An improved numerical prediction method of elastic properties based on two unit-cells models for 3D angle-interlock woven composites and experimental verification

-

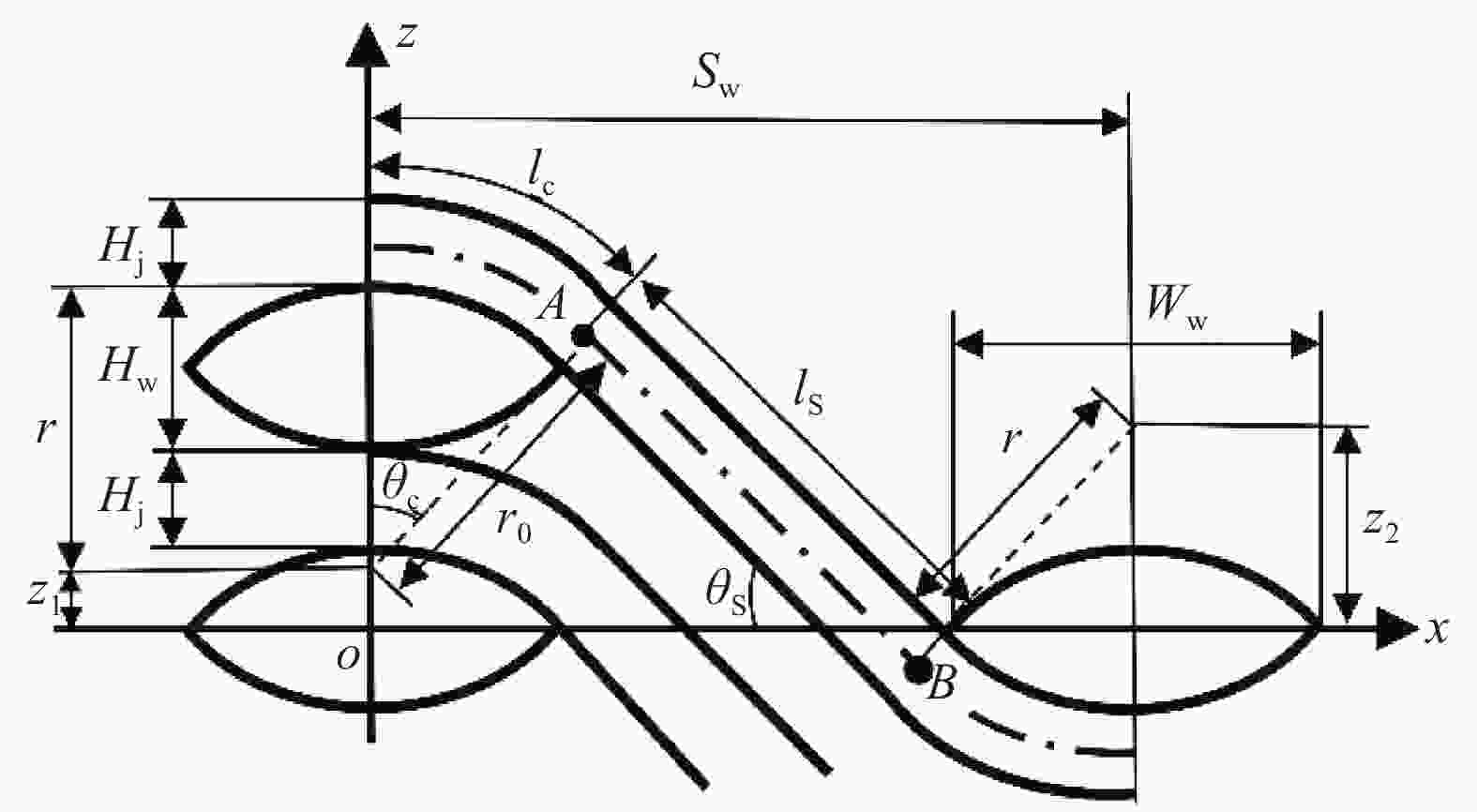

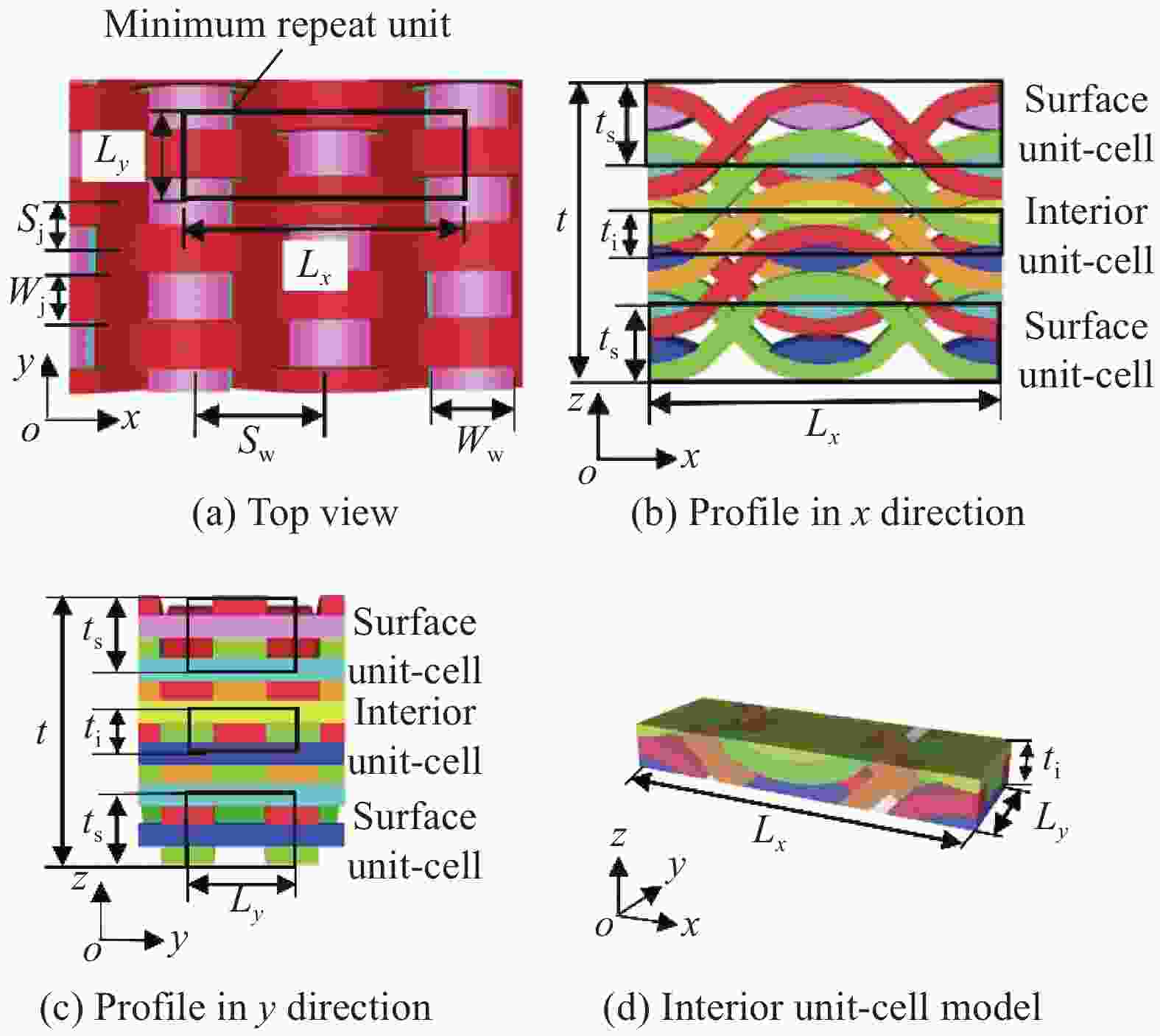

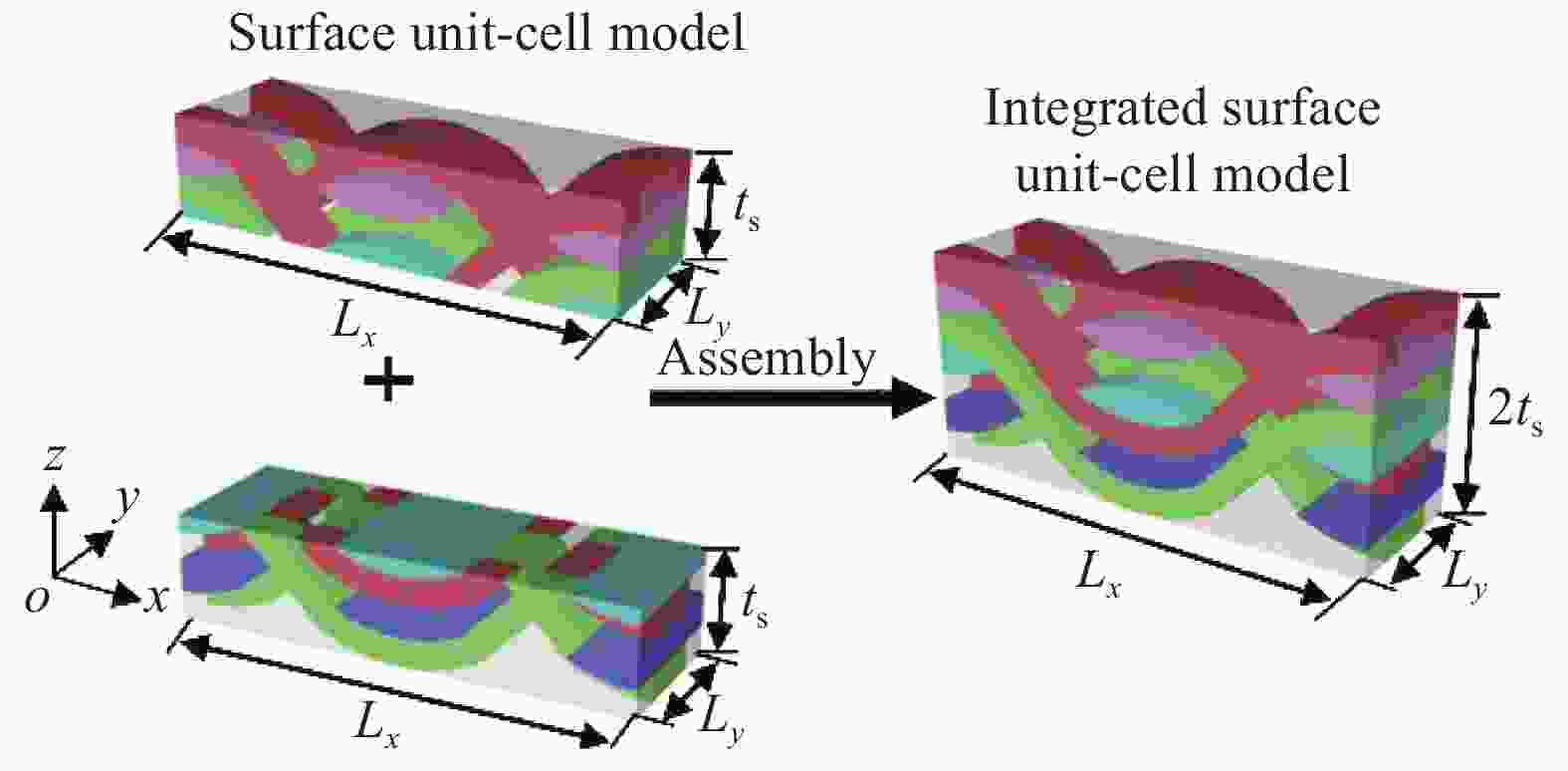

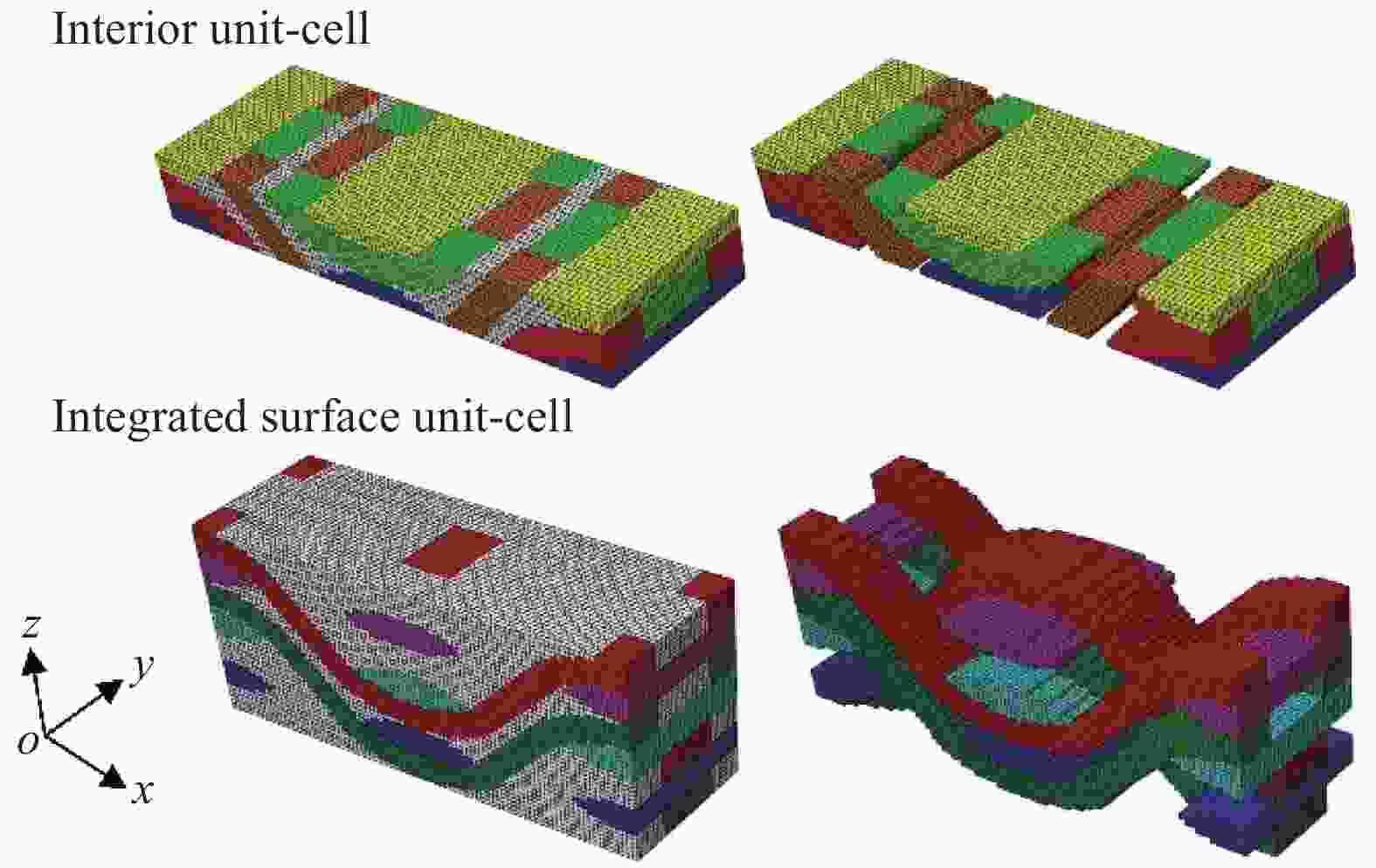

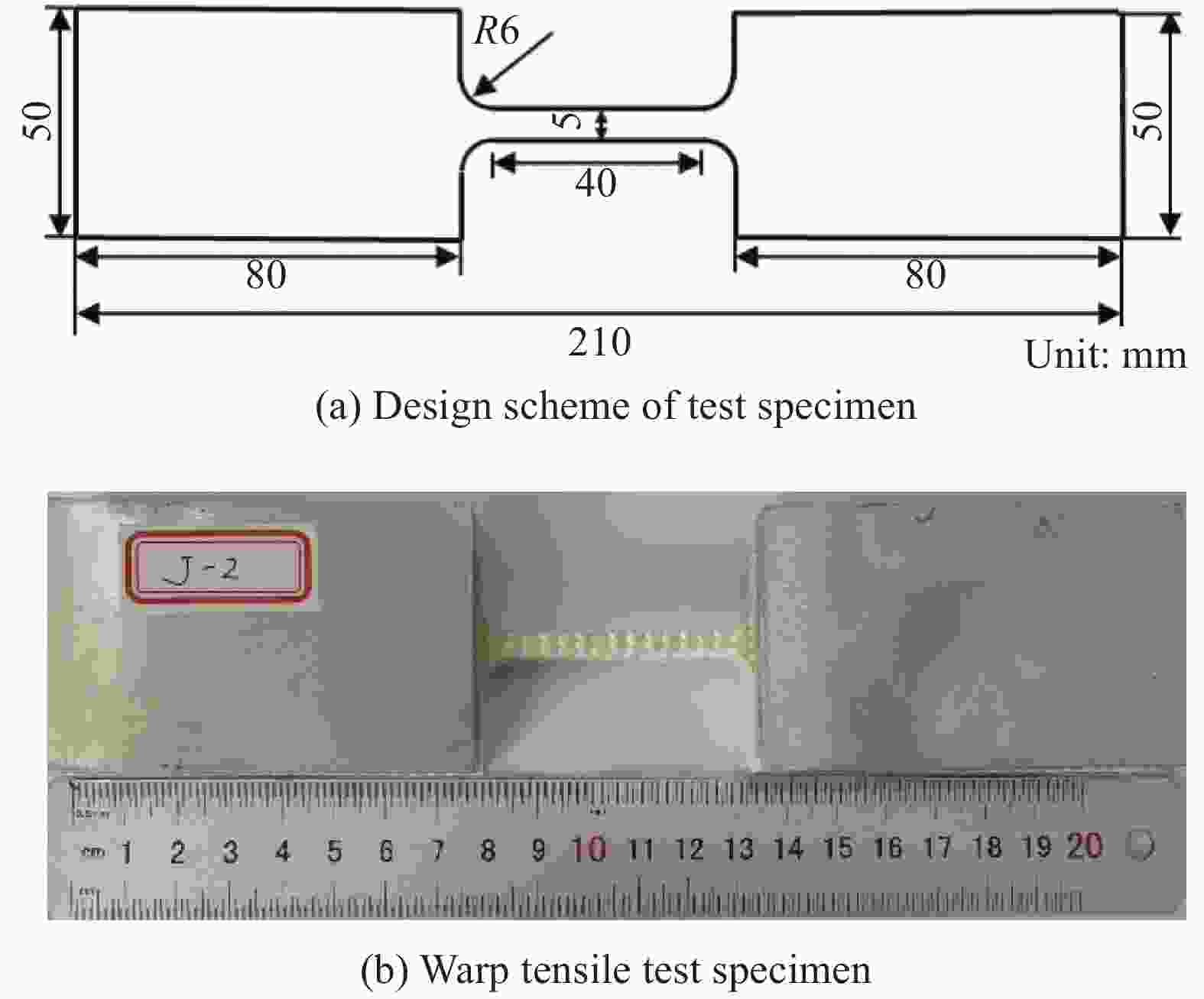

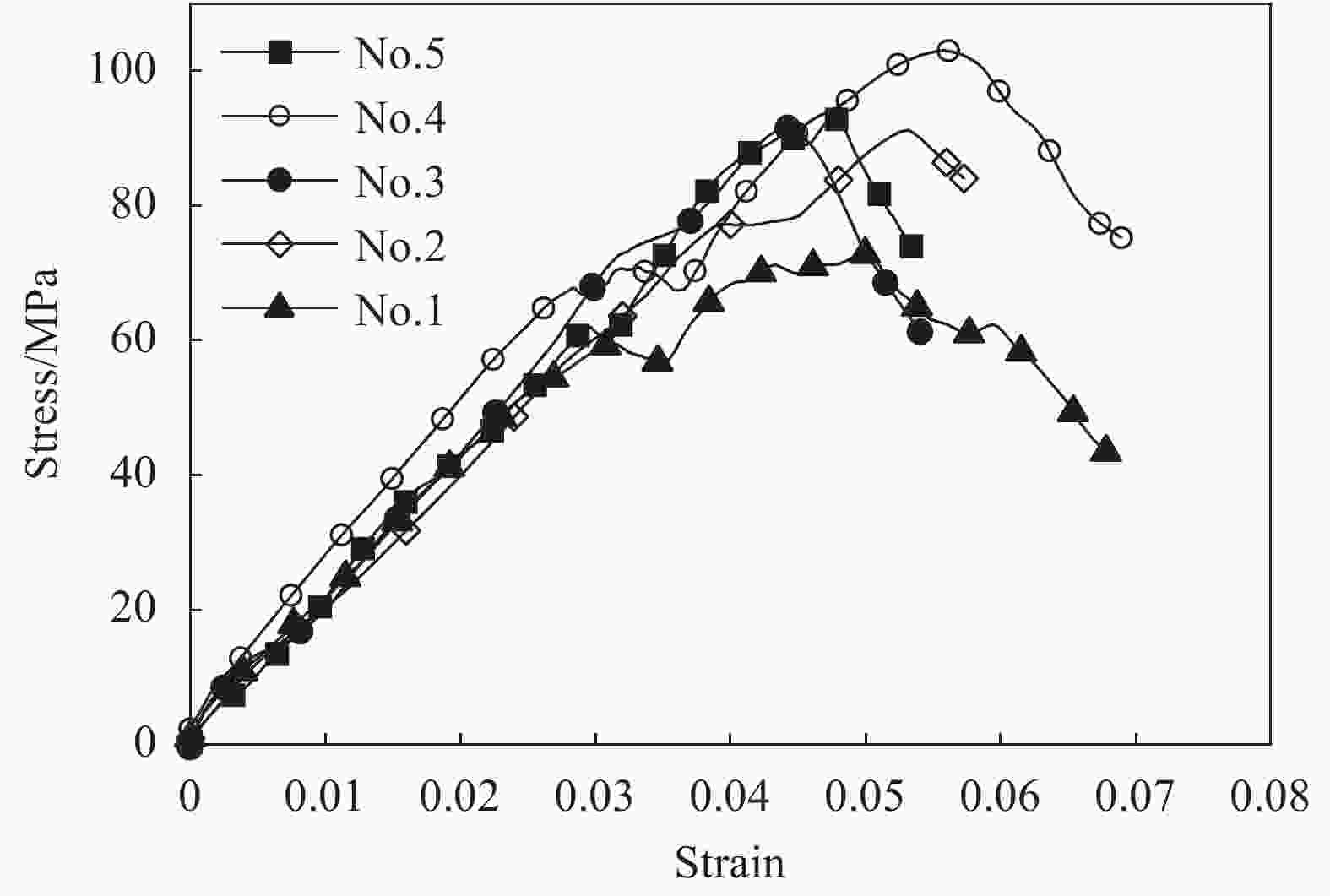

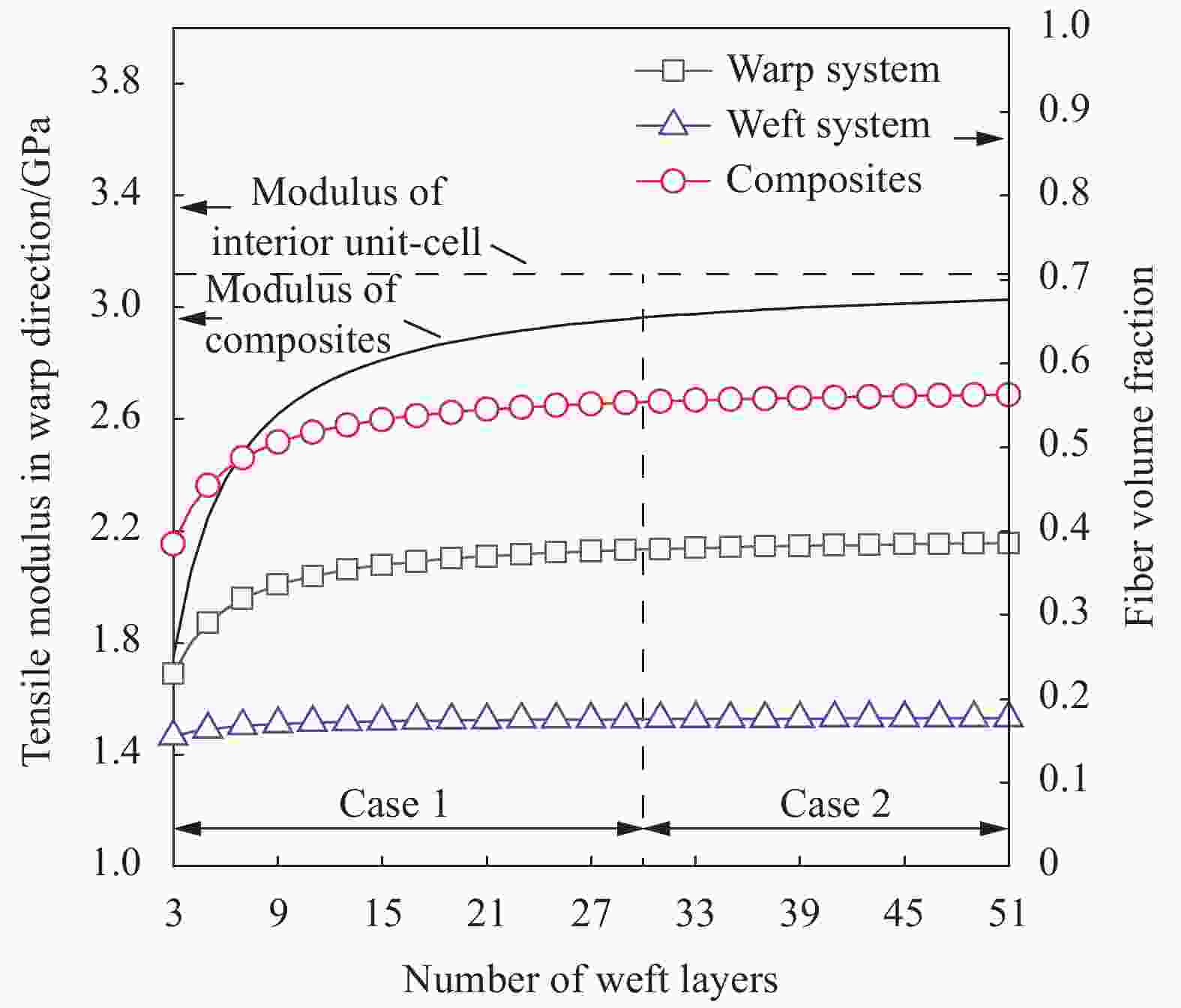

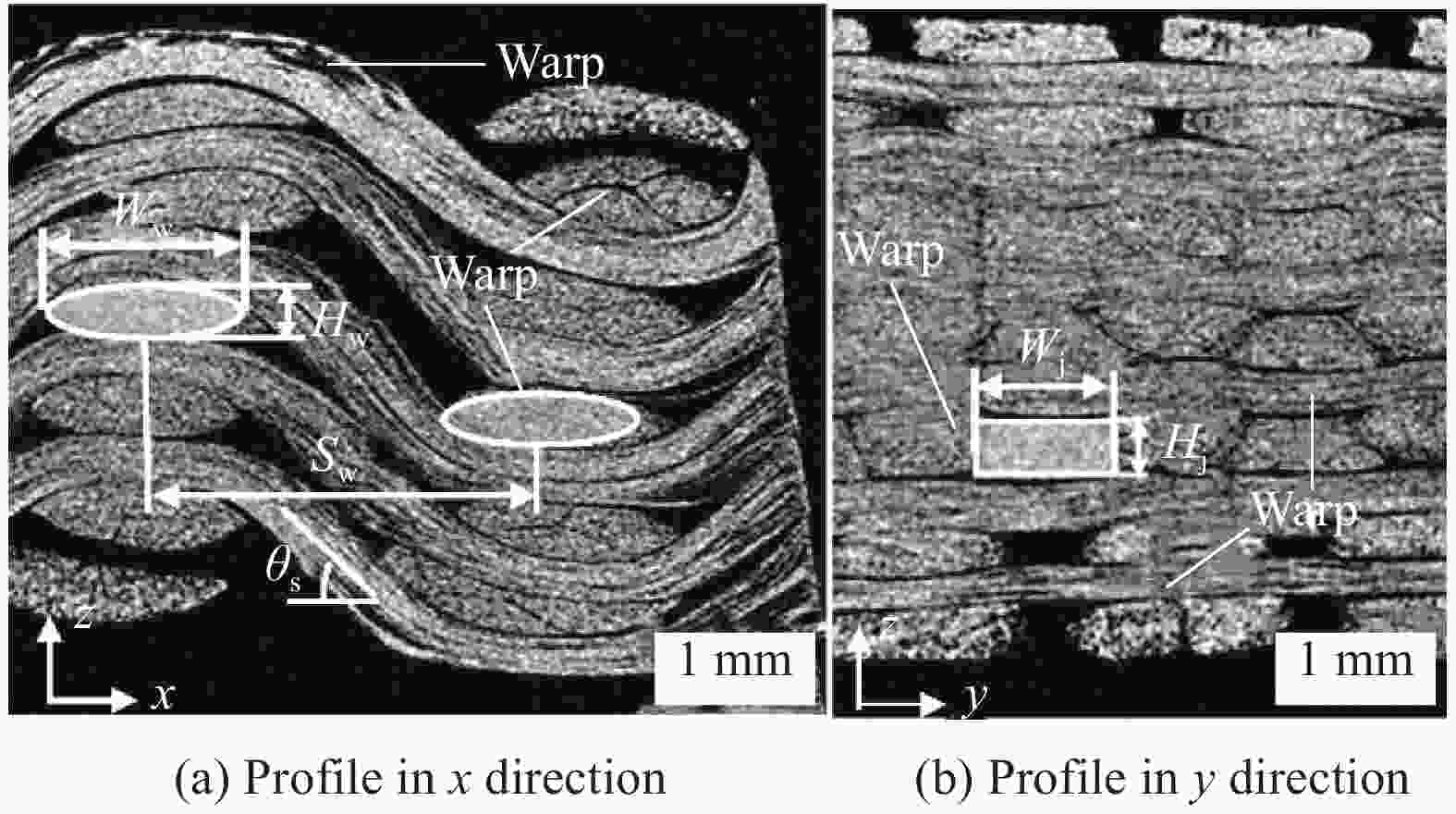

摘要: 为准确预测三维角联锁机织复合材料的宏观弹性性能,对基于CT图像几何参数实测数据建立的内单胞和面单胞细观实体模型进行数值分析,其中面单胞模型采用组合面单胞形式,并开展了三维角联锁机织超高分子量聚乙烯(UHMWPE)纤维/聚氨酯复合材料的经向拉伸实验。结果表明:基于两单胞模型预测该复合材料的宏观弹性模量与实验结果吻合较好,组合面单胞的经向拉伸模量小于内单胞;经向拉伸时复合材料在经纱间接触面处、纬纱沿宽度方向的端部和经纱与基体的交界面处易出现应力集中现象;当纬纱层数小于30层时,应该考虑表面区域对复合材料整体力学性能的影响。Abstract: To accurately predict the macroscopic elastic properties of 3D angle-interlock woven composites, interior and surface unit-cells mesoscopic solid models were established for numerical analysis based on the geometric parameters measured in CT images, and surface unit-cells were modeled in the form of integrated surface unit-cells. Then a tensile test in warp direction was conducted for 3D angle-interlock woven ultra-high molecular weight polyethylene (UHMWPE) fiber/polyurethane composites. The results show that the predicted macroscopic elastic modulus values of the composites based on two unit-cells models are in good agreement with the experimental values. The tensile modulus in the warp direction of the integrated surface unit-cells is smaller than that of the interior unit-cells. During the tensile test in the warp direction, stress concentration tends to occur at the interface among warp yarns, the end of weft yarns along the width and the interface between warp yarns and matrix. When the number of weft layers is less than 30, the effect of surface region on the overall mechanical properties of the composites should be considered.

-

Key words:

- 3D woven composites /

- unit cells /

- elastic modulus /

- finite element analysis /

- tensile test

-

图 11 三维角联锁机织UHWMPE纤维/聚氨酯复合材料经向拉伸模量和纤维体积含量随纬纱层数的变化规律

Case 1—Accurate modulus of composites obtained by interior unit-cell and integrated surface unit-cells models; Case 2—Accurate modulus of composites obtained by only interior unit-cell model

Figure 11. Change law of tensile modulus in warp direction and fiber volume fraction of 3D angle-interlock woven UHWMPE fiber/polyurethane composites with the number of weft layers

表 1 三维角联锁机织UHMWPE纤维/聚氨酯复合材料细观几何参数测量

Table 1. Mesoscopic geometric parameters’ measurements of 3D angle-interlock woven UHMWPE fiber/ polyurethane composites

Yarn Parameter Number of measurements Average value Variable coefficient Input value Weft Height Hw 408 0.492 mm 0.137 0.469 mm Width Ww 408 1.919 mm 0.042 1.919 mm Space Sw 306 3.651 mm 0.012 3.333* mm Warp Width Wj 300 1.139 mm 0.014 1.111* mm Height Hj 300 0.382 mm 0.143 0.398 mm Inclination θs 255 45.6° 0.074 Notes: * represents data obtained by equation (10). 表 2 UHMWPE纤维和聚氨酯力学性能参数

Table 2. Mechanical properties of UHMWPE fiber and polyurethane

UHWMPE fiber Ea*/GPa Et[19]/GPa Ga[19]/GPa 94 3.5 1.0 Gt[19]/GPa νa[19] νt[19] 1.2 0.29 0.45 Polyurethane Em*/MPa νm[19] 195 0.25 Notes:Ea, Ga and νa—Axial tensile modulus, shear modulus and Passion’s ratio of fiber, respectively;Et, Gt and νt—Transverse tensile modulus, shear modulus and Passion’s ratio of fiber, respectively;Em and νm—Modulus and Poisson’s ratio of matrix, respectively; * represents data obtained by experiments. 表 3 三维角联锁机织UHWMPE纤维/聚氨酯复合材料试件的经向拉伸模量实验结果

Table 3. Experimental results of tensile modulus in warp direction of 3D angle-interlock woven UHWMPE fiber/polyurethane composite specimens

Specimen Ex/GPa Average/GPa Variable coefficient/% No.1 2.02 2.19 5.34 No.2 2.14 No.3 2.27 No.4 2.33 No.5 2.20 Note:Ex—Tensile modulus in x direction. 表 4 三维角联锁机织UHWMPE纤维/聚氨酯复合材料弹性常数的数值预测值

Table 4. Results of elastic constants of 3D angle-interlock woven UHWMPE fiber/polyurethane composites by numerical analysis method

Elastic

constantInterior

unit-cellIntegrated surface

unit-cellOverall Ex/GPa 3.12 1.75 2.39 Ey/GPa 17.21 14.20 15.58 Ez/GPa 0.80 0.46 0.62 Gxz/GPa 0.79 0.29 0.52 Gyz/GPa 0.30 0.18 0.24 Gxy/GPa 0.31 0.20 0.25 νxz 0.35 0.30 0.32 νyz 0.01 0.01 0.01 νxy −0.06 −0.04 −0.05 Notes:Ex, Ey and Ez—Tensile moduli in x, y and z directions, respectively;Gxz, Gyz and Gxy—Shear moduli in xz, yz and xy directions, respectively;νxz, νyz and νxy—Poisson’s ratios in xz, yz and xy directions, respectively. -

[1] 杨彩云, 李嘉禄. 基于纱线真实形态的三维机织复合材料细观结构及其厚度计算[J]. 复合材料学报, 2005, 22(6):178-182. doi: 10.3321/j.issn:1000-3851.2005.06.031YANG Caiyun, LI Jialu. Microstructure and thickness equation of 3d woven composites based on yarn’s true configuration[J]. Acta Materiae Compositae Sinica,2005,22(6):178-182(in Chinese). doi: 10.3321/j.issn:1000-3851.2005.06.031 [2] 丁辛, 易洪雷. 三维机织结构的几何模型[J]. 复合材料学报, 2003, 20(5):108-113. doi: 10.3321/j.issn:1000-3851.2003.05.020DING Xin, YI Honglei. A geometric model of three dimensional woven structures[J]. Acta Materiae Compositae Sinica,2003,20(5):108-113(in Chinese). doi: 10.3321/j.issn:1000-3851.2003.05.020 [3] 张超, 许希武, 毛春见. 三维编织复合材料渐进损伤模拟及强度预测[J]. 复合材料学报, 2011, 28(2):222-230.ZHANG Chao, XU Xiwu, MAO Chunjian. Progressive damage simulation and strength prediction of 3D braided composites[J]. Acta Materiae Compositae Sinica,2011,28(2):222-230(in Chinese). [4] 郑君, 温卫东, 崔海涛, 等. 2.5维机织结构复合材料的几何模型[J]. 复合材料学报, 2008, 25(2):143-148. doi: 10.3321/j.issn:1000-3851.2008.02.024ZHENG Jun, WEN Weidong, CUI Haitao, et al. Geometric model of 2.5 dimensional woven structures[J]. Acta Materiae Compositae Sinica,2008,25(2):143-148(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.02.024 [5] 杨振宇, 俸翔, 苏洲, 等. 2.5D编织复合材料细观结构及弹性性能[J]. 宇航材料工艺, 2010, 40(2):67-71. doi: 10.3969/j.issn.1007-2330.2010.02.018YANG Zhenyu, FENG Xiang, SU Zhou, et al. Meso-structure and elastic properties of 2.5D braided composites[J]. Aerospace Materials & Technology,2010,40(2):67-71(in Chinese). doi: 10.3969/j.issn.1007-2330.2010.02.018 [6] 梁仕飞, 矫桂琼, 王波. 三维机织C/C-SiC复合材料弹性性能预测[J]. 复合材料学报, 2011, 28(1):138-142.LIANG Shifei, JIAO Guiqiong, WANG Bo. Prediction of elastic properties of three dimensional woven C/C-SiC composite[J]. Acta Materiae Compositae Sinica,2011,28(1):138-142(in Chinese). [7] ZHANG D T, CHEN L, WANG Y, et al. Stress field distribution of warp-reinforced 2.5D woven composites using an idealized meso-scale voxel-based model[J]. Journal of Materials Science,2017,52(11):6814-6836. doi: 10.1007/s10853-017-0921-0 [8] 卢子兴, 周原, 冯志海, 等. 2.5D机织复合材料压缩性能实验与数值模拟[J]. 复合材料学报, 2015, 32(1):150-159.LU Zixing, ZHOU Yuan, FENG Zhiyuan, et al. Experiment and numerical simulation compressive properties of 2.5D woven fabric composites[J]. Acta Materiae Compositae Sinica,2015,32(1):150-159(in Chinese). [9] ZENG X S, BROWN L P, ENDRUWEIT A, et al. Geometrical modelling of 3D woven reinforcements for polymer composites: Prediction of fabric permeability and composite mechanical properties[J]. Composites Part A: Applied Science and Manufacturing,2014,56:150-160. doi: 10.1016/j.compositesa.2013.10.004 [10] GREEN S D, MATVEEV M Y, LONG A C, et al. Mechanical modelling of 3D woven composites considering realistic unit cell geometry[J]. Composite Structures,2014,118:284-293. doi: 10.1016/j.compstruct.2014.07.005 [11] 仲苏洋. 三维机织复合材料损伤演化与失效行为研究[D]. 哈尔滨: 哈尔滨工业大学, 2015.ZHONG Suyang. Investigation of damage evolution and failure of the three-dimensional woven composites[D]. Harbin: Harbin Institute of Technology, 2015(in Chinese). [12] SHERBURN M. Geometric and mechanical modelling of textiles[D]. Nottingham: University of Nottingham, 2007. [13] LIN H, BROWN L P, LONG A C. Modelling and simulating textile structures using TexGen[J]. Advanced Materials Research,2011,331:44-47. doi: 10.4028/www.scientific.net/AMR.331.44 [14] BROWN L P, ENDRUWEIT A, LONG A, et al. Characterisa-tion and modelling of complex textile geometries usingTexGen[C]//13th International Conference on TextileComposites. Milan, Italy: IOP Publishing Ltd, 2018: 1-8. [15] 孙晓军, 赵晓明, 郑振荣, 等. 新型织物仿真软件TexGen的特点及其应用[J]. 纺织导报, 2013(4):70-73. doi: 10.3969/j.issn.1003-3025.2013.04.019SUN Xiaojun, ZHAO Xiaoming, ZHENG Zhenrong, et al. Introduction and application of a new fabric simulation software[J]. China Textile Leader,2013(4):70-73(in Chinese). doi: 10.3969/j.issn.1003-3025.2013.04.019 [16] ZHANG C, CURIEL-SOSA J L, BUI T Q, Comparison of periodic mesh and free mesh on the mechanical properties prediction of 3D braided composites[J]. Composite Structures, 2017, 159: 667-676. [17] 赖卫清, 王秀梅, 辛亮亮, 等. 基于RVE方法的二维机织复合材料弹性性能预测[J]. 玻璃钢/复合材料, 2019(6):64-72.LAI Weiqing, WANG Xiumei, XIN Liangliang, et al. Prediction of elastic properties of 2D woven composites based on RVE method[J]. Fiber Reinforced Plastics/Composites,2019(6):64-72(in Chinese). [18] ZHANG C, XU X W. Finite element analysis of 3D braided composites based on three unit-cells models[J]. Composite Structures,2013,98:130-142. doi: 10.1016/j.compstruct.2012.11.003 [19] RUSSELL B P, KARTHIKEYAN K, DESHP-ANDE V S, et al. The high strain rate response of ultra high molecular-weight polyethylene: From fibre to laminate[J]. International Journal of Impact Engineering 2013, 60: 1-9. [20] CHAMIS C C. Mechanics of composites materials: Past, present, and future[J]. Journal of Composites Technology and Research,1989,11(1):3-14. doi: 10.1520/CTR10143J [21] ZHANG D T, FENG G Y, SUN M Y, et al. Finite element analysis of mesh size effect of 3D angle-interlock woven composites using voxel-based method[J]. Applied Composite Materials,2018,25(4):905-920. doi: 10.1007/s10443-018-9723-z [22] 许善迎, 谭焕成, 关玉璞, 等. 三维四向编织复合材料力学性能预测及实验验证[J]. 材料工程, 2018, 46(6):132-140. doi: 10.11868/j.issn.1001-4381.2016.001135XU Shanying, TAN Huancheng, GUAN Yupu, et al. Predication and experimental verification on mechanical properties of three-dimensional and four-direction braided composites[J]. Journal of Materials Engineering,2018,46(6):132-140(in Chinese). doi: 10.11868/j.issn.1001-4381.2016.001135 [23] SUN Jin, WANG Yu, ZHOU Guangming, et al. Finite element analysis of mechanical properties of 3D surface-core braided composites[J]. Polymer Composites,2018,39(4):1076-1088. [24] LEVI-SASSON A, MESHI I, MUSTACCHI S, et al. Experimental determination of linear and nonlinear mechanical properties of laminated soft composite material system[J]. Composites Part B: Engineering,2014,57:96-104. doi: 10.1016/j.compositesb.2013.09.043 [25] 王宇. 三维斜交机织复合材料细观结构与力学性能研究[D]. 南京: 南京航空航天大学, 2017.WANG Yu. Research on microstructure and mechanical properties of 3D nonorthogonal woven composites[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2017(in Chinese). -

下载:

下载: