Effect of fused MgAl2O4 on high temperature creep properties of Al2O3-MgAl2O4 refractory

-

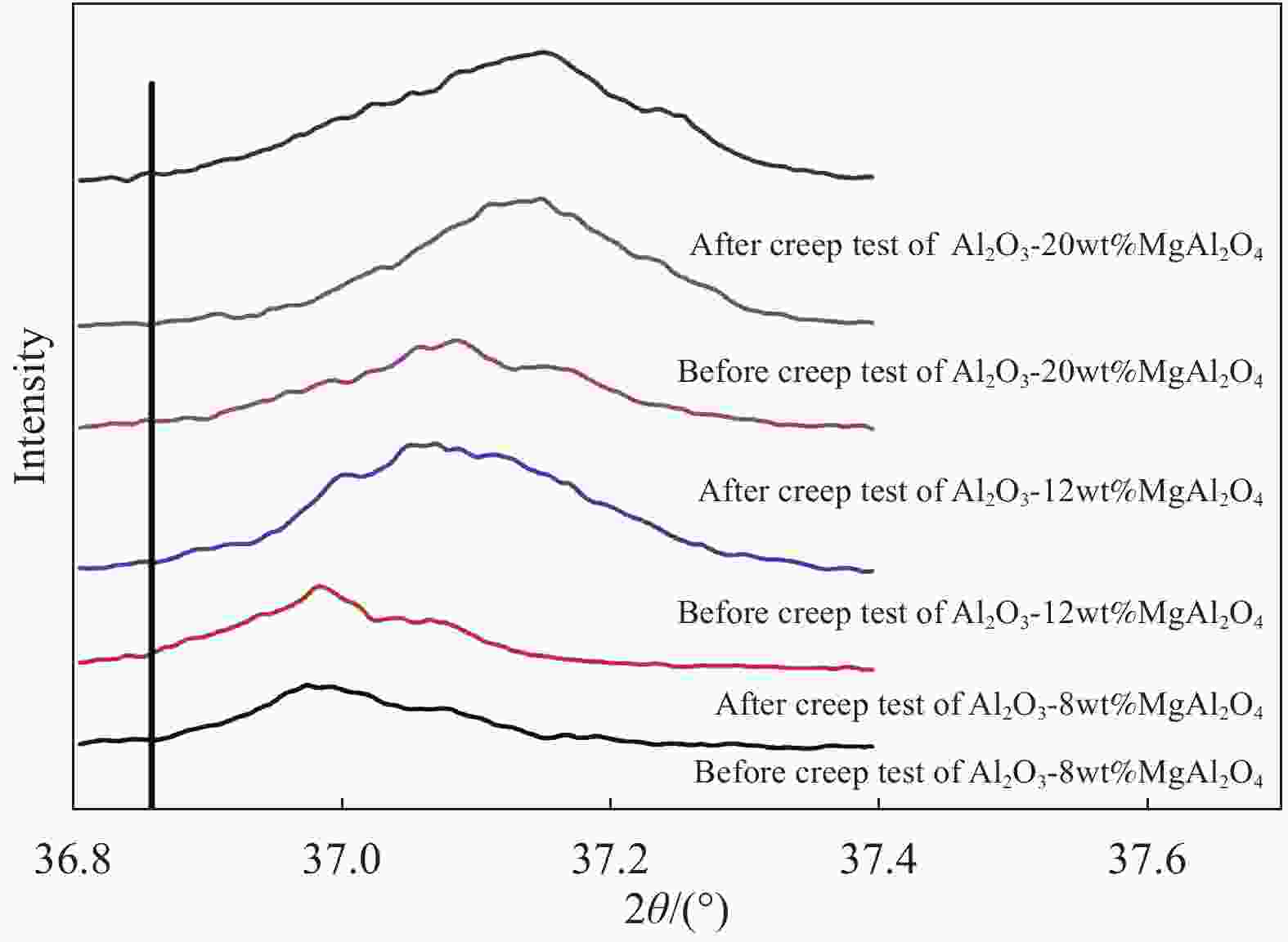

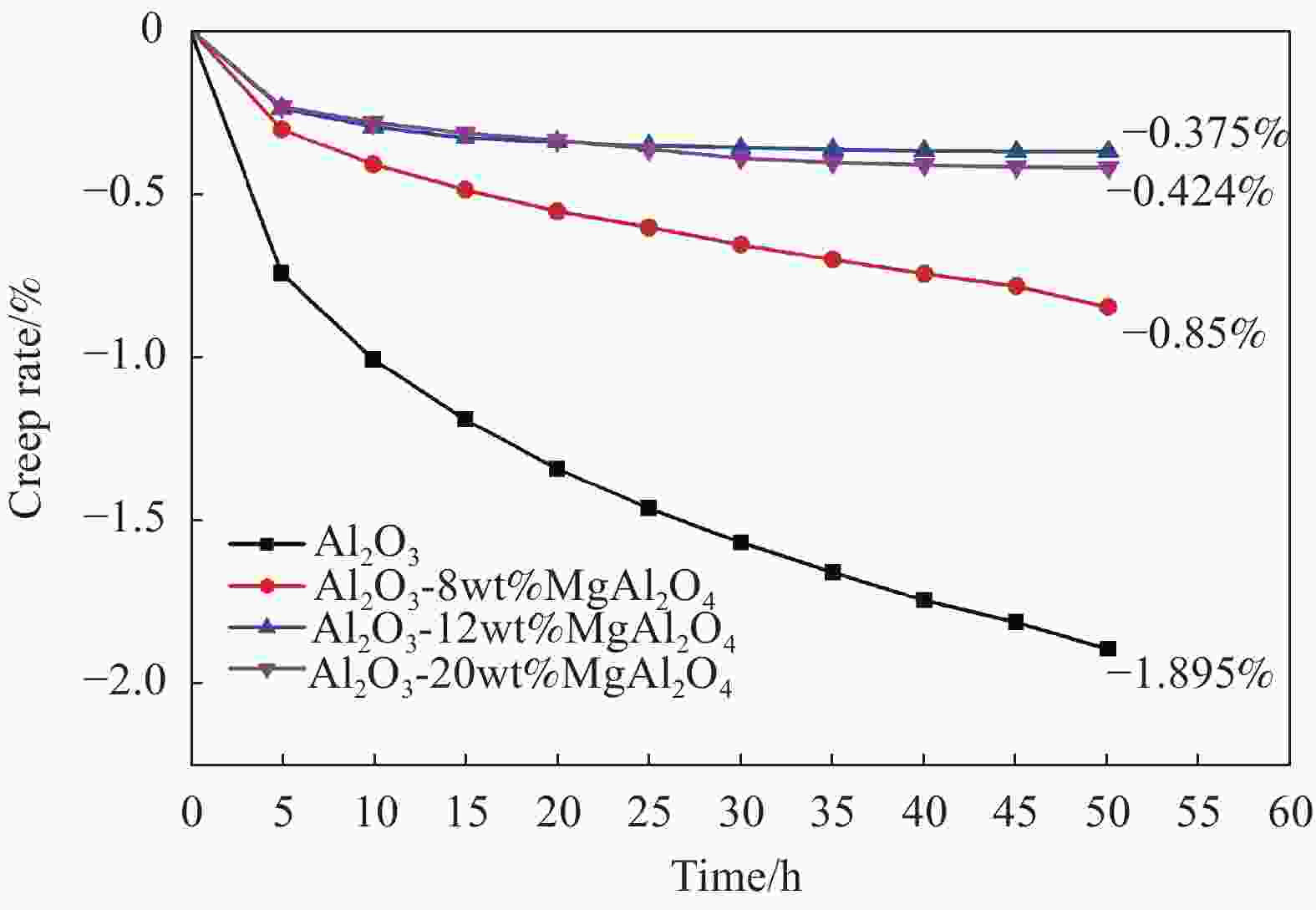

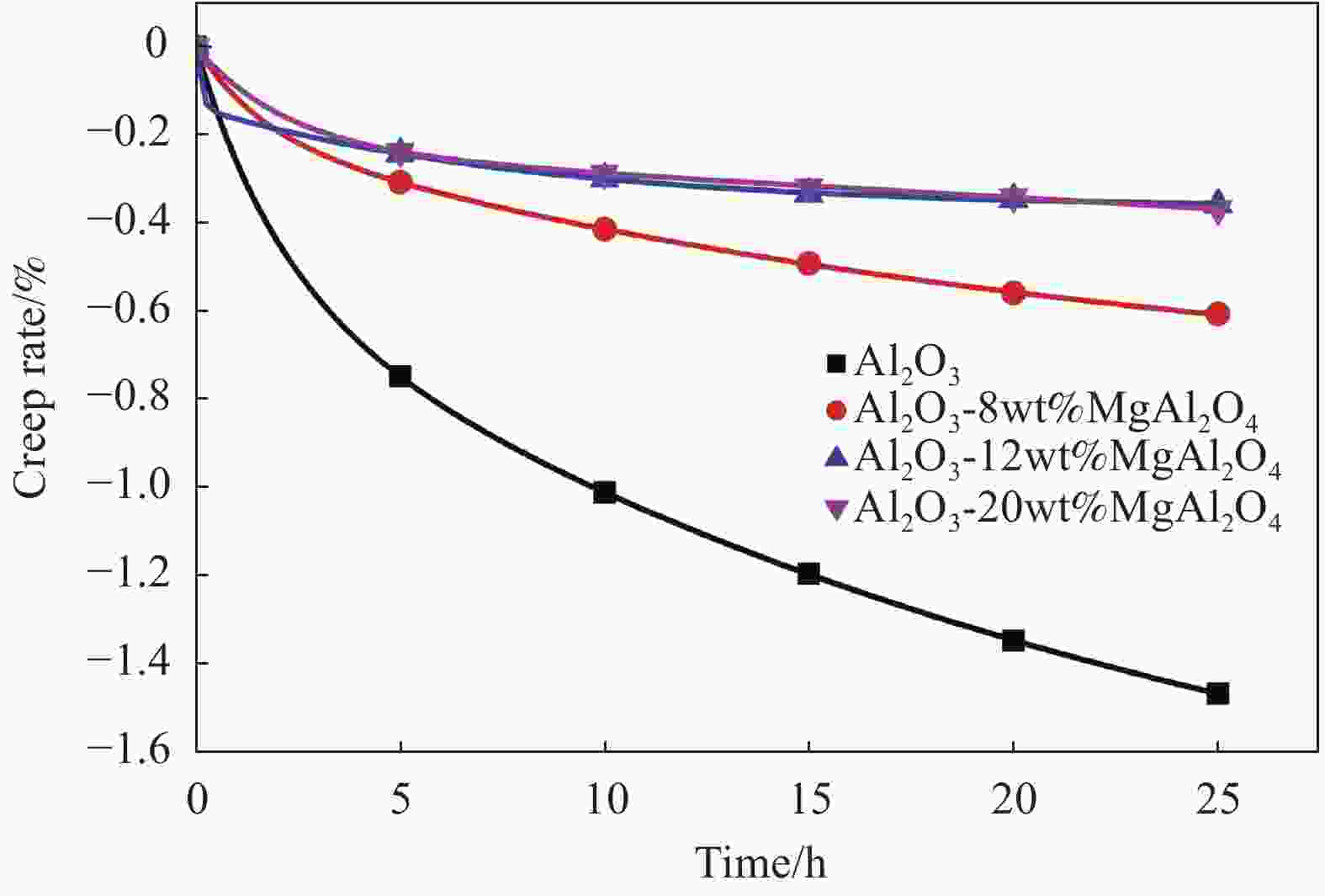

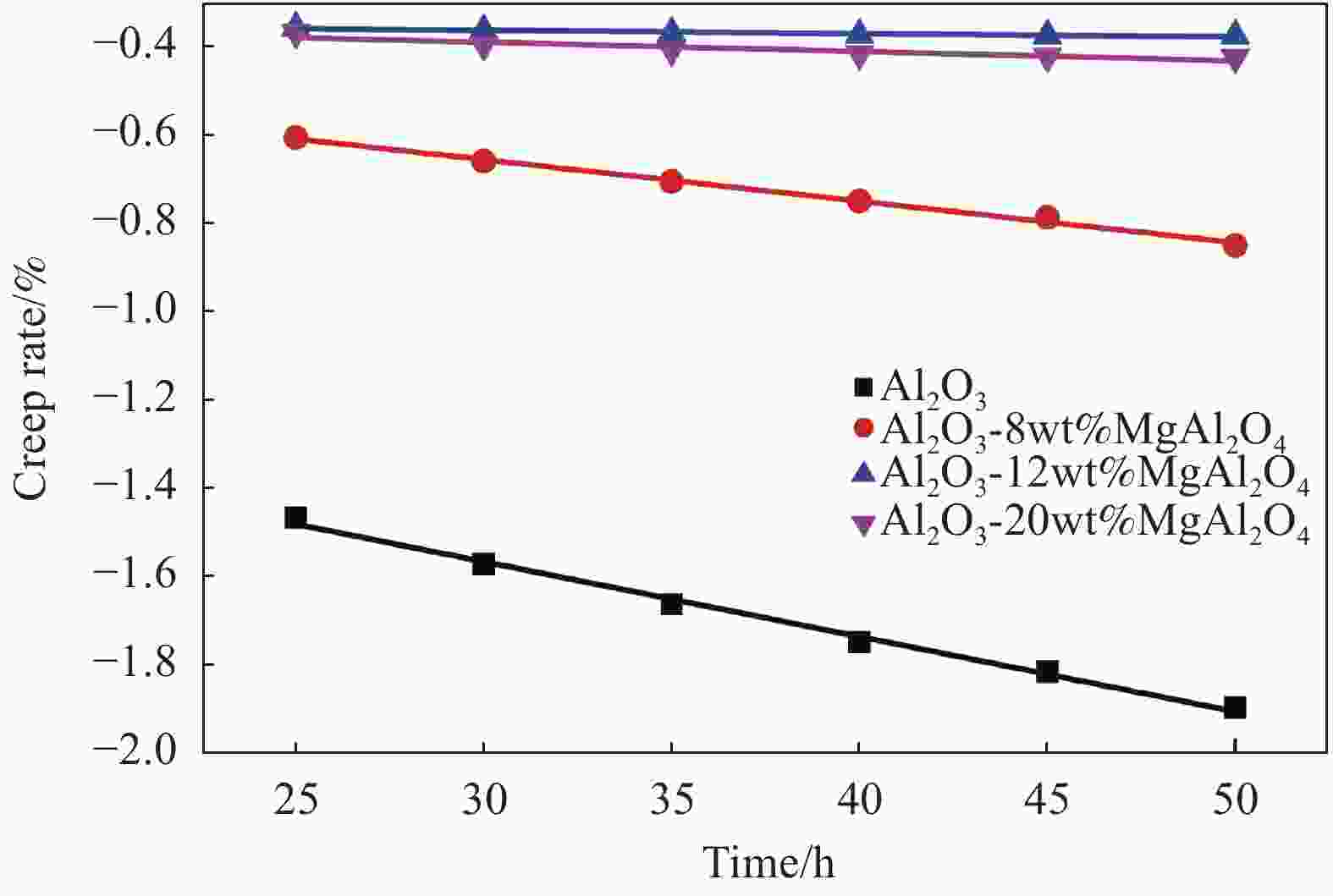

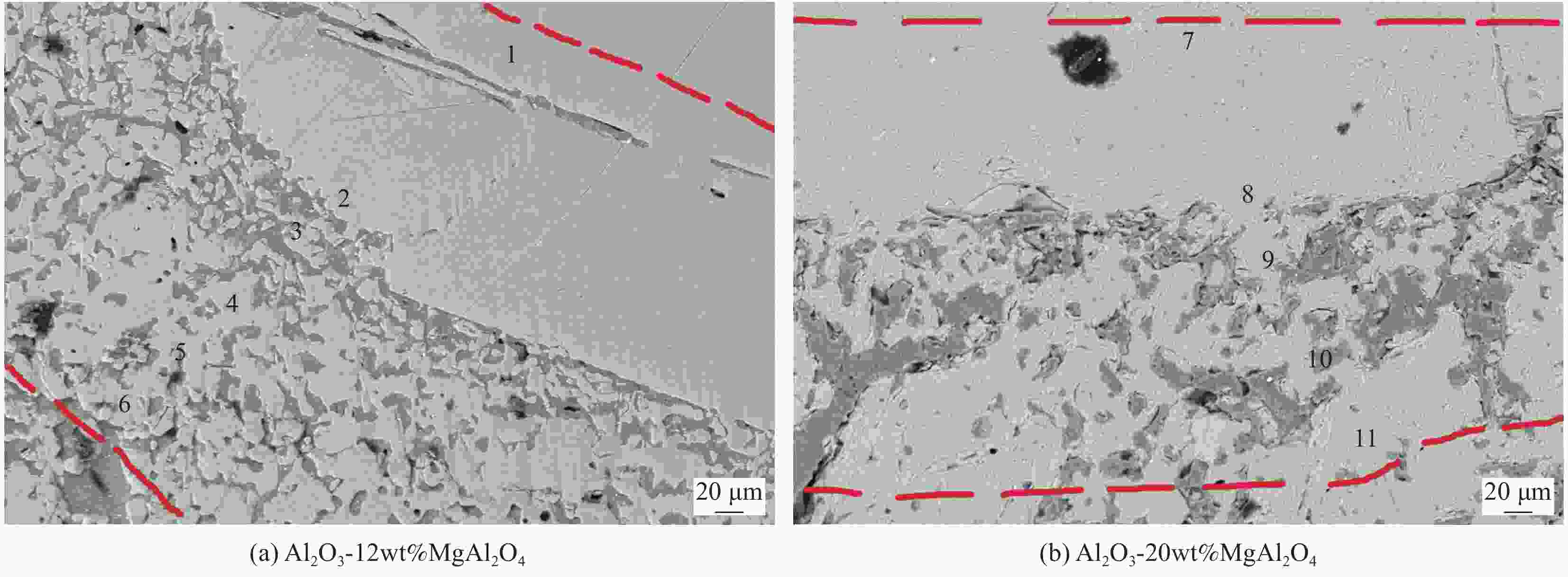

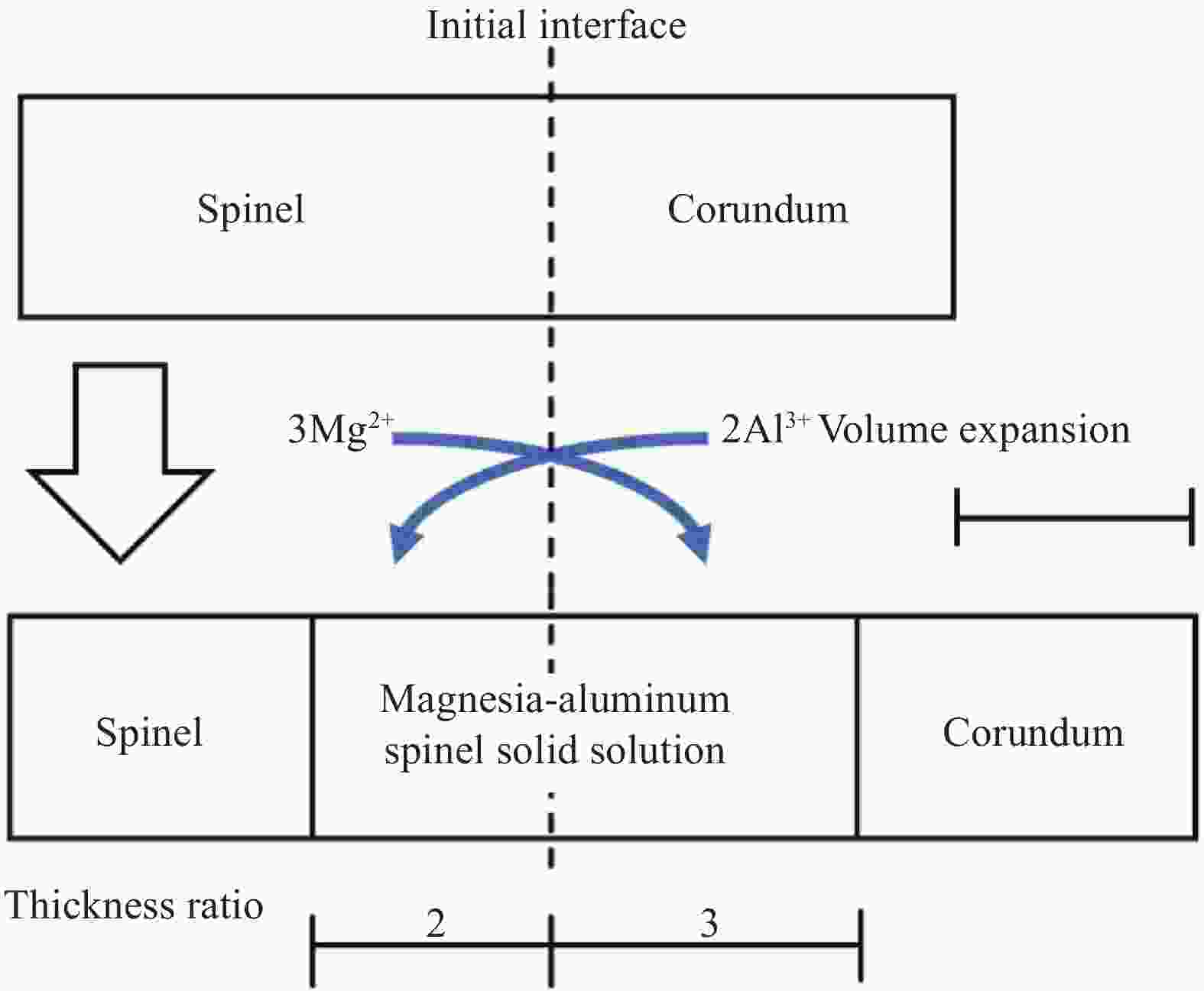

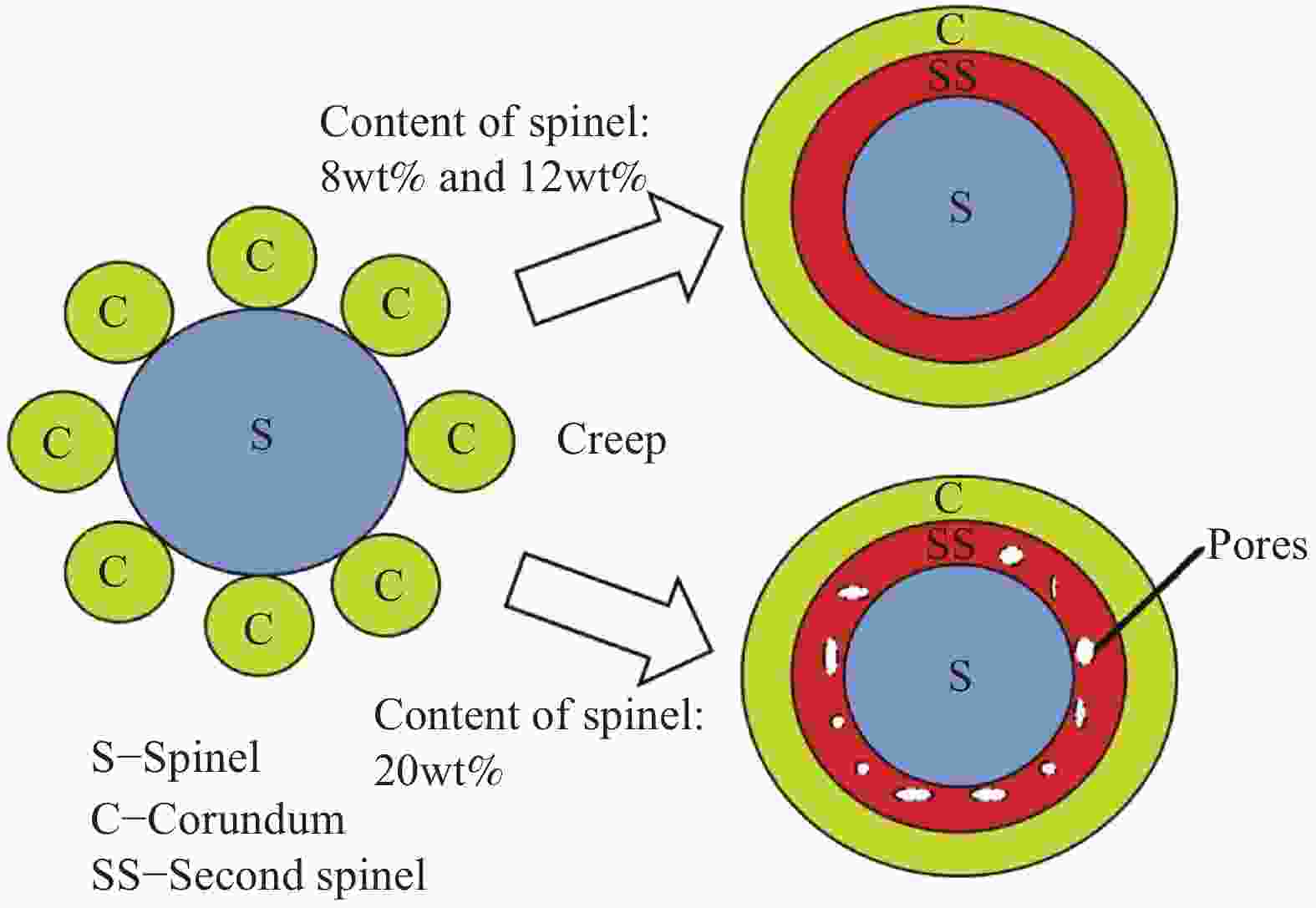

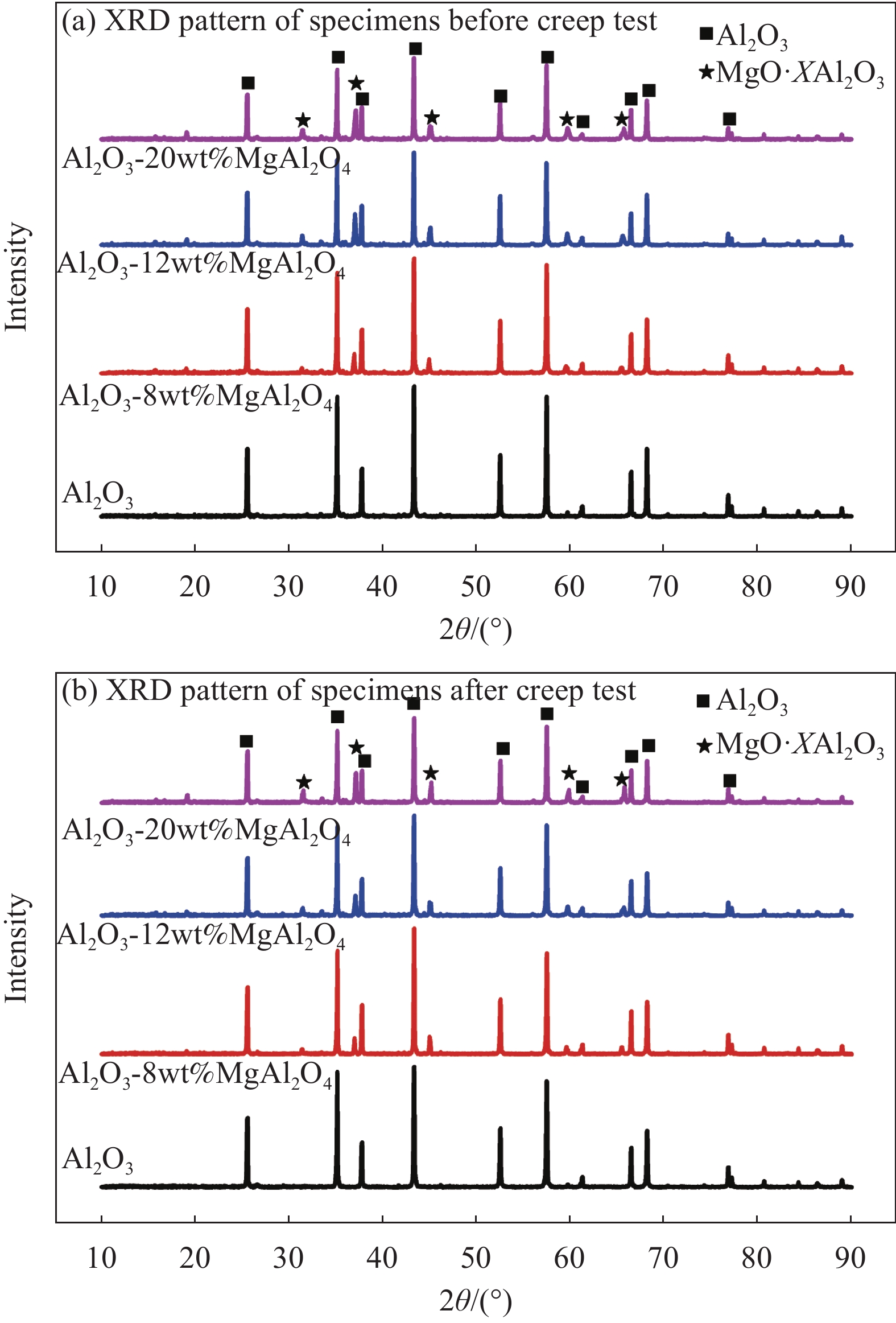

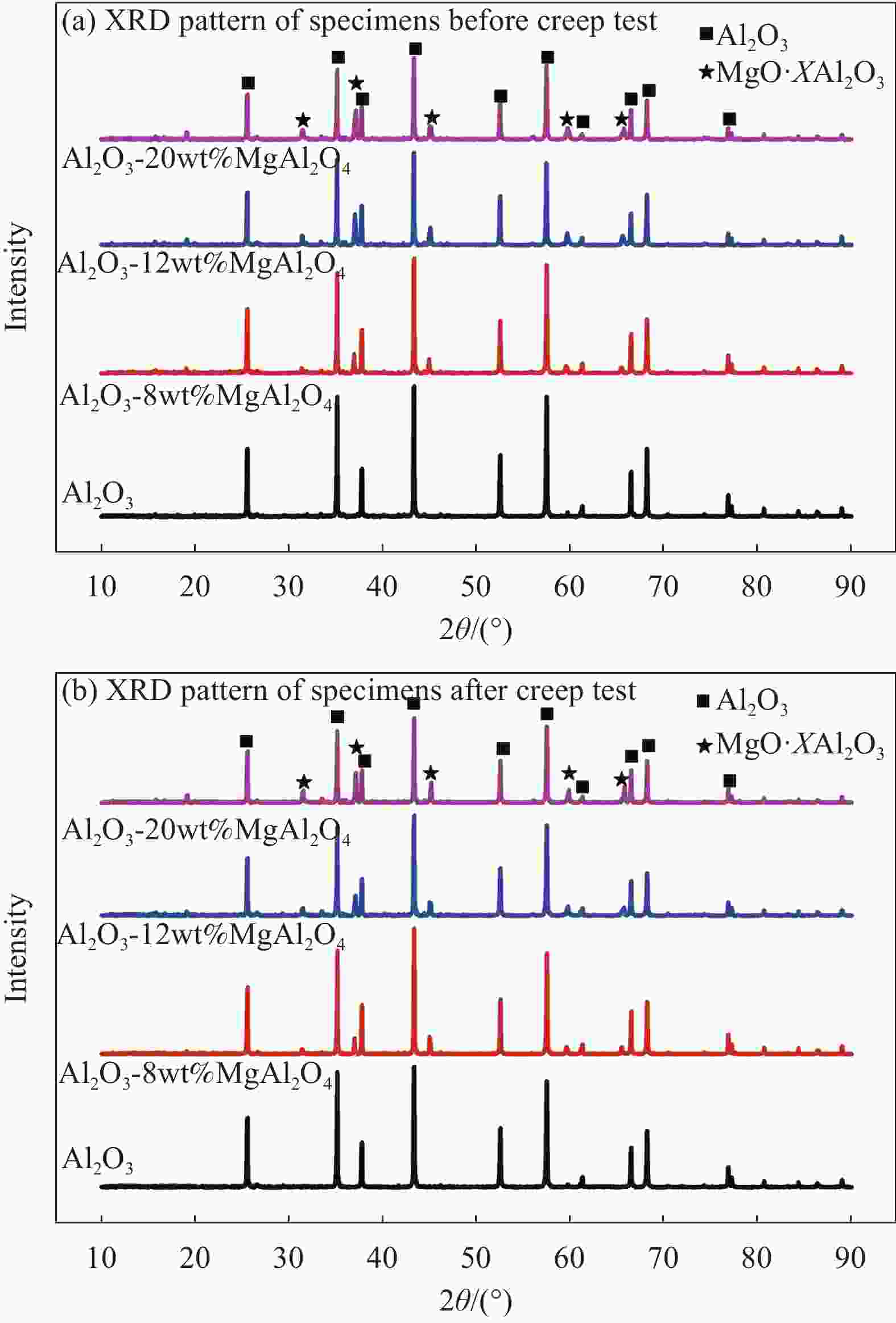

摘要: 以烧结板状刚玉和电熔镁铝尖晶石为原料、磷酸为结合剂,在1680℃下制备了刚玉-镁铝尖晶石复合耐火材料样品。在1500℃、0. 2 MPa的条件下保温50 h测试试样高温蠕变性能,采用 XRD、SEM和EDS分析蠕变前后试样的物相组成及显微结构,分析镁铝尖晶石添加量对刚玉-镁铝尖晶石复合耐火材料高温蠕变性能的影响。结果表明:刚玉-镁铝尖晶石复相材料较纯刚玉材料有着更好的抗蠕变性。镁铝尖晶石骨料在蠕变过程中会与氧化铝基质之间发生固溶反应而在尖晶石颗粒周围形成二次尖晶石层,有效连接了基质与骨料,提高了试样的抗蠕变性。在二次尖晶石层形成的过程中由于Mg2+有着更高的迁移速率和在反应界面两侧较高的厚度比,会诱发柯肯达尔效应,导致界面处空位大量积累和孔隙的产生。Abstract: The Al2O3 bonded MgAl2O4 fire-resistant composites were prepared with tabular alumina and fused magnesia-alumina spinel as raw materials, and phosphoric acid as binder and then sintered at 1680℃. The creep resistance test was conducted at 1500℃ under 0.2 MPa with insulation for 50 h, The specimens after creep resistance test were characterized and analyzed by XRD, SEM and EDS to investigate the effect of adding amount of MgAl2O4 on high temperature creep resistance of Al2O3 bonded MgAl2O4 fire-resistant composites as well as its mechanism. The results show that Al2O3 bonded MgAl2O4 fire-resistant composites has better creep resistance than Al2O3 composite. During the creep test, magnesium-aluminum spinel aggregate will react with alumina matrix to form secondary spinel layer around the spinel particles, which effectively connects the matrix and aggregate and improves the creep resistance of the specimens. During the formation of the secondary spinel layer, due to the higher migration rate of Mg2+ and the higher thickness ratio on both sides of the reaction interface, the Kirkendall effect will be induced, resulting in a large number of vacancies and pores at the interface.

-

表 1 原料化学组成

Table 1. Chemical composition of raw materials

wt% Al2O3 MgO SiO2 Fe2O3 Na2O Tabular corundum 99.55 — 0.04 0.03 0.3 Fused MA 71.4 27.8 0.19 0.33 0.28 Note: MA—Magnesia alumina spinel. 表 2 Al2O3-MgAl2O4复合耐火材料样品配比

Table 2. Proportion of Al2O3-MgAl2O4 refractory samples

Raw material/wt% Grain size/mm Al2O3 Al2O3-8wt%MgAl2O4 Al2O3-12wt%MgAl2O4 Al2O3-20wt%MgAl2O4 Tabular corundum 5-3 7 7 7 7 Tabular corundum 3-1 38 30 26 18 Fused MA 3-1 0 8 12 20 Tabular corundum 1-0 22 22 22 22 Tabular corundum <0.088 33 33 33 33 表 3 Al2O3-MgAl2O4复合耐火材料样品的物理性能指标

Table 3. Physical properties of Al2O3-MgAl2O4 refractory samples

Sample Apparent porosity/% Bulk density/(g·cm–3) Cold crushing/strength/MPa Al2O3 14.5 3.23 73 Al2O3-8wt%MgAl2O4 17.3 3.13 62 Al2O3-12wt%MgAl2O4 16.5 2.96 58 Al2O3-20wt%MgAl2O4 16.1 3.02 66 表 4 Al2O3-MgAl2O4复合耐火材料1500℃保温50 h蠕变曲线拟合方程

Table 4. Fitting equation of creep curve of Al2O3-MgAl2O4 refractory at 1500℃ for 50 h

Time/h Sample Equation R2 0-25 Al2O3 Y=0.517exp(−t/2.012)+1.488exp(−t/24.646)−2 0.999 Al2O3-8wt%MgAl2O4 Y=0.192exp(−t/1.569)+0.618exp(−t/22.462)−0.81 0.999 Al2O3-12wt%MgAl2O4 Y=0.137exp(−t/0.113)+0.23exp(−t/8.088)−0.367 0.999 Al2O3-20wt%MgAl2O4 Y=0.235exp(−t/2.22)+0.618exp(−t/239.243)−1.57 0.999 25-30 Al2O3 Y=−0.017t−1.056 0.994 Al2O3-8wt%MgAl2O4 Y=−0.009t−0.373 0.994 Al2O3-12wt%MgAl2O4 Y=−0.0007t−0.34 0.879 Al2O3-20wt%MgAl2O4 Y=−0.002t−0.33 0.824 Notes: Y—Creep rate; t—Time. Specimen Marked area Atom fraction/at% Mg Al O Al2O3-12wt%MgAl2O4 1 10.25 31.8 57.95 2 9.31 32.55 58.14 3 9.19 32.65 58.16 4 8.76 33.00 58.25 5 5.01 35.99 59.00 6 — 40 60 Al2O3-20wt%MgAl2O4 7 9.61 32.31 58.08 8 9.47 32.43 58.11 9 9.61 32.31 58.08 10 5.29 35.77 58.94 11 — 40 60 -

[1] 王恩会, 陈俊红, 侯新梅. 钢包工作衬用耐火材料的研究现状及最新进展[J]. 工程科学学报, 2019, 41(6):695-708.WANG Enhui, CHEN Junhong, HOU Xinmei. Current research and latest developments on refractories used as ladle linings[J]. Chinese Journal of Engineering,2019,41(6):695-708(in Chinese). [2] MARTINEZ A G, LUZ A P, PANDOLFELLI V C et al. Revisiting CA6 formation in cement-bonded alumina-spinel refractory castables[J]. Journal of the European Ceramic Society,2017,37(15):5023-5034. doi: 10.1016/j.jeurceramsoc.2017.07.003 [3] LONG B, XU G, BUHR A, et al. Fracture behaviour and microstructureof refractory materials for steel ladle purging plugs in the system Al2O3-MgO-CaO[J]. Ceramics International,2017,43(13):9679-9685. doi: 10.1016/j.ceramint.2017.04.141 [4] KO Y C. Role of spinel composition in the slag resistance of Al2O3-spinel and Al2O3-MgO cast-ables[J]. Ceramics International,2002,28(7):805-810. doi: 10.1016/S0272-8842(02)00046-9 [5] ZHANG P X, CHEN A B, GAO S, et al. Trace nanoscale Al2O3 in Al2O3-MgAl2O4 castable for improved thermal shock performance[J]. Ceramics International,2019,45(17):23029-23036. doi: 10.1016/j.ceramint.2019.07.350 [6] GANESH I, BHATTACHARJEE S, MAHAJAN Y R. An efficient MgAl2O4 spinel additive for improved slag erosion and penetration resistance of high-Al2O3 and MgO–C refractories[J]. Ceramics International,2002,28(3):245-253. doi: 10.1016/S0272-8842(01)00086-4 [7] JIN S, HARMUTH H, GRUBER D. Compressive creep testing of refractories at elevated loads—Device, material law and evaluation techniques[J]. Journal of the European Ceramic Society,2014,34(15):4037-4042. doi: 10.1016/j.jeurceramsoc.2014.05.034 [8] 张秀华, 李勇, 田志宏, 等. 压蠕变实验方法对硅砖蠕变结果的适应性探究[J]. 硅酸盐学报, 2020, 48(9):1505-1510.ZHANG Xiuhua, LI Yong, TIAN Zhihong, et al. Evaluation of creep results of silica brick by creep test method[J]. Journal of the Chinese Ceramic Society,2020,48(9):1505-1510(in Chinese). [9] DÍAZ L A, TORRECILLAS R. Hot bending strength and creep behaviour at 1000-1400℃ of high alumina refractory castables with spinel, periclase and dolomite additions[J]. Journal of the European Ceramic Society,2009,29(1):53-58. doi: 10.1016/j.jeurceramsoc.2008.05.044 [10] SAMADI S, JIN S S L, GRUBER D, et al. Creep parameter determination of a shaped alumina spinel refractory using statistical analysis[C]//Dannert C. Refractories Enabling High Temperature Technologies. Aachen: ECREF European Centre for Refractories Gemeinnützige GmbH, 2020: 89-93. [11] 国家标准化管理委员会. 致密定形耐火制品体积密度、显气孔率和真气孔率试验方法: GB/T 2997—2000[S]. 北京: 中国标准出版社, 2001.Standardization Administration of the People’s Republic of China. Test method for bulk density, apparent porosity and true porosity of dense shaped refractory products: GB/T 2997—2000[S]. Beijing: Standards Press of China, 2001(in Chinese). [12] 国家标准化管理委员会. 耐火材料常温耐压强度试验方法: GB/T 5072—2008[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Refractories-Determination of cold compressive strength: GB/T 5072—2008[S]. Beijing: Standards Press of China, 2009(in Chinese). [13] 国家标准化管理委员会. 耐火材料压蠕变试验方法: GB/T 5073—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Refractory products-Test method of creep in compression: GB/T 5073—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [14] KO Y C, LAY J T. Thermal expansion characteristics of alumina-magnesia and alumina-spinel castables in the temperature range 800-1 650℃[J]. Journal of the American Ceramic Society,2000,83(11):2872-2874. [15] 戴亚洁, 李亚伟, 金胜利. 耐火材料力学行为表征方法研究进展[J]. 硅酸盐学报, 2019, 47(8):1089-1094.DAI Yajie, LI Yawei JIN Shengli. Review on characterization methods for mechanical behavior of refractory materials[J]. Journal of the Chinese Ceramic Society,2019,47(8):1089-1094(in Chinese). [16] TONG Shanghao, LI Yong, ZHAO Jizeng, et al. Effect of Al addition on creep resistance of MgO-Al2O3 composite for sliding plate at 1400℃[J]. Ceramics International,2017,43(15):11610-11615. doi: 10.1016/j.ceramint.2017.05.330 [17] IBRAM G. A review on magnesium aluminate (MgAl2O4) spinel: Synthesis, processing and applications[J]. International Materials Reviews,2013,58(2):63-112. doi: 10.1179/1743280412Y.0000000001 [18] 仝尚好, 李勇, 焦智宇, 等. MgO 与 Al2O3对Al–MgO–Al2O3体系中 MgAlON 形成机理的影响[J]. 硅酸盐学报, 2019, 47(12):1746-1751.TONG Shanghao, LI Yong, JIAO Zhiyu, et al. Effect of MgO and Al2O3 on formation of MgAlON in Al–MgO–Al2O3 composites[J]. Journal of the Chinese Ceramic Society,2019,47(12):1746-1751(in Chinese). [19] 李楠, 顾华志, 赵惠忠. 耐火材料学[M]. 北京: 冶金工业出版社, 2012: 195.LI Nan, GU Huazhi, ZHAO Huizhong. Refractories[M]. Beijing: Metallurgical Industry Press, 2012: 195(in Chinese). [20] SAKO E Y, PANDOLFELLI V C, ZINNGREBE E, et al. Fundamentals and applications on in situ spinel formation mechanisms in Al2O3-MgO refractory castables[J]. Ceramics International,2012,38(3):2243-2251. doi: 10.1016/j.ceramint.2011.10.074 [21] RIGAUD M, BUHR A, PARR C, et al. Spinel-containing alumina-based refractory castables[J]. Ceramics International,2011,37(6):1705-1724. doi: 10.1016/j.ceramint.2011.03.049 -

下载:

下载: