Research progress of carbon-based fillers in polymer matrix insulating and thermally conductive composites

-

摘要: 集成电路产业的高质量发展对其产业链中配套材料的绝缘导热性能提出了更高的要求。具有高导热、低密度、活性表界面等优异特性的碳系材料在聚合物基复合材料中的基础研究,对于高性能绝缘导热材料的性能提升及应用发展至关重要。基于此,本文系统地综述了聚合物基绝缘导热复合材料中碳系填料的研究进展。首先,介绍了聚合物基复合材料的导热机制、绝缘机制及绝缘导热兼容机制。其次,对碳系填料的表面处理和空间结构及分布控制方法进行了综述,研究其绝缘导热性能控制机制。最后,对聚合物基绝缘导热复合材料研究工作中尚未解决的科学问题、技术难点及未来发展方向进行了总结和展望。Abstract: The high-quality development of the integrated circuit industry puts forward higher requirements for the insulation properties and thermal conductivity of supporting materials in its industrial chain. The basic research of carbon-based materials with excellent properties, such as high thermal conductivity, low density and active surface interface in polymer matrix composites, is essential for the performance improvement and application development of high-performance insulating and thermally conductive materials. This article systematically reviews the research progress of carbon-based fillers in polymer matrix insulating and thermally conductive composites. Firstly, the thermal conduction mechanism, insulation mechanism, and insulation and thermal conduction compatibility mechanism of polymer matrix composites were introduced. Secondly, the surface treatment, spatial structure and distribution control methods of carbon-based fillers were reviewed, and the control mechanism of insulation properties and thermal conductivity wass studied. Finally, the unresolved scientific problems, technical difficulties and future development directions in the research work of polymer matrix insulating and thermally conductive composites were summarized and prospected.

-

Key words:

- carbon-based fillers /

- thermal conductivity /

- electrical insulation /

- polymer matrix /

- composites

-

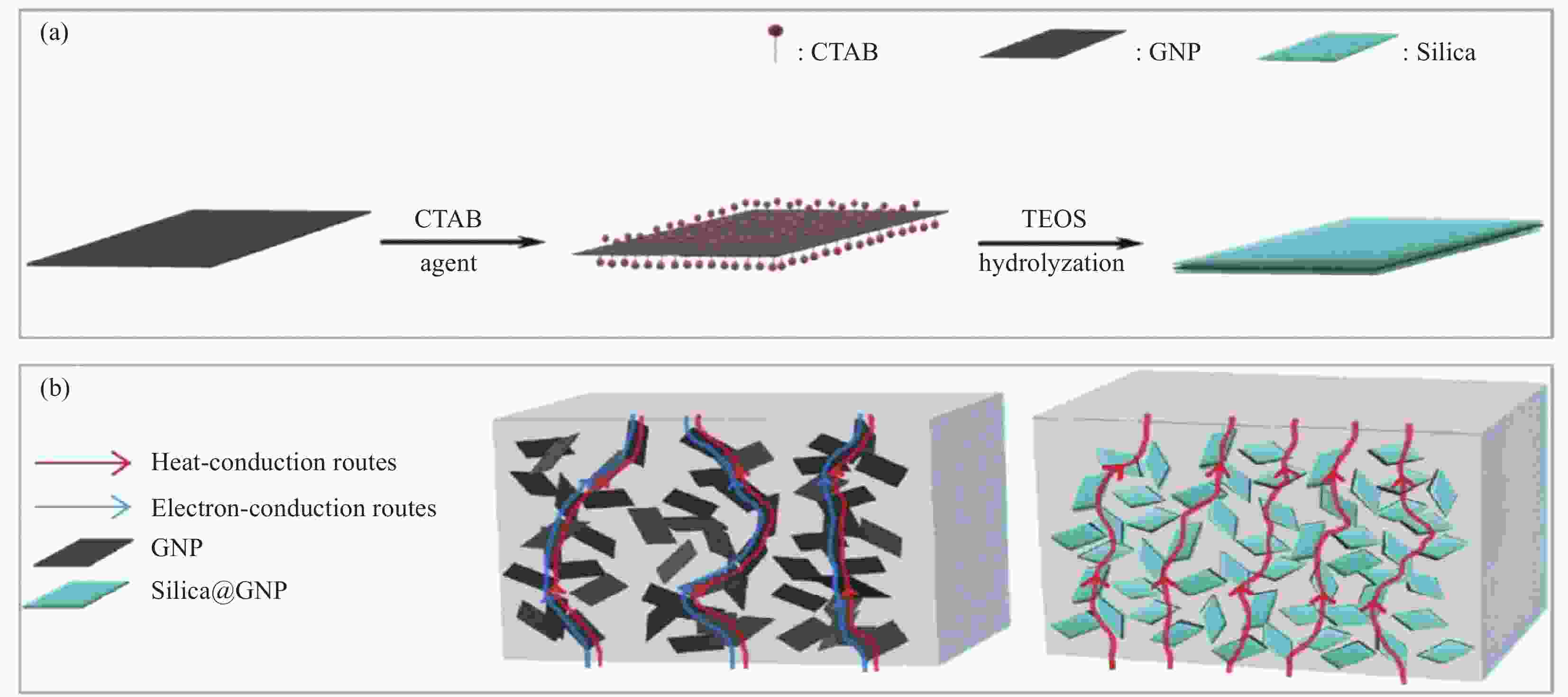

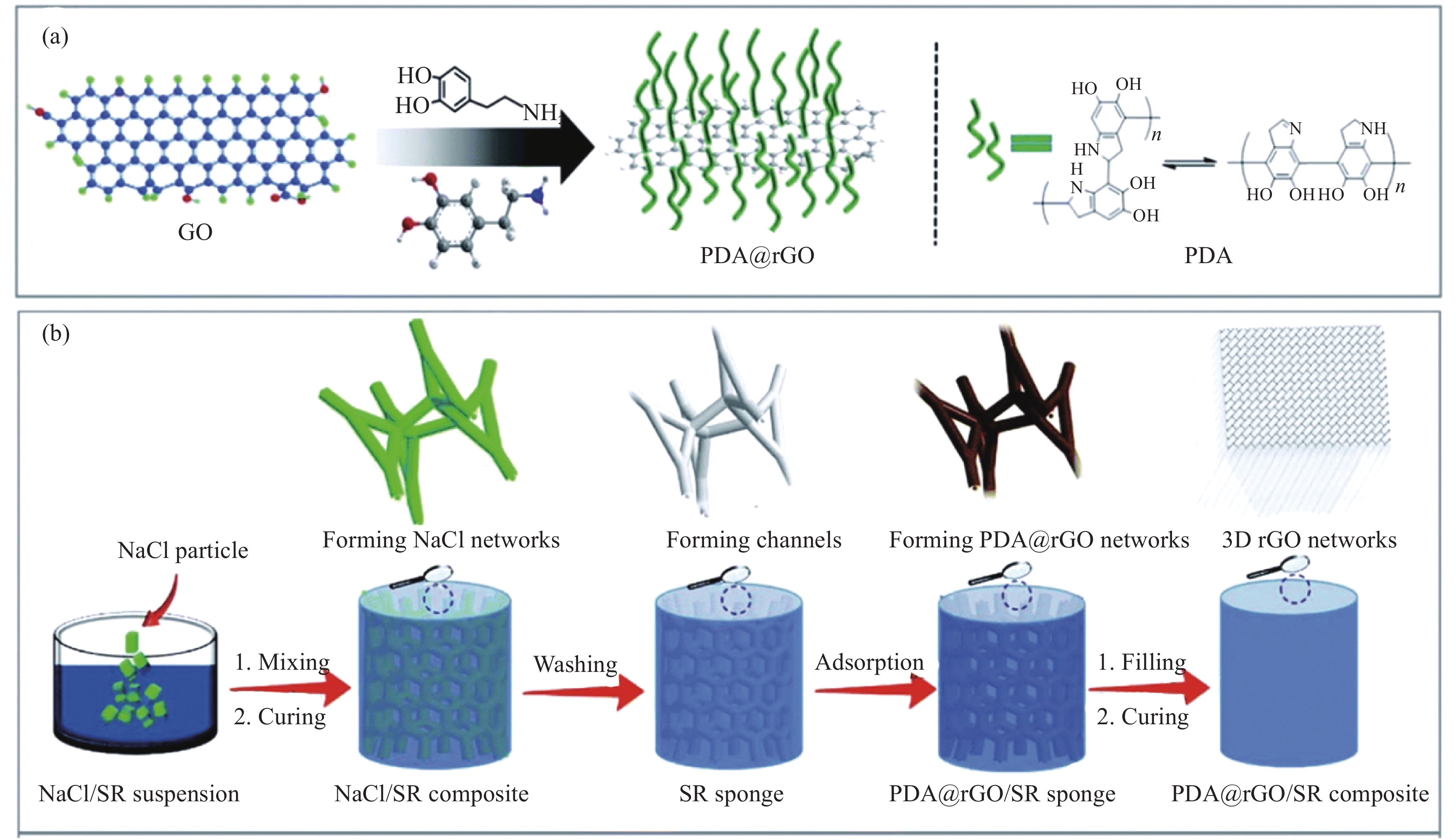

图 1 聚多巴胺封装还原氧化石墨烯(PDA@rGO)的制备示意图 (a)、三维互连石墨烯网络的PDA@rGO/硅橡胶(SR)复合材料的制备过程示意图 (b)[15]

Figure 1. Schematic illustration of the preparation of polydopamine-coated reduced graphene oxide (PDA@rGO) (a) , schematic illustration of the preparation process of the PDA@rGO/silicone rubber (SR) composite with 3D interconnected graphene networks (b)[15]

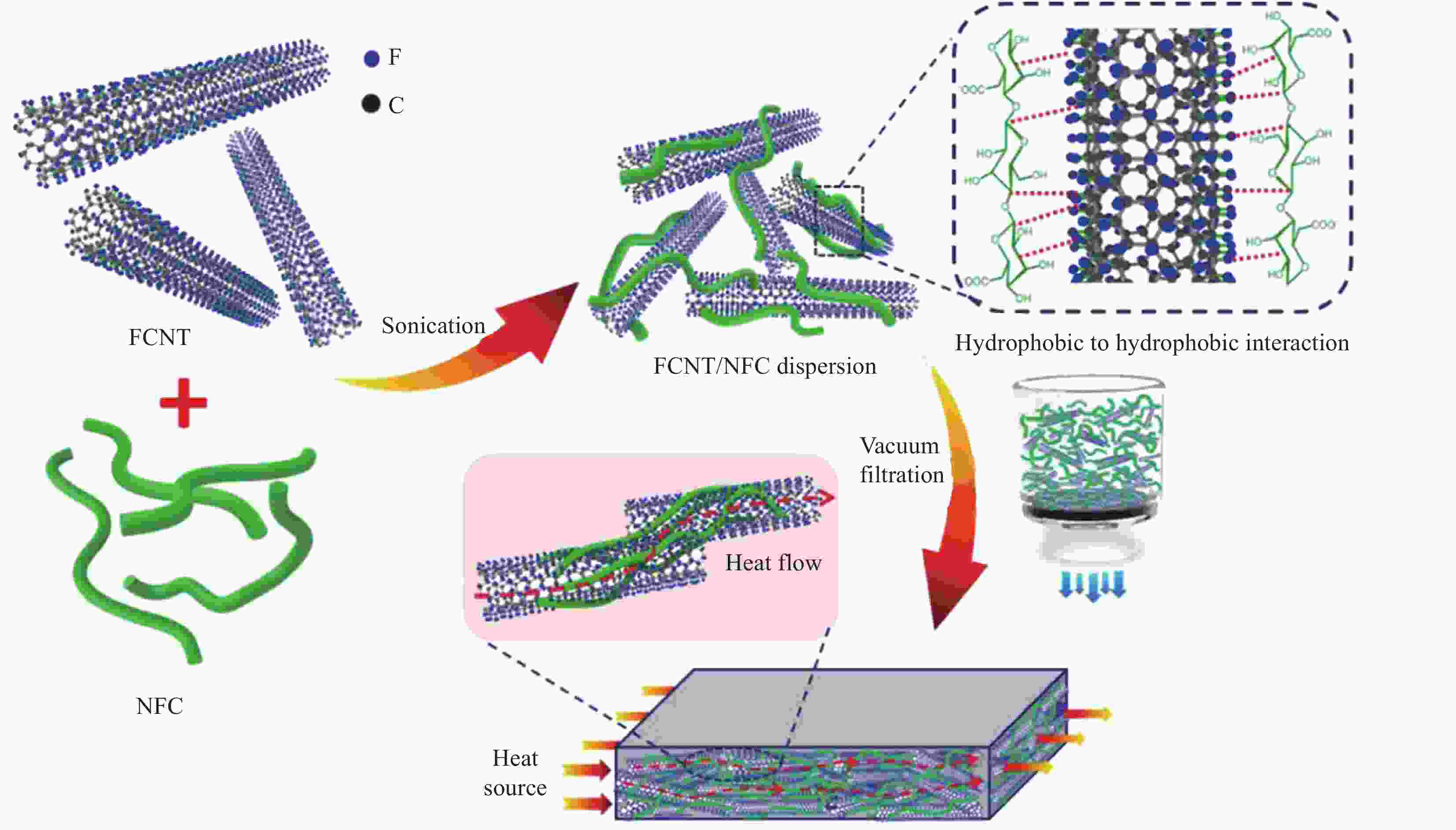

图 2 在石墨烯纳米片(GNP)上形成纳米SiO2涂层的示意图 (a)、GNP/聚二甲基硅氧烷(PDMS)和SiO2@GNP/PDMS复合材料中热和电子传输途径的示意图 (b)[17]

Figure 2. Schematic illustration of formation of nano SiO2 coating onto graphene nanoplatelet (GNP) (a) , schematic mechanism for formation of heat and electron transport pathways in the GNP/polydimethylsiloxane (PDMS) and SiO2@GNP/PDMS composites (b)[17]

CTAB—Cetyltrimethyl ammonium bromide; TEOS—Tetraethyl orthosilicate

表 1 部分聚合物基复合材料的绝缘导热性能及其控制机制

Table 1. Electrical insulation properties and thermal conductivity and its control mechanism of some polymer matrix composites

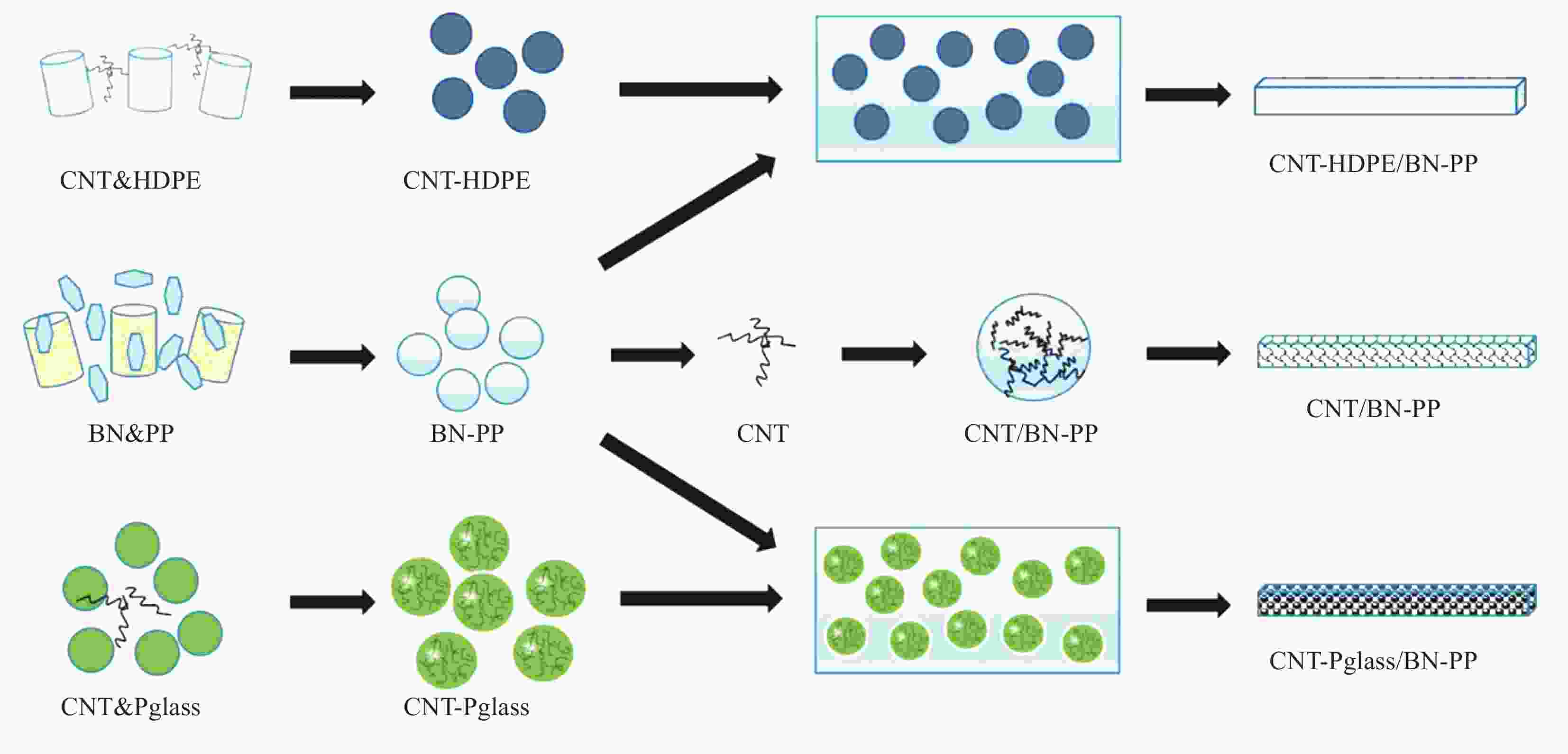

Sample Fraction Thermal conductivity/

(W·m−1·K−1)Electrical insulation properties Control mechanism PDA@CuNW-PDA@GO/EP[14] 2wt% 0.4 >1.2×1014 Ω·cm Polymer encapsulation PDA@rGO/SR[15] 1.5wt% 1.5 >1013 Ω·cm Polymer encapsulation MgO@CF/PA6[16] 20wt% 0.7 — Ceramic coating treatment SiO2@GNP/PDMS[17] 2wt% 0.5 9.2×1012 Ω·cm Ceramic coating treatment Al2O3@GNP/EP[23] 12wt% 1.5 6.7×10−9 S/m Ceramic coating treatment FCNT/NFC[24] 35wt% 14.1 >1010 Ω·cm Fluorination modification PMMA-g-FCNT/PMMA[25] 15wt% 1.2 >1013 Ω·cm Fluorination modification GFS/PVA[27] 93wt% 61.3 >1011 Ω·cm Fluorination modification BNNS-CNT/Cellulose[28] 15wt% 11.8 >1010 Ω·cm Micro-hybrid structure control CNT-NH2-Fe@h-BN/CER[29] 32wt% 0.9 <1.2×10−12 S/cm Micro-hybrid structure control BNNT-GONS/EP[30] 11.6vol% 4.5 55 kV/mm Micro-hybrid structure control h-BN-NfG/CER[31] 30wt% 3.4 6.1×10−12 S/cm Micro-hybrid structure control h-BN-mG/CER[32] 35wt% 1.3 <1.5×10−10 S/cm Micro-hybrid structure control BN-GS/EP[33] 15.9wt% 0.6 3.0×10−7 S/cm Micro-hybrid structure control AlN-BN/PP-AlN-MWCNT/PP[37] 70wt% 3.4 6.6×1013 Ω·cm Macro-layered structure control BN/SR-GNP/SR[38] 17.9vol% 8.5 ~1012 Ω·cm Macro-layered structure control Gt-MWCNT/HDPE-BN/HDPE[40] 32.6vol% 1.5 5×1013 Ω·cm Macro-layered structure control CF-BN/PS-PP[43] 32.5wt% 0.6 — Controllable selective distribution CNT-Pglass/BN-PP[44] 12.5wt% 0.9 ~6×10−5 S/m Controllable selective distribution h-BN-GNP/PA6[45] 18.8vol% 2.7 4.1×10−9 S/m Controllable selective distribution Notes: @—Coating relationship; PDA—Polydopamine; CuNW— Cu nanowire;GO—Graphene oxide; EP—Epoxy resin; SR—Silicone rubber; rGO—Reduced graphene oxide; PMMA—Polymethyl methacrylate; PDMS—Polydimethylsiloxane; Gt—Graphite; NFC—Nanofibrillated cellulose; CF—Carbon fiber; PS—Polystyrene; PP— Polypropylene; MWCNT—Multiwalled carbon nanotube; GNP—Graphene nanosheets; GONS—Graphene oxide nanosheets; BNNT—Boron nitride nanotube; HDPE—High-density polyethylene; CNT—Carbon nanotube; mG—Multilayer graphene; BNNS—BN nanosheets; NfG—Amino functionalized graphene; FCNT—Fluorinated carbon nanotubes; GS—Graphene sponge; PVA—Polyvinyl alcohol; Pglass—Phosphate glass; GFS—Fossilized fluoroalkene; PA6—Polyamide 6. -

[1] MOORE A L, LI S. Emerging challenges and materials for thermal management of electronics[J]. Materials Today,2014,17(4):163-174. doi: 10.1016/j.mattod.2014.04.003 [2] XU X F, CHEN J, ZHOU J, et al. Thermal conductivity of polymers and their nanocomposites[J]. Advanced Materials,2018,30(17):e1705544. doi: 10.1002/adma.201705544 [3] KIM G H, LEE D, SHANKER A, et al. High thermal con-ductivity in amorphous polymer blends by engineered interchain interactions[J]. Nature Materials,2015,14(3):295-300. doi: 10.1038/nmat4141 [4] CHEN X K, CHEN K Q. Thermal transport of carbon nanomaterials[J]. Journal of Physics: Condensed Matter,2019,32(15):153002. [5] KAMRAN U, HEO Y J, LEE J W, et al. Functionalized carbon materials for electronic devices: A review[J]. Micromachines (Basel),2019,10(4):234. doi: 10.3390/mi10040234 [6] YANG S Q, LI W Z, BAI S B, et al. Fabrication of morphologically controlled composites with high thermal con-ductivity and dielectric performance from aluminum nanoflake and recycled plastic package[J]. ACS Applied Materials & Interfaces,2019,11(3):3388-3399. doi: 10.1021/acsami.8b16209 [7] GONG Y, ZHOU W Y, SUI X Z, et al. Core-shell structured Al/PVDF nanocomposites with high dielectric permittivity but low loss and enhanced thermal conductivity[J]. Polymer Engineering & Science,2019,59(1):103-111. [8] TAO P F, LIU W, WANG Y G. Fabrication of two-layer SiC nanowire cladding tube with high thermal conductivity[J]. Journal of the European Ceramic Society,2020,40(9):3399-3405. doi: 10.1016/j.jeurceramsoc.2020.03.040 [9] WU Y M, YE K, LIU Z D, et al. Cotton candy-templated fabrication of three-dimensional ceramic pathway within polymer composite for enhanced thermal conductivity[J]. ACS Applied Materials & Interfaces,2019,11(47):44700-44707. doi: 10.1021/acsami.9b15758 [10] CHEN J, HUANG X Y, SUN B, et al. Highly thermally conductive yet electrically insulating polymer/boron nitride nanosheets nanocomposite films for improved thermal management capability[J]. ACS Nano,2019,13(1):337-345. doi: 10.1021/acsnano.8b06290 [11] GUAN C L, QIN Y, WANG B, et al. Highly thermally conductive polymer composites with barnacle-like nano-crystalline Diamond@Silicon carbide hybrid architecture[J]. Composites Part B: Engineering,2020,198:108167. doi: 10.1016/j.compositesb.2020.108167 [12] GUO Y Q, RUAN K P, SHI X T, et al. Factors affecting thermal conductivities of the polymers and polymer composites: A review[J]. Composites Science and Technology,2020,193:108134. doi: 10.1016/j.compscitech.2020.108134 [13] HAN Z D, FINA A. Thermal conductivity of carbon nano-tubes and their polymer nanocomposites: A review[J]. Progress in Polymer Science,2011,36(7):914-944. doi: 10.1016/j.progpolymsci.2010.11.004 [14] LI M N, TANG C, ZHANG L, et al. A thermally conductive and insulating epoxy polymer composite with hybrid filler of modified copper nanowires and graphene oxide[J]. Journal of Materials Science: Materials in Electronics,2017,29(6):4948-4954. [15] SONG S Q, WANG J Y, LIU C, et al. A facile route to fabricate thermally conductive and electrically insulating polymer composites with 3D interconnected graphene at an ultralow filler loading[J]. Nanoscale,2019,11(32):15234-15244. doi: 10.1039/C9NR05153H [16] ZHANG J X, DU Z J, ZOU W, et al. MgO nanoparticles-decorated carbon fibers hybrid for improving thermal con-ductive and electrical insulating properties of Nylon 6 composite[J]. Composites Science and Technology,2017,148:1-8. doi: 10.1016/j.compscitech.2017.05.008 [17] SHEN C X, WANG H, ZHANG T X, et al. Silica coating onto graphene for improving thermal conductivity and electrical insulation of graphene/polydimethylsiloxane nanocomposites[J]. Journal of Materials Science & Technology,2019,35(1):36-43. [18] ZHAO X W, SONG L Y, ZHU X D, et al. One-step enrichment of silica nanoparticles on milled carbon fibers and their effects on thermal, electrical, and mechanical properties of polymethyl-vinyl siloxane rubber composites[J]. Composites Part A: Applied Science and Manufacturing,2018,113:287-297. doi: 10.1016/j.compositesa.2018.08.001 [19] NI R F, CHEN Q, DING X F. Coordinating of thermal and dielectric properties for cyanate ester composites filled with silica-coated sulfonated graphene oxide hybrids[J]. Polymer Composites,2018,39(S3):E1565-E1573. doi: 10.1002/pc.24476 [20] LI W, FENG W, HUANG H Y. High-performance epoxy resin/silica coated flake graphite composites for thermal conductivity and electrical insulation[J]. Journal of Materials Science: Materials in Electronics,2016,27(6):6364-6370. doi: 10.1007/s10854-016-4571-9 [21] LI H T, CHEN W, XU J Z, et al. Enhanced thermal conductivity by combined fillers in polymer composites[J]. Thermochimica Acta,2019,676:198-204. doi: 10.1016/j.tca.2019.04.008 [22] GUO S H, ZHENG R, JIANG J T, et al. Enhanced thermal conductivity and retained electrical insulation of heat spreader by incorporating alumina-deposited graphene filler in nano-fibrillated cellulose[J]. Composites Part B: Engineering,2019,178:107489. doi: 10.1016/j.compositesb.2019.107489 [23] SUN R H, YAO H, ZHANG H B, et al. Decoration of defect-free graphene nanoplatelets with alumina for thermally conductive and electrically insulating epoxy compo-sites[J]. Composites Science and Technology,2016,137:16-23. doi: 10.1016/j.compscitech.2016.10.017 [24] WANG X W, WU P. Fluorinated carbon nanotube/nano-fibrillated cellulose composite film with enhanced toughness, superior thermal conductivity, and electrical insulation[J]. ACS Applied Materials & Interfaces,2018,10(40):34311-34321. doi: 10.1021/acsami.8b12565 [25] WANG X W, WU P Y. One-step photo-mediated grafting of poly (methyl methacrylate) onto fluorinated carbon nano-tube for the enhanced thermal conductive property of polymer composites[J]. Chemical Engineering Journal,2019,369:272-279. doi: 10.1016/j.cej.2019.03.006 [26] VU M C, KIM I H, CHOI W K, et al. Highly flexible graphene derivative hybrid film: An outstanding nonflammable thermally conductive yet electrically insulating material for efficient thermal management[J]. ACS Applied Materials & Interfaces,2020,12(23):26413-26423. doi: 10.1021/acsami.0c02427 [27] WANG X W, WU P Y. Highly thermally conductive fluorinated graphene films with superior electrical insulation and mechanical flexibility[J]. ACS Applied Materials & Interfaces,2019,11(24):21946-21954. doi: 10.1021/acsami.9b07377 [28] TIAN X J, PAN T, DENG B J, et al. Synthesis of sandwich-like nanostructure fillers and their use in different types of thermal composites[J]. ACS Applied Materials & Interfaces,2019,11(43):40694-40703. doi: 10.1021/acsami.9b15674 [29] SU Z, WANG H, HE J, et al. Fabrication of thermal conductivity enhanced polymer composites by constructing an oriented three-dimensional staggered interconnected network of boron nitride platelets and carbon nanotubes[J]. ACS Applied Materials & Interfaces,2018,10(42):36342-36351. doi: 10.1021/acsami.8b09703 [30] ZHANG C, HUANG R J, WANG Y G, et al. Self-assembled boron nitride nanotube reinforced graphene oxide aerogels for dielectric nanocomposites with high thermal management capability[J]. ACS Applied Materials & Interfaces,2020,12(1):1436-1443. doi: 10.1021/acsami.9b15993 [31] SU Z, WANG H, TIAN K H, et al. The combination of π-π interaction and covalent bonding can synergistically strengthen the flexible electrical insulating nanocompo-sites with well adhesive properties and thermal conductivity[J]. Composites Science and Technology,2018,155:1-10. doi: 10.1016/j.compscitech.2017.09.018 [32] SU Z, WANG H, YE X Z, et al. Synergistic enhancement of anisotropic thermal transport flexible polymer composites filled with multi-layer graphene (mG) and mussel-inspiring modified hexagonal boron nitride (h-BN)[J]. Compo-sites Part A: Applied Science and Manufacturing,2018,111:12-22. doi: 10.1016/j.compositesa.2018.04.021 [33] GUO Y L, HE J, WANG H, et al. Boron nitride-graphene sponge as skeleton filled with epoxy resin for enhancing thermal conductivity and electrical insulation[J]. Polymer Composites,2019,40(S2):E1600-E1611. doi: 10.1002/pc.25095 [34] REN J W, LI Q H, YAN L, et al. Enhanced thermal conductivity of epoxy composites by introducing graphene@boron nitride nanosheets hybrid nanoparticles[J]. Materials & Design,2020,191:108663. [35] HE X, WANG Y C. Highly thermally conductive polyimide composite films with excellent thermal and electrical insulating properties[J]. Industrial & Engineering Chemistry Research,2020,59(5):1925-1933. [36] XUE Y, LI X F, WANG H S, et al. Thermal conductivity improvement in electrically insulating silicone rubber composites by the construction of hybrid three-dimensional filler networks with boron nitride and carbon nanotubes[J]. Journal of Applied Polymer Science,2019,136(2):46929. doi: 10.1002/app.46929 [37] ZHANG Y, TANG B, LIU Y, et al. Dual-direction high thermal conductivity polymer composites with outstanding electrical insulation and electromagnetic shielding performance[J]. Polymer Composites,2020,41(4):1673-1682. doi: 10.1002/pc.25488 [38] FENG C P, WAN S S, WU W C, et al. Electrically insulating, layer structured SiR/GNPs/BN thermal management materials with enhanced thermal conductivity and breakdown voltage[J]. Composites Science and Technology,2018,167:456-462. doi: 10.1016/j.compscitech.2018.08.039 [39] ZHANG X L, ZHANG X M, YANG M T, et al. Ordered multilayer film of (graphene oxide/polymer and boron nitride/polymer) nanocomposites: An ideal EMI shielding material with excellent electrical insulation and high thermal conductivity[J]. Composites Science and Technology,2016,136:104-110. doi: 10.1016/j.compscitech.2016.10.008 [40] ZHANG X M, ZHANG J J, LI C H, et al. Endowing the high efficiency thermally conductive and electrically insulating composites with excellent antistatic property through selectively multilayered distribution of diverse functional fillers[J]. Chemical Engineering Journal,2017,328:609-618. doi: 10.1016/j.cej.2017.07.087 [41] ZHANG X M, ZHANG J J, XIA L C, et al. Achieving high-efficiency and robust 3D thermally conductive while electrically insulating hybrid filler network with high orientation and ordered distribution[J]. Chemical Engineering Journal,2018,334:247-256. doi: 10.1016/j.cej.2017.10.037 [42] GUO F M, SHEN X, ZHOU J M, et al. Highly thermally conductive dielectric nanocomposites with synergistic alignments of graphene and boron nitride nanosheets[J]. Advanced Functional Materials,2020,30(19):1910826. doi: 10.1002/adfm.201910826 [43] JIANG X L, MA P F, ZHOU C, et al. Simultaneously enhancing the thermal conductivity and dielectric constant of BN/CF hybrid filled polypropylene/polystyrene compo-sites via in situ reactive processing[J]. Polymer Compo-sites,2020,41(4):1234-1241. doi: 10.1002/pc.25449 [44] ZHANG L, LI X Y, DENG H, et al. Enhanced thermal conductivity and electrical insulation properties of polymer composites via constructing Pglass/CNTs confined hybrid fillers[J]. Composites Part A: Applied Science and Manufacturing,2018,115:1-7. doi: 10.1016/j.compositesa.2018.09.009 [45] ZHANG X, WU K, LIU Y H, et al. Preparation of highly thermally conductive but electrically insulating compo-sites by constructing a segregated double network in polymer composites[J]. Composites Science and Technology,2019,175:135-142. doi: 10.1016/j.compscitech.2019.03.017 [46] WU K, LI Y W, HUANG R, et al. Constructing conductive multi-walled carbon nanotubes network inside hexagonal boron nitride network in polymer composites for significantly improved dielectric property and thermal con-ductivity[J]. Composites Science and Technology,2017,151:193-201. doi: 10.1016/j.compscitech.2017.07.014 [47] BURGER N, LAACHACHI A, FERRIOL M, et al. Review of thermal conductivity in composites: Mechanisms, parameters and theory[J]. Progress in Polymer Science,2016,61:1-28. doi: 10.1016/j.progpolymsci.2016.05.001 [48] ZHANG F, FENG Y Y, QIN M M, et al. Stress controllability in thermal and electrical conductivity of 3D elastic graphene-crosslinked carbon nanotube sponge/polyimide nanocomposite[J]. Advanced Functional Materials,2019,29(25):1901383. doi: 10.1002/adfm.201901383 [49] LI Q, TIAN X J, WU N, et al. Enhanced thermal conductivity and isotropy of polymer composites by fabricating 3D network structure from carbon-based materials[J]. Journal of Applied Polymer Science,2020,138(5):49781. [50] GU J W, XIE C, LI H L, et al. Thermal percolation behavior of graphene nanoplatelets/polyphenylene sulfide thermal conductivity composites[J]. Polymer Composites,2014,35(6):1087-1092. doi: 10.1002/pc.22756 [51] WU Z H, XU C, MA C Q, et al. Synergistic effect of aligned graphene nanosheets in graphene foam for high-performance thermally conductive composites[J]. Advanced Materials,2019,31(19):e1900199. doi: 10.1002/adma.201900199 [52] XUE Z N, YU Y J, LI X Y, et al. Study of a generalized thermoelastic diffusion bi-layered structures with variable thermal conductivity and mass diffusivity[J]. Waves in Random and Complex Media,2017,29(1):34-53. [53] ZHAI S P, ZHANG P, XIAN Y Q, et al. Effective thermal conductivity of polymer composites: Theoretical models and simulation models[J]. International Journal of Heat and Mass Transfer,2018,117:358-374. doi: 10.1016/j.ijheatmasstransfer.2017.09.067 [54] XU J Z, GAO B Z, DU H D, et al. A statistical model for effective thermal conductivity of composite materials[J]. International Journal of Thermal Sciences,2016,104:348-356. doi: 10.1016/j.ijthermalsci.2015.12.023 [55] NAN C W, BIRRINGER R, CLARKE D R, et al. Effective thermal conductivity of particulate composites with interfacial thermal resistance[J]. Journal of Applied Physics,1997,81(10):6692-6699. doi: 10.1063/1.365209 [56] LIU J C, GUO Y F, WENG C X, et al. High thermal con-ductive epoxy based composites fabricated by multi-material direct ink writing[J]. Composites Part A: Applied Science and Manufacturing,2020,129:105684. doi: 10.1016/j.compositesa.2019.105684 [57] XUE Y, LI X F, WANG H S, et al. Improvement in thermal conductivity of through-plane aligned boron nitride/silicone rubber composites[J]. Materials & Design,2019,165:107580. [58] FOYGEL M, MORRIS R D, ANEZ D, et al. Theoretical and computational studies of carbon nanotube composites and suspensions: Electrical and thermal conductivity[J]. Physical Review B,2005,71(10):104201. doi: 10.1103/PhysRevB.71.104201 [59] VU M C, CHOI W K, LEE S G, et al. High thermal con-ductivity enhancement of polymer composites with vertically aligned silicon carbide sheet scaffolds[J]. ACS Applied Materials & Interfaces,2020,12(20):23388-23398. doi: 10.1021/acsami.0c02421 [60] JI C, WANG Y, YE Z Q, et al. Ice-templated MXene/Ag-epoxy nanocomposites as high-performance thermal management materials[J]. ACS Applied Materials & Interfaces,2020,12(21):24298-24307. doi: 10.1021/acsami.9b22744 [61] JI C, YAN C Z, WANG Y, et al. Thermal conductivity enhancement of CNT/MoS2/graphene-epoxy nanocompo-sites based on structural synergistic effects and interpenetrating network[J]. Composites Part B: Engineering,2019,163:363-370. doi: 10.1016/j.compositesb.2018.11.005 [62] FU C J, LI Q, LU J B, et al. Improving thermal conductivity of polymer composites by reducing interfacial thermal re-sistance between boron nitride nanotubes[J]. Composites Science and Technology,2018,165:322-330. doi: 10.1016/j.compscitech.2018.07.010 [63] SAMARAKOON D K, CHEN Z F, NICOLAS C, et al. Structural and electronic properties of fluorographene[J]. Small,2011,7(7):965-969. doi: 10.1002/smll.201002058 [64] WANG Z F, WANG J Q, LI Z P, et al. Synthesis of fluorinated graphene with tunable degree of fluorination[J]. Carbon,2012,50(15):5403-5410. doi: 10.1016/j.carbon.2012.07.026 [65] XIE L, ZHU Y T. Tune the phase morphology to design conductive polymer composites: A review[J]. Polymer Composites,2018,39(9):2985-2996. doi: 10.1002/pc.24345 [66] YANG H, YUAN L, YAO X F, et al. Piezoresistive response of graphene rubber composites considering the tunneling effect[J]. Journal of the Mechanics and Physics of Solids,2020,139:103943. doi: 10.1016/j.jmps.2020.103943 [67] SOMMER N, HÜPKES J, RAU U. Field emission at grain boundaries: Modeling the conductivity in highly doped polycrystalline semiconductors[J]. Physical Review Applied,2016,5(2):024009. doi: 10.1103/PhysRevApplied.5.024009 [68] MARSDEN A J, PAPAGEORGIOU D G, VALLÉS C, et al. Electrical percolation in graphene-polymer composites[J]. 2D Materials,2018,5(3):032003. doi: 10.1088/2053-1583/aac055 [69] CHEN L, ZHANG J M. Designs of conductive polymer composites with exceptional reproducibility of positive temperature coefficient effect: A review[J]. Journal of Applied Polymer Science,2020,138(3):49677. [70] YUAN H, WANG Y, LI T, et al. Highly thermal conductive and electrically insulating polymer composites based on polydopamine-coated copper nanowire[J]. Composites Science and Technology,2018,164:153-159. doi: 10.1016/j.compscitech.2018.05.046 [71] CHRONOPOULOS D D, BAKANDRITSOS A, PYKAL M, et al. Chemistry, properties, and applications of fluorographene[J]. Applied Materials Today,2017,9:60-70. [72] ISARN I, BONNAUD L, MASSAGUÉS L, et al. Enhancement of thermal conductivity in epoxy coatings through the combined addition of expanded graphite and boron nitride fillers[J]. Progress in Organic Coatings,2019,133:299-308. doi: 10.1016/j.porgcoat.2019.04.064 [73] ISARN I, BONNAUD L, MASSAGUÉS L, et al. Study of the synergistic effect of boron nitride and carbon nanotubes in the improvement of thermal conductivity of epoxy compo-sites[J]. Polymer International,2019,69(3):280-290. [74] HARUKI M, TANAKA K. Controlling thermal conductivities and electrical insulation properties of carbon nano-fiber/polyimide composites using surface coating techniques[J]. Polymer Composites,2020,41(8):2990-2997. doi: 10.1002/pc.25591 -

下载:

下载: