Research progress of power/energy storage battery separator based on selective ion migration strategy

-

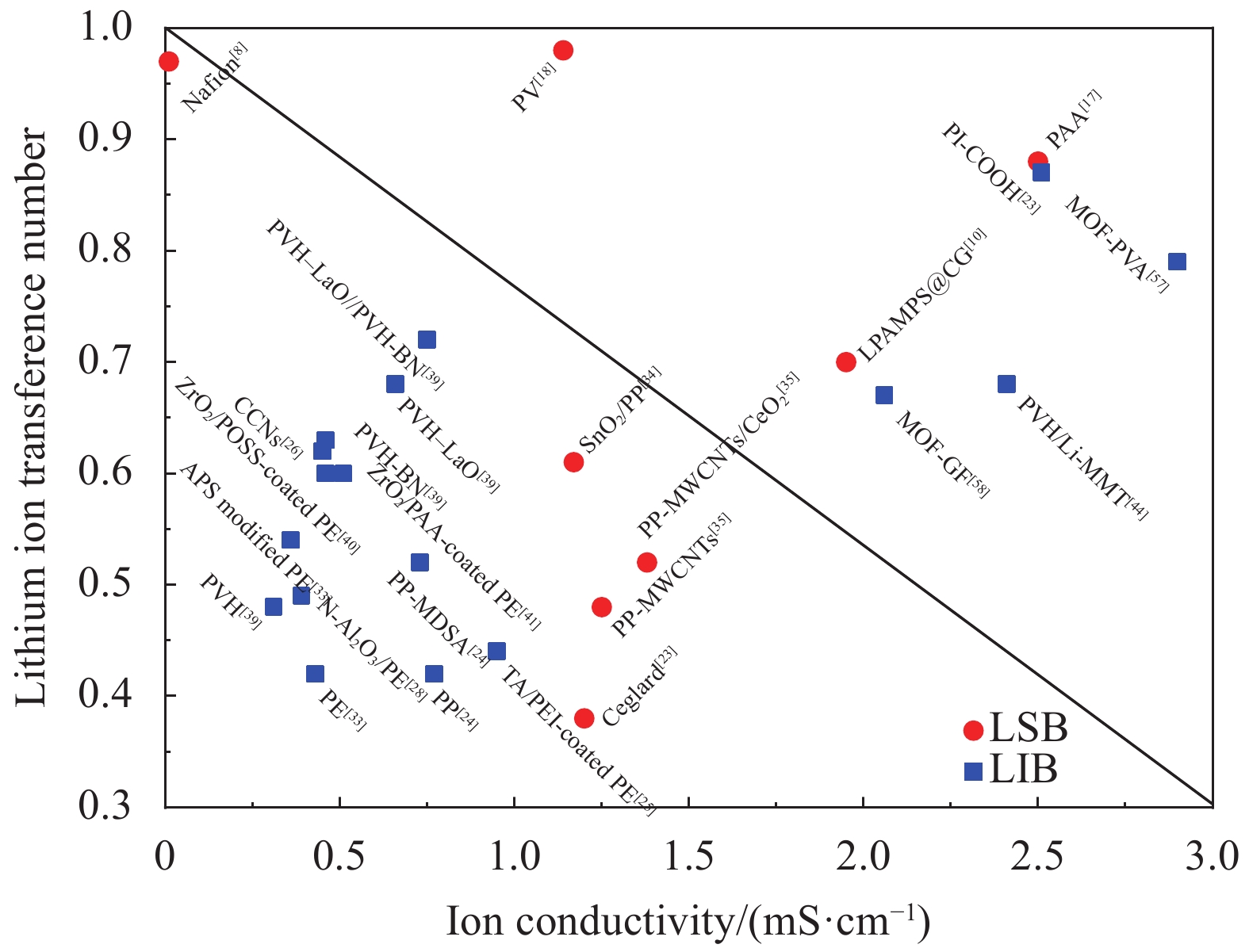

摘要: 随着锂离子电池等新能源电池在动力/储能领域的不断发展,传统商业聚烯烃隔膜由于润湿性与离子选择性差、孔隙率低等缺点已不能满足高性能锂电池的发展需要。近年来学者针对提升隔膜离子导电性能方面做了大量研究,然而锂电池充放电过程中通常只有阳离子传输参与氧化还原反应,二元电解质中锂离子通常被溶剂分子包围形成较大的溶剂鞘导致阴离子的移动能力反而强于锂离子,电池内部低的阳离子传输效率导致电池出现浓差极化、锂枝晶等问题,限制电池在高倍率下的应用,因此设计抑制阴离子穿梭促进阳离子快速迁移的新型电池隔膜在提升电池综合性能方面具有优异的发展前景。本文从近期的研究热点出发,主要从基团功能化设计、路易斯酸的俘获效应、空间筛分等策略详细介绍基于提升阳离子迁移能力的新型隔膜在电池领域的发展,最后总结指出电池隔膜领域存在的挑战和未来的发展方向。Abstract: With the continuous development of lithium-ion batteries and other new energy batteries in the power/energy storage field, traditional commercial polyolefin separators can no longer meet the development needs of high-performance lithium batteries due to the disadvantages of poor wettability, ion selectivity, and low porosity. In recent years, scholars have done a lot of research on improving the ionic conductivity of separators. However, during the charging and discharging process of lithium batteries, only cations can transport to participate in the redox reaction. Lithium ions in binary electrolytes are usually surrounded by solvent molecules to form a larger solvent sheath, which causes the mobility of anions to be stronger than that of lithium ions. The low cation transmission efficiency inside the battery leads to problems such as concentration polarization and lithium dendrites in the battery, which limits the application of the battery at high rates. Therefore, the design of a new type of battery separator that inhibits the shuttle of anions and promotes the rapid migration of cations has excellent development prospects in improving the electrochemical performance of the battery. Starting from recent research hotspots, this article mainly introduces the development of new separators based on the improvement of cation migration ability in the battery field from the functional design of groups, the trapping effect of Lewis acid, and spatial screening. Finally, it concludes that the battery separator field exists challenges and future development directions.

-

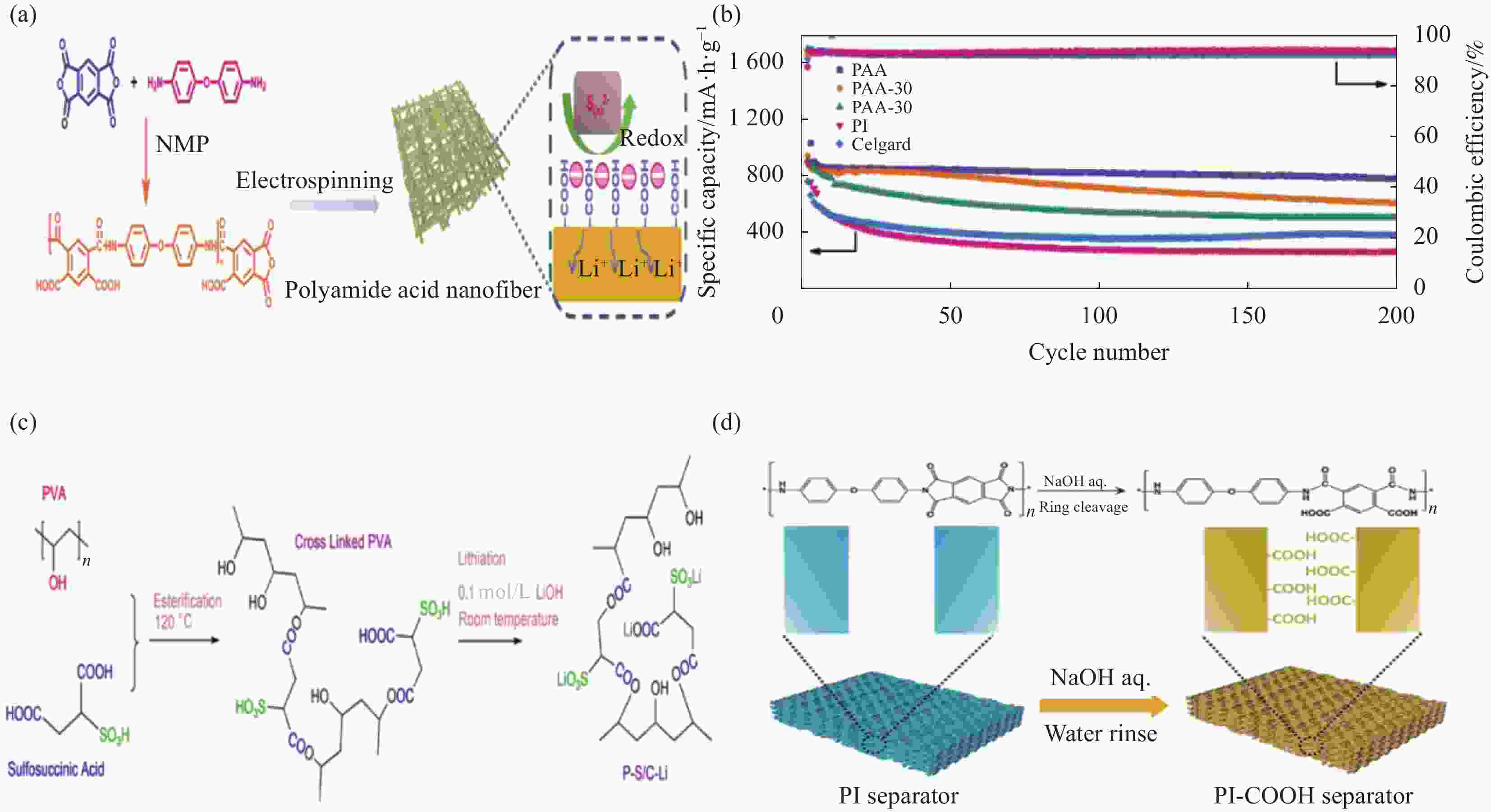

图 2 PAA纳米纤维隔膜的制备过程示意图[17](a);0.2C倍率下电池的循环性能和库仑效率[17](b);改性PVA功能隔膜的合成路线[21](c);聚酰亚胺隔膜的碱性水解示意图[23](d)

Figure 2. Schematic illustration of the preparation process of the PAA nanofiber separator[17](a); Cycle performance and coulombic efficiencies of the batteries at 0.2C[17](b); Synthesis route of the modified PVA new functional separator[21](c); Schematic for alkaline hydrolysis of the polyimide separator[23](d)

图 3 PP隔膜功能化的示意图[24](a);TA/PEI改性隔膜影响锂离子迁移示意图[25](b) ;电池在电流密度为0.2C至7C时的倍率能力[25](c);N-Al2O3/PE复合隔膜对锂离子迁移的影响示意图[28]

Figure 3. (a) Schematic illustration showing the functionalization of PP separator[24](a); Schematic of TA/PEI modified separator influence on lithium ion migration[25](b); Rate capability of the cells at the current densities range from 0.2C to 7C[25](c); Schematic of N-Al2O3/PE composite separator influence on lithium ion migration[28](d)

图 4 SnO2官能化PP的合成示意图[34](a);PP-MWCNTs /CeO2隔膜制备示意图[35](b);双层隔板的制备示意图[37](c);自组装过程示意图以及自组装前后的PE隔膜横截面示意图[40](d);原始和PAA / ZrO2 LbL改性PE隔膜横截面图及在PE隔膜上构建PAA / ZrO2多层的逐层自组装过程[41](e);13X沸石结构中的酸性位点[46](f)

Figure 4. (a)Schematic illustration of the synthesis of SnO2 functionalized PP[34](a); Schematic diagram for the preparation of PP-MWCNTs/CeO2 separators[35](b); Schematic illustration of preparation of bi-layer separators[39](c); Schematic illustrations for Self-assembly process and cross-sectional diagram of PE separator before and after self-assembly[40](d); Cross-sectional diagram of pristine and PAA/ZrO2 LbL-modified PE separators and layer-by-layer self assembly process for the construction of PAA/ZrO2 multilayers on PE separator[41](e); Acidic sites in the 13X zeolite structure[46](f)

图 5 过滤制备Ni3(HITP)2/PP隔膜的过程及其在Li-S电池中的组装[53](a);Ni-MOF / MWCNT改性PE隔膜用于阻止多硫化锂迁移到Li-S电池锂阳极示意图[54](b);功能性电纺MOF-PVA膜吸附阴离子并促进锂离子的运输示意图[57](c);GF、MOF-GF复合隔膜和MOF-GF中离子传输行为的放大图[58](d);Mn-BTC MOF涂层的Li-S电池循环前后的电化学阻抗谱[59](e);亲水性微孔膜的快速离子传输和高离子分子选择性的工作原理[64](f)

Figure 5. Illustration of the preparation process of the Ni3(HITP)2-modified separator by filtration and its assembly into the Li−S battery[51](a); Schematic illustration of Ni-MOF/MWCNT-coated PE separator for blocking lithium polysulfide migration to the lithium anode in the lithium-sulfur cell[52](b); Schematics showing a functional electrospun MOF–PVA for adsorbing anions and facilitating the transport of lithium ions[55](c); Schematic illustrations of glass fiber; MOF-GF composite separator and an enlarged view showing ion transport behaviours in MOG[56](d); Electrochemical impedance spectra for the Li-S cell with Mn-BTC MOF -coated membrane before and after cycling[57](e); Working principle of hydrophilic microporous membranes for fast ion transport and high ionic and molecular selectivity[62](f)

-

[1] RYU H S, GUO Z P, AHN H J, et al. Investigation of discharge reaction mechanism of lithium vertical bar liquid electrolyte vertical bar sulfur battery[J]. Journal of Power Sources,2009,189(2):1179-1183. doi: 10.1016/j.jpowsour.2008.12.073 [2] CANO Z P, BANHAM D, YE S Y, et al. Batteries and fuel cells for emerging electric vehicle markets[J]. Nature Energy,2018,3(4):279-289. doi: 10.1038/s41560-018-0108-1 [3] HAO Z, ZHANG Q, XU X, et al. Nanochannels regulating ionic transport for boosting electrochemical energy storage and conversion: A review[J]. Nanoscale,2020,12(30):15923-15943. doi: 10.1039/D0NR02464C [4] YE G, JANZEN N, GOWARD G R. Solid-state NMR study of two classic proton conducting polymers: Nafion and sulfonated poly(ether ether ketone)s[J]. Macromolecules,2006,39(9):3283-3290. doi: 10.1021/ma0523825 [5] HSU W Y, GIERKE T D. Elastic theory for ionic clustering in perfluorinated ionomers[J]. Macromolecules,1982,15(1):101-105. doi: 10.1021/ma00229a020 [6] YU X W, JOSEPH J, MANTHIRAM A. Polymer lithium-sulfur batteries with a Nafion membrane and an advanced sulfur electrode[J]. Journal of Materials Chemistry A,2015,3(30):15683-15691. doi: 10.1039/C5TA04289E [7] ZAHN R, LAGADEC M F, HESS M, et al. Improving ionic conductivity and lithium-ion transference number in lithium-ion battery separators[J]. ACS Applied Materials & Interfaces,2016,8(48):32637-32642. [8] HUANG J Q, ZHANG Q, PENG H J, et al. Ionic shield for polysulfides towards highly-stable lithium-sulfur batteries[J]. Energy & Environmental Science,2014,7(1):347-353. [9] SHIN W K, KIM D W. High performance ceramic-coated separators prepared with lithium ion-containing SiO2 particles for lithium-ion batteries[J]. Journal of Power Sources,2013,226:54-60. doi: 10.1016/j.jpowsour.2012.10.082 [10] HAREENDRAKRISHNAKUMAR H, CHULLIYOTE R, JOSEPH M G, et al. Sulfonic groups stemmed ionic shield for polysulfides towards high performance Li-S batteries[J]. Electrochimica Acta,2019,321:134697. doi: 10.1016/j.electacta.2019.134697 [11] SHI L, ZENG F L, CHENG X, et al. Enhanced performance of lithium-sulfur batteries with high sulfur loading utilizing ion selective MWCNT/SPANI modified separator[J]. Chemical Engineering Journal,2018,334:305-312. doi: 10.1016/j.cej.2017.08.015 [12] BABU D B, GIRIBABU K, RAMESHA K. Permselective SPEEK/nafion composite-coated separator as a potential polysulfide crossover barrier layer for Li-S batteries[J]. ACS Applied Materials & Interfaces,2018,10(23):19721-19729. [13] ABBAS S A, IBRAHEM M A, HU L H, et al. Bifunctional separator as a polysulfide mediator for highly stable Li-S batteries[J]. Journal of Materials Chemistry A,2016,4(24):9661-9669. doi: 10.1039/C6TA02272C [14] LU Y, GU S, GUO J, et al. Sulfonic groups originated dual-functional interlayer for high performance lithium-sulfur battery[J]. ACS Applied Materials & Interfaces,2017,9(17):14878-14888. [15] FREITAG A, STAMM M, IONOV L. Separator for lithium-sulfur battery based on polymer blend membrane[J]. Journal of Power Sources,2017,363:384-391. doi: 10.1016/j.jpowsour.2017.07.077 [16] LU Y Y, TIKEKAR M, MOHANTY R, et al. Stable cycling of lithium metal batteries using high transference number electrolytes[J]. Advanced Energy Materials,2015,5(9):1402073. doi: 10.1002/aenm.201402073 [17] LUO X, LU X B, ZHOU G Y, et al. Ion-selective polyamide acid nanofiber separators for high-rate and stable lithium-sulfur batteries[J]. ACS Applied Materials & Interfaces,2018,10(49):42198-42206. [18] MA L, NATH P, TU Z Y, et al. Highly conductive, sulfonated, UV-cross-linked separators for Li-S batteries[J]. Chemistry of Materials,2016,28(14):5147-5154. doi: 10.1021/acs.chemmater.6b02190 [19] YU X W, JOSEPH J, MANTHIRAM A. Suppression of the polysulfide-shuttle behavior in Li-S batteries through the development of a facile functional group on the polypropylene separator[J]. Materials Horizons,2016,3(4):314-319. doi: 10.1039/C6MH00043F [20] SONG S L, SHI L, LU S Y, et al. A new polysulfide blocker-poly(acrylic acid) modified separator for improved performance of lithium-sulfur battery[J]. Journal of Membrane Science,2018,563:277-283. doi: 10.1016/j.memsci.2018.05.050 [21] JIANG K, GAO S, WANG R X, et al. Lithium sulfonate/carboxylate-anchored polyvinyl alcohol separators for lithium sulfur batteries[J]. ACS Applied Materials & Interfaces,2018,10(21):18310-18315. [22] LI Z, HAN Y, WEI J H, et al. Suppressing shuttle effect using janus cation exchange membrane for high-performance lithium-sulfur battery separator[J]. ACS Applied Materials & Interfaces,2017,9(51):44776-44781. [23] LIN C E, ZHANG H, SONG Y Z, et al. Carboxylated polyimide separator with excellent lithium ion transport properties for a high-power density lithium-ion battery[J]. Journal of Materials Chemistry A,2018,6(3):991-998. doi: 10.1039/C7TA08702K [24] ZHU W Y, WANG Z, QIU W J, et al. Improving the Electrochemical Performance of Polypropylene Separator through Instantaneous Photo-Induced Functionalization[J]. Journal of the Electrochemical Society,2018,165(9):1909-1914. doi: 10.1149/2.1511809jes [25] ZHANG Y, YUAN J J, SONG Y Z, et al. Tannic acid/polyethyleneimine-decorated polypropylene separators for Li-ion batteries and the role of the interfaces between separator and electrolyte[J]. Electrochimica Acta,2018,275:25-31. doi: 10.1016/j.electacta.2018.03.099 [26] ZHANG T W, CHEN J L, TIAN T, et al. Sustainable separators for high-performance lithium ion batteries enabled by chemical modifications[J]. Advanced Functional Materials,2019,29(28):1902023. doi: 10.1002/adfm.201902023 [27] LU H, WANG J L, LI T, et al. Improved performance of lithium-sulfur battery by a functional separator design[J]. Journal of Solid State Electrochemistry,2018,22(3):953-958. doi: 10.1007/s10008-017-3808-8 [28] ZHANG H, SHENG L, BAI Y, et al. Amino-functionalized Al2O3 particles coating separator with excellent lithium-ion transport properties for high-power density lithium-ion batteries[J]. Advanced Engineering Materials,2020,22(11):1901545. [29] ZHANG J W, HUANG X B, WEI H, et al. Preparation and electrochemical behaviors of composite solid polymer electrolytes based on polyethylene oxide with active inorganic-organic hybrid polyphosphazene nanotubes as fillers[J]. New Journal of Chemistry,2011,35(3):614-621. doi: 10.1039/c0nj00717j [30] FU W, XU R, ZHANG X, et al. Enhanced wettability and electrochemical performance of separators for lithium-ion batteries by coating core-shell structured silica-poly(cyclotriphosphazene-co-4,4′-sulfonyldiphenol) particles[J]. Journal of Power Sources,2019,436:226839. doi: 10.1016/j.jpowsour.2019.226839 [31] KIM K J, KWON Y K, YIM T, et al. Functional separator with lower resistance toward lithium ion transport for enhancing the electrochemical performance of lithium ion batteries[J]. Journal of Industrial and Engineering Chemistry,2019,71:228-233. doi: 10.1016/j.jiec.2018.11.029 [32] ZHU M, WANG Q, ZHOU H, et al. Binder-free TiO2-coated polypropylene separators for advanced lithium-ion batteries[J]. Energy Technology,2020,8(7):2000228. doi: 10.1002/ente.202000228 [33] AHN Y K, KWON Y K, KIM K J. Surface-modified polyethylene separator with hydrophilic property for enhancing the electrochemical performance of lithium-ion battery[J]. International Journal of Energy Research,2020,44(8):6651-6659. doi: 10.1002/er.5401 [34] XIANG Y, WANG Z, QIU W, et al. Interfacing soluble polysulfides with a SnO2 functionalized separator: An efficient approach for improving performance of Li-S battery[J]. Journal of Membrane Science,2018,563:380-387. doi: 10.1016/j.memsci.2018.06.004 [35] ZHU W, ZHANG Z, WEI J, et al. A synergistic modification of polypropylene separator toward stable lithium-sulfur battery[J]. Journal of Membrane Science,2020,597:117646. doi: 10.1016/j.memsci.2019.117646 [36] CAI H, YANG G, MENG Z, et al. Water-dispersed poly(p-phenylene terephthamide) boosting nano-Al2O3-coated polyethylene separator with enhanced thermal stability and ion diffusion for lithium-ion batteries[J]. Polymers,2019,11(8):1362. [37] WANG Q, YANG J, WANG Z, et al. Dual-scale Al2O3 particles coating for high-performance separator and lithium metal anode[J]. Energy Technology,2020,8(5):1901429. doi: 10.1002/ente.201901429 [38] LIN W, JIAO J, LI H, et al. Organic-inorganic composite porous membrane for stable and high-performance lithium-ion battery[J]. ChemistrySelect,2020,5(4):1308-1314. doi: 10.1002/slct.201903876 [39] WAQAS M, ALI S, CHEN D, et al. A robust bi-layer separator with Lewis acid-base interaction for high-rate capacity lithium-ion batteries[J]. Composites Part B: Engineering,2019,177:107448. doi: 10.1016/j.compositesb.2019.107448 [40] CHI M, SHI L, WANG Z, et al. Excellent rate capability and cycle life of Li metal batteries with ZrO2/POSS multilayer-assembled PE separators[J]. Nano Energy,2016,28:1-11. doi: 10.1016/j.nanoen.2016.07.037 [41] XU W, WANG Z, SHI L, et al. Layer-by-layer deposition of organic-inorganic hybrid multilayer on microporous polyethylene separator to enhance the electrochemical performance of lithium-ion battery[J]. ACS Applied Materials & Interfaces,2015,7(37):20678-20686. doi: 10.1021/acsami.5b05457 [42] MA Y, LI L B, GAO G X, et al. Effect of montmorillonite on the ionic conductivity and electrochemical properties of a composite solid polymer electrolyte based on polyvinylidenedifluoride/polyvinyl alcohol matrix for lithium ion batteries[J]. Electrochimica Acta,2016,187:535-542. doi: 10.1016/j.electacta.2015.11.099 [43] ZHAO H, KANG W, DENG N, et al. A fresh hierarchical-structure gel poly-m-phenyleneisophthalamide nanofiber separator assisted by electronegative nanoclay-filler towards high-performance and advanced-safety lithium-ion battery[J]. Chemical Engineering Journal,2020,384:123312. doi: 10.1016/j.cej.2019.123312 [44] ZHAO J, CHEN D, BOATRNG B, et al. Atomic interlamellar ion path in polymeric separator enables long-life and dendrite-free anode in lithium ion batteries[J]. Journal of Power Sources,2020,451:227773. doi: 10.1016/j.jpowsour.2020.227773 [45] POURAZAR M B, MOHAMMADI T, NASR M R J, et al. Preparation of 13X zeolite powder and membrane: Investigation of synthesis parameters impacts using experimental design[J]. Materials Research Express,2020,7(3):035004. doi: 10.1088/2053-1591/ab7217 [46] POURAZAR M B, MOHAMMADI T, NASR M R J, et al. Preparation and characterization of poly(vinylidene fluoride)-13X zeolite mixed matrix membranes for lithium ion batteries’ separator with enhanced performance[J]. Journal of Applied Polymer Science,2020,137(44):49367. [47] LI Y, WANG X, LIANG J, et al. Design of a high performance zeolite/polyimide composite separator for lithium-ion batteries[J]. Polymers,2020,12(4):764-776. doi: 10.3390/polym12040764 [48] ZHANG J, XIANG Y, JAMIL M I, et al. Polymers/zeolite nanocomposite membranes with enhanced thermal and electrochemical performances for lithium-ion batteries[J]. Journal of Membrane Science,2018,564:753-761. doi: 10.1016/j.memsci.2018.07.056 [49] MCKEOWN N B, BUDD P M. Polymers of intrinsic microporosity (PIMs): Organic materials for membrane separations, heterogeneous catalysis and hydrogen storage[J]. Chemical Society Reviews,2006,35(8):675-683. doi: 10.1039/b600349d [50] LI C Y, WARD A L, DORIS S E, et al. Polysulfide-blocking microporous polymer membrane tailored for hybrid Li-sulfur flow batteries[J]. Nano Letters,2015,15(9):5724-5729. doi: 10.1021/acs.nanolett.5b02078 [51] DORIS S E, WARD A L, FRISCHMANN P D, et al. Understanding and controlling the chemical evolution and polysulfide-blocking ability of lithium-sulfur battery membranes cast from polymers of intrinsic microporosity[J]. Journal of Materials Chemistry A,2016,4(43):16946-16952. doi: 10.1039/C6TA06401A [52] WARD A L, DORIS S E, LI L, et al. Materials genomics screens for adaptive ion transport behavior by redox-switchable microporous polymer membranes in lithium-sulfur batteries[J]. ACS Central Science,2017,3(5):399-406. doi: 10.1021/acscentsci.7b00012 [53] CHEN H, XIAO Y, CHEN C, et al. Conductive MOF-modified separator for mitigating the shuttle effect of lithium-sulfur battery through a filtration method[J]. ACS Applied Materials & Interfaces,2019,11(12):11459-11465. doi: 10.1021/acsami.8b22564 [54] LEE D H, AHN J H, PARK M S, et al. Metal-organic framework/carbon nanotube-coated polyethylene separator for improving the cycling performance of lithium-sulfur cells[J]. Electrochimica Acta,2018,283:1291-1299. doi: 10.1016/j.electacta.2018.07.031 [55] ZHOU C, HE Q, LI Z, et al. A robust electrospun separator modified with in situ grown metal-organic frameworks for lithium-sulfur batteries[J]. Chemical Engineering Journal,2020,395:124979. doi: 10.1016/j.cej.2020.124979 [56] WU J F, GUO X. Nanostructured metal-organic framework (MOF)-derived solid electrolytes realizing fastlithium ion transportation kinetics in solid-state batteries[J]. Small,2019,15(27):1804413. [57] ZHANG C, SHEN L, SHEN J, et al. Anion-sorbent composite separators for high-rate lithium-ion batteries[J]. Advanced Materials,2019,31(21):1808338. doi: 10.1002/adma.201808338 [58] SHEN L, WU H B, LIU F, et al. Anchoring anions with metal-organic framework-functionalized separators for advanced lithium batteries[J]. Nanoscale Horizons,2019,4(3):705-711. doi: 10.1039/C8NH00342D [59] SURIYAKUMAR S, KANAGARAJ M, KATHIRESAN M, et al. Metal-organic frameworks based membrane as a permselective separator for lithium-sulfur batteries[J]. Electrochimica Acta,2018,265:151-159. doi: 10.1016/j.electacta.2018.01.155 [60] CHANG Z, QIAO Y, WANG J, et al. Fabricating better metal-organic frameworks separators for Li-S batteries: Pore sizes effects inspired channel modification strategy[J]. Energy Storage Materials,2020,25:164-171. doi: 10.1016/j.ensm.2019.10.018 [61] KIM S H, YEON J S, KIM R, et al. A functional separator coated with sulfonated metal-organic framework/nafion hybrids for Li-S batteries[J]. Journal of Materials Chemistry A,2018,6(48):24971-24978. doi: 10.1039/C8TA08843H [62] GUO Y, SUN M H, LIANG H Q, et al. Blocking polysulfides and facilitating lithium-ion transport: Polystyrene sulfonate@HKUST-1 membrane for lithium-sulfur batteries[J]. ACS Applied Materials & Interfaces,2018,10(36):30451-30459. [63] TIAN Y, LIN C, WANG Z, et al. Polymer of intrinsic microporosity-based macroporous membrane with high thermal stability as a Li-ion battery separator[J]. RSC Advances,2019,9(37):21539-21543. doi: 10.1039/C9RA02308A [64] TAN R, WANG A, MALPASS-EVANS R, et al. Hydrophilic microporous membranes for selective ion separation and flow-battery energy storage[J]. Nature Materials,2020,19(2):195-202. doi: 10.1038/s41563-019-0536-8 -

下载:

下载: