Influence of warp and weft fiber volume fractions on tensile mechanical properties of alkali-resistant glass textile reinforced concrete

-

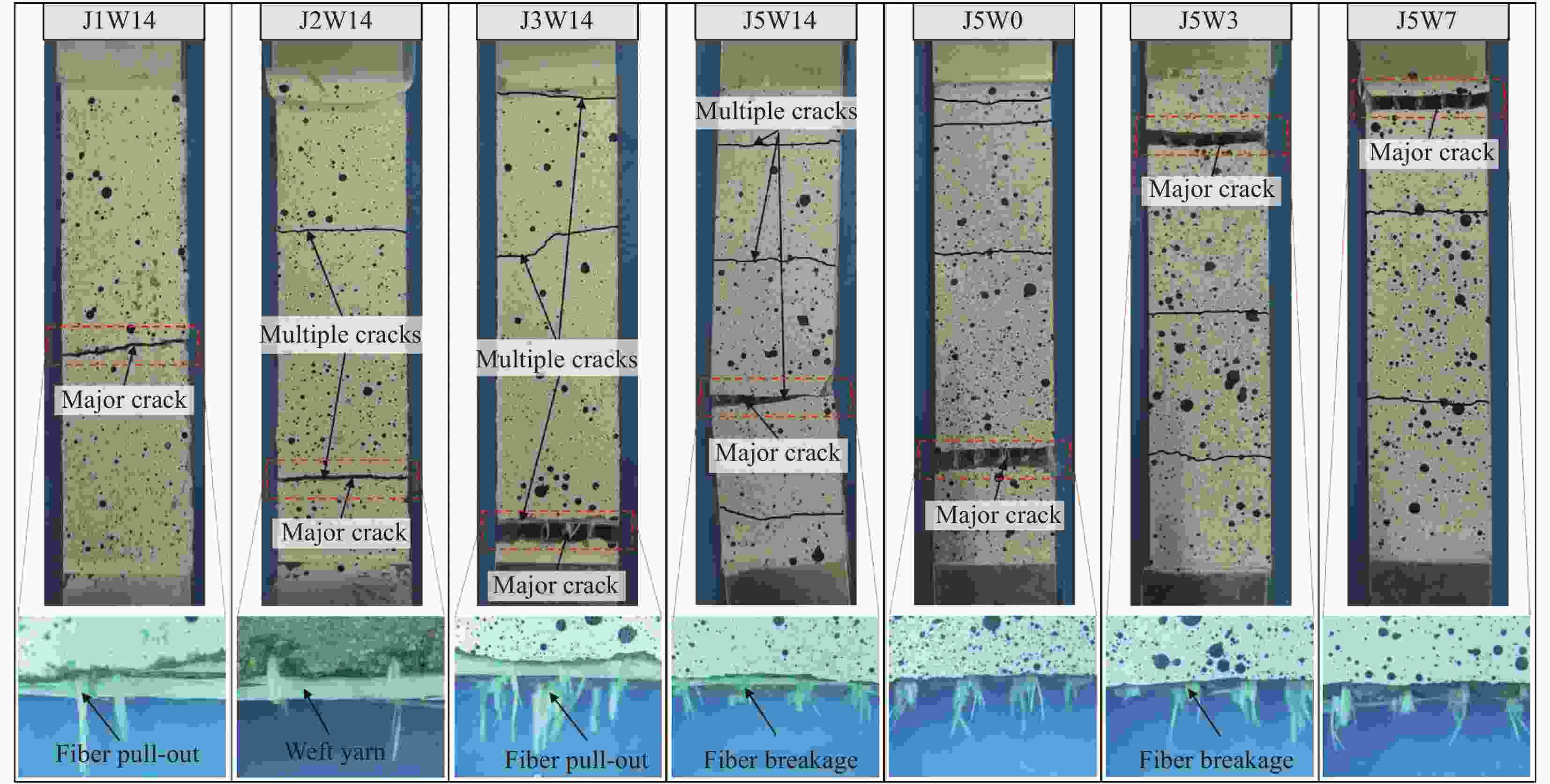

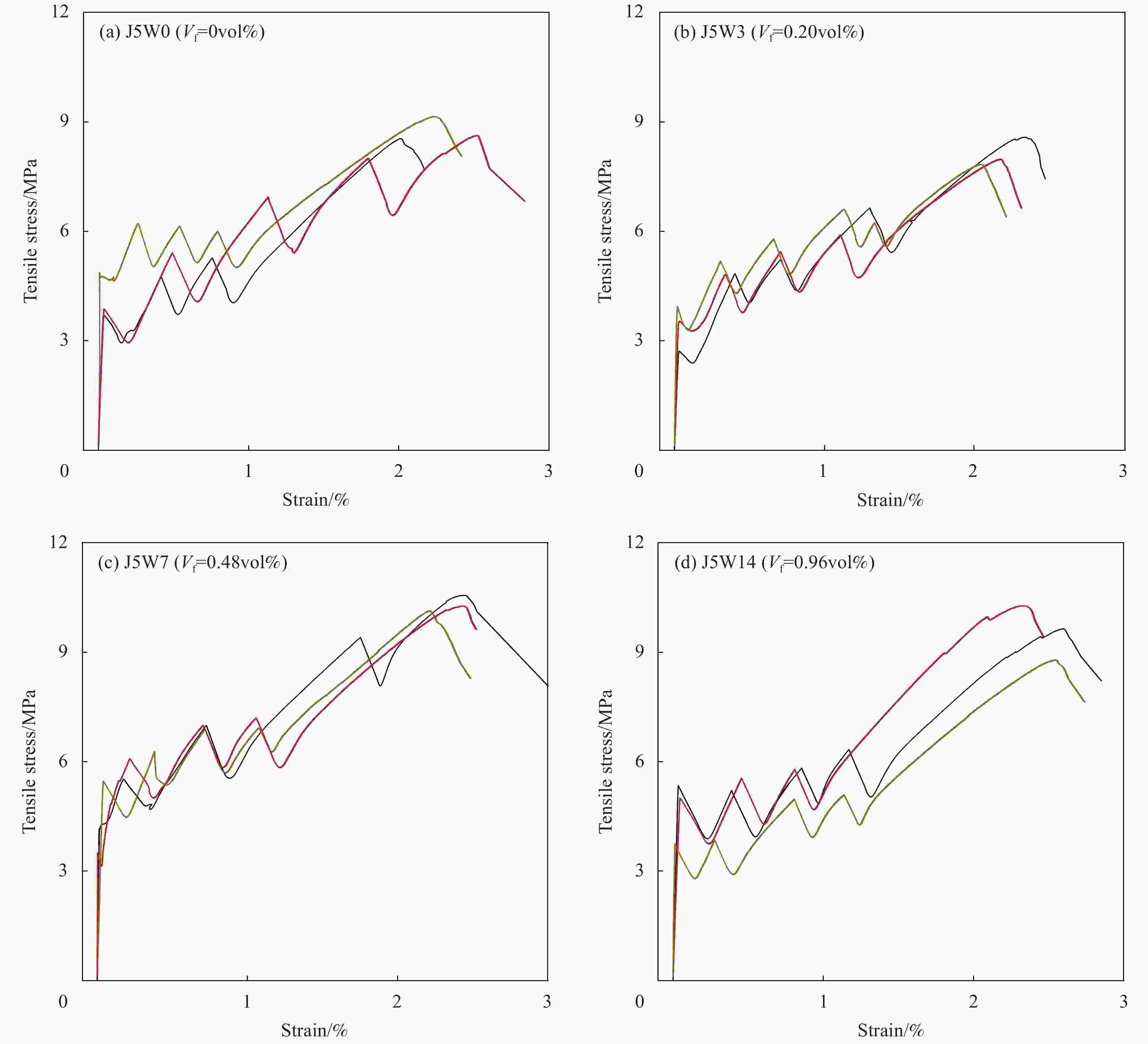

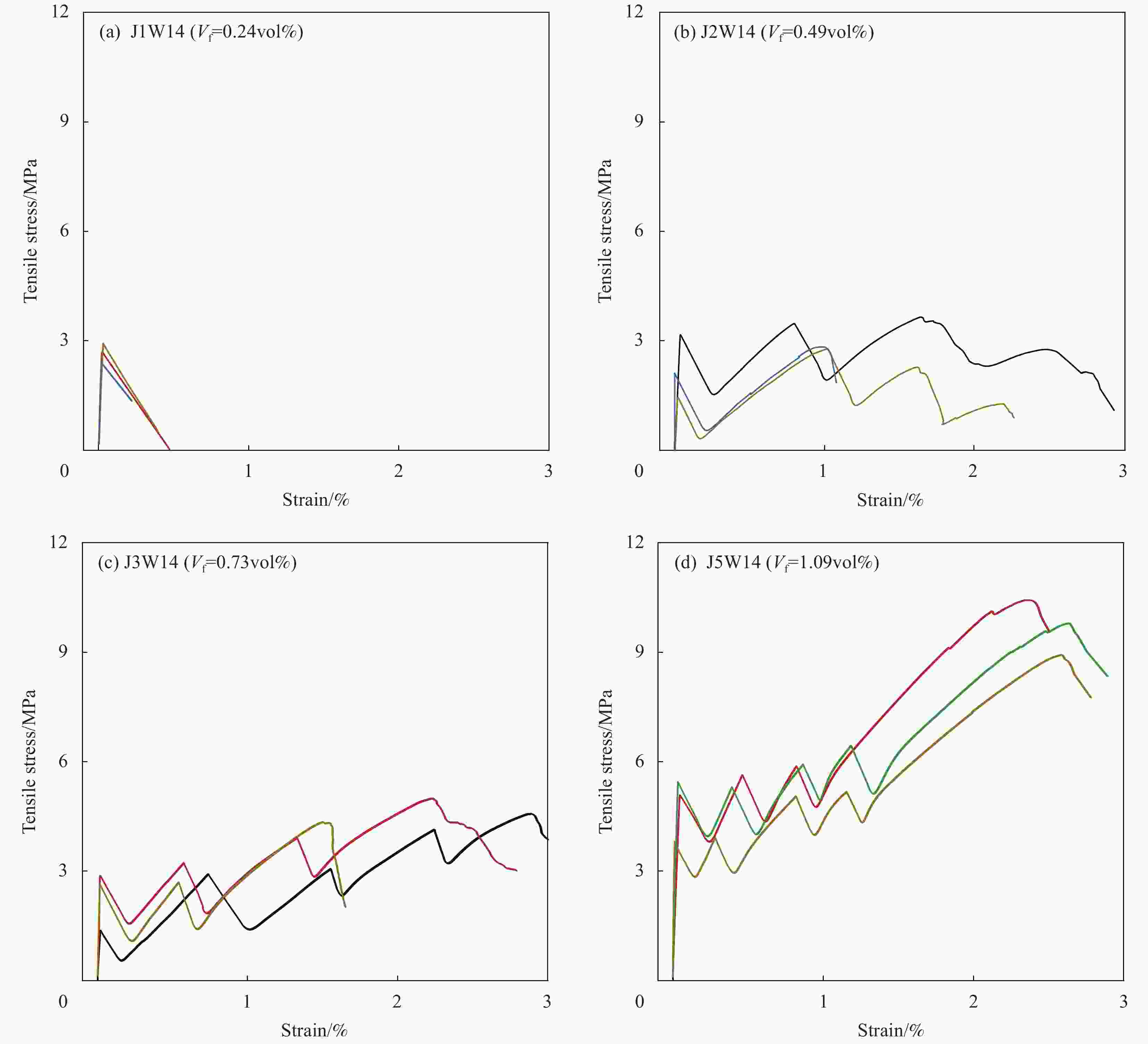

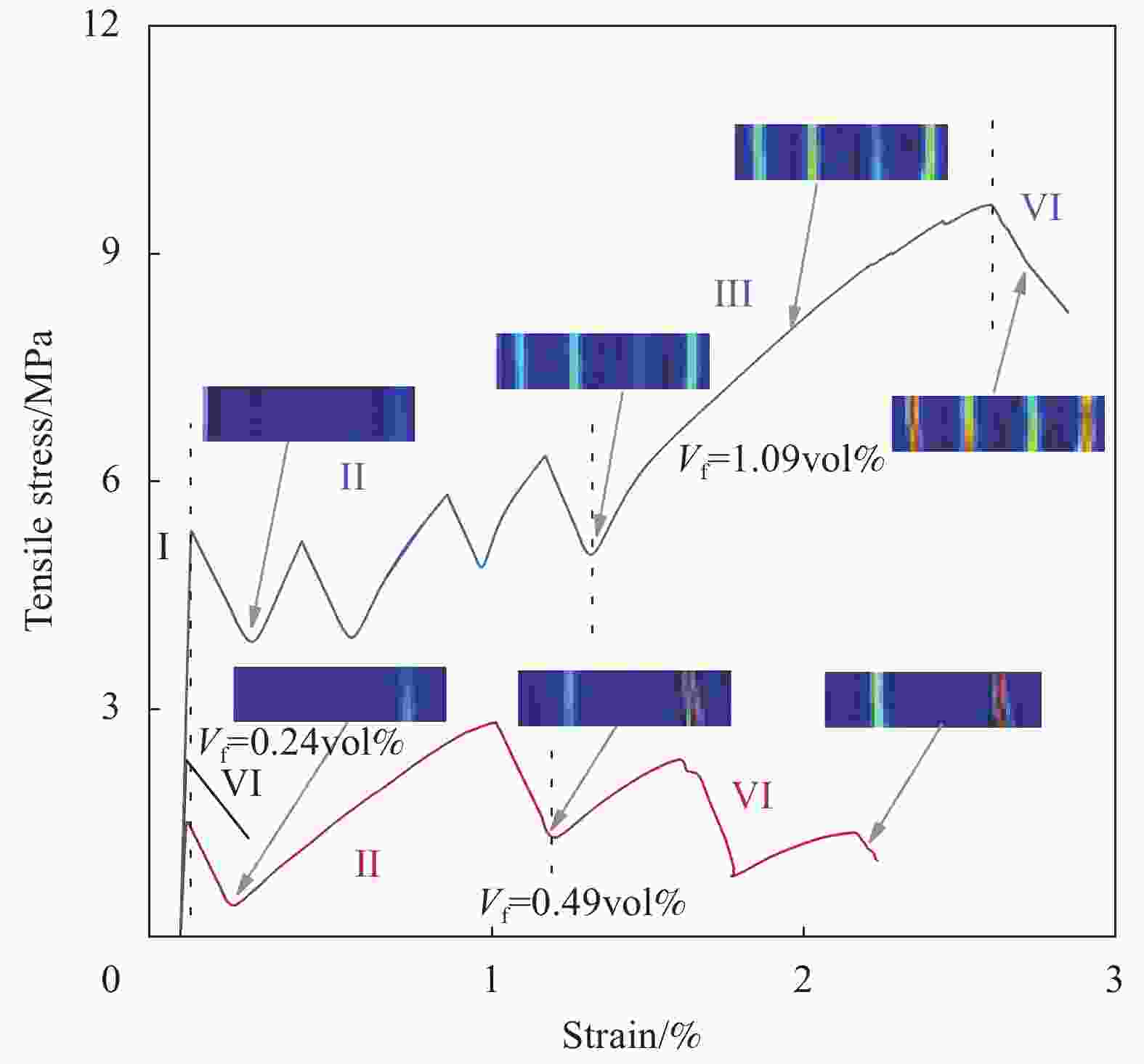

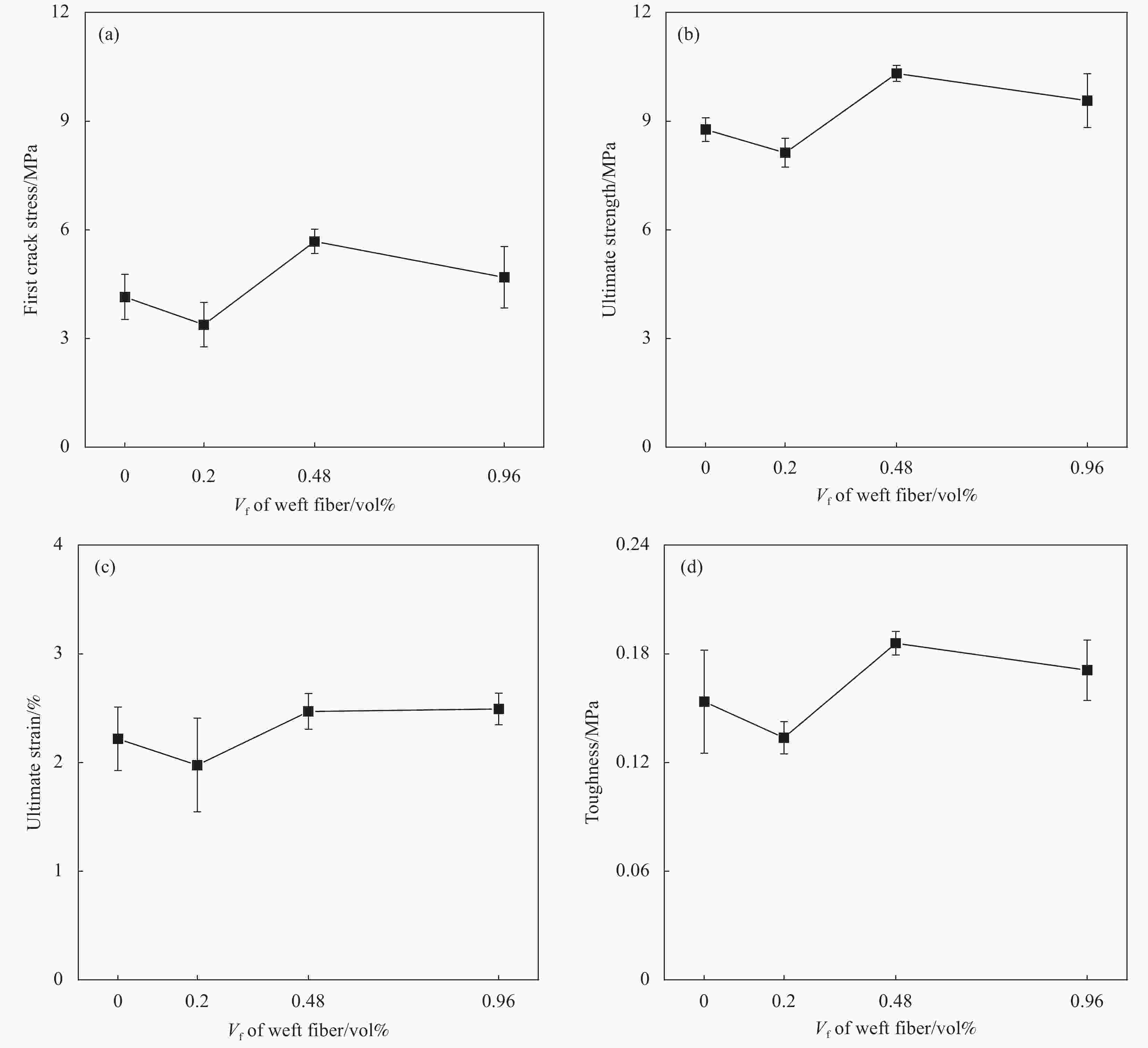

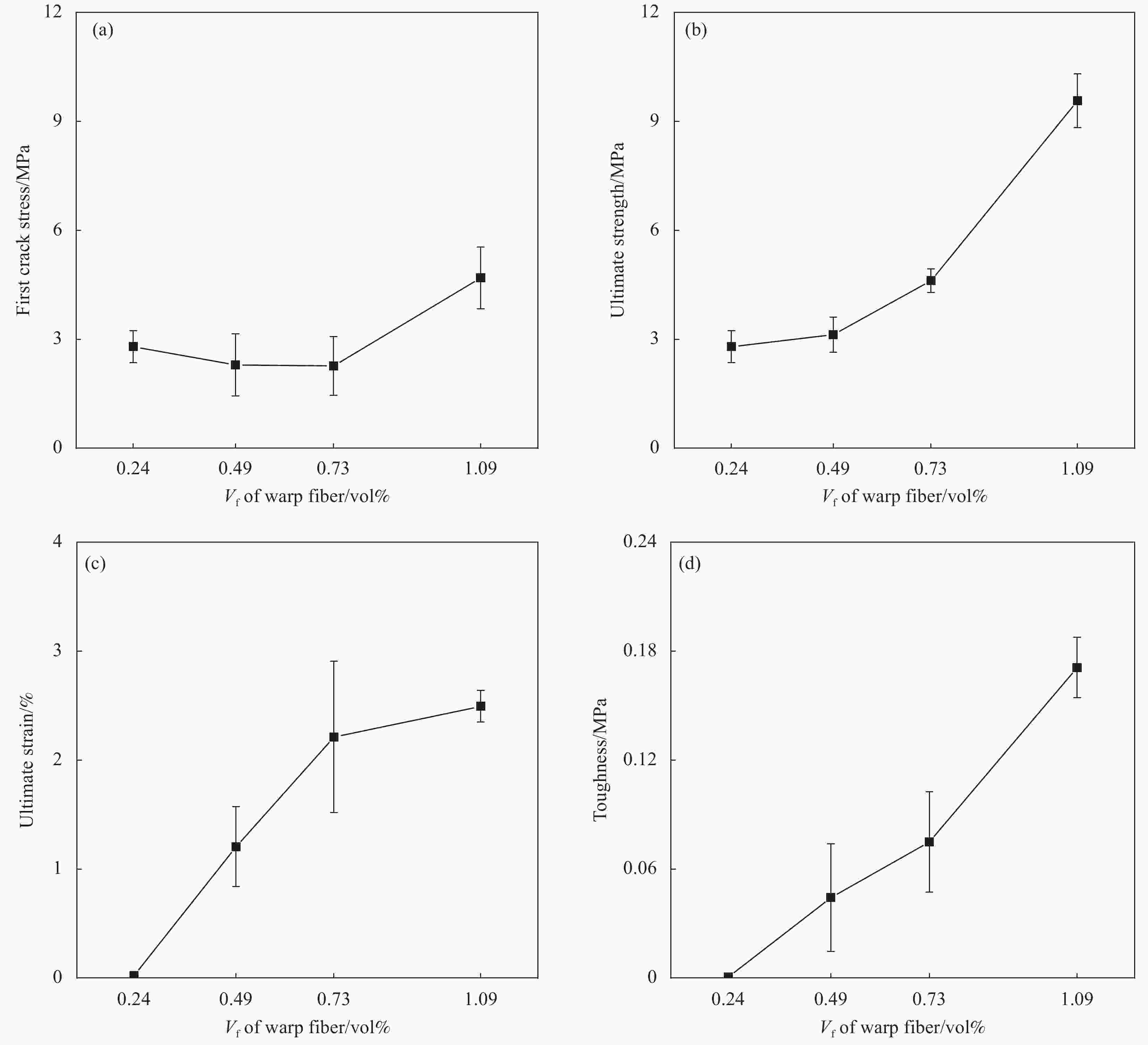

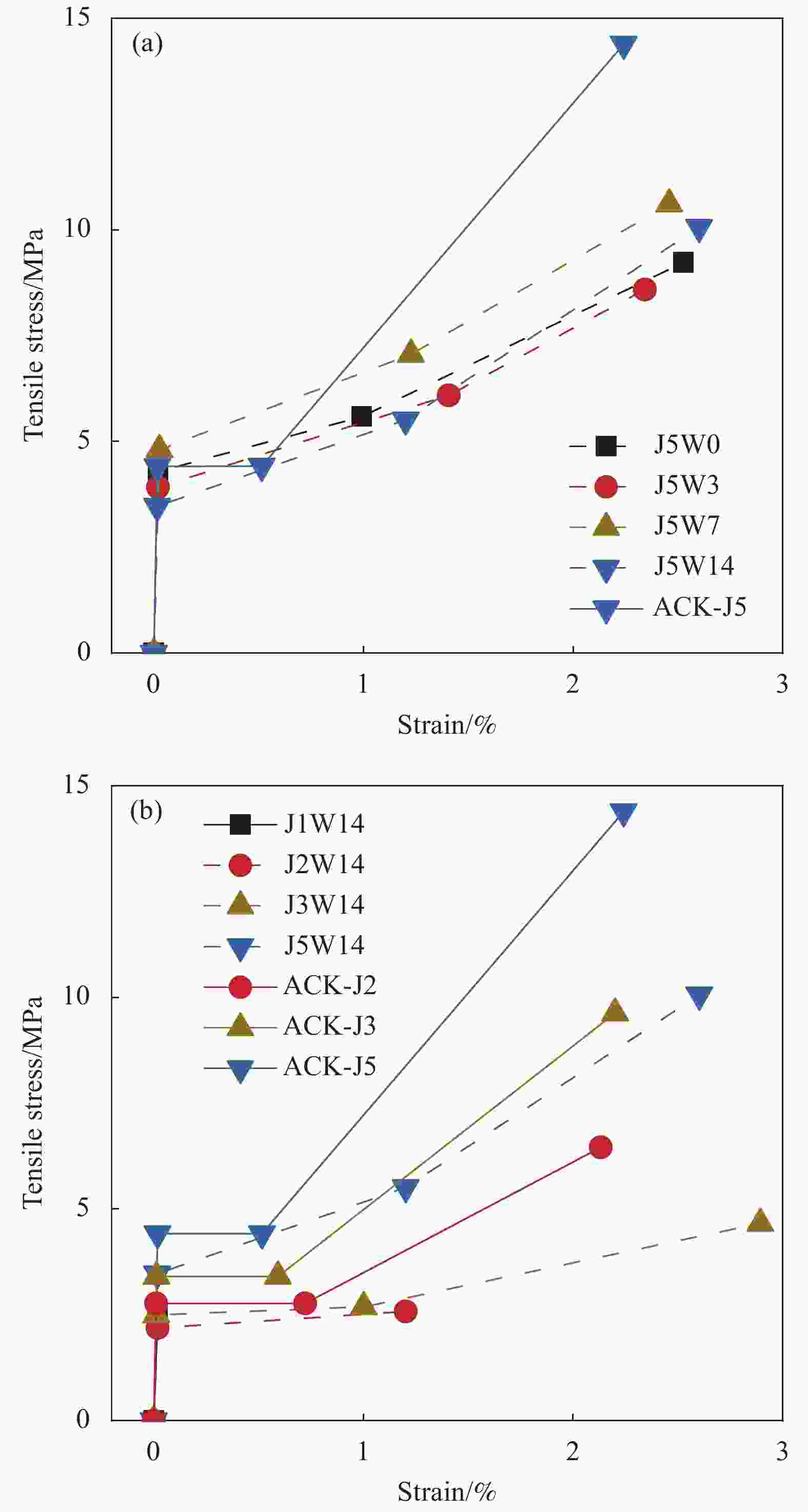

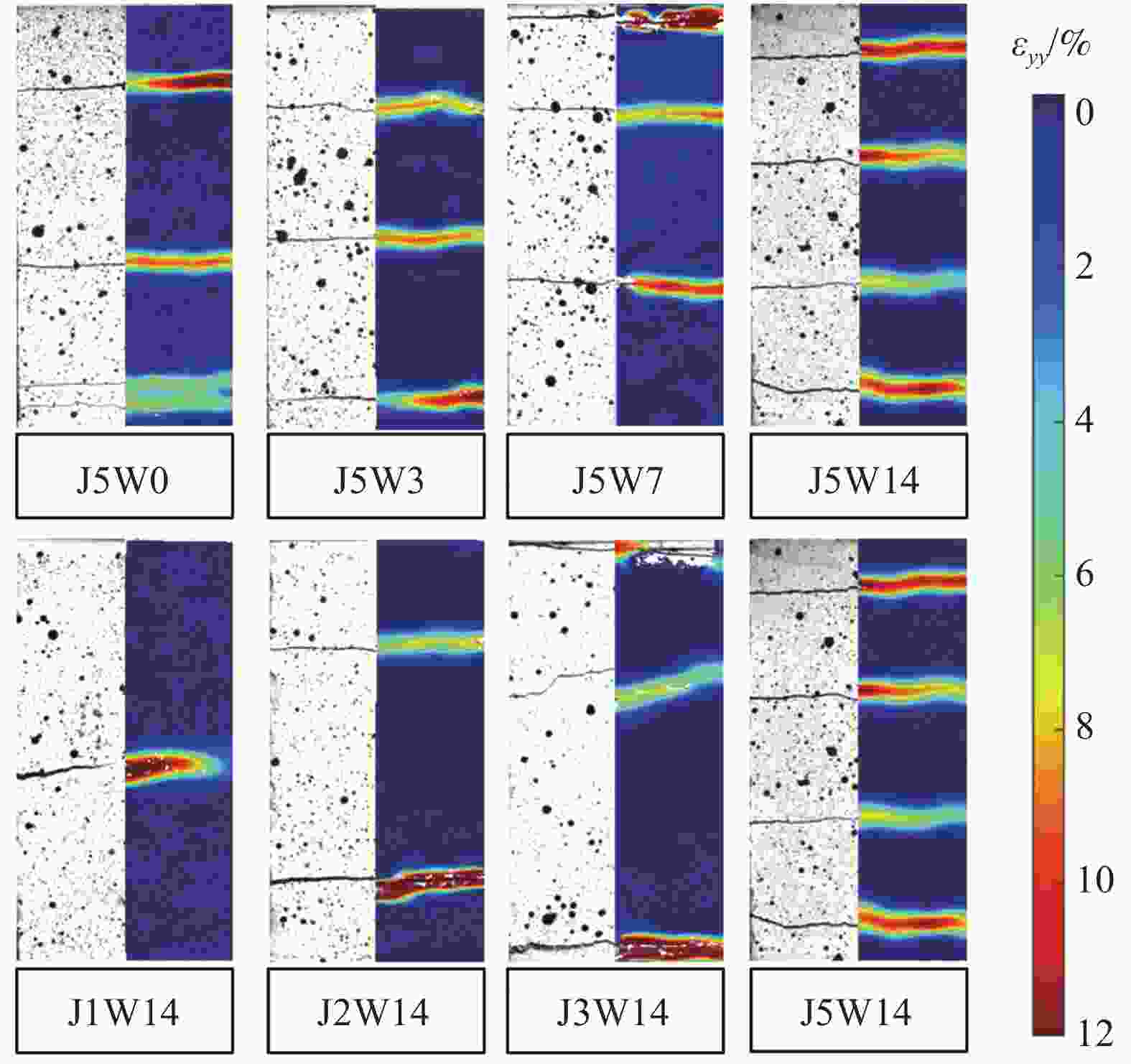

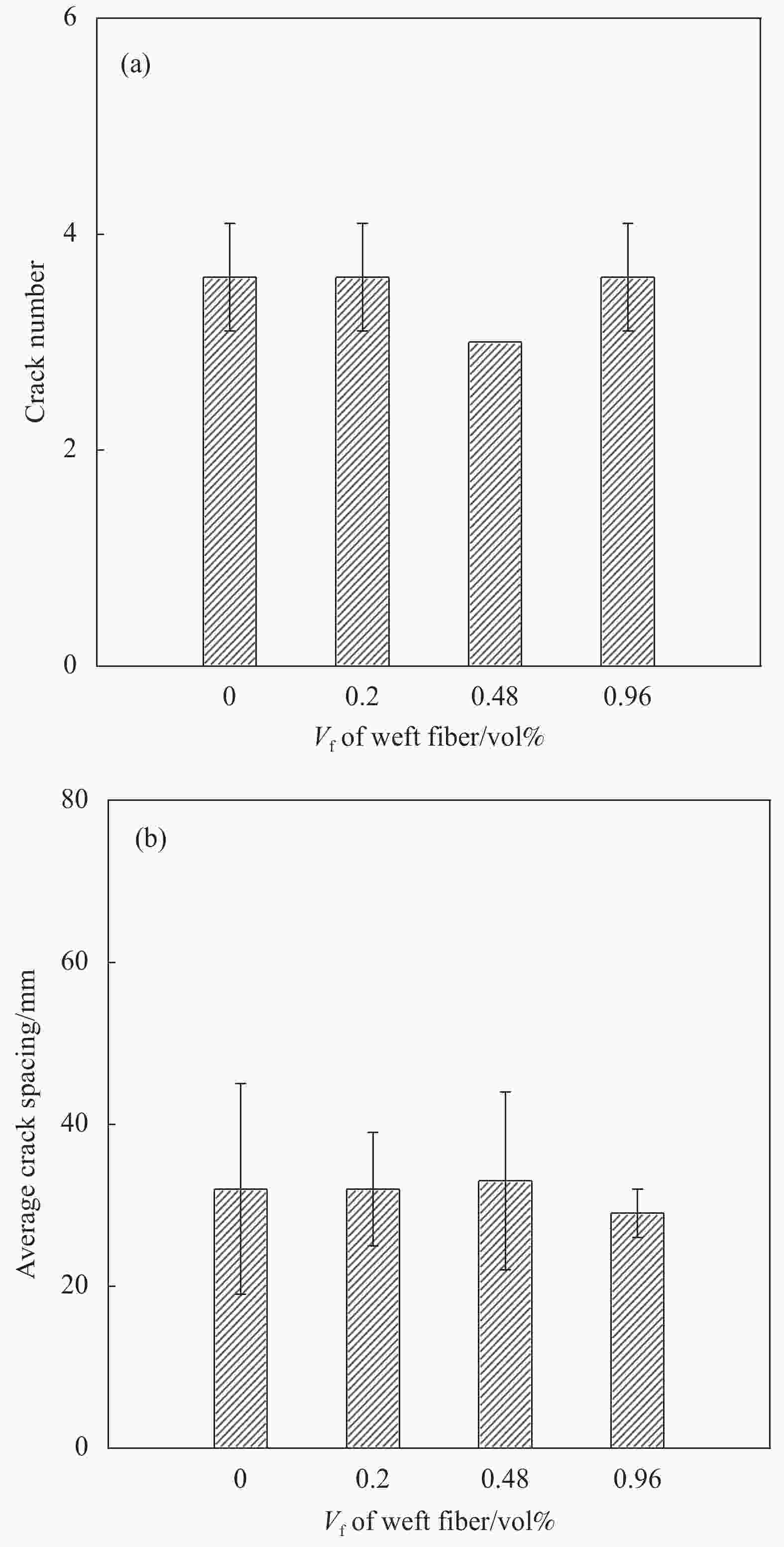

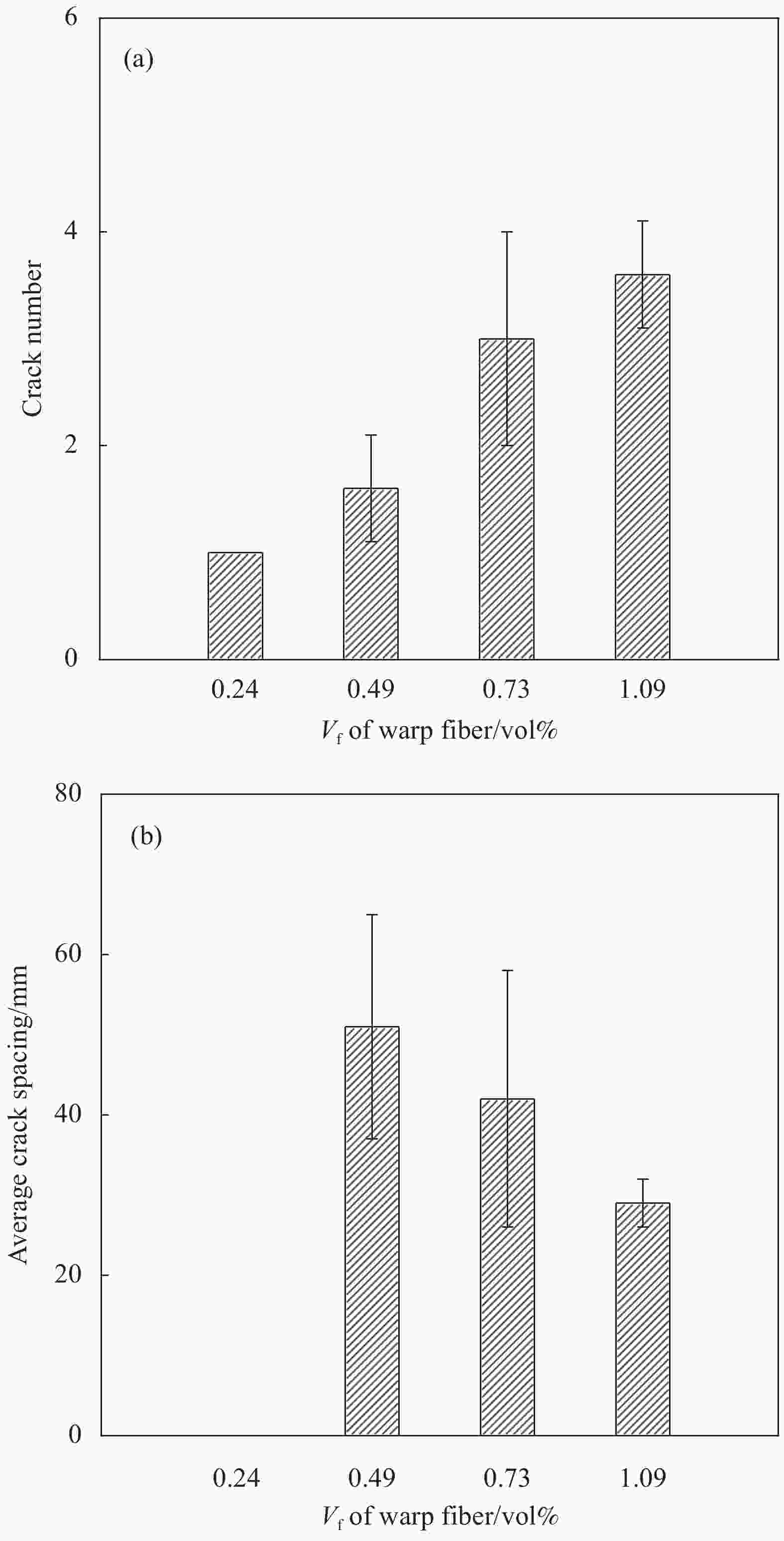

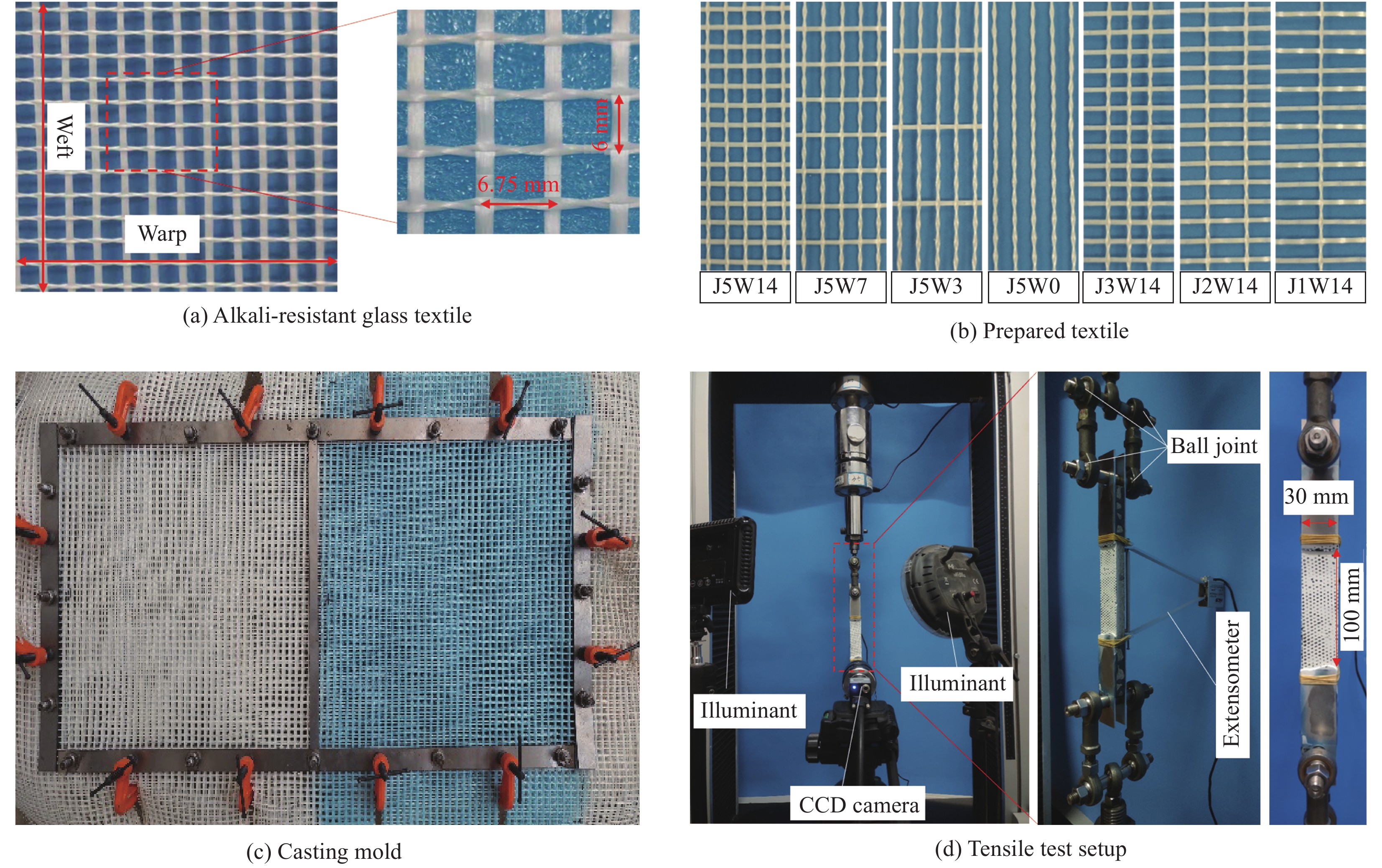

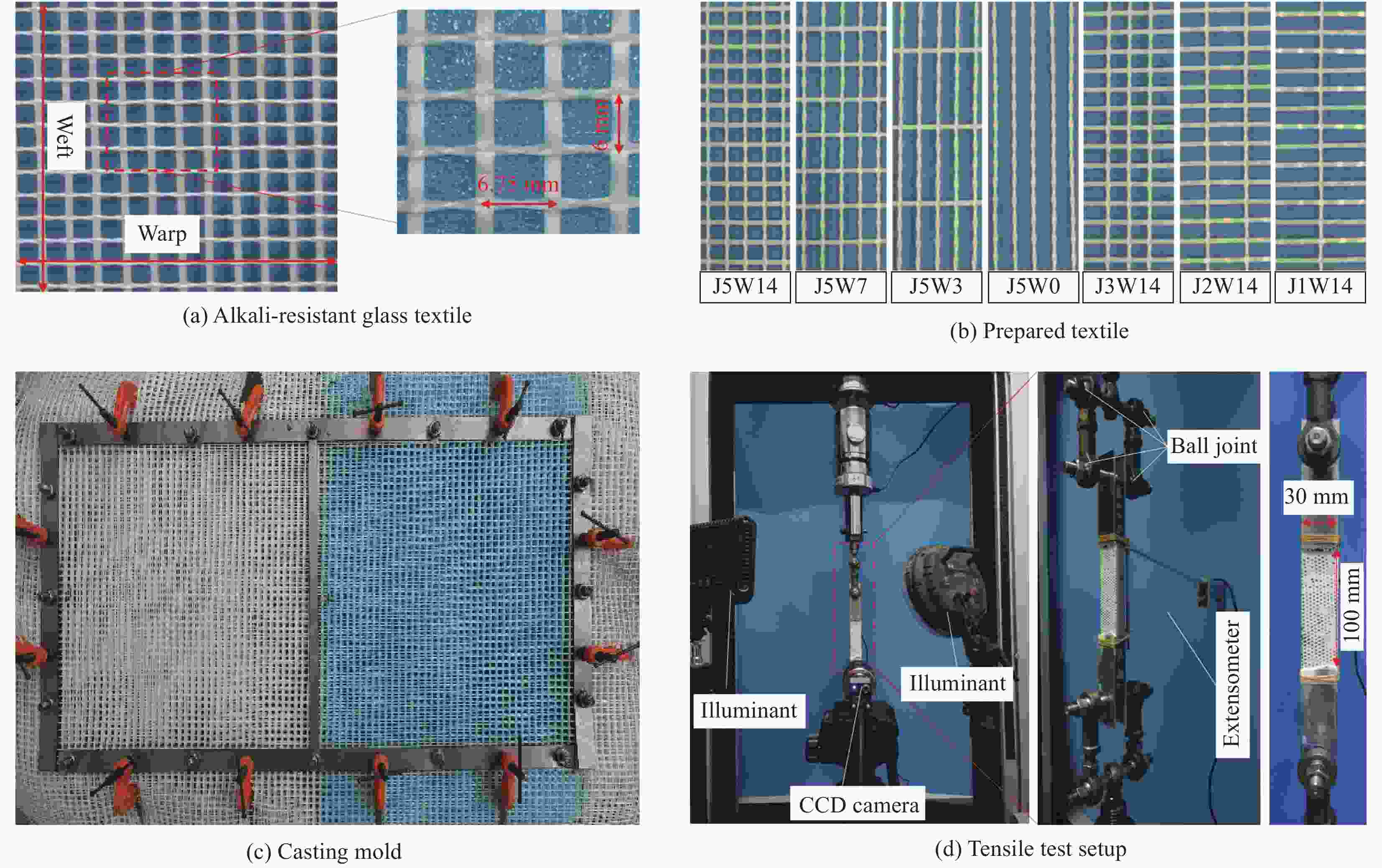

摘要: 为了研究经纬向纤维体积分数对耐碱玻璃纤维织物增强混凝土(ARG-TRC)拉伸力学性能的影响,通过万能试验机对不同经向纤维体积分数(0.24vol%、0.49vol%、0.73vol%和1.09vol%)和纬向纤维体积分数(0vol%、0.20vol%、0.48vol%和0.96vol%)的试件进行准静态拉伸试验,并结合数字图像相关分析得到拉伸状态下裂纹与应变分布。结果表明:ARG-TRC的拉伸力学性能和破坏形态主要取决于经向纤维体积分数,而纬向纤维体积分数对其影响不大;随着经向纤维体积分数的增加,极限强度、峰值应变和韧性明显增大,裂纹条数明显增加。对拉伸应力-应变曲线化进行三线性拟合,得到简化模型并与ACK模型进行对比。基于现有的裂纹间距计算模型和试验数据,修正了裂纹间距计算公式,其结果与文献数据吻合较好。该成果将有助于织物增强混凝土(TRC)中纤维织物的优化配置,提高纤维织物的利用率,对TRC的性能设计具有指导意义。Abstract: In order to study the influence of the warp and weft fiber volume fractions on the tensile mechanical properties of alkali-resistant glass textile reinforced concrete (ARG-TRC), quasi-static tensile tests were conducted on specimens with various volume fractions of warp yarn (0.24vol%, 0.49vol%, 0.73vol% and 1.09vol%) and weft yarn (0vol%, 0.20vol%, 0.48vol% and 0.96vol%) by a universal testing machine, and the crack strain distribution was obtained by digital image correlation (DIC) method. The results show that the tensile mechanical properties and failure modes of ARG-TRC mainly depend on the volume fractions of warp yarn, and the volume fractions of weft yarn do not show obvious effect. With the increase of the volume fractions of the warp yarn, the ultimate strength, peak strain and toughness increase significantly as well as the number of cracks. A trilinear model was obtained by fitting the experimental tensile stress-strain curves, and was compared with the ACK model. The crack-spacing calculation formula was modified based on the existing crack-spacing calculation model and experimental data, which show good consistency with the literature data. The findings will be helpful for the optimization of the configuration of textile in textile reinforced concrete (TRC), and for the improvement of the utilization efficiency of textiles, and be available for the performance design of TRC.

-

Key words:

- alkali resistant glass textile /

- fiber volume fractions /

- tensile test /

- DIC /

- constitutive model /

- crack spacing

-

表 1 基体配合比设计

Table 1. Mix design of the matrix

kg/m3 Cement Fly ash Silica fume Water Sand (0-0.6 mm) Sand (0.6-1.2 mm) Superplasticizer Defoamer Thickener 472 168 35 262 250 500 1.9 2.8 0.2 表 2 耐碱玻璃纤维网格布性能参数

Table 2. Performance parameters of alkali-resistant glass textile

Type Grammage/(g·mm−2) Coating Cross section area of single yarn/mm2 Ultimate strength of single yarn/MPa Warp Weft Warp Weft ARNP300 250 Butyl benzene latex 0.24 0.25 987.5 820 表 3 耐碱玻璃纤维织物增强混凝土(ARG-TRC)试件编号和对应的纤维体积分数

Table 3. Specimen ID and corresponding fiber volume fractions of alkali-resistant glass textile reinforced concrete (ARG-TRC)

Specimen ID Amount of warp yarn Amount of weft yarn ${V_{\rm{f}}}$ of warp yarn/vol% ${V_{\rm{f}}}$ of weft yarn/vol% J5W0 5 0 1.09 0.00 J5W3 5 3 1.09 0.20 J5W7 5 7 1.09 0.48 J1W14 1 14 0.24 0.96 J2W14 2 14 0.49 0.96 J3W14 3 14 0.73 0.96 J5W14 5 14 1.09 0.96 Notes:J1, J2, J3 and J5 represent that there are 1, 2, 3 and 5 warp yarns in each layer of textile;W0, W3, W7 and W14 represent that there are 0, 3, 7 and 14 weft yarns in each layer of textile;${V_{\rm{f}}}$—Volume fraction. 表 4 不同经纬向纤维体积分数的ARG-TRC的性能参数

Table 4. Properties parameters of ARG-TRC with various volume fractions of warp and weft fibers

Specimen

IDFirst crack

stress/MPaElastic

modulus/GPaUltimate

strength/MPaUltimate

strain/%Toughness/

MPaEfficiency

factorCrack

numberCrack

spacing/mmJ1W14 2.79(0.43) 17.01(6.58) 2.79(0.43) 0.02(0) 0(0) 1.17(0.24) 1(0) — J2W14 2.29(0.8) 15.42(10.15) 3.12(0.40) 1.20(0.36) 0.04(0.02) 0.67(0.12) 1.6(0.5) 51(14) J3W14 2.27(0.8) 18.03(0.70) 4.08(1.10) 2.21(0.69) 0.07(0.02) 0.65(0.06) 3(1) 42(16) J5W0 4.14(0.62) 12.16(2.69) 8.76(0.32) 2.21(0.29) 0.15(0.02) 0.83(0.03) 3.6(0.5) 32(13) J5W3 3.38(0.61) 21.71(6.73) 8.13(0.39) 1.97(0.43) 0.13(0) 0.76(0.05) 3.6(0.5) 32(7) J5W7 5.68(0.34) 24.10(12.55) 10.30(0.24) 2.46(0.16) 0.18(0) 0.93(0.04) 3(0) 33(11) J5W14 4.69(0.84) 20.25(9.34) 9.56(0.74) 2.49(0.14) 0.17(0.01) 0.97(0.05) 3.6(0.5) 29(3) Notes: The values in the parentheses are standard deviations. 表 5 ARG-TRC试验拟合模型和ACK模型关键参数

Table 5. Critical parameters of test fitting model and ACK model for ARG-TRC

Specimen ID ${V_{\rm{f}}}$/vol% ${E_{\rm I}}$/GPa ${E_{{\rm I}{\rm I}}}$/GPa ${E_{{\rm I}{\rm I}{\rm I}}}$/GPa εI/% σI/MPa εII/% σII/MPa εIII/% σIII/MPa J1W14 0.24 14.67 — — 0.018 2.59 — — — — J2W14 0.49 12.16 0.102 — 0.018 2.19 1.201 2.58 — — ACK-J2 0.49 25.13 0 0.262 0.011 2.77 0.722 2.77 2.132 6.46 J3W14 0.73 20.82 0.103 0.104 0.012 2.50 1.001 2.69 2.893 4.66 ACK-J3 0.73 25.20 0 0.387 0.013 3.41 0.592 3.41 2.200 9.63 J5W14 1.09 22.33 0.121 0.325 0.016 3.47 1.201 5.51 2.601 10.06 ACK-J5 1.09 25.30 0 0.578 0.017 4.41 0.515 4.41 2.241 14.39 J5W0 1.09 20.78 0.189 0.237 0.021 4.29 0.992 5.59 2.527 9.23 J5W3 1.09 20.03 0.175 0.267 0.020 3.92 1.407 6.09 2.342 8.59 J5W7 1.09 18.02 0.168 0.288 0.027 4.81 1.227 7.06 2.458 10.61 Notes: ${E_{\rm I}}$, ${E_{{\rm I}{\rm I}}}$ and ${E_{{\rm I}{\rm I}{\rm I}}}$—Modulus of ACK model in the first, second and third stage respectively; εI, εII and εIII—Strain of ACK model in the first, second and third stage respectively; σI, σII and σIII—Stress of ACK model in the first, second and third stage respectively. 表 6 ARG-TRC关键参数

Table 6. Critical parameters of AGR-TRC

Case Fabric type Mesh size/mm Layers $r$/mm ${V_{\rm{f}}}$/vol% Crack spacing/mm Reference 1 Warp-knitted 3 × 5 1 0.34* 1.45 24 [28] 3 2.18 15 2 2.90 13 2 Bonded 10 × 10 7 0.50* 4.50 10 [29] 3 Bonded 3.3 × 3.3 6 0.40 6.00 12 [30] Notes: r —Equivalent radius of the yarn; The asterisk in the radius column indicates that the data was calculated based on fiber fractions, mesh size and specimen size. -

[1] MECHTCHERINE, VIKTOR. Novel cement-based composites for the strengthening and repair of concrete structures[J]. Construction and Building Materials,2013,41:365-373. doi: 10.1016/j.conbuildmat.2012.11.117 [2] TRUONG B T, BUI T T, LIMAM A, et al. Experimental investigations of reinforced concrete beams repaired/reinforced by TRC composites[J]. Composite Structures,2017,168:826-839. doi: 10.1016/j.compstruct.2017.02.080 [3] ORTLEPP R, ORTLEPP S. Textile reinforced concrete for strengthening of RC columns: A contribution to resource conservation through the preservation of structures[J]. Construction and Building Materials,2017,132:150-160. doi: 10.1016/j.conbuildmat.2016.11.133 [4] XU G, HANNANT D J. Flexural behaviour of combined polypropylene network and glass fibre reinforced cement[J]. Cement and Concrete Composites,1992,14(1):51-61. doi: 10.1016/0958-9465(92)90039-X [5] 艾珊霞, 尹世平, 徐世烺. 纤维编织网增强混凝土的研究进展及应用[J]. 土木工程学报, 2015, 48(1):27-40.AI S X, YIN S P, XU S L. A review on the development of research and application of textile reinforced concrete[J]. China Civil Engineering Journal,2015,48(1):27-40(in Chinese). [6] DU Y, ZHANG M, ZHOU F, et al. Experimental study on basalt textile reinforced concrete under uniaxial tensile loading[J]. Construction and Building Materials,2017,138:88-100. doi: 10.1016/j.conbuildmat.2017.01.083 [7] BRAMESHUBER W. Report 36: Textile reinforced concrete-state-of-the-art report of RILEM TC 201-TRC[M]. Bagneux: RILEM Publications, 2006, 134-135. [8] SILVA F d A, BUTLER M, MECHTCHERINE V, et al. Strain rate effect on the tensile behaviour of textile-reinforced concrete under static and dynamic loading[J]. Materials Science and Engineering A,2011,528(3):1727-1734. doi: 10.1016/j.msea.2010.11.014 [9] SORANAKOM C, MOBASHER B. Modeling of tension stiffening in reinforced cement composites: Part I. Theoretical modeling[J]. Materials and Structures,2010,43(9):1217-1230. doi: 10.1617/s11527-010-9594-8 [10] PELED A, COHEN Z, PASDER Y, et al. Influences of textile characteristics on the tensile properties of warp knitted cement based composites[J]. Cement and Concrete Composites,2008,30(3):174-183. doi: 10.1016/j.cemconcomp.2007.09.001 [11] GOPINATH S, GETTU R, IYER N R. Influence of prestressing the textile on the tensile behaviour of textile reinforced concrete[J]. Materials and Structures,2018,51:64. [12] 尹世平, 徐世烺. 纤维编织网增强混凝土的拉伸力学模型[J]. 复合材料学报, 2012, 29(5):222-229.YIN S P, XU S L. Tensile mechanical model of textile reinforced concrete[J]. Acta Materiae Compositae Sinica,2012,29(5):222-229(in Chinese). [13] HEGGER J, WILL N, BRUCKERMANN O, et al. Load-bearing behaviour and simulation of textile reinforced concrete[J]. Materials and Structures,2006,39(8):765-776. doi: 10.1617/s11527-005-9039-y [14] YAO Y, SILVA F A, BUTLER M, et al. Tension stiffening in textile-reinforced concrete under high speed tensile loads[J]. Cement and Concrete Composites,2015,64:49-61. doi: 10.1016/j.cemconcomp.2015.07.009 [15] ZHU D, LIU S, YAO Y, et al. Effects of short fiber and pre-tension on the tensile behavior of basalt textile reinforced concrete[J]. Cement and Concrete Composites,2019,96:33-45. doi: 10.1016/j.cemconcomp.2018.11.015 [16] YAO Y, BONAKDAR A, FABER J, et al. Distributed cracking mechanisms in textile-reinforced concrete under high speed tensile tests[J]. Materials and Structures,2016,49(7):2781-2798. doi: 10.1617/s11527-015-0685-4 [17] LIOR N, EREZ G, ALVA P. Tensile behavior of fabric-cement-based composites reinforced with non-continuous load bearing yarns[J]. Construction and Building Materials,2020,236:117432. doi: 10.1016/j.conbuildmat.2019.117432 [18] COLOMBO I G, MAGRI A, ZANI G, et al. Textile reinforced concrete: Experimental investigation on design parameters[J]. Materials and Structures,2013,46(11):1933-1951. doi: 10.1617/s11527-013-0017-5 [19] PELED A, BENTUR A, YANKELEVSKY D. Effects of woven fabric geometry on the bonding performance of cementitious composites[J]. Advanced Cement Based Materials,1998,7(1):20-27. doi: 10.1016/S1065-7355(97)00012-6 [20] 徐世烺, 阎轶群. 低配网率纤维编织网增强混凝土轴拉力学性能[J]. 复合材料学报, 2011, 28(5):206-213.XU S L, YAN Y Q. Mechanical properties of textile reinforced concrete plate at low textile ratios[J]. Acta Materiae Compositae Sinica,2011,28(5):206-213(in Chinese). [21] 朱德举, 李高升. 短切纤维及预应力对玄武岩织物增强水泥基复合材料拉伸力学性能的影响[J]. 复合材料学报, 2017, 34(11):2631-2641.ZHU D J, LI G S. Effect of short fibers and prestress on the tensile mechanical properties of bas-alt textile reinforced cementitious matrix composite[J]. Acta Materiae Compositae Sinica,2017,34(11):2631-2641(in Chinese). [22] 沈荣熹, 崔琪, 李清海. 新型纤维增强水泥基复合材料[M]. 北京: 中国建材工业出版社, 2004, 66-71.SHEN R X, CUI Q, LI Q H. New type fiber reinforced cement based composites[M]. Beijing: China Building Materials Press, 2004, 66-71(in Chinese). [23] CAGGEGI C, LANOYE E, DJAMA K, et al. Tensile behaviour of a basalt TRM strengthening system: Influence of mortar and reinforcing textile ratios[J]. Composites Part B: Engineering,2017,130:90-102. doi: 10.1016/j.compositesb.2017.07.027 [24] OHNO S, HANNANT D J. Modeling the stress-strain response of continuous fiber reinforced cement composites[J]. ACI Materials Journal,1994,91(3):306-312. [25] BLABER J, ADAIR B, ANTONIOU A. Ncorr: Open-source 2D digital image correlation matlab software[J]. Experimental Mechanics,2015,55(6):1105-1122. doi: 10.1007/s11340-015-0009-1 [26] FILIPPOU C A, CHRYSOSTOMOU C Z. Analytical model for textile reinforced mortar under monotonic loading[J]. Construction and Building Materials,2020,258:120178. doi: 10.1016/j.conbuildmat.2020.120178 [27] European Committee for Standardization. Design of concrete structures: General rules and rules for buildings: EN1992-1-1.2004[S]. Brussels: CEN, 2004. [28] CONTAMINE R, LARBI A S, HAMELIN P. Contribution to direct tensile testing of textile reinforced concrete (TRC) composites[J]. Materials Science and Engineering A,2011,528(29-30):8589-8598. doi: 10.1016/j.msea.2011.08.009 [29] MOBASHER B, PELED A, PAHILAJANI J. Distributed cracking and stiffness degradation in fabric-cement composites[J]. Materials and Structures,2006,39(3):317-331. [30] PELED A, MOBASHER B. Tensile behavior of fabric cement-based composites: Pultruded and cast[J]. Journal of Materials in Civil Engineering,2007,19(4):340-348. doi: 10.1061/(ASCE)0899-1561(2007)19:4(340) -

下载:

下载: