Buckling characteristics of composite grid/corrugated sandwich structure based on refined plate theory

-

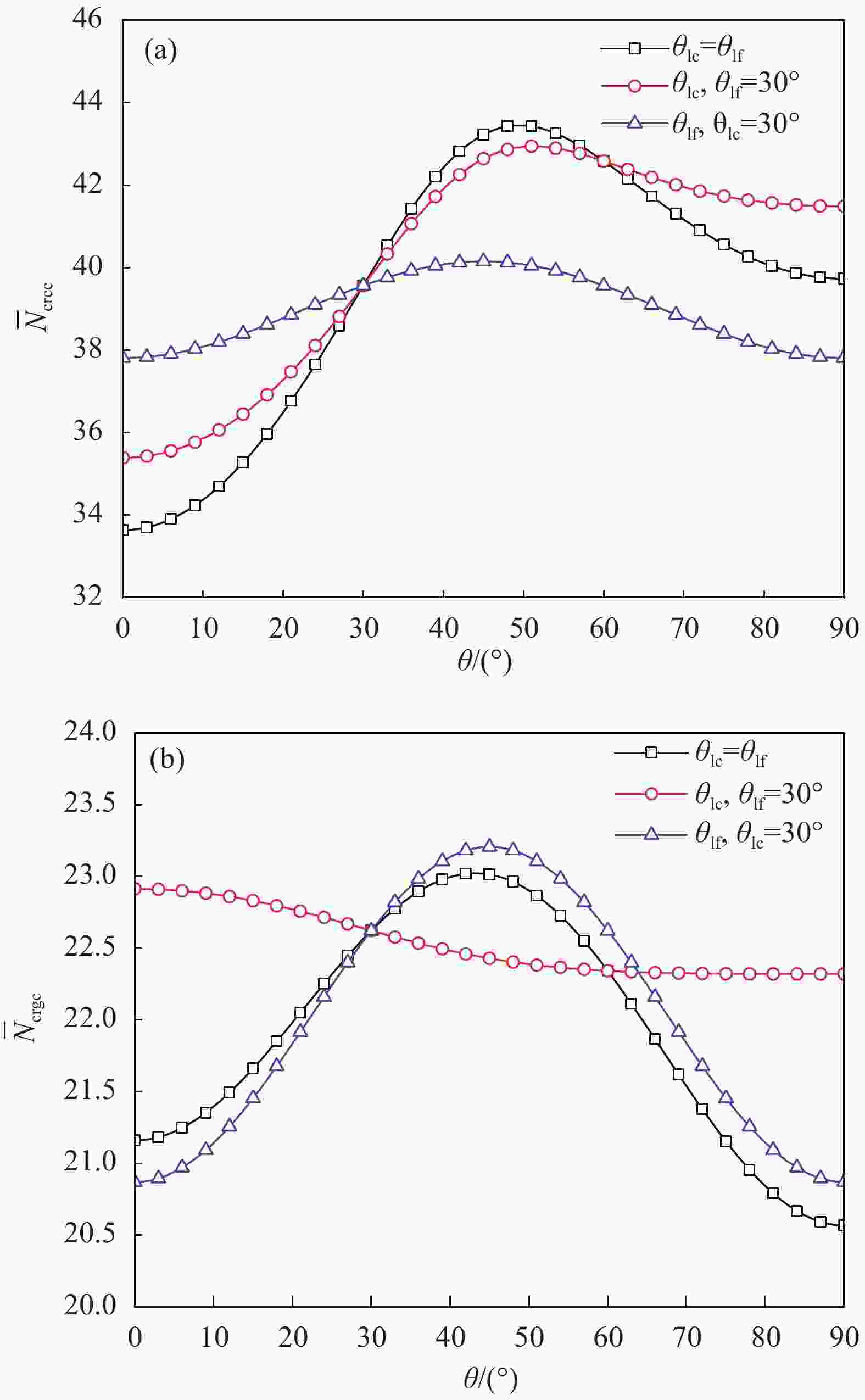

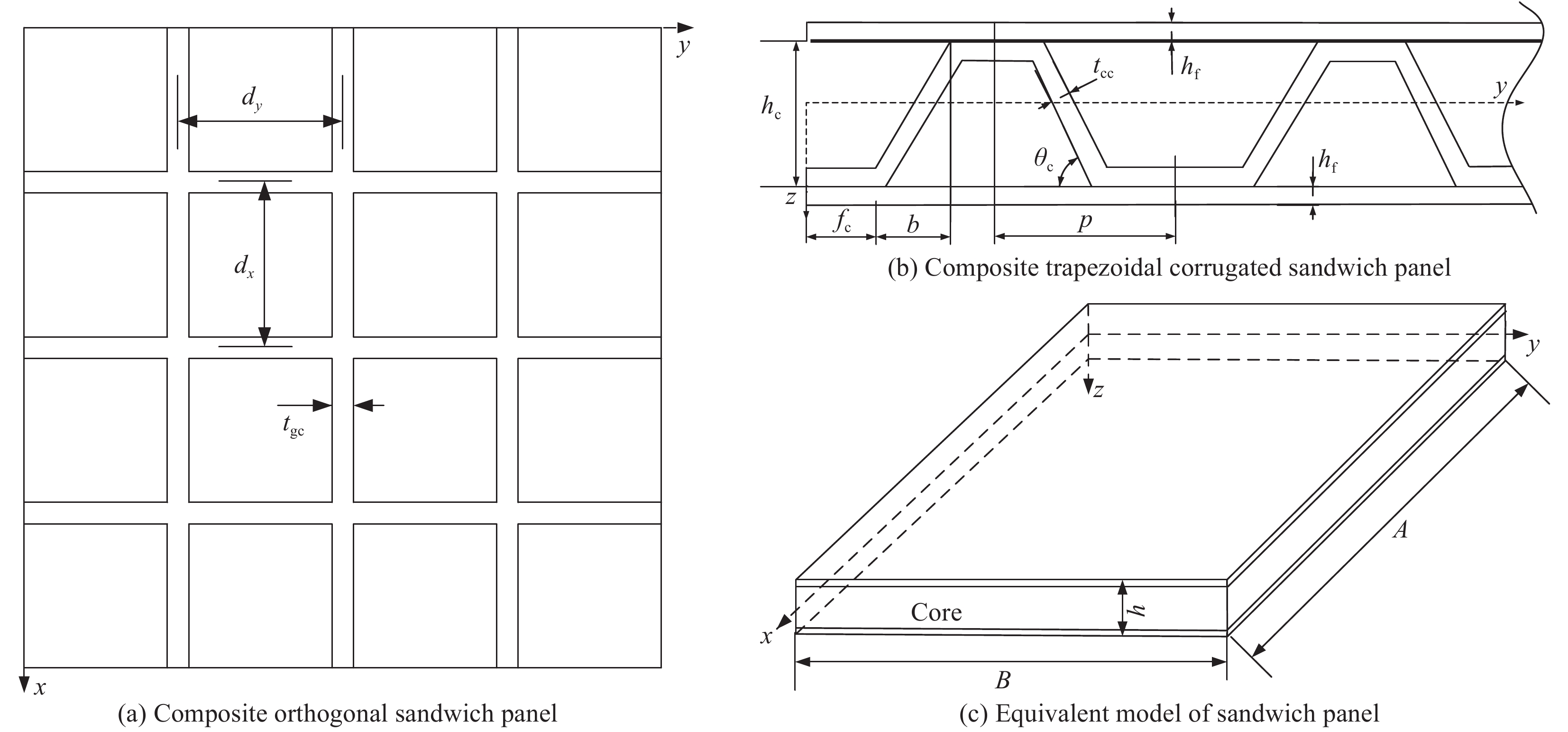

摘要: 提供了一种分析全复合材料格栅/波纹夹芯板屈曲特性的解析模型。将格栅、波纹芯子视为连续性单层,基于精确板理论推导了全复合材料波纹/格栅夹芯板的内力-应变关系;在考虑复合材料芯子壁板各向异性和横向剪切变形的基础上,基于均质化理论分别推导了复合材料正交格栅和梯形波纹芯子的等效弹性常数;利用最小势能原理得到了全复合材料格栅/波纹夹芯板屈曲平衡微分方程,求解了3种边界条件下的屈曲临界载荷,解析计算的结果与有限元仿真结果进行对比的误差在5%以内,验证了解析模型的正确性和有效性。基于验证过的模型对比分析了铺层角度、铺层数等铺层参数以及芯子高度、波纹倾角和格栅间距等结构参数对全复合材料格栅/波纹夹芯板屈曲临界载荷、比屈曲临界载荷的影响规律,为该类型结构的屈曲特性分析和优化设计提供理论指导。Abstract: An analytical model for analyzing the buckling characteristics of full composite grid/corrugated sandwich panels was provided. Regarding the corrugation and the grid core as a continuous single layer, the internal force-strain relationship of the full composite corrugated/grid sandwich panel was derived based on the refined plate theory. On the basis of considering the anisotropy and transverse shear deformation of the composite core panel, the equivalent elastic constants of composite orthogonal grid and trapezoidal corrugations cores were deduced based on the homogenization theory. Using the minimum potential energy principle, the buckling balance differential equation of full composite grid/corrugated sandwich panels was obtained, and the critical buckling load under three boundary conditions was transformed. The analytical results were compared with the finite element simulation and the errors are within 5%, which validates the correctness and effectiveness of the analytical model. The verified model was used to compare and analyze the effect of the layers angle, number of layers as well as the height of core, inclination angle of corrugation and grid spacing on the critical buckling load and the specific critical buckling load of the full composite grid/corrugated sandwich pane, which provides theoretical guidance for the buckling characteristic analysis and optimal design of this type of structure.

-

图 1 复合材料格栅/波纹夹芯板及其等效连续模型

Figure 1. Composite grid/corrugated sandwich panels and the equivalent continuous model

dx, dy and tgc—Width, length and wall thickness of orthogonal grid core; fc, b and p—Horizontal segment length, horizontal length of oblique segment and total length of trapezoidal corrugated core; θc and tcc—Inclination angle and wall thickness of trapezoidal corrugated core; hc, hf and h—Core thickness, facesheet thickness and total thickness of sandwich panels; A and B—Width and length of sandwich panels

表 1 碳纤维增强树脂基复合材料(CFRP)单层的弹性参数

Table 1. Elastic parameters of carbon fiber reinforced polymer (CFRP) material layer

Elastic parameter Value Longitudinal elastic modulus E1/GPa 115 Normal elastic modulus E2=E3/GPa 6.2 In-plane shear modulus G12=G13/GPa 4.0 Out-plane shear modulus G23/GPa 3.0 In-plane Poisson’s ratio v12=v13 0.31 Out-plane Poisson’s ratio v23 0.33 Average single layer thickness t/mm 0.2 Density ρ/(g·cm−3) 1.55 表 2 本文方法与有限元仿真得到的CFRP复合材料梯形波纹夹芯板(CCSP)和复合材料格栅夹芯板(CGSP)屈曲临界载荷

Table 2. Critical buckling load of the CFRP composite trapezoidal corrugated sandwich panel (CCSP) and composite grid sandwich panel (CGSP) by present method and numerical simulation

Example Boundary condition Numerical results under different mesh sizes Present Average error/% 25 20 15 10 5 CCSP SSFF 22.29 22.11 21.94 21.79 21.34 22.71 3.70 SSSS 38.89 38.66 38.40 38.19 38.06 39.49 2.74 SSCC 78.79 78.10 77.28 76.62 76.35 78.14 0.93 CGSP SSFF 13.46 13.47 13.35 13.17 13.22 13.03 −2.26 SSSS 22.60 23.59 23.34 23.07 22.71 22.65 −2.63 SSCC 39.99 39.98 39.11 38.55 38.10 40.90 4.53 Notes:SSFF—Loading opposite sides simply supported and the others free;SSSS—Four sides simply supported;SSCC—Loading opposite sides simply supported and the others clamped. 表 3 芯子壁板铺层数对CFRP复合材料夹芯板屈曲特性的影响

Table 3. Effect of the number of layers of core siding on the buckling characteristics of CFRP composite sandwich panel

hc nc ${\overline N _{{\rm{crcc}}}}$ Kcc ${\overline N _{{\rm{crgc}}}}$ Kgc SSFF SSSS SSCC SSFF SSSS SSCC SSFF SSSS SSCC SSFF SSSS SSCC 15 1 22.71 39.49 78.14 37.36 64.98 128.58 13.03 22.62 40.90 22.82 39.62 71.63 2 27.54 48.70 95.81 27.35 48.36 95.15 13.62 23.61 42.88 16.70 28.94 52.56 3 34.81 65.92 122.21 21.66 41.02 76.05 14.22 24.60 44.85 13.41 23.19 42.41 20 1 57.11 100.68 194.83 118.21 208.39 403.27 28.11 48.85 88.22 54.40 94.56 170.75 2 65.50 114.09 225.83 84.50 147.20 291.37 29.89 51.81 94.13 38.56 66.85 121.46 3 76.43 136.06 265.91 65.59 116.75 228.17 31.66 54.77 100.05 30.64 53.00 96.82 4 91.92 173.01 322.22 53.85 101.37 188.79 33.45 57.74 105.98 25.89 44.70 82.05 25 1 126.69 229.15 428.38 315.12 569.97 1065.54 52.15 90.66 163.74 108.42 188.47 340.39 2 138.09 242.00 472.33 217.69 381.48 744.59 56.34 97.63 177.69 75.29 130.48 237.47 3 154.53 269.63 533.38 166.85 291.12 575.89 60.54 104.63 191.66 59.62 103.03 188.74 4 175.33 312.38 609.83 134.80 240.18 468.87 64.75 111.64 205.66 50.48 87.03 160.33 5 203.83 379.63 713.60 113.64 211.66 397.85 68.97 118.68 219.69 44.50 76.57 141.74 Notes:hc —Thickness of core; nc—Number of groups of core plies; ${\overline N _{{\rm{crcc}}}}$—Critical buckling load of CCSP; Kcc—Specific critical buckling load of CCSP; ${\overline N _{{\rm{crgc}}}}$—Critical buckling load of CGSP; Kgc—Specific critical buckling load of CGSP. -

[1] 刘建良, 梅志远, 张焱冰, 等. 浮力材料和橡胶格栅夹层板振动响应试验对比研究[J]. 中国舰船研究, 2019, 14(4):1-6, 13.LIU J L, MEI Z Y, ZHANG Y B, et al. Comparative study on vibration response test of buoyancy-core and rubber-core grid sandwich panels[J]. Chinese Journal of Ship Research,2019,14(4):1-6, 13(in Chinese). [2] 燕瑛, 刘玉佳, 廖宝华, 等. 先进复合材料格栅结构与大型飞机[J]. 航空制造技术, 2009(2):26-29.YAN Ying, LIU Yujia, LIAO Baohua, et al. Advanced composite grid structure and large aircraft[J]. Aviation Manufacturing Technology,2009(2):26-29(in Chinese). [3] GIUSTO G, TOTARO G, SPENA P, et al. Composite grid structure technology for space applications[J]. Materials Today: Proceedings,2021,34(Part 1):332-340. [4] ZANGANA S, EPAARACHCHI J, FERDOUS W, et al. A novel hybridised composite sandwich core with Glass, Kevlar and Zylon fibres – Investigation under low-velocity impact[J]. International Journal of Impact Engineering,2020,137:103430. doi: 10.1016/j.ijimpeng.2019.103430 [5] CHEN Liming, PENG Shiwei, LIU Jian, et al. Compressive response of multi-layered thermoplastic composite corrugated sandwich panels: Modelling and experiments[J]. Composites Part B: Engineering,2020,189:107899. doi: 10.1016/j.compositesb.2020.107899 [6] HU Yang, LI Wanxin, AN Xiyue, et al. Fabrication and mechanical behaviors of corrugated lattice truss composite sandwich panels[J]. Composites Science and Technology,2016,125:114-122. doi: 10.1016/j.compscitech.2016.02.003 [7] 徐世南, 吴催生. 导弹结构热防护一体化设计与优化[J]. 国防科技大学学报, 2020, 42(2):78-84.XU Shinan, WU Cuisheng. Design and optimization of structure-thermal protection intergrated for missile[J]. Journal of National University of Defense Technology,2020,42(2):78-84(in Chinese). [8] 时圣波, 唐硕, 梁军. 临近空间飞行器防隔热/承载一体化热结构设计及力/热行为[J]. 装备环境工程, 2020, 17(1):36-42.SHI Shengbo, TANG Shuo, LIANG Jun. Design and thermomechanical behavior of full-composite structurally integrated thermal protection structure for near space vehicles[J]. Equipment Environmental Engineering,2020,17(1):36-42(in Chinese). [9] LI Ying, ZHANG Lu, HE Rujie, et al. Integrated thermal protection system based on C/SiC composite corrugated core sandwich plane structure[J]. Aerospace Science and Technology,2019,91:607-616. doi: 10.1016/j.ast.2019.05.048 [10] SUN Jian, GUAN Qinghua, LIU Yanju, et al. Morphing aircraft based on smart materials and structures: A state-of-the-art review[J]. Journal of Intelligent Material Systems and Structures,2016,27(17):2289-2312. doi: 10.1177/1045389X16629569 [11] HIROKI Takahashi, TOMOHIRO Yokozeki, YOSHIYASU Hirano. Development of variable camber wing with morphing leading and trailing sections using corrugated structures[J]. Journal of Intelligent Material System Structures,2016,27(20):2827-2836. doi: 10.1177/1045389X16642298 [12] 骆伟. 混杂夹层结构低速冲击及剩余弯曲强度研究[D]. 北京: 中国舰船研究院, 2018.LUO Wei. Investigation of low-velocity and residual bending strength characteristics of hybrid sandwich structures[D]. Beijing: China Ship Research and Development Academy, 2018 (in Chinese). [13] 石姗姗, 孙直, 任明法, 等. 格栅非均匀分布效应对复合材料格栅加筋圆锥壳体稳定性的影响[J]. 工程力学, 2012, 29(4):43-48.SHI Shanshan, SUN Zhi, REN Mingfa, et al. The effect of non-uniform distribution of grid on stability of advanced grid stiffened composite conical shell[J]. Engineering Mechanics,2012,29(4):43-48(in Chinese). [14] 石姗姗, 陈秉智, 孙直, 等. 基于变环肋间距的碳纤维/环氧树脂复合材料格栅加筋截顶圆锥壳体稳定性[J]. 复合材料学报, 2018, 35(8):2032-2038.SHI Shanshan, CHEN Bingzhi, SUN Zhi, et al. Stability of advanced grid stiffened carbon fiber/epoxy composite conical shells with novel distribution of circumferential ribs[J]. Acta Materiae Composite Sinica,2018,35(8):2032-2038(in Chinese). [15] 石姗姗, 孙直, 任明法, 等. 温度-机械混合载荷作用下先进复合材料格栅加筋截顶圆锥壳体的屈曲分析[J]. 复合材料学报, 2013, 30(6):209-214.SHI Shanshan, SUN Zhi, REN Mingfa, et al. Buckling resistance of advanced grid stiffened composite trapped conical shells under thermal and mechanical mixed loading[J]. Acta Materiae Composite Sinica,2013,30(6):209-214(in Chinese). [16] 陈烈民, 杨宝宁. 复合材料的力学分析[M]. 北京: 中国科学技术出版社, 2006: 174-314.CHEN Liemin, YANG Baoning. Mechanical analysis for composite materials[M]. Beijing: China Science and Technology Press, 2006: 174-314 (in Chinese). [17] ZHU Xiujie, XIONG Chao, YIN Junhui, et al. Bending experiment and mechanical properties analysis of composite sandwich laminated box beams[J]. Materials,2019,12(18):2959. doi: 10.3390/ma12182959 [18] 李华东, 周振龙, 陈国涛. 基于高阶剪切理论的复合材料格栅夹层板弯曲特性[J]. 复合材料学报, 2019, 36(12):2745-2755.LI H D, ZHOU Z L, CHEN G T. Bending characteristic of composite grid sandwich plate based on high-order shear theory[J]. Acta Materiae Composite Sinica,2019,36(12):2745-2755(in Chinese). [19] 谈超, 李玉龙, 郭亚洲. 复合材料夹芯管胶接连接结构力学特性分析[J]. 复合材料学报, 2014, 31(6):1532-1542.TAN Chao, LI Yulong, GUO Yazhou. Mechanical property analysis of composite adhesively bonded sandwich pipe joints[J]. Acta Materiae Composite Sinica,2014,31(6):1532-1542(in Chinese). [20] 富明慧, 尹久仁. 蜂窝芯层的等效弹性参数[J]. 力学学报, 1999(1):113-118.FU Minghui, YIN Jiuren. Equivalent elastic parameters of the honeycomb core[J]. Acta Mechanica Sinica,1999(1):113-118(in Chinese). [21] GIBSON L J, ASHBY M F, SCHAJER G S. The mechanics of two-dimension cellular materials[J]. Proceedings of the Royal Society of London, 1982, 382(1782): 43-59. [22] CHEN H J. Analysis and optimum design of composite grid structures[J]. Journal of Composite Materials,1996,30(4):503-533. [23] 郑青. 新型格栅结构设计及力学性能研究[D]. 长沙: 国防科技大学, 2017.ZHENG Qin. Design and mechanical properties of novel lattice structures[D]. Changsha: National University of Defense Technollogy, 2017 (in Chinese). [24] PENG L X, LIEW K M, KITIPORNCHAI, S. Analysis of stiffened corrugated plates based on the FSDT via the mesh-free method[J]. International Journal of Mechanical Sciences,2006,49(3):364-378. [25] PARK K J, JUNG K, KIM Y W. Evaluation of homogenized effective properties for corrugated composite panels[J]. Composite Structures,2016,140:644-654. doi: 10.1016/j.compstruct.2016.01.002 [26] BARTOLOZZI Giorgio, BALDANZINI Niccolò, PIERINI Marco. Equivalent properties for corrugated cores of sandwich structures: A general analytical method[J]. Composite Structures,2014,108:736-746. doi: 10.1016/j.compstruct.2013.10.012 [27] REDDY J N. Mechanics of laminated composite plates and shells: Theory and analysis[M]. New York: CRC Press, 2004: 669-720. [28] SHIMPI R P, PATEL H G. A two variable refined plate theory for orthotropic plate analysis[J]. International Journal of Solids and Structures,2006,43(22):6783-6799. [29] THAI H T, CHOI D H. A simple first-order shear deformation theory for laminated composite plates[J]. Composite Structures,2013,106:754-763. doi: 10.1016/j.compstruct.2013.06.013 [30] 周涛, 宋彦琦. 基于4变量精确平板理论的剪切效应分析[J]. 应用数学和力学, 2018, 39(11):1268-1281.ZHOU Tao, SONG Yanqi. Shear effect analysis on plates based on the 4-variable refined plate theory[J]. Applied Mathematics and Mechanics,2018,39(11):1268-1281(in Chinese). [31] SAYYAD A S, GHUGAL Y M. Bending, buckling and free vibration of laminated composite and sandwich beams: A critical review of literature[J]. Composite Structures,2017,171:486-504. doi: 10.1016/j.compstruct.2017.03.053 [32] 于天崇, 聂国隽, 仲政. 变刚度矩形板弯曲问题的Levy解[J]. 力学季刊, 2012, 33(1):53-59.YU Tianchong, NIE Guojun, ZHONG Zheng. Levy-type solution for the bending of rectangular plates with variable stiffness[J]. Chinese Quarterly of Mechanics,2012,33(1):53-59(in Chinese). -

下载:

下载: