Surface state of domestic ZT7H carbon fiber and interface property of composites

-

摘要: 目前我国在高性能碳纤维研发生产方面已取得了突破性的进展。本文选用不同批次和牌号的国产ZT7H碳纤维,对其进行去浆和上浆处理,并制备碳纤维增强环氧树脂基复合材料,探究国产H1型上浆剂对ZT7H碳纤维表面形貌和微观界面性能的影响及不同牌号碳纤维复合材料界面性能的差异。研究表明,H1上浆剂增加了碳纤维表面粗糙度和极性组分含量,增强了湿热老化前后复合材料的微观界面力学性能。同时,碳纤维织物的编织方式对其复合材料的静态力学性能和界面性能有很大影响。实验证明,国产ZT7H碳纤维的性能已超过东丽T700碳纤维,但其加工工艺性仍有待提升。Abstract: At present, China has made great breakthrough in the development and production of high-performance carbon fiber. In this paper, different batches and grades of domestic ZT7H carbon fibers were selected and processed for desizing and sizing, and then carbon fiber reinforced epoxy resin composites were prepared. The effect of domestic H1 sizing agent on the surface morphology and micro-interface properties of ZT7H carbon fibers was explored, as well as the differences in interface performance of composites made from different grades of carbon fibers. Studies have shown that H1 sizing agent increases the surface roughness and polar component content of carbon fibers, enhancing the micro-interface mechanical properties of the composite before and after hygrothermal treat. At the same time, the weaving method of carbon fiber fabric has a great influence on the static mechanical properties and interface properties of its composites. Experiments have proved that the performance of domestic ZT7H carbon fiber has exceeded Toray T700 carbon fiber, but its product performance stability still needs to be improved.

-

Key words:

- carbon fiber /

- sizing agent /

- composites /

- interface property /

- mechanical property

-

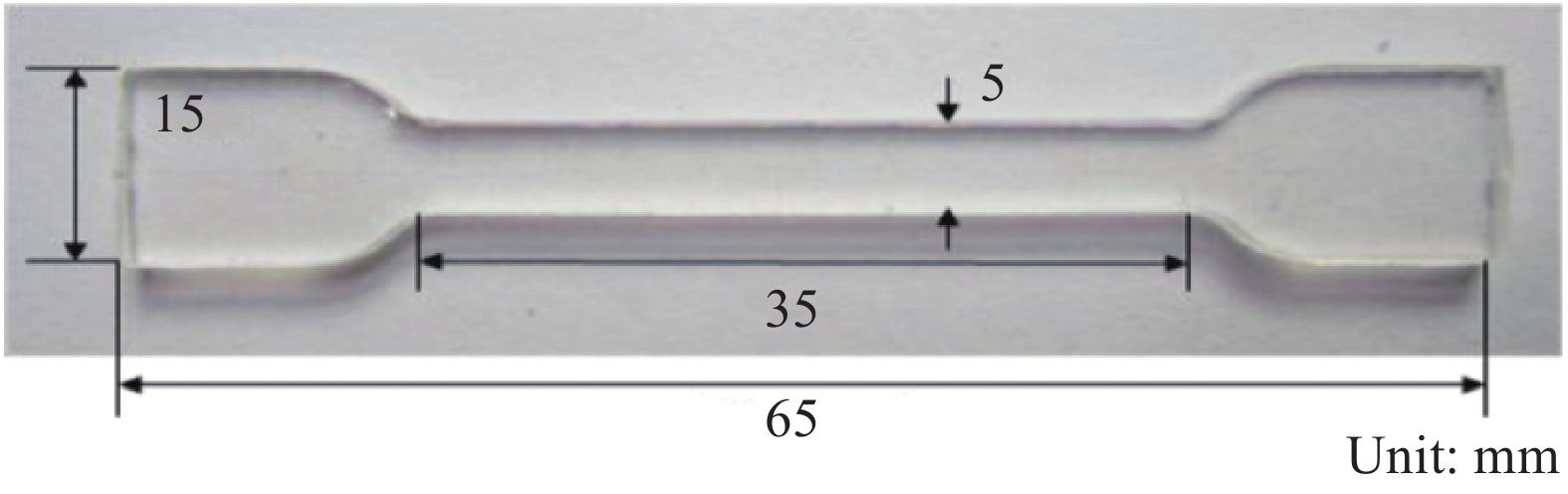

表 1 ZT7E/9368和ZT7E3205P/6808碳纤维/环氧树脂复合材料力学性能测试基本参数

Table 1. Basic parameters of mechanical properties test of ZT7E/9368 and ZT7E3205P/6808 carbon fiber/epoxy composite

表 2 ZT7H 碳纤维表面元素成分及含量

Table 2. Element composition and content of ZT7H carbon fiber surface

Carbon

fiberC 1s O 1s N 1s S 2p Si 2p O/C Binding energy/

eVAtom fraction/

at%Binding energy/

eVAtom fraction/

at%Binding energy/

eVAtom fraction/

at%Binding energy/

eVAtom fraction/

at%Binding energy/

eVAtom fraction/

at%Bare fiber 284.8 67.75 532.7 21.27 400.9 3.81 168.6 0.42 102.3 6.75 0.31 H1 sizing 284.8 75.30 532.7 18.84 400.9 2.06 168.6 0.59 102.3 3.22 0.25 表 3 ZT7H碳纤维表面XPS的C1s拟合峰结果

Table 3. C1s fitting peak results of XPS on ZT7H carbon fiber surface

Carbon fiber —C—C— or —C—H— —C—OH— or —C—OR —C= O —COOH or —COOR Binding energy/eV Perssad content/% Binding energy/eV Perssad content/% Binding energy/eV Perssad content/% Binding energy/eV Perssad content/% Bare fiber 284.8 66.92 286.4 29.75 287.8 3.33 — — H1 sizing 284.8 65.87 286.3 32.00 287.0 2.12 — — 表 4 ZT7H碳纤维接触角和表面能组成

Table 4. Contact angle and surface energy composition of ZT7H carbon fiber

Carbon

fiberInfiltrating

perimeter/mmContact angle/(°) Surface

energy/(m·Nm)Polar

component/(m·Nm)Non-polar

component/(m·Nm)Water Diiodomethane Bare fiber 2.50 67.82 44.63 41.58 12.59 28.99 H1 sizing 3.46 68.60 56.21 37.56 15.08 22.48 表 5 ZT7H碳纤维单丝拉伸测试结果

Table 5. Monofilament tensile test results of ZT7H carbon fiber

Carbon

fiberNumber of samples Shape parameter m Tensile strength/MPa Bare fiber 30 4.65 4 122.39 H1 sizing 30 7.09 4 249.17 表 6 自然干态和湿热处理后ZT7H碳纤维复合材料的IFSS及保持率

Table 6. IFSS and retention of ZT7H carbon fiber composites at natural dry state and after hygrothermal treat

Carbon fiber IFSS/MPa Retention rate/% Dry state Hygrothermal treat Bare fiber 23.87 7.02 29.4 H1 sizing 33.09 16.68 50.4 表 7 室温干态和高温干态下ZT7E/9368和ZT7E3205P/6808复合材料的静态力学性能及保持率

Table 7. Static mechanical properties and retention rate of ZT7E/9368 and ZT7E3205P/6808 composites at room temperature and high temperature

Property ZT7E/9368 ZT7E3205P/6808 Room temperature

dry stateHigh temperature

dry stateRetention

rate/%Room temperature

dry stateHigh temperature

dry stateRetention

rate/%0° Compression strength/MPa 950 800 84.21 500 350 70.00 0° Compression modulus/GPa 115 110 95.65 50 40 80.00 90° Tensile strength/MPa 30 25 83.33 600 500 83.33 90° Tensile modulus/GPa 8 7 87.50 60 50 83.33 Flexural strength/MPa 1 500 1 200 80.00 700 600 85.71 Flexural modulus/GPa 115 110 95.65 55 45 81.82 Interlaminar shear strength/MPa 85 60 70.59 55 40 72.73 -

[1] 王茂章. 碳纤维及其复合材料[J]. 新型炭材料, 1989(4):5-11. doi: 10.3321/j.issn:1007-8827.1989.01.001WANG Maozhang. Carbon fiber and its composite materials[J]. New Carbon Materials,1989(4):5-11(in Chinese). doi: 10.3321/j.issn:1007-8827.1989.01.001 [2] 李建利, 张新元, 张元, 等. 碳纤维的发展现状及开发应用[J]. 成都纺织高等专科学校学报, 2016(2):158-164.LI Jianli, ZHANG Xinyuan, ZHANG Yuan, et al. Development status and application of carbon fiber[J]. Journal of Chengdu Textile College,2016(2):158-164(in Chinese). [3] 贺福, 孙微. 碳纤维复合材料在大飞机上的应用[J]. 高科技纤维与应用, 2007, 32(6):5-8.HE Fu, SUN Wei. Application of carbon fiber composite materials in large aircraft[J]. Hi-Tech Fibers & Applications,2007,32(6):5-8(in Chinese). [4] JACOBASCH H J, GRUNDKE K, UHLMANN P, et al. Comparison of surface-chemical methods for characterizing carbon fiber-epoxy resin composites[J]. Composite Interfaces,1995,3(4):293-320. doi: 10.1163/156855495X00093 [5] 戎光道. 我国碳纤维产业发展现状及建议[J]. 合成纤维工业, 2013, 36(2):41-45. doi: 10.3969/j.issn.1001-0041.2013.02.012RONG Guangdao. Development status and suggestion on China carbon fiber industry[J]. China Synthetic Fiber Industry,2013,36(2):41-45(in Chinese). doi: 10.3969/j.issn.1001-0041.2013.02.012 [6] 陆洲, 王习. 国防军工行业: 光威复材VS中简科技对比分析[R]. 2019.LU Zhou, WANG Xi. National defense and military industry: Guangwei composite VS China jian technology comparative analysis[R]. 2019(in Chinese). [7] 杜帅, 何敏, 刘玉飞, 等. 碳纤维表面改性研究进展[J]. 纺织导报, 2017(6):58-61.DU Shuai, HE Min, LIU Yufei, et al. Research progress on surface modification of PAN carbon fiber[J]. China Textile Leader,2017(6):58-61(in Chinese). [8] 战奕凯, 赵潜, 李莉萍, 等. 碳纤维表面改性研究进展[J]. 工程塑料应用, 2019, 47(10):135-139. doi: 10.3969/j.issn.1001-3539.2019.10.025ZHAN Yikai, ZHAO Qian, LI Liping, et al. Research progress of carbon fiber surface modification[J]. Engineering Plastics Application,2019,47(10):135-139(in Chinese). doi: 10.3969/j.issn.1001-3539.2019.10.025 [9] KIM J, MAI Y. Engineered interfaces in fiber reinforced composites[J]. Elsevier, 1998: 329-365. [10] 石峰晖, 代志双, 张宝艳. 碳纤维表面性质分析及其对复合材料界面性能的影响[J]. 航空材料学报, 2010, 30(3):43-47. doi: 10.3969/j.issn.1005-5053.2010.3.010SHI Fenghui, DAI Zhishuang, ZHANG Baoyan. Characterization of surface properties ofcarbon fibers and interfacial properties of carbon fibers reinforced matrix composites[J]. Journal of Aeronautical Materials,2010,30(3):43-47(in Chinese). doi: 10.3969/j.issn.1005-5053.2010.3.010 [11] WU Z, CUI H, CHEN L, et al. Interfacially reinforced unsaturated polyester carbon fiber composites with a vinyl ester-carbon nanotubes sizing agent[J]. Composites Science and Technology,2018,164:195-203. doi: 10.1016/j.compscitech.2018.05.051 [12] TETI R. Machining of composite materials[J]. CIRP Annals Manufacturing Technology,2002,51(2):611-634. doi: 10.1016/S0007-8506(07)61703-X [13] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [14] JYONGSIK J, HOJUNG Y. The effect of surface treatment on the performance improvement of carbon fiber/polybenzoxazine composites[J]. Journal of Materials Science,2000,35(9):2297-2303. doi: 10.1023/A:1004791313979 [15] PARK S J, KIM M H. Effect of acidic anode treatment on carbon fibers for increasing fiber-matrix adhesion and its relationship to interlaminar shear strength of composites[J]. Journal of Materials Science,2000,35(8):1901-1905. doi: 10.1023/A:1004754100310 [16] HO K K C, LAMORINIERE S, KALINKA G, et al. Interfacial behavior between atmospheric-plasma-fluorinated carbon fibers and poly (vinylidene fluoride)[J]. Journal of Colloid and Interface Science,2007,313(2):476-484. doi: 10.1016/j.jcis.2007.04.076 [17] 高艳, 杨小兵, 廖国峰, 等. 碳纤维用耐高温型环氧树脂上浆剂的制备及性能研究[J]. 高科技纤维与应用, 2020, 45(4):15-19. doi: 10.3969/j.issn.1007-9815.2020.04.003GAO Yan, YANG Xiaobing, LIAO Guofeng, et al. The Preparation and performance study of high temperature resistant epoxy resin sizing agent for carbon fiber[J]. Hi-Tech Fibers and Application,2020,45(4):15-19(in Chinese). doi: 10.3969/j.issn.1007-9815.2020.04.003 [18] 曹莉娟, 杨禹, 吕春祥. 碳纳米管改性乳液上浆剂对炭纤维复合材料界面性能的影响[J]. 新型炭材料, 2016, 31(2):151-158.CAO Lijuan, YANG Yu, LV Chunxiang. A sizing agent modified with carbon nanotubes used for the production of carbon fiber/bisphenol a epoxy composites[J]. New Carbon Materials,2016,31(2):151-158(in Chinese). [19] LI L Z, WANG J, LIU W B, et al. Remarkable improvement in interfacial shear strength of carbon fiber/epoxy compo-site by large-scare sizing with epoxy sizing agent containing amine-treated MWCNTs[J]. Polymer Composites,2018,39(8):2734-2742. doi: 10.1002/pc.24263 [20] WU Z J, MA L H, LIU L, et al. Interface enhancement of carbon fiber reinforced unsaturated polyester composites with sizingagent containing carbon nanotubes[J]. Journal of Reinforced Plastics and Composites,2014,33(3):242-251. doi: 10.1177/0731684413507623 [21] WOLFF E G. Moisture effects on polymer matrix compo-sites[J]. SAMPE Journal(USA),1993,29(3):11-19. [22] MENG M, RIZVI M J, LE H R, et al. Multi-scale modelling of moisture diffusion coupled with stress distribution in CFRP laminated composites[J]. Composite Structures,2016,138:295-304. doi: 10.1016/j.compstruct.2015.11.028 [23] 黄彬瑶, 段跃新, 杨喆, 等. 上浆剂对国产碳纤维复合材料界面性能的影响[J]. 材料科学与工艺, 2014(5):60-65. doi: 10.11951/j.issn.1005-0299.20140514HUANG Binyao, DUAN Yuexin, YANG Zhe, et al. Effects of sizing agent on the interface properties of domestic carbon fiber composites[J]. Materials Science & Technology,2014(5):60-65(in Chinese). doi: 10.11951/j.issn.1005-0299.20140514 [24] 肇研, 罗云烽, 丁东, 等. 不同上浆剂的国产碳纤维复合材料湿热性能研究[J]. 材料工程, 2009(10):36-40. doi: 10.3969/j.issn.1001-4381.2009.10.008ZHAO Yan, LUO Yunfeng, DING Dong, et al. Hygrothermal property of CCF/BMI composites with different sizing on the carbon fiber[J]. Materials Engineering,2009(10):36-40(in Chinese). doi: 10.3969/j.issn.1001-4381.2009.10.008 [25] ASTM International. Standard test method for tensile strength and Young’s modulus for high-modulus single-filament materials: ASTM D3379[S]. West Conshohocken: ASTM International. 1989. [26] 全国纤维增强塑料标准化技术委员会. 碳纤维复丝拉伸性能试验方法: GB/T 3362—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Test method for tensile properties of carbon fiber multifilament: GB/T 3362—2005[S]. Beijing: China Standard Press, 2005(in Chinese). [27] KELLEY A, TYSON W. Tensile properties of fiber-reinforced metals[J]. Journal of Mechanical and Physical Solids,1965,13:329-350. doi: 10.1016/0022-5096(65)90035-9 [28] 贺福, 王润娥. 碳纤维强度的Weibull分析[J]. 碳素, 1987(2):14-17.HE Fu, WANG Rune. Weibull analysis of carbon fiber strength[J]. Carbon,1987(2):14-17(in Chinese). [29] 吴琪琳, 潘鼎. 碳纤维强度的WEIBULL分析理论[J]. 高科技纤维与应用, 1999(6):41-44.WU Qilin, PAN Ding. WEIBULL analysis of carbon fiber strength[J]. Hi-Tech Fiber & Application,1999(6):41-44(in Chinese). [30] 袁辉, 温卫东, 崔海涛. 纤维单丝及纤维束强度统计学分析[J]. 纺织学报, 2008, 29(1):29-33. doi: 10.3321/j.issn:0253-9721.2008.01.008YUAN Hui, WEN Weidong, CUI Haitao. Statistical analysis of the strength of single fibers and fiber bundles[J]. Journal of Textile Research,2008,29(1):29-33(in Chinese). doi: 10.3321/j.issn:0253-9721.2008.01.008 [31] 邓梁波, 范赋群, 周红玲. 单向纤维增强复合材料强度的统计分析[J]. 复合材料学报, 1992, 9(3):93-102.DENG Liangbo, FAN Fuqun, ZHOU Hongling. Statistical analysis of failure of unidirectionally fiber-reinforced composites with local load-sharing[J]. Chinese Journal of Composites,1992,9(3):93-102(in Chinese). [32] GURVICH M R, DIBENEDETTO A T. Evaluation of the statistical parameters of a Weibull distribution[J]. Journal of Materials Science,1997(32):3711-3716. [33] 全国纤维增强塑料标准化技术委员会. 单向纤维增强塑料平板压缩性能试验方法: GB/T 3856—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Test method for compressive properties of unidirectional fiber reinforced plastic plates: GB/T3856—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [34] 全国纤维增强塑料标准化技术委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People's Republic of China. Test method for tensile properties of oriented fiber reinforced polymer matrix composites: GB/T 3354—2014[S]. Beijing: China Standard Press, 2014(in Chinese). [35] 全国纤维增强塑料标准化技术委员会. 定向纤维增强聚合物基复合材料弯曲性能试验方法: GB/T 3356—2014[S]. 北京: 中国标准出版社, 2014.Standardization Administration of the People's Republic of China. Test method for flexural properties of oriented fiber reinforced polymer matrix composites: GB/T 3356—2014[S]. Beijing: China Standard Press, 2014(in Chinese). [36] 全国纤维增强塑料标准化技术委员会. 纤维增强塑料短梁法测定层间剪切强度: JC/T 773—2010[S]. 北京: 中国标准出版社, 2010.Ministry of Industry and Information Technology. Fiber-reinforced plastics composites-Determination of apparentinterlaminar shear strength by short-beammethod: JC/T 773—2010[S]. Beijing: StandardPress of China, 2010(in Chinese). [37] NISHIKAWA M, OKABE T, TAKEDA N. Determination of interface properties from experiments on the fragmentation process in single-fiber composites[J]. Materials Science and Engineering: A,2008,480(1-2):549-557. doi: 10.1016/j.msea.2007.07.067 [38] SUN L, JIA Y, MA F, et al. Analysis of interfacial adhesion behaviors by single-fiber composite tensile tests and surface wettability tests[J]. Polymer Composites,2010,31(8):1457-1464. doi: 10.1002/pc.20932 [39] SANTULLI C. Critical length measurements in carbon fibers during single fiber fragmentation tests using acoustic emission[J]. Journal of Materials Science,2004,39(8):2905-2907. doi: 10.1023/B:JMSC.0000021477.09656.97 [40] BARRÉ S, BENZEGGAGH M L. On the use of acoustic emission to investigate damage mechanisms in glass-fibre-reinforced polypropylene[J]. Composites Science and Technology,1994,52(3):369-376. doi: 10.1016/0266-3538(94)90171-6 [41] 刘刚, 张朋, 杨喆, 等. 尼龙无纺布结构化增韧层增韧碳纤维/环氧树脂复合材料的湿热力学性能[J]. 复合材料学报, 2015, 32(6):1633-1640.LIU Gang, ZHANG Peng, YANG Zhe, et al. Hygrothermal mechanical properties of carbon fabric/epoxy composites toughened by structural toughening layer of polyamide non-woven fabric[J]. Acta Materiae Compositae Sinica,2015,32(6):1633-1640(in Chinese). -

下载:

下载: