Design and modification progress of binders for silicon-based anodes of lithium-ion batteries

-

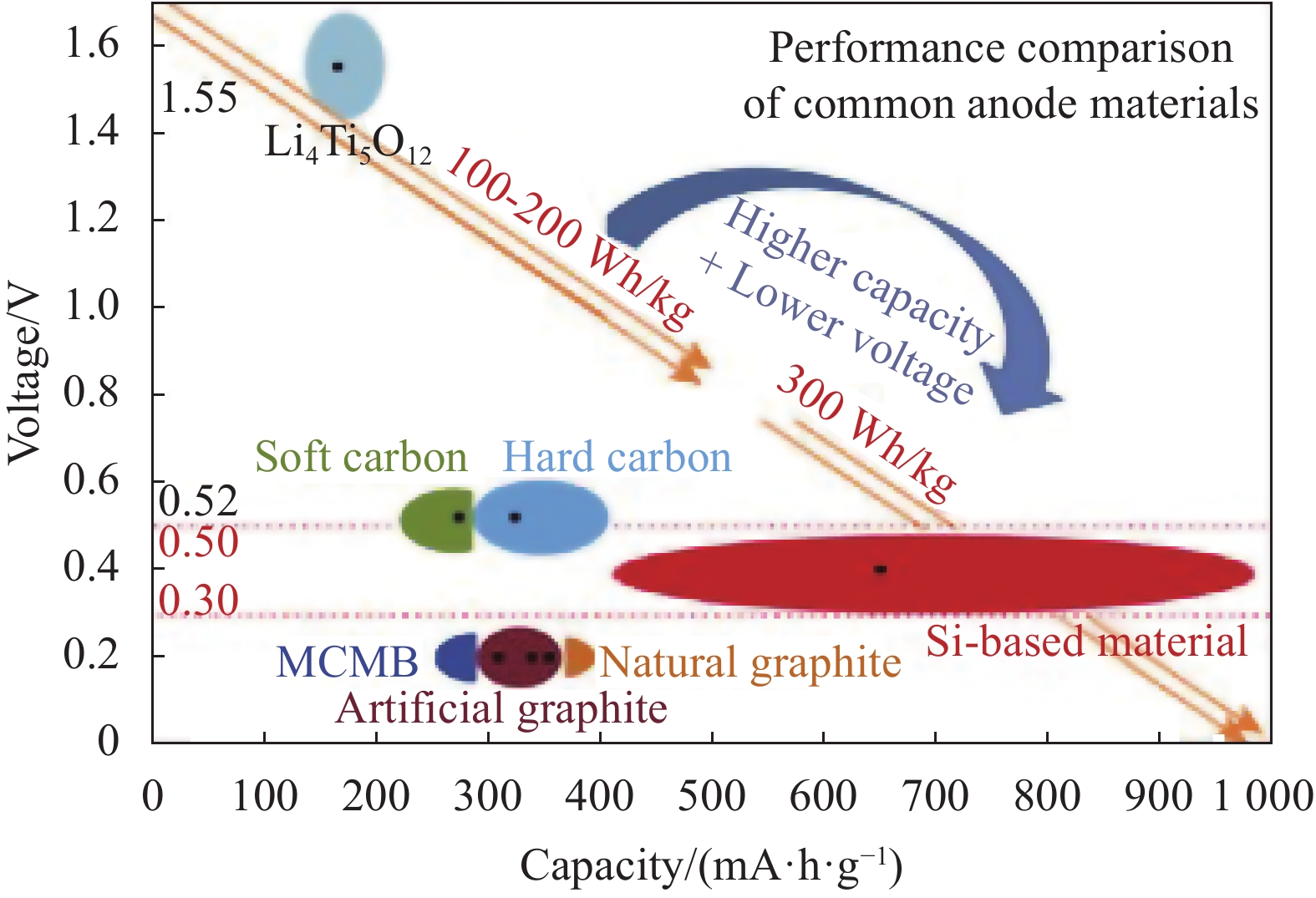

摘要: 发展锂离子电池是缓解当前能源和环境问题的有力措施,但其能量密度已无法满足未来储能装置的高要求。发展高比能量型锂离子电池必须从提高电极材料的性能入手。硅基材料具有容量高、成本低、平台电压低等优点,被认为是最具潜力的负极材料。然而,该类材料在充放电过程中会发生巨大的体积变化(300%),导致电池容量下降严重甚至失效。近年来,研究者们开始着眼于通过对电极中的粘结剂进行结构设计和复合改性来提升硅基负极的性能,并取得了显著的效果。基于硅基负极目前存在的问题,总结了适用于硅基负极的粘结剂类型,并从粘结剂分子链结构设计和增强电极微粒间作用力这两个方面综述了近年来硅基负极中粘结剂的设计改性进展,最终展望了硅基负极用粘结剂的发展趋势和未来前景。Abstract: Developing lithium-ion batteries (LIBs) is a powerful measure to alleviate current energy and environmental problems, but their energy density can no longer meet the high requirements of future energy storage devices. The development of LIBs with high energy density must start from improving the performance of electrode materials. Silicon-based materials have the advantages of high capacity, low cost, and low platform voltage, and are considered to be the most promising anode materials. However, this type of material would undergo a huge volume change (300%) during charging and discharging processes, resulting in serious capacity decline or even failure. In recent years, researchers have begun to focus on improving the performance of silicon-based anodes through structural design and composite modification of the binder in the electrode, and significant results have been achieved. In this paper, the existing problems of silicon-based anodes were briefly introduced, and the types of the binders suitable for silicon-based anodes were summarized. The progress in the design and modification of the binders in silicon-based anodes in recent years was reviewed from the aspects of molecular chain structure design of the binders and enhancement of inter particle force in the electrode. Finally, the development trend and future prospect of the binders for silicon-based anodes were prospected.

-

Key words:

- batteries /

- anodes /

- silicon /

- lithium ions /

- binders /

- energy /

- environmental

-

图 2 <100>、<110>、<111>方向的膨胀和裂纹行为的统计分析和无定形硅纳米管阵列嵌锂后形态[16]

Figure 2. Statistical analysis on the expansion and fracture behavior of the <100>, <110>, <111>, and amorphous silicon nanotubes after full lithiation[16]((a) Schematics of the cross-sectional shape and fracture angles of nanotubes; (b) Variations of wall thickness; (c) Cross-sectional area and hollow area; (d) Height; (e) Volume of Si nanotubes)

图 3 <100> (a)、<110> (b)、<111> (c) 纳米管阵列嵌锂后裂纹的角度分布;径向应力分布示意图 (d);应力积累与嵌锂时间关系曲线(e);<111>纳米管阵列不同角度应力积累与嵌锂时间关系曲线(f);不同角度应力积累的径向分布曲线 (g);嵌锂后的应力积累和裂纹比率与内径(h);管厚(i)和厚度/外径 (j) 之间的关系曲线[16]

Figure 3. <100> (a), <110> (b), <111> (c), the angular distribution of the crack after the nanotube array is lithium-inserted, and the schematic diagram of the radial stress distribution (d) , Stress accumulation and lithium insertion time relationship curve (e), <111>Nanotube array different angle stress accumulation and lithium insertion time relationship curve (f), different angle stress accumulation radial distribution curve (g), after lithium insertion The relationship between stress accumulation and crack ratio and inner diameter (h), tube thickness (i) and thickness/outer diameter (j)[16]

图 4 体电解质界面(SEI)膜的可视化3D成像,其中不同颜色箭头代表着不同的反应路径:路径1为室温且无电解液添加剂的充放电过程,路径2为55℃且无电解液添加剂的充放电过程,路径3为室温且有电解液添加剂的充放电过程[17]

Figure 4. 3D visual imaging of solid electrolyte interface (SEI) film, in which different color arrows represent different reaction paths: Path 1 is the charge and discharge process at room temperature without electrolyte additive, path 2 is the charge and discharge process at 55℃ without electrolyte additive, path 3 is the charge and discharge process at room temperature with electrolyte additive[17]

图 6 预先设计裂纹的光学显微镜图像[40]

Figure 6. Optical microscopy image of predesigned crack[40]((a)-(c)) Prepared and after 1.5 and 3 h on pyrimidone (Upy)-polyethylene glycol (PEG)-Si-15 electrode; (d)-(f), (g)-(i) Prepared and after 13 and 25 h on Upy-PEG-Si-15 and polyacrylic acid (PAA)-Si-15 electrode, respectively; (j) Proposed mechanism for self-healing of Upy-PEG binders)

图 7 黏结机制示意图[14]

Figure 7. Schematic illustration of the binding mechanism[14]((a) Diffusion/penetrating process during electrode preparation; (b) Formation of mechanical interlocking during the drying process; (c) Interfacial bonding forces include intermolecular forces and chemical bonds; (d) Polymer states in a bonding system: Bonded polymer, fixed polymer, and excessive polymer)

图 8 提出的用于SiMP阳极的PR-PAA粘结剂的应力耗散机制[43]

Figure 8. Proposed stress dissipation mechanism of PR-PAA binder for SiMP anodes[43]((a) Pulley principle to lower the force in lifting an object; (b) Graphical representation of the operation of PR-PAA binder to dissipate the stress during repeated volume changes of SiMPs, together with chemical structures of polyrotaxane and PAA; (c) Schematic illustration of the pulverization of the PAA-SiMP electrode during cycling and its consequent SEI layer growth)

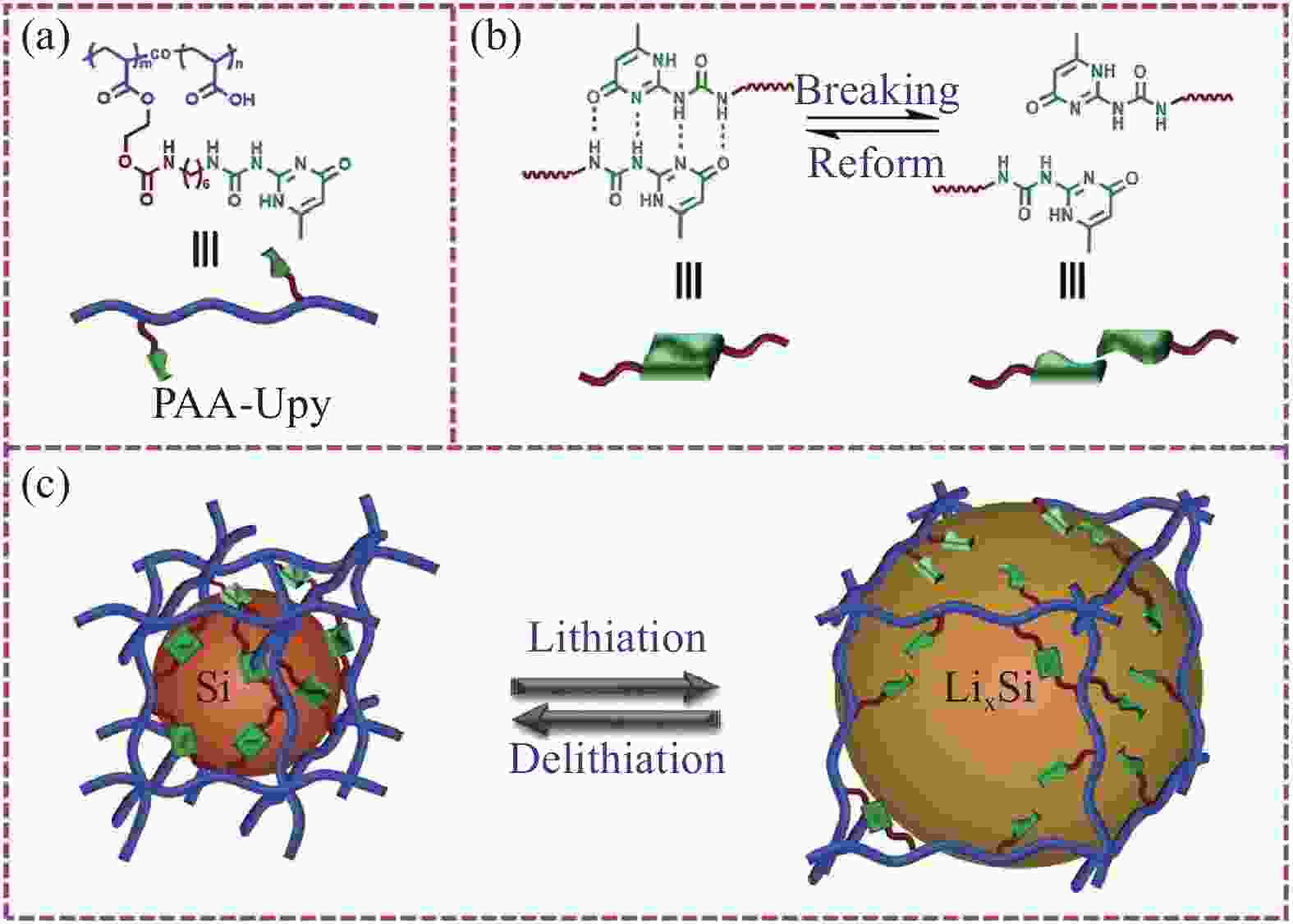

图 9 以自固化PAA-Upy聚合物为粘结剂的硅阳极充放电过程示意图[49]

Figure 9. Schematic illustration of the charge–discharge process of silicon anodes using self-healable PAA-Upy polymer as binder[49]((a) Chemical structure of PAA-Upy supramolecular polymer; (b) Upy-Upy dimers could reversibly break and reform based on quadruple hydrogen bonding; (c) Large volume expansion of silicon particles during the charge process results in the dissociation of the noncovalent crosslinking of Upy dimers, and these crosslinking networks can be rebuilt when the battery undergoes delithiation process even after many cycles due to the reversibility of quadruple hydrogen bonding)

图 10 海藻酸盐(Alg) (a) 和β-CDp (b) 粘合剂的结构式和示意图;硅(球)在锂化/脱锂过程中SiAlg (c) 和Siβ-CDp (d) 的粘结剂变化示意图[50]

Figure 10. Structural formulas and graphical representations of the Alginate (Alg) (a) and β-CD polymer (β-CDp) (b) binders; Schematic representations of Si-binder configurations for SiAlg (c) and Siβ-CDp (d) during lithiation/delithiation of Si (sphere)[50]

图 11 NaPAA与羧甲基纤维素基聚合物(CMC)主链共价接枝的合成方案 (a)、NaPAA-g-CMC粘合剂适应循环过程中Si颗粒体积变化的可能机制 (b)[52]

Figure 11. Synthetic scheme for covalent graft of NaPAA onto carboxymethyl cellulose (CMC) backbone (a), possible working mechanism of NaPAA-g-CMC binder to accommodate the lager volume change of Si particles during cycling (b)[52]

-

[1] LI X, HE C, ZHENG J, et al. Preparation of promising anode materials with Sn-MOF as precursors for superior lithium and sodium storage[J]. Journal of Alloys and Compounds,2020,842:155605. doi: 10.1016/j.jallcom.2020.155605 [2] LUAIS E, GHAMOUSS F, WOLFMAN J, et al. Mesoporous silicon negative electrode for thin film lithium-ion microbatteries[J]. Journal of Power Sources,2015,274:693-700. doi: 10.1016/j.jpowsour.2014.10.084 [3] DOBROVOLSKY Y A, EVSHCHIK E Y, ZYUBIN A S, et al. Silicon rods as a negative electrode material for lithium-ion cells: Quantum chemical modeling[J]. Chemical Physics,2019,519:45-51. doi: 10.1016/j.chemphys.2018.12.002 [4] WANG Y, DANG D, LI D, et al. Influence of polymeric binders on mechanical properties and microstructure evolution of silicon composite electrodes during electrochemical cycling[J]. Journal of Power Sources,2019,425:170-178. doi: 10.1016/j.jpowsour.2019.04.006 [5] WU R, LIU X, ZHENG Y, et al. Unveiling the intrinsic reaction between silicon-graphite composite anode and ionic liquid electrolyte in lithium-ion battery[J]. Journal of Power Sources,2020,473:228481. doi: 10.1016/j.jpowsour.2020.228481 [6] KIM K H, SHON J, JEONG H, et al. Improving the cyclability of silicon anodes for lithium-ion batteries using a simple pre-lithiation method[J]. Journal of Power Sources,2020,459:228066. doi: 10.1016/j.jpowsour.2020.228066 [7] BATOOL S, IDREES M, KONG J, et al. Assessment of the electrochemical behaviour of silicon@carbon nanocomposite anode for lithium-ion batteries[J]. Journal of Alloys and Compounds,2020,832:154644. doi: 10.1016/j.jallcom.2020.154644 [8] WEI J, QIN C, SU H, et al. A review of silicon/carbon composite anode materials with an encapsulated structure for lithium-ion rechargeable batteries[J]. Carbon,2020,170:685-687. [9] NAN J, SHIY, XIANG Z, et al. Ultrathin NiCo2O4 nanosheets assembled on biomass-derived carbon microsheets with polydopamine for high-performance hybrid supercapacitors[J]. Electrochimica Acta,2019,301:107-116. doi: 10.1016/j.electacta.2019.01.167 [10] SONG J, ZHOU M, YI R, et al. Interpenetrated gel polymer binder for high-performance silicon anodes in lithium-ion batteries[J]. Advanced Functional Materials,2014,24:5904-5910. doi: 10.1002/adfm.201401269 [11] 王保峰, 汪浩立, 吴宝柱, 等. 锂离子电池硅电极新型粘合剂的研究进展[J]. 上海电力学院学报, 2020, 36:17-25.WANG B F, WANG H L, WU B Z, et al. Advances of new binders for silicon anode in lithium-ion batteries[J]. Journal of Shanghai University of Electric Power,2020,36:17-25(in Chinese). [12] 谭毅, 王凯. 高比能量锂离子电池硅基负极材料研究进展[J]. 无机材料学报, 2019, 34(4):349-357. doi: 10.15541/jim20180347TAN Y, WANG K. Silicon-based anode materials applied in high specific energy lithium-ion batteries: A review[J]. Journal of Inorganic Materials,2019,34(4):349-357(in Chinese). doi: 10.15541/jim20180347 [13] 李延良, 夏清华, 张杰. 水性粘结剂在硅基负极中的应用研究进展[J]. 广东化工, 2019, 46:106-107. doi: 10.3969/j.issn.1007-1865.2019.15.045LI Y L, XIA Q H, ZHANG J. Application of water-soluble binder in Si-based anodes[J]. Guangdong Chemical Industry,2019,46:106-107(in Chinese). doi: 10.3969/j.issn.1007-1865.2019.15.045 [14] CHEN H, LING M, LUKE H, et al. Exploring chemical, mechanical, and electrical functionalities of binders for advanced energy-storage devices[J]. Chemical Reviews,2018,118:8936-8982. doi: 10.1021/acs.chemrev.8b00241 [15] SUN P, YI H, PENG T, et al. Ultrathin MnO2 nanoflakes deposited on carbon nanotube networks for symmetrical supercapacitors with enhanced performance[J]. Journal of Power Sources,2017,341:27-35. doi: 10.1016/j.jpowsour.2016.11.112 [16] WANG C, WEN J, LUO F, et al. Anisotropic expansion and size dependent fracture of silicon nanotubes during lithiation[J]. Journal of Materials Chemistry A,2019,7:15113-15122. doi: 10.1039/C9TA00519F [17] ZHENG J, ZHENG H, WANG R, et al. 3D visualization of inhomogeneous multi-layered structure and Young's modulus of the solid electrolyte interphase (SEI) on silicon anodes for lithium ion batteries[J]. Physical Chemistry Chemical Physics,2014,16:13229-13238. doi: 10.1039/C4CP01968G [18] WANG X, ZHANG Y, MA L, et al. Recent development on binders for silicon-based anodes in lithium-ion batteries[J]. Acta Chimica Sinica,2019,77:24-40. doi: 10.6023/A18070272 [19] GAO S, SUN F, BRADY A, et al. Ultra-efficient polymer binder for silicon anode in high-capacity lithium-ion batteries[J]. Nano Energy,2020,73:104804. doi: 10.1016/j.nanoen.2020.104804 [20] ZHU L, CHEN Y, WU C, et al. Double-carbon protected silicon anode for high performance lithium-ion batteries[J]. Journal of Alloys and Compounds,2019,812:151848. [21] LIU C, LI Q, CAO J, et al. Superstructured a-Fe2O3 nanorods as novel binder-free anodes for high-performing fiber-shaped Ni/Fe battery[J]. Science Bulletin,2019,65:812-819. [22] CAO Z, ZHENG X, HUANG W, et al. Dynamic bonded supramolecular binder enables high-performance silicon anodes in lithium-ion batteries[J]. Journal of Power Sources,2020,463:228208. doi: 10.1016/j.jpowsour.2020.228208 [23] SUN S, HE D, LI P, et al. Improved adhesion of cross-linked binder and SiO2-coating enhances structural and cyclic stability of silicon electrodes for lithium-ion batteries[J]. Journal of Power Sources,2020,454:227907. doi: 10.1016/j.jpowsour.2020.227907 [24] ZHANG J, WANG N, ZHANG W, et al. A cycling robust network binder for high performance Si-based negative electrodes for lithium-ion batteries[J]. Journal of Colloid & Interface Science,2020,578:452-460. [25] JIN B, WANG D, SONG L, et al. Biomass-derived fluorinated corn starch emulsion as binder for silicon and silicon oxide based anodes in lithium-ion batteries[J]. Electrochimica Acta,2021,365:137359. doi: 10.1016/j.electacta.2020.137359 [26] YAO D, FENG J, WANG J, et al. Synthesis of silicon anode binders with ultra-high content of catechol groups and the effect of molecular weight on battery performance[J]. Journal of Power Sources,2020,463:228188. doi: 10.1016/j.jpowsour.2020.228188 [27] WANG S, DUAN Q, LEI J, et al. Slime-inspired polyacrylic acid-borax crosslinked binder for high-capacity bulk silicon anodes in lithium-ion batteries[J]. Journal of Power Sources,2020,468:228365. doi: 10.1016/j.jpowsour.2020.228365 [28] YANG Y, WU S, ZHANG Y, et al. Towards efficient binders for silicon based lithium-ion battery anodes[J]. Chemical Engineering Journal,2021,406:126807. doi: 10.1016/j.cej.2020.126807 [29] ROHAN R, KUO T C, CHIOU C Y, et al. Low-cost and sustainable corn starch as a high-performance aqueous binder in silicon anodes via in situ cross-linking[J]. Journal of Power Sources,2018,396:459-466. doi: 10.1016/j.jpowsour.2018.06.045 [30] YE Q, ZHENG P, AO X, et al. Novel multi-block conductive binder with polybutadiene for Si anodes in lithium-ion batteries[J]. Electrochimica Acta,2019,315:58-66. doi: 10.1016/j.electacta.2019.05.093 [31] ZHENG T, ZHANG T, MAURICIO S D L F, et al. Aqueous emulsion of conductive polymer binders for Si anode materials in lithium ion batteries[J]. European Polymer Journal,2019,114:265-270. doi: 10.1016/j.eurpolymj.2019.02.041 [32] HU S, WANG L, HUANG T, et al. A conductive self-healing hydrogel binder for high-performance silicon anodes in lithium-ion batteries[J]. Journal of Power Sources,2019,449:227472. [33] SON J H, VO T N, CHO S W, et al. Acrylic random copolymer and network binders for silicon anodes in lithium-ion batteries[J]. Journal of Power Sources,2020,458:228054. doi: 10.1016/j.jpowsour.2020.228054 [34] LIU J, ZHANG Q, ZHANG T, et al. Robust ion-conductive biopolymer as a binder for Si anodes of lithium-ion batteries[J]. Advanced Functional Materials,2015,25:3599-3605. doi: 10.1002/adfm.201500589 [35] CHOI D, CHOY K L. Spider silk binder for Si-based anode in lithium-ion batteries[J]. Materials & Design,2020,191:108669. [36] TANG R, MA L, ZHANG Y, et al. A flexible and conductive binder with strong adhesion for high performance silicon-based lithium-ion battery anode[J]. ChemElectroChem,2020,7:1992-2000. doi: 10.1002/celc.201902152 [37] 陈祥祯, 唐佳易, 孙迎辉, 等. 硅基锂离子电池新型粘结剂的研究进展[J]. 电池工业, 2020, 24:94-100. doi: 10.3969/j.issn.1008-7923.2020.02.008CHEN X Z, TANG J Y, SUN Y H, et al. Research pro gress of new binders for silicon-based anode materials of Li-ion batteries[J]. Chinese Battery Industry,2020,24:94-100(in Chinese). doi: 10.3969/j.issn.1008-7923.2020.02.008 [38] ZENG W, WANG L, PENG X, et al. Enhanced ion conductivity in conducting polymer binder for high-performance silicon anodes in advanced lithium-ion batteries[J]. Advanced Energy Materials,2018,8:1702314. doi: 10.1002/aenm.201702314 [39] WANG C, WU H, CHEN Z, et al. Self-healing chemistry enables the stable operation of silicon microparticle anodes for high-energy lithium-ion batteries[J]. Nature Chemistry,2013,5:1042-1048. doi: 10.1038/nchem.1802 [40] YANG J, ZHANG L, ZHANG T, et al. Self-healing strategy for si nanoparticles towards practical application as anode materials for Li-ion batteries[J]. Electrochemistry Communications,2018,87:22-26. doi: 10.1016/j.elecom.2017.12.023 [41] MUNAOKA T, YAN X, LOPEZ J, et al. Ionically conductive self-healing binder for low cost Si microparticles anodes in Li-ion batteries[J]. Advanced Energy Materials,2018,8:1703138. doi: 10.1002/aenm.201703138 [42] LIM S, CHU H, LEE K, et al. Physically cross-linked polymer binder induced by reversible acid-base interaction for high-performance silicon composite anodes[J]. ACS Applied Materials & Interfaces,2015,7:23545-23553. [43] CHOI S, KWON T, COSKUN A, et al. Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries[J]. Science,2017,357:279-283. doi: 10.1126/science.aal4373 [44] JEENA M T, BOK T, KIM S H, et al. A siloxane-incorporated copolymer as an in situ cross-linkable binder for high performance silicon anodes in Li-ion batteries[J]. Nanoscale,2016,8:9245-9253. doi: 10.1039/C6NR01559J [45] CHOI S J, YIM T, CHO W, et al. Rosin-embedded poly (acrylic acid) binder for silicon/graphite negative electrode[J]. ACS Sustainable Chemistry & Engineering,2016,4:6362-6370. [46] YU L, LIU J, HE S, et al. A novel high-performance 3D polymer binder for silicon anode in lithium-ion batteries[J]. Journal of Physics and Chemistry of Solids,2019,135:109113. doi: 10.1016/j.jpcs.2019.109113 [47] WEI D, MAO J, ZHENG Z, et al. Achieving a high loading Si anode via employing a triblock copolymer elastomer binder, metal nanowires and a laminated conductive structure[J]. Journal of Materials Chemistry A,2018,6:20982-20991. doi: 10.1039/C8TA07956K [48] LIU T F, CHU Q L, YAN C, et al. Interweaving 3D network binder for high-areal-capacity Si anode through combined hard and soft polymers[J]. Advanced Energy Materials,2019,9:1802645. doi: 10.1002/aenm.201802645 [49] ZHANG G, YANG Y, CHEN Y, et al. A quadruple-hydrogen-bonded supramolecular binder for high-performance silicon anodes in lithium-ion batteries[J]. Small,2018,14:1801189. doi: 10.1002/smll.201801189 [50] JEONG Y K, KWON T W, LEE I, et al. Hyperbranched beta-cyclodextrin polymer as an effective multidimensional binder for silicon anodes in lithium rechargeable batteries[J]. Nano Letters,2014,14:864-870. doi: 10.1021/nl404237j [51] YANG S, HUANG Y, SU S, et al. Hybrid humics/sodium carboxymethyl cellulose water-soluble binder for enhancing the electrochemical performance of a Li-ion battery cathode[J]. Powder Technology,2019,351:203-211. doi: 10.1016/j.powtec.2019.04.027 [52] WEI L, CHEN C, HOU Z, et al. Poly (acrylic acid sodium) grafted carboxymethyl cellulose as a high performance polymer binder for silicon anode in lithium ion batteries[J]. Scientific Reports,2016,6:19583. doi: 10.1038/srep19583 [53] LING M, ZHAO H, XIAO X, et al. Low cost and environmentally benign crack-blocking structures for long life and high power Si electrodes in lithium ion batteries[J]. Journal of Materials Chemistry A,2015,3:2036-2042. doi: 10.1039/C4TA05817H [54] MAZOUZI D, GRISSA R, PARIS M, et al. CMC-citric acid Cu(II) cross-linked binder approach to improve the electrochemical performance of Si-based electrodes[J]. Electrochimica Acta,2019,304:495-504. doi: 10.1016/j.electacta.2019.03.026 [55] JUNG C H, KIM K H, HONG S H. Stable silicon anode for lithium-ion batteries through covalent bond formation with a binder via esterification[J]. ACS Applied Materials & Interfaces,2019,11:26753-26763. [56] LIU Y, TAI Z, ZHOU T, et al. An all-integrated anode via interlinked chemical bonding between double-shelled-yolk-structured silicon and binder for lithium-ion batteries[J]. Advanced Materials,2017,29:1703028. doi: 10.1002/adma.201703028 -

下载:

下载: