| [1] |

KUMAR V, TYAGI L, SINHA S. Wood flour-reinforced plastic composites: A review[J]. Reviews in Chemical Engineering,2011,27:253-264.

|

| [2] |

MITCHELL M R, LINK R E, HAMEL S E, et al. Tension and compression creep apparatus for wood-plastic compo-sites[J]. Journal of Testing and Evaluation,2011,39(6):103715. doi: 10.1520/JTE103715

|

| [3] |

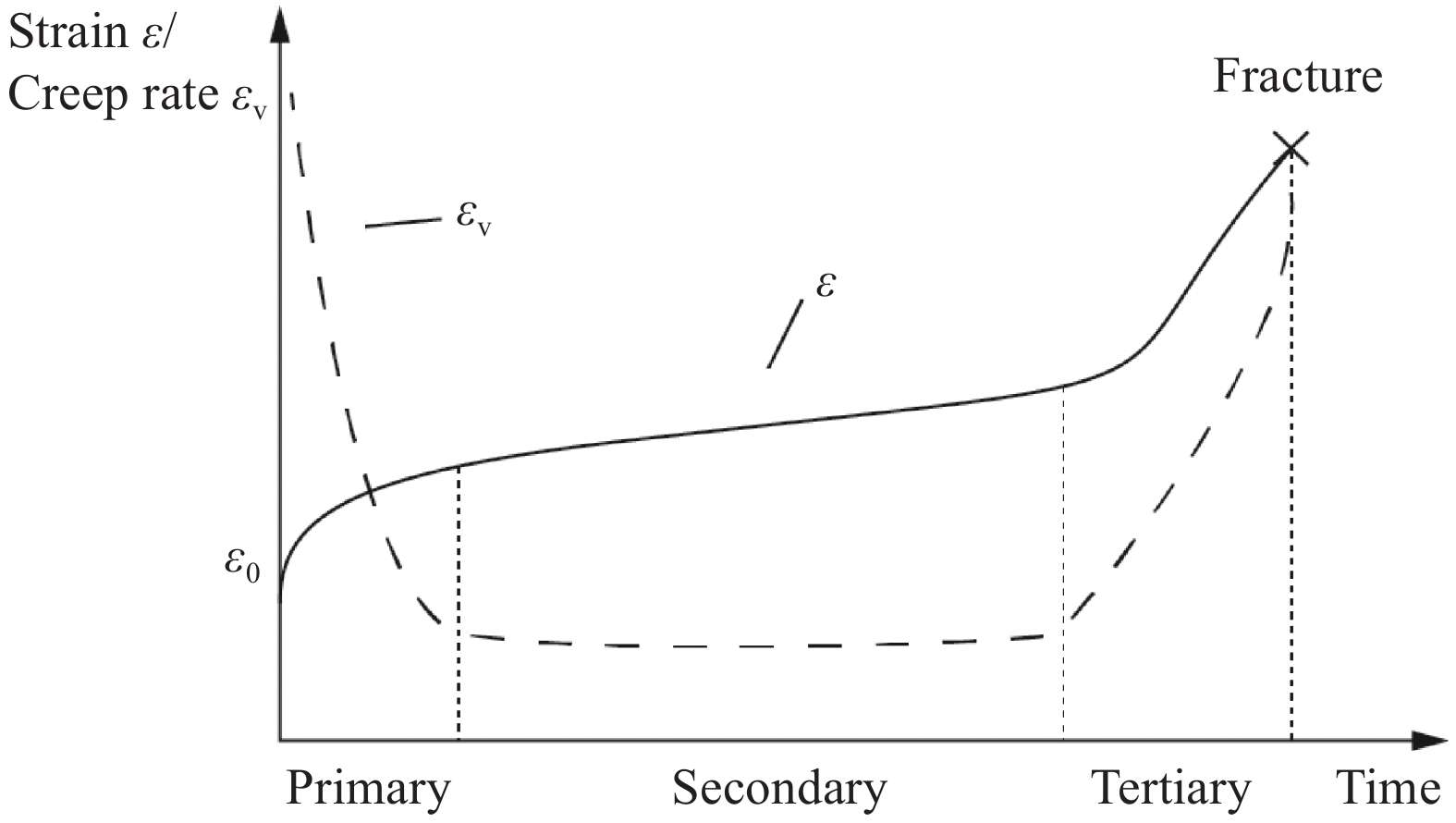

尹权福, 邸明伟. 木塑复合材料蠕变性能的研究进展[J]. 塑料工业, 2011, 39(7):10-14.YIN Quanfu, DI Mingwei. Research progress for creep properties of wood-plastic composites[J]. China Plastics Industry,2011,39(7):10-14(in Chinese).

|

| [4] |

薛菁. Hdpe/木粉复合材料抗蠕变性能研究[D]. 北京: 北京化工大学, 2010.XUE Jing. Research of the bending resistance HDPE/wood-polymer composites[D]. Beijing: Beijing University of Chemical Technology, 2010(in Chinese).

|

| [5] |

CHANG F C, LAM F, KADLA J F. The effect of temperature on creep behavior of wood-plastic composites[J]. Journal of Reinforced Plastics and Composites,2014,33(9):883-892. doi: 10.1177/0731684414523691

|

| [6] |

HOMKHIEW C, RATANAWILAI T, THONGRUANG W. Time-temperature and stress dependent behaviors of composites made from recycled polypropylene and rubberwood flour[J]. Construction and Building Materials,2014,66:98-104. doi: 10.1016/j.conbuildmat.2014.05.048

|

| [7] |

曹岩, 徐海龙, 王伟宏, 等. 模压成型的杨木纤维/高密度聚乙烯复合材料蠕变性能和蠕变模型[J]. 复合材料学报, 2016, 33(6):1174-1178.CAO Yan, XU Hailong, WANG Weihong, et al. Creep properties and creep model of poplar wood fiber/high density polyethylene composites prepared by compression molding[J]. Acta Materiae Composite Sinica,2016,33(6):1174-1178(in Chinese).

|

| [8] |

梅生启, 唐广, 杨斌, 等. 基于分数阶黏弹性模型的木塑复合材料蠕变/回复性能分析[J]. 复合材料学报, 2020, 37(8):2055-2064.MEI Shengqi, TANG Guang, YANG Bin, et al. Creep/recovery behavior analysis of wood-plastic composites based on fractional order viscoelastic model[J]. Acta Materiae Compositae Sinica,2020,37(8):2055-2064(in Chinese).

|

| [9] |

YEO S S, HSUAN Y G. Evaluation of creep behavior of high density polyethylene and polyethylene-terephthalate geogrids[J]. Geotextiles and Geomembranes,2010,28(5):409-421. doi: 10.1016/j.geotexmem.2009.12.003

|

| [10] |

石恒冲, 李斌. 木塑复合材料界面相容剂的研究进展[J]. 化学与粘合, 2007, 29(1):44-48.SHI Hengchong, LI Bin. Progress in research of interfacial compatibilizers for wood plastics composites[J]. Chemistry and Adhesion,2007,29(1):44-48(in Chinese).

|

| [11] |

XU Y, LEE S Y, WU Q. Creep analysis of bamboo high-density polyethylene composites: Effect of interfacial treatment and fiber loading level[J]. Polymer Composites,2011,32(5):692-699. doi: 10.1002/pc.21088

|

| [12] |

杜虎虎, 王伟宏, 王海刚, 等. 木纤维含量对木塑复合材料蠕变特性的影响[J]. 建筑材料学报, 2015, 18(2):333-339.DU Huhu, WANG Weihong, WANG Haigang, et al. Influence of wood fiber content on the creep behavior of wood fiber-plastic composite[J]. Journal of Building Materials,2015,18(2):333-339(in Chinese).

|

| [13] |

WANG W H, HUANG H B, DU H H, et al. Effects of fiber size on short-term creep behavior of wood fiber/HDPE composites[J]. Polymer Engineering & Science,2015,55(3):693-700.

|

| [14] |

LI Y. Effect of coupling agent concentration, fiber content, and size on mechanical properties of wood/hdpe compo-sites[J]. International Journal of Polymeric Materials,2012,61(11):882-890. doi: 10.1080/00914037.2011.617338

|

| [15] |

曹岩, 王伟宏, 王海刚, 等. 制备方法对木塑复合材料弯曲性能的影响[J]. 复合材料学报, 2013, 30(S1):311-314.CAO Yan, WANG Weihong, WANG Haigang, et al. Effect of preparation method on the flexural properties of WPC[J]. Acta Materiae Composite Sinica,2013,30(S1):311-314(in Chinese).

|

| [16] |

徐海龙, 曹岩, 王伟宏, 等. 杨木纤维尺寸对热压成型杨木纤维/高密度聚乙烯复合材料力学和蠕变性能的影响[J]. 复合材料学报, 2016, 33(6):1168-1173.XU Hailong, CAO Yan, WANG Weihong, et al. Effects of poplar wood fiber size on mechanical and creep properties of poplar wood fiber/high-density polyethylene composites prepared by hot-compression molding[J]. Acta Materiae Composite Sinica,2016,33(6):1168-1173(in Chinese).

|

| [17] |

GEORGIOPOULOS P, KONTOU E, CHRISTOPOULOS A. Short-term creep behavior of a biodegradable polymer reinforced with wood-fibers[J]. Composites Part B: Engineering,2015,80:134-144. doi: 10.1016/j.compositesb.2015.05.046

|

| [18] |

陈冬梅, 姜良朋, 刘丁宁, 等. 四种壳类纤维/聚氯乙烯木塑复合材料的蠕变及磨损性能[J]. 复合材料学报, 2018, 35(6):1464-1471.CHEN Dongmei, JIANG Liangpeng, LIU Dingning, et al. Creep and wear properties of four different types of husk fibers/polyvinyl choride composites[J]. Acta Materiae Composite Sinica,2018,35(6):1464-1471(in Chinese).

|

| [19] |

TAN W, HAO X L, FAN Q, et al. Bamboo particle reinforced polypropylene composites made from different fractions of bamboo culm: Fiber characterization and analysis of composite properties[J]. Polymer Composites,2019,40(12):4619-4628. doi: 10.1002/pc.25329

|

| [20] |

MU B S, WANG H G, HAO X L, et al. Morphology, mechanical properties and dimensional stability of biomass particles/high density polyethylene composites: Effect of species and composition[J]. Polymers,2018,10(3):308. doi: 10.3390/polym10030308

|

| [21] |

WANG H B, LIN F Z, QIU P P, et al. Effects of extractives on dimensional stability, dynamic mechanical properties, creep, and stress relaxation of rice straw/high-density polyethylene composites[J]. Polymers,2018,10(10):1176. doi: 10.3390/polym10101176

|

| [22] |

OU R X, XIE Y J, WOLCOTT M P, et al. Effect of wood cell wall composition on the rheological properties of wood particle/high density polyethylene composites[J]. Composites Science and Technology,2014,93:68-75. doi: 10.1016/j.compscitech.2014.01.001

|

| [23] |

OU R X, XIE Y J, WOLCOTT M P, et al. Morphology, mechanical properties, and dimensional stability of wood particle/high density polyethylene composites: Effect of removal of wood cell wall composition[J]. Materials & Design,2014,58:339-345.

|

| [24] |

CHAN C M, VANDI L, PRATT S, et al. Composites of wood and biodegradable thermoplastics: A review[J]. Polymer reviews,2017,58(3):444-494.

|

| [25] |

SAIN M M, BALATINECZ J, LAW S. Creep fatigue in engineered wood fiber and plastic compositions[J]. Journal of Applied Polymer Science,2000,77(2):260-268. doi: 10.1002/(SICI)1097-4628(20000711)77:2<260::AID-APP3>3.0.CO;2-H

|

| [26] |

TAJVIDI M, SIMON L C. High-temperature creep behavior of wheat straw isotactic/impact-modified polypropylene composites[J]. Journal of Thermoplastic Composite Materials,2013,28(10):1406-1422.

|

| [27] |

NAJAFI K S. Use of recycled plastics in wood plastic composites-A review[J]. Waste Management,2013,33(9):1898-1905. doi: 10.1016/j.wasman.2013.05.017

|

| [28] |

XU Y J, WU Q L, LEI Y, et al. Creep behavior of bagasse fiber reinforced polymer composites[J]. Bioresource Technology,2010,101(9):3280-3286. doi: 10.1016/j.biortech.2009.12.072

|

| [29] |

NAJAFI A, NAJAFI S K. effect of load levels and plastic type on creep behavior of wood sawdust/HDPE compo-sites[J]. Journal of Reinforced Plastics and Composites,2008,28(21):2645-2653.

|

| [30] |

ZHOU Y H, FAN M Z, LIN L Y. Investigation of bulk and in situ mechanical properties of coupling agents treated wood plastic composites[J]. Polymer Testing,2017,58:292-299. doi: 10.1016/j.polymertesting.2016.12.026

|

| [31] |

LEE S Y, YANG H S, KIM H J, et al. Creep behavior and manufacturing parameters of wood flour filled polypropylene composites[J]. Composite Structures,2004,65(3-4):459-469. doi: 10.1016/j.compstruct.2003.12.007

|

| [32] |

JIA M Y, XUE P, ZHAO Y S, et al. Creep behaviour of wood flour/poly (vinyl chloride) composites[J]. Journal of Wuhan University of Technology (Materials Science Edition),2009,24(3):440-447. doi: 10.1007/s11595-009-3440-2

|

| [33] |

王晓钦. 聚丙烯基木塑复合材料流变及力学性能的研究[D]. 哈尔滨: 东北林业大学, 2013.WANG Xiaoqin. Study on rheological and mechanical properties of wood-plastic composites based on polypropylene[D]. Harbin: Northeast Forestry University, 2013(in Chinese).

|

| [34] |

ADHIKARY K B, PARK C B, ISLAM M R, et al. Effects of lubricant content on extrusion processing and mechanical properties of wood flour-high-density polyethylene composites[J]. Journal of Thermoplastic Composite Materials,2010,24(2):155-171.

|

| [35] |

LI H, LAW S, SAIN M. Process rheology and mechanical property correlationship of wood flour-polypropylene composites[J]. Journal of Reinforced Plastics and Composites,2004,23(11):1153-1158. doi: 10.1177/0731684404035416

|

| [36] |

王霞. 润滑剂对pp基木塑复合材料流变性能的影响[D]. 哈尔滨: 东北林业大学, 2016.WANG Xia. Effects of lubricant on rheological properties of wood fiber/polypropylene composites[D]. Harbin: Northeast Forestry University, 2016(in Chinese).

|

| [37] |

DAI L, WANG X, ZHANG J M, et al. Effects of lubricants on the rheological and mechanical properties of wood flour/polypropylene composites[J]. Journal of Applied Polymer Science,2019,136(25):47667. doi: 10.1002/app.47667

|

| [38] |

PULNGERN T, CHUCHEEPSAKUL S, PADYENCHEAN C, et al. Effects of cross-section design and loading direction on the creep and fatigue properties of wood/PVC compo-site beams[J]. Journal of Vinyl and Additive Technology,2010,16(1):42-49. doi: 10.1002/vnl.20227

|

| [39] |

BIRMAN V, KARDOMATEAS G A. Review of current trends in research and applications of sandwich structures[J]. Composites Part B: Engineering,2018,142:221-240. doi: 10.1016/j.compositesb.2018.01.027

|

| [40] |

DU Y C, YAN N, KORTSCHOT M T. An experimental study of creep behavior of lightweight natural fiber-reinforced polymer composite/honeycomb core sandwich panels[J]. Composite Structures,2013,106:160-166. doi: 10.1016/j.compstruct.2013.06.007

|

| [41] |

HSU C Y, YANG T C, WU T L, et al. Effects of a layered structure on the physicomechanical properties and extended creep behavior of bamboo-polypropylene compo-sites (BPCS) determined by the stepped isostress method[J]. Holzforschung,2018,72(7):589-597. doi: 10.1515/hf-2017-0165

|

| [42] |

MOHAMMADABADI M, YADAMA V, GENG J. Creep behavior of 3D core wood-strand sandwich panels[J]. Holzforschung,2018,72(6):513-519. doi: 10.1515/hf-2017-0088

|

| [43] |

NITTA K H, MAEDA H. Creep behavior of high density polyethylene under a constant true stress[J]. Polymer Testing,2010,29(1):60-65. doi: 10.1016/j.polymertesting.2009.09.005

|

| [44] |

MOSIEWICKI M A, MARCOVICH N E, ARANGUREN M I. Creep behavior of wood flour composites made from linseed oil-based polyester thermosets[J]. Journal of Applied Polymer Science,2011,121(5):2626-2633. doi: 10.1002/app.33989

|

| [45] |

HAO X L, ZHOU H Y, MU B S, et al. Effects of fiber geometry and orientation distribution on the anisotropy of mechanical properties, creep behavior, and thermal expansion of natural fiber/HDPE composites[J]. Compo-sites Part B: Engineering,2020,185:107778. doi: 10.1016/j.compositesb.2020.107778

|

| [46] |

CHEVALI V S, JANOWSKI G M. Flexural creep of long fiber-reinforced thermoplastic composites: Effect of processing-dependent fiber variables on creep response[J]. Composites Part A: Applied Science and Manufacturing,2010,41(9):1253-1262. doi: 10.1016/j.compositesa.2010.05.008

|

| [47] |

OEVER M V D, MOLENVELD K. Creep deflection of wood polymer composite profiles at demanding conditions[J]. Case Studies in Construction Materials,2019,10:e224.

|

| [48] |

CHANG F C, LAM F, KADLA J F. Using master curves based on time-temperature superposition principle to predict creep strains of wood-plastic composites[J]. Wood Science and Technology,2013,47(3):571-584. doi: 10.1007/s00226-012-0518-3

|

| [49] |

PULNGERN T, CHITSAMRAN T, CHUCHEEPSAKUL S, et al. Effect of temperature on mechanical properties and creep responses for wood/PVC composites[J]. Construction and Building Materials,2016,111:191-198. doi: 10.1016/j.conbuildmat.2016.02.051

|

| [50] |

FINI S H, ERCHIQUI F, FARZANEH M. Investigating the elastic deformation of wood-plastic composites at cold temperature using the bubble inflation technique[J]. Journal of Thermoplastic Composite Materials,2013,28(3):431-441.

|

| [51] |

NAVI P, PITTET V, PLUMMER C J G. Transient moisture effects on wood creep[J]. Wood Science and Technology,2002,36(6):447-462. doi: 10.1007/s00226-002-0157-1

|

| [52] |

HSIEH T Y, CHANG F C. Effects of moisture content and temperature on wood creep[J]. Holzforschung,2018,72(12):1071-1078. doi: 10.1515/hf-2018-0056

|

| [53] |

NAJAFI S K, SHARIFNIA H, TAJVIDI M. Effects of water absorption on creep behavior of wood-plastic compo-sites[J]. Journal of Composite Materials,2008,42(10):993-1002. doi: 10.1177/0021998307088608

|

| [54] |

KAZEMI N S, YOUNESI K H. Effect of sea water on water absorption and flexural properties of wood-polypropylene composites[J]. European Journal of Wood and Wood Products,2011,69(4):553-556. doi: 10.1007/s00107-010-0518-7

|

| [55] |

LIN W S, PRAMANICK A K, SAIN M. Determination of material constants for nonlinear viscoelastic predictive model[J]. Journal of Composite Materials,2016,38(1):19-29.

|

| [56] |

KAMDEM D P, PIZZI A, JERMANNAUD A. Durability of heat-treated wood[J]. European Journal of Wood and Wood Products,2002,60(1):1-6. doi: 10.1007/s00107-001-0261-1

|

| [57] |

KABOORANI A, FAEZIPOUR M, EBRAHIMI G. Feasibility of using heat treated wood in wood/thermoplastic composites[J]. Journal of Reinforced Plastics and Composites,2008,27(16-17):1689-1699. doi: 10.1177/0731684407084207

|

| [58] |

AYRILMIS N, JARUSOMBUTI S, FUEANGVIVAT V, et al. Effect of thermal-treatment of wood fibres on properties of flat-pressed wood plastic composites[J]. Polymer Degradation and Stability,2011,96(5):818-822. doi: 10.1016/j.polymdegradstab.2011.02.005

|

| [59] |

YANG T C, YI C C, WU T L, et al. Effects of heat-treated wood particles on the physico-mechanical properties and extended creep behavior of wood/recycled-hdpe compo-sites using the time-temperature superposition principle[J]. Materials,2017,10(4):365.

|

| [60] |

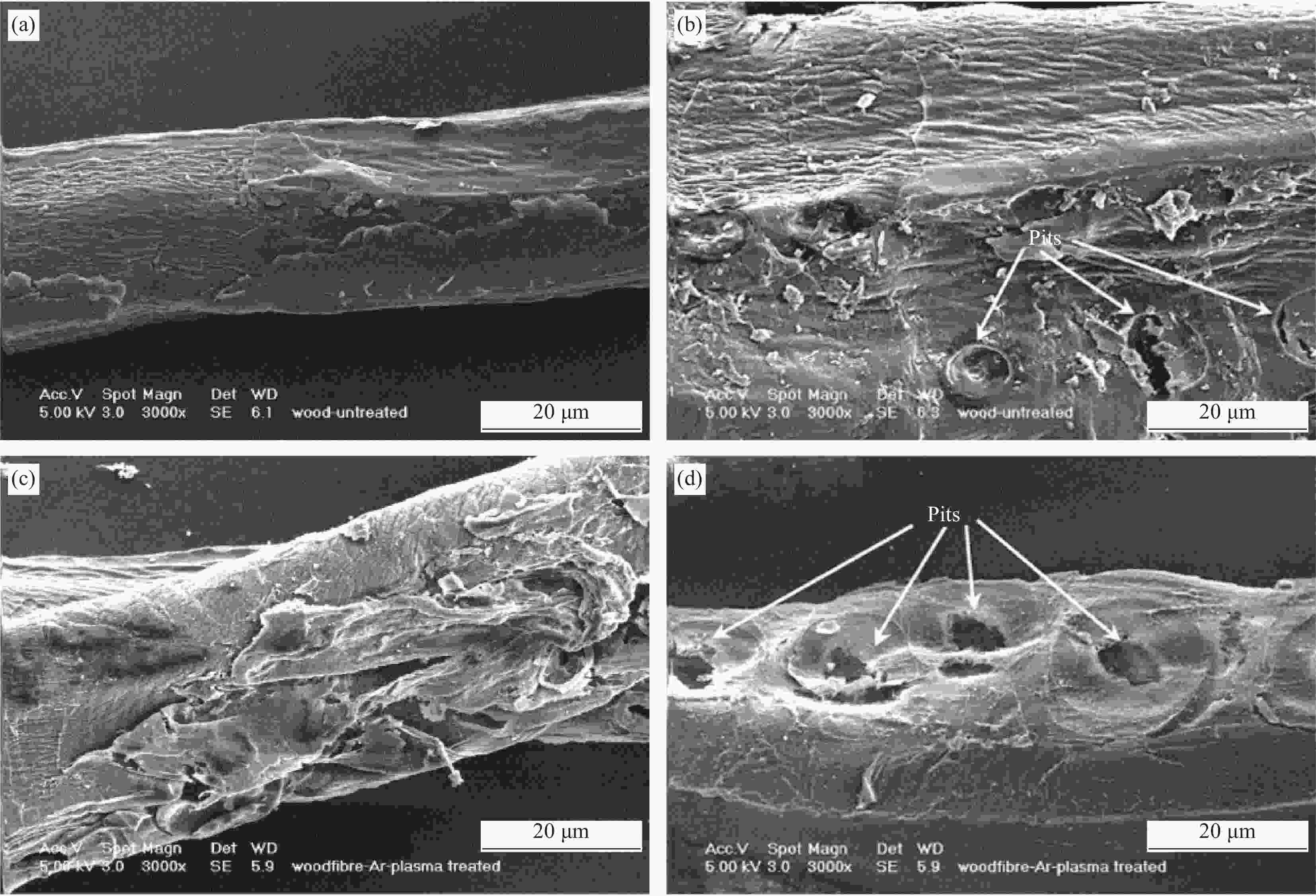

YUAN X W, JAYARAMAN K, BHATTACHARYYA D. Effects of plasma treatment in enhancing the performance of woodfibre-polypropylene composites[J]. Composites Part A: Applied Science and Manufacturing,2004,35(12):1363-1374. doi: 10.1016/j.compositesa.2004.06.023

|

| [61] |

MILITKY J, JABBAR A. Comparative evaluation of fiber treatments on the creep behavior of jute/green epoxy composites[J]. Composites Part B: Engineering,2015,80:361-368.

|

| [62] |

LI X, TABIL L G, PANIGRAHI S. Chemical treatments of natural fiber for use in natural fiber-reinforced compo-sites: A review[J]. Journal of Polymers and the Environment,2007,15(1):25-33. doi: 10.1007/s10924-006-0042-3

|

| [63] |

GODA K, SREEKALA M S, GOMES A, et al. Improvement of plant based natural fibers for toughening green composites-effect of load application during mercerization of ramie fibers[J]. Composites Part A: Applied Science and Manufacturing,2006,37(12):2213-2220. doi: 10.1016/j.compositesa.2005.12.014

|

| [64] |

JABBAR A, MILITKÝ J, MADHUKAR KALE B, et al. Modeling and analysis of the creep behavior of jute/green epoxy composites incorporated with chemically treated pulverized nano/micro jute fibers[J]. Industrial Crops and Products,2016,84:230-240. doi: 10.1016/j.indcrop.2015.12.052

|

| [65] |

BLEDZKI A K, MAMUN A A, LUCKA-GABOR M, et al. The effects of acetylation on properties of flax fibre and its polypropylene composites[J]. Express Polymer Letters,2008,2(6):413-422. doi: 10.3144/expresspolymlett.2008.50

|

| [66] |

HUNG K C, WU T L, CHEN Y L, et al. Assessing the effect of wood acetylation on mechanical properties and extended creep behavior of wood/recycled-polypropylene composites[J]. Construction and Building Materials,2016,108:139-145. doi: 10.1016/j.conbuildmat.2016.01.039

|

| [67] |

ZAFEIROPOULOS N E, BAILLIE C A. A study of the effect of surface treatments on the tensile strength of flax fibres: Part II. Application of weibull statistics[J]. Composites Part A: Applied Science and Manufacturing,2007,38(2):629-638. doi: 10.1016/j.compositesa.2006.02.005

|

| [68] |

WANG X, PETRŮ M, YU H. The effect of surface treatment on the creep behavior of flax fiber reinforced composites under hygrothermal aging conditions[J]. Construction and Building Materials,2019,208:220-227. doi: 10.1016/j.conbuildmat.2019.03.001

|

| [69] |

GUO C G, WANG Q W. Influence of m-isopropenyl-α, α-dimethylbenzyl isocyanate grafted polypropylene on the interfacial interaction of wood-flour/polypropylene composites[J]. Journal of Applied Polymer Science,2008,109(5):3080-3086. doi: 10.1002/app.27800

|

| [70] |

XU Y, KAWATA S, HOSOI K, et al. Thermomechanical properties of the silanized-kenaf/polystyrene compo-sites[J]. Express Polymer Letters,2009,3(10):657-664. doi: 10.3144/expresspolymlett.2009.82

|

| [71] |

ACHA B A, REBOREDO M M, MARCOVICH N E. Creep and dynamic mechanical behavior of PP-jute composites: Effect of the interfacial adhesion[J]. Composites Part A: Applied Science and Manufacturing,2007,38(6):1507-1516. doi: 10.1016/j.compositesa.2007.01.003

|

| [72] |

GAO H, XIE Y J, OU R X, et al. Grafting effects of polypropylene/polyethylene blends with maleic anhydride on the properties of the resulting wood-plastic composites[J]. Composites Part A: Applied Science and Manufacturing,2012,43(1):150-157. doi: 10.1016/j.compositesa.2011.10.001

|

| [73] |

HONG H Q, LIU T, HE H, et al. Effect of interfacial modifiers on physical properties and flammability properties of PE/wood composites[J]. Polymers and Polymer Compo-sites,2018,19(8):639-646.

|

| [74] |

HONG H Q, XU H X, HE H, et al. Effect of ternary monomer graft copolymers on morphology and properties of rice chaff filled polypropylene composites[J]. Plastics, Rubber and Composites,2013,38(1):21-26.

|

| [75] |

HONG H, LIAO H, ZHANG H, et al. Significant improvement in performance of recycled polyethylene/wood flour composites by synergistic compatibilization at multi-scale interfaces[J]. Composites Part A: Applied Science and Manufacturing,2014,64:90-98. doi: 10.1016/j.compositesa.2014.04.022

|

| [76] |

LAPCIK L, JINDROVA P, LAPCIKOVA B, et al. Effect of the talc filler content on the mechanical properties of polypropylene composites[J]. Journal of Applied Polymer Science,2008,110(5):2742-2747. doi: 10.1002/app.28797

|

| [77] |

DEKA B K, MAJI T K. Effect of silica nanopowder on the properties of wood flour/polymer composite[J]. Polymer Engineering & Science,2012,52(7):1516-1523.

|

| [78] |

FARUK O, MATUNA L. Nanoclay reinforced hdpe as a matrix for wood-plastic composites[J]. Composites Science and Technology,2008,68(9):2073-2077. doi: 10.1016/j.compscitech.2008.03.004

|

| [79] |

SMITS V, CHEVALIER P, DEHEUNYNCK D, et al. A new filler dispersion technology[J]. Reinforced Plastics,2008,52(11):37-43. doi: 10.1016/S0034-3617(08)70406-5

|

| [80] |

GWON J G, LEE S Y, CHUN S J, et al. Physical and mechanical properties of wood-plastic composites hybridized with inorganic fillers[J]. Journal of Composite Materials,2011,46(3):301-309.

|

| [81] |

HUUHILO T, MARTIKKA O, BUTYLINA S, et al. Mineral fillers for wood-plastic composites[J]. Wood Material Science & Engineering,2010,5(1):34-40.

|

| [82] |

HUUHILO T, MARTIKKA O, BUTYLINA S, et al. Impact of mineral fillers to the moisture resistance of wood-plastic composites[J]. Baltic Forestry,2010,16(1):126-131.

|

| [83] |

NIKOLAEVA M, KÄRKI T. Influence of mineral fillers on the fire retardant properties of wood-polypropylene composites[J]. Fire and Materials,2013,37(8):612-620. doi: 10.1002/fam.2160

|

| [84] |

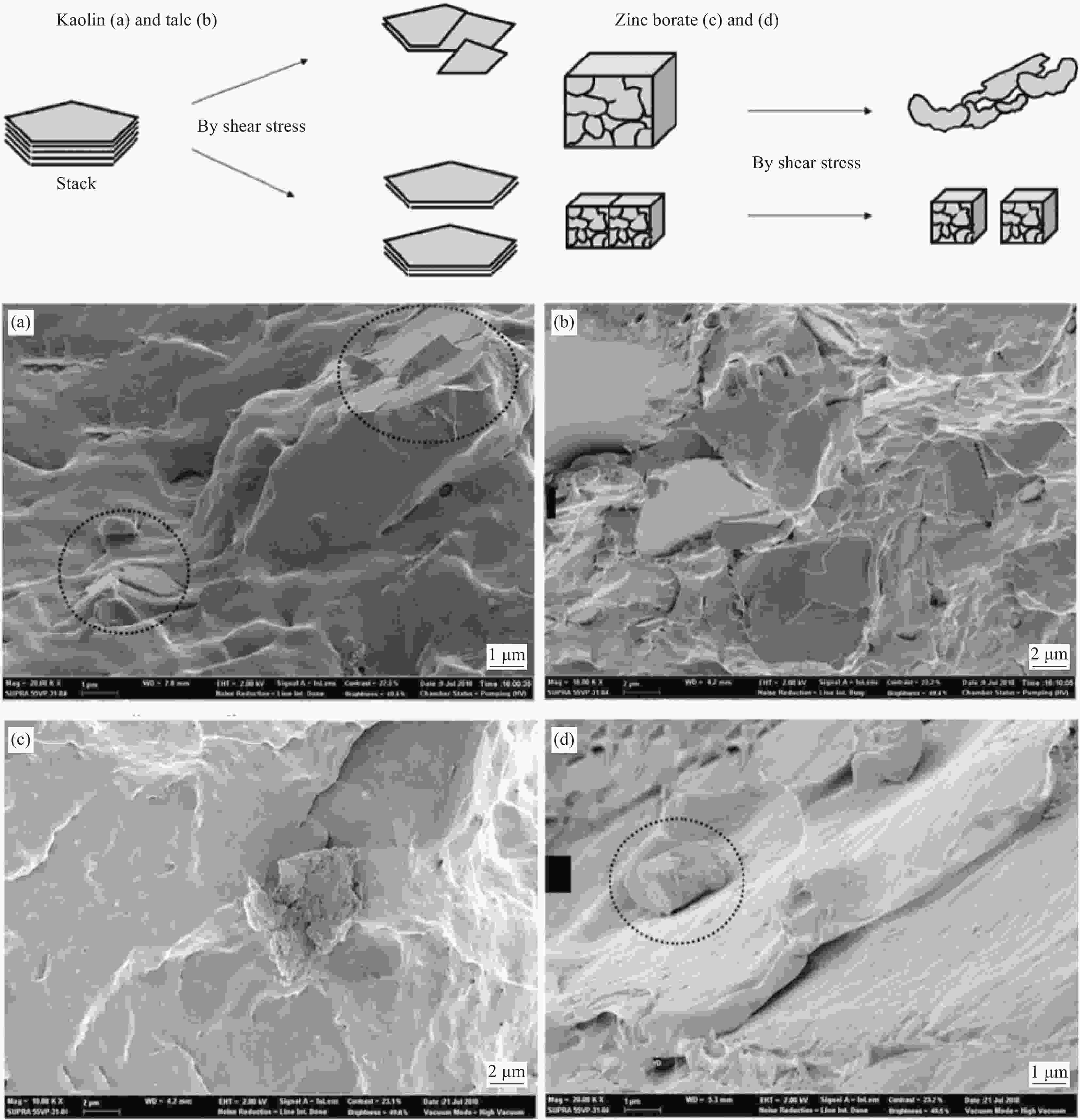

GODARA A, RAABE D, BERGMANN I, et al. Influence of additives on the global mechanical behavior and the microscopic strain localization in wood reinforced polypropylene composites during tensile deformation investigated using digital image correlation[J]. Composites Science and Technology,2009,69(2):139-146. doi: 10.1016/j.compscitech.2008.08.031

|

| [85] |

KORD B, SHEYKHOLESLAMI A, NAJAFI A. Effect of nanoclay on the flexural creep behavior of wood/plastic composites[J]. Mechanics of Composite Materials,2016,51(6):731-736. doi: 10.1007/s11029-016-9543-x

|

| [86] |

YANG J L, ZHANG Z, FRIEDRICH K, et al. Creep resistant polymer nanocomposites reinforced with multiwalled carbon nanotubes[J]. Macromolecular Rapid Communications,2007,28(8):955-961. doi: 10.1002/marc.200600866

|

| [87] |

JIA Y, PENG K, GONG X L, et al. Creep and recovery of polypropylene/carbon nanotube composites[J]. International Journal of Plasticity,2011,27(8):1239-1251. doi: 10.1016/j.ijplas.2011.02.004

|

| [88] |

STARKOVA O, BUSCHHORN S T, MANNOV E, et al. Creep and recovery of epoxy/MWCNT nanocomposites[J]. Composites Part A: Applied Science and Manufacturing,2012,43(8):1212-1218. doi: 10.1016/j.compositesa.2012.03.015

|

| [89] |

FARUK O, MATUANA L M. Reinforcement of rigid PVC/wood-flour composites with multi-walled carbon nanotubes[J]. Journal of Vinyl and Additive Technology,2008,14(2):60-64. doi: 10.1002/vnl.20145

|

| [90] |

王若丞, 张云鹤, 刘烁, 等. 碳纳米管/木塑复合材料的抗蠕变性能研究[C]. 第三届中国国际复合材料科技大会. 杭州, 2017.WANG Ruocheng, ZHANG Yunhe, LIU Shuo, et al. Creep resistance of carbon nanotubes/wood-plastic compo-sites[C]//The 3th China International Congress on Composition Materials. Hangzhou, 2017(in Chinese).

|

| [91] |

CHAHARMAHALI M, HAMZEH Y, EBRAHIMI G, et al. Effects of nano-graphene on the physico-mechanical properties of bagasse/polypropylene composites[J]. Polymer Bulletin,2014,71(2):337-349. doi: 10.1007/s00289-013-1064-3

|

| [92] |

SHESHMANI S, ASHORI A, ARAB FASHAPOYEH M. Wood plastic composite using graphene nanoplatelets[J]. International Journal of Biological Macromolecules,2013,58:1-6. doi: 10.1016/j.ijbiomac.2013.03.047

|

| [93] |

PULNGERN T, KAEWKALYA P, ROSARPITAK V, et al. Experimental and computational investigations of creep responses of wood/pvc composite members[J]. International Polymer Processing,2014,29(3):307-316. doi: 10.3139/217.2927

|

| [94] |

PULNGERN T, PADYENCHEAN C, ROSARPITAK V, et al. Flexural and creep strengthening for wood/PVC compo-site members using flat bar strips[J]. Materials & Design,2011,32(6):3431-3439.

|

| [95] |

PULNGERN T, CHIMKHLAI A, ROSARPITAK V, et al. Analytical, numerical and experimental investigations on flexural strengthening for wood/PVC composite members using flat bar strips[J]. Construction & Building Materials,2013,41:545-556.

|

| [96] |

NAGHIPOUR M, NEMATZADEH M, YAHYAZADEH Q. Analytical and experimental study on flexural performance of WPC-FRP beams[J]. Construction and Building Materials,2011,25(2):829-837. doi: 10.1016/j.conbuildmat.2010.06.104

|

| [97] |

王清文, 欧荣贤, 易欣, 等. 一种木塑包覆实木复合材料及其制备方法, 中国: ZL 201910014163.8[P]. 2019-12-17.WANG Qingwen, OU Rongxian, YI Xin, et al. A WPCs coated solid wood composite and its preparation method, China: ZL 201910014163.8[P]. 2019-12-17(in Chinese).

|

| [98] |

WANG X Y, SONG K Y, OU R X. effects of carbon black and titanium dioxide on ultraviolet weathering of wood flour-hdpe/lumber composites using multi-phase co-extrusion technology[J]. Bioresources,2017,12(3):6173-6186.

|

| [99] |

傅海涛, 孙理超, 王海刚, 等. 单板层积材-木粉/高密度聚乙烯共挤出复合材料抗低速冲击性能[J]. 复合材料学报, 2018, 35(1):200-207.FU Haitao, SUN Lichao, WANG Haigang, et al. Low-velocity impact performance of laminated veneer lumber-wood/high density polyethylene co-extruded compo-sites[J]. Acta Materiae Composite Sinica,2018,35(1):200-207(in Chinese).

|

| [100] |

王海刚, 傅海涛, 王清文, 等. WPC-LVL共挤出复合材料的抗弯性能[J]. 建筑材料学报, 2018, 21(4):695-700.WANG Haigang, FU Haitao, WANG Qingwen, et al. Flexural performance of composites manufactured by wood plastic composites co-extruded with laminated veneer lumber[J]. Journal of Building Materials,2018,21(4):695-700(in Chinese).

|

| [101] |

FU H T, DUN M Y, WANG H G, et al. Creep response of wood flour-high-density polyethylene/laminated veneer lumber coextruded composites[J]. Construction and Building Materials,2020,237:117499. doi: 10.1016/j.conbuildmat.2019.117499

|

| [102] |

ZONG G G, HAO X L, HAO J X, et al. High-strength, lightweight, co-extruded wood flour-polyvinyl chloride/lumber composites: effects of wood content in shell layer on mechanical properties, creep resistance, and dimensional stability[J]. Journal of Cleaner Production,2020,244:118860. doi: 10.1016/j.jclepro.2019.118860

|

| [103] |

龚新怀, 陈良壁. 茶粉/聚丙烯复合材料自然老化性能[J]. 复合材料学报, 2016, 33(7):1437-1445.GONG Xinhuai, CHEN Liangbi. Performances of tea dust/polypropylene composites under naturel weathering[J]. Acta Materiae Compositae Sinica,2016,33(7):1437-1445(in Chinese).

|

| [104] |

周吓星, 林巧佳, 陈礼辉. 自然气候老化对木塑复合材料蠕变性能的影响[J]. 福州大学学报(自然科学版), 2011, 39(1):96-100.ZHOU Xiaxing, LIN Qiaojia, CHEN Lihui. Impact of the natural weathering on the creep behavior of wood-platic composite[J]. Journal of Fuzhou University (Natural Science Edition),2011,39(1):96-100(in Chinese).

|

| [105] |

FERRY J D. Viscoelastic properties of polymers[M]. New York: John Wiley & Sons, 1980.

|

| [106] |

TAMRAKAR S, LOPEZ-ANIDO R A, KIZILTAS A, et al. Time and temperature dependent response of a wood-polypropylene composite[J]. Composites Part A: Applied Science and Manufacturing,2011,42(7):834-842. doi: 10.1016/j.compositesa.2011.03.011

|

| [107] |

LI G, LEE-SULLIVAN P, THRING R W. Determination of activation energy for glass transition of an epoxy adhesive using dynamic mechanical analysis[J]. Journal of Thermal Analysis and Calorimetry,2000,60(2):377-390. doi: 10.1023/A:1010120921582

|

| [108] |

TAJVIDI M, FALK R H, HERMANSON J C. Time-temperature superposition principle applied to a kenaf-fiber/high-density polyethylene composite[J]. Journal of Applied Polymer Science,2005,97(5):1995-2004. doi: 10.1002/app.21648

|

| [109] |

CHANG F C, LAM F, KADLA J F. Application of time-temperature-stress superposition on creep of wood-plastic composites[J]. Mechanics of Time-Dependent Materials,2013,17(3):427-437. doi: 10.1007/s11043-012-9194-9

|

| [110] |

DURANTE M, FORMISANO A, BOCCARUSSO L, et al. Creep behaviour of polylactic acid reinforced by woven hemp fabric[J]. Composites Part B: Engineering,2017,124:16-22. doi: 10.1016/j.compositesb.2017.05.038

|

| [111] |

HADID M, RECHAK S, TATI A. Long-term bending creep behavior prediction of injection molded composite using stress-time correspondence principle[J]. Materials Science and Engineering: A,2004,385(1-2):54-58. doi: 10.1016/j.msea.2004.04.023

|

| [112] |

JAZOULI S, LUO W, BREMAND F, et al. Application of time-stress equivalence to nonlinear creep of polycarbonate[J]. Polymer Testing,2005,24(4):463-467. doi: 10.1016/j.polymertesting.2005.01.002

|

| [113] |

QAISER A A, PRICE J. Estimation of long-term creep behavior of polycarbonate by stress-time superposition and effects of physical aging[J]. Mechanics of Time-Dependent Materials,2011,15(1):41-50. doi: 10.1007/s11043-010-9124-7

|

| [114] |

董智贤. 聚丙烯木塑复合材料蠕变行为的模拟与预测[J]. 高分子材料科学与工程, 2010, 26(5):89-92.DONG Zhixian. Modeling and prediction of creep behavior of PP/wood-flour composite[J]. Polymer Materials Science and Engineering,2010,26(5):89-92(in Chinese).

|

| [115] |

DASTOORIAN F, TAJVIDI M, EBRAHIMI G. Evaluation of time dependent behavior of a wood flour/high density polyethylene composite[J]. Journal of Reinforced Plastics and Composites,2008,29(1):132-143.

|

| [116] |

ALWIS K G N C, BURGOYNE C J. Accelerated creep testing for aramid fibres using the stepped isothermal method[J]. Journal of Materials Science,2008,43(14):4789-4800. doi: 10.1007/s10853-008-2676-0

|

| [117] |

ACHEREINER F, ENGELSING K, BASTIAN M, et al. Accelerated creep testing of polymers using the stepped isothermal method[J]. Polymer Testing,2013,32(3):447-454. doi: 10.1016/j.polymertesting.2013.01.014

|

| [118] |

HUANG C W, YANG T C, WU T L, et al. Effects of maleated polypropylene content on the extended creep behavior of wood-polypropylene composites using the stepped isothermal method and the stepped isostress method[J]. Wood Science and Technology,2018,52(5):1313-1330. doi: 10.1007/s00226-018-1037-7

|

| [119] |

GIANNOPOULOS I P, BURGOYNE C J. Prediction of the long-term behaviour of high modulus fibres using the stepped isostress method (SSM)[J]. Journal of Materials Science,2011,46(24):7660-7671. doi: 10.1007/s10853-011-5743-x

|

| [120] |

GIANNOPOULOS I P, BURGOYNE C J. Stress limits for aramid fibres[J]. Structures and Buildings,2009,162(4):221-232.

|

| [121] |

TANKS J, RADER K, SHARP S, et al. Accelerated creep and creep-rupture testing of transverse unidirectional carbon/epoxy lamina based on the stepped isostress method[J]. Composite Structures,2017,159:455-462. doi: 10.1016/j.compstruct.2016.09.096

|

| [122] |

HADID M, GUERIRA B, BAHRI M, et al. Assessment of the stepped isostress method in the prediction of long term creep of thermoplastics[J]. Polymer Testing,2014,34:113-119. doi: 10.1016/j.polymertesting.2014.01.003

|

下载:

下载: