Preparation of covalently functionalized graphene superhydrophobic anticorrosive composite coating materials

-

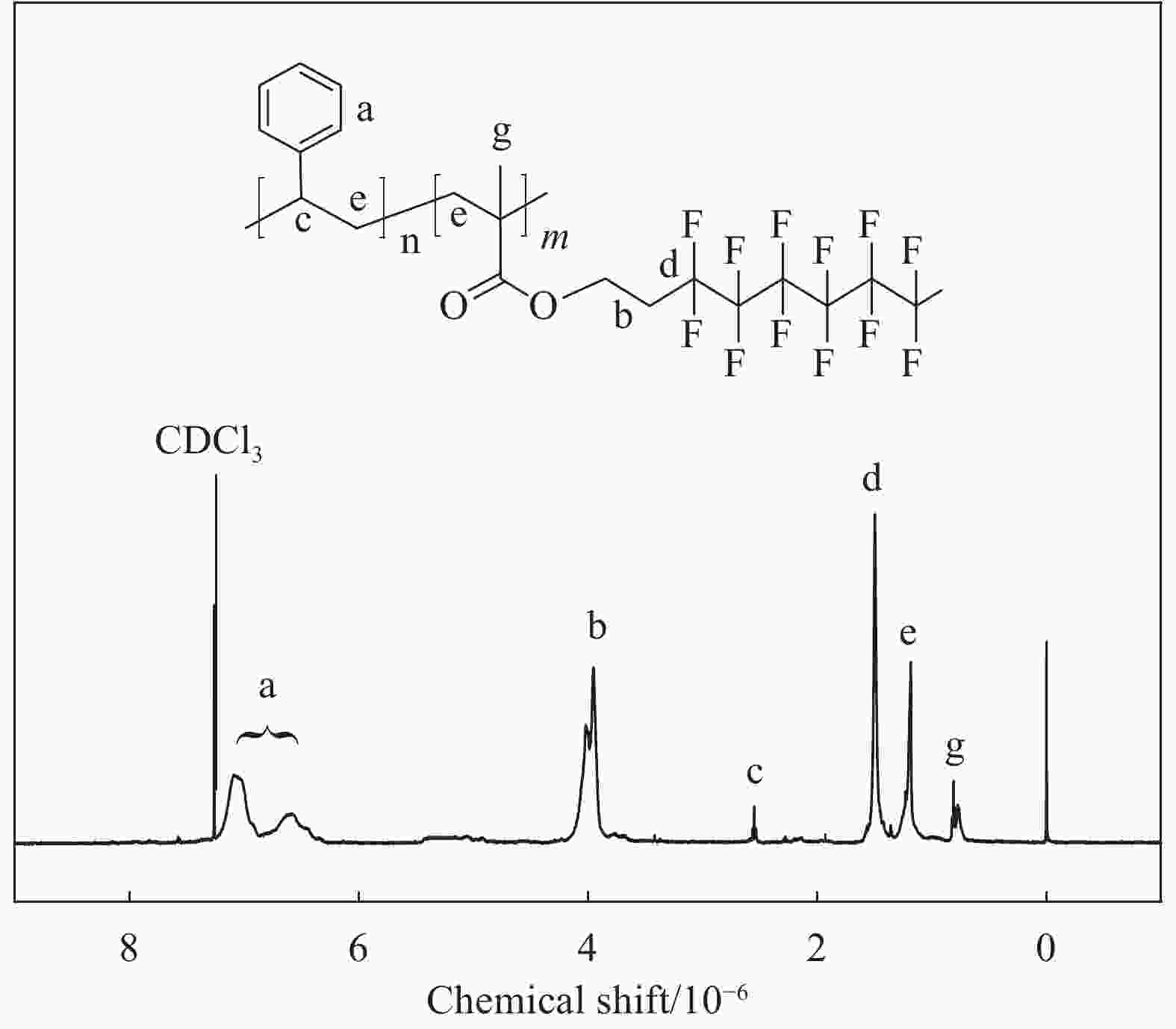

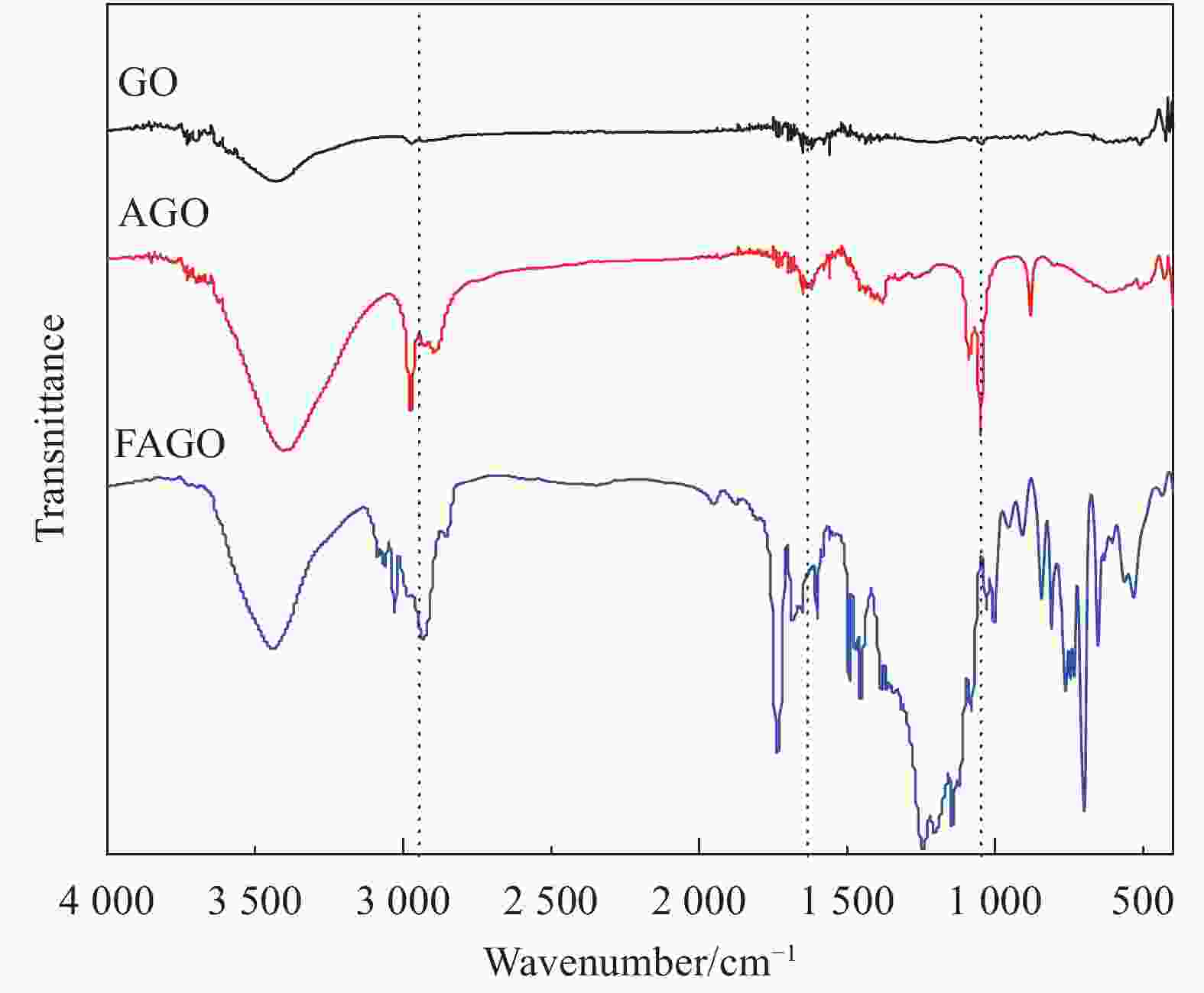

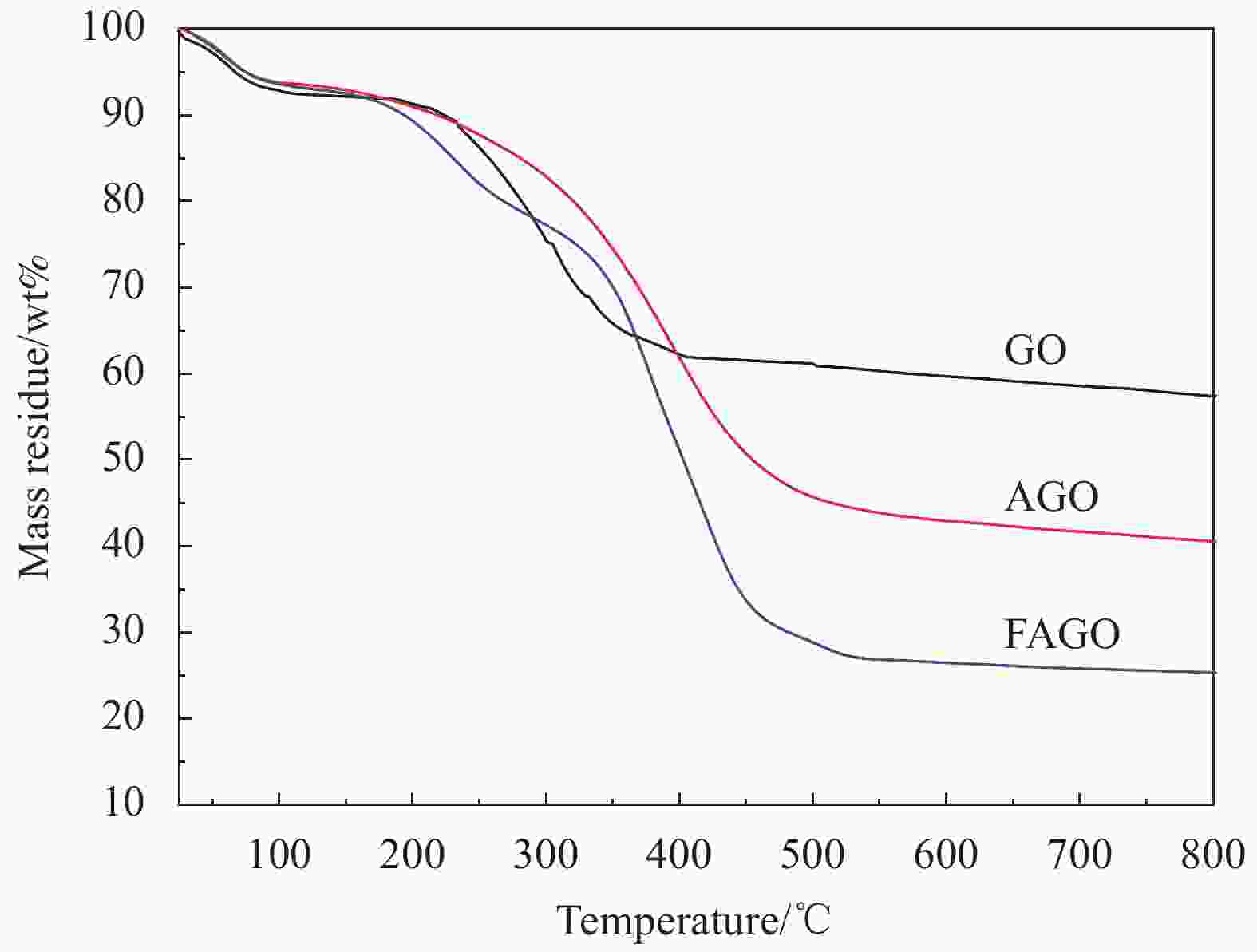

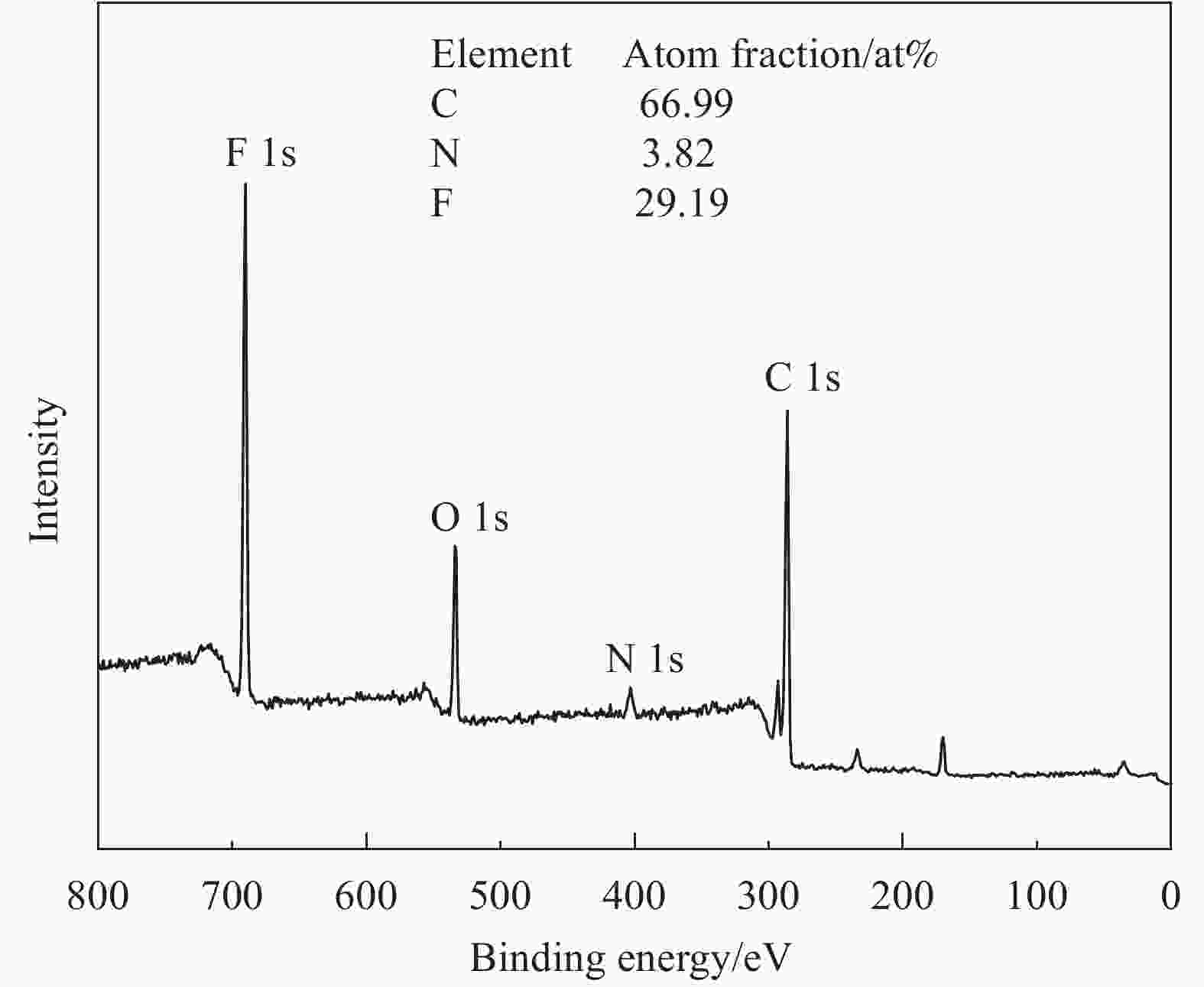

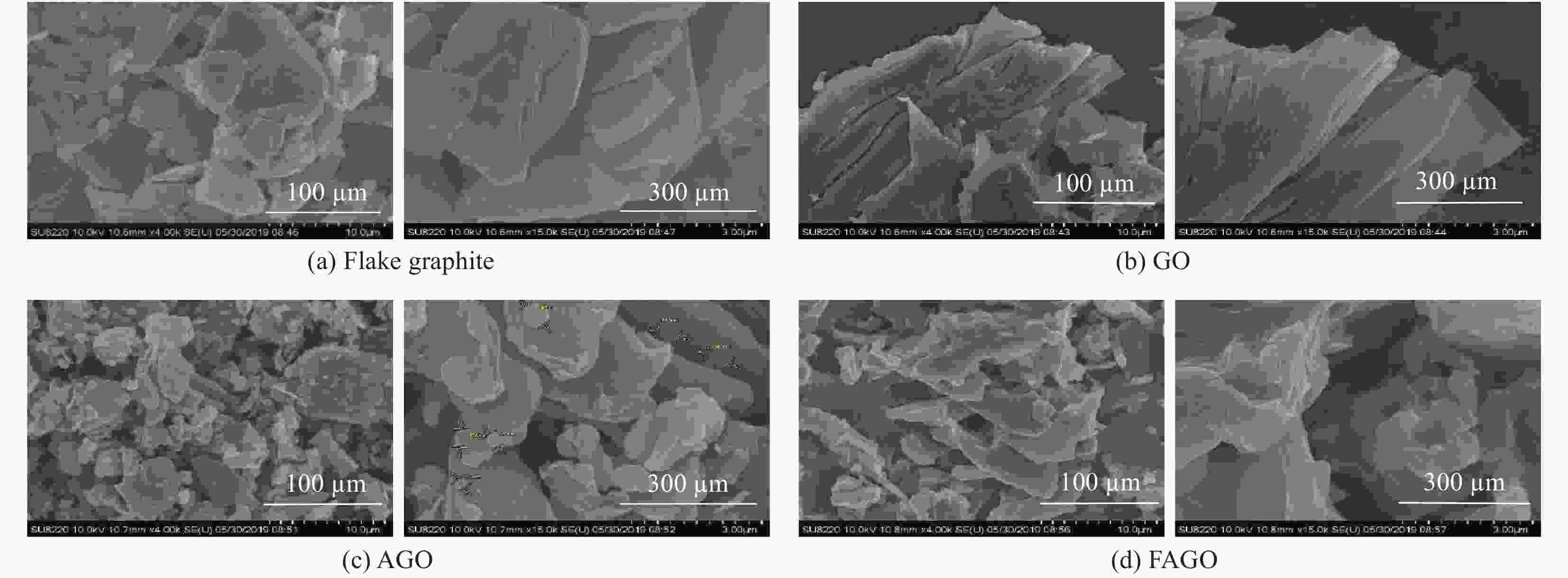

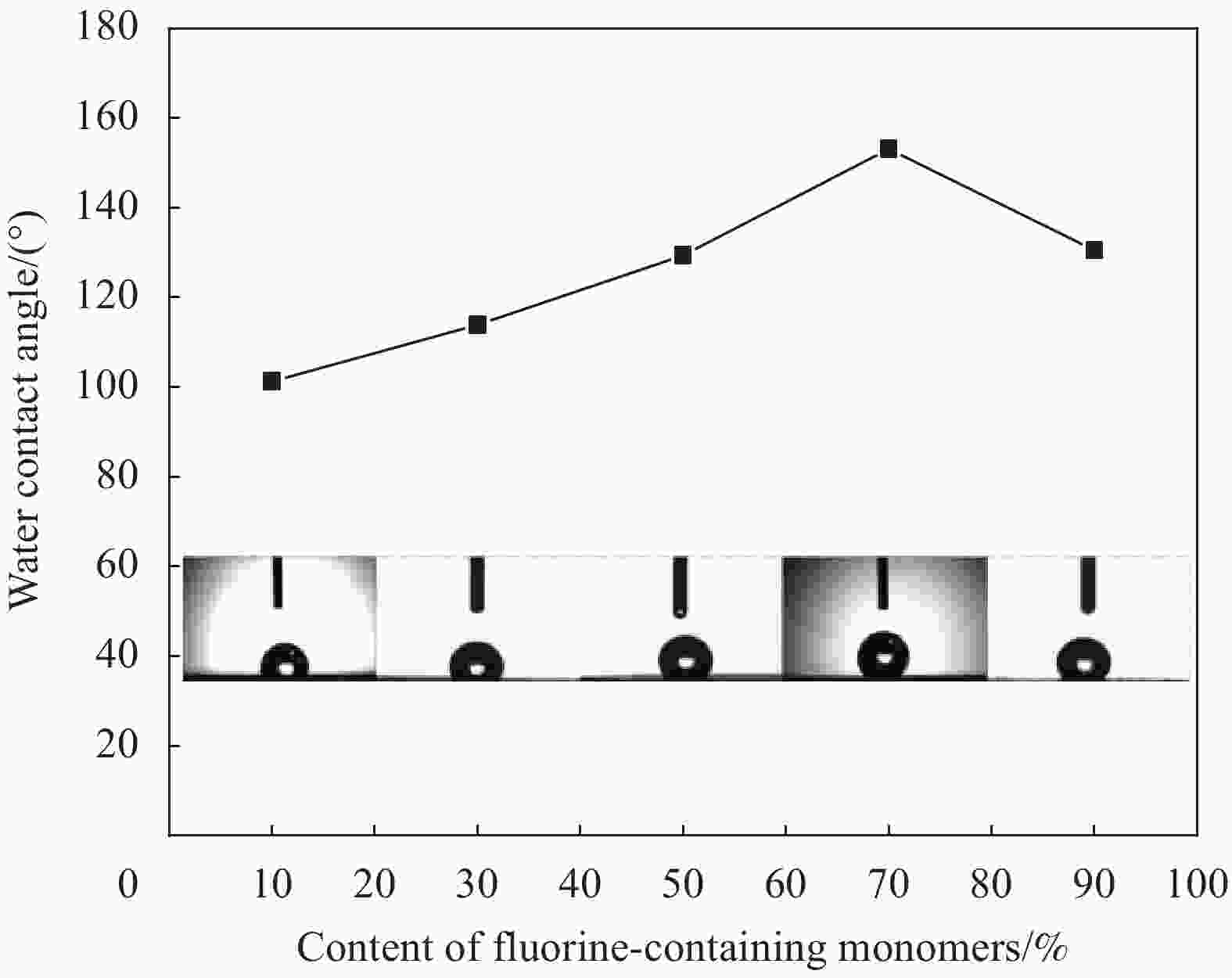

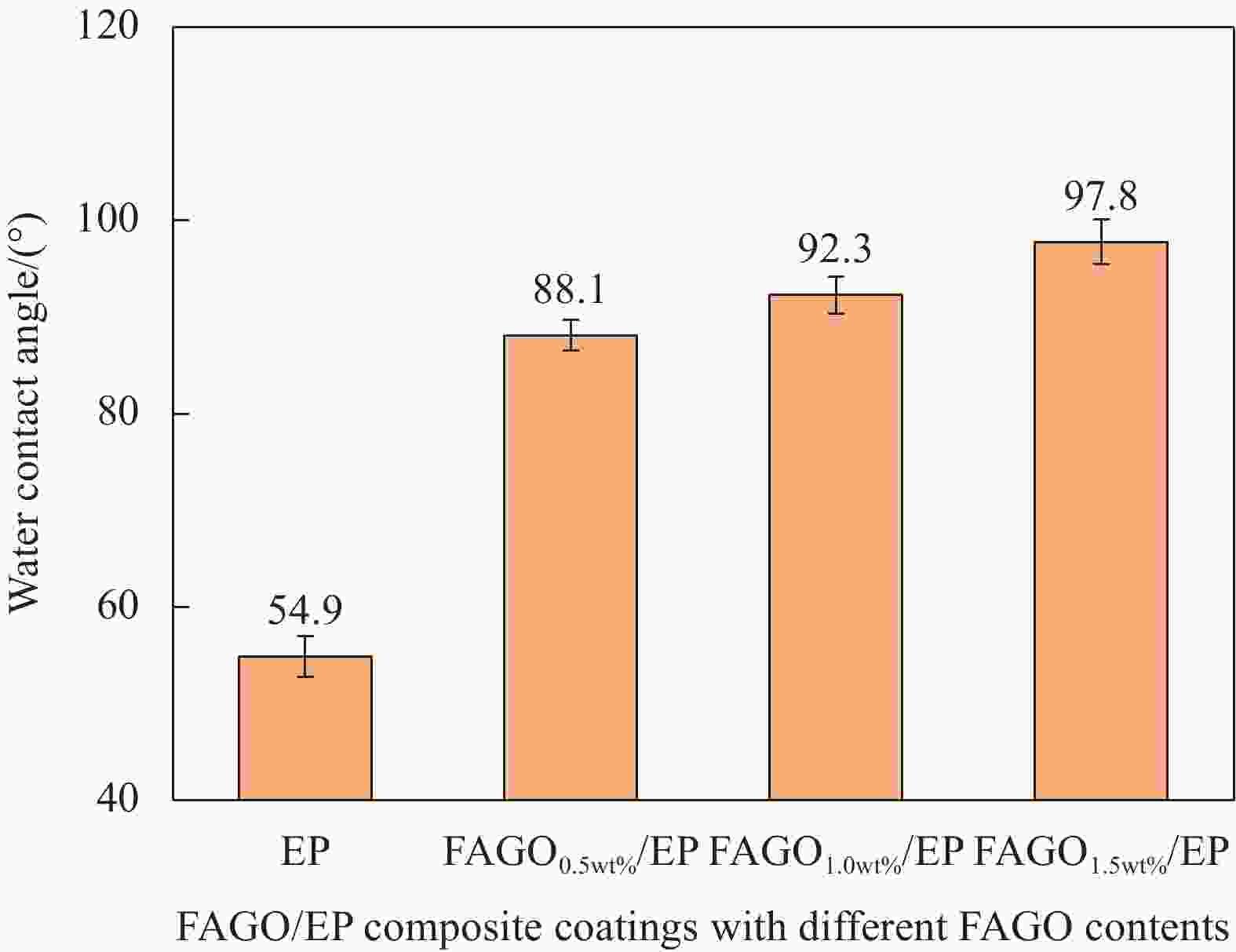

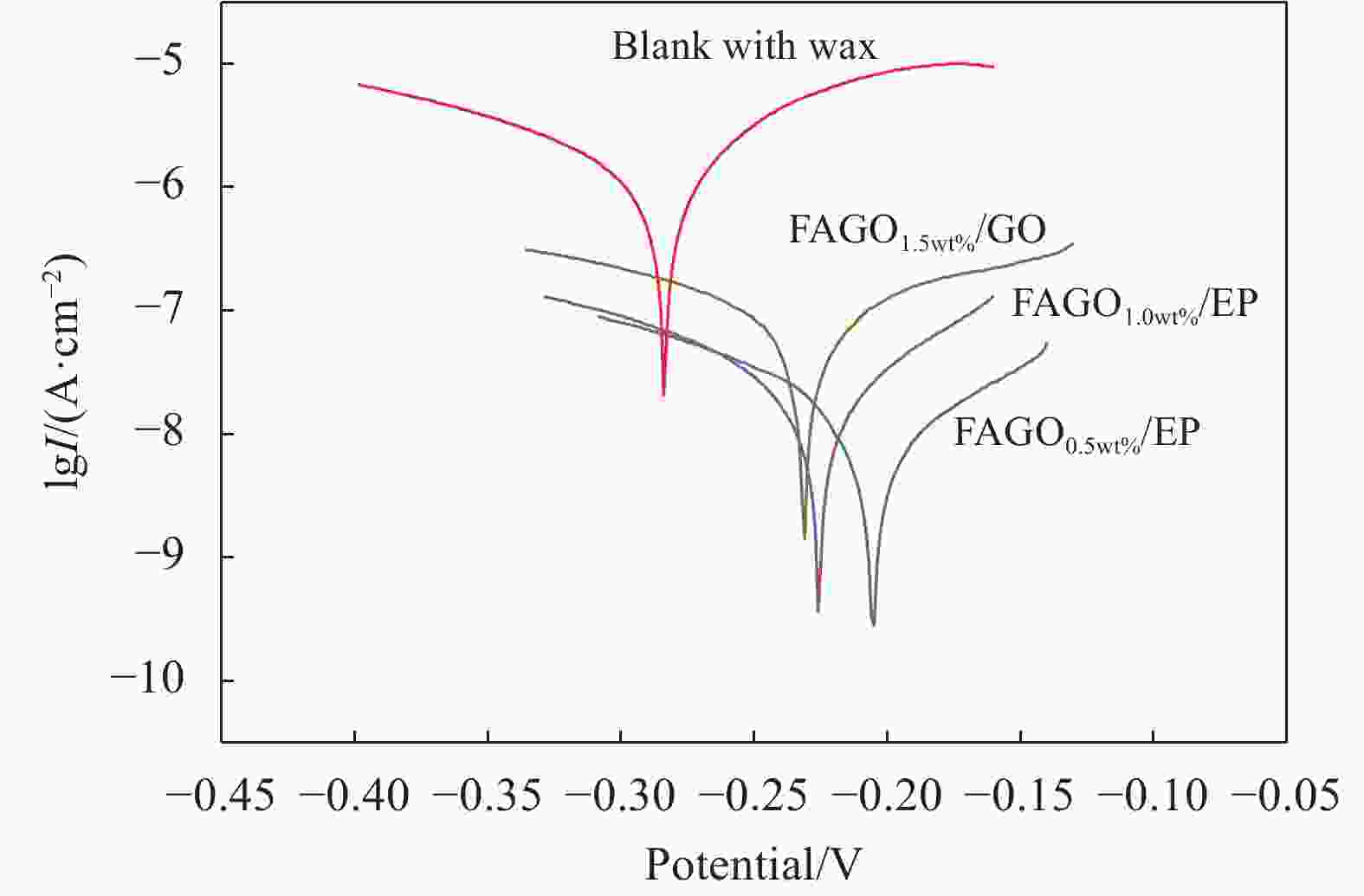

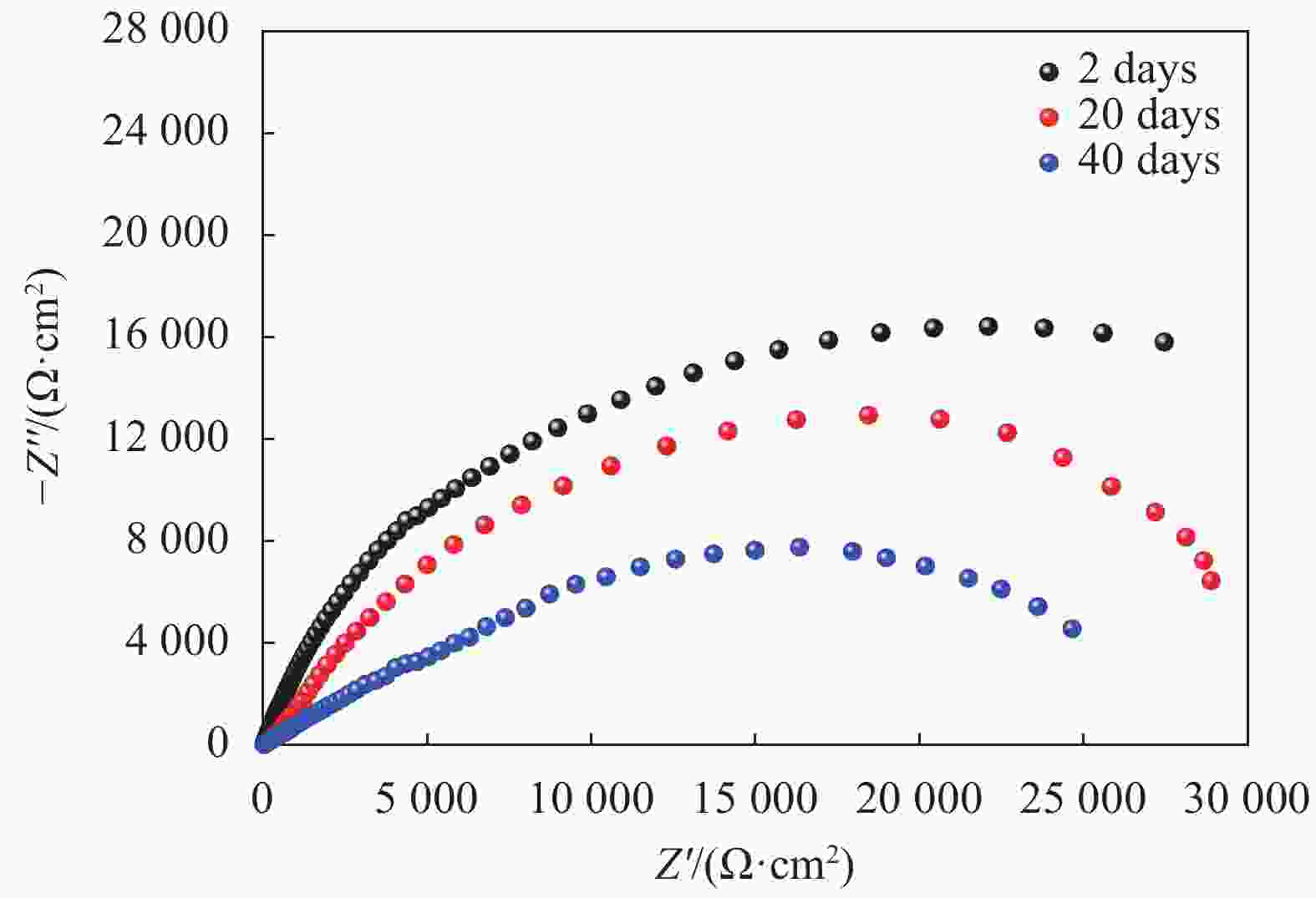

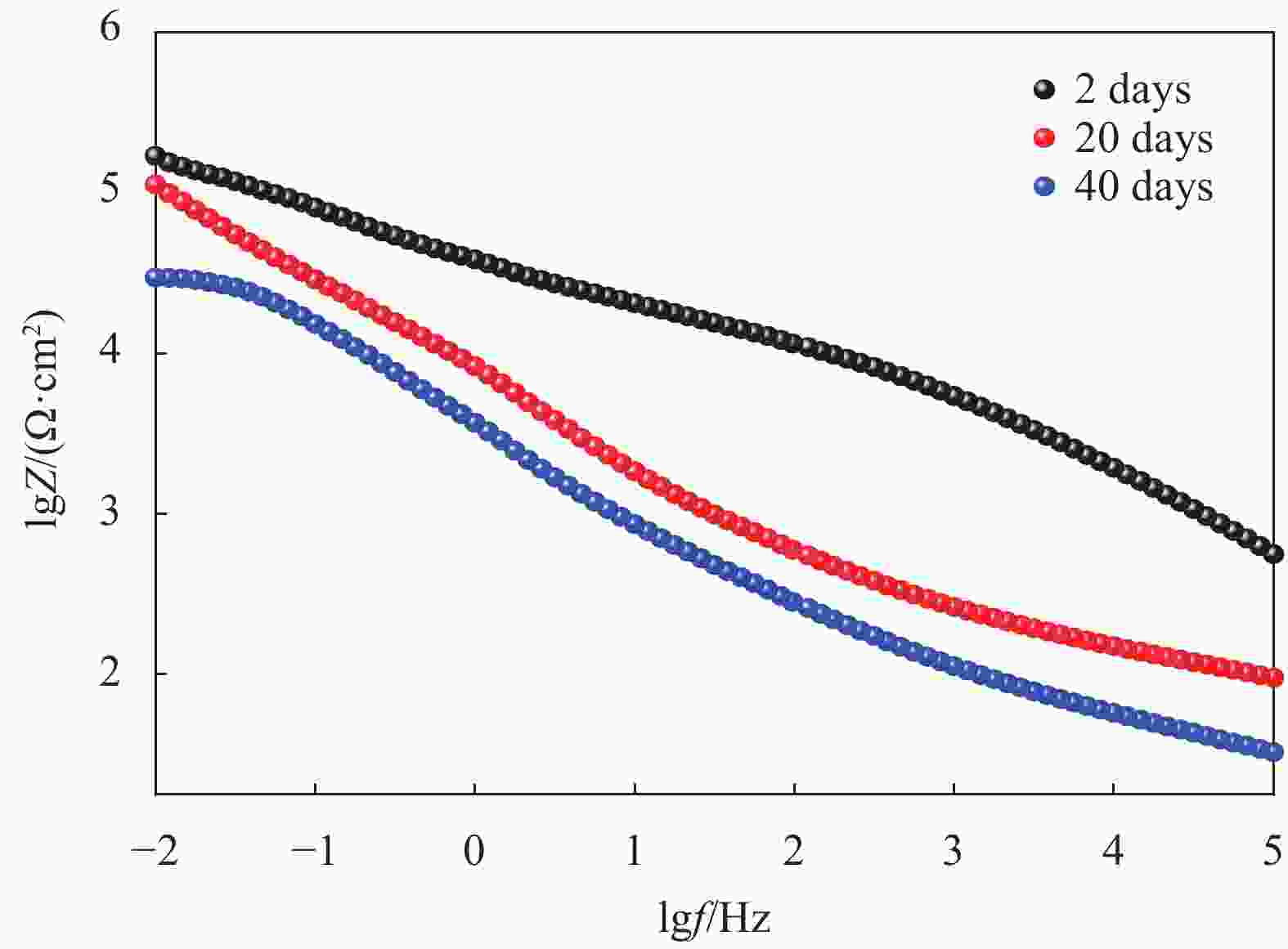

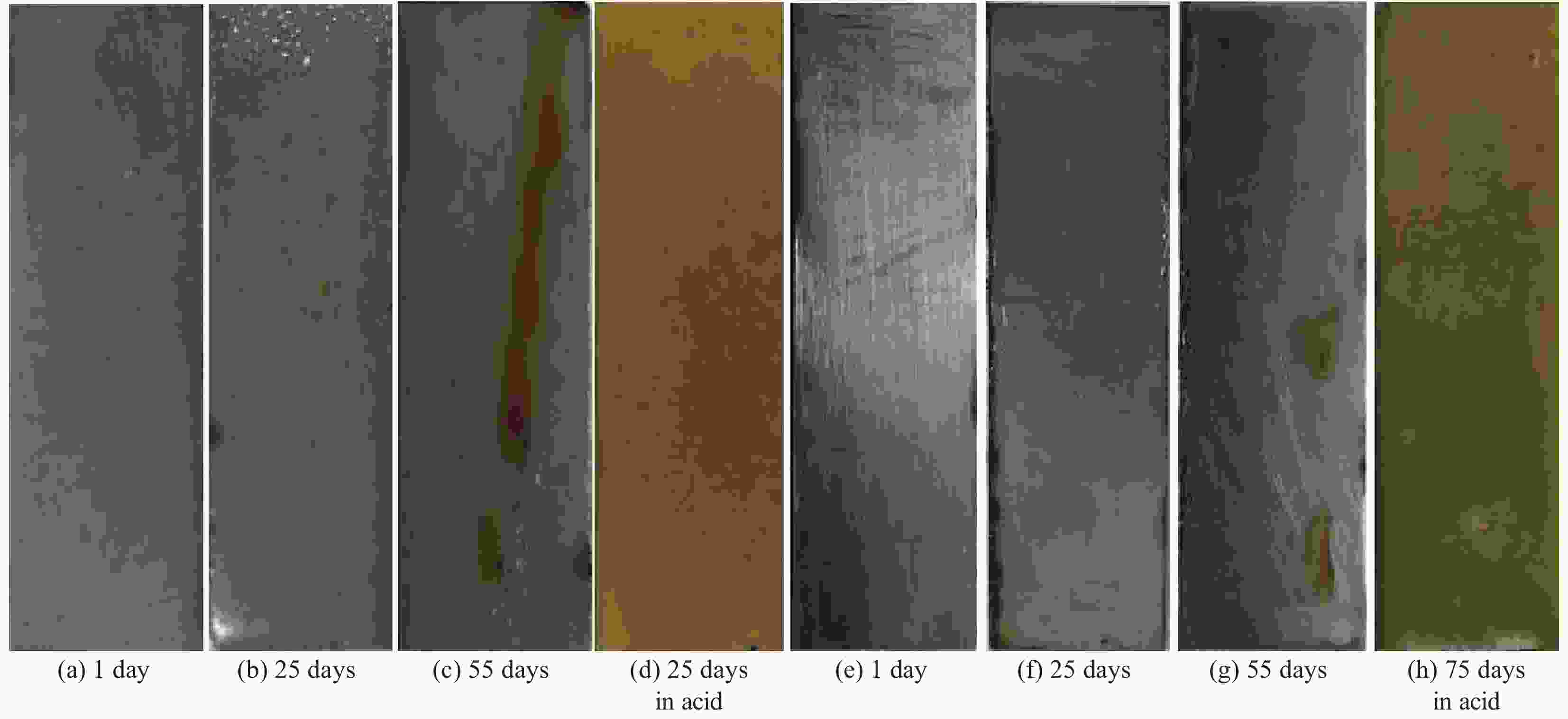

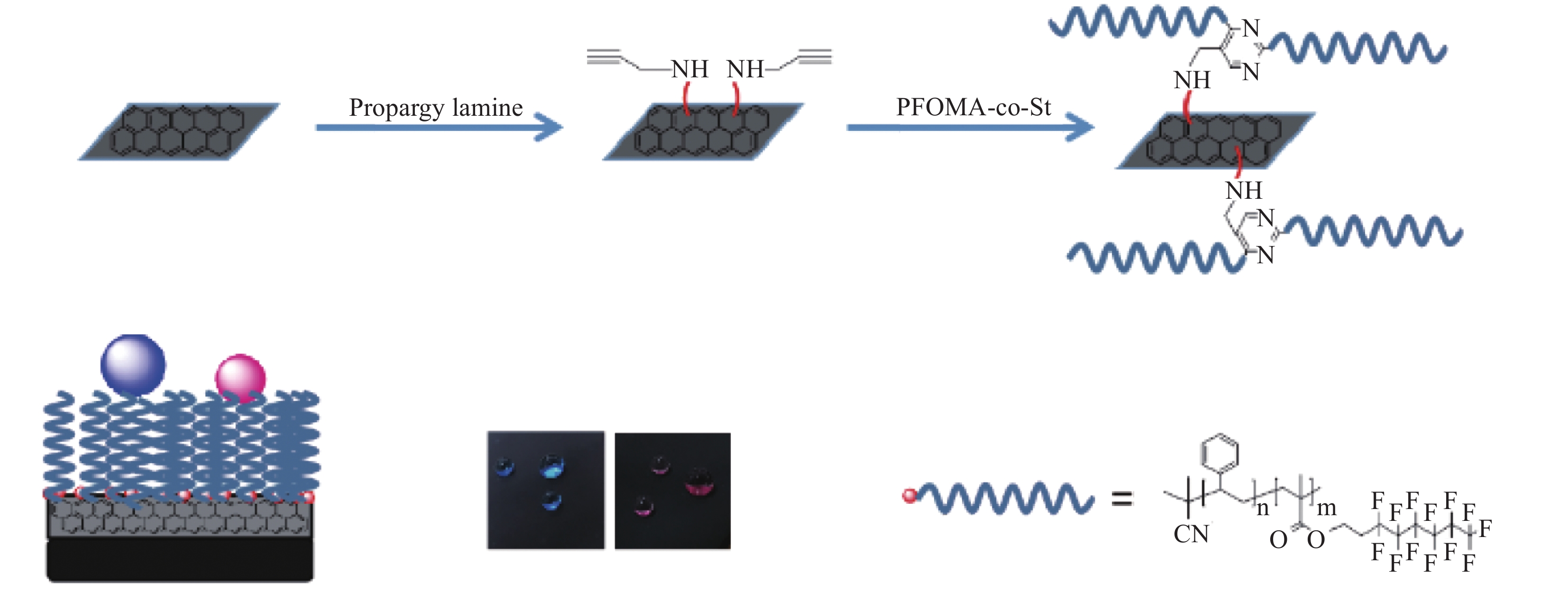

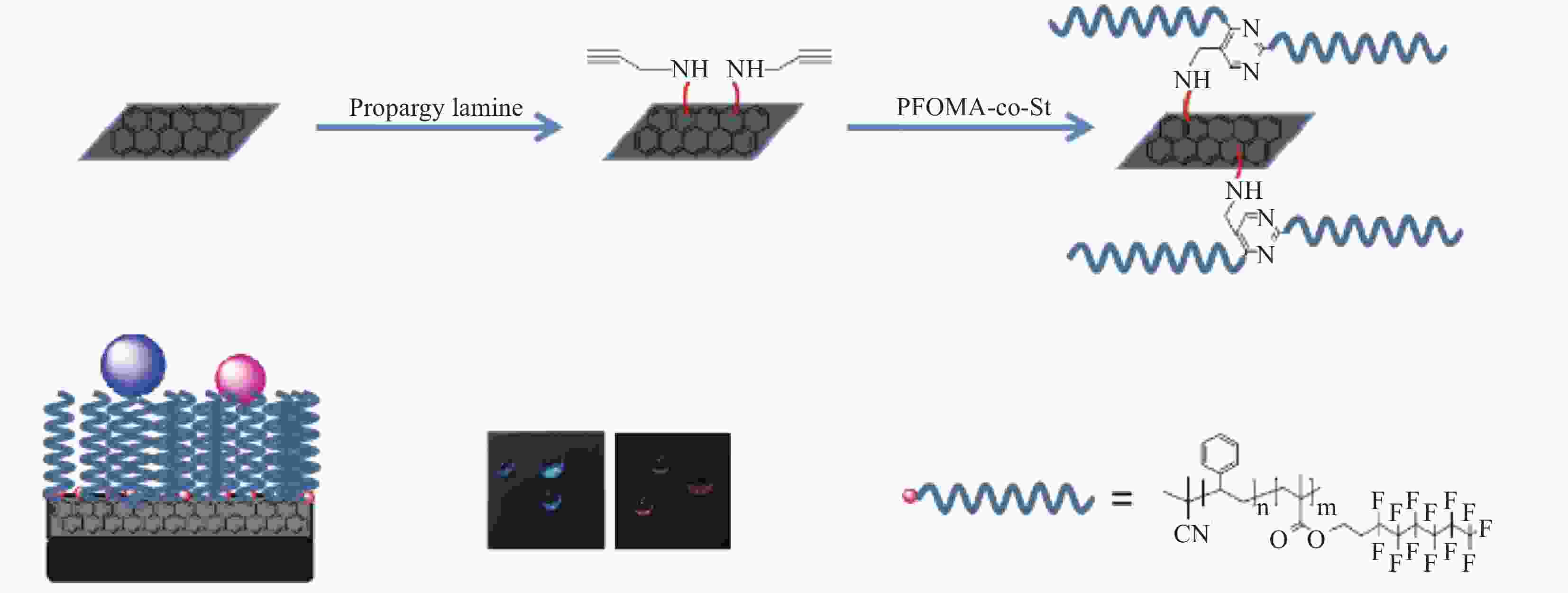

摘要: 石墨烯/有机聚合物复合涂层材料较纯聚合物材料具有更优越的阻隔性能,然而由于石墨烯之间高表面能和分子间作用力,使石墨烯在防腐等领域的应用潜力无法充分发挥。本文首先以传统自由基共聚方法合成一种含氟丙烯酸酯共聚物,并采用丙炔胺对氧化石墨烯改性合成炔基化氧化石墨烯,然后利用含氟丙烯酸酯共聚物末端氰基通过点击化学反应以共价键形式接枝在炔基化氧化石墨烯表面。疏水性分析表明,含氟共聚物功能化石墨烯的水接触角达到153°,将制备的功能化石墨烯涂敷于钢板基体时,水接触角提高到171.3°。扫描电镜显示,在炔基化石墨烯表面生长有大量300~600 nm的半球形接枝物。同时,将含氟共聚物功能化石墨烯/环氧树脂复合材料应用于碳素结构钢中,通过Tafel曲线和电化学阻抗谱对其耐蚀性能进行表征。结果显示,氟化石墨烯含量为0.5wt%的复合涂层的电流密度Icorr最低(8.872×10−9 A/cm2),比其他涂层样品低1~2个数量级。综上所述,本实验所制备的涂层材料具有良好的防腐性能,这一研究为开发石墨烯防腐蚀涂层材料提供了一种新的策略。Abstract: Graphene/organic polymeric composite coating materials have superior barrier properties compared with pure polymeric materials. However, due to high surface energy and intermolecular force between graphene, the potential application of graphene in anticorrosion and other fields is limited. In this paper, a fluorinated acrylate copolymer was synthesized by conventional free radical copolymerization, and then acetylized graphene oxide was synthesized by modifying graphene oxide with propargylamine. Then, the terminal cyano group of fluorinated acrylate copolymer was grafted onto the surface of acetylized graphene oxide by covalent bond through click chemistry reaction. Hydrophobicity analysis indicates that the water contact angle of the fluorine-containing copolymer functionalized graphene is 153°, and the water contact angle is increased to 171.3° when the prepared functionalized graphene is applied to the steel-plate substrate. The scanning electron microscope indicates that the 300-600 nm hemispherical grafted part is grown on the alkynylated-graphene surface. The fluorine-containing copolymer functionalized graphene/epoxy resin composites are applied to the carbon structural steel, and the corrosion protection performance is characterized by both Tafel curves and electrochemical impedance spectroscopy. The results show that the current density Icorr of the prepared composite coating with fluorinated graphene content of 0.5wt% is the lowest (8.872×10−9 A/cm2), which is 1-2 orders of magnitude lower than that of other coating samples. In summary, the coating materials prepared in this experiment have excellent anticorrosion properties. This research provides a new strategy for the development of graphene anticorrosion coating materials.

-

Key words:

- graphene /

- functionalization /

- superhydrophobicity /

- composite coating /

- anticorrosion

-

表 1 涂覆涂层的45#碳钢在3.5wt% NaCl溶液中通过Tafel极化曲线拟合得到的腐蚀参数

Table 1. Fitting corrosion data of coated 45# carbon steel samples in 3.5wt% NaCl solution by Tafel polarization curves

Sample Ecorr/V Icorr/(a·cm−2) ba/(V·dec−1) bc /(V·dec−1) vcorr/(mm·year−1) Wax −0.284 1.665×10−6 7.801 −11.732 1.932×10−2 FAGO0.5wt%/EP −0.206 8.872×10−9 16.890 −13.401 1.032×10−4 FAGO1.0wt%/EP −0.226 1.999×10−8 12.817 −13.913 2.327×10−4 FAGO1.5wt%/EP −0.231 2.111×10−7 4.583 −4.905 2.454×10−3 Notes: Corrosion current density (Icorr), anodic Tafel slope (ba ), corrosion potential (Ecorr), corrosion rate (vcorr) and cathodic Tafel slope (bc) were calculated via electrochemical analyzer instrument. -

[1] DENG Q, CHEN C, LIE Q, et al. Adsorption of aniline from aqueous solution using graphene oxide-modified attapulgite composites[J]. RSC Advances,2018,8(41):23382-23389. doi: 10.1039/C8RA04143A [2] LUO H, SUI Y, QI J, et al. Mechanical enhancement of copper matrix composites with homogeneously dispersed graphene modified by silver nanoparticles[J]. Journal of Alloys and Compounds,2017,729:293-302. doi: 10.1016/j.jallcom.2017.09.102 [3] ZHANG X, SHI C, LIU E, et al. Effect of interface structure on the mechanical properties of graphene nanosheets reinforced copper matrix composites[J]. ACS Applied Materials & Interfaces,2018,10(43):37586-37601. [4] HOU K, GONG P, WANG J, et al. Construction of highly ordered fluorinated graphene composite coatings with various fluorine contents for enhanced lubrication performance[J]. Tribology Letters,2015,60(1):1-12. doi: 10.1007/s11249-015-0577-3 [5] WANG S, PAN L, LI Q. Tribological behaviors of polytetrafluoroethylene composites under dry sliding and seawater lubrication[J]. Journal of Applied Polymer Science,2013,130(4):2523-2531. doi: 10.1002/app.39454 [6] GEORGAKILAS V, GEORGITSOPOULOU S, KARAKASSIDES A. Interfacial asymmetric post functionalization of graphene, amphiphilic graphene derivatives self-assembled to 3D superstructures[J]. Chemistry-A European Journal,2018,65(24):17356-17360. [7] 周浪, 王涛. 石墨烯/功能聚合物复合材料[J]. 复合材料学报, 2020, 37(5):997-1014.ZHOU L, WANG T. Graphene/functional polymer compo-sites[J]. Acta Materiae Compositae Sinica,2020,37(5):997-1014(in Chinese). [8] 李玮, 程先华. 稀土Ce接枝碳纳米管-碳纤维多尺度增强体对环氧树脂基复合材料界面性能的影响[J]. 复合材料学报, 2020, 37(11):2789-2797.LI W, CHENG X H. Effect of rare earth Ce grafted carbon nanotubes-carbon fiber multi-scale reinforcement on interfacial properties of epoxy matrix composites[J]. Acta Materiae Compositae Sinica,2020,37(11):2789-2797(in Chinese). [9] OU B, LI D. Preparation of polystyrene/silica nanocompo-sites by radical copolymerization of styrene with silica macromonomer[J]. Science in China Series B: Chemistry,2007,50(3):385-391. [10] QIU S, LI W, ZHENG W, et al. Synergistic effect of polypyrrole-intercalated graphene for enhanced corrosion protection of aqueous coating in 3.5% NaCl solution[J]. ACS Applied Materials & Interfaces,2017,9:34294-34304. [11] OU B, ZHOU Z, LIU Q, et al. Covalent functionali zation of graphene with poly(methyl methacrylate) by atom transfer radical polymerization at room temperature[J]. Polymer Chemistry,2012,3:2768-2775. doi: 10.1039/c2py20438j [12] 胡小雨, 蒋秋冉, 魏毅, 等. 碳纤维-氧化石墨烯/环氧树脂复合材料的制备及表征[J]. 复合材料学报, 2018, 35(7):1691-1699.HU X Y, JIANG Q R, WEI Y, et al. Preparation and characterization of carbon fiber-graphene oxide/epoxy composites[J]. Acta Materiae Compositae Sinica,2018,35(7):1691-1699(in Chinese). [13] NASIRI M, SAXON D, REINEKE T. Enhanced mechanical and adhesion properties in sustainable triblock copolymers via non-covalent Interactions[J]. Macromolecules,2018,51(7):2456-2465. doi: 10.1021/acs.macromol.7b02248 [14] OU B, LI D. Preparation of well-defined polystyrene/silica hybrid nanoparticles by ATRP[J]. Science in China Series B: Chemistry,2008,51(1):51-57. doi: 10.1007/s11426-007-0070-4 [15] ZHAO J, LI Y, WANG Y, et al. Mild thermal reduction of graphene oxide as a lubrication additive for friction and wear reduction[J]. RSC Advances,2017,7(3):1766-1770. doi: 10.1039/C6RA26488C [16] WEI J, CAO Z, WANG M, et al. Origin of hydration lubrication of zwitterions on graphene[J]. Nanoscale,2018,10:16887-16894. doi: 10.1039/C8NR05724A [17] FURTAT P, LENZLEITE M, IONESCU E, et al. Synthesis of fluorine-modified polysilazanes via Si–H bond activation and their application as protective hydrophobic coatings[J]. Journal of Materials Chemistry A,2017,5:25509-25521. doi: 10.1039/C7TA07687H [18] LIU G, ZHANG K, HUANG S, et al. Transparent omniphobic coating with glass-like wear resistance and polymer like bendability[J]. Angewandte Chemie International Edition,2019,58(35):12004-12009. doi: 10.1002/anie.201904210 [19] IBRAHIM B, ZAGIDULIN D, BEHAZIN M, et al. The corrosion of copper in irradiated and unirradiated humid air[J]. Corrosion Science,2018,141:53-62. doi: 10.1016/j.corsci.2018.05.024 [20] ZHAO M, LI H, WEN L, et al. Synthesis and characterization of fluorine-containing polyurethane–acrylate core-shell emulsion[J]. Journal of Applied Polymer Science,2016,133(17):43357-43363. [21] SEONGJUN J, SEUNGBAE J, TAESUK J, et al. Fluorine-containing styrenic block copolymers toward high χ and perpendicular lamellae in thin films[J]. Macromolecules,2018,51(18):7152-7159. doi: 10.1021/acs.macromol.8b01325 [22] LI L, BAI Y, LI L, et al. A Superhydrophobic smart coating for flexible and wearable sensing electronics[J]. Advanced Materials,2017,29:1702517-1702524. doi: 10.1002/adma.201702517 [23] GUO G, LIU L, ZHANG Q, et al. Solution-processable, durable, scalable, fluorine-grafted graphene-based superhydrophobic coating for highly efficient oil/water separation under harsh environment[J]. New Journal of Chemistry,2018,42(5):3819-3827. doi: 10.1039/C7NJ05182D [24] SUN W, WU T, WANG L, et al. The role of graphene loading on the corrosion-promotion activity of graphene/epoxy nanocomposite coatings[J]. Composites Part B: Engineering,2019,173:106916-106923. doi: 10.1016/j.compositesb.2019.106916 [25] WAN C, CHEN B. Reinforcement and interphase of polymer/graphene oxide nanocomposites[J]. Journal of Materials Chemistry,2012,22:3637-3646. doi: 10.1039/c2jm15062j [26] OU B, CHEN M, HUANG R, et al. Preparation and application of novel biodegradable polyurethane copolymer[J]. RSC Advances,2016,6(52):47138-47144. doi: 10.1039/C6RA03064E [27] GUO S, JEANETTE J, ZHOU X, et al. Effects of flow, Si inhibition, and concurrent corrosion of dissimilar metals on the corrosion of aluminium in the environment following a loss-of-coolant accident[J]. Corrosion Science,2017,128:100-109. doi: 10.1016/j.corsci.2017.09.012 [28] LIU X, WANG Z, ZHAO C, et al. Preparation and characterization of silane-modified SiO2, particles reinforced resin composites with fluorinated acrylate polymer[J]. Journal of the Mechanical Behavior of Biomedical Materials,2018,80:11-19. doi: 10.1016/j.jmbbm.2018.01.004 [29] YANG D, WANG F. Preparation, characterization, and electrochemical performances of graphene/ Ni(OH)2 hybrid nanomaterials[J]. Nanoparticle Research,2013,15(6):1762-1776. doi: 10.1007/s11051-013-1762-7 [30] 余东升, 付芳, 贾铁昆, 等. 亲水型功能化石墨烯的分散性及其对水泥基复合材料力学性能的影响[J]. 复合材料学报, 2021, 38(2): 622-629.YU D S, FU F, JIA T K, et al. Dispersity of hydrophilic functional graphene and its impact onmechanical properties of cement based composites[J]. Acta Materiae Compositae Sinica, 2021, 38(2): 622-629(in Chinese). [31] LI L, ZHANG G, SU Z. One-step assembly of phytic acid metal complexes for superhydrophilic coatings[J]. Angewandte Chemie International Edition,2016,55:9093-9096. doi: 10.1002/anie.201604671 [32] ZHONG J, ZHOU G, HE P, et al. 3D Printing strong and conductive geo-polymer nanocomposite structures modified by graphene oxide[J]. Carbon,2017,117:421-426. doi: 10.1016/j.carbon.2017.02.102 -

下载:

下载: