Mechanical properties of composite bi-directional corrugated sandwich structure

-

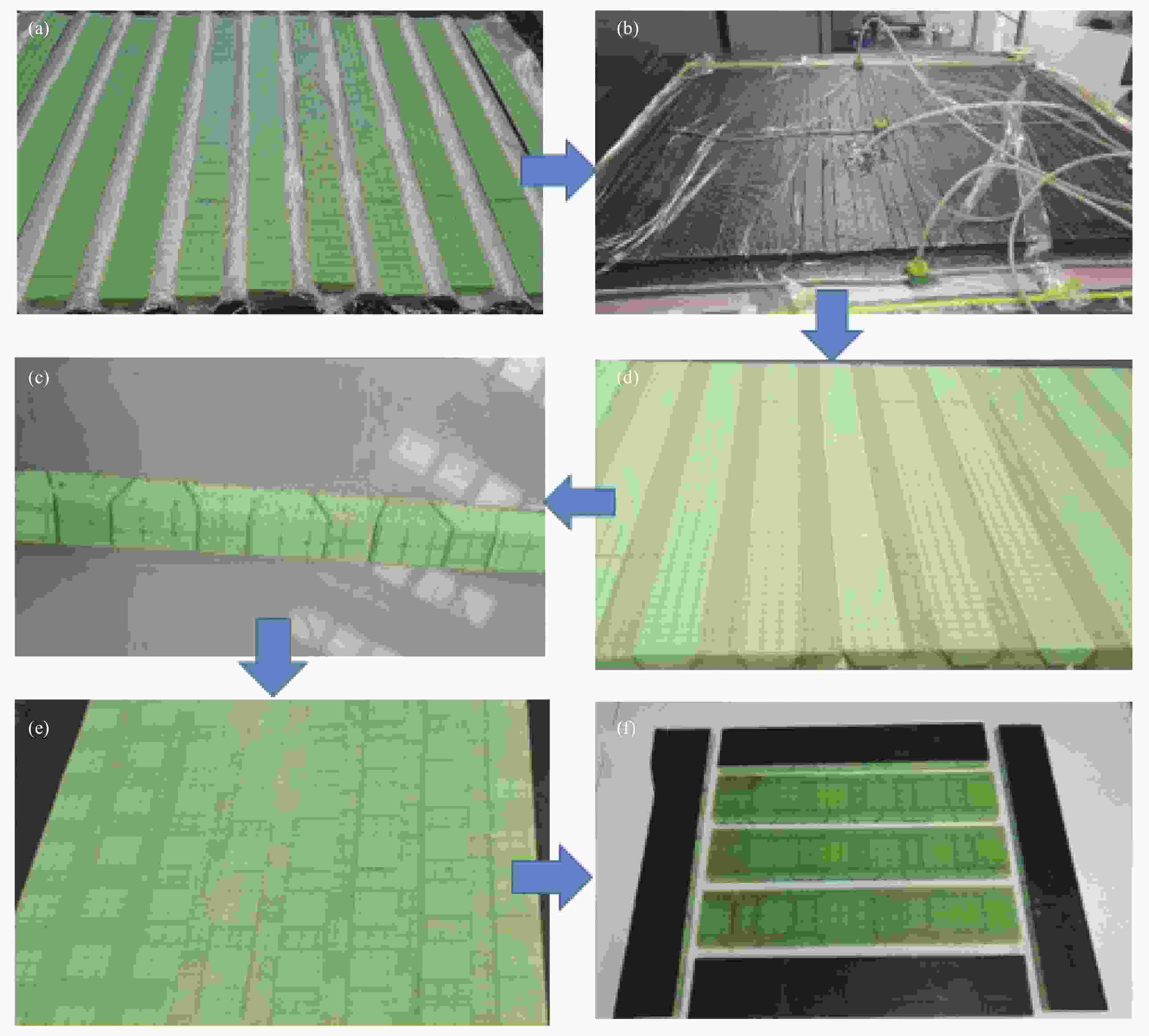

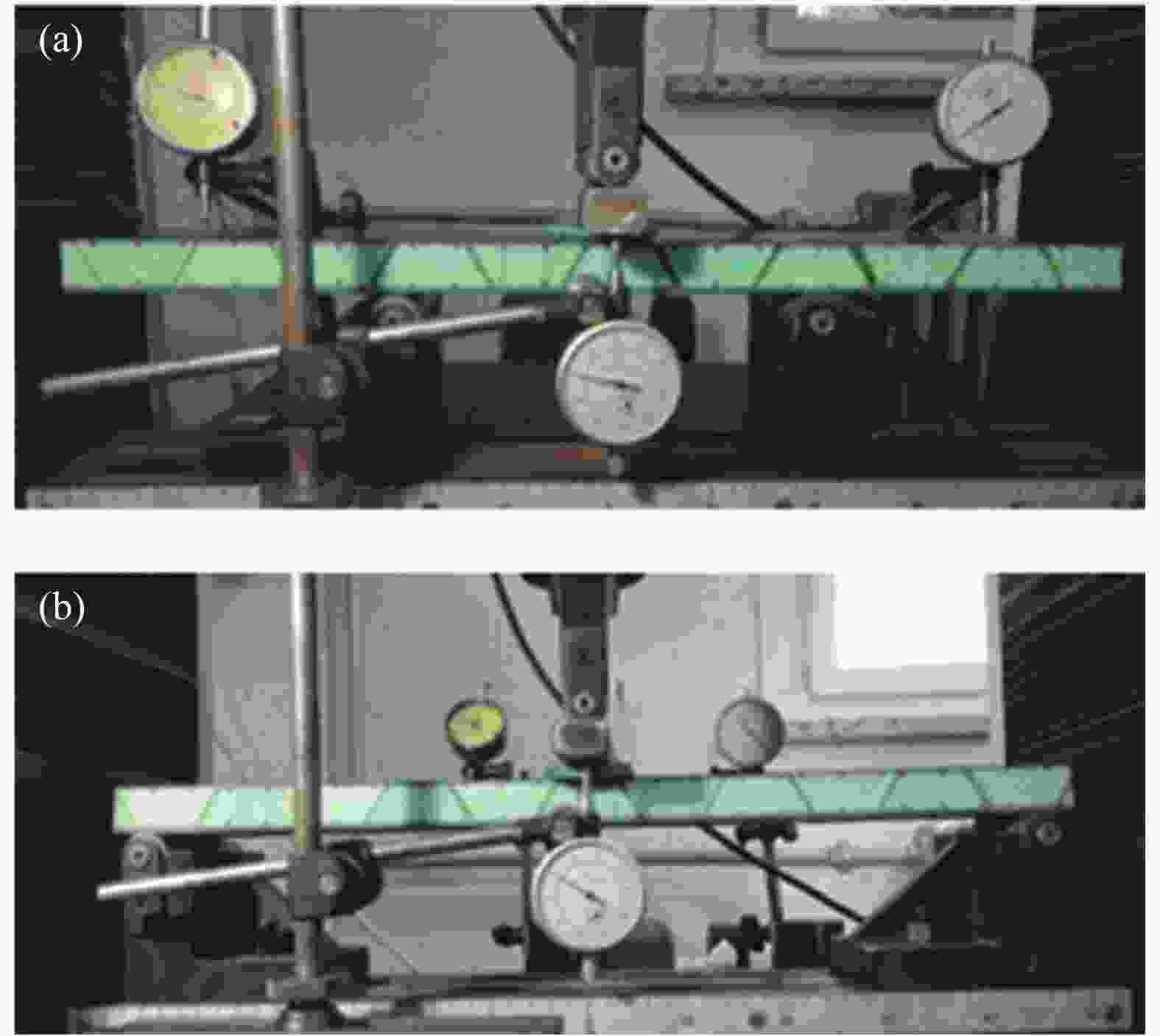

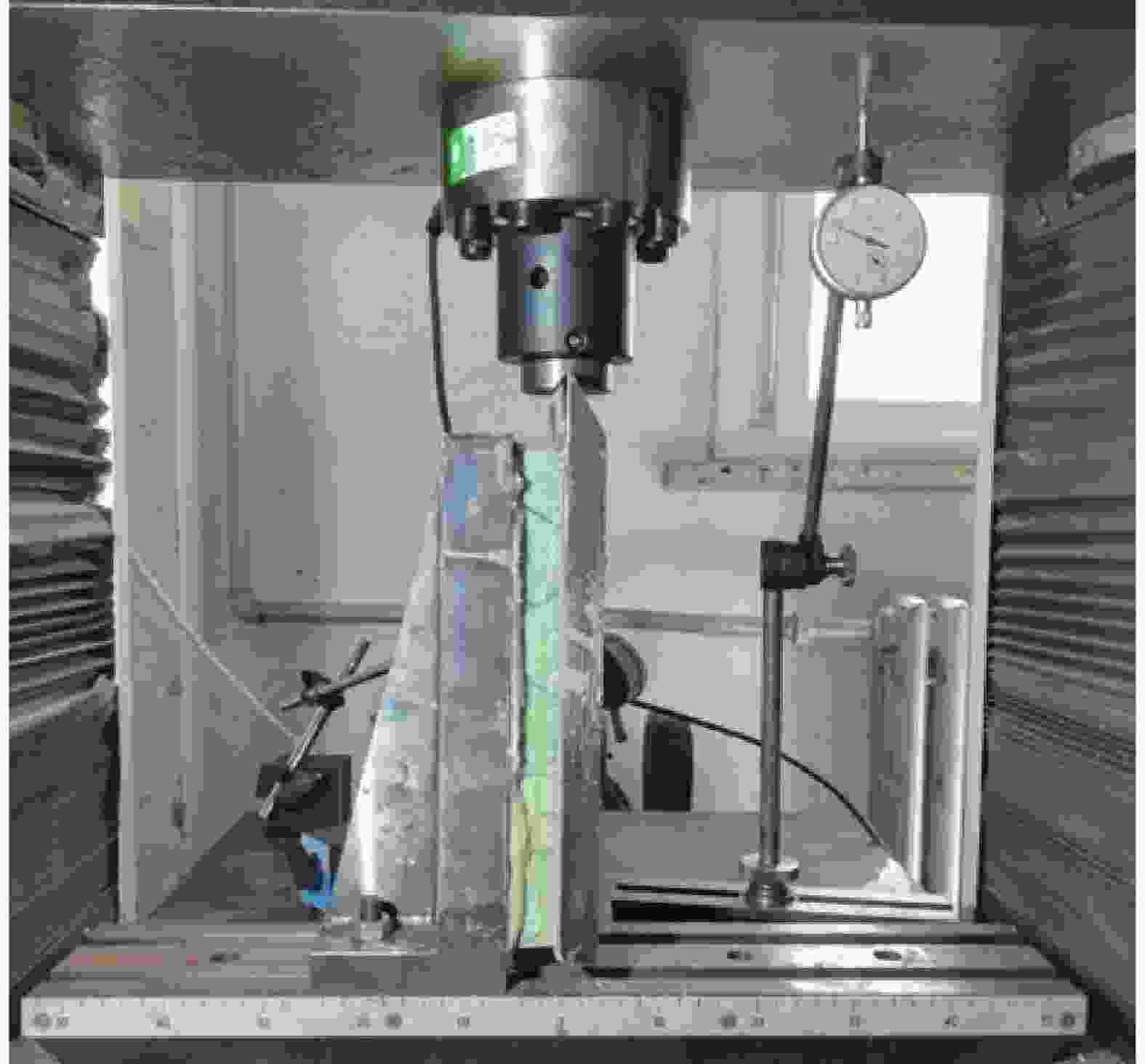

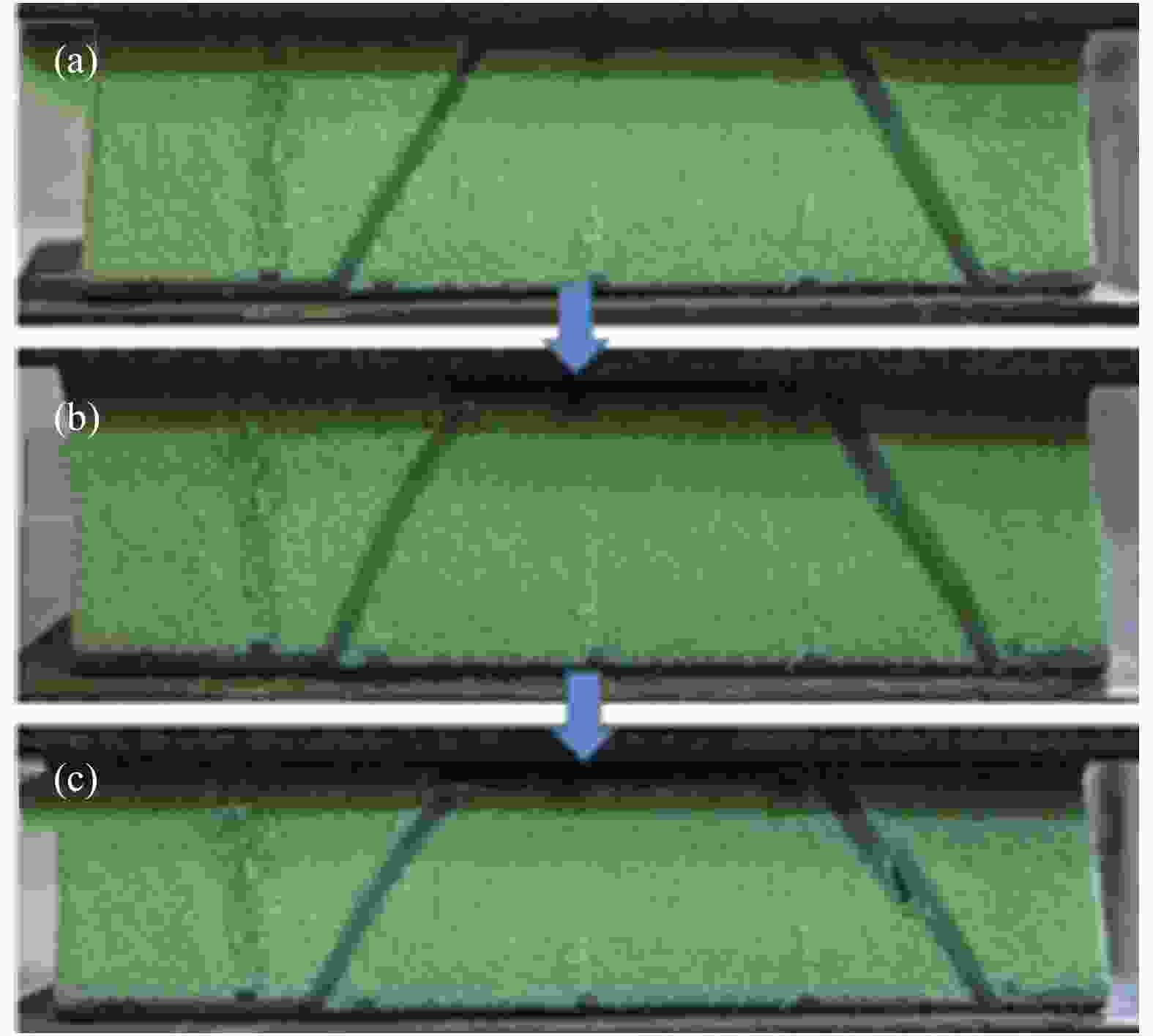

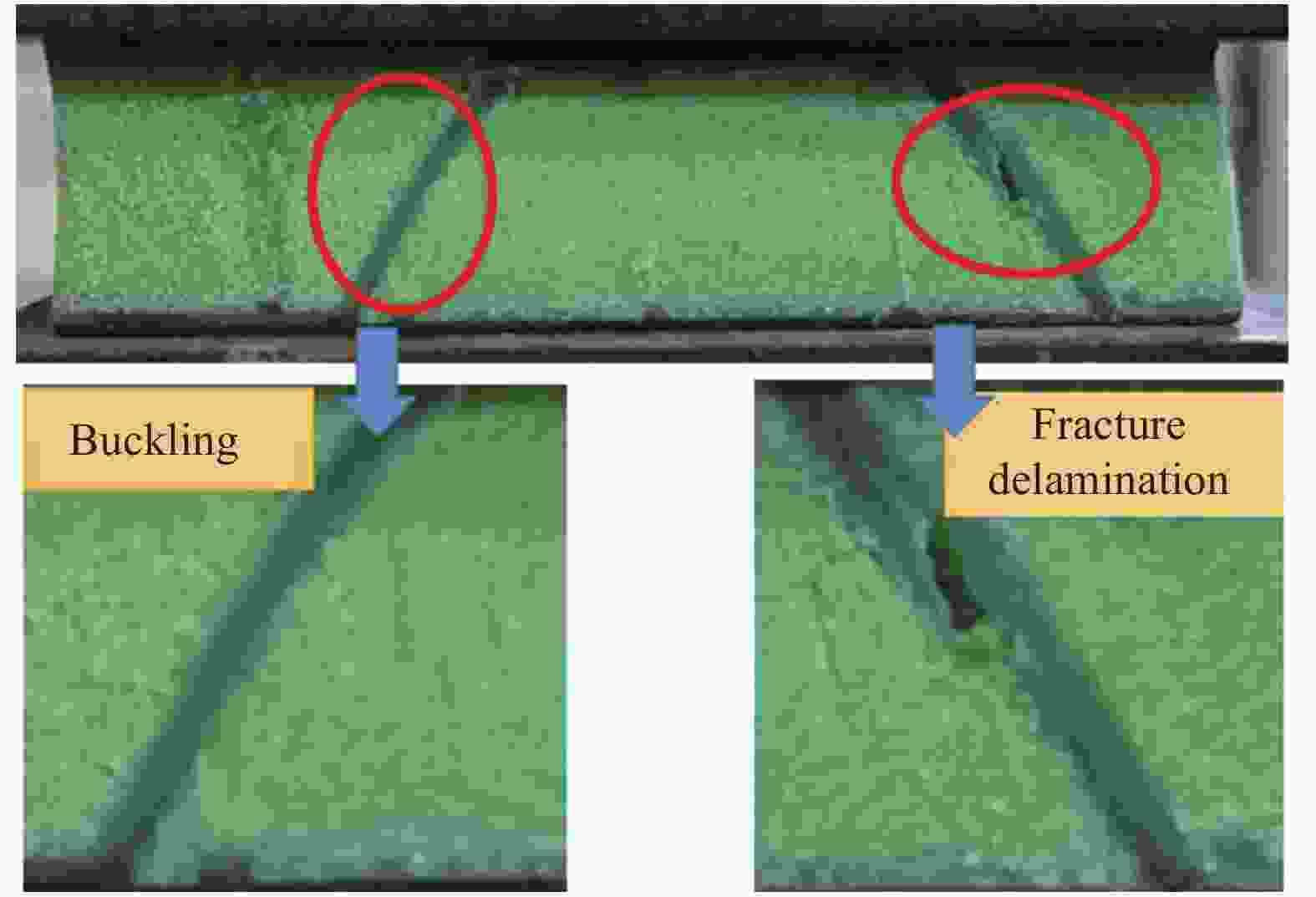

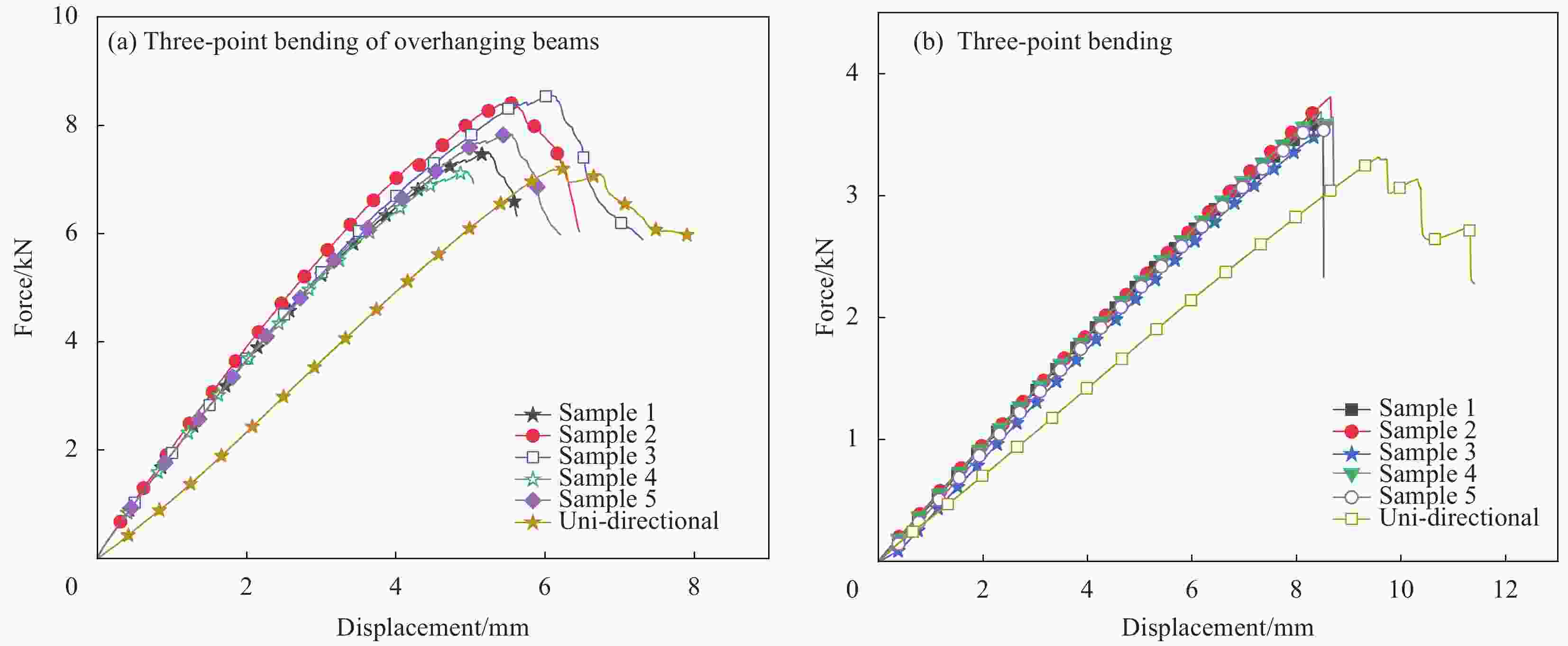

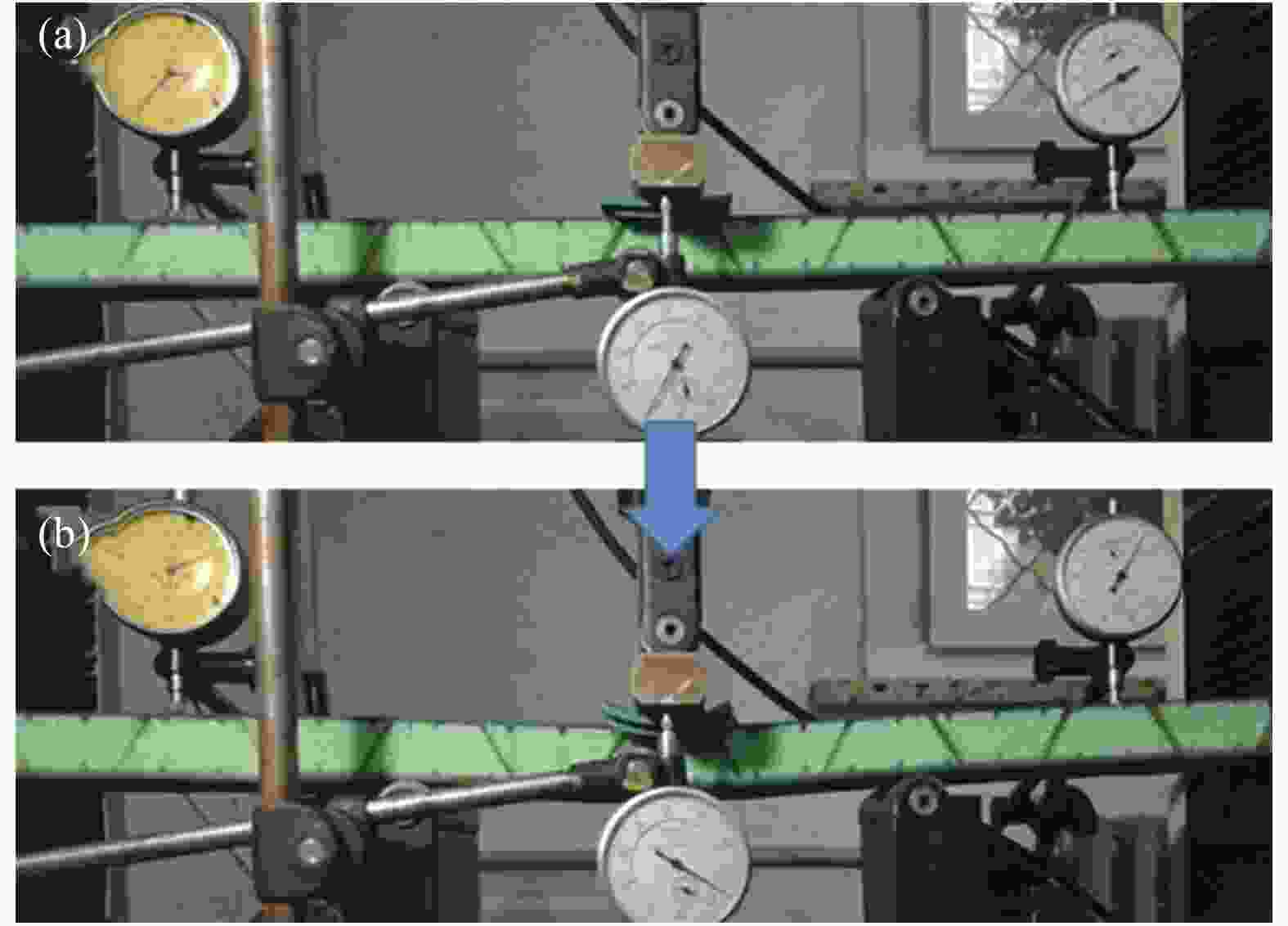

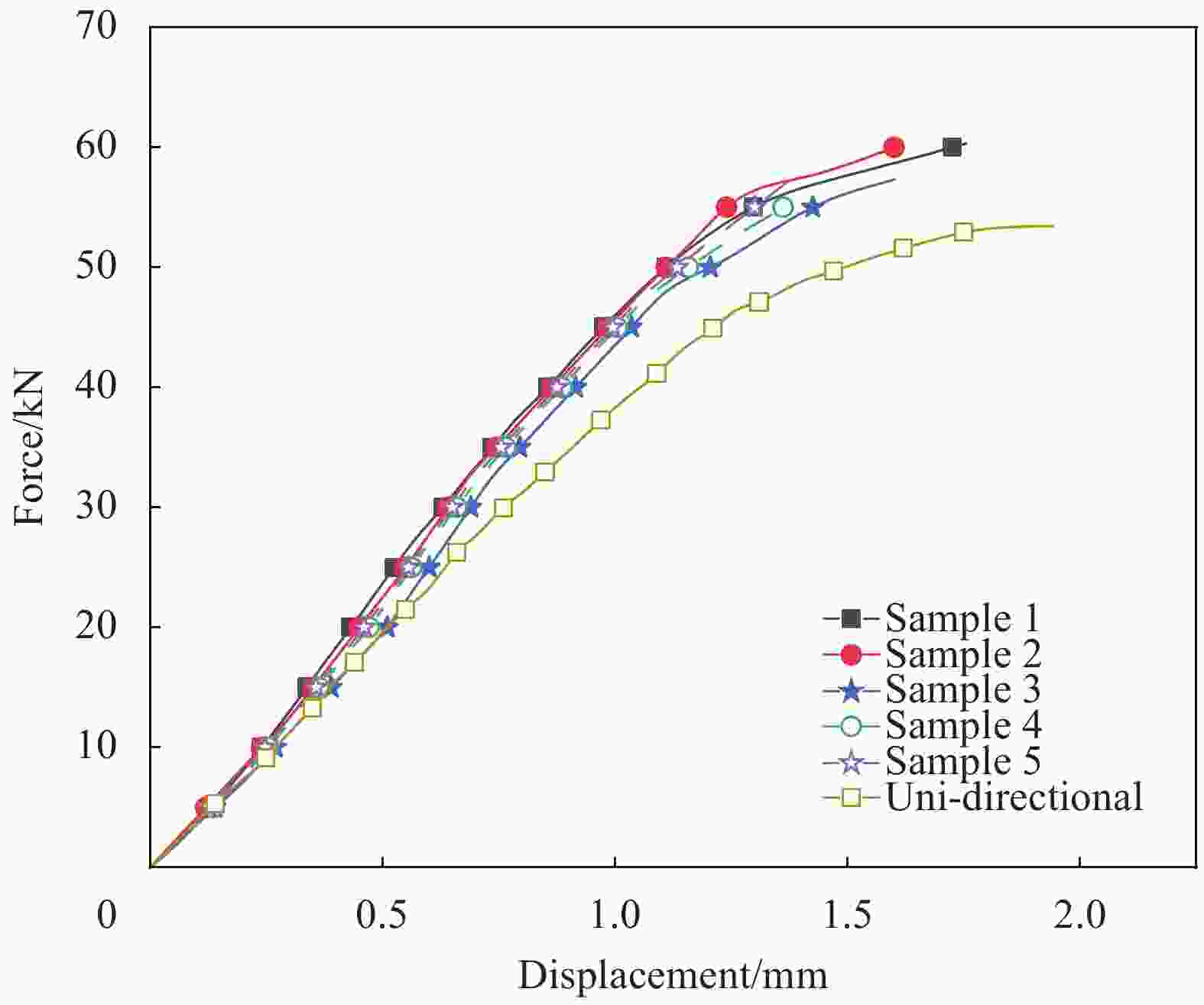

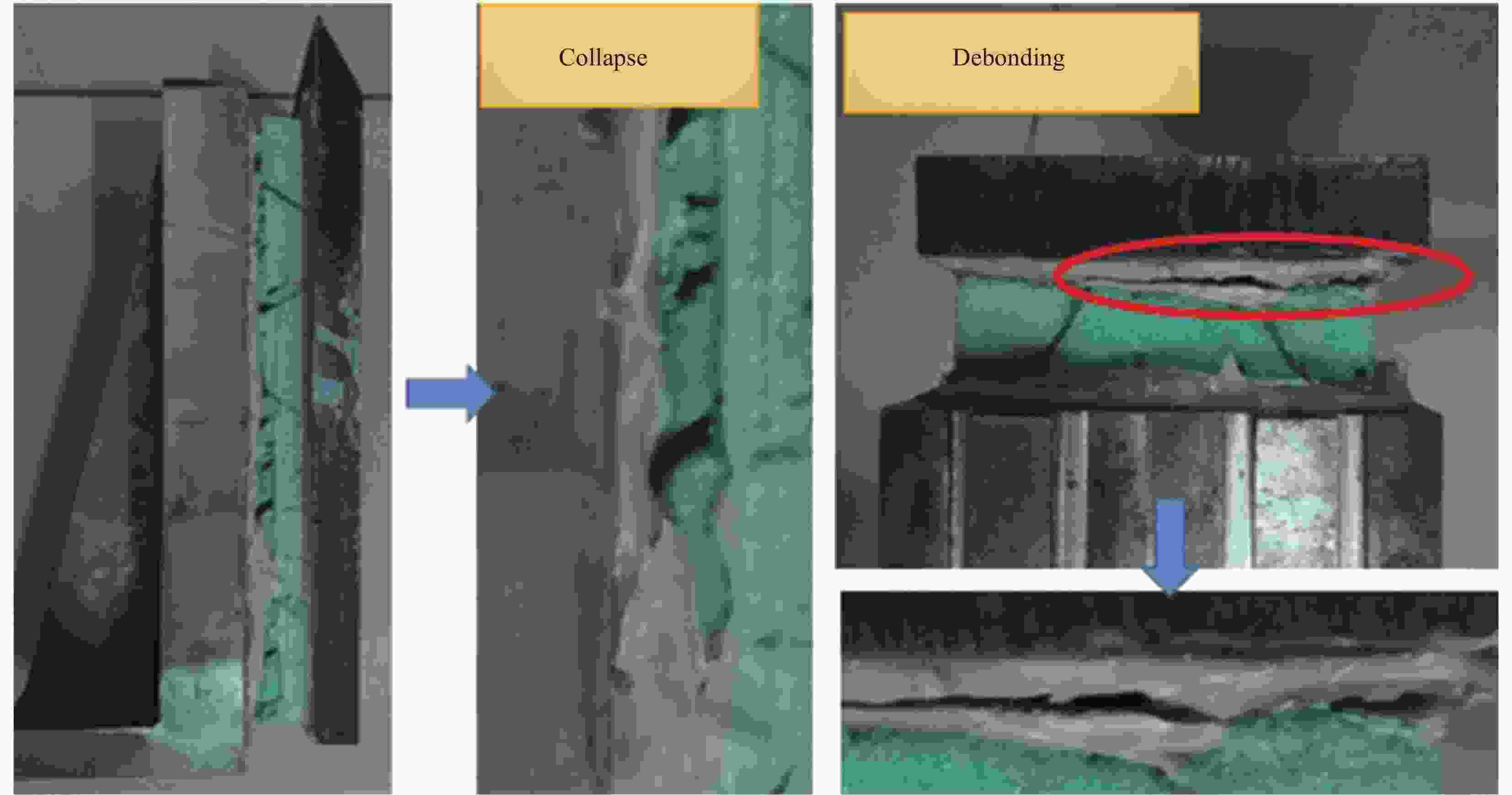

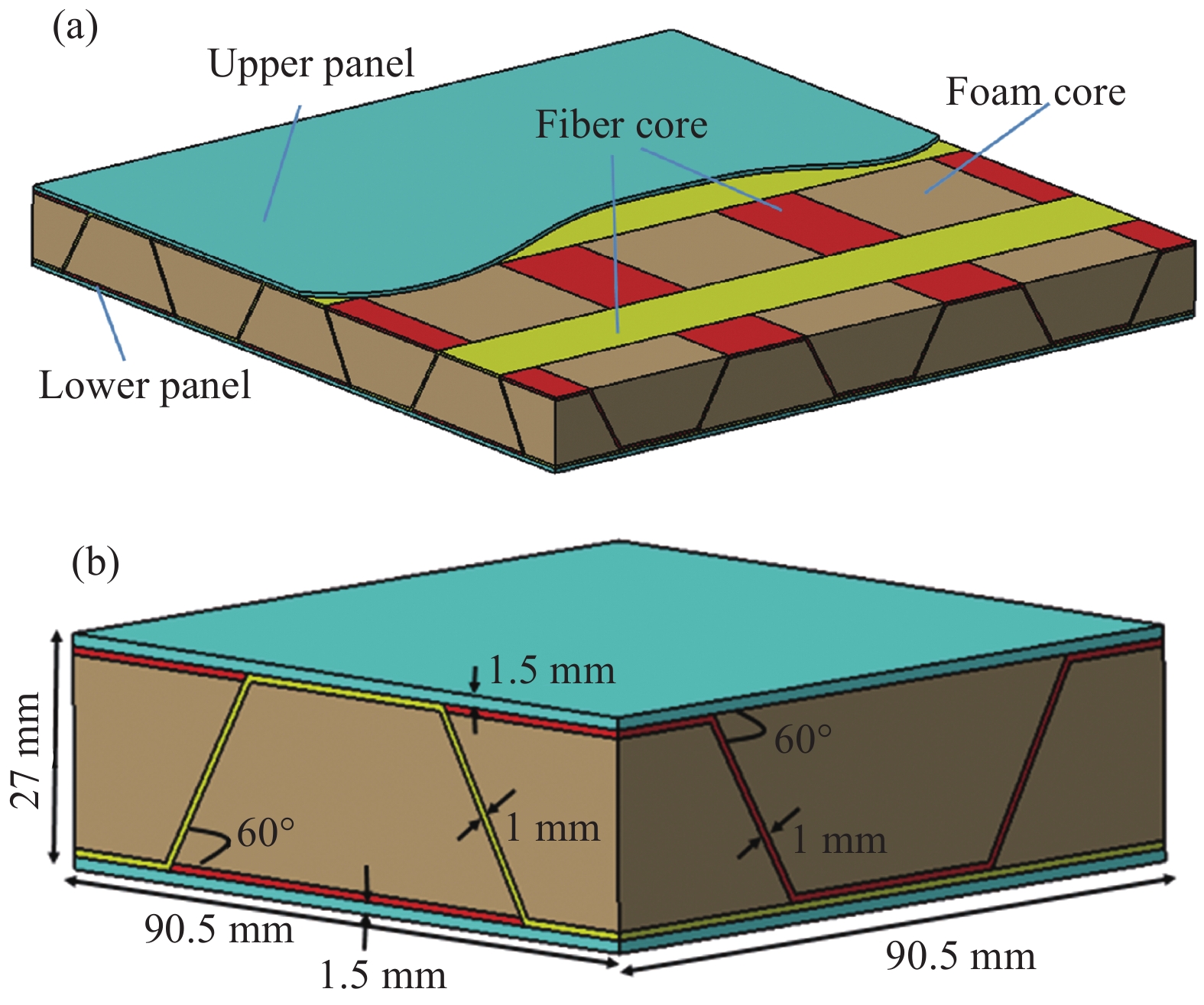

摘要: 为改进传统单向波纹夹层结构横向力学性能较差的缺点,设计了一种新型复合材料双向波纹夹层结构。考虑复合材料双向夹层结构制备困难,研究了整套真空辅助成型工艺(VARI)工艺制备方案,实现双向波纹夹层结构的高效制备,以满足工程应用的需要。对制备出的复合材料双向波纹夹层结构与单向波纹夹层结构分别进行面外压缩、弯曲和剪切实验,分析了双向波纹夹层结构在不同载荷下的破坏模式及其失效机制,计算了该结构在不同荷载条件下的强度和模量,并将其与单向波纹夹层结构进行对比分析。结果表明,在压缩荷载作用下,玻璃纤维/环氧树脂芯子为主要承载部分,结构的失效主要体现在芯子的屈曲、断裂和分层;在弯曲荷载的作用下,由于纤维的抗压强度远小于抗拉强度,所以压头下方的上面板最先达到破坏荷载,结构的弯曲失效形式主要为上面板的断裂和脱粘;结构的剪切失效主要以泡沫与面板的脱粘和压溃为主,芯子和面板未见明显的破坏现象;与单向波纹夹层结构相比,双向波纹夹层结构力学性能显著提升。Abstract: To improve the transverse mechanical heterogeneity of conventional uni-directional corrugated sandwich structures, a new type of bi-directional composite corrugated sandwich structure was designed. Considering the difficulty of manufacturing the bi-directional corrugated sandwich structure, a procese based on vacuum assistant resin infusion (VARI) was proposed for high efficiency and quality preparation. The prepared structures were subjected to compression, bending and shear tests. The failure modes and mechanism of the bi-directional composite sandwich structures were analyzed, the strength and modulus of the structure under different load conditions were obtained, and the comparison between the bi-directional and uni-directional corrugated sandwich structure was made. The results show that the glass fiber/epoxy resin core is the main bearing part under the compression load, and the failure of the structure is mainly reflected in the buckling, fracture and delamination of the core. Under the bending load, caused by the lower compressive strength than its tensile strength of fiber, the upper panel first reaches the failure load under the pressure head. The bending failure modes of the structure are mainly the fracture and debonding of upper panel. The shear failure of the structure is mainly caused by the debonding of the foam and the panel and the collapse of the foam, but the core and the panel are not obviously destroyed. Compared with uni-directional corrugated sandwich structure, the mechanical properties of bi-directional corrugated sandwich structure are significantly improved.

-

表 1 制备复合材料双向波纹夹层结构材料的材料属性:(a)碳纤维平纹织物/环氧(CF/EP)复合材料和玻璃纤维平纹织物/环氧(GF/EP)复合材料;(b)聚氯乙烯(PVC)泡沫

Table 1. Properties of the materials used to produce the bi-directional corrugated-core sandwich panels: (a) Carbon fiber/epoxy (CF/EP) and glass fiber/epoxy (GF/EP) composites; (b) Polyvinyl chloride (PVC) foam

(a) Properties of CF/EP and GF/EP composites Property E11/GPa E22/GPa E33/GPa G12/GPa G13,G23/GPa υ12/GPa υ13, υ13/GPa ρ/(kg·m−3) Value(GF/EP) 22 22 8.9 4.4 5.3 0.3 0.45 1800 Value(CF/EP) 72 72 10 4.5 5.6 0.34 0.45 1600 (b) Properties of PVC foam Property Density/(kg·m−3) Elasticity modulus/MPa Poisson's ratio Value 80 90 0.4 Notes: E11—Longitudinal stiffness; E22—Transverse stiffness; E33—Out-of-plane stiffness; υ12, υ13,υ23—Poisson's ratio; G12, G13,G23—Shear modulus. 表 2 复合材料单向和双向波纹夹层结构压缩性能

Table 2. Compressive properties of composite uni-directional and bi-directional corrugated sandwich structure

Sample 1 2 3 4 5 Uni-directional Compression strength/MPa 7.15 10.38 9.72 7.78 9.66 7.83 Compression modulus/MPa 199.43 212.32 218.92 232.35 263.92 135.36 表 3 复合材料单向和双向波纹夹层结构弯曲性能

Table 3. bending properties of composite uni-directional and bi-directional corrugated sandwich structure

Sample 1 2 3 4 5 Uni-directional Bending strength/MPa 142.17 152.23 138.74 144.11 142.75 112.59 Bending stiffness/(kN·m2) 1.50 1.56 1.72 1.60 1.65 1.17 表 4 复合材料单向和双向波纹夹层结构剪切性能

Table 4. Shear properties of composite uni-directional and bi-directional corrugated sandwich structure

Sample 1 2 3 4 5 Uni-directional Shear strength/MPa 2.77 3.00 2.87 2.82 2.98 2.21 Shear modulus/MPa 50.77 50.28 52.20 51.00 51.8 41.5 -

[1] MARTINEZ O A, SANKAR B V, HAFTKA R T, et al. Micromechanical analysis of composite corrugated-core sandwich panels for integral thermal protection systems[J]. AIAA Journal,2007,45(9):2323-2336. doi: 10.2514/1.26779 [2] THILL C, ETCHES J A, BOND I P, et al. Composite corru-gated structures for morphing wing skin applications[J]. Smart Materials and Structures,2010,19(12):1-10. [3] KNOX E M, COWLING M J, WINKLE I E J M S. Adhesively bonded steel corrugated core sandwich construction for marine applications[J]. Marine Structures, 1998, 11(4): 185-204. [4] LIANG C C, YANG M F, WU P W. Optimum design of metallic corrugated core sandwich panels subjected to blast loads[J]. Ocean Engineering,2001,28(7):825-861. doi: 10.1016/S0029-8018(00)00034-2 [5] DUBINA D, UNGUREANU V, GîLIA L. Cold-formed steel beams with corrugated web and discrete web-to-flange fasteners[J]. Steel Construction, 2013, 6(2): 74-81. [6] CARTIE D D, FLECK N A. The effect of pin reinforcement upon the through-thickness compressive strength of foam-cored sandwich panels[J]. Composites Science and Technology,2003,63(16):2401-2409. doi: 10.1016/S0266-3538(03)00273-2 [7] PETRAS A, SUTCLIFFE M P F. Failure mode maps for honey-comb sandwich panels[J]. Composite Structures,1999,44(4):237-252. doi: 10.1016/S0263-8223(98)00123-8 [8] FENG L J, YANG Z T, YU G C, et al. Compressive and shear properties of carbon fiber composite square honeycombs with optimized high-modulus hierarchical phases[J]. Composite Structures,2018,201:845-856. doi: 10.1016/j.compstruct.2018.06.080 [9] FINNEGAN K, KOOISTRA G, WADLEY H N G, et al. The compressive response of carbon fiber composite pyramidal truss sandwich cores[J]. International journal of materials research,2007,98(12):1264-1272. doi: 10.3139/146.101594 [10] XIONG J, MA L, VAZIRI A, et al. Mechanical behavior of carbon fiber composite lattice core sandwich panels fabri-cated by laser cutting[J]. Acta Materialia,2012,60(13-14):5322-5334. doi: 10.1016/j.actamat.2012.06.004 [11] XU G D, ZHAI J J, ZENG T, et al. Response of composite sandwich beams with graded lattice core[J]. Composite Structures,2015,119:666-676. doi: 10.1016/j.compstruct.2014.09.042 [12] ZHANG G Q, WANG B, MA L, et al. Response of sandwich structures with pyramidal truss cores under the compression and impact loading[J]. Composite Structures,2013,100:451-63. doi: 10.1016/j.compstruct.2013.01.012 [13] KHALID Y A, CHAN C L, SAHARI B B, et al. Bending behaviour of corrugated web beams[J]. Journal of Materials Processing Technology,2004,150(3):242-254. doi: 10.1016/j.jmatprotec.2004.02.042 [14] VALDEVIT L, WEI Z, MERCER C, et al. Structural perfor-mance of near-optimal sandwich panels with corrugated cores[J]. International Journal of Solids and Structures,2006,43(16):4888-4905. doi: 10.1016/j.ijsolstr.2005.06.073 [15] CHANG W S, VENTSEL E, KRAUTHAMMER T, et al. Ben-ding behavior of corrugated-core sandwich plates[J]. Composite Structures,2005,70(1):81-89. doi: 10.1016/j.compstruct.2004.08.014 [16] MALCOM A J, ARONSON M T, DESHPANDE V S, et al. Compressive response of glass fiber composite sandwich structures[J]. Composites Part A: Applied Science and Manufacturing,2013,54:88-97. doi: 10.1016/j.compositesa.2013.07.007 [17] GAZOR M S, RAHIMI G H, FARROKHABADI A. The effect of the arrangement of corrugated composite on the R-curve of the sandwich structures with hybrid corrugated/foam core under mode I loading[J]. Theoretical and Applied Fracture Mechanics,2018,96:326-333. doi: 10.1016/j.tafmec.2018.05.011 [18] SHU C F, HOU S J. Theoretical prediction on corrugated sandwich panels under bending loads[J]. Acta Mechanica Sinica,2018,34(5):925-935. doi: 10.1007/s10409-018-0767-y [19] DAYYANI I, ZIAEI-RAD S, SALEHI H. Numerical and experi-mental investigations on mechanical behavior of compo-site corrugated core[J]. Applied Composite Materials,2012,19(3-4):705-721. doi: 10.1007/s10443-011-9238-3 [20] XU G D, WANG Z H, ZENG T, et al. Mechanical response of carbon/epoxy composite sandwich structures with three-dimensional corrugated cores[J]. Composites Science and Technology,2018,156:296-304. doi: 10.1016/j.compscitech.2018.01.015 [21] ZHANG J, SUPERNAK P, MUELLER-ALANDER S, et al. Improving the bending strength and energy absorption of corrugated sandwich composite structure[J]. Materials & Design,2013,52:767-773. doi: 10.1016/j.matdes.2013.05.018 [22] THILL C, ETCHES J A, BOND I P, et al. Investigation of trapezoidal corrugated aramid/epoxy laminates under large tensile displacements transverse to the corrugation direction[J]. Composites Part A: Applied Science and Manufacturing,2010,41(1):168-176. doi: 10.1016/j.compositesa.2009.10.004 [23] REJAB M R M, CANTWELL W J. The mechanical behaviour of corrugated-core sandwich panels[J]. Composites Part B: Engineering,2013,47:267-277. doi: 10.1016/j.compositesb.2012.10.031 [24] HOU S J, SHU C F, ZHAO S Y, et al. Experimental and numerical studies on multi-layered corrugated sandwich panels under crushing loading[J]. Composite Structures,2015,126:371-385. doi: 10.1016/j.compstruct.2015.02.039 [25] KAZEMAHVAZI S, ZENKERT D. Corrugated all-composite sandwich structures. Part 1: Modeling[J]. Composites Science and Technology,2009,69(7-8):913-919. doi: 10.1016/j.compscitech.2008.11.030 [26] KAZEMAHVAZI S, TANNER D, ZENKERT D. Corrugated all-composite sandwich structures. Part 2: Failure mecha-nisms and experimental programme[J]. Composites Science and Technology,2009,69(7-8):920-925. doi: 10.1016/j.compscitech.2008.11.035 [27] SHIMANSKY R A, LELE M M. Transverse stiffness of a sinusoidally corrugated plate[J]. Mechanics Based Design of Structures and Machines,1995,23(3):439-451. doi: 10.1080/08905459508905246 [28] SEONG D Y, JUNG C G, YANG D Y, et al. Quasi-isotropic bending responses of metallic sandwich plates with bi-di-rectionally corrugated cores[J]. Materials & Design,2010,31(6):2804-2812. doi: 10.1016/j.matdes.2010.01.009 [29] LI H, GE L, LIU B, et al. An equivalent model for sandwich panel with double-directional trapezoidal corrugated core[J]. Journal of Sandwich Structures & Materials,2019,22(7):2445-2465. [30] XING Y, YANG S, LU S, et al. Effect of bonding parameters on compression mechanical properties of bi-directional corrugated honeycomb aluminum[J]. Journal of Adhesion,2020(2):1-10. [31] XING Y D, YANG S Y, LU S Q, et al. Mechanical properties of bi-directional corrugated honeycomb aluminum filled with expanded polypropylene under quasi-static compression[J]. International Journal of Crashworthiness,2020,Ahead-of-print:1-10. [32] LI S G, FENG Y X, WANG M Y, et al. Mechanical behavior of natural fiber-based bi-directional corrugated lattice sandwich structure[J]. Materials,2018,11(12):14. [33] LI S G, FENG Y X, QIN J K, et al. Bending performance of a jute fiber and epoxy resin composite sandwich structure with a bi-directional corrugated truss core[J]. Fibers and Polymers,2019,20(10):2166-2174. doi: 10.1007/s12221-019-1204-y [34] YANG X F, MA J X, SHI Y L, et al. Crashworthiness investigation of the bio-inspired bi-directionally corrugated core sandwich panel under quasi-static crushing load[J]. Materials & Design,2017,135:275-290. doi: 10.1016/j.matdes.2017.09.040 [35] 李会民, 周磊, 雷红帅, 等. 一种双向波纹点阵增强型复合材料夹层结构: 中国, CN109318541A [P]. 2019-02-12.LI Huimin, ZHOU Lei, LEI Hongshuai, et al. A bidirectional corrugated lattice reinforced composite sandwich structure: China, CN109318541A[P].2019-02-12(in Chinese). [36] 中国国家标准化管理委员会(标准制定单位). 纤维增强复合材料弹性常数测试方法: GB/T 32376—2015[S]. 北京: 中国标准出版社, 2015.Standardization Administration of the People's Republic of China. Elastic constant test method for fibre reinforced composites: GB/T 32376—2015[S]. Beijing: China Standards Press, 2015(in Chinese). [37] 中国国家标准化管理委员会(标准制定单位). 夹层结构或芯子平压性能试验方法: GB/T 1453-2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Test method for flatwise compression properties of sandwich construction or cores: GB/T 1453—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [38] 中国国家标准化管理委员会(标准制定单位). 夹层结构弯曲性能试验方法: GB/T 1456—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Test method for flexural properties of sandwich constructions: GB/T 1456—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [39] 中国国家标准化管理委员会(标准制定单位). 夹层结构或芯子剪切性能试验方法: GB/T 1455—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Test method for shear properties of sandwich constructions or cores: GB/T 1455—2005[S]. Beijing: China Standards Press, 2005(in Chinese). -

下载:

下载: