Influence of the fresh ultra-high performance fiber reinforced concrete flowability on its compressive strength

-

摘要: 钢纤维掺入能提高超高性能纤维增强混凝土(Ultra-high performance fiber reinforced concrete,UHPFRC)的抗压强度,但削弱新拌浆体的流动性能,降低了对抗压强度的增强效果,且影响UHPFRC的工作性能。为研究这种不利影响,以钢纤维体积分数和长径比为变量,进行了A、B两组试验。A组固定水胶比为0.18,不控制流动性能,主要研究钢纤维对流动性能和抗压强度的影响。试验结果表明,新拌UHPFRC流动性能随钢纤维的体积分数、长径比增加而下降;当钢纤维体积率超过一定值(2.00vol%)时,流动性能明显下降,抗压强度增强效果也相应下降。通过X-ray CT扫描发现钢纤维掺入减弱浆体的自密实能力,导致硬化后的基体内部孔隙尺寸增大和孔隙率增加,进而削弱抗压强度。综合考虑钢纤维掺入对抗压强度的正、负效应,提出了抗压强度的半经验预测公式。B组改变水胶比,控制扩展度为240 mm,对比A组研究流动性能控制后,钢纤维体积分数和长径比对抗压强度的影响规律。结果表明,钢纤维体积分数较大时,增大水胶比,保持一定流动性能,能有效提高纤维的增强效果;钢纤维体积分数较小时,在满足流动性能要求的前提下,减小水胶比,可以进一步提高抗压强度。在UHPFRC配合比设计时,应考虑钢纤维对流动性能的不利影响,以提高纤维的增强效应并保证其良好的工作性能。

-

关键词:

- 超高性能纤维增强混凝土 /

- 流动性能 /

- 钢纤维 /

- X-ray CT扫描 /

- 抗压强度

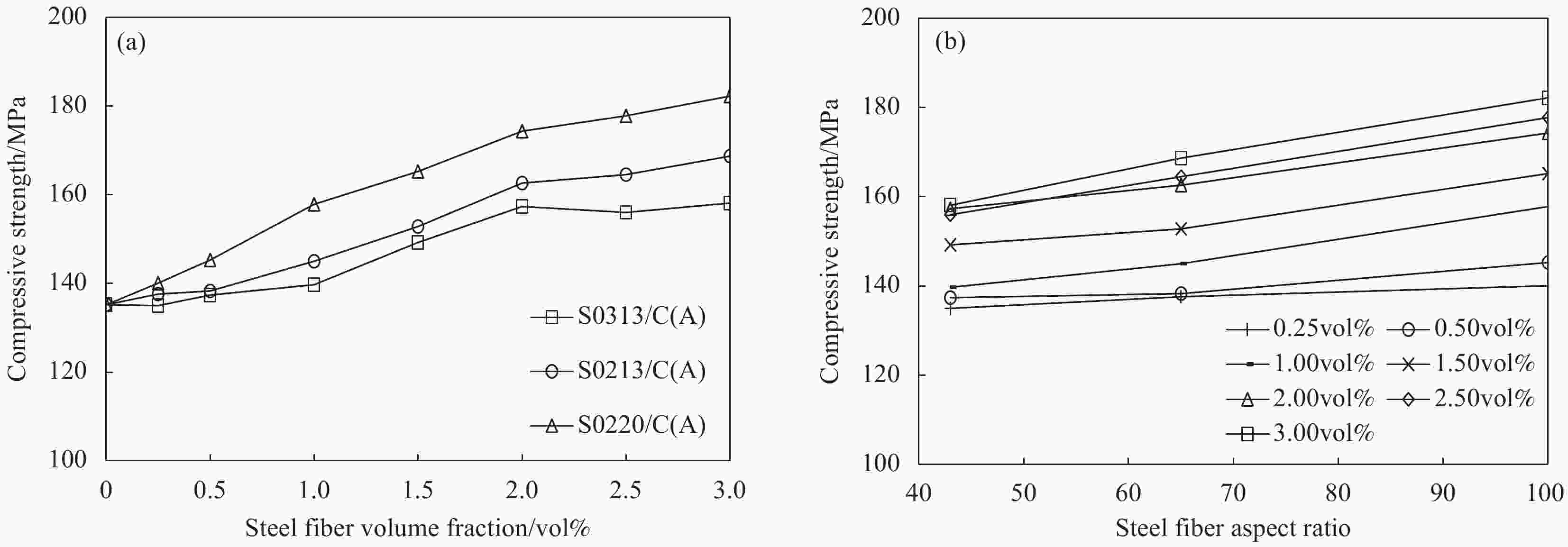

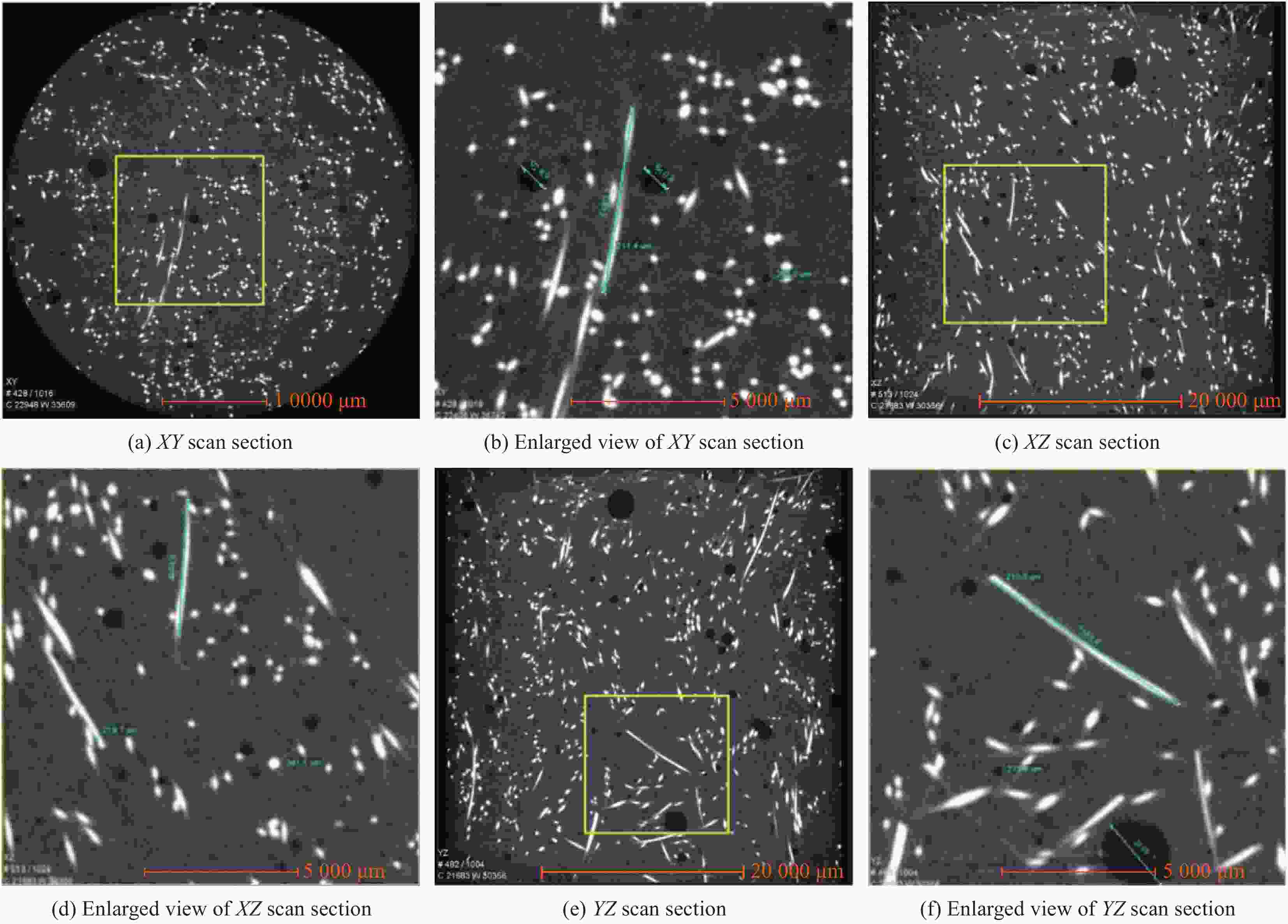

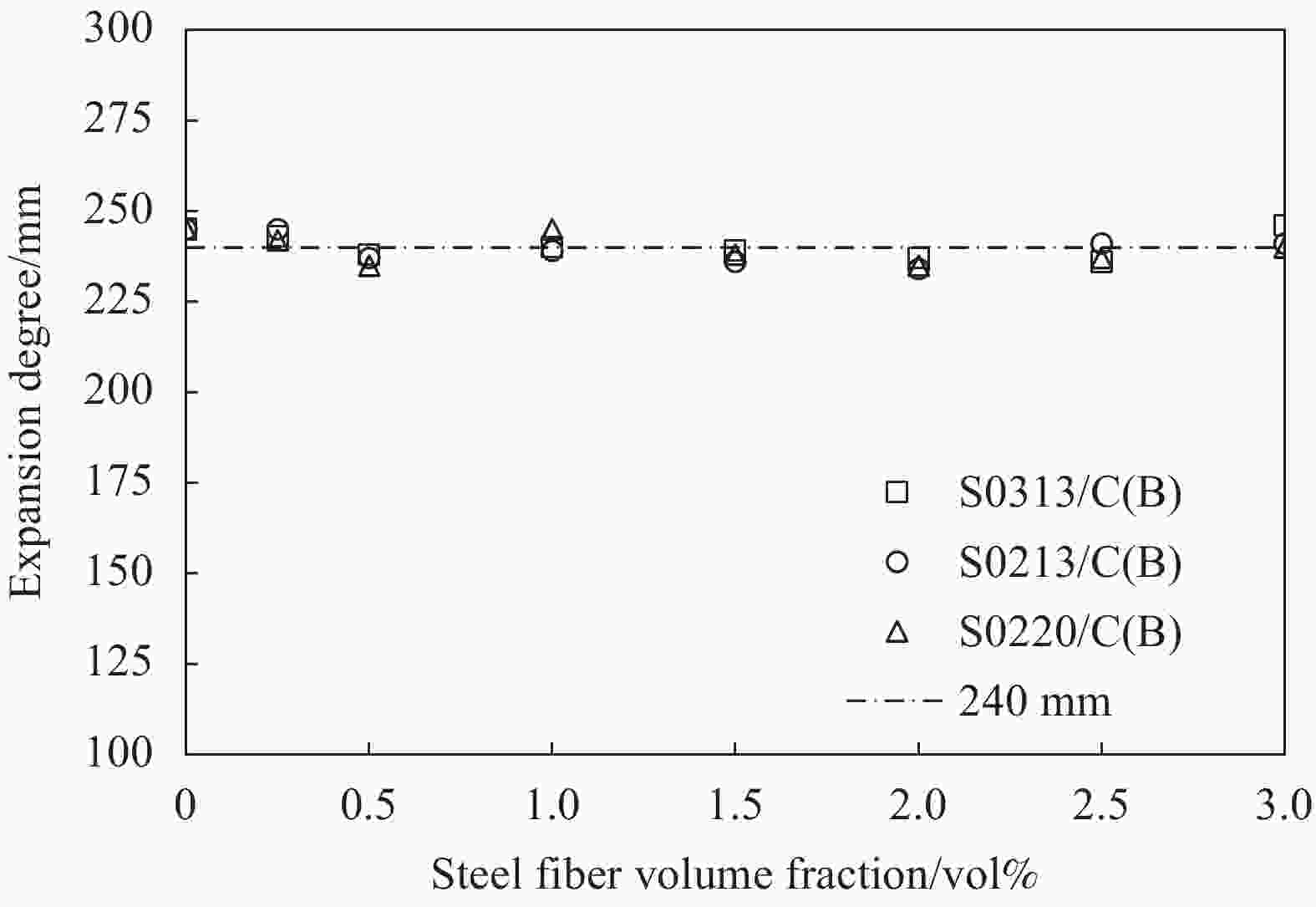

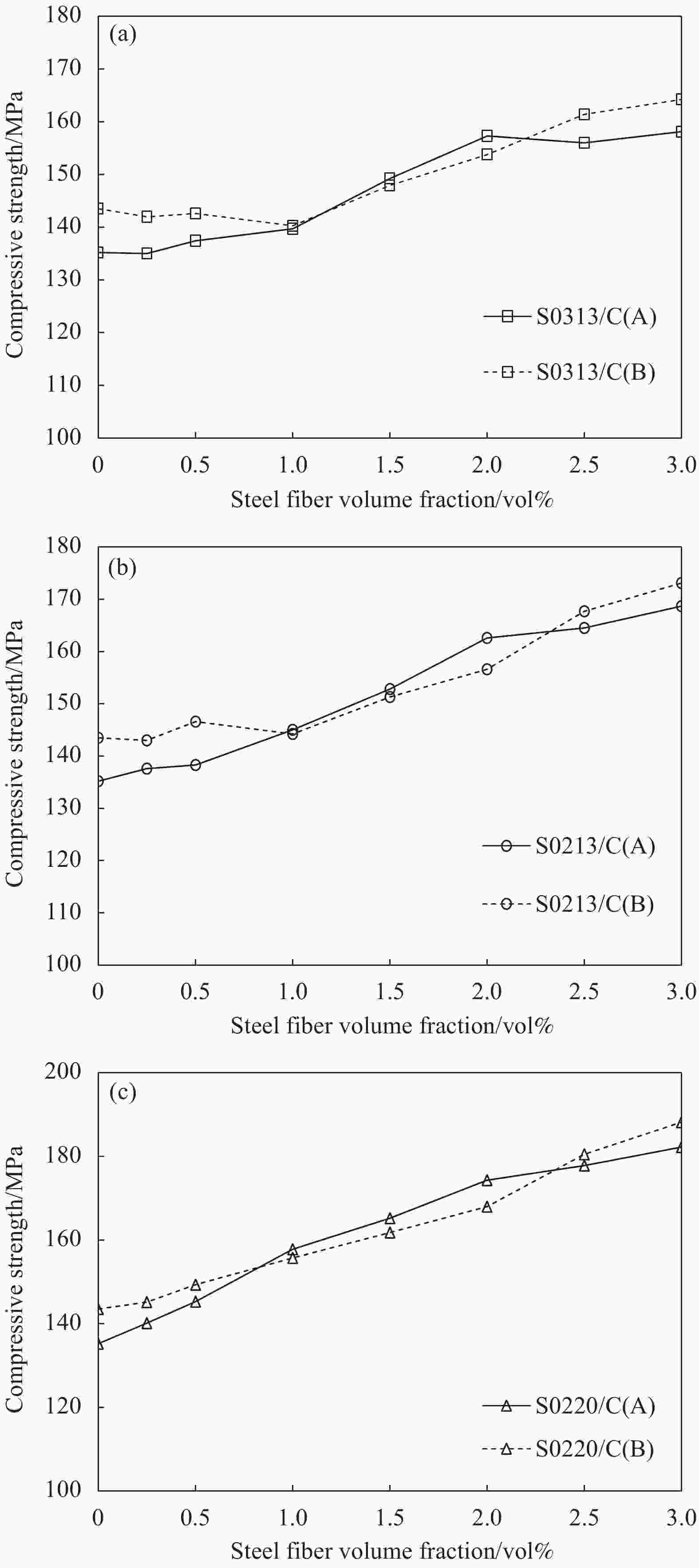

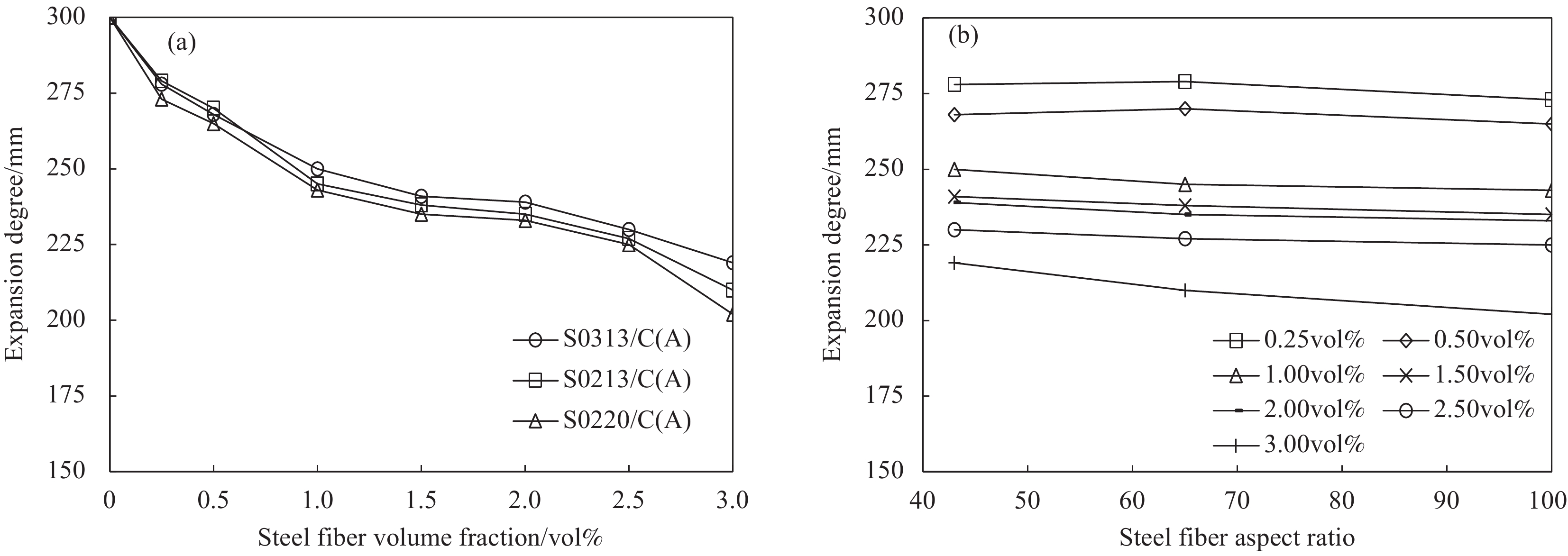

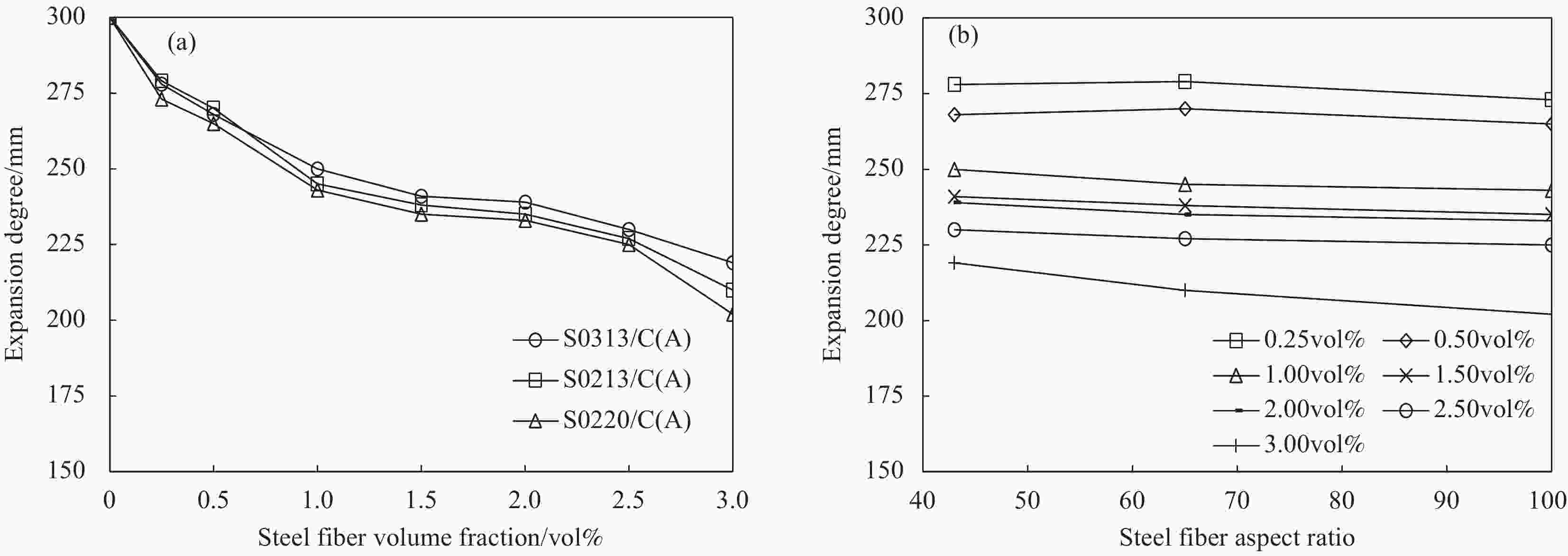

Abstract: Steel fiber can reinforce the compressive strength of ultra-high performance fiber reinforced concrete (UHPFRC), but it will reduce the flowability of fresh UHPFRC, thus weaken this reinforcement effect and the work performance of UHPFRC. In order to study this adverse effect, two sets of tests A and B were carried out with steel fiber volume fraction and aspect ratio as variables. In the A series test, the fixed water-to-binder ratio was 0.18 and didn’t control the flowability. It mainly studied the effect of steel fiber on flowability and compressive strength. The test results show that the flowability of fresh UHPFRC decreases with the increase of the volume fraction or aspect ratio of steel fiber; when the volume fraction of steel fiber exceeds a certain value (2.00vol%), the expansion degree decreases significantly, and the corresponding compressive strength enhancement effect also decreases. The X-ray CT scan test finds that the incorporation of steel fiber weaken the self-compacting ability of the fresh slurry, increasing in the internal pore size and porosity of the hardened matrix, thereby weakening the compressive strength. Comprehensively considering the positive and negative effects of steel fiber incorporation into compressive strength, a semi-empirical prediction formula for compressive strength was proposed. In the B series test, the water-binder ratio was changed and the expansion degree was controlled to 240 mm. Through comparative analysis of the A series test results, the effect of the volume fraction and aspect ratio of the steel fiber on the compressive strength after the control of the flowability was studied. The results show that when the volume fraction of steel fiber is large, the water-binder ratio should be increased to ensure a certain flowability, which can effectively improve the reinforcement effect of the fiber; when the volume fraction of fiber is small, the water-binder ratio should be decreased on the premise of meeting the flowability requirements, which can further improve the compressive strength. In the design of the UHPFRC mix ratio, in order to improve the reinforcing effect of steel fiber and ensure that UHPFRC has good working performance, the adverse effect of incorporating steel fiber on the flowability of UHPFRC should be considered. -

表 1 钢纤维的命名及其基本信息

Table 1. Naming and basic information of steel fiber

Number Diameter/mm Length/mm Aspect ratio Tensile strength/MPa Elastic modulus/GPa S0220 0.2 20 100 2850 210 S0213 0.2 13 65 2850 210 S0313 0.3 13 43 2850 210 Notes: Sijkl—Steel fiber; ij—Diameter of fiber; kl—Length of the fiber. 表 2 基体配合比

Table 2. Matrix mix

Mass ratio Binder Aggregate Superplasticizer Cement Silica

fume40-70 mesh

(0.212-0.428 mm)20-40 mesh

(0.428-0.850 mm)10-20 mesh

(0.850-1.700 mm)400 mesh

(0.038 mm)1.0 0.3 0.14 0.41 0.53 0.09 0.025 表 3 A组和B组试验的钢纤维和水胶比方案

Table 3. Steel fiber and water-to-binder ratio schemes of group A and group B tests

Steel fiber volume fraction/vol% Water-binder

ratio of group AWater-binder

ratio of group BS0313 S0213 S0220 0.00 0.00 0.00 0.18 0.16 0.25 0.25 0.25 0.17 0.50 0.50 0.50 0.17 1.00 1.00 1.00 0.18 1.50 1.50 1.50 0.19 2.00 2.00 2.00 0.19 2.50 2.50 2.50 0.20 3.00 3.00 3.00 0.21 表 4 A组UHPFRC试件的试验结果

Table 4. Test results of group A UHPFRC specimens

Fiber volume

fraction/vol%Expansion degree/mm Compressive strength/MPa S0313/C(A) S0213/C(A) S0220/C(A) S0313/C(A) S0213/C(A) S0220/C(A) 0.00 300 - - 135.2 - - 0.25 278 279 273 135.0 137.6 140.1 0.50 268 270 265 137.4 138.3 145.3 1.00 250 245 243 139.7 145.0 157.8 1.50 241 238 235 149.2 152.8 165.2 2.00 239 235 233 157.3 162.6 174.3 2.50 230 227 225 156.0 164.5 177.8 3.00 219 210 202 158.1 168.7 182.2 表 5 B组UHPFRC试件的试验结果

Table 5. Test results of group B UHPFRC specimen

Steel fiber

volume fraction/vol%Water-binder ratio Expansion degree/mm Compressive strength/MPa S0313/C(B) S0213/C(B) S0220/C(B) S0313/C(B) S0213/C(B) S0220/C(B) 0.00 0.16 241 - - 143.5 - - 0.25 0.17 244 246 243 142.0 143.0 145.1 0.50 0.17 239 238 236 142.6 146.6 149.3 1.00 0.18 241 240 246 140.3 144.2 155.7 1.50 0.19 240 237 239 147.9 151.3 161.8 2.00 0.19 238 235 236 153.8 156.6 168.0 2.50 0.20 236 241 237 161.4 167.7 180.5 3.00 0.21 246 241 240 164.2 173.1 188.2 -

[1] 陈宝春, 韦建刚, 苏家战, 等. 超高性能混凝土(UHPFRC)应用进展[J]. 建筑科学与工程学报, 2019, 36(2):10-20. doi: 10.3969/j.issn.1673-2049.2019.02.003CHEN Baochun, WEI Jiangang, SU Jiazhan, et al. State-of-the-art progress on application of ultra-high performance concrete[J]. Journal of Architecture and Civil Engineering,2019,36(2):10-20(in Chinese). doi: 10.3969/j.issn.1673-2049.2019.02.003 [2] 陈宝春, 林毅焌, 杨简, 等. 超高性能纤维增强混凝土中纤维作用综述[J]. 福州大学学报自然科学版, 2020, 48(1):58-68.CHEN Baochun, LIN Yijun, YANG Jian, et al. Review on fiber function in ultra-high performance fiber reinforced concrete[J]. Journal of Fuzhou University(Natural Science Edition),2020,48(1):58-68(in Chinese). [3] 史才军, 何稳, 吴泽媚, 等. 纤维对UHPFRC力学性能的影响研究进展[J]. 硅酸盐通报, 2015, 34(8):2227-2247.SHI Caijun, HE Wen, WU Zhimei, et al. Influence of fibers on mechanical properties of UHPC[J]. Bulletin of the Chinese Ceramic Society,2015,34(8):2227-2247(in Chinese). [4] MENG Weina, KHAYAT K. H. Effect of hybrid fibers on fresh properties, mechanical properties, and autogenous shrinkage of cost-effective UHPFRC[J]. Journal of Materials in Civil Engineering,2018,30(4):1-8. [5] YOO D Y, KIM S, PARK G J, et al. Effects of fiber shape, aspect ratio, and volume fraction on flexural behavior of ultra-high-performance fiber-reinforced cement composites[J]. Composite Structures,2017,174(8):375-388. [6] THARUN M, SENTHIL KUMAR G. Compressive and flexural behavior of ultra high performance concrete with hybrid steel fiber[J]. Journal of Industrial Pollution Control,2017,33(S3):1364-1369. [7] HANNAWI K, BIAN H, PRINCE-AGBODJAN W, et al. Effect of different types of fibers on the microstructure and the mechanical behavior of ultra-high performance fiber-reinforced concretes[J]. Composites Part B: Engineering,2016,86(2):214-220. [8] WU Zemei, SHI Caijun, HE Wen, et al. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete[J]. Construction and Building Materials,2016,103:8-14. doi: 10.1016/j.conbuildmat.2015.11.028 [9] 梁咏宁, 陈宝春, 季韬, 等. 砂胶比、水胶比和钢纤维掺量对RPC性能的影响[J]. 福州大学学报自然科学版, 2011(5):748-753.LIANG Yongning, CHEN Baochun, JI Tao, et al. Effects of sand-binder ratio, water-binder ratio and volume percentage of steel fiber on the performance of RPC[J]. Journal of Fuzhou University (Natural Science Edition),2011(5):748-753(in Chinese). [10] 徐魏魏, 刘中宪, 赵永娇, 等. 钢纤维超高性能混凝土单轴受压试验研究[J]. 工业建筑, 2016(12):104-109.XU Weiwei, LIU Zhongxian, ZHAO Yongjiao, et al. Experimental research on the uniaxial compression of steel fiber reinforced ultra-high performance concrete[J]. Industrial Construction,2016(12):104-109(in Chinese). [11] MARTINIE L, ROSSI P, ROUSSEL N. Rheology of fiber reinforced cementitious materials: classification and prediction[J]. Cement and Concrete Research,2010,40(2):226-234. doi: 10.1016/j.cemconres.2009.08.032 [12] LE HOANG A, FEHLING E. Influence of steel fiber content and aspect ratio on the uniaxial tensile and compressive behavior of ultrahigh performance concrete[J]. Construction and Building Materials,2017,153:790-806. doi: 10.1016/j.conbuildmat.2017.07.130 [13] PHILIPP Hadl, HOANG Kim, NGUYEN Viet Tue. Experimental investigations on the scattering in the post cracking tensile behavior of UHPFRC[C]. International Interactive Symposium on UHPFRC, 2016. [14] BABSKI V. Characterization of ultra-high performance fibre reinforced concrete (UHPFC) under tensile loading by acoustic emission and optical deformation analysis[C]. Proceedings of HiPerMat 2016-4th International Sympo-sium on Ultra-High Performance Concrete and High Performance Construction Materials Kassel, 2016: 1-9. [15] LEE J H, HONG S G, JOH C, et al. Biaxial tension-compression strength behavior of UHPFRC in-plane elements[J]. Materials and Structures,2017,50(20):3-17. [16] 苏家战, 林毅焌, 陈宝春, 等. 不同形状钢纤维对UHPC受拉性能影响的试验研究[J]. 宁夏大学学报(自然科学版), 2020, 41(3):246-251.SU Jiazhan, LIN Yijun, CHEN Baochun, et al. Experimental study on the tensile properties of ultra-high performance concrete with different types of steel fiber[J]. Journal of Ningxia University (Natural Science Edition),2020,41(3):246-251(in Chinese). [17] 苏家战, 林毅焌, 陈宝春, 等. 混杂钢纤维UHPC单轴拉伸性能的混杂效应分析[J]. 南昌大学学报(工科版), 2019, 41(4):358-364.SU Jiazhan, LIN Yijun, CHEN Baochun, et al. Hydrid effects of steel fibers on the uniaxial tensile properties of ultra-high performance concrete[J]. Journal of Nanchang University (Engineering & Technology),2019,41(4):358-364(in Chinese). [18] RYDVAL M, TOMÁ B, KOLÍSKO J, et al. Impact of steel fibers on workability and properties of UHPC[J]. Solid State Phenomena,2016,249:57-61. doi: 10.4028/www.scientific.net/SSP.249.57 [19] 中国建筑材料工业协会. 水泥砂浆流动度测试标准: GB2419—2005[S]. 北京. 中国标准出版社, 2005.China Building Material Council. Test methods for flowability of cement paste: GB2419—2005[S]. Beijing: Standards Press of China, 2005(in Chinese). [20] 中国国家标准化管理委员会. 活性粉末混凝土: GB/T 31387—2015[S]. 北京. 中国标准出版社, 2015.Standardization Administration of the People's Republic of China. Reactive powder concrete: GB/T 31387—2015[S]. Beijing: Standards Press of China, 2015(in Chinese). [21] ALSALMAN A, DANG C N, PRINZ G S, et al. Evaluation of modulus of elasticity of ultra-high performance concrete[J]. Construction and Building Materials,2017,153:918-928. doi: 10.1016/j.conbuildmat.2017.07.158 [22] 何峰, 黄政宇. 原材料对RPC强度的影响初探[J]. 湖南大学学报(自科版), 2001, 28(2):89-94.HE Feng, HUANG Zhengyu. Study on the effect of materials on RPC strength[J]. Journal of Hunan University (Na-tural Sciences),2001,28(2):89-94(in Chinese). [23] 赵秋山, 徐慎春, 刘中宪. 钢纤维增强超高性能混凝土抗压性能的细观数值模拟[J]. 复合材料学报, 2018, 35(6):1661-1673.ZHAO Chunshan, XU Shenchun, LIU Zhongxian. Microscopic numerical simulation of the uniaxial compression of steel fiber reinforced ultra-high performance concrete[J]. Acta Materiae Compositae Sinica,2018,35(6):1661-1673(in Chinese). [24] HASSAN A M T, JONES S W, MAHMUD G H. Experimental test methods to deter mine the uniaxial tensile and compressive behavior of ultra high performance fibre reinforced concrete (UHPFRC)[J]. Construction & Building Materials,2012,37:874-882. [25] PYO S, KIM H K, LEE B Y. Effects of coarser fine aggregate on tensile properties of ultra high performance concrete[J]. Cement and Concrete Composites,2017,84:28-35. doi: 10.1016/j.cemconcomp.2017.08.014 [26] REDON C, CHERMANT L, CHERMANT J L, et al. Assessment of fibre orientation in reinforced concrete using Fourier image transform[J]. Journal of Microscopy,2010,191(3):258-265. [27] LATASTE J F, BEHLOUL M, BREYSSE D. Characterization of fibres distribution in a steel fibre reinforced concrete with electrical resistivity measurements[J]. NDT & E International,2008,41(8):638-647. [28] LIU J, SUN W, MIAO C, et al. Assessment of fiber distribution in steel fiber mortar using image analysis[J]. Journal of Wuhan University of Technology,2012,27:166-171. doi: 10.1007/s11595-012-0429-z [29] 中华人民共和国住房和城乡建设部. 普通混凝土配合比设计规程: JGJ55—2000[S]. 北京: 中国建筑工业出版社, 2001.Ministry of Housing and Urban-Rural Development of People's Republic of China. Specification for mix proportion design of ordinary concrete: JGJ55—2000[J]. Beijing: China Architecture & Building Press, 2001(in Chinese). [30] YOO D Y, LEE J H, YOON Y S. Effect of fiber content on mechanical and fracture properties of ultra high performance fiber reinforced cementitious composites[J]. Composite Structures,2013,106(12):742-753. [31] SU Yu, LI Jun, WU Chengqing, et al. Effects of steel fibres on dynamic strength of UHPC[J]. Construction & Building Materials,2016,114(71):708-718. [32] WILLE K, KIM D J, NAAMAN A E. Strain-hardening UHP-FRC with low fiber contents[J]. Materials and Structures,2011,44(3):583-598. doi: 10.1617/s11527-010-9650-4 [33] LI Ye, TAN Kanghai, ZHANG Dong. Optimization of compressive strength and tensile strength of ultra-high performance concrete[C]. Proceedings of the International Symposium on Ultra-High Performance Concrete and High Performance Materials (HiperMat 2016), Kassel, 2016. [34] ASHOUR S A, WAFA F F, KAMAL M I. Effect of the concrete compressive strength and tensile reinforcement ratio on the flexural behavior of fibrous concrete beams[J]. Engineering Structures,2000,22(9):1145-1158. doi: 10.1016/S0141-0296(99)00052-8 [35] PYO S, TAFESSE M, KIM H, et al. Effect of chloride content on mechanical properties of ultra high performance concrete[J]. Cement and Concrete Composites,2017,84:175-187. doi: 10.1016/j.cemconcomp.2017.09.006 [36] LIM W Y, HONG S G. Compressive behavior of hybrid steel fiber reinforced ultra-high performance concrete[J]. Journal of the Korea Concrete Institute,2016,28(2):213-221. doi: 10.4334/JKCI.2016.28.2.213 [37] NEUNZIG C, HEIERMANN T, RAUPACH M. Deter mination of the uniaxial tensile strength of concrete with a modified test setup[C]. 4th International Conference on Strain-Hardening Cement-Based Composites. Dresden: Strain-Hardening Cement-Based Composites, 2018:316-323. [38] HUNG C C, LEE H S, CHAN S N. Tension-stiffening effect in steel-reinforced UHPFRC composites: Constitutive model and effects of steel fibers, loading patterns, and rebar sizes[J]. Composites Part B: Engineering,2018,158:1-23. [39] WILLE K, NAAMAN A E, EL-TAWIL S, et al. Ultra-high performance concrete and fiber reinforced concrete: Achieving strength and ductility without heat curing[J]. Materials & Structures,2012,45(3):309-324. [40] ORGASS M, KLUG Y. Fibre reinforced ultra-high strength concretes[C]. Proceedings of the International Symposium on Ultra High Performance Concrete. Kassel, 2004. [41] GRÜNEWALD S, SCHIPPER R, HORDIJK D. Double-curved panels produced in a flexible mold with self-compacting fibre-reinforced concrete[J]. Ultra-High Performance Concrete and High Performance Construction Materials (HIPERMAT),2016,27:1-8. [42] GUENET T, BABY F, MARCHAND P, et al. Flexural failure modes and ductility assessment of ribbed triangular UHPFRC plates[C]. First International Interactive Symposium on UHPC, Kassel: University of Kassel. 2016:1-8. [43] PREM P R, MURTHY A R, BHARATKUMAR B H. Influence of curing regime and steel fibres on the mechanical properties of UHPFRC[J]. Magazine of Concrete Research,2015,67(17-18):1-15. [44] WU Z, SHI C, HE W, et al. Static and dynamic compressive properties of ultra-high performance concrete (UHPFRC) with hybrid steel fiber reinforcements[J]. Cement & Concrete Composites,2017,79:148-157. [45] EMPELMANN M, TEUTSCH M, STEVEN G. Improvement of the post fracture behavior of UHPFRC by fibres[C]. Second International Symposium on Ultra High Performance Concrete, Kassel: University of Kassel. 2008: 177-183. [46] HOANG A L, FEHLING E, THAI D K, et al. Evaluation of axial strength in circular STCC columns using UHPFRC and UHPFRC[J]. Journal of Constructional Steel Research,2018,153:533-549. [47] HEROLD G, MÜLLER H S. Measurement of porosity of ultra high strength fibre reinforced concrete[C]. Proceedings of the International Symposium on Ultra-High Performance Concrete, Kassel: University of Kassel. 2004: 685-694. -

下载:

下载: