Structure damage identification method of inverse finite element method-pseudo-excitation method based on 2D continuous wavelet transform and data fusion technology

-

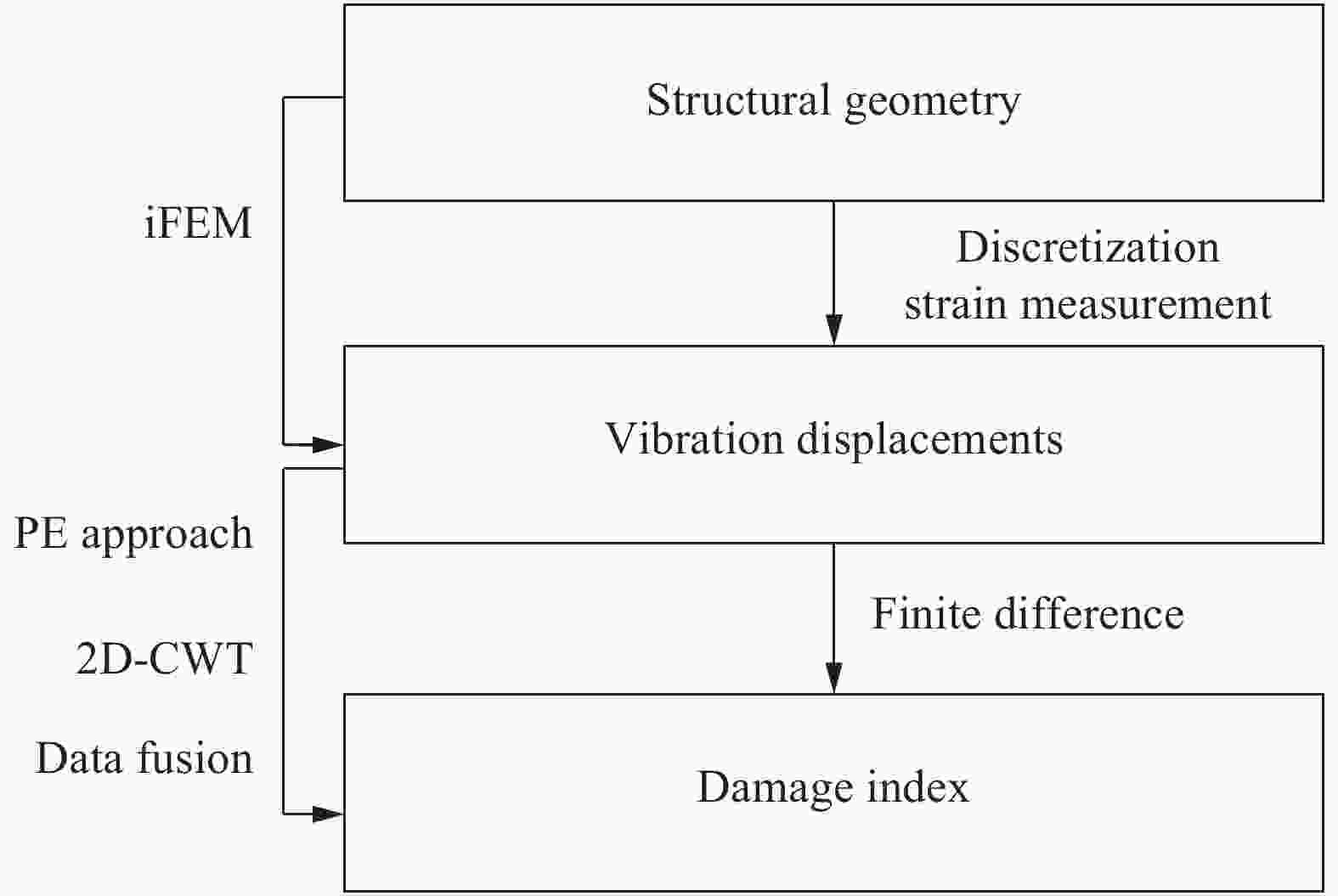

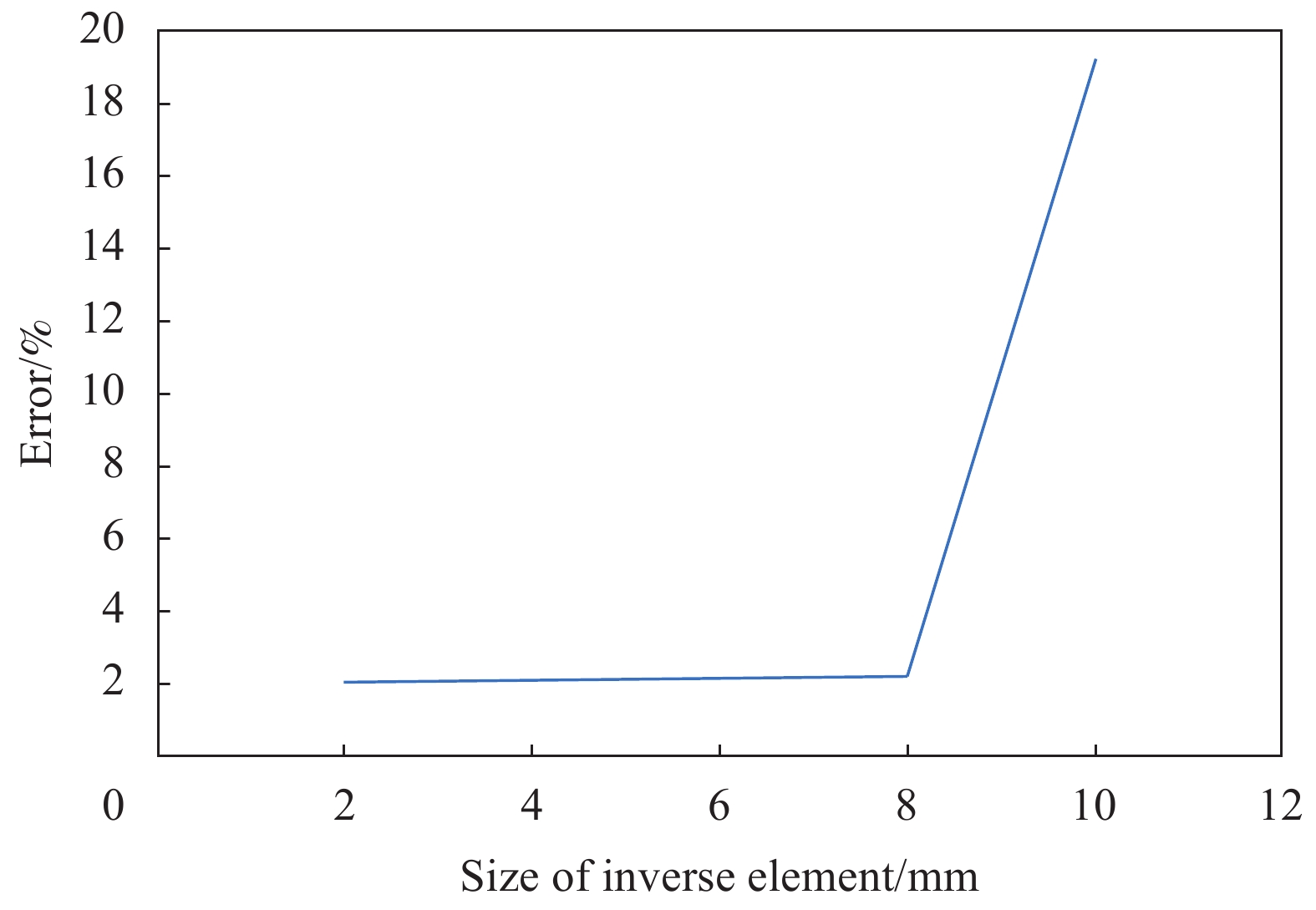

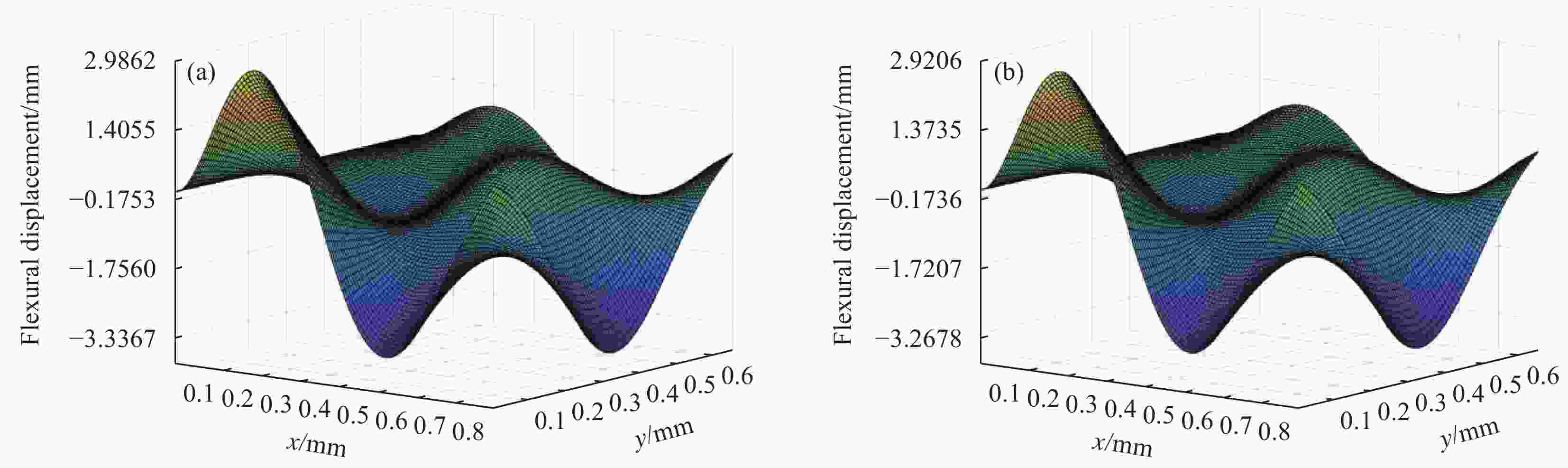

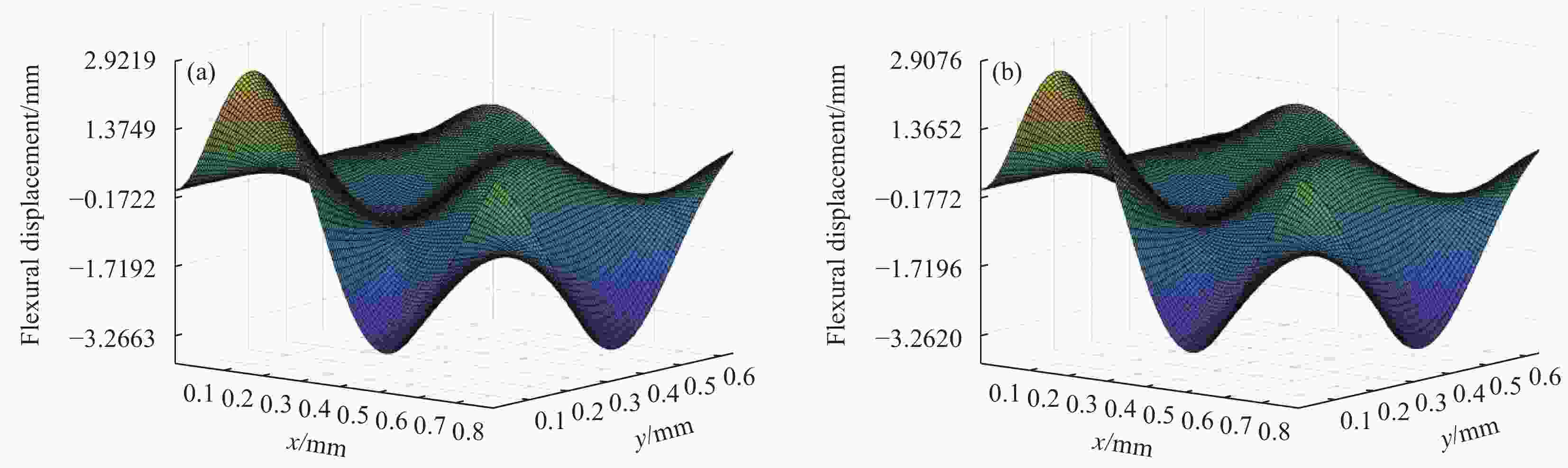

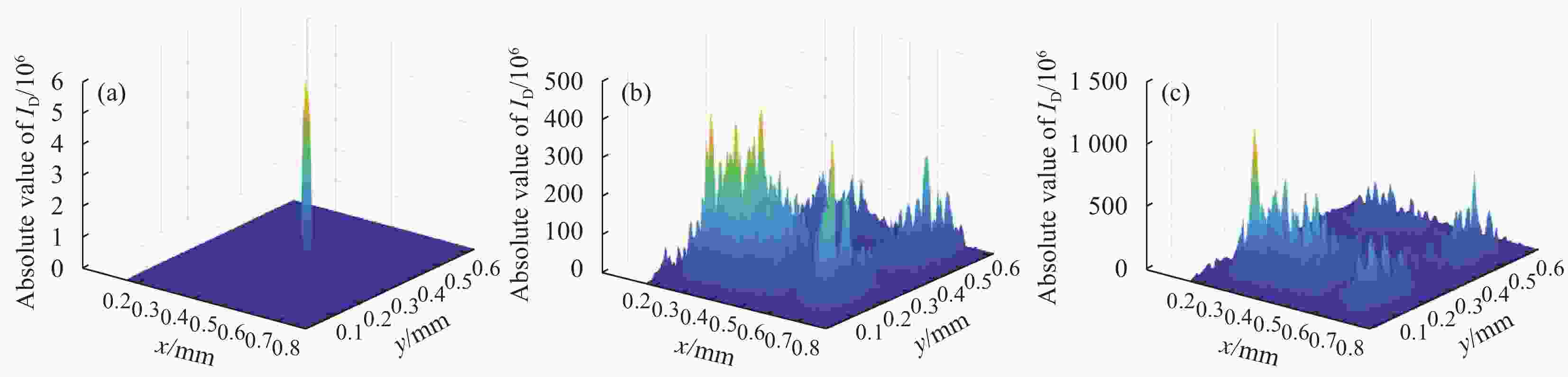

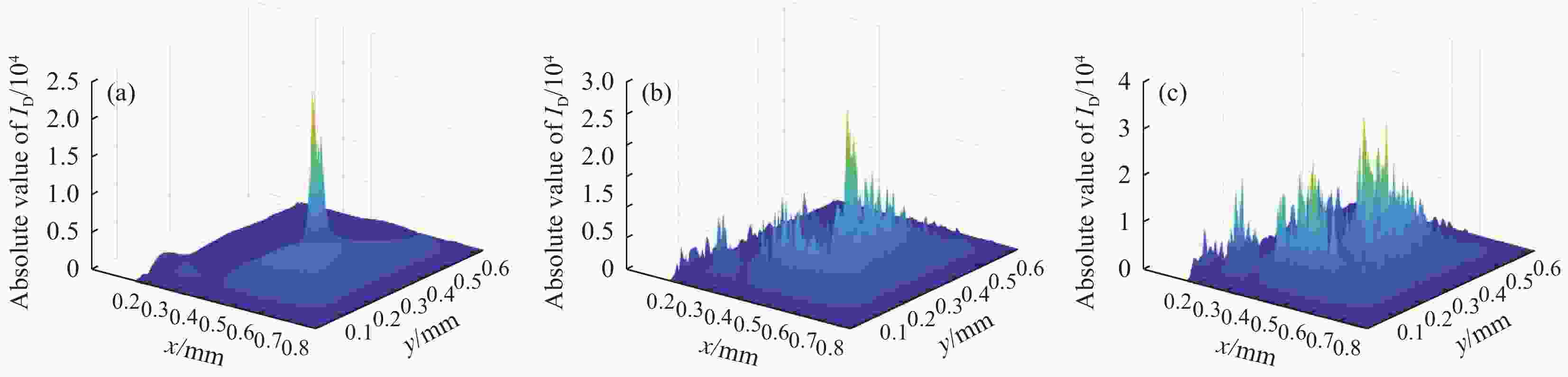

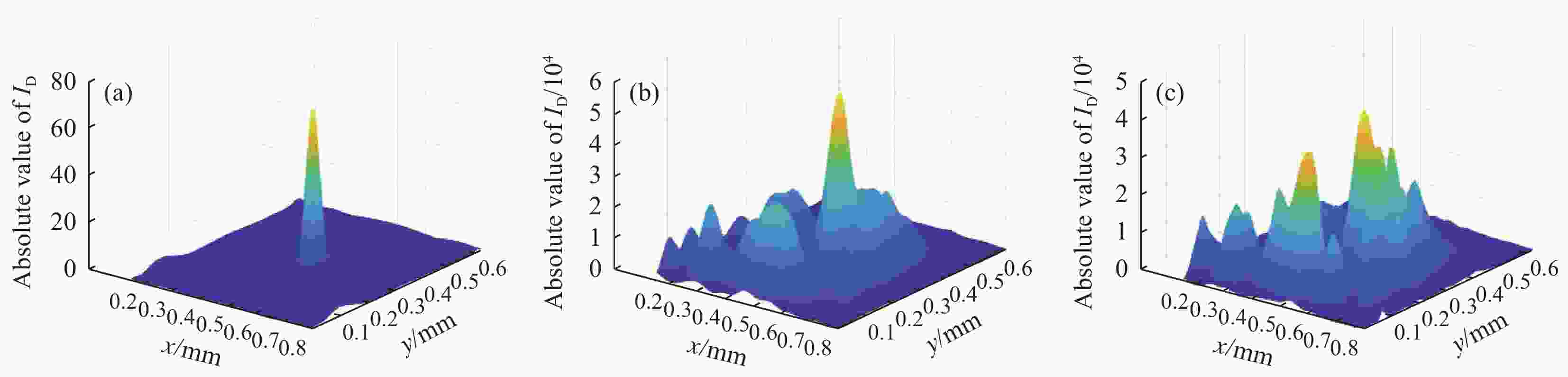

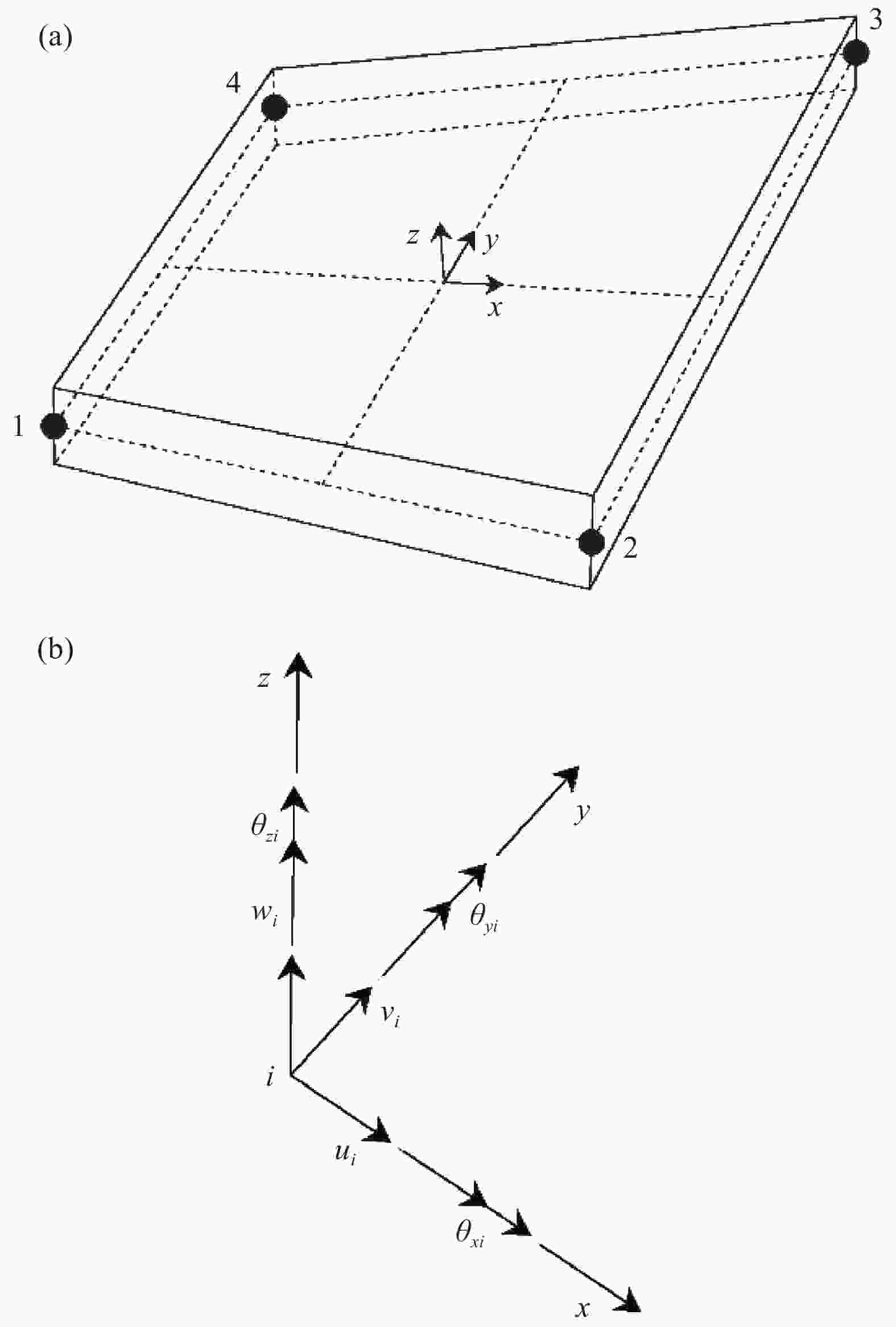

摘要: 在逆有限元法(iFEM)与伪激励法(PE)相结合的损伤识别方法框架下,通过引入二维连续小波变换与数据融合技术,增强了iFEM-PE方法的抗噪能力及工程适用性。通过算例分析可知,iFEM能够借助有限应变测量数据实时准确地重构结构位移,进而使PE方法摆脱了对在线位移测量的依赖。另一方面,PE法对结构损伤具有高敏感性,适用于损伤的精确定位与定量。针对iFEM-PE方法对噪声的敏感性,二维连续小波变换可以在时频域实现信号联合分析,加强损伤特征并抑制噪音。另一方面,数据融合技术通过对不同工况下损伤识别结果的综合处理,有效提升了损伤识别的适用性与稳定性。结果显示,以上方法在噪音影响下可对复合材料结构的分层损伤进行精确定位。Abstract: The two-dimensional continuous wavelet transform (2D-CWT) and data fusion technique to enhance the noise immunity and engineering applicability of the framework of damage called iFEM-PE method which combines the inverse finite element method (iFEM) and pseudo-excitation method (PE) to identify damage were introduced. The example analyses show that iFEM can reconstruct the structural displacement accurately in real time with the finite strain measurement data, which makes the PE method get rid of the dependence of online displacement measurement. On the other hand, PE method has high sensitivity to structural damage, which is suitable for accurate location and quantification of damage. Because the iFEM-PE method is sensitive to the noise, 2D-CWT can realize joint signal analysis in time and frequency domain, strengthen damage characteristics and suppress noise. Moreover, data fusion technology effectively improves the applicability and stability of damage identification through the comprehensive processing of damage identification results under different working conditions. The results show that the above methods can accurately locate the delamination damage of composite structures under the influence of noise.

-

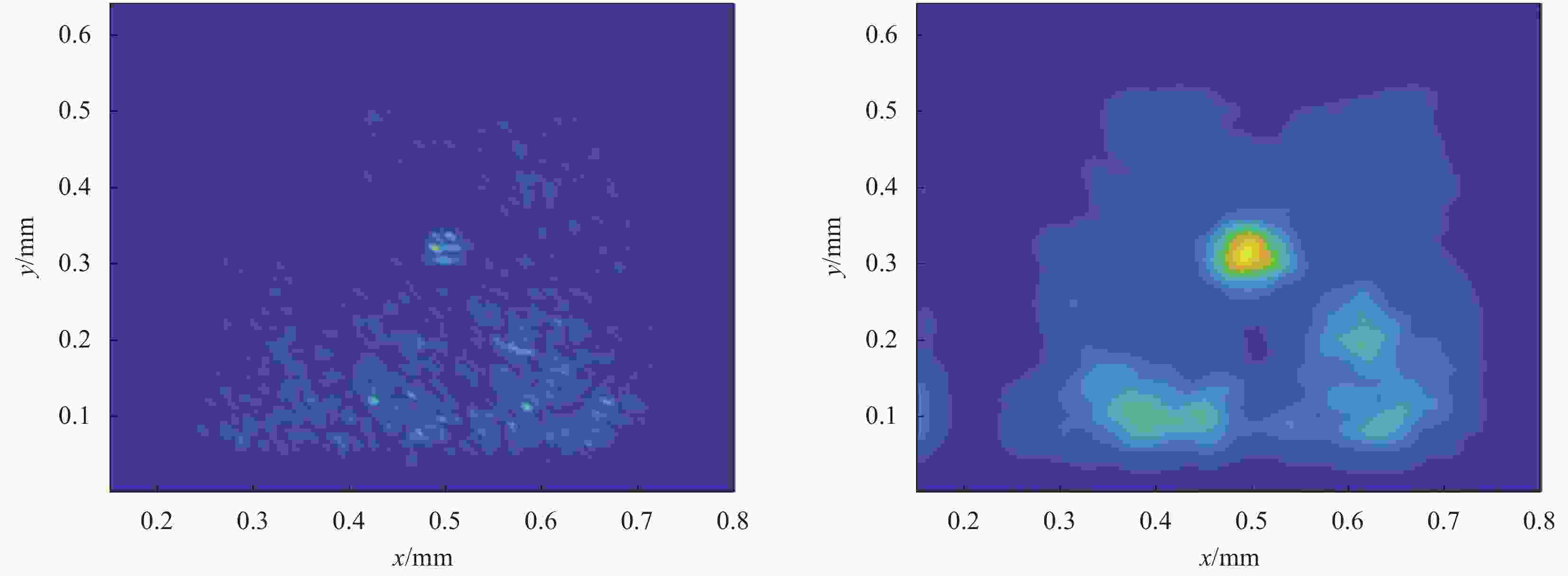

图 1 iQS4逆壳单元 (a) 和其局部自由度 (b)

Figure 1. iQS4 inverse element (a) and its local nodal degrees of freedom (b)

u, v—Displacement of x and y directions in the plane, respectively; w—Transverse deflection displacement in the z direction; θx, θy and θz—Rotation angles with the positive x, y and z axes as normals, respectively

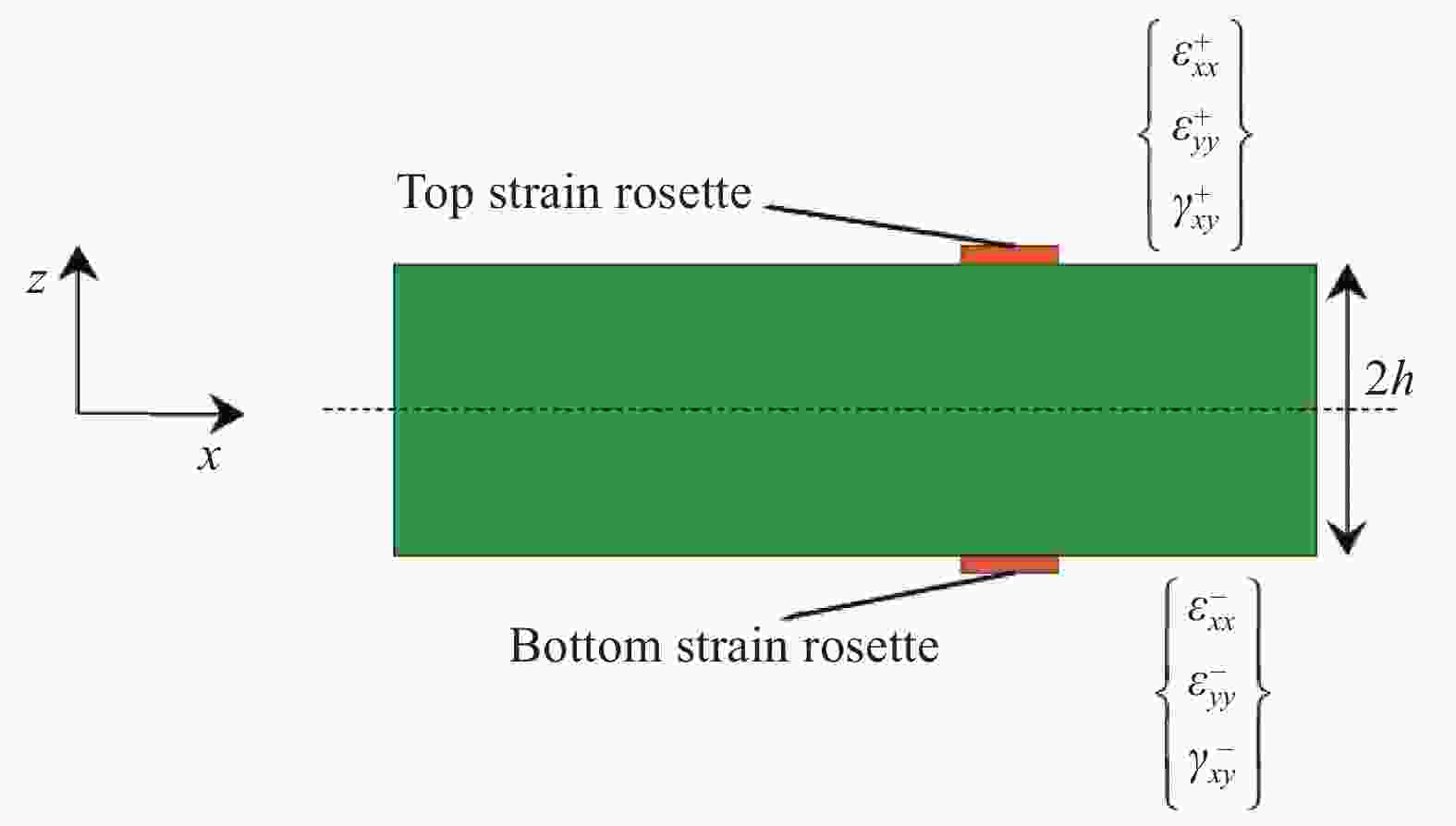

图 2 iQS4单元上离散应变测量

Figure 2. Discrete surface strains measured on the iQS4 element

${\varepsilon _{xx}^ + } $ , ${\varepsilon _{yy}^ + } $ , ${\gamma _{xy}^ + } $ , ${\varepsilon _{xx}^{\rm{ - }}} $ , ${\varepsilon _{yy}^{\rm{ - }}} $ , ${\gamma _{xy}^{\rm{ - }}} $ —Strain components measured on structural surface; h—Element thickness

-

[1] TAKEDA S I, AOKI Y, et al. Damage monitoring of CFRP stiffened panels under compressive load using FBG sensors Composite Structures,2012,94(3):813-819. doi: 10.1016/j.compstruct.2011.02.020 [2] ZOU Y, TONG L, STEVEN G. Vibration-based model-dependent damage (delamination) identification and health monitoring for composite structures-A review Journal of Sound & Vibration,2000,230(2):357-378. [3] YANG Z, LIU K, ZHOU K, et al. Investigation of thermo-acoustoelastic guided waves by semi-analytical finite element method Ultrasonics,2020,106:106141. doi: 10.1016/j.ultras.2020.106141 [4] WU Z, YANG Z, ZHANG J, et al. Acoustoelastic guided wave propagation in axial stressed arbitrary cross-section Smart Materials and Structures,2018,28(4):045013. [5] 张佳奇, 陈铎, 郑跃滨, 等. 基于压电传感器的树脂基复合材料固化过程监测[J]. 复合材料学报, 2020, 37(11):2776-2781.ZHANG Jiaqi, CHEN Duo, ZHENG Yuebin, et al. Piezoelectric transducers based curing monitoring of resin matrix composites Acta Materiae Compositae Sinica,2020,37(11):2776-2781(in Chinese). [6] FARRAR C R, DOEBLING S W, et al. Vibration-based structural damage identification Philosophical Transactions of the Royal Society A Mathematical Physical & Engineering Sciences,2001. [7] FAN W, QIAO P. Vibration-based damage identification methods: A review and comparative study Structural Health Monitoring,2011,9(1):83-111. [8] LEE Y S, CHUNG M J. A study on crack detection using eigenfrequency test data Computers & Structures,2000,77(3):327-342. [9] ALVANDI A, CREMONA C. Assessment of vibration-based damage identification techniques Journal of Sound and Vibration,2006,292(1-2):179-202. doi: 10.1016/j.jsv.2005.07.036 [10] YAM L H, YAN Y J, JIANG J S. Vibration-based damage detection for composite structures using wavelet transform and neural network identification Composite Structures,2003,60(4):403-412. doi: 10.1016/S0263-8223(03)00023-0 [11] XU H, CHENG L, SU Z, et al. Identification of structural damage based on locally perturbed dynamic equilibrium with an application to beam component Journal of Sound and Vibration,2011,330(24):5963-5981. doi: 10.1016/j.jsv.2011.07.028 [12] XU H, CHENG L, SU Z, et al. Damage visualization based on local dynamic perturbation: Theory and application to characterization of multi-damage in a plane structure Journal of Sound and Vibration,2013,332(14):3438-3462. doi: 10.1016/j.jsv.2013.01.033 [13] XU H, SU Z, CHENG L, et al. A “Pseudo-excitation” approach for structural damage identification: From “Strong” to “Weak” modality Journal of Sound and Vibration,2015:181-198. [14] XU H, SU Z, CHENG L, et al. Reconstructing interfacial force distribution for identification of multi-debonding in steel-reinforced concrete structures using noncontact laser vibrometry Structural Health Monitoring-An International Journal,2013:507-521. [15] TESSLER A, SPANGLER J L. A least-squares variational method for full-field reconstruction of elastic deformations in shear-deformable plates and shells Computer Methods in Applied Mechanics and Engineering,2005,194(2):327-339. [16] KEFAL A, MAYANG J B, OTERKUS E, et al. Three dimensional shape and stress monitoring of bulk carriers based on iFEM methodology Ocean Engineering,2018:256-267. [17] KEFAL A, OTERKUS E. Displacement and stress monitoring of a Panamax containership using inverse finite element method Ocean Engineering,2016,119:16-29. [18] KEFAL A, OTERKUS E. Displacement and stress monitoring of a chemical tanker based on inverse finite element method Ocean Engineering,2016,112:33-46. [19] CERRACCHIO P, GHERLONE M, TESSLER A, et al. Real-time displacement monitoring of a composite stiffened panel subjected to mechanical and thermal loads Meccanica,2015,50(10):2487-2496. doi: 10.1007/s11012-015-0146-8 [20] ZHAO Y, DU J, BAO H, et al. Optimal sensor placement based on eigenvalues analysis for sensing deformation of wing frame using iFEM Sensors,2018,18(8):2424. doi: 10.3390/s18082424 [21] 孙哲, 王建锋, 王静, 等. 基于时空变中值滤波的随机噪声压制方法[J]. 石油地球物理勘探, 2016, 51(6): 1094-1102.SUN Zhe, WANG Jianfeng, WANG Jing, et al. Random noise suppression method based on spatiotemporal bimodal median filter[J]. Oil Geophysical Prospecting, 2016, 51(6): 1094-1102(in Chinese). [22] 廖立坚, 杨新安, 叶培旭, 等. 基于时空域的探地雷达杂波的去除[J]. 勘察科学技术, 2008, 153(3):59-61. doi: 10.3969/j.issn.1001-3946.2008.03.015LIAO Lijian, YANG Xinan, YE Peixu, et al. Ground penetrating radar clutter clutter removal based on space-time domain Site Investigation Science and Technology,2008,153(3):59-61(in Chinese). doi: 10.3969/j.issn.1001-3946.2008.03.015 [23] 黄敏, 朱德兵, 郭政学, 等. 连续小波变换在探地雷达信号分析中的应用研究[J]. 物探化探计算技术, 2012, 34(5):593-598.HUANG Min, ZHU Debing, GUO Zhengxue, et al. Application of continuous wavelet transform in ground penetrating radar signal analysis Computing Techniques for Geophysical and Geochemical Exploration,2012,34(5):593-598(in Chinese). [24] ANTOINE J P, MURENZI R, VANDERGHEYNS T P, et al. Two-dimensional wavelets and their relatives[M]. Cambridge: Cambridge University Press, 2004. [25] BISKRI S, ANTOINE J P, INHESTER B, et al. Extraction of solar coronal magnetic loops with the directional 2D morlet wavelet transform Solar Physics,2010,262(2):373-385. doi: 10.1007/s11207-010-9533-4 -

下载:

下载: