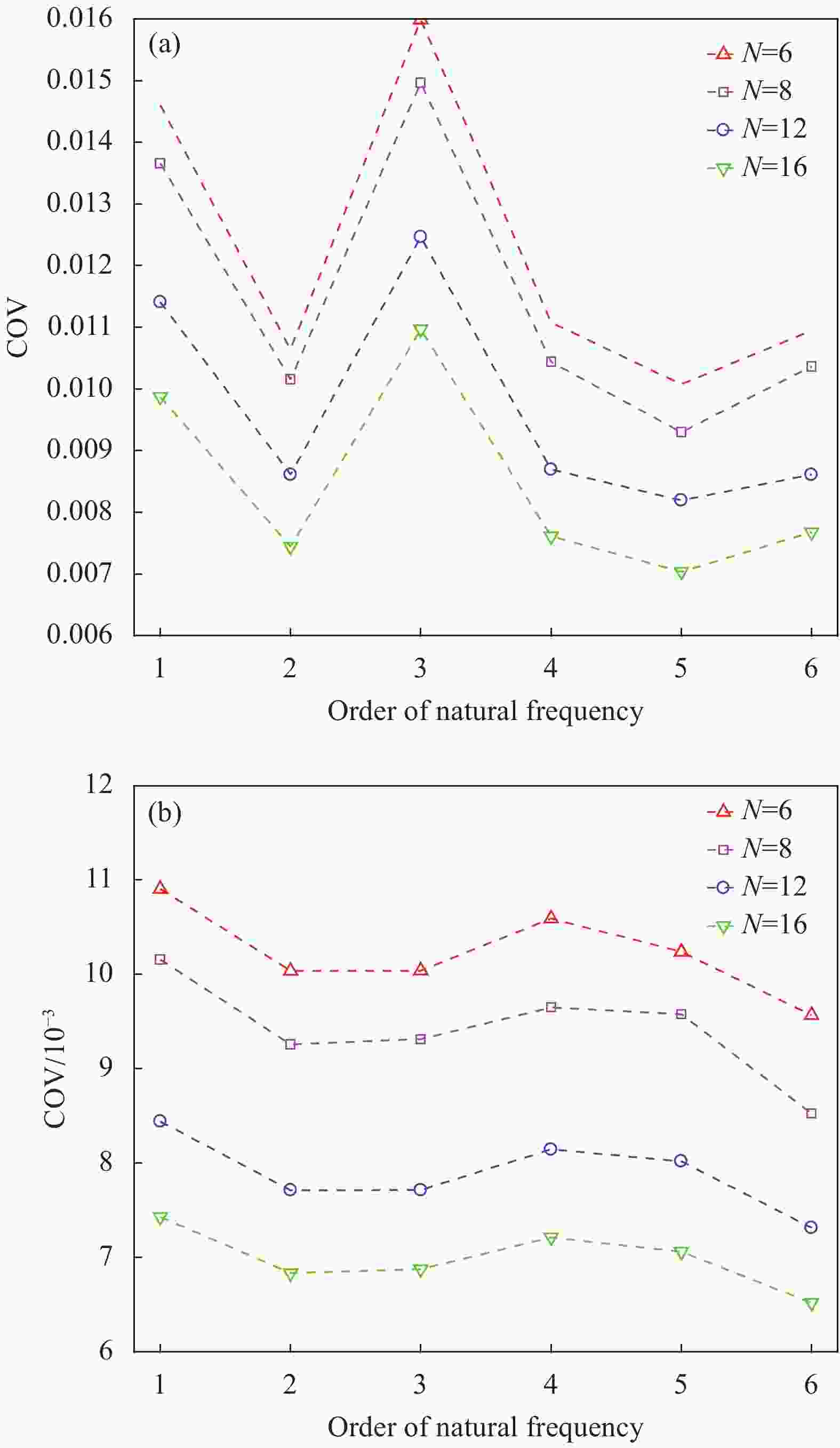

图 9 T300碳纤维/QY8911环氧树脂复合材料层合板垂尾蒙皮结构基于5000次模拟的前6阶固有频率均值(a)、标准差(b)和变异系数(c)

Figure 9. Mean value (a), standard deviation (S.D. )(b) and coefficient of variation (COV) (c) for the first-six natural frequencies of the T300 carbon fiber/QY8911 epoxy composite laminate vertical tail skin structure based on 5000 simulations

图 10 T300碳纤维/QY8911环氧树脂复合材料层合板垂尾蒙皮结构两种铺层方案的前6阶固有频率变异系数:(a)方案1:45°和−45°交替铺层;(b)方案2:0°和90°交替铺层

Figure 10. Coefficient of variation (COV) of the first 6-order natural frequencies of the T300 carbon fiber/QY8911 epoxy composite laminate vertical tail skin structure with two laying schemes: (a) Scheme 1: 45° and −45° alternate laying; (b) Scheme 2: 0° and 90° alternate laying

表 1 T300碳纤维/QY8911环氧树脂复合材料层合板的材料属性

Table 1. Material properties of T300 carbon fiber/QY8911 epoxy composite laminates

Ef1/GPa Ef2/GPa Gf12/GPa Gf23/GPa ν12 Em/GPa Gm/GPa νm ρ/(kg·m−3) 221 13.8 9 4.8 0.25 3.6 2.34 0.3 1578 Notes:Ef1, Ef2—Fiber longitudinal and transverse elasticity moduli; Gf12, Gf23—Fiber longitudinal and transverse shear moduli; ν12—Longitudinal Poisson’s ratio of fiber; Em, Gm—Elasticity modulus and shear modulus of matrix; νm—Poisson's ratio of matrix; ρ—Equivalent density of composites. -

[1] JU F, LEE H P, LEE K H. Free vibration of composite plates with delaminations around cutouts[J]. Composite Structures,1995,31(2):177-183. doi: 10.1016/0263-8223(95)00016-X [2] WANG S. Free vibration analysis of skew fibre-reinforced composite laminates based on first-order shear deformation plate theory[J]. Computers & Structures,1997,63(3):525-538. [3] HU N, FUKUNAGA H, KAMEYAMA M, et al. Vibration analysis of delaminated composite beams and plates using a higher-order finite element[J]. International Journal of Mechanical Sciences,2002,44(7):1479-1503. doi: 10.1016/S0020-7403(02)00026-7 [4] NAYYAR K. Static and modal analyses of laminated composite plates using hierarchical finite element method[D]. Montreal: Concordia University, 2006. [5] 吉桂秀. 含多分层复合材料层合板和加筋板的自由振动特性研究[D]. 大连: 大连理工大学, 2006.JI Guixu. Study on free vibration characteristics for composite laminates and stiffened plates with multiple delaminations[D]. Dalian: Dalian University of Technology, 2006 (in Chinese). [6] 高希光, 宋迎东, 孙志刚. 纤维位置随机引起的复合材料性能分散性研究[J]. 航空动力学报, 2005, 20(4):584-589.GAO Xiguang, SONG Yingdong, SUN Zhigang. Research on the discrepancy of composite effective properties induced dy the stochastic fiber location[J]. Journal of Aerospace Power,2005,20(4):584-589(in Chinese). [7] 高希光, 宋迎东, 孙志刚. 纤维尺寸随机引起的复合材料性能分散性研究[J]. 材料科学与工程学报, 2005, 23(3):335-340.GAO Xiguang, SONG Yingdong, SUN Zhigang. Research on variation of effective performance of composites induces by the stochastic fiber size[J]. Journal of Materials Science & Engineering,2005,23(3):335-340(in Chinese). [8] 俸翔, 卢子兴. 基于随机场的复合材料单层板模量分散性研究[J]. 机械强度, 2010, 32(4):622-626.FENG Xiang, LU Zixing. Studies on the modules discrepancy of single-layer composite plate based on random field theory[J]. Jouranl of Mechanical Strength,2010,32(4):622-626(in Chinese). [9] 山美娟, 赵丽滨. CFRP复合材料螺栓连接失效载荷不确定性的评估方法[J]. 复合材料学报, 2021, 38(5):1468-1475.SHAN Meijuan, ZHAO Libin. An evaluation method for the uncertainty in failure load of CFRP composite bolted joints[J]. Acta Materiae Compositae Sinica,2021,38(5):1468-1475(in Chinese). [10] VANMARCKE E, SHINOZUKA M, NAKAGIRI S, et al. Random fields and stochastic finite elements[J]. Structural Safety,1986,3(3-4):143-166. doi: 10.1016/0167-4730(86)90002-0 [11] VANMARCKE E, GRIGORIU M. Stochastic finite element analysis of simple beams[J]. Journal of Engineering Mechanics,1983,109(5):1203-1214. doi: 10.1061/(ASCE)0733-9399(1983)109:5(1203) [12] VANMARCKE E. Random fields: Analysis and synthesis[M]. Hackensack: World Scientific, 2010: 13-41. [13] KIUREGHIAN A D, KE J B. The stochastic finite element method in structural reliability[J]. Probabil Engineering Mechanics,1988,3(2):83-91. doi: 10.1016/0266-8920(88)90019-7 [14] TAKADA T, SHINOZUKA M. Local integration method in stochastic finite element analysis[C]. New York: Structural Safety & Reliability, 2015. [15] LIU W K, BELYTSCHKO T, MANI A. Random field finite elements[J]. International Journal for Numerical Methods in Engineering,2010,23(10):1831-1845. [16] ATKINSON, KENDALL E. The numerical solution of integral equations of the second kind: Iteration method[J]. Numerische Mathematik,1997,19(3):248-259. [17] HUANG S P, QUEK S T, PHOON K K. Convergence study of the truncated Karhunen-Loeve expansion for simulation of stochastic processes[J]. International Journal for Numerical Methods in Engineering,2001,52(9):1029-1043. doi: 10.1002/nme.255 [18] ZHANG X, LIU Q, HUANG H. Numerical simulation of random fields with a high-order polynomial based Ritz-Galerkin approach[J]. Probabil Engineering Mechanics,2019,55:17-27. [19] SASIKUMAR P, SURESH R, VIJAYAGHOSH P K, et al. Experimental characterisation of random field models for CFRP composite panels[J]. Composite Structures,2015,120:451-471. doi: 10.1016/j.compstruct.2014.10.023 [20] YUN G J, ZHAO L, IARVE E. Probabilistic mesh-independent discrete damage analyses of laminate composites[J]. Composite Structures,2015,133:22-30. [21] 俸翔, 马元春, 卢子兴. 复合材料夹层板屈曲强度的分散性分析[J]. 复合材料学报, 2011, 28(1):132-137.FENG Xiang, MA Yuanchun, LU Zixing. Critical buckling load discrepancy of composite laminates[J]. Acta Materiae Compositae Sinica,2011,28(1):132-137(in Chinese). [22] 胥小强. 纤维增强复合材料层合板振动响应分析与优化[D]. 南京: 南京航空航天大学, 2015.XU Xiaoqiang. Analysis and optimization of the vibration response for fiber reinforced composites with laminated structure[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2015 (in Chinese). [23] 臧晓蕾, 殷奇, 梁海啸. 碳纤维复合材料地铁车顶板固有频率概率分析[J]. 复合材料科学与工程, 2020(8):18-24.ZANG Xiaolei, YIN Qi, LIANG Haixiao. Probabilistic free vibration analysis of carbon fiber reinforced composite metro roof panels[J]. Composites Science and Engineering,2020(8):18-24(in Chinese). [24] 陈烈民, 杨宝宁. 复合材料的力学分析[M]. 北京: 中国科学技术出版社, 2006: 88-98.CHEN Liemin, YANG Baoning. Mechanical analysis of composites[M]. Beijing: China Science and Technology Press, 2006: 88-98 (in Chinese). [25] 张秉杰, 臧朝平, PETROV E P. 基于高保真有限元模型失谐叶盘受迫响应的统计特性[J]. 航空动力学报, 2019, 34(1):135-141.ZHANG Bingjie, ZANG Chaoping, PETROV E P. Statistical characteristics of forced response in mistuned bladed disks based on high-fidelity finite element model[J]. Journal of Aerospace Power,2019,34(1):135-141(in Chinese). -

下载:

下载: