Axial crushing response and failure mechanism of variable stiffness carbon fiber/epoxy resin composite thin-walled tube

-

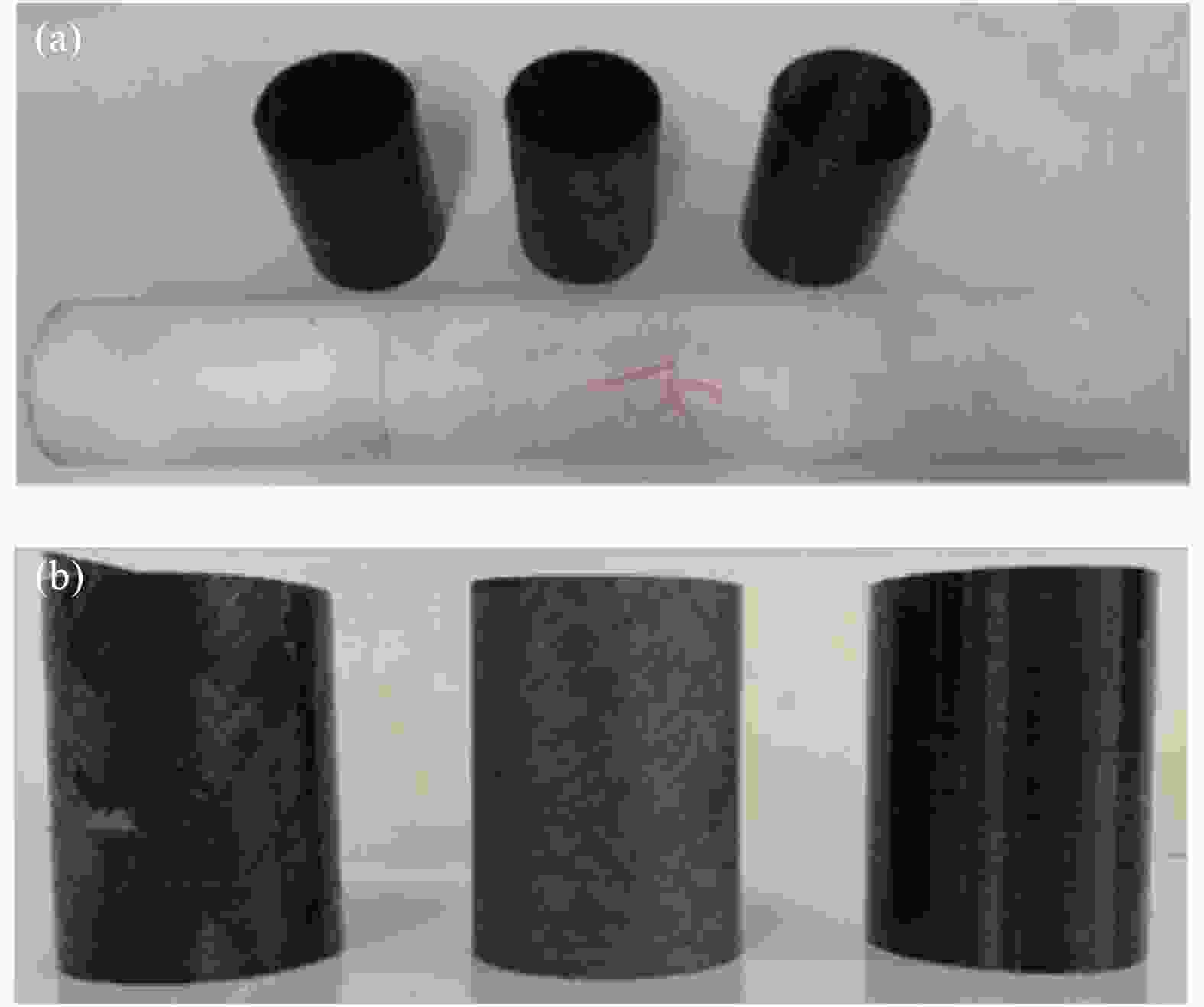

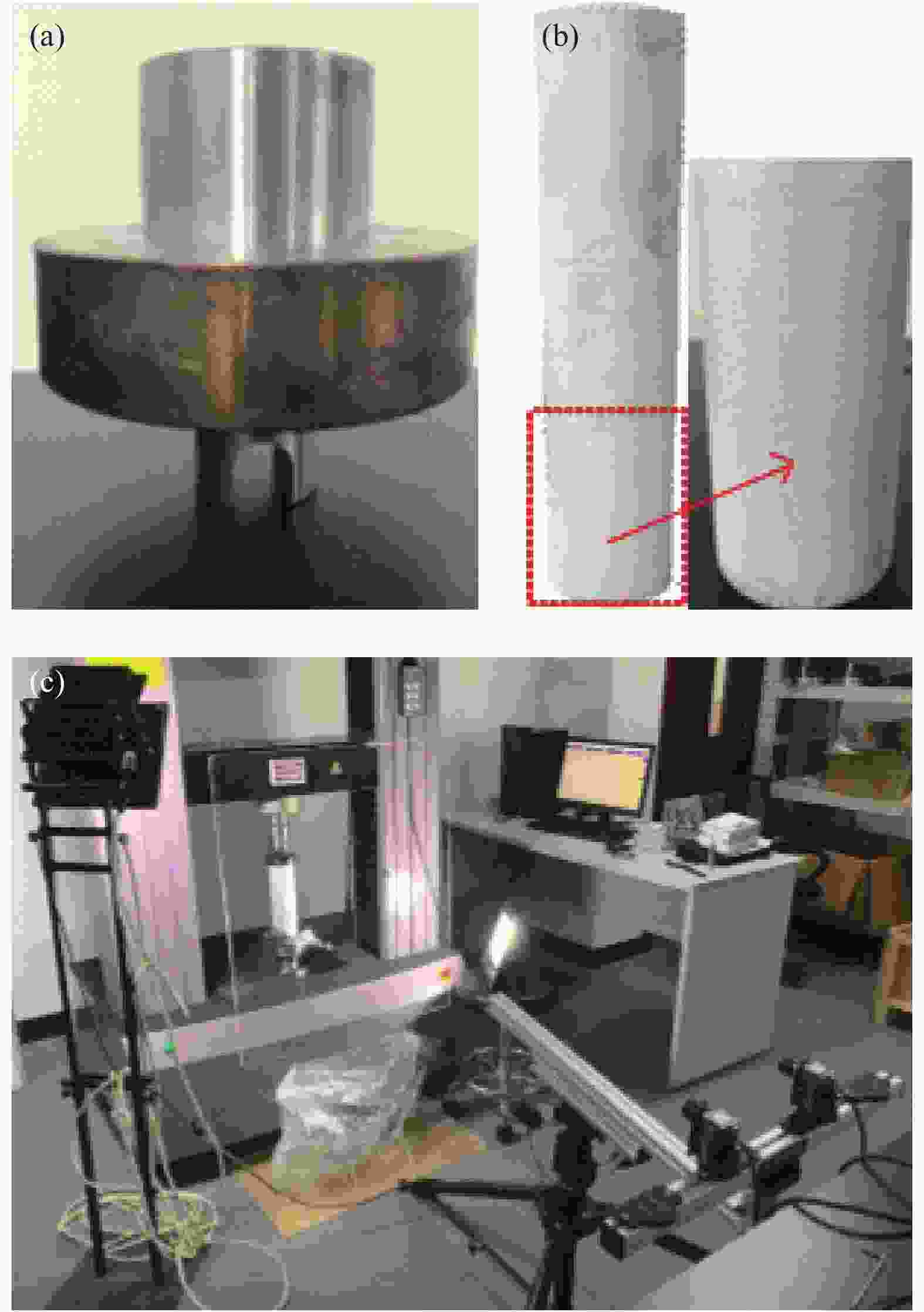

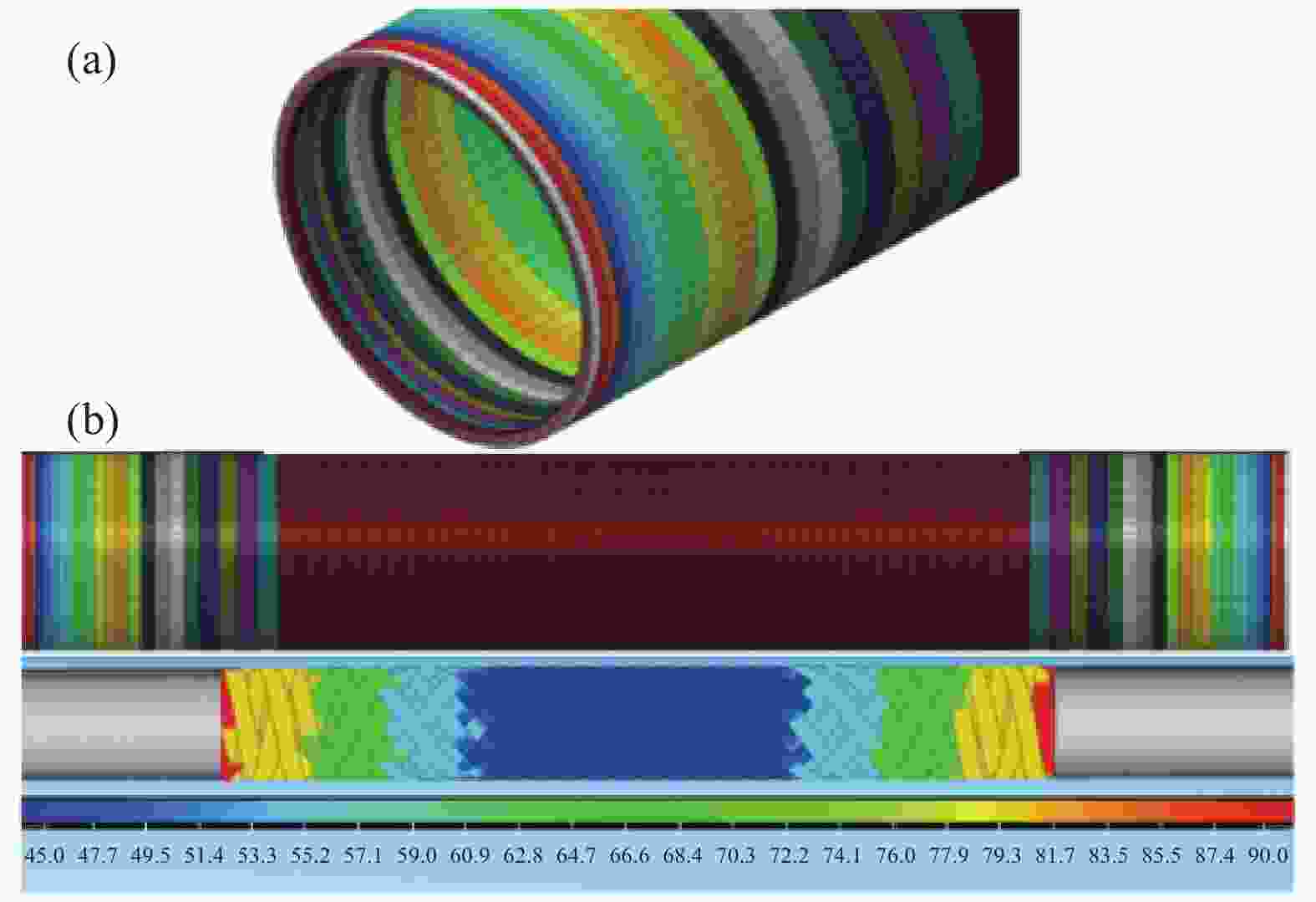

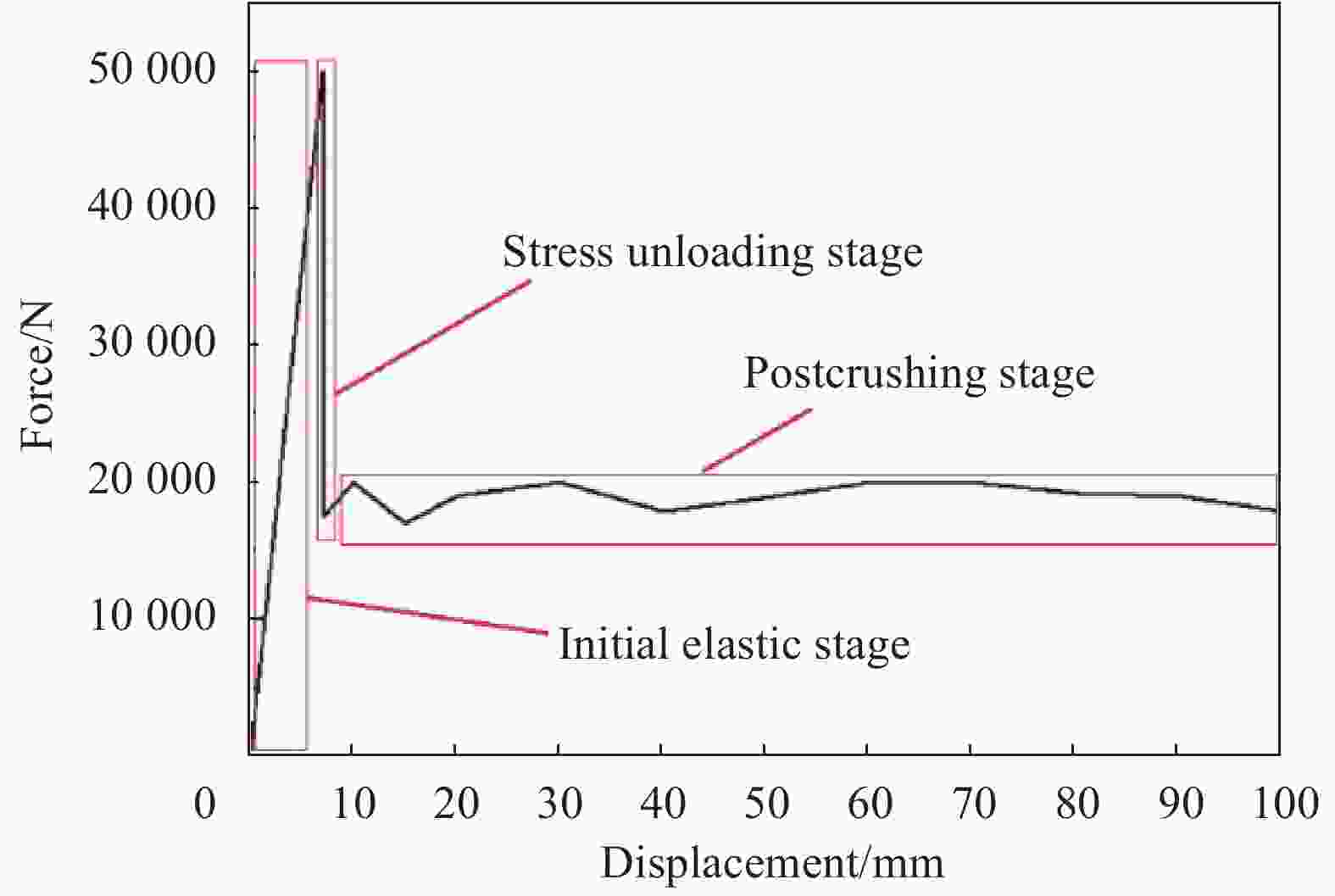

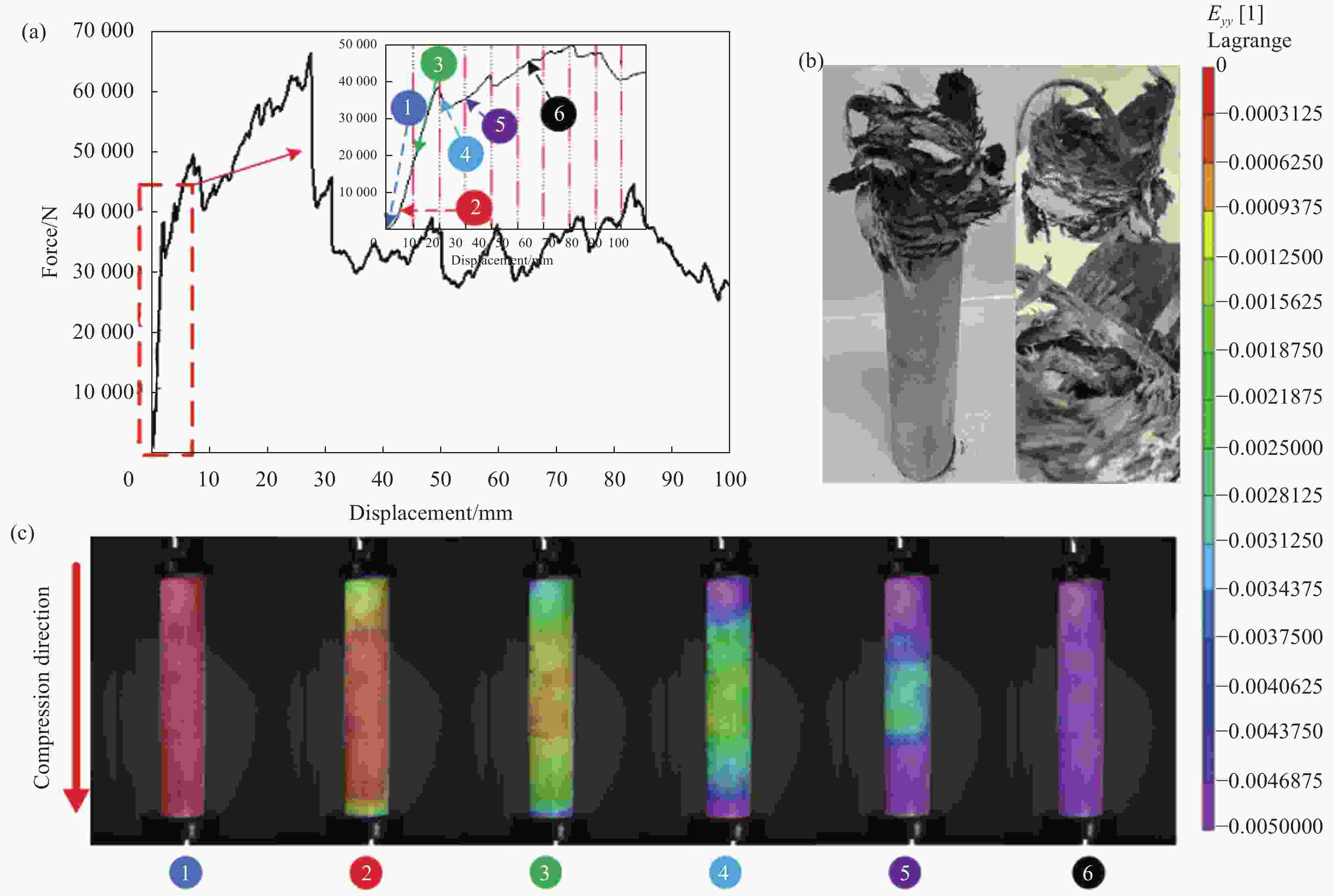

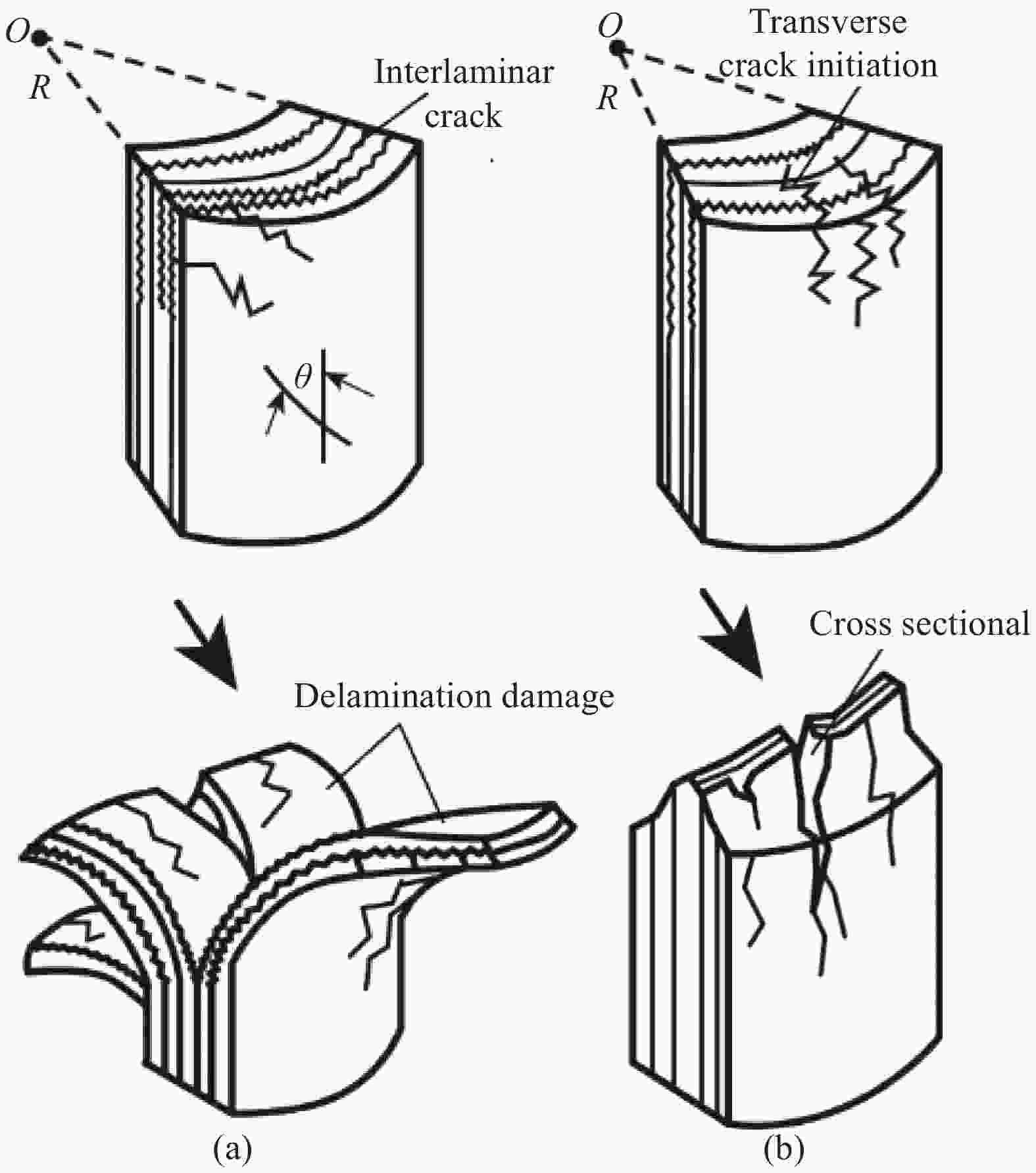

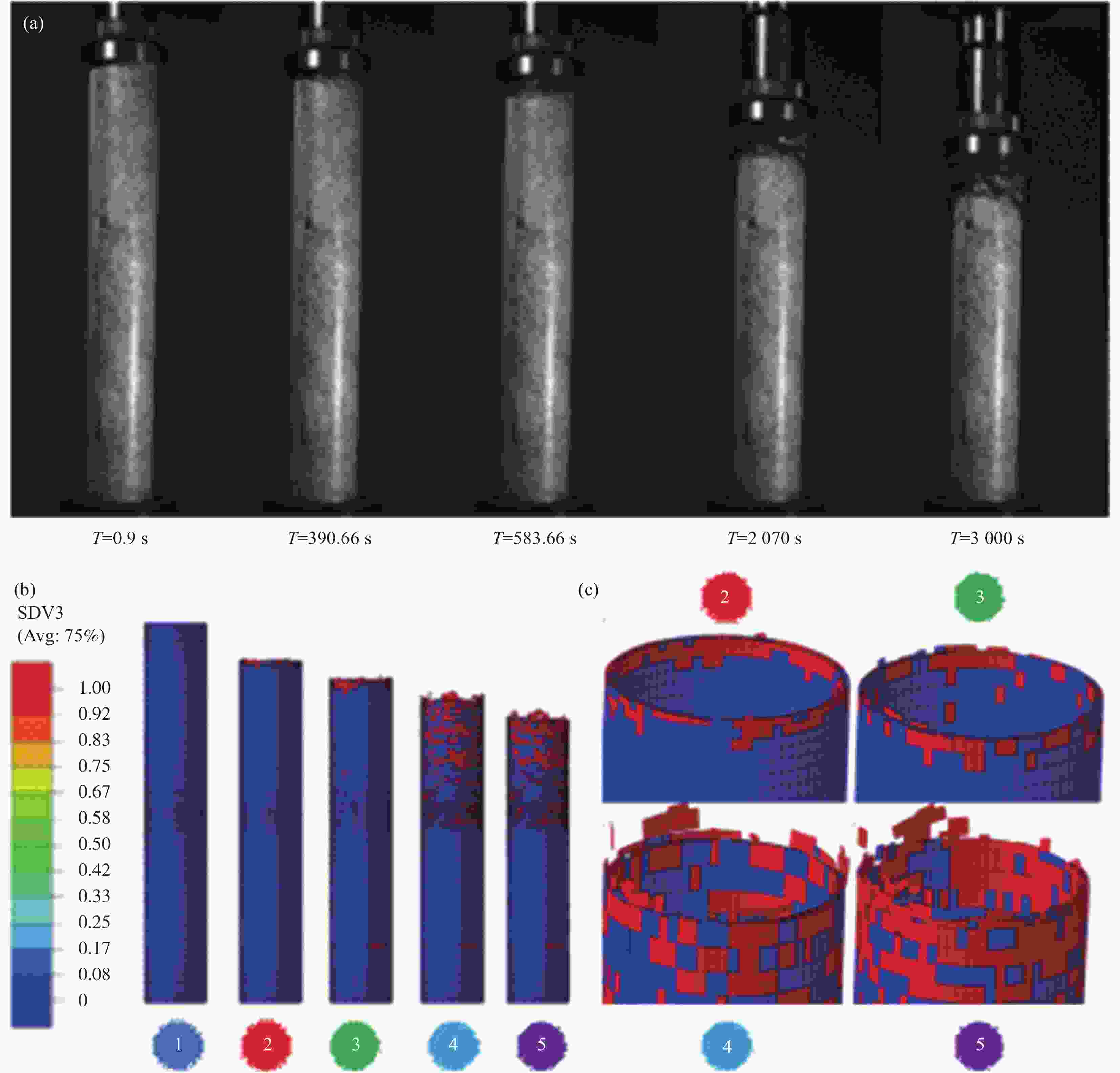

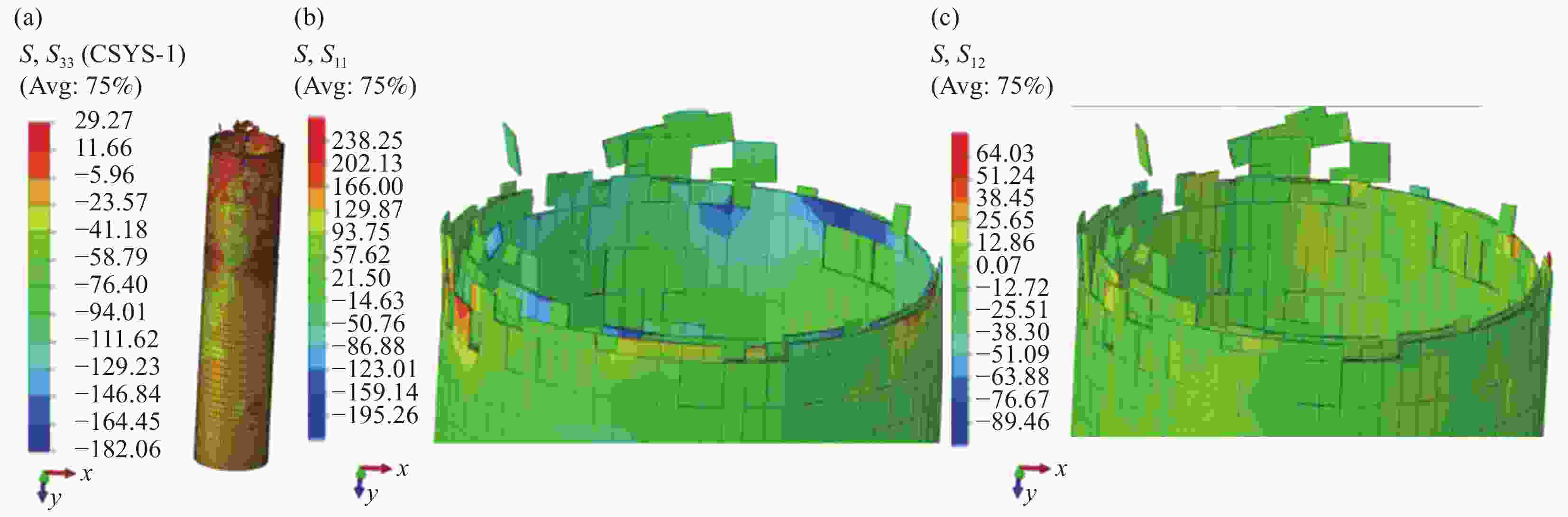

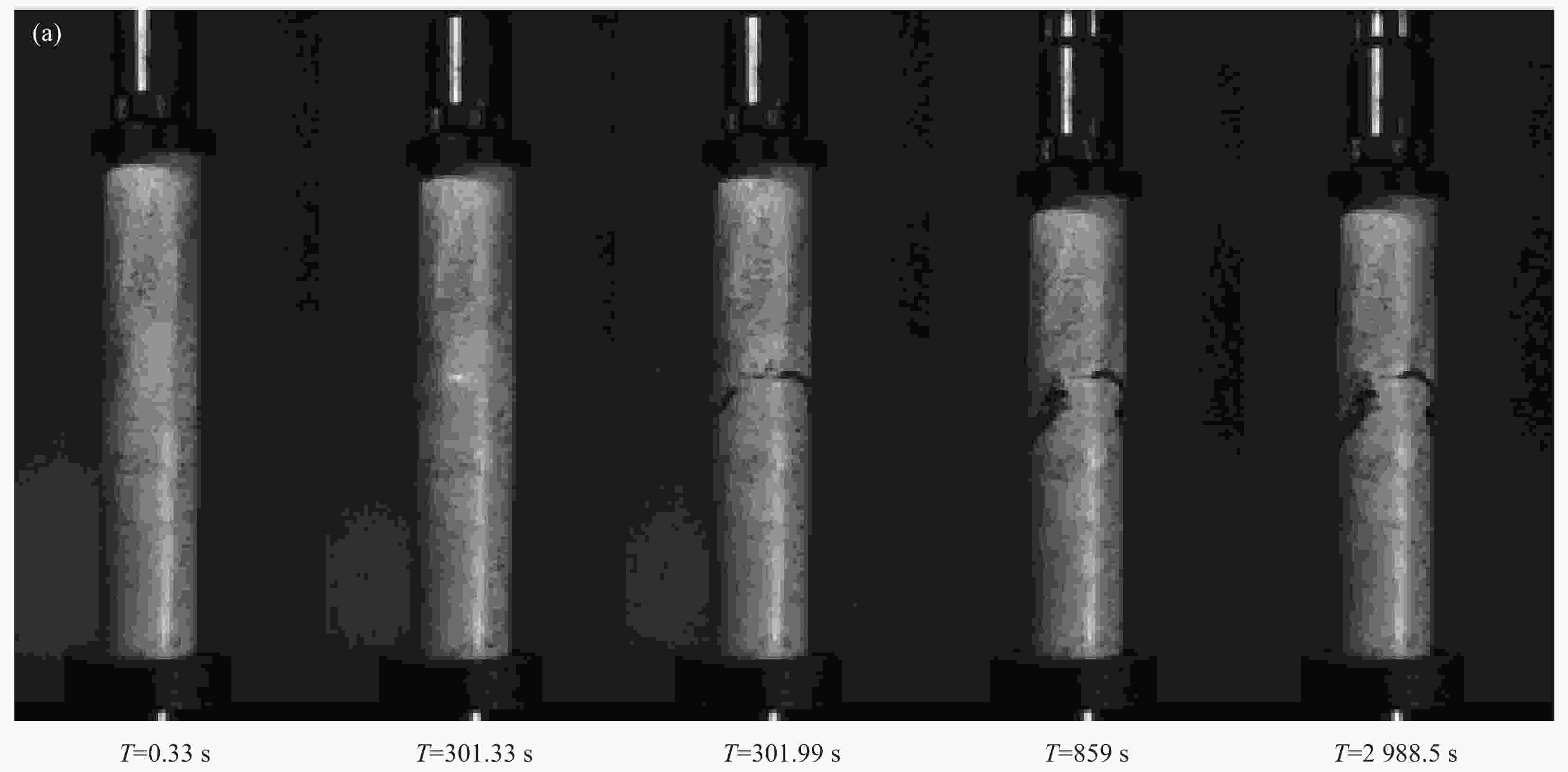

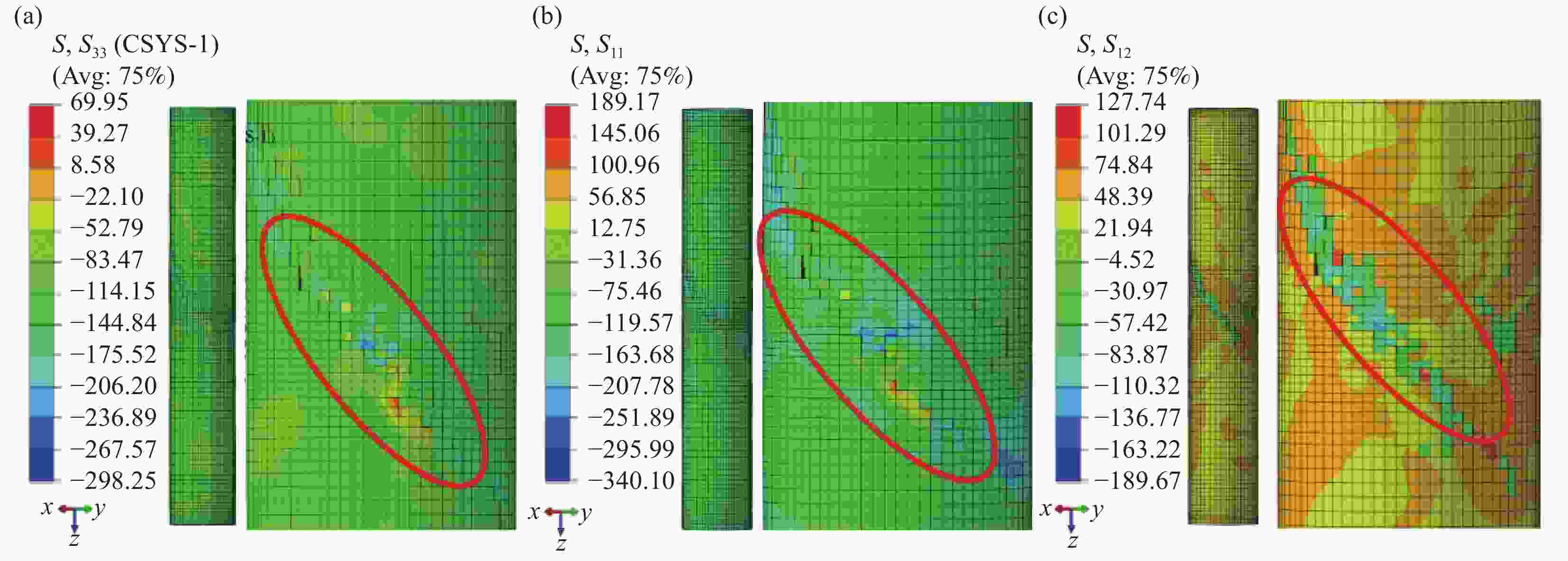

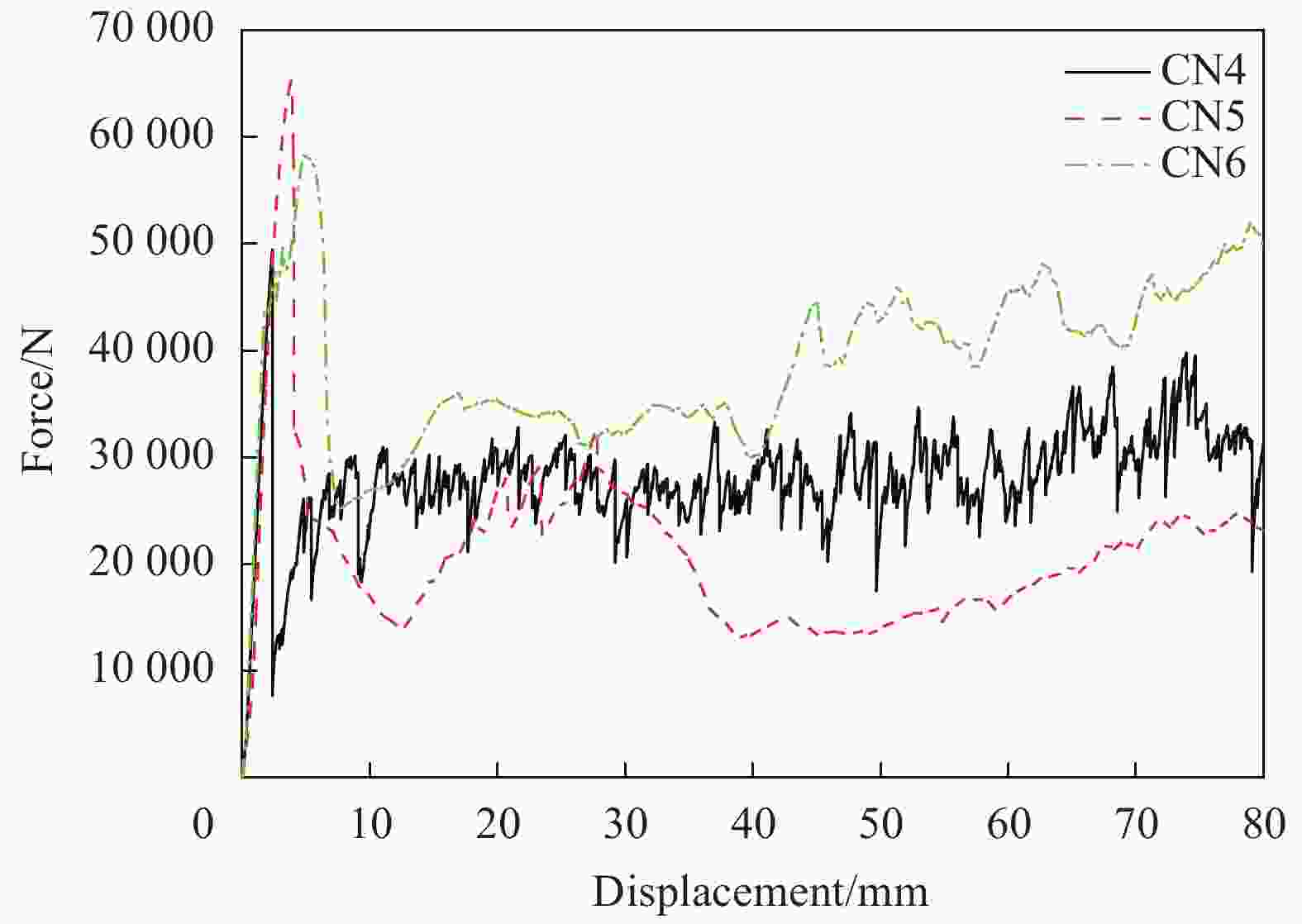

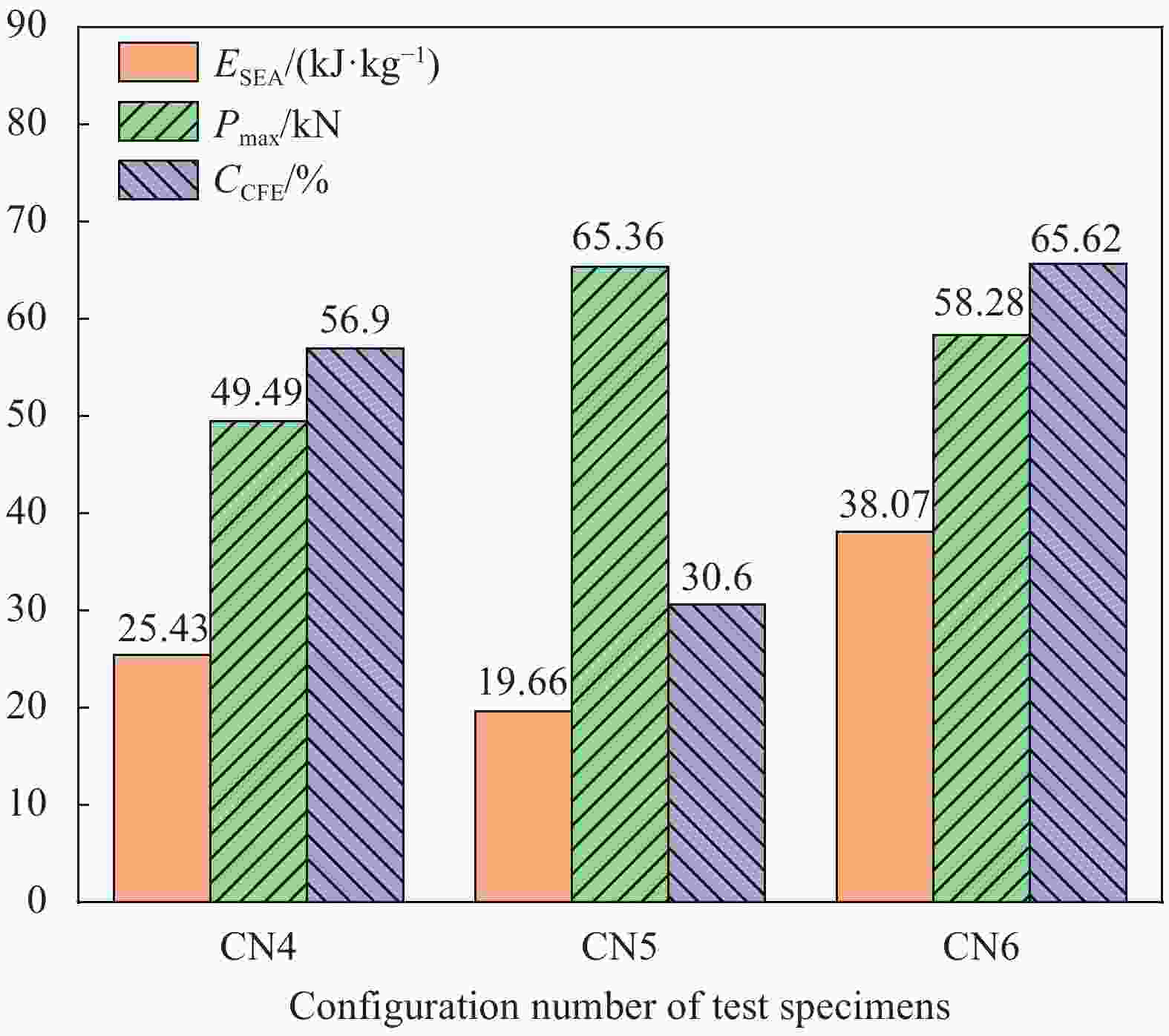

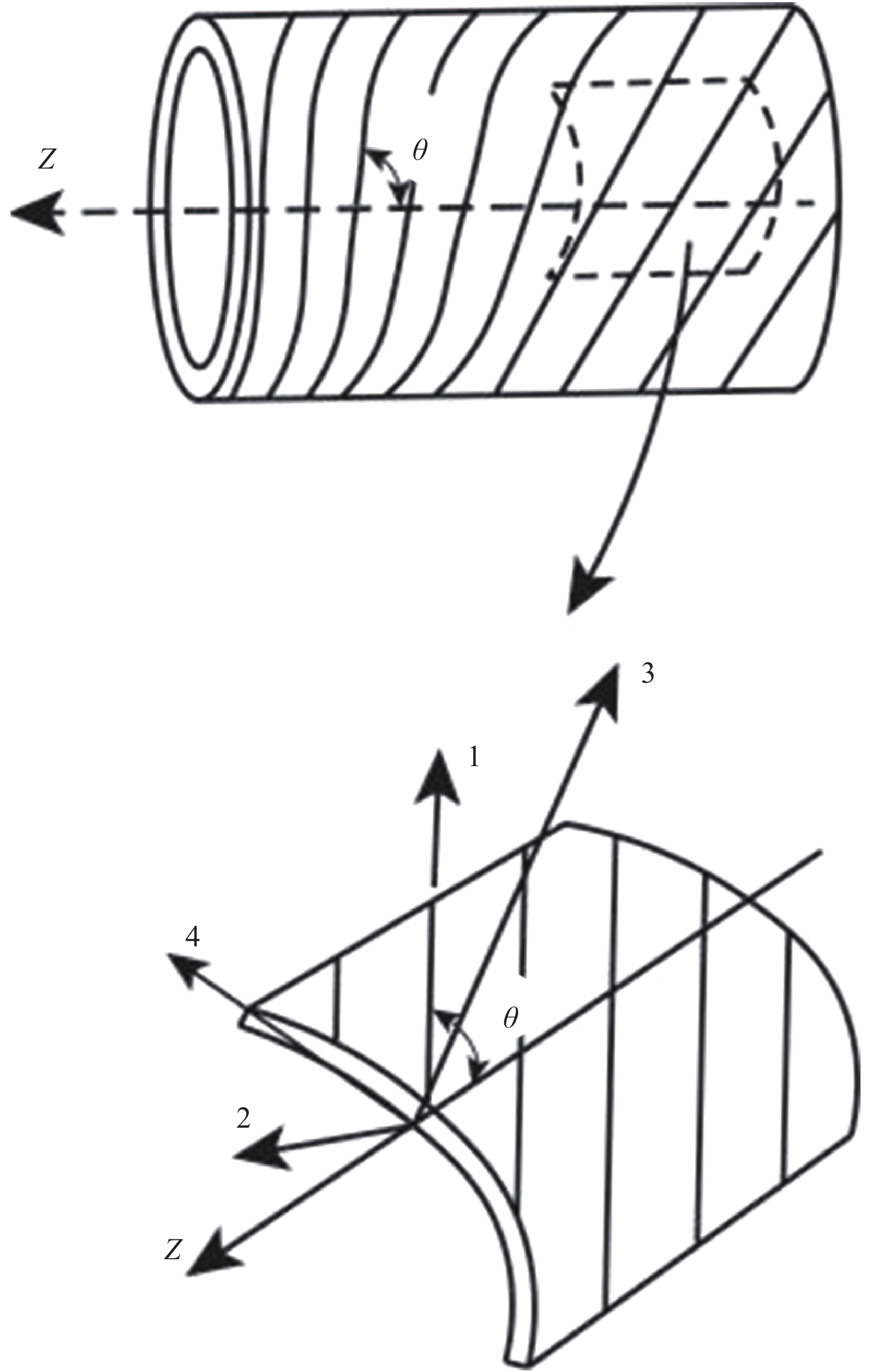

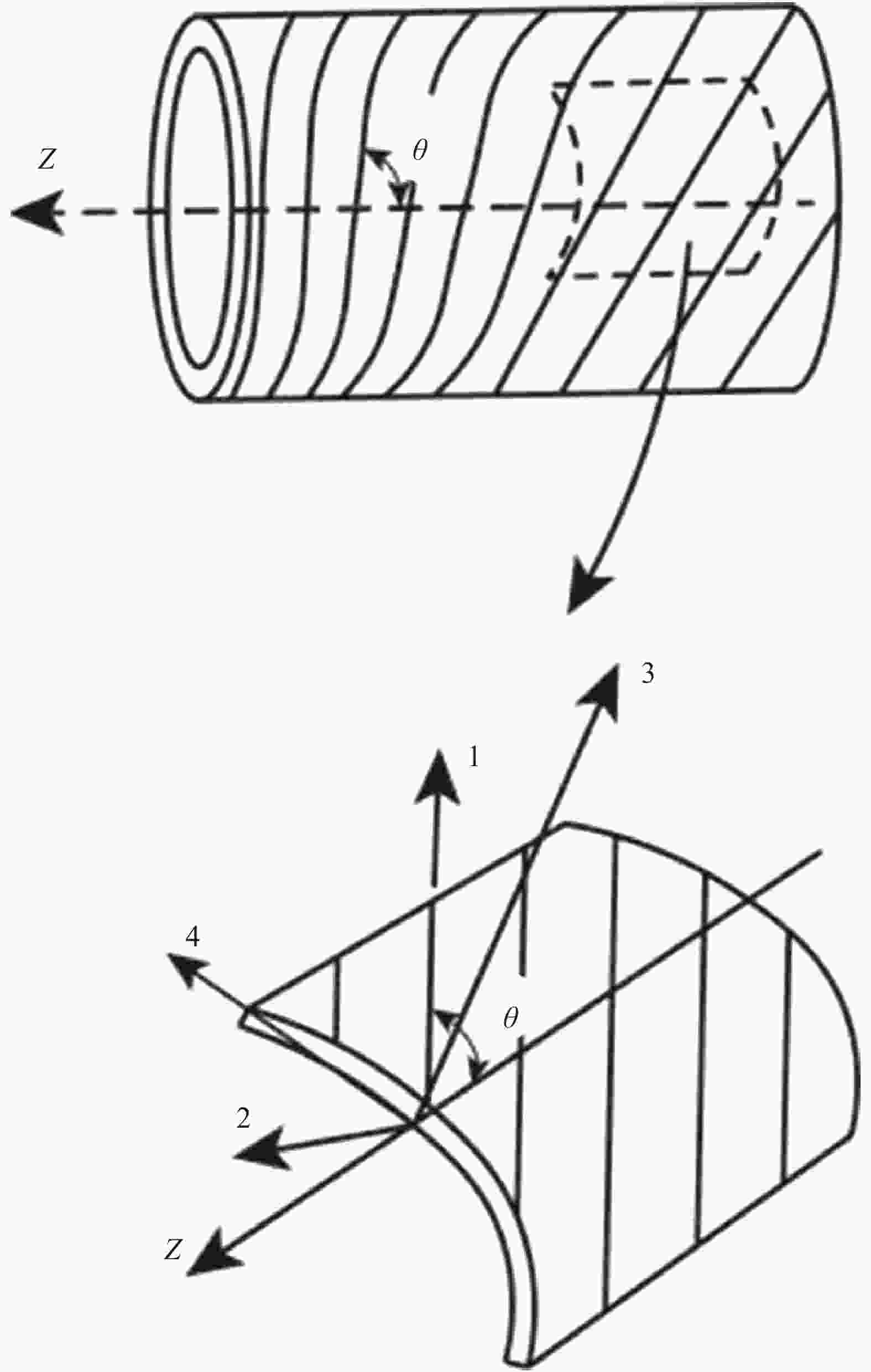

摘要: 通过控制缠绕线型改变轴管纤维角度,制备了一种轴向刚度渐变、压溃稳定的碳纤维增强树脂基复合材料(CFRP)变刚度薄壁圆管。对变刚度、[±45°]n以及[90°]n三类CFRP缠绕轴管进行轴向准静态压缩测试,结合数字图像相关技术(DIC)及有限元结果,对比三类结构压溃初始应变模式、损伤演化与应力状态结果,研究了变刚度结构的压溃响应与破坏机制。结果表明:不同纤维角度CFRP轴管因轴向刚度不同,压溃的初始破坏与损伤演化过程相异,三类结构产生不同的压溃响应与破坏模式。变刚度区连续变化的大角度纤维能有效地引发分层和“开花式”混合破坏,缓慢释放应变能,使变刚度CFRP轴管吸能效果明显优于其他两类结构。其峰值载荷为66.97 kN,压溃效率为50.8%,比吸能为10.1 kJ/kg,相对于[±45°]n结构比吸能提升156.35%,压溃效率提升518.76%,相对于[90°]n结构比吸能提升16.9%,压溃效率降低27.3%。Abstract: The fiber angles of the winding tubes were changed by controlling the winding lines to realize the gradual change of the stiffness along the axial direction, and then the collapse-stable carbon fiber/epoxy resin composite thin-walled tubes with variable stiffness were fabricated. Finally, the axial quasi-static crushing tests were carried out for three types of winding tubes with variable stiffness, [±45°]n and [90°]n structures. Combined with digital image correlation (DSC) technology and finite element analysis results, the initial strain modes, damage evolution and stress states were compared to study the crushing response and failure mechanism of variable stiffness structures. The results show that the initial failure and damage evolution of the tubes with different fiber angles are different due to the various axial stiffness, so the different crushing response and failure modes are generated respectively, and the continuously changing circular fibers in the variable stiffness zone can effectively cause the delaminated and “flowering” mode mixed damage to release the strain energy slowly. Therefore, the energy absorption effect of the variable stiffness structure is obviously better than that of other two structures. Its peak load is 66.97 kN, crushing efficiency is 50.8%, and specific energy absorption is 10.1 kJ/kg. Compared with the [±45°]n structure, the specific energy absorption increases by 156.35%, and the crushing efficiency increases by 518.76%. Compared with the [90°]n structure, the specific energy absorption increases by 16.9%, and the crushing efficiency reduces by 27.3%.

-

表 1 CFRP薄壁圆管整体压溃试样参数

Table 1. Parameters of the whole crushing test of CFRP thin-walled tube specimens

CN SN m/g L/mm l/mm Winding angle/(°) 1 W-CS-[90°]n 397.65 451.10 — 90 2 W-CS-[±45°]n 361.45 447.90 — 45 3 W-VS-100-45 376.17 448.10 100 90-45 Notes: CN—Configuration number of test specimens; SN—Serial number of test specimens; m—Mass; L—Total length; l—Length of one-side variable stiffness zone; W—Whole crushing test; CS—Constant stiffness structure; VS—Variable stiffness structure; 100-45—Structure with one-side variable stiffness length of 100 mm and central target angle of 45°. 表 2 CFRP薄壁圆管单侧压溃试样参数

Table 2. Parameters of one-side crushing test of CFRP thin-walled tube specimens

CN SN m/g L/mm Winding angle/(°) 4 S-VS-[90°]n 88.26 100.30 90 5 S-VS-[±45°]n 84.84 100.10 45 6 S-VS-100-45 81.19 99.91 90-45 Note: S—One-side crushing test. 表 3 T700SC 12K碳纤维/环氧树脂复合材料力学性能参数

Table 3. Mechanical property parameters of T700SC 12K carbon fiber/epoxy resin composites

Parameter Value Xt/Yt /MPa 2393/57 E1t/E2t /GPa 146/9.57 υ12/υ13 0.33 υ23 0.1 Xc/Yc /MPa 1000/106.07 G12 /GPa 6.19 τ12 /MPa 68 G13/G23 /GPa 3.5 τ13/τ23 /MPa 100 Ply thickness /mm 0.25 Notes: E1t, E2t—Tensile elastic modulus; υ12, υ13, υ23—Poisson’s ratio; G12, G13, G23—Shear modulus; Xt—Longitudinal tensile strength; Xc—Longitudinal compressive strength; Yt—Transverse tensile strength; Yc—Transverse compressive strength; τ12—In-plane shear stress; τ13, τ23—Interlaminar shear stress. -

[1] 蒋致禹, 顾敏童, 赵永生. 一种薄壁吸能结构的设计优化[J]. 振动与冲击, 2010, 29(2):111-116. doi: 10.3969/j.issn.1000-3835.2010.02.025JIANG Zhiyu, GU Mintong, ZHAO Yongsheng. Design and optimization of an energy-absorbing thin-walled structure[J]. Journal of Vibration and Shock,2010,29(2):111-116(in Chinese). doi: 10.3969/j.issn.1000-3835.2010.02.025 [2] HUO Peng, LI Jianping, XU Shucai, et al. A review on lightweight design and crashworthiness requirements of thin-walled tubular structure[J]. Journal of Mechanical Strength,2020,42(6):1377-1388. [3] 汪洋, 吴志斌, 刘富. 复合材料货舱地板立柱压溃响应实验[J]. 复合材料学报, 2020, 37(9):2200-2206.WANG Yang, WU Zhibin, LIU Fu. Crush experiment of composite cargo floor stanchions[J]. Acta Materiae Compositae Sinica,2020,37(9):2200-2206(in Chinese). [4] 陈静, 唐傲天, 田凯, 等. 碳纤维复合材料防撞梁轻量化设计[J]. 汽车工程, 2020, 42(3):390-395.CHEN Jing, TANG Aotian, TIAN Kai, et al. Lightweight design of carbon fiber composite anti-collision beam[J]. Automotive Engineering,2020,42(3):390-395(in Chinese). [5] AHMAD B, MUSTAFA S, ABDUL G O. On the crashworthiness performance of thin-walled energy absorbers: Recent advances and future developments[J]. Thin-Walled Structures,2017,118:137-163. doi: 10.1016/j.tws.2017.05.018 [6] REUTER C, TROSTER T. Crashworthiness and numerical simulation of hybrid aluminium-CFRP tubes under axial impact[J]. Thin-Walled Structures,2017,117:1-9. [7] 黄建城. 含薄弱环节复合材料圆管轴向吸能特性研究[D]. 南京: 南京航空航天大学, 2011.HUANG Jiancheng. On the axial energy absorption behaviour of composite tubes with crush triggers[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2011 (in Chinese). [8] SIVAKUMAR P, WIM V P, JORIS D, et al. Parametric study of crushing parameters and failure patterns of pultruded composite tubes using cohesive elements and seam, Part I: Central delamination and triggering modelling[J]. Polymer Testing,2010,29(6):729-741. doi: 10.1016/j.polymertesting.2010.05.010 [9] 程群峰, 许亚洪, 廖建伟, 等. 引发机制对复合材料波形梁吸能性能的影响及其破坏形貌分析[J]. 复合材料学报, 2008, 25(1):161-167. doi: 10.3321/j.issn:1000-3851.2008.01.027CHENG Qunfeng, XU Yahong, LIAO Jianwei, et al. Effects of triggers on the energy absorption behavior of sine-wave beam and the crush morphology[J]. Acta Materiae Compositae Sinica,2008,25(1):161-167(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.027 [10] SUPIAN A B M, SAPUAN S M, ZUHRI M Y M, et al. Hybrid reinforced thermoset polymer composite in energy absorption tube application: A review[J]. Defence Technology,2018,14(4):291-305. doi: 10.1016/j.dt.2018.04.004 [11] 曹文锋. CFRP薄壁圆管轴向压溃响应及耐撞性研究[D]. 长沙: 湖南大学, 2017.CAO Wenfeng. The research on crushing response and crashworthiness under axial compression of thin-walled CFRP tubes[D]. Changsha: Hunan University, 2017 (in Chinese). [12] 张纯金, 任勇生, 张玉环. 受力状态下的复合材料传动轴变形分析[J]. 机械设计与制造, 2019, (9):67-70. doi: 10.3969/j.issn.1001-3997.2019.09.017ZHANG Chunjin, REN Yongsheng, ZHANG Yuhuan. Analysis deformation of the composite material drive shaft under forces condition[J]. Machinery Design & Manufacture,2019, (9):67-70(in Chinese). doi: 10.3969/j.issn.1001-3997.2019.09.017 [13] LOKMAN G. Investigation of the effect of stacking sequence on low velocity impact response and damage formation in hybrid composite pipes under internal pressure. A comparative study[J]. Composites Part B:Engineering,2018,153:217-232. doi: 10.1016/j.compositesb.2018.07.056 [14] 王璠, 何一帆, 宋毅, 等. 引发方式、铺层对纤维增强复合材料圆柱壳吸能特性影响的冲击试验研究[J]. 振动工程学报, 2013, 26(1):33-40. doi: 10.3969/j.issn.1004-4523.2013.01.006WANG Fan, HE Yifan, SONG Yi, et al. The impact experimental study of evoking type and layup type on absorption energy of fiber reinforced composite cylindrical shell[J]. Journal of vibration Engineering,2013,26(1):33-40(in Chinese). doi: 10.3969/j.issn.1004-4523.2013.01.006 [15] JOOSTEN M W. Experimental and numerical investigation of triggered composite energy absorbing structures[D]. Sydney: School of Mechanical and Manufacturing Engineering University of New South Wales, 2011. [16] 孙士平, 张冰, 邓同强, 等. 复合载荷作用变刚度复合材料回转壳屈曲优化[J]. 复合材料学报, 2019, 36(4):1052-1061.SUN Shiping, ZHANG Bing, DENG Tongqiang, et al. Buckling optimization of variable stiffness composite rotary shell under combined loads[J]. Acta Materiae Compositae Sinica,2019,36(4):1052-1061(in Chinese). [17] 钟继凡. 基于代理模型的变刚度复合材料结构优化设计[D]. 武汉: 华中科技大学, 2018.ZHONG Jifan, Optimization design of variable stiffness composite structures based on meta-models[D]. Wuhan: Huazhong University of Science and Technology, 2018 (in Chinese). [18] 孙滔. 碳/环氧编织复合材料层合板挤压特性研究[D]. 南昌: 南昌大学, 2017.SUN Tao. Study on the bearing properties of braided carbon/epoxy composite laminates[D]. Nanchang: Nanchang University, 2017 (in Chinese). [19] FERHAT K, MURAT D. Failure behaviour of the single lap joints of angle-plied composites under three point bending tests[J]. Journal of Adhesion Science and Technology,2020,34(5):531-548. doi: 10.1080/01694243.2019.1674101 [20] DANNANA D, PRASHANT E, MARIMUTHU K P. Simulative estimation of reaction force and drill accuracy of CFRP composites[J]. Materials Science Forum,2020,4863:344-350. [21] 马聪承. 轻质吸能结构改善汽车碰撞安全性研究[D]. 广州: 华南理工大学, 2017.MA chengcong. Improvement of vehicle crashworthiness bylightweight energy absorbing structure[D]. Guangzhou: South China University of Technology, 2017 (in Chinese) [22] MEREDITH J, BILSON E, POWE R, et al. A performance versus cost analysis of prepreg carbon fibre epoxy energy absorption structures[J]. Composite Structures,2015,124:206-213. doi: 10.1016/j.compstruct.2015.01.022 [23] 吴悦雷. 基于有限元仿真的CFRP复合材料抗冲击性能优化[D]. 天津: 中国民航大学, 2018.WU Yuelei. Optimization of impact resistance of CFRP composites based on finite element simulation[D]. Tianjin: Civil Aviation University of China, 2018 (in Chinese). -

下载:

下载: