Simulation of manufacture of the hat-stiffened composite plate based on multidisciplinary coupling

-

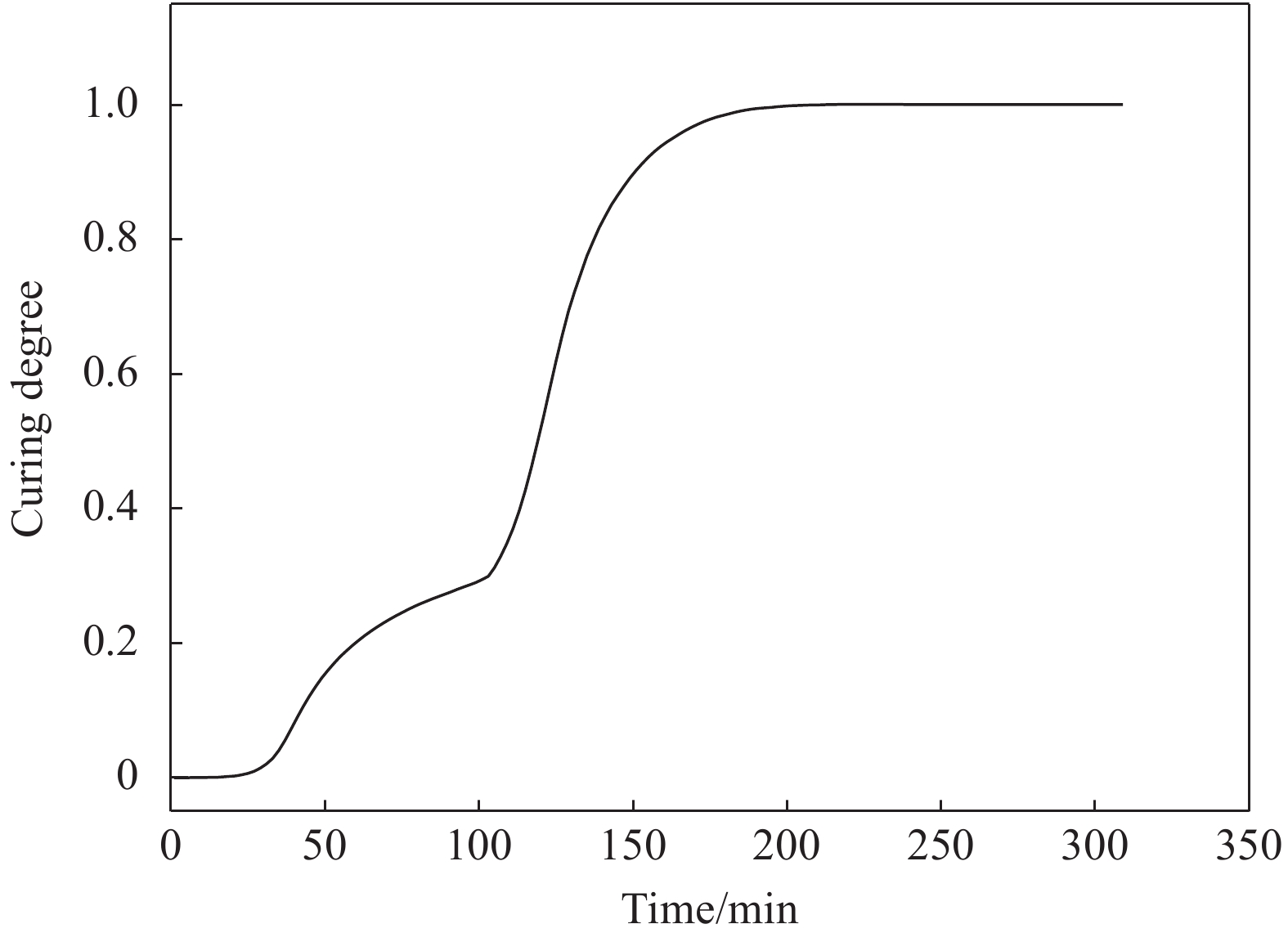

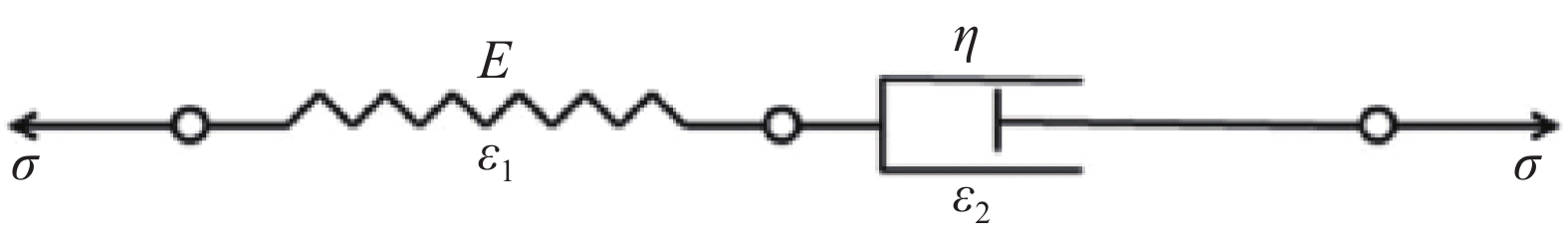

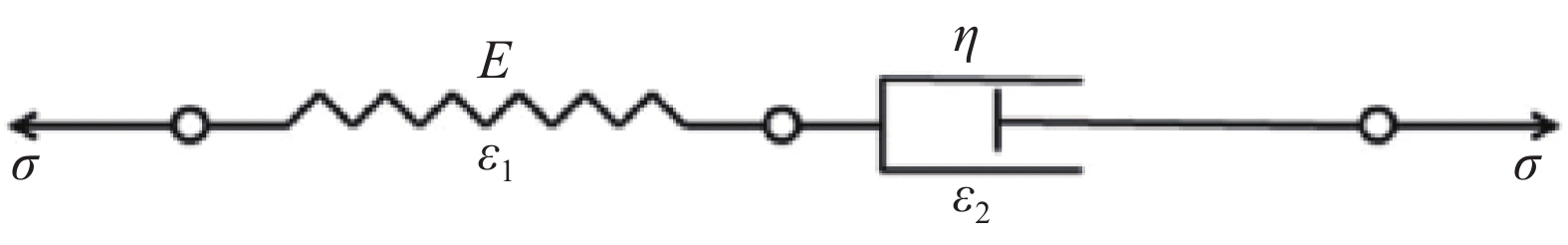

摘要: 民机复合材料帽型壁板自动化制造包含自动铺丝(AFP)和热压罐固化过程,工艺复杂,故有必要对其进行理论研究和建模。分别建立粘弹性力学和多孔渗流耦合模型对铺丝过程进行仿真;建立复合材料热传导、化学交联反应、固化动力学、多孔介质渗流和材料性能时变性耦合模型对固化过程进行仿真。应用所建立的耦合模型对AS4/3051-6系列碳纤维/环氧树脂(CFRP)预浸料热压罐固化制备复合材料平板工艺进行仿真,并将其结果与实验结果对比,验证了此方法的有效性。随后,将此方法应用于大型复合材料帽型壁板制造过程仿真,仿真结果表明:(1) AFP头在经过帽型腔体时存在下陷,下陷量与硅橡胶气囊支撑性能相关,应用本文设计芯模下陷量仿真值为原先的38%,铺丝头对蒙皮的影响面积仿真值为原先的30%;(2) 帽型加筋板内部温度与工艺温度不同,其最高温度出现在保温过程结束后升温阶段初期,预测值为工艺温度的106%,且接合处内外层温度差别明显;(3) 帽型加筋壁板内部黏度随时间先减小后急剧上升,内层黏度较外层黏度变化速率更大;(4) 帽型加筋板蒙皮平均厚度预测值由成型前的4.5 mm减少至4 mm,测量厚度为3.88 mm,仿真误差为3.1%。

-

关键词:

- 多学科耦合 /

- CFRP复合材料帽型加筋板 /

- 过程仿真 /

- 自动化制造 /

- 芯模

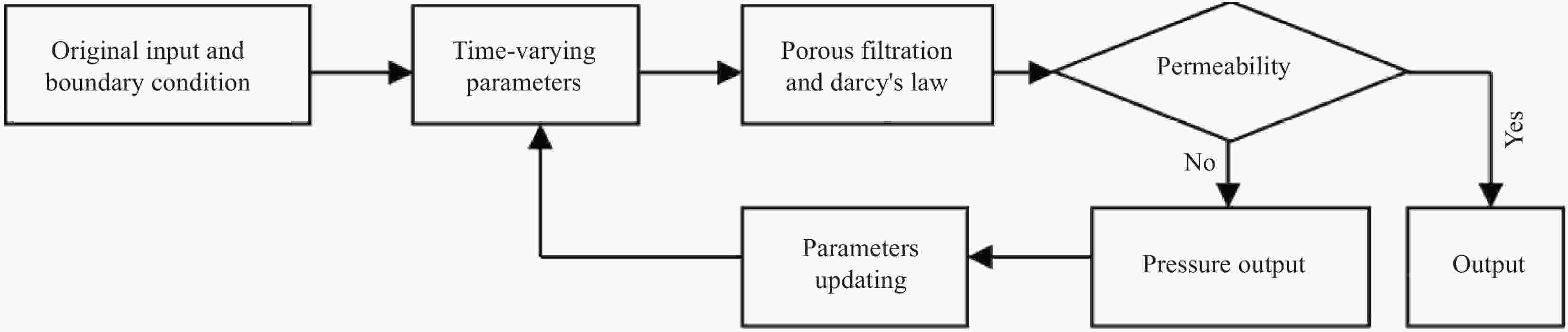

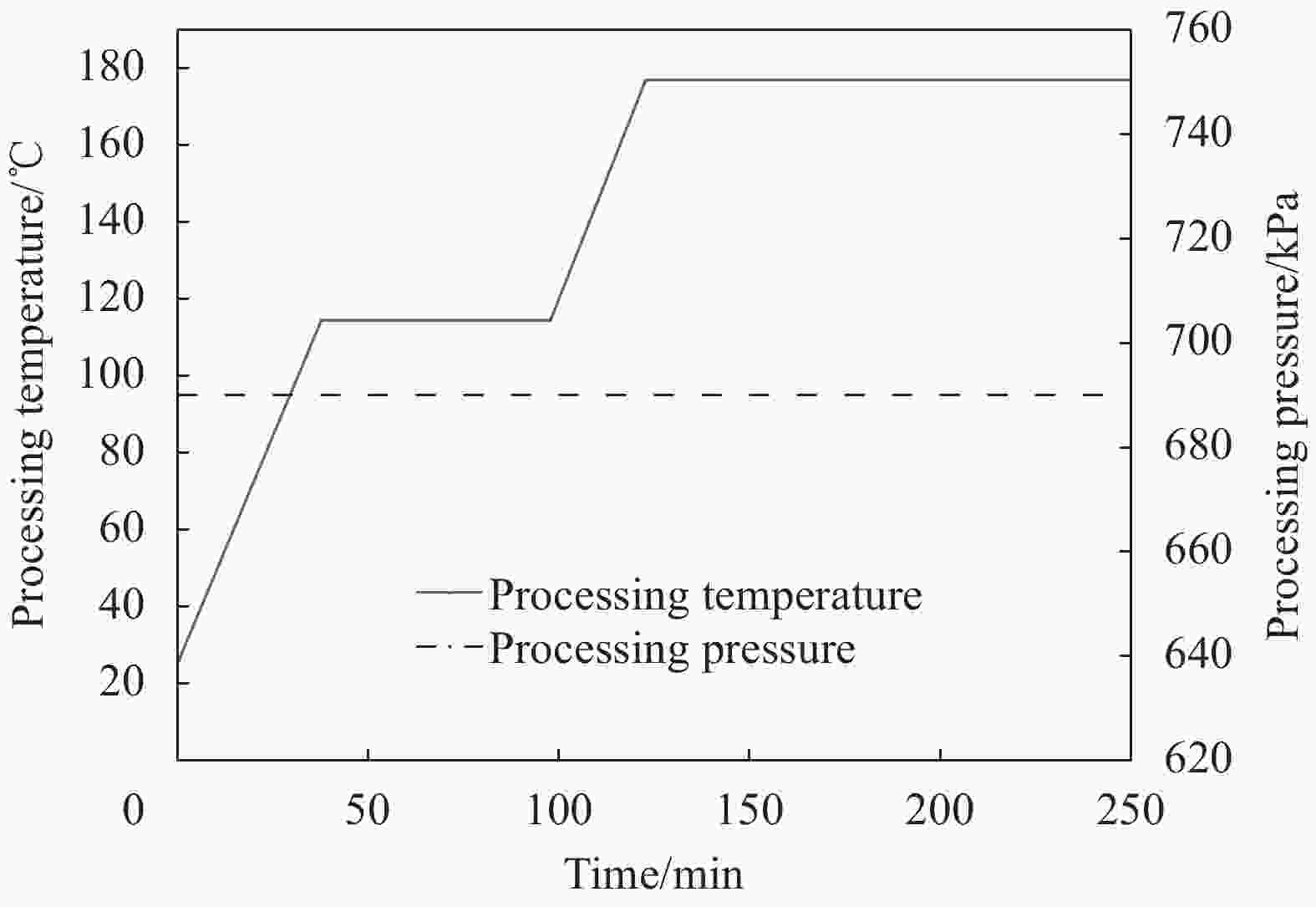

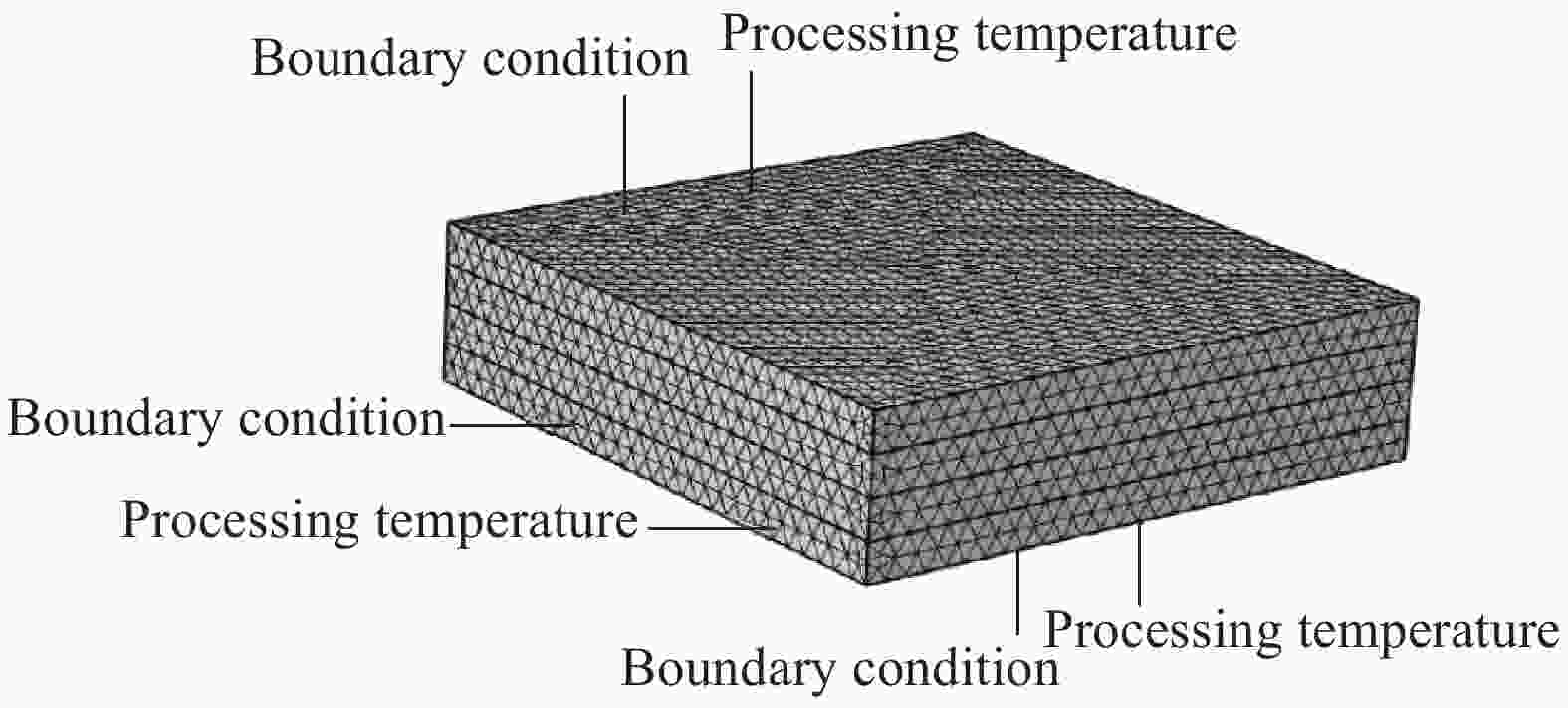

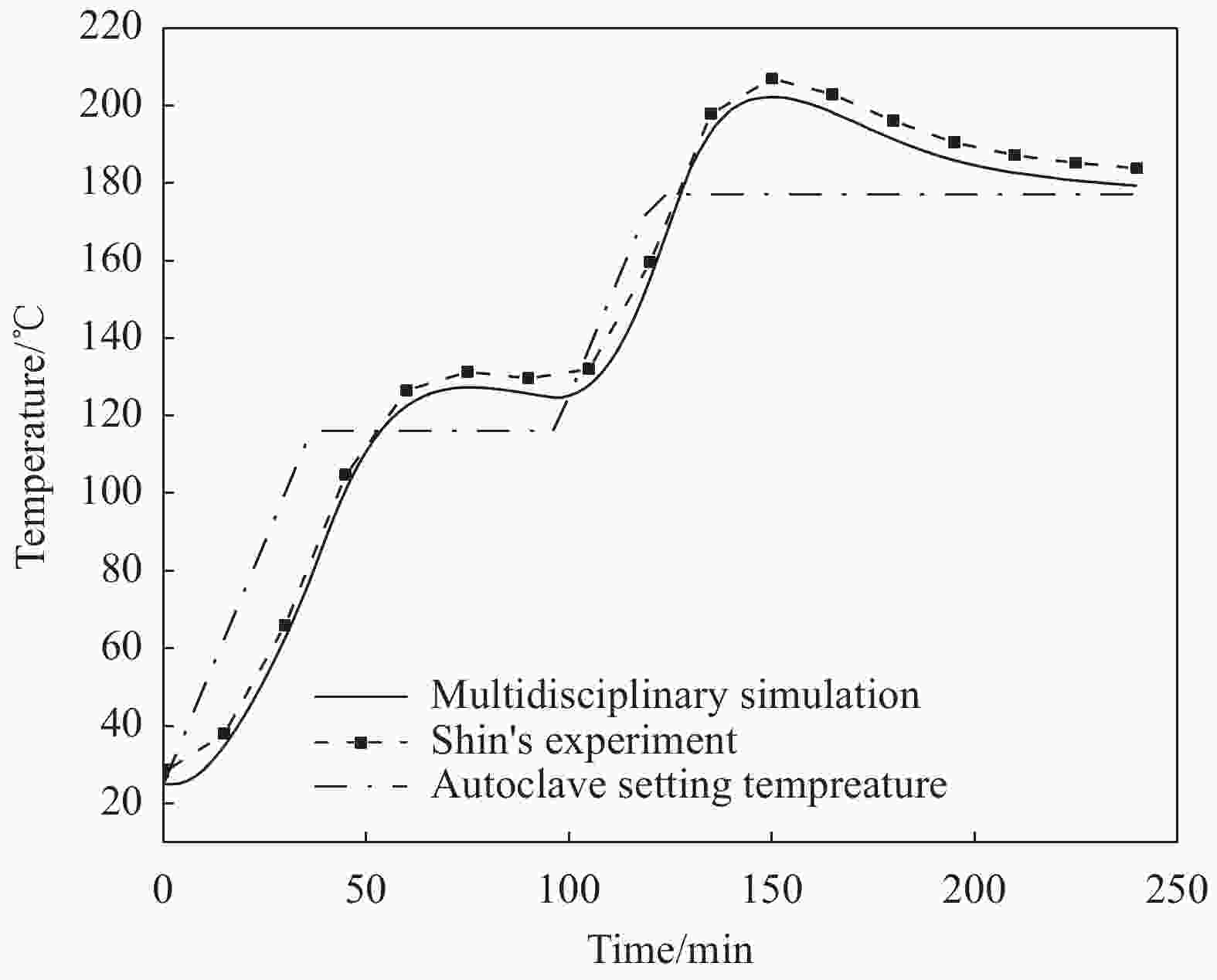

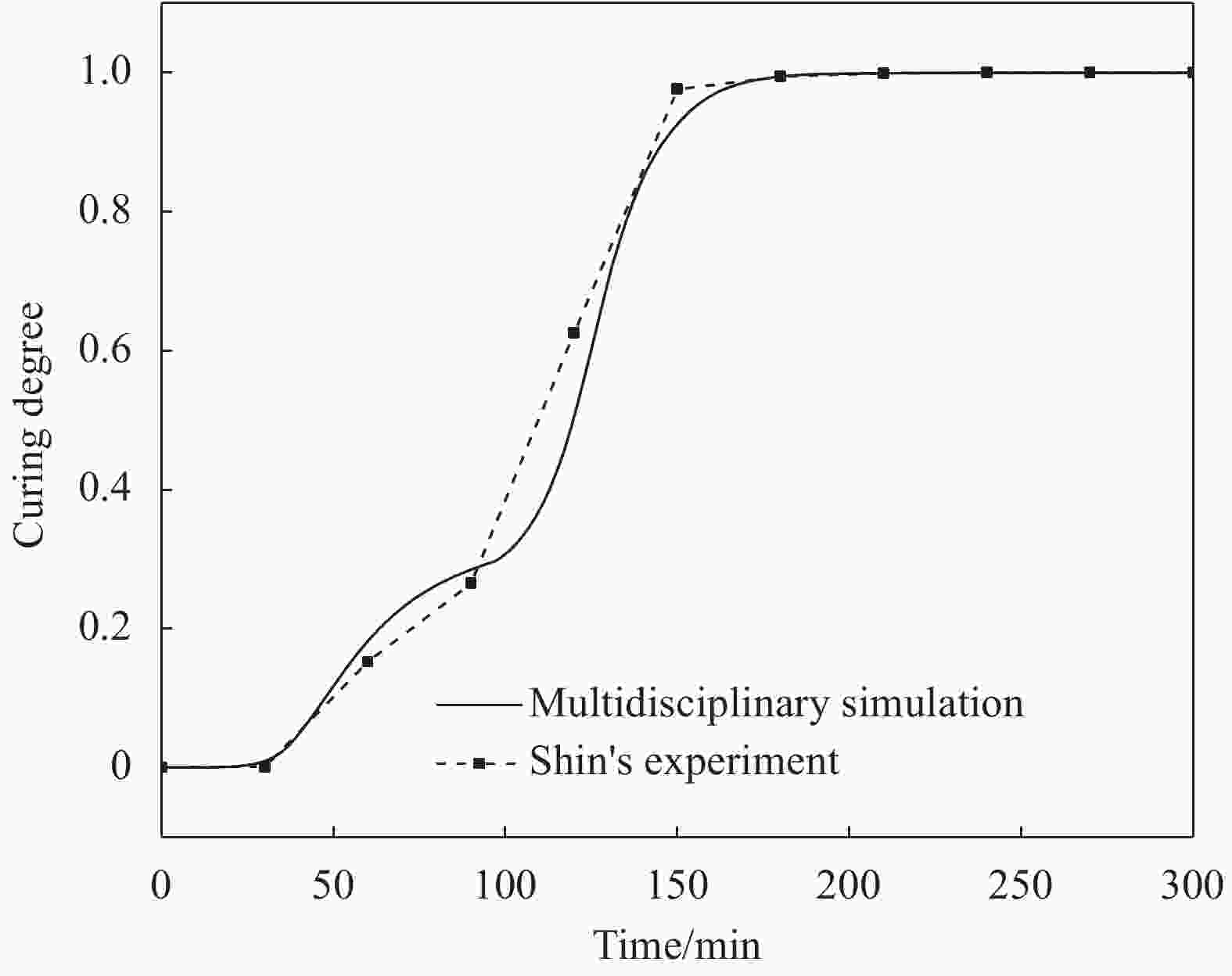

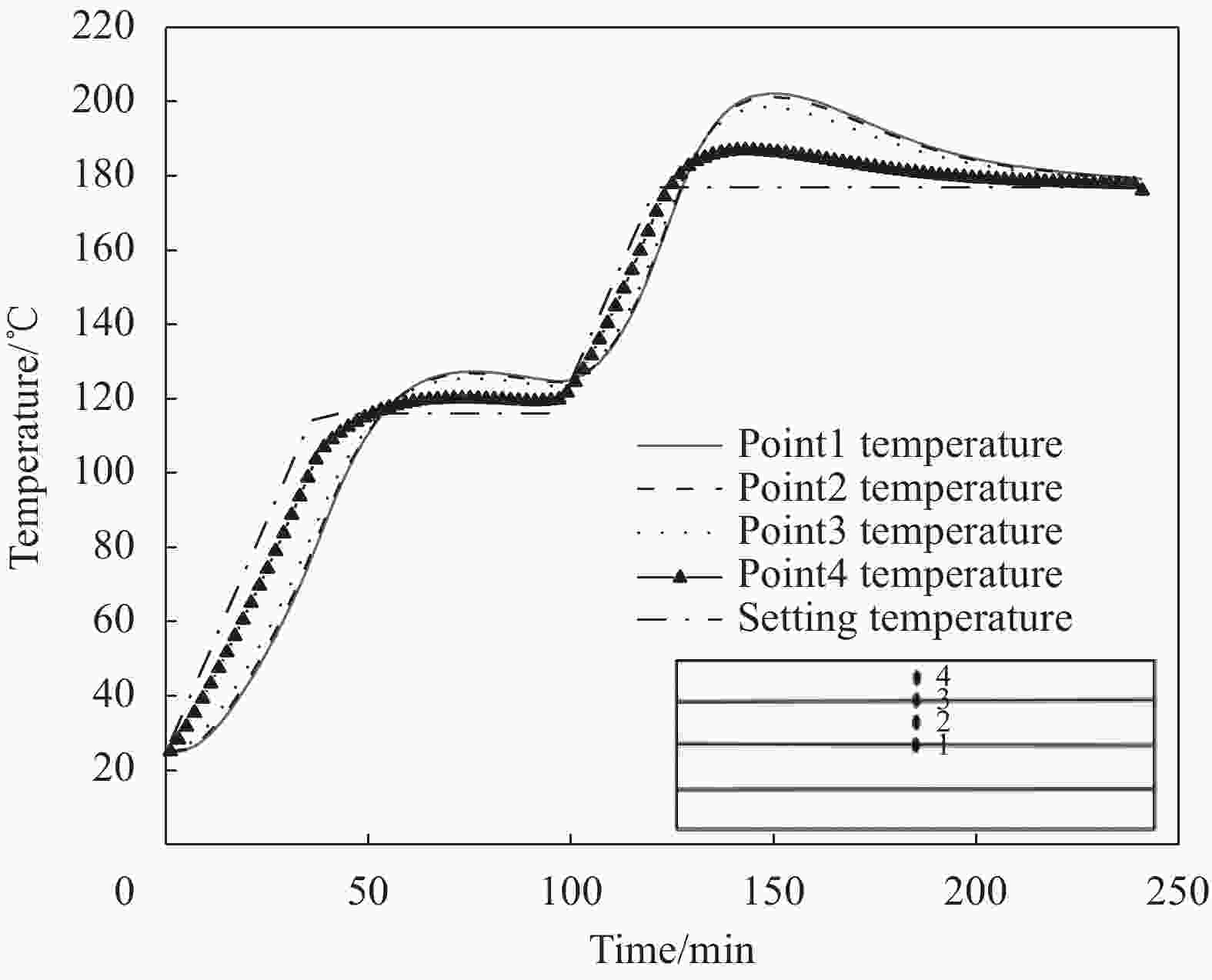

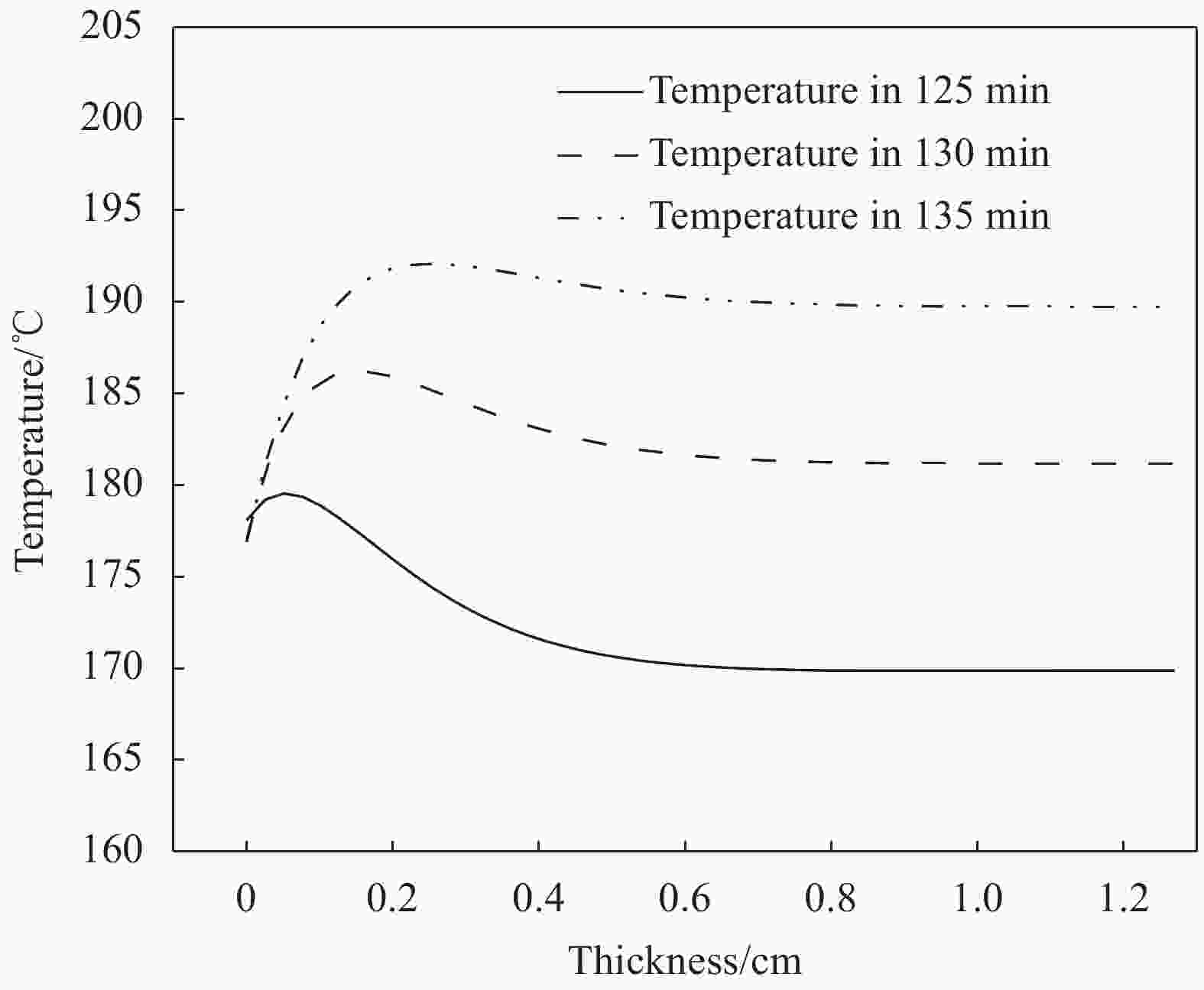

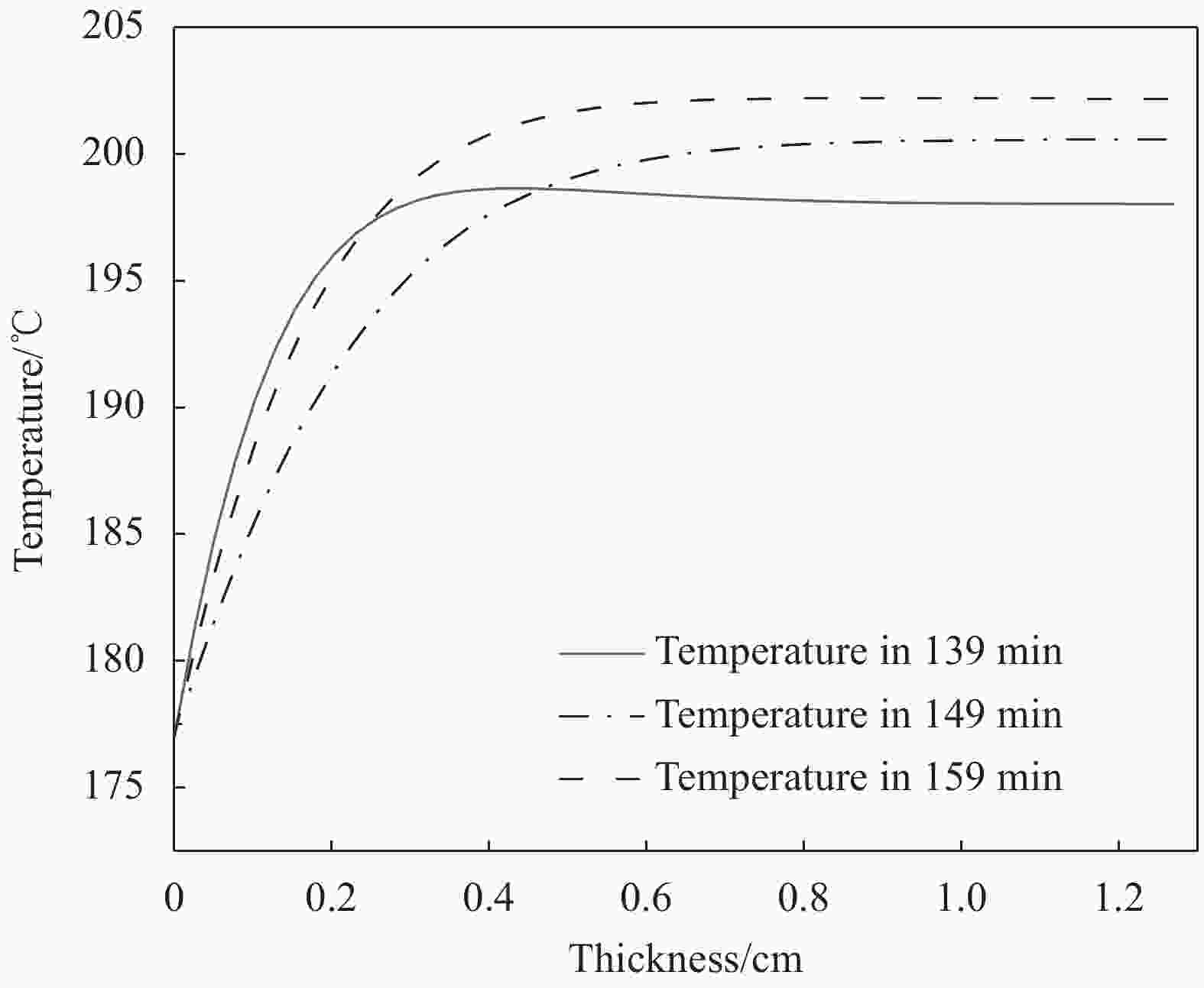

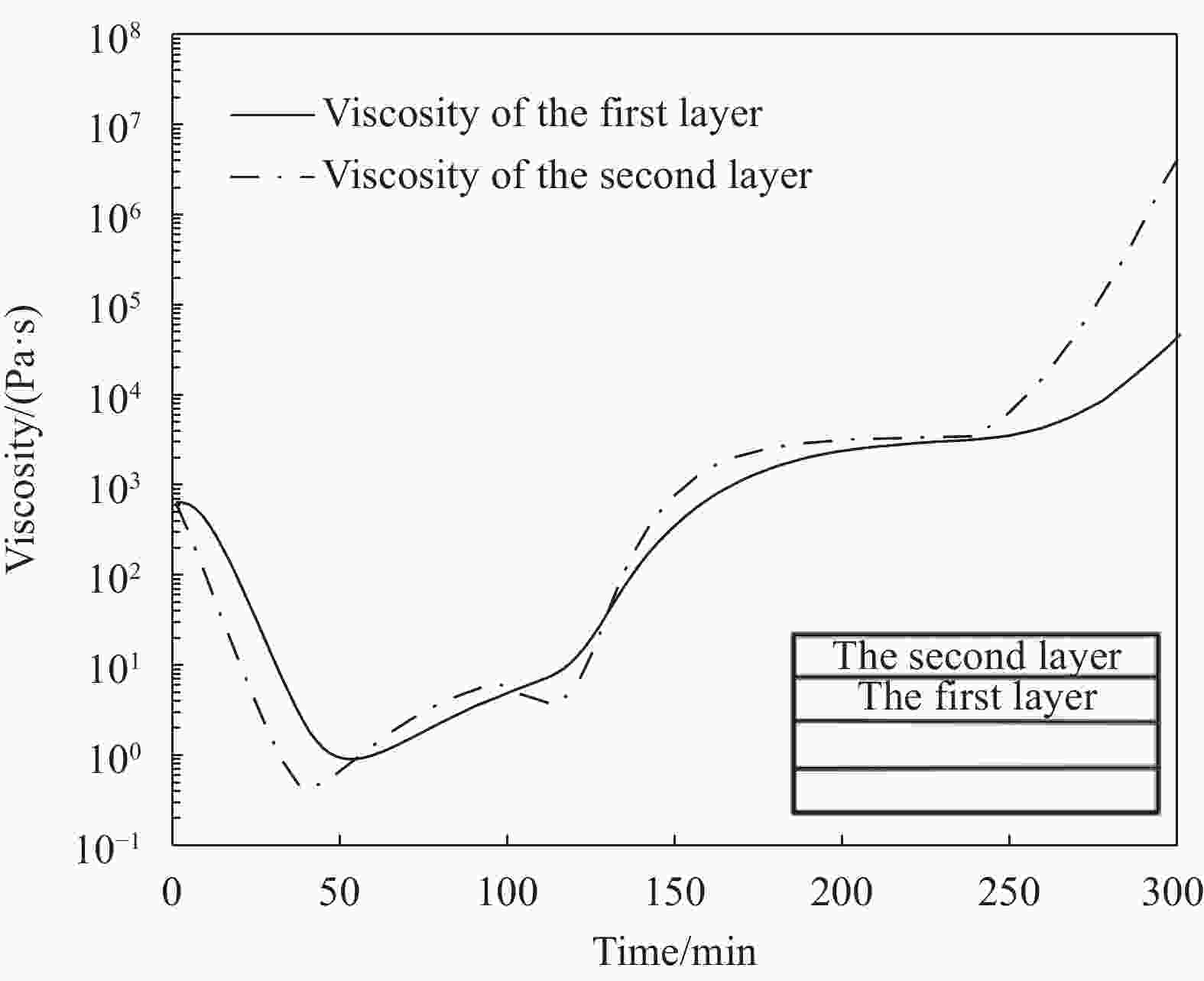

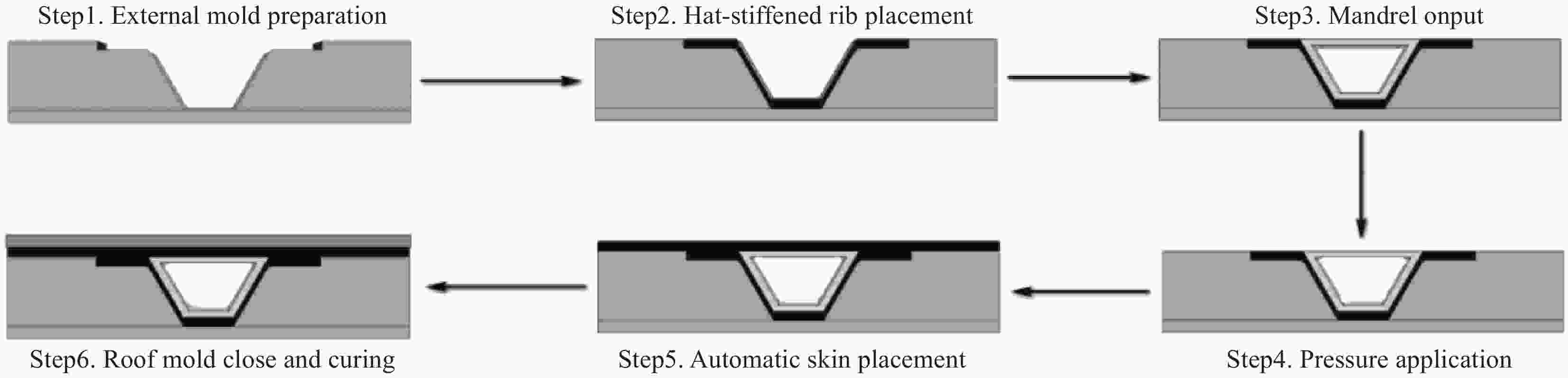

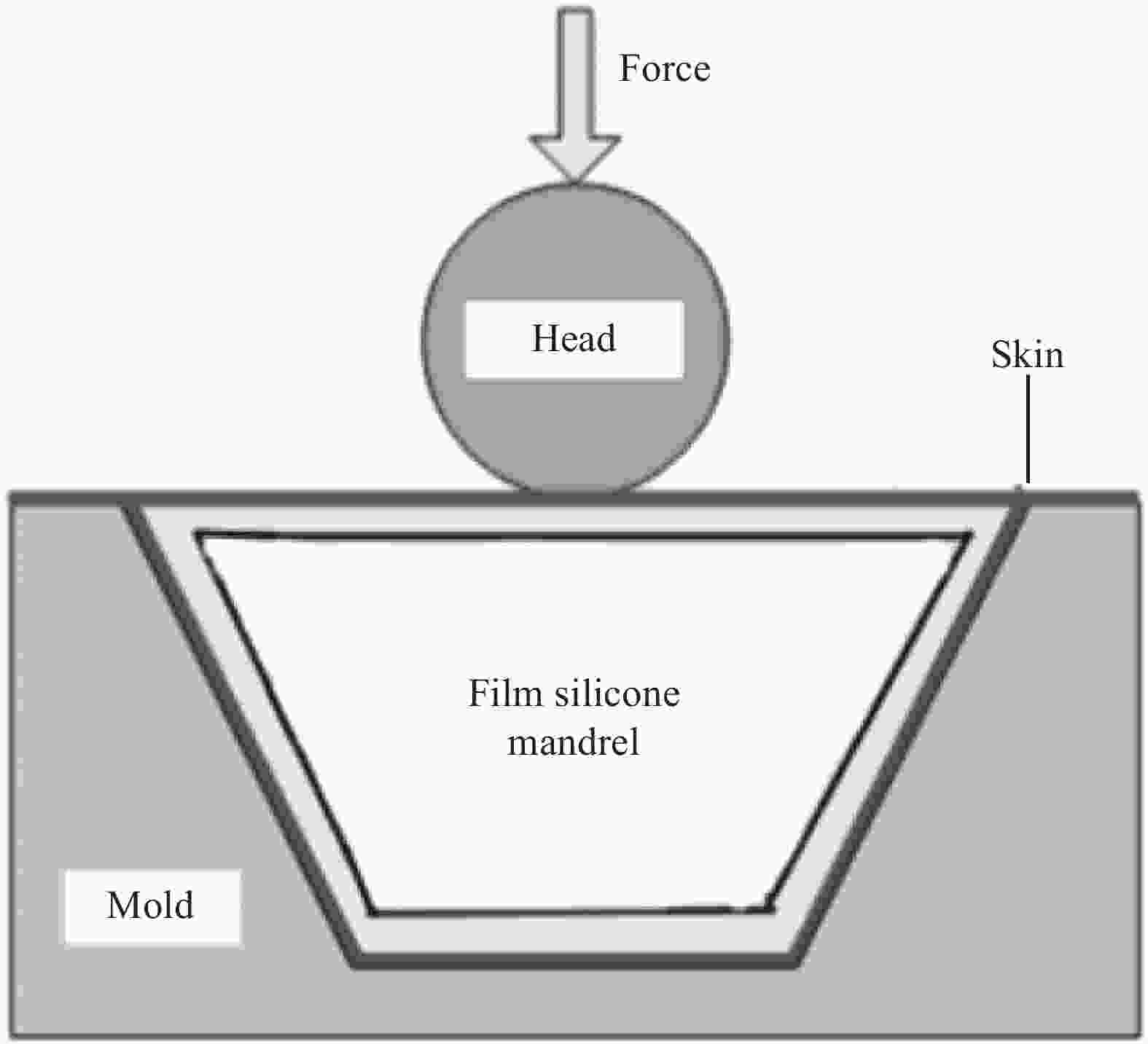

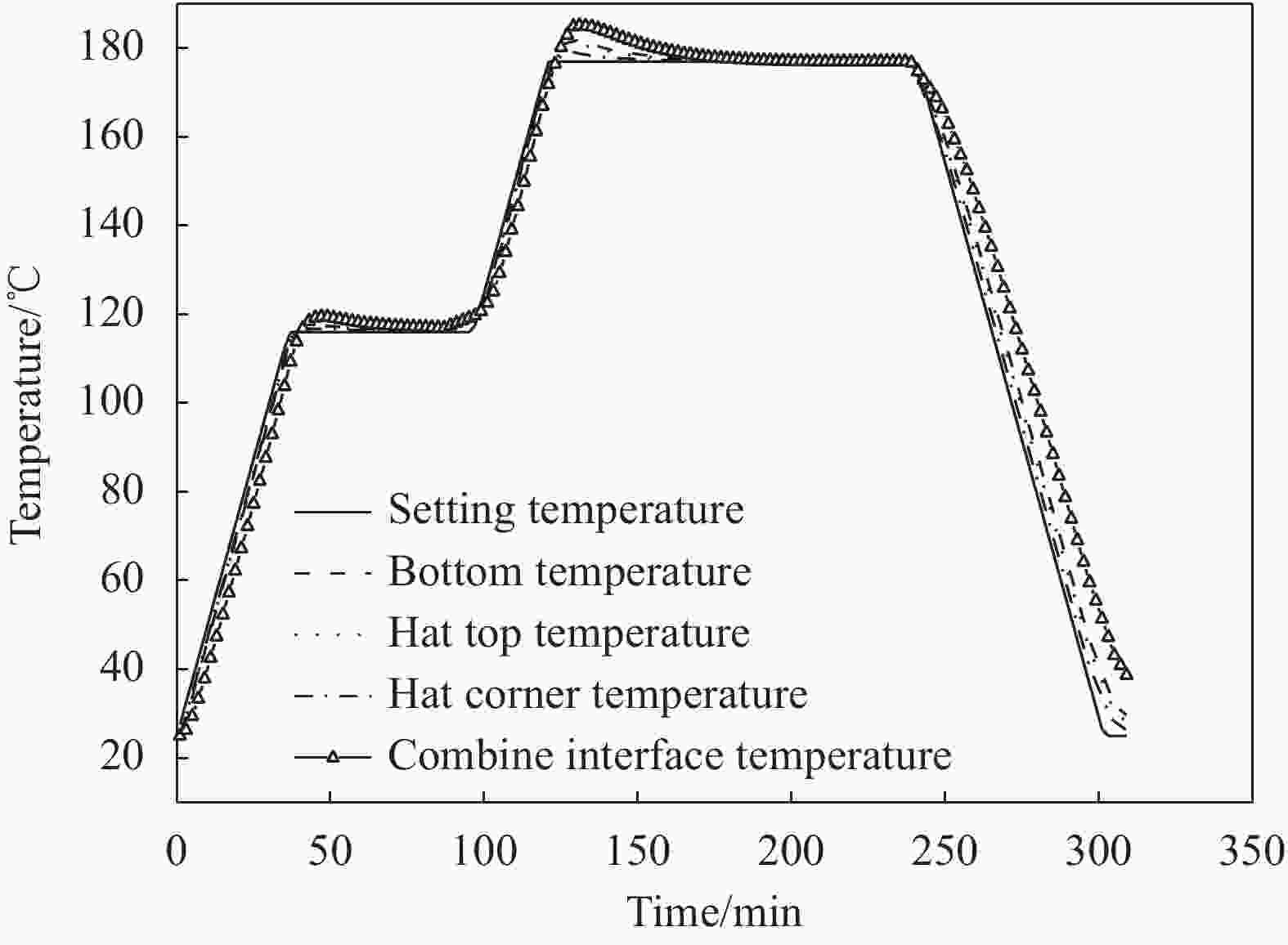

Abstract: The carbon fiber reinforced polymer (CFRP) hat-stiffened plate which is fabricated in wide-bodied airplane is concluded in line with manufacturing crafts of automatic fiber placement (AFP) and autoclave forming that is very complex, so it is necessary to make theoretical research and modeling. Viscoelastic mechanics and percolation model were used to simulate the AFP process, while the composite material heat conduction, curing crosslinking chemical reaction, curing dynamics and porous media percolation model were employed in the simulation of the autoclave process, every multidisciplinary model sharing coupling relationship. On this base, numerical simulation of curing process of manufacturing simple carbon fiber reinforced epoxy resin multilayer under the AS4/3501-6 resin system was carried out. The consequences of simulation were verified when compared with the experimental results. Applying this approach of simulation in CFRP hat-stiffened plate, the results manifest that: (1) The operating head of the AFP equipment can generate a sag whose extend is related to the mandrel’s supporting property, after adding the supporting structure, the simulated sag value and the affecting area value decreases to 38% and 30% compared with the original mandrel; (2) The internal temperature of the hat-stiffened plate is different from the setting process temperature, and the maximum temperature appears in the early heating stage after the end of the insulation process, the predicted value is 106% of the process temperature, and the temperature difference between the inner and outer layers at the joint is obvious; (3) The internal viscosity of the hat-stiffened panels decreases first and then increases sharply, and the change rate of the inner layer viscosity is greater than that of the outer layer; (4) The predicted average skin thickness of the hat-stiffened plate reduces from 4.5 mm before forming to 4 mm, the measured thickness is 3.88 mm, the simulation error is 3.1%. -

表 1 AS4/3501-6碳纤维/环氧树脂复合材料时变性性能

Table 1. Time-dependent property of AS4/3501-6 carbon fiber/epoxy composites

Parameter Linear time-varying description ${\rho _{\rm{r}}}$/(${\rm{kg}} \cdot {{\rm{m}}^{ - 3}}$) ${\rho _{\rm{r} } } = \left\{ \begin{array}{l}90\alpha + 1\;232\quad \alpha \leqslant0.45\\1\;272\qquad \quad \;\;\alpha \geqslant0.45\end{array} \right.$ ${C_{\rm{r}}}$/(${\rm{J}} \cdot {\rm{k}}{{\rm{g}}^{ - 1}} \cdot {{\rm{K}}^{ - 1}}$) ${C_{\rm{r} } } = 4\;184\left( {0.47 + 6 \times { {10}^{ - 4} }T - 0.14\alpha } \right)$ ${C_{\rm{f}}}$/(${\rm{J}} \cdot {\rm{k}}{{\rm{g}}^{ - 1}} \cdot {{\rm{K}}^{ - 1}}$) ${C_{\rm{f} } } = 1\;390 + 4.5T$ ${K_{\rm{r}}}$/(${\rm{W}} \cdot {{\rm{m}}^{ - 1}} \cdot {{\rm{K}}^{ - 1}}$) ${K_{\rm{r}}} = 0.042\left[ {3.85 + \left( {0.035T - 0.14} \right)\alpha } \right]$ ${K_{\rm{f}}}$/(${\rm{W}} \cdot {{\rm{m}}^{ - 1}} \cdot {{\rm{K}}^{ - 1}}$) $K_{\rm{f}}^{\rm{L}} = 0.742 + 9.02 \times {10^{ - 4}}T$ Notes: ${\rho _{\rm{r}}}$—Density of resin; ${C_{\rm{r}}}$ and ${C_{\rm{f}}}$—Specific heat capacity of resin and fibers; ${K_{\rm{r}}}$ and ${K_{\rm{f}}}$—Heat conductivity coefficient of resin and fibers; $\alpha $—Curing degree; T—Internal instantaneous temperature. 表 2 多学科模型及耦合关系

Table 2. Multi-disciplinary model and coupling connections

Disciplinary model Equation Coupling object Mode Output/Input parameter Thermal conduction Fourier heat equation Chemical reaction & Curing kinetic Bi-direction T Chemical reaction Crosslinking equation Thermal conduction & Curing kinetic Bi-direction Q Curing kinetic Partial differential equation Porous filtration & Chemical reaction Bi-direction dα/dt, α Porous filtration Darcy’s law Thermal conduction Uni-direction P, ${V_i}$, h Time-varying behavior Linear equation All models Bi-direction K, C, $\rho $ Viscoelastic mechanics Constitutive equation Filtration in AFP Uni-direction $\sigma $ Notes: AFP—Automatic fiber placement; Q—Chemical reaction heat; P—Tnner forming pressure; Vi—Flow rate during curing process; h—Thickness of the plate or the hat; K—Heat conductivity coefficient; C—Specific heat; ρ—Density of the composite; σ—Stress in AFP. 表 3 CFRP复合材料板多学科性能

Table 3. Multi-disciplinary behavior of CFRP plate

Parameter Value Parameter Value ${A_1}/{\min ^{ - 1}}$ 2.102×109 $\Delta {E_\mu }/\left( {{\rm{J}} \cdot {\rm{mo}}{{\rm{l}}^{ - 1}}} \right)$ 9.43×104 ${A_2}/{\min ^{ - 1}}$ −2.014×109 ${{R/} }\left( { {\rm{J} } \cdot {\rm{mo} }{ {\rm{l} }^{ - 1} } \cdot { {\rm{K} }^{ - 1} } } \right)$ 8.3143 ${A_3}/{\min ^{ - 1}}$ 1.96×105 ${\mu _\infty }/\left( {{\rm{Pa}} \cdot {\rm{s}}} \right)$ 7.93×10−14 $\Delta {E_1}/\left( {{\rm{J}} \cdot {\rm{mo}}{{\rm{l}}^{ - 1}}} \right)$ 8.07×104 ${r_{\rm{f}}}$/m 4×10−6 $\Delta {E_2}/\left( {{\rm{J}} \cdot {\rm{mo}}{{\rm{l}}^{ - 1}}} \right)$ 7.78×104 ${K_{\rm{c}}}$(Parallel to fiber) 0.6 $\Delta {E_3}/\left( {{\rm{J}} \cdot {\rm{mo}}{{\rm{l}}^{ - 1}}} \right)$ 5.66×104 ${K_{\rm{c}}}$(Vertical to fiber) 14.2 Notes: A1, A2, A3—Frequency factors; ∆E1, ∆E2, ∆E3—Activation energy; $\Delta {E_\mu }$—Activation energy of viscous; ${\mu _\infty }$—Constant; R—Universal gas constant; ${r_{\rm{f}}}$—Radius of carbon fiber; ${K_{\rm{c}}}$—Kozeny constant. -

[1] 杜善义, 关志东. 我国大型客机先进复合材料技术应对策略思考[J]. 复合材料学报, 2008, 25(1):1-10. doi: 10.3321/j.issn:1000-3851.2008.01.001DU Shanyi, GUAN Zhidong. Strategy consideration for development of advanced technology for large commercial aircraft in China[J]. Acta Materiae Compositae Sinica,2008,25(1):1-10(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.001 [2] PRUSTY B G. Free vibration and bulking response of hat-stiffened composite plate under general loading[J]. International Journal of Mechanical Science,2008,50(8):1326-1333. doi: 10.1016/j.ijmecsci.2008.03.003 [3] KIM G H, CHOI J H, KWEON J H. Manufacture and performance evaluation of the composite hat-stiffened plate[J]. Composite Structures,2010,92(9):2276-2284. doi: 10.1016/j.compstruct.2009.07.019 [4] 姜茂川, 赵龙, 刘强, 等. VARI液体成型工艺制备复合材料帽型泡沫夹心构件的工艺模拟及验证[J]. 复合材料学报, 2013(S1):266-272.JIANG Maochuan, ZHAO Long, LIU Qiang, et al. Process simulation of composite cap sharped foam core sandwich structure by VAIR process[J]. Acta Materiae Compositae Sinica,2013(S1):266-272(in Chinese). [5] LI Shujian, PU Yongwei. Effect of mandrel structures on co-curing quality for polymer composite hat stiffened structures[J]. Fiber and Polymers,2015,16(9):1898-1907. doi: 10.1007/s12221-015-5051-1 [6] 蒲永伟, 湛利华. 复合材料帽型结构热压共固化成型质量研究[J]. 航空材料学报, 2015, 35(5):75-81.PU Yongwei, ZHAN Lihua, et al. Research on quality of autoclave co-curing manufacture of composite hat stiffened structure[J]. Journal of Aeronautical Materials,2015,35(5):75-81(in Chinese). [7] 马成, 赵聪, 王显峰. 气囊硬度对固化后帽型长桁厚度的影响[J]. 航空学报, 2018, 35(6):162-170.MA Cheng, ZHAO Cong, WANG Xianfeng. Effect of thickness of stringer with the hardness of airbag[J]. Acta Aeronautica et Astronautica Sinica,2018,35(6):162-170(in Chinese). [8] LOOS A C, SPRINGER G S. Curing of epoxy matrix compo-site[J]. Journal of Composite Materials,1983,17(2):135-169. doi: 10.1177/002199838301700204 [9] 唐占文, 张博明. 复合材料设计制造一体化技术中的固化变形预测技术[J]. 航空制造技术, 2014(15):32-37. doi: 10.3969/j.issn.1671-833X.2014.15.003TANG Zhanwen, ZHANG Boming. The prediction technique of curing deformation in manufacture-design integration of composite material[J]. Aeronautical Manufacturing Technology,2014(15):32-37(in Chinese). doi: 10.3969/j.issn.1671-833X.2014.15.003 [10] COSTA V A F, SOUSA A C M. Modeling of flow thermo-kinetics during the cure of thick laminated composites[J]. International Journal of Thermal Sciences,2003,42(1):15-22. doi: 10.1016/S1290-0729(02)00003-0 [11] LI J, YAO X, LIU Y., et al. A study of integrated composite material structure under different fabrication processing[J]. Composite Part A: Applied Science and Manufacturing,2009,40(4):455-462. doi: 10.1016/j.compositesa.2008.10.022 [12] WANG C, YUE G, BAI G, et al. Compaction behavior and permeability property tests of preforms in vacuum-assisted resin transfer molding using a combined device[J]. Measurement,2016,90:357-364. doi: 10.1016/j.measurement.2016.04.058 [13] SIMACEK P, SINHA S, et al. A process model for the compaction and saturation of partially impregnated thermoset prepreg tapes[J]. Composites Part A: Applied Science and Manufacturing,2014,64(21):234-244. [14] 刘勇, 吴颂平. 热压工艺热-化学-应力三维数值模型及有限元分析[J]. 复合材料学报, 2009, 26(1):134-139. doi: 10.3321/j.issn:1000-3851.2009.01.023LIU Yong, WU Songpin. Three dimensional thermol-chemical-stress numerical model and finite element analysis for hot pressing process[J]. Acta Materiae Compositae Sinica,2009,26(1):134-139(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.01.023 [15] KIM Y K, WHITE S R. Process-induced stress relation analysis of AS4/3501-6 laminate[J]. Journal of Reinforced Plastics and Composites,1997,16(1):2-16. doi: 10.1177/073168449701600102 [16] DANIEL D, SHIN H, THOMAS H. Compaction of thick composites: Simulation and experiment[J]. Polymer Compo-sites,2004,25(1):49-59. doi: 10.1002/pc.20004 [17] KIM Y K, SCOTT R W. Viscoelastic analysis of processing-induced residual stresses in thick composite laminates[J]. Mechanics of Advanced Materials and Structures,1997,4(4):361-387. doi: 10.1080/10759419708945889 [18] 元振毅, 王永军, 王俊彪. 基于材料性能时变性的复合材料固化过程多场耦合数值模拟[J]. 复合材料学报, 2015, 32(1):167-175.YUAN Zhenyi, WANG Yongjun, WANG Junbiao. Multi-field coupled numerical simulation for curing process of composite with time-depended properties of materials[J]. Acta Materiae Compositae Sinica,2015,32(1):167-175(in Chinese). [19] ZOCHER M A, GROVES S E, ALLEN D H. A three-dimensional finite element formulation for thermoviscoelastic orthotropic media[J]. International Journal for Numerical Methods in Engineering,1997,40(12):2267-2288. doi: 10.1002/(SICI)1097-0207(19970630)40:12<2267::AID-NME156>3.0.CO;2-P [20] 谢福原, 王雪明, 李敏, 等. T形加筋板热压罐成型过程压力分布与树脂流动实验研究[J]. 复合材料学报, 2009, 26(6):66-71.XIE F Y, WANG X M, LI M, et al. Experimental research on pressure distribution and resin flow of T-stiffened skins in autoclave process[J]. Acta Materiae Compositae Sinica,2009,26(6):66-71(in Chinese). [21] GUTOWSKI T G, DILLON G. The elastic deformation of lubricated carbon fiber bundles: Comparison of theory and experiments[J]. Journal of Composite Materials,1992,26(16):2330-2347. doi: 10.1177/002199839202601601 [22] 胡汉平. 热传导理论[M].北京: 中国科学技术大学出版社, 2010.HU Hanping. Heat transport theory[M]. Beijing: University of Science and Technology of China Press, 2010(in Chinese). [23] TWARDOWSKI T E, LIN S E, GEIL P H. Curing in thick composite laminates: Experiments and simulation[J]. Journal of Composite Materials,1993,27(3):216-250. doi: 10.1177/002199839302700301 [24] WALCZYK D, KUPPERS J. Thermal press curing of advanced thermoset composite laminate parts[J]. Compo-sites Part A: Applied Science and Manufacturing,2012,43(4):635-646. doi: 10.1016/j.compositesa.2011.12.008 [25] GOURICHON B, BINETRUY C, KRAWCZAK P. A new numerical procedure to predict dynamic void content in liquid composite molding[J]. Composites Part A: Applied Science and Manufacturing,2006,37(11):1961-1969. doi: 10.1016/j.compositesa.2005.12.017 [26] SPRINGER G S, TSAI S W. Thermal conductivities of unidirectional materials[J]. Journal of Composite Materials,1979,1(2):166-173. [27] 史明. 航空复合材料帽型加筋板热压罐成型芯模及包含此芯模的热压罐成型全套模具: 中国, CN111572058A[P]. 2020-08-25.SHI Ming. The autoclave curing mandrel and the whole set of the mold including the mandrel using to manufacture the composite hat-stiffened plate that use in aeronautics, China, CN111572058A[P]. 2020-08-25(in Chinese). -

下载:

下载: