| [1] |

SPENDLEY P R. Design allowables for composite aerospace structures[D]. Guildford: University of Surrey, 2012.

|

| [2] |

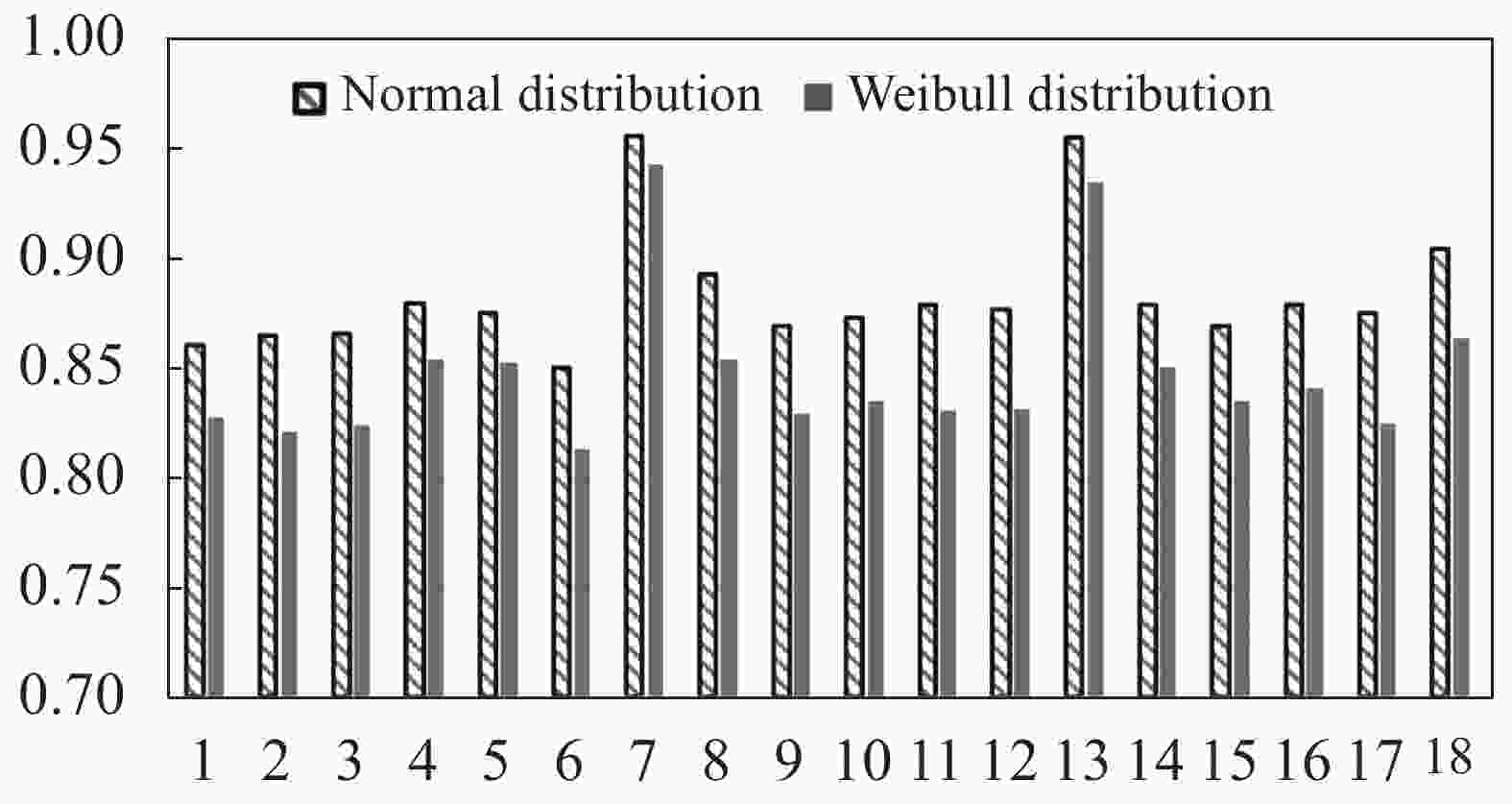

YURVIANY, TAMAZA D, WIDAGDO D, et al. Statistical analysis of CFRP mechanical properties using B-basis based on weibull and ANOVA distribution analysis[J]. IOP Conference Series: Materials Science and Engineering,2020,852(1):012078.

|

| [3] |

HAN X L. Normalized B-basis of the space of trigonometric polynomials and curve design[J]. Applied Mathematics & Computation,2015,251:336-348.

|

| [4] |

EKVALL J C, GRIFFIN C F. Design allowables for T300/5208 graphite/epoxy composite materials[J]. Journal of Aircraft, 1982, 19(8): 661-667.

|

| [5] |

王思雍. T800级碳纤维/环氧树脂复合材料性能测试与B基准值计算研究[D]. 哈尔滨: 哈尔滨工业大学, 2020.WANG Siyong. Study on mechanical properties and B-basis calculation of T800 carbon fiber reinforced epoxy resin composites[D]. Harbin: Harbin Institute of Technology, 2020(in Chinese).

|

| [6] |

郝新超. 基于Anderson-Darling检验的复合材料厚板层间拉伸强度性能研究及B基准值[J]. 材料导报, 2020, 34(S1):480-485.HAO Xinchao. Interlaminar tensile strength behavior and B-basis value of thick laminates based on anderson-darling test[J]. Material Guide,2020,34(S1):480-485(in Chinese).

|

| [7] |

赵晖, 张立同, 张家鑫. 基于小样本物理测试的复合材料B基准许用值分析计算[J]. 玻璃钢/复合材料, 2019(4):62-66, 74.ZHAO Hui, ZHANG Litong, ZHANG Jiaxin. Composite material B-basis allowable simulation based on small sample physical tests[J]. FRP/Composite Materials,2019(4):62-66, 74(in Chinese).

|

| [8] |

BARBERO E, FERNÁNDEZ-SÁEZ J, NAVARRO C. Statistical analysis of the mechanical properties of composite materials[J]. Composites Part B: Engineering, 2000, 31(5): 375-381.

|

| [9] |

ELIZABETH C. Hexcel 8552 IM7 unidirectional prepreg 190 gsm & 35% RC qualification statistical analysis report[R]. USA: WichitaState University, National Institute for Aviation Research, 2012: 1-104.

|

| [10] |

ABUMERI G, HOUSNER J, GARG M, et al. Determination of composites A-and B-basis allowables with reduced testing[C]//The Society for the Advancement of Material and Process Engineering. California: 2011.

|

| [11] |

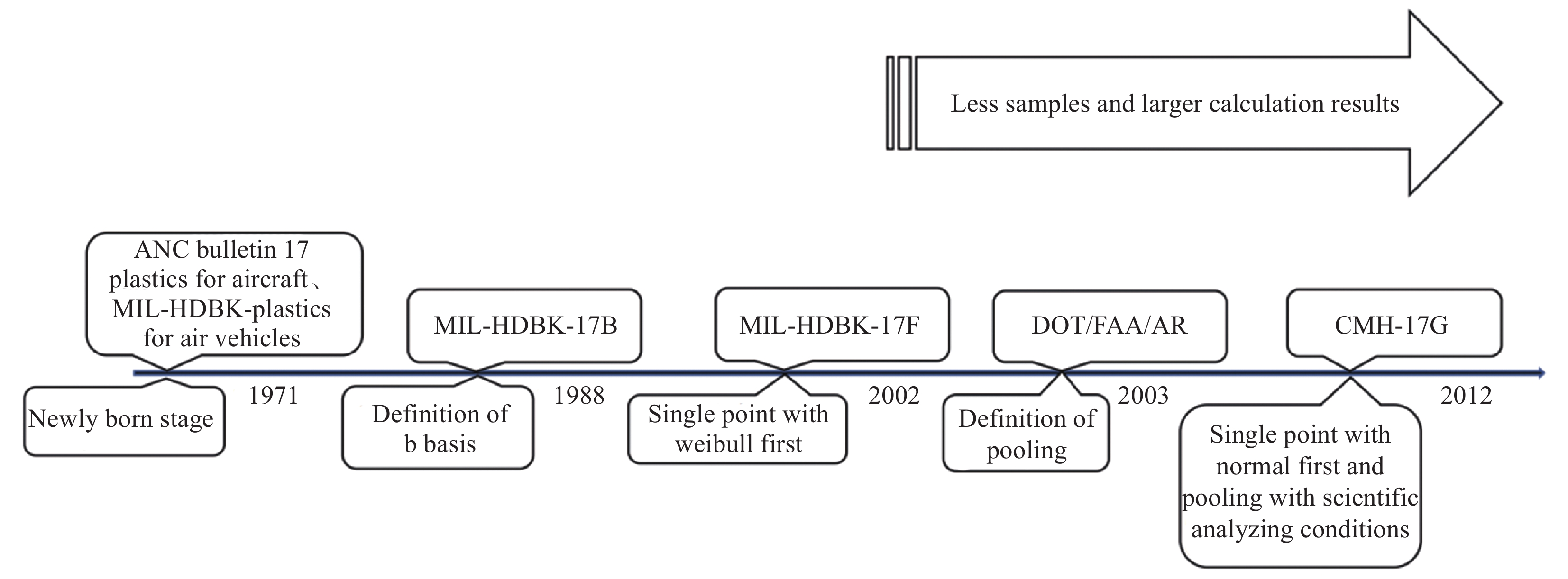

Federal Aviation Administration. Composite materials handbook-Volume 1. Polymer matrix composites: Guidelines for characterization of structural materials: MIL-HDBK-17-1F[S]. Washington: Federal Aviation Administration, 2002.

|

| [12] |

TOMBLIN J S, NG Y C, RAJU K S. Material qualification and equivalency for polymer matrix composite material systems: Updated procedure: DOT/FAA/AR-03/19[R]. Washington: Federal Aviation Administration, 2003.

|

| [13] |

沈薇, 杨胜春, 沈真. 复合材料力学性能表征标准化研究新进展[J]. 航空制造技术, 2009(S1):25-27, 29.SHEN Wei, YANG Shengchun, SHEN Zhen. New progress in standardization of mechanical properties characterization of composite materials[J]. Aviation Manufacturing Technology,2009(S1):25-27, 29(in Chinese).

|

| [14] |

Society of Automotive Engineers International. Composite materials handbook-Volume 1: Polymer matrix compo-sites: Guidelines for characterization of structural materials: CMH-17G[S]. Warrendale: SAE International, 2012.

|

| [15] |

孙坚石, 叶强. 复合材料力学性能数据B基准值计算程序[J]. 航空制造技术, 2009(S1):19-21, 24.SUN Jianshi, YE Qiang. Aeronautical manufacturing technology composite material mechanical performance data B benchmark value calculation program[J]. Aviation Manufacturing Technology,2009(S1):19-21, 24(in Chinese).

|

| [16] |

WHITEHEAD R S, KAN H P, CORDERO R, et al. Certification testing methodology for composite structure[R]. Atlanta, 1986.

|

| [17] |

ZHANG Y, KIM N H, PALLIYAGURU U R, et al. Reduced allowable strength of composite laminate for unknown distribution due to limited tests[J]. Journal of Composite Materials,2020,54(21):0021998320903781.

|

| [18] |

ZHANG Y, SCHUTTE J, MEEKER J, et al. Predicting B-basis allowable at untested points from experiments and simulations of plates with holes[C]//12th World Congress on Structural and Multidisciplinary Optimization, Braunschweig, 2017.

|

| [19] |

王艺. 航空材料性能设计许用值统计分析与软件开发[D]. 沈阳: 东北大学, 2012.WANG Yi. Statistical analysis and software development of the allowable value for the performance design of aviation materials[D]. Shenyang: Northeastern University, 2012(in Chinese).

|

| [20] |

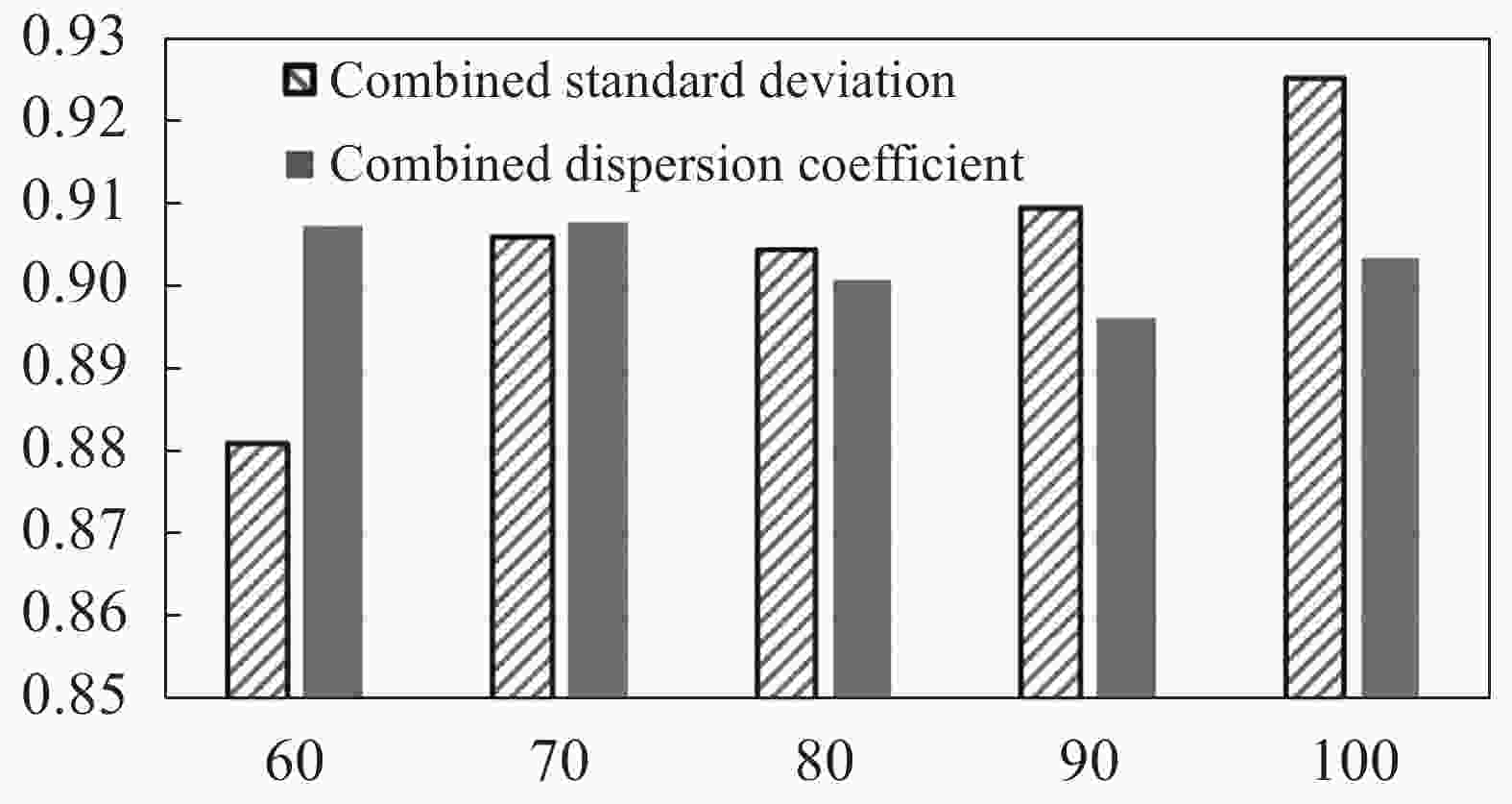

王翔, 陈新文, 王海鹏, 等. 基于统计的复合材料B基准值计算方法研究[J]. 失效分析与预防, 2010, 5(4):210-215. doi: 10.3969/j.issn.1673-6214.2010.04.004WANG Xiang, CHEN Xinwen, WANG Haipeng, et al. Statistic-based calculation methods B-basis value of composites[J]. Failure Analysis and Prevention,2010,5(4):210-215(in Chinese). doi: 10.3969/j.issn.1673-6214.2010.04.004

|

| [21] |

冯振宇, 刘星星, 魏书有, 等. 复合材料B基准值统计方法的对比分析[J]. 材料导报, 2012, 26(S2):147-149.FENG Zhenyu, LIU Xingxing, WEI Shuyou, et al. The comparision of statistical analysis methods on composite B basis value[J]. Materials Review,2012,26(S2):147-149(in Chinese).

|

下载:

下载: