Preparation process and new progress in carbon fiber reinforced magnesium matrix composites

-

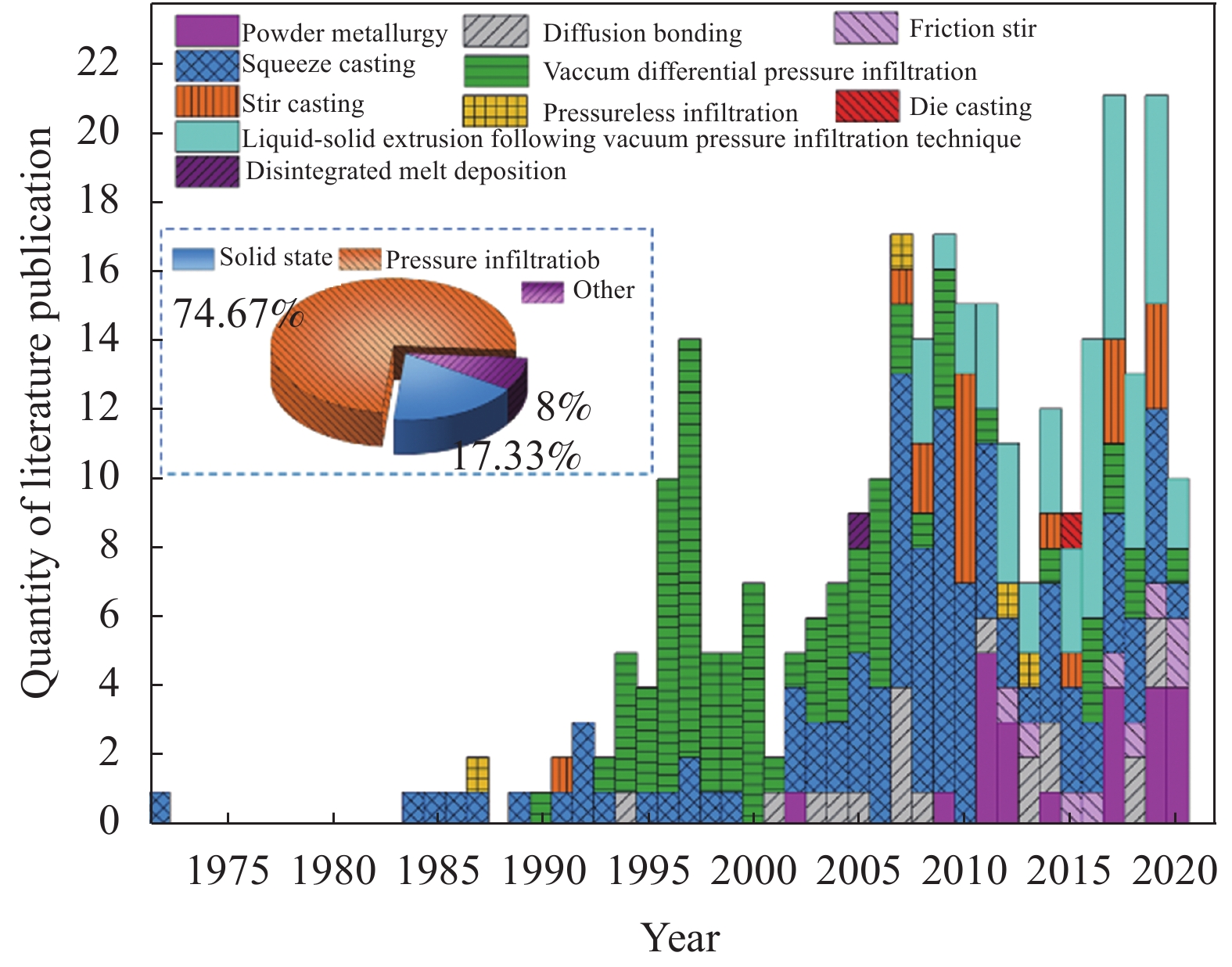

摘要: 碳纤维增强镁基(Cf/Mg)复合材料以其高比强度、高比刚度、接近于零的热膨胀系数及良好尺寸稳定性等独特优势,在航空、航天、车辆等领域具有广阔的应用前景。本文综述了可用于制备Cf/Mg复合材料的粉末冶金、扩散黏结、挤压铸造等方法的工艺原理和特点、国内外发展现状及面临的关键技术问题。在此基础上,梳理了近年来Cf/Mg复合材料制备技术取得的新进展,并介绍了对国防和国民经济领域产生显著推动作用和具有潜在应用前景的工程应用案例,分析了Cf/Mg复合材料所面临的挑战,对未来发展方向进行了展望。Abstract: The carbon fiber reinforced magnesium matrix (Cf/Mg) composites are considered as the most promising structural materials with great potential in both aerospace and automotive applications, which have high specific strength, high specific stiffness, excellent thermal conductivity, great electrical conductivity and good damping properties, as well as close to zero thermal expansion coefficient and good dimensional stability. In the present review, the craft principles and characteristics, as well as the current development status and the key technical problems of powder metallurgy, diffusion bonding, squeeze casting, etc that can be used to prepare Cf/Mg composites are discussed deeply. Then the new progresses made in the preparation of Cf/Mg composites in recent years are hackled. Furthermore, engineering application cases of Cf/Mg composite that have a significant promotion effect and potential application prospects in the fields of national defense and national economy are introduced. Additionally, the facing challenges of Cf/Mg composite are analyzed, and the future development directions are prospected.

-

Key words:

- carbon fiber /

- magnesium /

- composites /

- preparation process /

- application

-

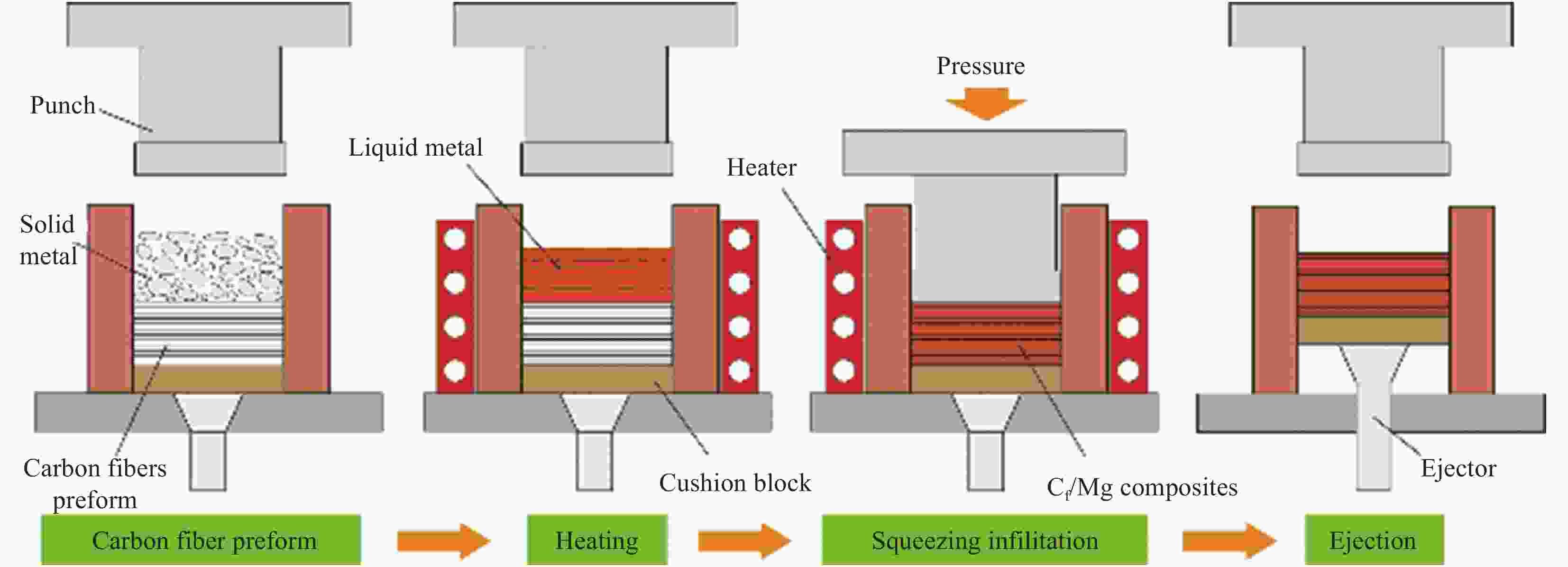

图 12 真空吸渗挤压(LSEVI)装置示意图

Figure 12. Schematic of liquid-solid extrusion following vacuum pressure infiltration technique (LSEVI)

1—Ar cylinder; 2—Gas pipe; 3, 4, 5, 6—Valve; 7—Pressure gage; 8—Pouring pipe; 9, 11—Sealing block; 10—Punch; 12—Cavity die; 13—Liquid Mg alloy; 14—Carbon fiber preform; 15—Preheating furnace; 16—Ejector; 17—Die-set; 18—Smelting furnace; 19—Vacuum pump

表 1 Cf/Mg工业产品中的代表性应用

Table 1. Representative applications of Cf/Mg composites industrial products

Category Component Product Agency Figure Space structure Parabolic antenna structure[55] Space vehicle U.S. Navy Solar cell array substrate, collimating mirror frame structure of satellite system[56] NASA Honeycomb support structure

of space reflector[57]NASA

Truss structure (Diameter is

50 mm, length is 1.2 m)[58]Space truss Lockheed Martin

Corporation Maine

Fiber Materials Corporation

Sector mirror, foldable butterfly antenna ribs, elliptical antenna feed pillars[56,59] Hubble space telescope NASA Weaponry Mirror frame, measuring components[59] Exoatmospheric Kill Vehicle (EKV) Metal Matrix Foundry Composites (U.S.)

Transportation Engine piston[60-61] Diesel truck RWTH Aachen University Engine piston[62] Commercial vehicle Bavarian Motor Works 表 2 Cf/Mg实验室研发阶段的潜在应用

Table 2. Potential applications of Cf/Mg composites in the laboratory development stage

Time Development department Preparation process Potential application Significance Figure 1994 NASA; Foster-Miller Corporation (U.S.) Vacuum pressure infiltration Space truss and connecting parts (U-joints) that can be used in commercial applications[30] It can solve the problem of difficult welding of carbon fiber reinforced metal matrix composites

2003 Federal Laboratories for Materials Testing and Research (Swiss); University of Zurich (Saviss) Squeeze casting CERN’s large hadron collide[63] It can replace beryllium and its alloys to improve the rigidity and heat dissipation of materials

2003 National Sun Yat-sen University (Taiwan, China) Diffusion bonding Aircraft fuselage, lower wing skin and tail skin[20] Lightweight aircraft can be achieved, and the impact resistance and fatigue performance of materials can be improved 2005 University of Liverpool (UK) University of Liverpool (UK) Upper fuselage of Airbus A380[21] Lightweight aircraft can be achieved, and the impact resistance and fatigue performance of materials can be improved 2006 Institute of Materials Science and Testing (Austria); Vienna University of Technology (Austria); Federal Laboratories for Materials Testing and Research (Swiss) Squeeze casting Inner ring high precision bearing[64] It can reduce the weight of the bearing and improve the high temperature dimensional stability of material

2006 Delft University of Technology (Netherlands) Diffusion bonding Aircraft fuselage skin[65] It can replace aluminum alloy to achieve lightweight aircraft and improve the impact resistance of the fuselage 2007 Harbin Institute of Technology (China) Squeeze casting Bearing wheel[66] It can reduce the weight of the bearing and improve the high temperature dimensional stability

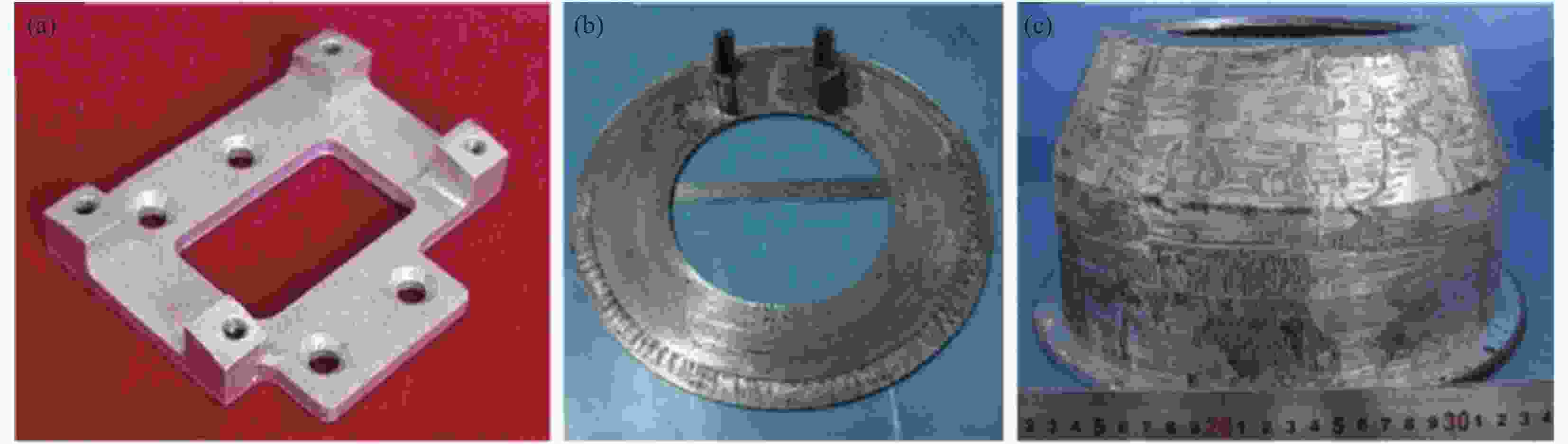

2009 Nagaoka University of Technology (Japan) Squeeze casting Engine piston[26] Lightweight vehicles can be achieved, and the dimensional stability and wear resistance of materials can be improved 2010 Northwestern Polytechnical University (China) Liquid-solid extrusion following vacuum infiltration (LSEVI) Aerospace bracket[46] It can replace aluminum and its composite materials to achieve lightweight

2011 Pusan National University (Korea); Institute of Materials Science (Korea) Squeeze casting Arm processing system of high-precision industrial robot[27] It can realize the lightweight, dimensional stability and positioning accuracy of the robot 2016 Northwestern Polytechnical University (China) LSEVI Cylindrical piece of weapon equipment[48] It can achieve the application goals of weapon system weight reduction, rapid response capability and voyage improvement

2017 Northwestern Polytechnical University (China) LSEVI Thin plate special-shaped parts for aerospace[67] It can replace aluminum and its composite materials to achieve lightweight

2017 Ufa State Aviation Technical University (Russia) Squeeze casting Compressor blades of aeroengine[68] Lightweight aircraft can be achieved, the damping performance of the blades can be improved, and the blade vibration can be reduced 2017 Shanghai Jiaotong University (China); Northeastern University (China); Harbin Engineering University (China) Powder metallurgy LED metal substrate (heat sink material)[69] Compared with traditional heat dissipation materials (copper, aluminum), it can achieve lighter weight, higher heat dissipation and service life 2019 Osaka University (Japan) Diffusion bonding High-speed rail body[70] It can substitute aluminum alloy, replace bolts, rivets, adhesives and other connection methods, reduce weight by 20%–30%, and solve the problem of adhesives harmful to humans -

[1] ZHANG T, QI L H, FU J W, et al. Microstructure and thermal expansion behavior of a novel Cf-SiCNWs/AZ91D composite with dual interface[J]. Ceramics International,2019,45(9):12563-12569. doi: 10.1016/j.ceramint.2019.03.073 [2] 镁动力. 轻质镁合金材料在航空军工领域中扮演不一样的角色[EB/OL]. (2018-12-13) [2020-7-16]. http://www.magppc.com/mg/8635.html.

Magnesium Power. Lightweight magnesium alloy materials play a different role in the aviation and military industry[EB/OL]. (2018-12-13) [2020-7-16]. http://www.magppc.com/mg/8635.html(in Chinese).[3] LEVITT A P, CESARE E D, WOLF S M. Fabrication and properties of graphite fiber reinforced magnesium[J]. Metallurgical Transactions,1972,3(9):2455-2459. doi: 10.1007/BF02647049 [4] DOHNOMOTO T, TANAKA A. Composite material with carbon reinforcing fibers and magnesium alloy matrix including zinc: European Patent, EP19850104981[P]. 1990-07-25. [5] MASON J F, WARWICK C M, SMITH P J, et al. Magnesium-lithium alloys in metal matrix composites: A preliminary report[J]. Journal of Materials Science,1989,24(11):3934-3946. doi: 10.1007/BF01168957 [6] 王浩伟, 商宝禄, 郑来苏, 等. 涂层碳纤维增强镁基复合材料[J]. 复合材料学报, 1992, 9(2):73-76.WANG H W, SHANG B L, ZHENG L S, et al. Coating carbon fiber reinforced magnesium composites[J]. Acta Materiae Compositae Sinica,1992,9(2):73-76(in Chinese). [7] BABU J S S, NAIR K P, UNNIKRISHNAN G, et al. Fabrication and properties of magnesium (AM50)-based hybrid composites with graphite nanofiber and alumina short fiber[J]. Journal of Composite Materials,2009,44(8):971-987. [8] HUFENBACH W, ANDRICH M, LANGKAMP A, et al. Fabrication technology and material characterization of carbon fibre reinforced magnesium[J]. Journal of Materials Processing Technology,2006,175(1):218-224. [9] CARREÑO-MORELLI E, CUTARD T, SCHALLER R, et al. Processing and characterization of aluminium-based MMCs produced by gas pressure infiltration[J]. Materials Science and Engineering A,1998,251(1):48-57. [10] FELDHOFF A, PIPPEL E, WOLTERDORF J. Interface engineering of carbon-fiber reinforced Mg-Al alloys[J]. Advanced Engineering Materials,2000,2(8):471-480. doi: 10.1002/1527-2648(200008)2:8<471::AID-ADEM471>3.0.CO;2-S [11] KÖRNER C, SCHÄFF W, OTTMÜLLER M, et al. Carbon long fiber reinforced magnesium alloys[J]. Advanced Engineering Materials,2000,2(6):327-337. doi: 10.1002/1527-2648(200006)2:6<327::AID-ADEM327>3.0.CO;2-W [12] 李坤, 石南林, 孙超. 碳纤维增强镁基复合材料界面研究进展[J]. 材料导报, 2005, 19(s2):425-427. doi: 10.3321/j.issn:1005-023X.2005.z2.134LI K, SHI N L, SUN C. Review on interface of carbon fiber reinforce magnesium matrix composites[J]. Materials Reports,2005,19(s2):425-427(in Chinese). doi: 10.3321/j.issn:1005-023X.2005.z2.134 [13] 欧阳海波, 齐乐华, 李贺军. 液态浸渗法制备碳纤维增强镁基复合材料研究进展[J]. 特种铸造及有色合金, 2008(s1):67-73.OUYANG H B, QI L H, LI H J. Development of the carbon fiber reinforced magnesium matrix composites fabricated by liquid metal infiltration[J]. Special Casting & Nonferrous Alloys,2008(s1):67-73(in Chinese). [14] 杨钊, 许红雨, 胡茂良, 等. 固相合成制备短碳纤维增强镁基复合材料的结构与性能[J]. 哈尔滨理工大学学报, 2019, 24(5):13-18.YANG Z, XU H Y, HU M L, et al. Microstructures and properties of SCFs/AZ31 composite fabricated by solid state synthesis[J]. Journal of Harbin University of Science and Technology,2019,24(5):13-18(in Chinese). [15] XU H Y, YANG Z, HU M L, et al. Effect of short carbon fiber content on SCFs/AZ31 composite microstructure and mechanical properties[J]. Results in Physics,2020,17:103074. doi: 10.1016/j.rinp.2020.103074 [16] REN F Z, GAO J C, LI W, et al. Effect of interface properties on the mechanical performance of carbon fiber/Mg composites fabricated by powder metallurgy[J]. Carbon,2012,50(1):343. [17] 任富忠, 吴思展, 石维. 镍涂层短碳纤维增强AZ91D镁基复合材料的界面特征和阻尼性能[J]. 材料研究学报, 2017, 31(1):74-80.REN F Z, WU S Z, SHI W. Interface characteristics and damping performance of Ni-coated short carbon fiber reinforced AZ91D magnesium matrix composites[J]. Chinese Journal of Materials Research,2017,31(1):74-80(in Chinese). [18] INOUE Y, KIM J, YONEZAWA S, et al. Enhanced mechanical strength of nickel-copper-coated carbon fiber/magnesium alloy composites fabricated using powder metallurgy[J]. Chemistry Letters,2012,41(5):531-532. doi: 10.1246/cl.2012.531 [19] YANG Z, XU H Y, WANG Y, et al. Microstructures and mechanical properties of SCF/AZ31B composites fabricated by multi-times hot-extrusion[J]. Results in Physics,2019,12:888-895. doi: 10.1016/j.rinp.2018.12.039 [20] KUO M C, HUANG J C, CHEN M, et al. Fabrication of high performance magnesium/carbon-fiber/PEEK laminated composites[J]. Materials Transactions,2003,44(8):1613-1619. doi: 10.2320/matertrans.44.1613 [21] CORTÉS P, CANTWELL W J. The fracture properties of a fibre-metal laminate based on magnesium alloy[J]. Composites Part B: Engineering,2005,37(2):163-170. [22] JEN M H, TSENG Y C, LI P Y. Fatigue response of hybid magnesium/carbon-fiber/PEEK nanocomposite laminates at elevated temperature (Ⅱ)[J]. Key Engineering Materials,2007,334-335:693-696. doi: 10.4028/www.scientific.net/KEM.334-335.693 [23] BADINI C, FERRARIS M, MARCHETTI F. Interfacial reaction in AZ61/AZ91/P100 Mg/graphite composite: An auger spectroscopy investigation[J]. Materials Letters,1994,21(1):55-61. doi: 10.1016/0167-577X(94)90123-6 [24] RAWAL S. Interface structure in graphite-fiber-reinforced metal-matrix composites[J]. Surface and Interface Analysis,2001,31(7):692-700. doi: 10.1002/sia.1095 [25] MATSUNAGA T, YOSHIDA M, SASAKI G, et al. Preparation and mechanical properties of carbon fiber reinforced AZ91D magnesium alloy composite fabricated by squeeze casting process[C]//The Proceedings of the JSME Materials and Processing Conference. Honolulu: JSME, 2002: 347-351. [26] HONMA T, NAGAI K, KATOU A, et al. Synthesis of high-strength magnesium alloy composites reinforced with Si-coated carbon nanofibres[J]. Scripta Materialia,2009,60(6):451-454. doi: 10.1016/j.scriptamat.2008.11.024 [27] LEE W, LEE J, LEE S, et al. Thermal shock cracking behaviors of 2D woven carbon fiber reinforced magnesium matrix composite[C]//18th International Conference on Composite Materials. Jeju: 2011. [28] 武高辉, 乔菁, 姜龙涛. Al及其复合材料尺寸稳定性原理与稳定化设计研究进展[J]. 金属学报, 2019, 55(1):33-44.WU G H, QIAO J, JIANG L T. Research progress on principle of dimensional stability and stabilization design of Al and its composites[J]. Acta Metallurgica Sinica,2019,55(1):33-44(in Chinese). [29] 武高辉, 匡泽洋. 装备升级换代背景下金属基复合材料的发展机遇和挑战[J]. 中国工程科学, 2020, 22(2):79-90.WU G H, KUANG Z Y. Opportunities and challenges for metal matrix composites in the context of equipment upgrading[J]. Strategic Study of CAE,2020,22(2):79-90(in Chinese). [30] LEE J A, KASHALIKAR U, MAJKOWSKI P. Casting of weldable graphite/magnesium metal matrix composites with built-in metallic inserts[C]//The Fourth National Technology Transfer Conference and Exposition. Washington: NASA, 1994. [31] DEGISCHER H P, SCHULZ P A, LACOM W. Properties of continuous fibre reinforced Al- and Mg-matrix composites produced by gas pressure infiltration[J]. Key Engineering Materials,1996,127-131:99-110. doi: 10.4028/www.scientific.net/KEM.127-131.99 [32] 费铸铭, 张国定, 周耀民, 等. 非连续石墨纤维增强镁基复合材料热性能研究[J]. 机械工程材料, 1996(4):1-3.FEI Z M, ZHANG G D, ZHOU Y M, et al. The thermal properties of uncontinued graphite fiber reinforced magnesium matrix composites[J]. Materials for Mechanical Engineering,1996(4):1-3(in Chinese). [33] 张小农, 陈思根, 张荻, 等. Gr/Mg复合材料的阻尼行为研究[J]. 材料工程, 1997(8):19-21.ZHANG X N, CHEN S G, ZHANG D, et al. Study on damping behavior of Gr/Mg composite[J]. Journal of Materials Engineering,1997(8):19-21(in Chinese). [34] CHOWDHURY A S M F. Mechanical spectroscopy of interface stress relaxation in magnesium matrix composites[D]. Lausanne: Swiss federal Institute of Technology in Lausanne, 2009. [35] 陈美怡, 秦富生, 李自德, 等. Gr(C)/Mg复合材料纤维分布均匀性及其改善途径[J]. 铸造, 1996(5):1-5. doi: 10.3321/j.issn:1001-4977.1996.05.001CHEN M Y, QIN F S, LI Z D, et al. Fibre distribution and its improvement in Gr(C)/Mg composite[J]. Foundry,1996(5):1-5(in Chinese). doi: 10.3321/j.issn:1001-4977.1996.05.001 [36] WANG W G, XIAO B L, MA Z Y. Evolution of interfacial nanostructures and stress states in Mg matrix composites reinforced with coated continuous carbon fibers[J]. Composites Science and Technology,2012,72(2):152-158. doi: 10.1016/j.compscitech.2011.10.008 [37] UOZUMI H, KOBAYASHI K, NAKANISHI K, et al. Wettability of carbon fiber and aluminum borate whisker hybrid preform by molten magnesium[C]//International SAMPE Symposium and Exhibition (Proceedings). Baltimore: 2007. [38] KACAR A S, RANA F, STEFANESCU D M. Kinetics of gas-to-liquid transfer of particles in metal matrix composites[J]. Materials Science and Engineering A,1991,135:95-100. doi: 10.1016/0921-5093(91)90543-V [39] 黄勇. 搅拌铸造Csf/AZ91镁基复合材料的组织与性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2007.HUANG Y. The study on microstructure and properties of Csf/AZ91 magnesium matrix composite fabricated by stir-casting[D]. Harbin: Harbin Institute of Technology, 2007(in Chinese). [40] YAO Y Q, XU Z F, SUGIO K, et al. Fabrication of vapor-grown carbon fiber-reinforced magnesium-calcium alloy composites by compo-casting process[J]. Materials Transactions,2017,58(4):673-678. doi: 10.2320/matertrans.MBW201607 [41] YAO Y Q, XU Z F, SUGIO K, et al. Nickel formation on graphite sheet surface for improving wettability with magnesium alloy[J]. Materials Transactions,2015,56(10):1693-1697. doi: 10.2320/matertrans.MAW201506 [42] 常海, 黄勇, 胡小石, 等. 搅拌铸造法制备短碳纤维/AZ91复合材料的组织与性能[J]. 复合材料学报, 2019, 36(1):159-166.CHANG H, HUANG Y, HU X S, et al. Microstructure and mechanical properties of short carbon fiber/AZ91 composite fabricated by stir casting[J]. Acta Materiae Compositae Sinica,2019,36(1):159-166(in Chinese). [43] MERTENS A, SIMAR A, MONTRIEUX H, et al. Friction stir processing of magnesium matrix composites reinforced with carbon fibres: Influence of the matrix characteristics and of the processing parameters on microstructural developments[C]//Proceedings of the 9th International Conference On Magnesium Alloys and their Apllications. Vancouver: Helmholtz-Zentrum Geesthacht and NSERC MagNET, 2012. [44] AFRINALDI A, KAKIUCHI T, NAKAGAWA S, et al. Fabrication of recycled carbon fiber reinforced magnesium alloy composite by friction stir processing using 3-flat pin tool and its fatigue properties[J]. Materials Transactions,2018,59(3):475-481. doi: 10.2320/matertrans.M2017297 [45] 李贺军, 齐乐华, 周计明. 液固高压成形技术与应用[M]. 北京: 国防工业出版社, 2013.LI H J, QI L H, ZHOU J M. Technology and application of liquid solid forming under high pressure[M]. Beijing: National Defense Industry Press, 2013(in Chinese). [46] 关俊涛. 真空吸渗挤压制备Cf/Mg复合材料制件及其性能研究[D]. 西安: 西北工业大学, 2010.GUAN J T. Fabrication and properties of Cf/Mg composites by extrusion directly following vacuum pressure infiltration technique[D]. Xi’an: Northwesten Polytechnical University, 2010(in Chinese). [47] 苏常青, 齐乐华, 张丽丹, 等. 连续碳纤维/Mg复合材料异形薄板件预制体制备与成型[J]. 复合材料学报, 2017, 34(6):1285-1292.SU C Q, QI L H, ZHANG L D, et al. Fabrication and forming of preforms for carbon fiber/Mg composites sheet-shaped component[J]. Acta Materiae Compositae Sinica,2017,34(6):1285-1292(in Chinese). [48] QI L H, WEI X L, JU L Y, et al. Design and application of forming device for the thin-walled Cf/Mg composite component[J]. Journal of Materials Processing Technology,2016,238:459-465. doi: 10.1016/j.jmatprotec.2016.08.007 [49] 吴炳尧. 镁合金压铸技术分析[J]. 铸造, 2000, 49(8):443-449. doi: 10.3321/j.issn:1001-4977.2000.08.001WU B Y. Analysis for die-casting technology of magnesium alloy[J]. Foundry,2000,49(8):443-449(in Chinese). doi: 10.3321/j.issn:1001-4977.2000.08.001 [50] OLSZÓWKA-MYALSKA A, MYALSKI J. Magnesium alloy AZ31-short carbon fiber composite obtained by pressure die casting[J]. Solid State Phenomena,2015,229:115-122. doi: 10.4028/www.scientific.net/SSP.229.115 [51] GUPTA M, LAI M O, SOO C Y. Processing-microstructure-mechanical properties of an Al-Cu/SiC metal matrix composite synthesized using disintegrated melt deposition technique[J]. Materials Research Bulletin,1995,30(12):1525-1534. doi: 10.1016/0025-5408(95)00141-7 [52] WONG W L E, GUPTA M. Using hybrid reinforcement methodology to enhance overall mechanical performance of pure magnesium[J]. Journal of Materials Science,2005,40(11):2875-2882. doi: 10.1007/s10853-005-2429-2 [53] GUPTA M, MEENASHISUNDARAM G K. Insight into designing biocompatible magnesium alloys and composites: Processing, mechanical and corrosion characteristics[M]. Springer, 2015. [54] 中国粉体网. 2025年碳纤维增强金属基复合材料市场规模将达到275亿美元[EB/OL]. (2020-07-22) [2020-08-30]. https://news.cnpowder.com.cn/56292.html.China Powder Network. The market size of carbon fiber reinforced metal matrix composites will reach $27.5 billion in 2025[EB/OL]. (2020-07-22) [2020-08-30]. https://news.cnpowder.com.cn/56292.html (in Chinese). [55] WENDT R G, MISRA M S. Fabrication of near-net shape graphite/magnesium composites for large mirrors[C]//1990 Technical Symposium on Optics, Electro-Optics, and Sensors. Orlando: SPIE, 1990. [56] 秦富生, 陈美怡. 高压差充型制备金属基复合材料[J]. 铸造设备与工艺, 1996(6):19-21, 26.QIN F S, CHEN M Y. Preparation of metal matrix composite material by high-pressure infiltration[J]. Foundry Equipment and & Technology,1996(6):19-21, 26(in Chinese). [57] CORNIE J A, BALLARD L, CHEN E, et al. Development of graphite fiber reinforced magnesium alloys for lightweight mirror substrates and Zero CTE metering structures[C]//National Space and Missile Materials Symposium. Seattle: 2004. [58] RAWAL S P. Metal-matrix composites for space applications[J]. JOM,2001,53(4):14-17. doi: 10.1007/s11837-001-0139-z [59] 孙振明, 胡小石, 张春雷, 等. 连续碳纤维增强镁基复合材料制备工艺研究[J]. 上海航天, 2019, 36(2):60-65.SUN Z M, HU X S, ZHANG C L, et al. Design and fabrication of continuous carbon fiber reinforced magnesium matrix composites[J]. Aerospace Shanghai,2019,36(2):60-65(in Chinese). [60] ATAYA S, ALSALEH N A, EL-SAYED SELEMAN M M. Strength and wear behavior of Mg alloy AE42 reinforced with carbon short fibers[J]. Acta Metallurgica Sinica (English Letters),2019,32(1):31-40. doi: 10.1007/s40195-018-0771-z [61] ATAYA S, EL-MAGD E. Quasi-static behavior of Mg-alloys with and without short-fiber reinforcement[J]. Theoretical and Applied Fracture Mechanics,2007,47(2):102-112. doi: 10.1016/j.tafmec.2006.11.002 [62] 程振彪. 宝马公司开发纤维增强镁活塞[J]. 汽车科技, 1998(6):37.CHENG Z B. BMW develops fiber-reinforced magnesium piston[J]. Auto Sci-Tech,1998(6):37(in Chinese). [63] VAUCHER S, BEFFORT O, KÜBLER J, et al. An orthotropic magnesium-carbon composite as a lightweight heat-guide material with high specific stiffness and radiation transparency[J]. Advanced Engineering Materials,2003,5(9):669-672. doi: 10.1002/adem.200300370 [64] DEGISCHER H P, RAMMERSTORFER F G, BEFFORT O. Design rules for selective reinforcement of Mg-castings by MMC inserts[M]//KAINER K U. Magnesium Alloys and their Applications. Weinheim: Wiley, 2000. [65] ALDERLIESTEN R, RANS C, BENEDICTUS R. The applicability of magnesium based fibre metal laminates in aerospace structures[J]. Composites Science and Technology,2008,68(14):2983-2993. doi: 10.1016/j.compscitech.2008.06.017 [66] 王宁. Grf/ZM6复合材料的力学和热膨胀性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2007.WANG N. Study of mechanical and thermal expansion properties of Grf/ZM6 composites[D]. Harbin: Harbin Institute of Technology, 2007(in Chinese). [67] 鞠录岩. 真空吸渗挤压Cf/Mg复合材料损伤研究及异形件制备[D]. 西安: 西北工业大学, 2017.JU L Y. Damage study and fabrication technology of Cf/Mg composite part by liquid-solid extrusion following vacuum infiltration technique[D]. Xi’an: Northwesten Polytechnical University, 2017(in Chinese). [68] ASTANIN V, NURULLINA D, ZARIPOVA A, et al. Carbon fiber reinforced magnesium alloy in a Ti-6Al-4V shell[C]//International Conference on Modern Trends in Manufacturing Technologies and Equipment (ICMTMTE 2017). Sevastopol: EDP Sciences, 2017 [69] HOU L G, WU R Z, WANG X D, et al. Microstructure, mechanical properties and thermal conductivity of the short carbon fiber reinforced magnesium matrix composites[J]. Journal of Alloys and Compounds,2017,695:2820-2826. doi: 10.1016/j.jallcom.2016.11.422 [70] KOHEI K, KIYOKAZU Y. Utrasonic joining of carbon fiber reinforced thermoplastic and magnesium alloy[C]//2018 IEEE CPMT Symposium Japan (ICSJ). Kyoto: IEEE, 2019. -

下载:

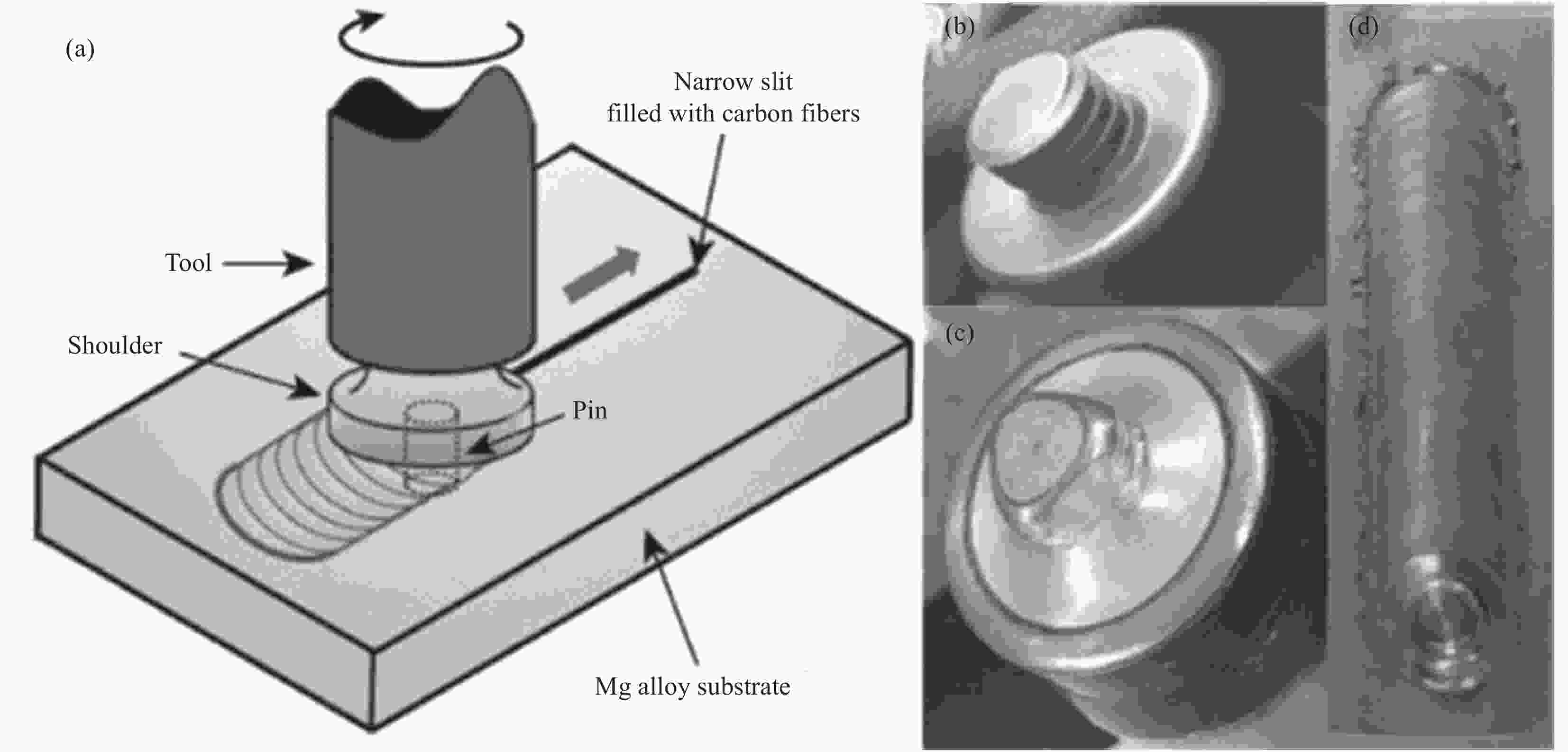

下载: