Research progress on prediction of mechanical properties of 4D printing soft composite

-

摘要: 4D打印是一门新兴的制造技术,所打印结构的形状、属性或功能在外部环境的刺激下会随着时间的推移而变化。智能软物质材料由于变形大,激励响应机制多,响应速度快等特点被广泛使用于4D打印中,尤其是形状记忆水凝胶和形状记忆聚合物。目前对复合软材料的刚度和弯曲形状的控制是4D打印在应用上的两个难题,建立4D打印复合结构的等效模量和曲率预测模型对复合软材料的力学性能的设计具有指导意义。本文对现有的4D打印复合结构的等效模量及弯曲曲率模型进行了概述,首先介绍了4D打印结构在静态和动态下的弹性模量预测模型,然后,重点综述了Stoney理论,Timoshenko理论和复合材料力学在复合软材料弯曲曲率建模上的应用。最后探讨了现有4D打印复合软材料力学预测模型存在的问题及主要发展的方向。Abstract: 4D printing is an emerging manufacturing technology, the shape, property, or functionality of the printed structure will change with time under the stimulation of external environment. Smart soft matter is widely used in 4D printing due to its large deformation, multiple excitation response mechanisms and fast response speed, especially shape memory hydrogels and shape memory polymers. At present, the control of rigidity and bending shape of soft composite is two difficult problems in the application of 4D printing, and the establishment of equivalent modulus and curvature prediction models has guiding significance for the design of mechanical properties of 4D printed composite structures. This article gave an overview of the equivalent modulus and bending curvature models of the existing 4D printed composite structures, the elastic modulus prediction models of 4D printed structures under static and dynamic conditions were introduced. Then, the application of Stoney theory, Timoshenko theory and composite material mechanics in flexural curvature modeling of soft composite was emphatically reviewed. In the end, the existing problems of the existing 4D printing soft composite mechanics prediction model and the main development direction were discussed.

-

Key words:

- 4D printing /

- manufacturing technology /

- soft composite /

- equivalent modulus /

- curvature /

- prediction model

-

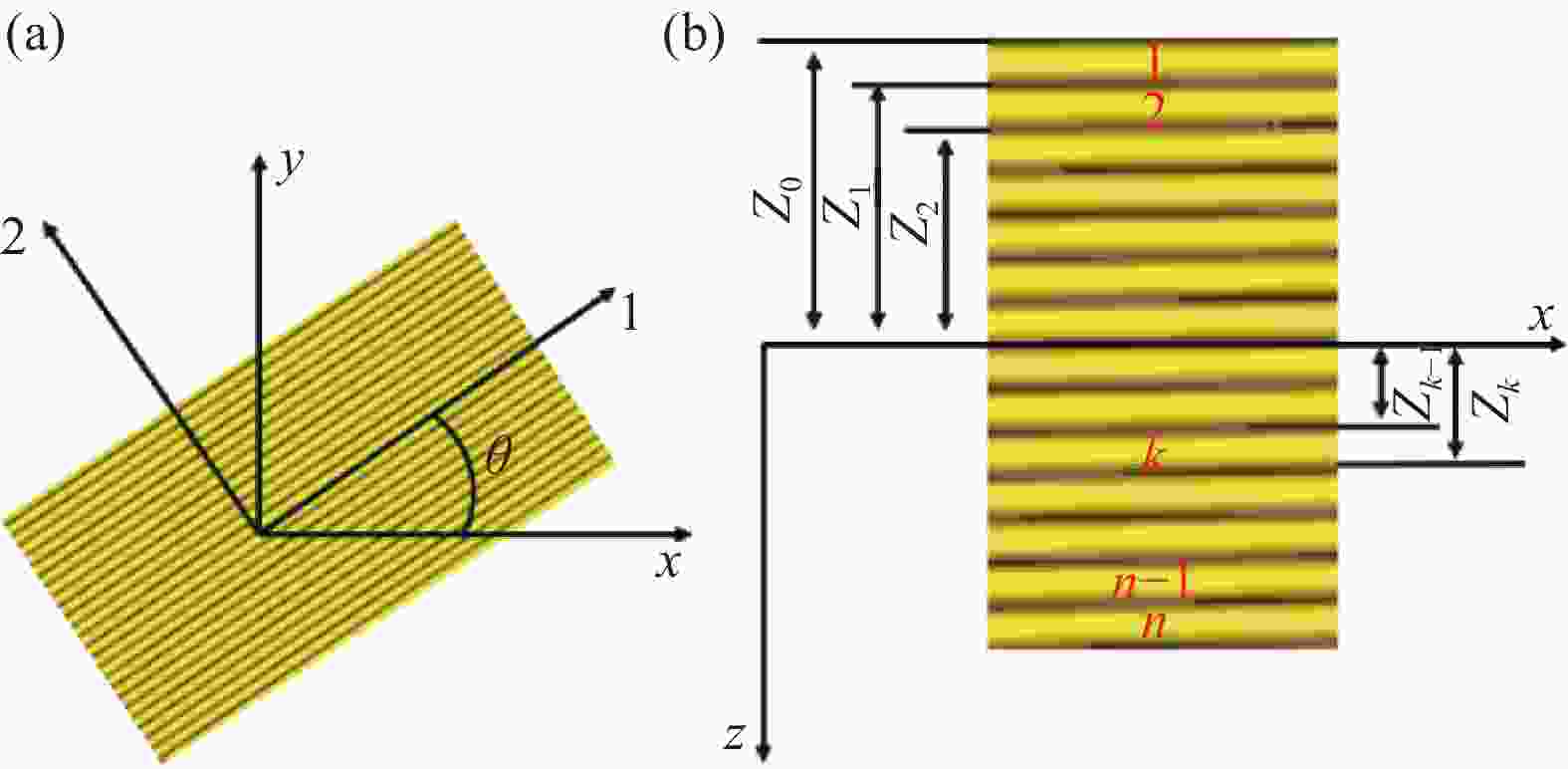

图 4 三角形单元和六边形单元填充结构参数[35]

Figure 4. Filling structure parameters of triangular elements and hexagonal elements[35] ((a) Loading in the [0] direction; (b) Loading in the [90] direction; (c) Optical image and geometry of the cross section of printed multilayer structure; (d) Hexagonal element of a two-dimensional model of printed structure)

σx—Stress in x direction; σy—Stress in y direction; δ1—Deflection of beam AB; δ2—Axial deformation of beam AB; δ3—Axial deformation of beam BC; PB1—Force applied on beam AB; PB2—Force applied on beam BC

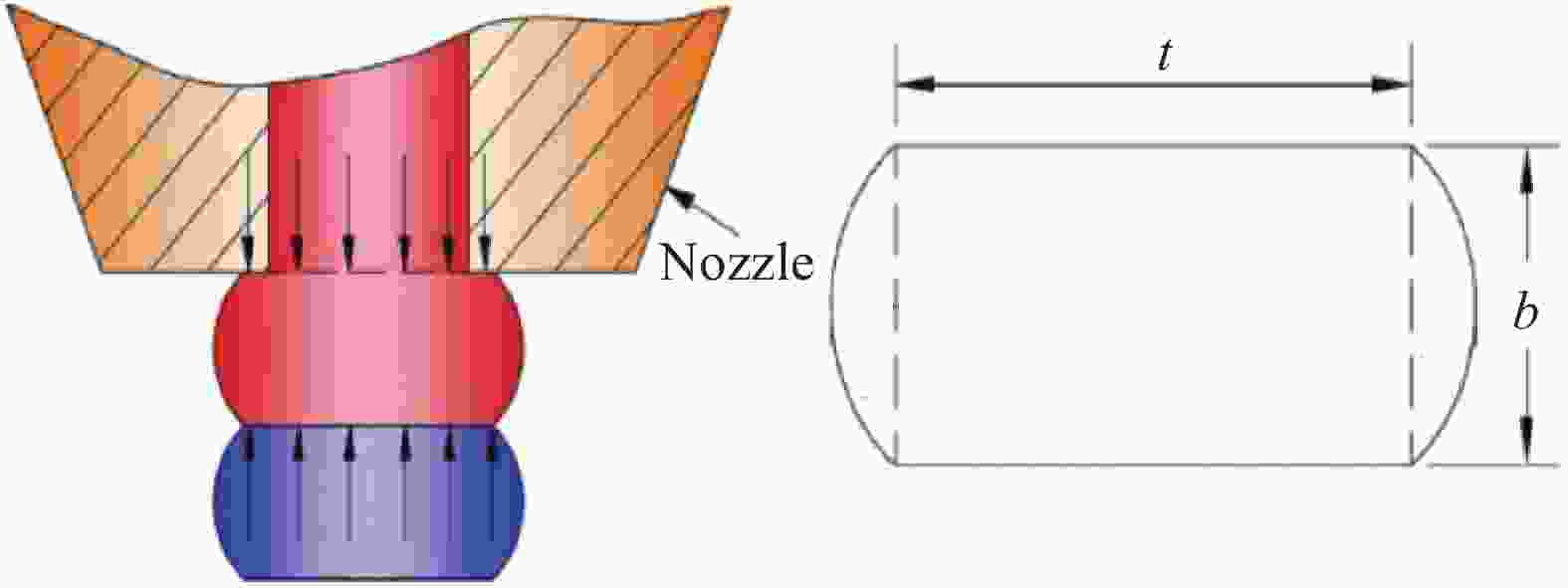

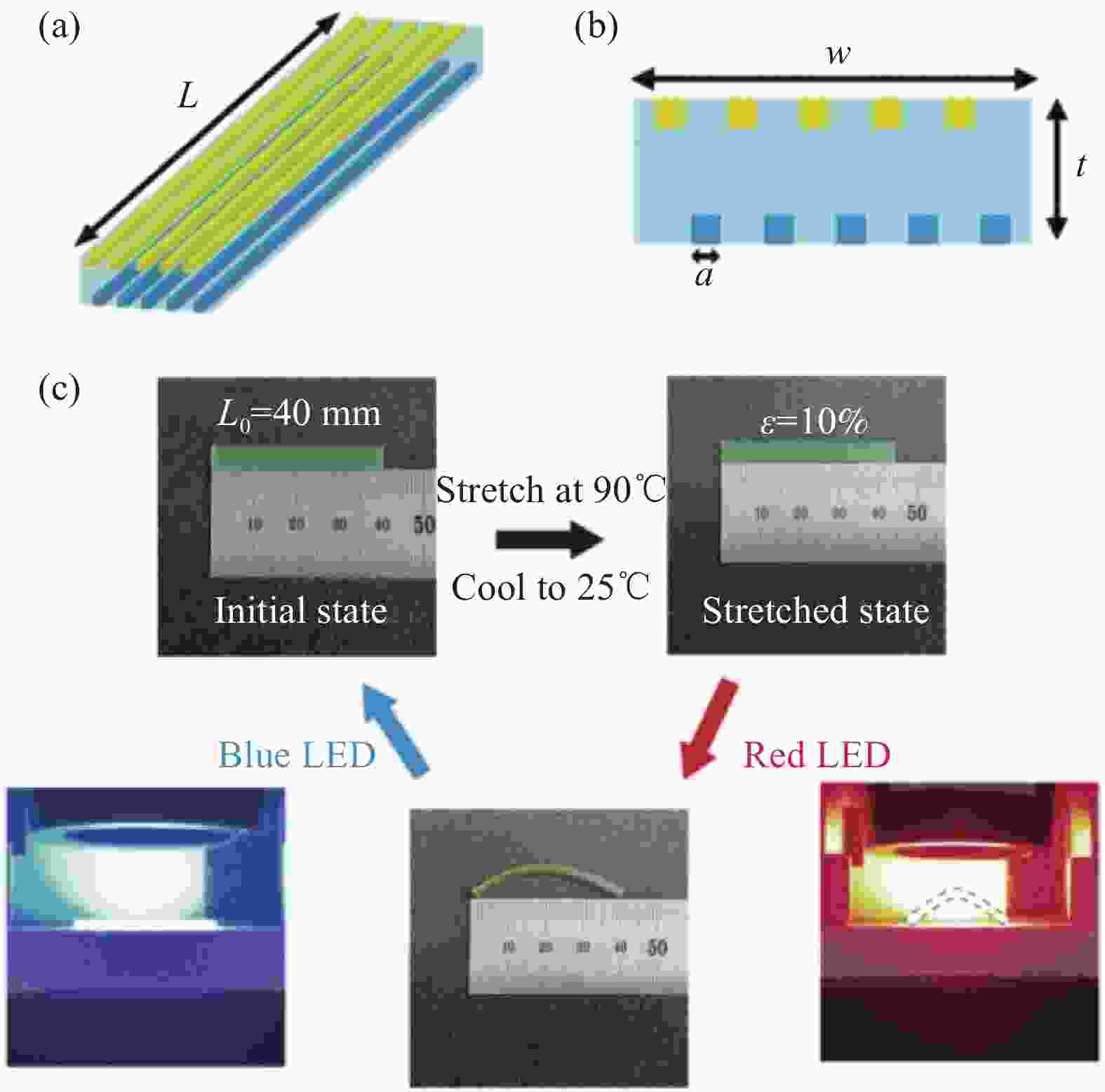

图 21 嵌入连续纤维复合材料可编程变形[75]

Figure 21. Programmable deformation of embedded continuous fiber composite material[75] ((a) Printing process; ((b)-(c)) Cross-section of the double-layer fiber; ((d)-(f)) Relationship between the curvature and the fiber bundle)

HC—Fiber thickness; HP—Resin thickness; b—Fiber width; B—Width between fiber bundles; ka, kb—Curvature vector of single fiber surface; k1—Principal curvature vector

-

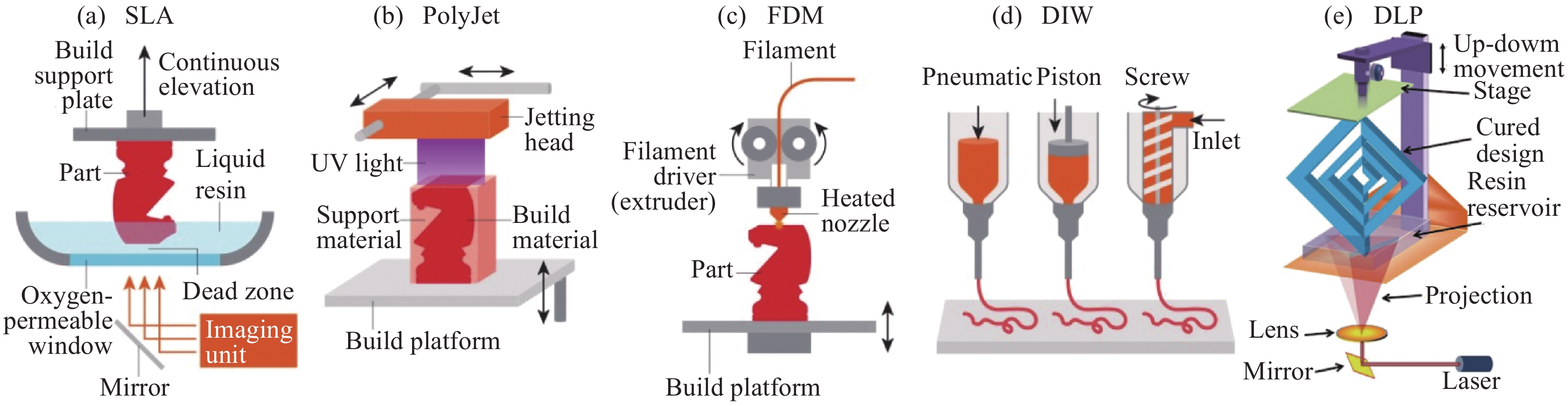

[1] LEWIS J A, AHN B Y. Device fabrication: Three-dimensional printed electronics[J]. Nature,2015,518(7537):42. doi: 10.1038/518042a [2] SUN K, WEI T S, AHN B Y, et al. 3D printing of interdigitated Li-ion microbattery architectures[J]. Advanced Materials,2013,25(33):4539-4543. doi: 10.1002/adma.201301036 [3] GOYANES A, FINA F, MARTORANA A, et al. Development of modified release 3D printed tablets (print lets) with pharmaceutical excipients using additive manufacturing[J]. International Journal of Pharmaceutics,2017,527(1):21. [4] MANNOOR M S, JIANG Z, JAMES T, et al. 3D printed bionic ears[J]. Nano Letters,2013,13(6):2634-2639. doi: 10.1021/nl4007744 [5] LINAS J, DARIUS G, et al. Optically clear and resilient free-form µ-optics 3D-printed via ultrafast laser lithography[J]. Materials,2017,10(1):12. doi: 10.3390/ma10010012 [6] ZHANG C, ANZALONE N C, FARIA R P, et al. Open-source 3D-printable optics equipment[J]. Plos One,2013,8(3):e59840. doi: 10.1371/journal.pone.0059840 [7] HUANG W C, CHANG K P, WU P H, et al. 3D printing optical engine for controlling material microstructure[J]. Physics Procedia,2016,83:847-853. doi: 10.1016/j.phpro.2016.08.088 [8] TIBBITS S. 4D printing: Multi-material shape change[J]. Architectural Design,2014,84(1):116-121. doi: 10.1002/ad.1710 [9] HUANG W, YANG B, AN L, et al. Water-driven programmable polyurethane shape memory polymer: Demonstration and mechanism[J]. Applied Physics Letters,2005,86(11):114105. doi: 10.1063/1.1880448 [10] LENDLEIN A, JIANG H, JUNGER O, et al. Light-induced shape-memory polymers[J]. Nature,2005,434(7035):879. doi: 10.1038/nature03496 [11] BAKARICH S E , GORKIN R , PANHUIS M , et al. 4D Printing with mechanically robust, thermally actuating hydrogels[J]. Macromolecular Rapid Communications, 2015, 36(12):1211-1217. [12] LAN X, LIU Y, LV H, et al. Fiber reinforced shape-memory polymer composite and its application in a deployable hinge[J]. Smart Materials & Structures. 2009, 18(2): 024002. [13] LIU Y, LV H, LAN X, et al. Review of electro-active shape-memory polymer composite[J]. Composites Science & Technology,2009,69(13):2064-2068. [14] MOHR R, KRATZ K, WEIGEL T, et al. Initiation of shape-memory effect by inductive heating of magnetic nanoparticles in thermoplastic polymers[J]. Proceedings of the National Academy of Sciences of the United States of America,2006,103(10):3540-3545. doi: 10.1073/pnas.0600079103 [15] NADGORNY M, XIAO Z, CHEN C, et al. Three-dimensional printing of ph-responsive and functional polymers on an affordable desktop printer[J]. ACS Applied Materials & Interfaces,2016,8:28946-28954. doi: 10.1021/acsami.6b07388 [16] MENG H, LI G. A review of stimuli-responsive shape memory polymer composites[J]. Polymer,2013,54:2199-2221. doi: 10.1016/j.polymer.2013.02.023 [17] GURUNG D. Technological comparison of 3D and 4D printing[M]. Helsinki: Arcada University of Applied Sciences Press, 2017. [18] TRUBY R L, LEWIS J A. Printing soft matter in three dimensions[J]. Nature,2016,540(7633):371. doi: 10.1038/nature21003 [19] WU H, LI D, TANG Y, et al. Rapid fabrication of alumina-based ceramic cores for gas turbine blades by stereolithography and gelcasting[J]. Journal of Materials Processing Technology,2009,209(18-19):5886-5891. [20] CHUA C K, LEONG K F. 3D printing and additive manufacturing: Principles and applications: Fourth edition of rapid prototyping[M]. Singapore: World Scientific, 2015. [21] INVERNIZZI M, TURRI S, LEVI M, et al. 4D printed thermally activated self-healing and shape memory polycaprolactone-based polymers[J]. European Polymer Journal,2018,101:169-176. [22] GE L, DONG L, WANG D, et al. A digital light processing 3D printer for fast and high-precision fabrication of soft pneumatic actuators[J]. Sensors and Actuators A: Physical,2018,273:285-292. doi: 10.1016/j.sna.2018.02.041 [23] LEWIS J A. Direct ink writing of 3D functional materials[J]. Advanced Functional Materials,2006,16(17):2193-2204. [24] SIDDHARTH J, KRISHNA R, KARUNAKA-RAN C, et al. 4D printing of materials for the future: Opportunities and challenges[J]. Materials Today,2020,18:100490. [25] GAO B, YANG Q, ZHAO X, et al. 4D Bioprinting for biomedical applications[J]. Trends in Biotechnology,2016,34(9):746-756. [26] LI Y J, ZHANG F H, LIU Y J, et al. 4D printed shape memory polymers and their structures for biomedical applications[J]. Science China (Technological Sciences),2020,63(04):545-560. doi: 10.1007/s11431-019-1494-0 [27] KUANG X, CHEN K, DUNN C K, et al. 3D printing of highly stretchable, shape-memory and self-healing elastomer toward novel 4D printing[J]. ACS Applied Materials & Interfaces,2018,10(8):7381-7388. [28] ZHANG K L, CHENG X D, ZHANG Y J, et al. Weather-manipulated smart broadband electromagnetic metamaterials[J]. ACS Applied Materials & Interfaces,2018,10(47):40815-40823. [29] BAKARICH S E, GORKIN R, PANHUIS M I H, et al. 4D printing with mechanically robust, thermally actuating hydrogels[J]. Macromolecular Rapid Communications,2015,36(12):1211-1217. doi: 10.1002/marc.201500079 [30] MA S Q, ZHANG Y P, WANG M, et al. Recent progress in 4D printing of stimuli-responsive polymeric materials[J]. Science China (Technological Sciences),2020,63(4):532-544. doi: 10.1007/s11431-019-1443-1 [31] ZHONG X K, JOANNE E M T, YONG L. 3D printing of smart materials: A review on recent progresses in 4D printing[J]. Virtual and Physical Prototyping,2015,10(3):103-122. [32] 赵先锋, 汤朋飞, 史红艳, 等. 4D打印技术研究与应用进展[J]. 华南理工大学学报(自然科学版), 2021, 49(3): 34-46, 54.ZHAO Xianfeng, TANG Pengfei, SHI Hongyan, et al. Research and application progress of 4D printing technology[J]. Journal of South China University of Technology (Natural Science Edition), 2021, 49(3): 34-46, 54. [33] SUN L, HUANG W M, DING Z, et al. Stimulus responsive shape memory materials: A review[J]. Materials & Design, 2012, 33: 577-640. [34] MOMENI F, SEYED M H N, LIU X, et al. A review of 4D printing[J]. Materials & design,2017,122(15):42-79. [35] LIU T Z, LIU L W, ZENG C J, et al. 4D printed anisotropic structures with tailored mechanical behaviors and shape memory effects[J]. Composites Science and Technology,2020,186:107935. [36] 沈观林, 胡更开, 复合材料力学[M]. 北京: 清华大学出版社, 2010.SHEN Guanlin, HU Gengkai. Composite mechanics[M]. Beijing: Tsinghua University Press, 2010(in Chinese). [37] CHEN X F, ZHANG Y P. Research about the ways to control the error of FDM forming workpiece[J]. Modern Manufacturing Engineering,2011,31(11):36-39. [38] BODAGHI M A, DAMANPACK R, LIAO W H. Adaptive metamaterials by functionally graded 4D printing[J]. Materials & Design,2017,135:26-36. [39] ZHAO H M, HE Y, FU J Z, et al. Inclined layer printing for fused deposition modeling without assisted supporting structure[J]. Robotics and Computer-Integrated Manufacturing,2018,51:1-13. [40] FU M H, YIN J R. Equivalent elastic parameters of the honeycomb core[J]. Acta Mechanica Sinica,1999,15(1):113-118. [41] CHOONG Y Y C, MALEKSAEEDI S, ENG H, et al. High speed 4D printing of shape memory polymers with nanosilica[J]. Applied Materials Today,2020,18:100515. [42] AFFDL J C H, KARDOS J L. The Halpin-Tsai equations: A review[J]. Polymer Engineering & Science,1976,16(5):344-352. [43] MORI T, TANAKA K. Average stress in a matrix and average elastic energy of materials with mistfitting inclusions[J]. Acta Metallurgica et Materialia,1973,42:597-629. [44] LUO J J, DANIEL I M. Characterization and modeling of mechanical behavior of polymer/clay nanocomposites[J]. Composites Science & Technology,2003,63(11):1607-1616. [45] YOUSUF M H, ABUZAID W, ALKHADER M. 4D printed auxetic structures with tunable mechanical properties[J]. Additive Manufacturing,2020,35:101364. [46] MASTERS I G, EVANS K E. Models for the elastic deformation of honeycombs[J]. Composite Structures,1996,35(4):403-422. doi: 10.1016/S0263-8223(96)00054-2 [47] LIU Y, ZHANG W, ZHANG F H, et al. Microstructural design for enhanced shape memory behavior of 4D printed composites based on carbon nanotube/polylactic acid filament[J]. Composites Science and Technology,2019,181:107692. [48] WU L, ZHANG F, SUN B, et al. Finite element analyses on three-point low-cyclic bending fatigue of 3-D braided composite materials at microstructure level[J]. International Journal of Mechanical ences,2014,84:41-53. doi: 10.1016/j.ijmecsci.2014.03.036 [49] 王海雷, 高艳秋, 范雨娇. 三维编织复合材料研究及应用现状[J]. 新材料产业, 2017(3):51-54. doi: 10.3969/j.issn.1008-892X.2017.03.012WANG Hailei, GAO Yanqiu, FAN Yujiao. Re search and application status of three-dimensional braided composite materials[J]. New Materials Industry,2017(3):51-54(in Chinese). doi: 10.3969/j.issn.1008-892X.2017.03.012 [50] 郝天泽, 肖华平, 刘书海, 等. 形状记忆聚合物在4D打印技术下的研究及应用[J]. 浙江大学学报(工学版), 2020, 54(1):1-16.HAO Tianze, XIAO Huaping, LIU Shuhai, et al. Research and application of shape memory polymers under 4D printing technology[J]. Journal of Zhejiang University (Engineering Science Edition),2020,54(1):1-16(in Chinese). [51] GE Q, DUNN C K, QI H J, et al. Active origami by 4D printing[J]. Smart Materials and Structures,2014,23(9):094007. doi: 10.1088/0964-1726/23/9/094007 [52] MAXWELL J C. A dynamical theory of the electromagnetic field[J]. Physics Bulletin,1983,34(12):522. [53] MAO Y Q, KAI Y, MICHAEL S, et al. Sequential self-folding structures by 3D printed digital shape memory polymers[J]. Scientific Reports,2015,5:13616. [54] DING Z, YUAN C, PENG X, et al. Direct 4D printing via active composite materials[J]. Science Advances,2017,3(4):e1602890. doi: 10.1126/sciadv.1602890 [55] YU K, GE Q, QI H J. Reduced time as a unified parameter determining fixity and free recovery of shape memory polymers[J]. Nature Communications,2014,5(1):1-9. [56] ZHANG Q, YAN D, ZHANG K, et al. Pattern transformation of heat-shrinkable polymer by three-dimensional (3D) printing technique[J]. Scientific Reports,2015,5:8936. [57] STONEY G G. The tension of metallic films deposited by electrolysis[J]. Proceedings of the Royal Society of London,1909,82(553):172-175. [58] TIMOSHENKO S. Analysis of Bi-metal thermostats[J]. Journal of the Optical Society of America,1925,11(3):233. doi: 10.1364/JOSA.11.000233 [59] WANG W, YAO L, CHENG C Y, et al. Harnessing the hygroscopic and biofl uorescent behaviors of genetically tractable microbial cells to design biohybrid wearables[J]. Science Advances,2017,3(5):1601984. doi: 10.1126/sciadv.1601984 [60] NA J H, EVANS A A, BAE J, et al. Programming reversibly self-folding origami with micropatterned photo-crosslinkable polymer trilayers[J]. Advanced Materials,2015,27(1):79. doi: 10.1002/adma.201403510 [61] JEONG H Y, WOO B H, KIM N, et al. Multicolor 4D printing of shape-memory polymers for light-induced selective heating and remote actuation[J]. Scientific Reports,2020,10(1):6258. [62] SU J W, TAO X, DENG H, et al. 4D printing of a self-morphing polymer driven by a swellable guest medium[J]. Soft Matter,2018,14(5):765-772. doi: 10.1039/C7SM01796K [63] CHOI W, KIM T Y, LEE Y G. Rolling of 3D printed dual-layer beam into a cylinder by ethanol absorption[J]. Macromolecular Materials and Engineering,2018,303(6). [64] GLADMAN S A, MATSUMOTO E A, NUZZO R G, et al. Biomimetic 4D printing[J]. Nature Materials,2016,15(4):413-418. [65] AHARONI H, SHARON E. KUPFERMAN R. Geometry of thin nematic elastomer sheets[J]. Physical Review Letters,2014,113:257801. doi: 10.1103/PhysRevLett.113.257801 [66] ARMON S, EFRATI E, KUPFERMAN R, et al. Geometry and mechanics in the opening of chiral seed pods[J]. Science 333,2011:1726-1730. [67] ZHANG Q, ZHANG K, HU G K. Smart three-dimensional lightweight structure triggered from a thin composite sheet via 3D printing technique[J]. Scientific Reports,2016,6(1):201700675. [68] TSCHOEGL N W. The phenomenological theory of linear viscoelastic behavior[M]. Berlin: Spring Verlag, 1989. [69] TOBUSHI H, HASHIMOTO T, HAYASHI S, et al. Thermomechanical constitutive modeling in shape memory polymer of polyurethane series[J]. Journal of Intelligent Material Systems and Structures,1997,8(8):711-718. doi: 10.1177/1045389X9700800808 [70] MOMENI F, SABZPOUSHAN S, VALIZADEH R, et al. Plant leaf-mimetic smart wind turbine blades by 4D printing[J]. Renewable Energy,2019,130:329-351. [71] MOMENI F, NI J. Nature-inspired smart solar concentrators by 4D printing[J]. Renewable Energy,2018,122:35-44. doi: 10.1016/j.renene.2018.01.062 [72] CASAVOLA C, CAZZATO A, MORAMARCO V, et al. Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory[J]. Materials & Design,2016,90:453-458. [73] HOA S V. Factors affecting the properties of composites made by 4D printing (moldless composites manufacturing)[J]. Advanced Manufacturing: Polymer & Compo-sites Science,2017,3(3):1-9. [74] BOGETTI T A, GILLESPIE J W. Process-induced stress and deformation in thick-section thermoset composite laminates[J]. Journal of Composite Materials,1992,26(5):68. [75] WANG Q R, T X Y, HUANG L, et al. Programmable morphing composites with embedded continuous fibers by 4D printing[J]. Materials & Design,2018,155:404-413. [76] LEE AY, AN J, CHUA C K, et al. Preliminary investigation of the reversible 4D printing of a dual-layer component[J]. Engineering,2019,5(6):1159-1170. [77] VERO F. Fullcure material[EB/OL]. [2019-1-13]. https://www.goengineer.com/products/vero-family/. [78] RITGER P L, PEPPAS N A. A simple equation for description of solute release I. Fickian and non-fickian release from non-swellable devices in the form of slabs, spheres, cylinders or discs[J]. Journal of Controlled Release,1987,5(1):23-36. doi: 10.1016/0168-3659(87)90034-4 [79] FLORY P J, REHNER J. Statistical mechanics of cross-linked polymer networks II. swelling[J]. Journal of Chemical Physics,1943,11(11):512-520. doi: 10.1063/1.1723791 [80] SOSSOU G, DEMOLY F, BELKEBIR H, et al. Design for 4D printing: A voxel-based modeling and simulation of smart materials[J]. Materials & Design, 2019, 175: 107798. [81] SOSSOU G, DEMOLY F, BELKEBIR H, et al. Design for 4D printing: Modeling and computation of smart materials distributions[J]. Materials & Design,2019,181:108074. [82] KIM B, LAFLAMME K, PEPPAS N A. Dynamic swelling behavior of pH-sensitive anionic hydrogels used for protein delivery[J]. Journal of Applied Polymer Science,2003,89(6):1606-1613. doi: 10.1002/app.12337 [83] 卢宇源, 安立佳, 王健. 高分子黏弹性的经典唯象模型[J]. 高分子学报, 2016(6):688-697. doi: 10.11777/j.issn1000-3304.2016.16108LU Yuyuan, AN Lijia, WANG Jian. Classical phenomenological model of polymer viscoelasticity[J]. Acta Polymerica Sinica,2016(6):688-697(in Chinese). doi: 10.11777/j.issn1000-3304.2016.16108 -

下载:

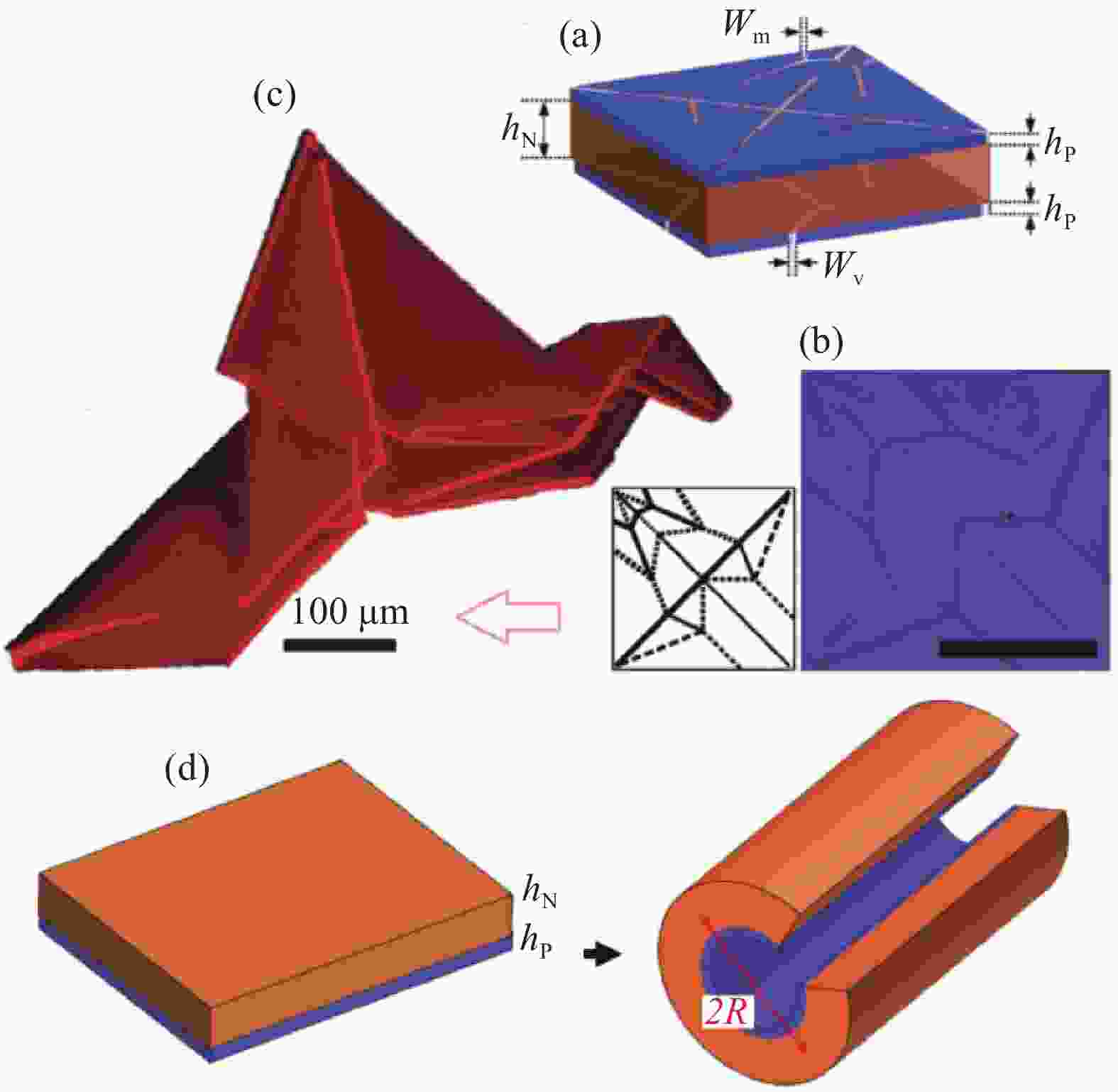

下载: